Optical Cable Lifespan Prediction Method Based on Autoformer

Abstract

1. Introduction

2. Factors Impacting OPGW Lifespan

2.1. Environmental Impacts on OPGW Lifespan

2.2. Effect of Residual Length on OPGW Lifespan

2.3. Intrinsic Influences on OPGW Lifespan

3. Related Work

3.1. Definition

3.2. Optical Cable Length Calculation Method

- Temperature-Induced Length Alterations: Changes in ambient temperature prompt thermal expansion or contraction in the optical cable materials, thereby inducing fluctuations in their length.

- Load-Related Deformation: Variations in stress or load can lead to deformation in the optical cable. While the optical fibers themselves primarily exhibit elastic behavior, other components may experience different types of deformation, consequently leading to corresponding alterations in length.

3.3. Optical Cable Stress Calculation Method

3.4. Calculation Method for Optical Cable Load Ratio

- Lightning Strike Assessment: During a lightning strike, determining whether the current surpasses the cable’s capacity is crucial. Exceeding this limit leads to immediate cable interruption and retirement. If the current remains below the maximum carrying capacity, the optical cable will not experience direct interruption, yet it will still be subject to the aforementioned self-weight load and other external loads.

- Wind Force Influence Calculation: When wind affects the optical cable, the calculation of the combined impact of the self-weight ratio and wind pressure ratio becomes essential. Specifically, the formula for wind pressure ratio is

3.5. Historical Data Collection and Processing

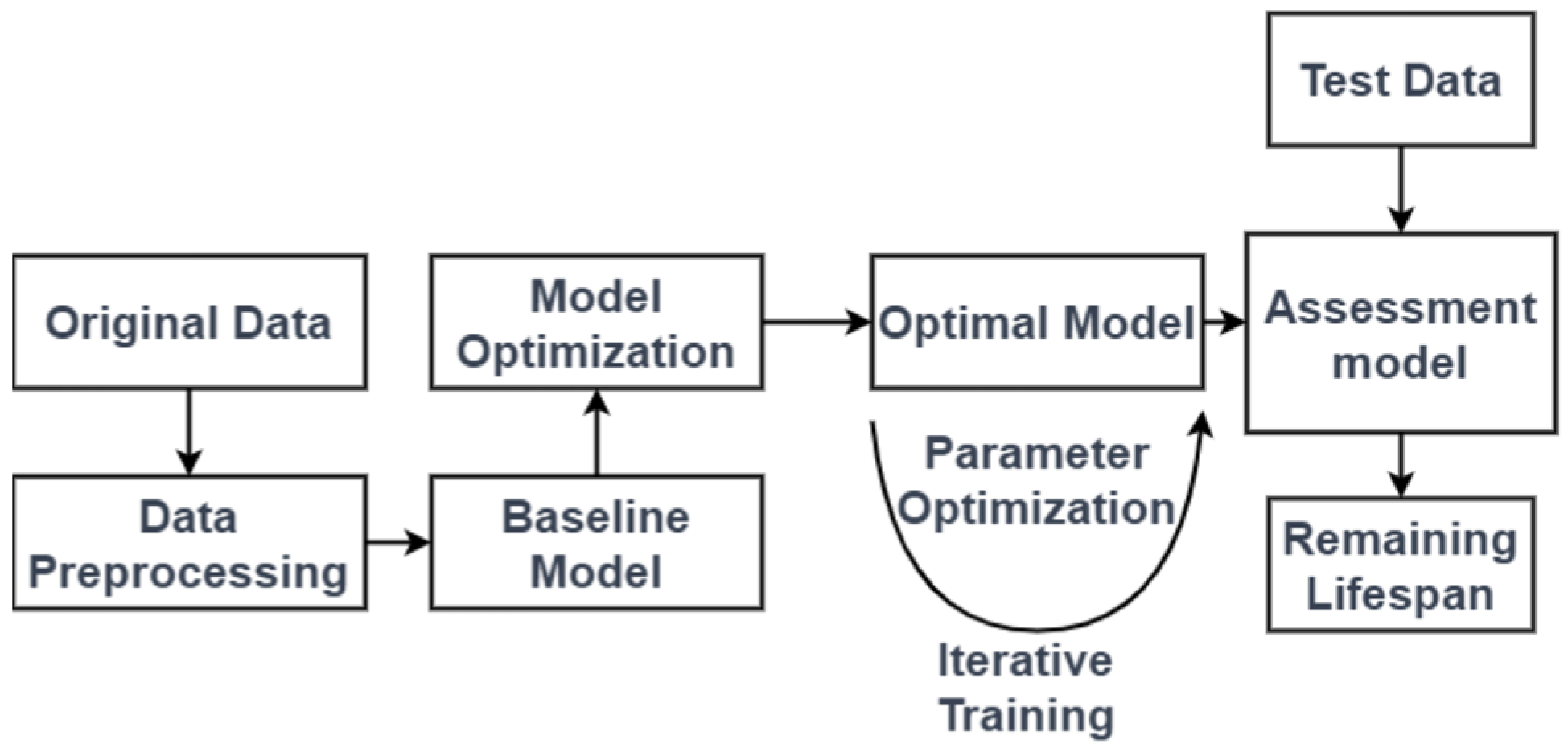

4. Autoformer-Based Optical Cable Life Prediction Model

4.1. Architecture of Autoformer

4.2. Prediction Process Based on the Autoformer Model

- Data Preprocessing: This study utilizes measured meteorological data from January 2011 to December 2023 in Guangzhou, including daily maximum and minimum temperatures and wind speed. Subsequently, leveraging the daily average temperature and wind speed, the corresponding optical cable lengths are calculated using a dedicated formula. For anomalous values, the Lagrange interpolation method is employed for estimation and imputation.

- Model Construction: The model is constructed following the architectural schematic of Autoformer, with input comprising the processed data and labels representing the residual lifespan at that time step. The output is a time series for the remaining lifespan prediction.

- Model Training and Testing: The model is trained on the training dataset and then evaluated on a separate test dataset.

5. Analysis of Cable Life Prediction Model Based on Autoformer

5.1. Comparison of Cable Life Prediction Model Results

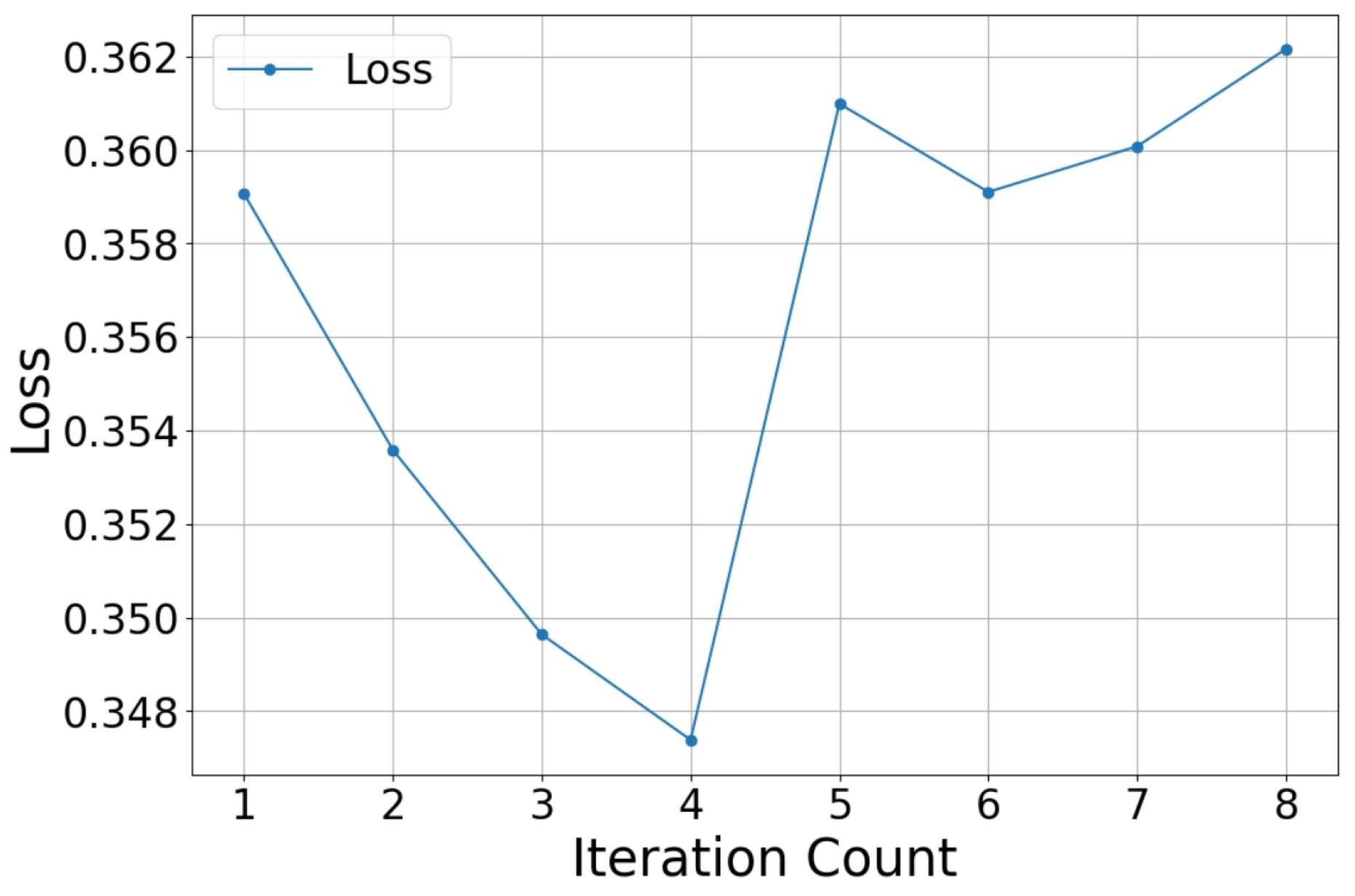

5.2. The Impact of Iteration Count on the Performance of the Autoformer Model

5.3. The Impact of Learning Rate on the Performance of the Autoformer Model

5.4. The Impact of Time Window Length on the Performance of the Autoformer Model

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grunvalds, R.; Ciekurs, A.; Porins, J.; Supe, A. Evaluation of Fibre Lifetime in Optical Ground Wire Transmission Lines. Latv. J. Phys. Tech. Sci. 2017, 54, 40–49. [Google Scholar] [CrossRef]

- Burdin, V.; Andreev, V.; Bourdine, A.; Dashkov, M.; Nizhgorodov, A. Reliability and lifetime estimations for field-aged optical cable. In Proceedings of the Internet of Things, Smart Spaces, and Next Generation Networks and Systems: 20th International Conference, NEW2AN 2020, and 13th Conference, ruSMART 2020, St. Petersburg, Russia, 26–28 August 2020. [Google Scholar]

- Burdin, V.A.; Nizhgorodov, A.O. Lifetime prediction algorithm for an optical cable of cable link under exploitation. In Proceedings of the Optical Technologies for Telecommunications, Bellingham, WA, USA, 22 May 2020. [Google Scholar]

- Burdin, V.A.; Nikulina, T.G.; Praporshchikov, D.E. Method for predicting the lifetime of an optical cable after the maintenance cycle. In Proceedings of the Optical Technologies for Telecommunications, Bellingham, WA, USA, 25 July 2022. [Google Scholar]

- Nizhgorodov, A.O. Simple Approximate Formula for Forecast of The Lifetime of the Optical Fibers of a Cable Communication Line. Infokommunikacionnye Tehnol. 2021, 19, 29–34. [Google Scholar]

- Han, W.; Hao, C.; Kong, D.; Yang, G. Cable Temperature Prediction Based on RF-GPR for Digital Twin Applications. Appl. Sci. 2023, 13, 7700. [Google Scholar] [CrossRef]

- Han, W.; Yang, G.; Hao, C.; Kong, D.; Dong, Y. A Data-Driven Model of Cable Insulation Defect Based on Convolutional Neural Networks. Appl. Sci. 2022, 12, 8374. [Google Scholar] [CrossRef]

- Wu, H.; Xu, J.; Wang, J.; Long, M. Autoformer: Decomposition transformers with auto-correlation for long-term series forecasting. Adv. Neural Inf. Process. Syst. 2021, 34, 22419–22430. [Google Scholar]

- Zhou, S.; Zhang, X.; Liu, J.; Zhang, Y.; Wei, P.; Wang, Y.; Zhang, J. Long-Term Prediction of Particulate Matter2.5 Concentration with Modal Autoformer Based on Fusion Modal Decomposition Algorithm. Atmosphere 2024, 15, 4. [Google Scholar] [CrossRef]

- Borzycki, K. Influence of temperature and aging on polarization mode dispersion of tight-buffered optical fibers and cables. J. Telecommun. Inf. Technol. 2005, 30, 96–104. [Google Scholar] [CrossRef]

- Günday, A.; Karlık, S.E. Optical fiber distributed sensing of temperature, thermal strain and thermo-mechanical force formations on OPGW cables under wind effects. In Proceedings of the 2013 8th International Conference on Electrical and Electronics Engineering (ELECO), Piscataway, NJ, USA, 28 November 2013. [Google Scholar]

- Malyszko, O.; Zenczak, M. Current-carrying capacity of overhead power transmission lines in different weather conditions. In Proceedings of the XV International Symposium on Theoretical Engineering, Berlin, Germany, 22 June 2009. [Google Scholar]

- Burdin, V.A. The method for a measurement of the excess fiber length on the cable delivery length by using the polarization reflectometry. In Proceedings of the Optical Technologies for Telecommunications, Bellingham, WA, USA, 6 April 2017. [Google Scholar]

- Setayeshgar, A. Principles of Mechanical Design in Overhead Transmission Lines. Master’s Thesis, Aalto University, Espoo, Finland, 2016. [Google Scholar]

- Li, Y.-Q.; Zhao, H.-W.; Yue, Z.-X.; Li, Y.W.; Zhang, Y.; Zhao, D.C. Real-Time Intelligent Prediction Method of Cable’s Fundamental Frequency for Intelligent Maintenance of Cable-Stayed Bridges. Sustainability 2023, 15, 4086. [Google Scholar] [CrossRef]

- Ashfaq, A.; Chen, Y.; Yao, K.; Sun, G.; Yu, J. Microbending loss caused by stress in optical fiber composite low voltage cable. In Proceedings of the 12th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Xi’an, China, 20 May 2018. [Google Scholar]

- Qin, J.; Gao, C.; Wang, D. LCformer: Linear Convolutional Decomposed Transformer for Long-Term Series Forecasting. In Proceedings of the International Conference on Neural Information Processing, Changsha, China, 20 November 2023. [Google Scholar]

- Alrasheedi, F.; Zhong, X.; Huang, P.C. Padding module: Learning the padding in deep neural networks. IEEE Access 2023, 11, 7348–7357. [Google Scholar] [CrossRef]

- Henry, M. An ultra-precise Fast Fourier Transform. Meas. Sens. 2024, 32, 101039. [Google Scholar] [CrossRef]

| Model | RMSE | MAE | MSE |

|---|---|---|---|

| LSTM | 1.3184 | 1.0828 | 1.7383 |

| Bi-LSTM | 1.2361 | 0.9582 | 1.5278 |

| Bi-LSTM + Attention | 0.9131 | 0.7321 | 0.8338 |

| Autoformer | 0.5893 | 0.3687 | 0.3473 |

| Learning Rate | RMSE | MAE | MSE |

|---|---|---|---|

| 1 × 10−3 | 0.6091 | 0.3711 | 0.3535 |

| 5 × 10−5 | 0.6088 | 0.3707 | 0.3496 |

| 2.5 × 10−5 | 0.5893 | 0.3687 | 0.3473 |

| 1.25 × 10−5 | 0.6141 | 0.3771 | 0.3609 |

| 6.25 × 10−6 | 0.6186 | 0.3827 | 0.3591 |

| 3.125 × 10−6 | 0.6121 | 0.3746 | 0.3601 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, M.; Li, Y.; Zhu, J. Optical Cable Lifespan Prediction Method Based on Autoformer. Appl. Sci. 2024, 14, 6286. https://doi.org/10.3390/app14146286

Niu M, Li Y, Zhu J. Optical Cable Lifespan Prediction Method Based on Autoformer. Applied Sciences. 2024; 14(14):6286. https://doi.org/10.3390/app14146286

Chicago/Turabian StyleNiu, Mengchao, Yuan Li, and Jiaye Zhu. 2024. "Optical Cable Lifespan Prediction Method Based on Autoformer" Applied Sciences 14, no. 14: 6286. https://doi.org/10.3390/app14146286

APA StyleNiu, M., Li, Y., & Zhu, J. (2024). Optical Cable Lifespan Prediction Method Based on Autoformer. Applied Sciences, 14(14), 6286. https://doi.org/10.3390/app14146286