Study on L-Bending Springback of 45 Steel Leather Cutting Tool Coupled with Local Induction Heating

Abstract

:1. Introduction

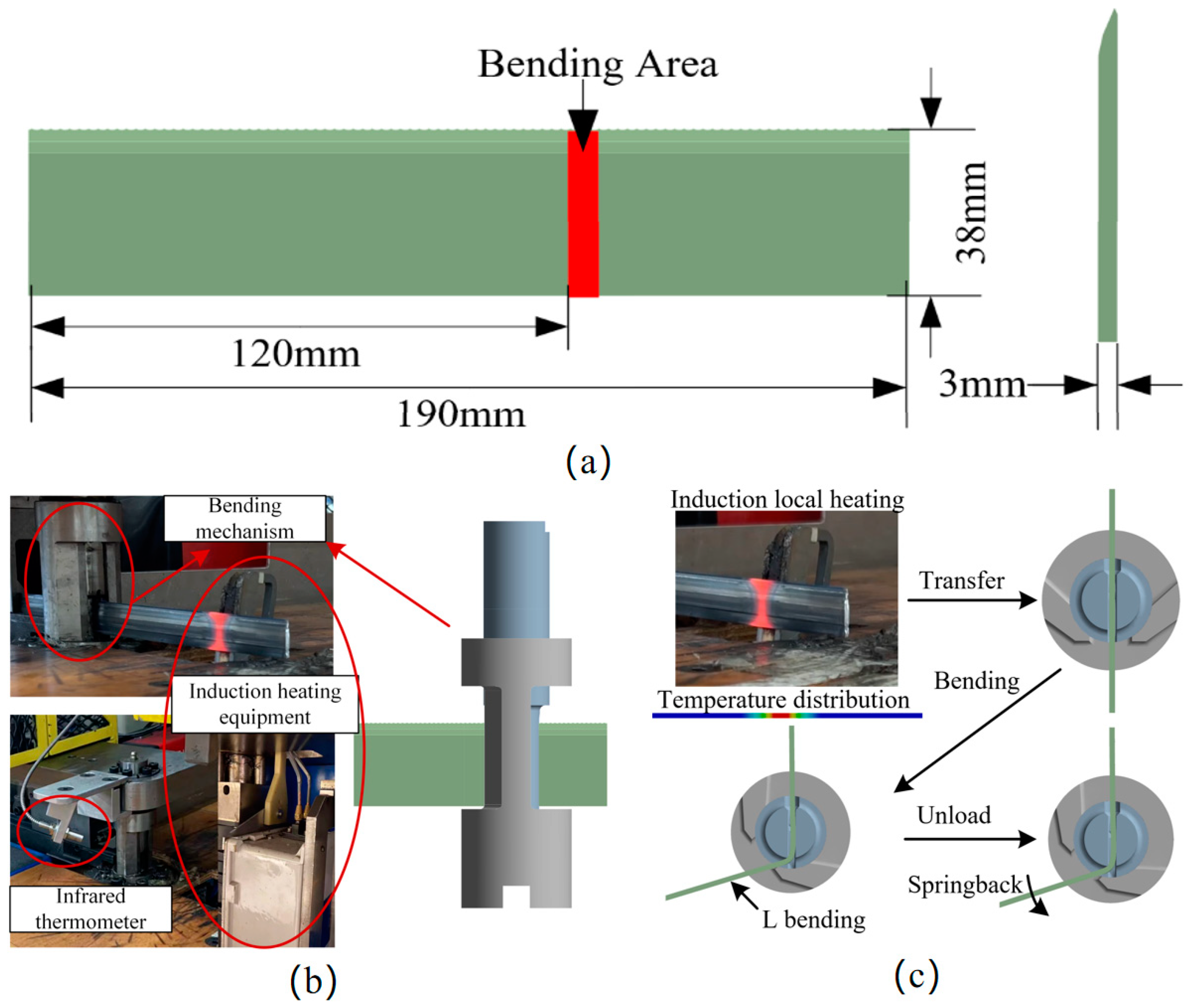

2. Materials and Methods

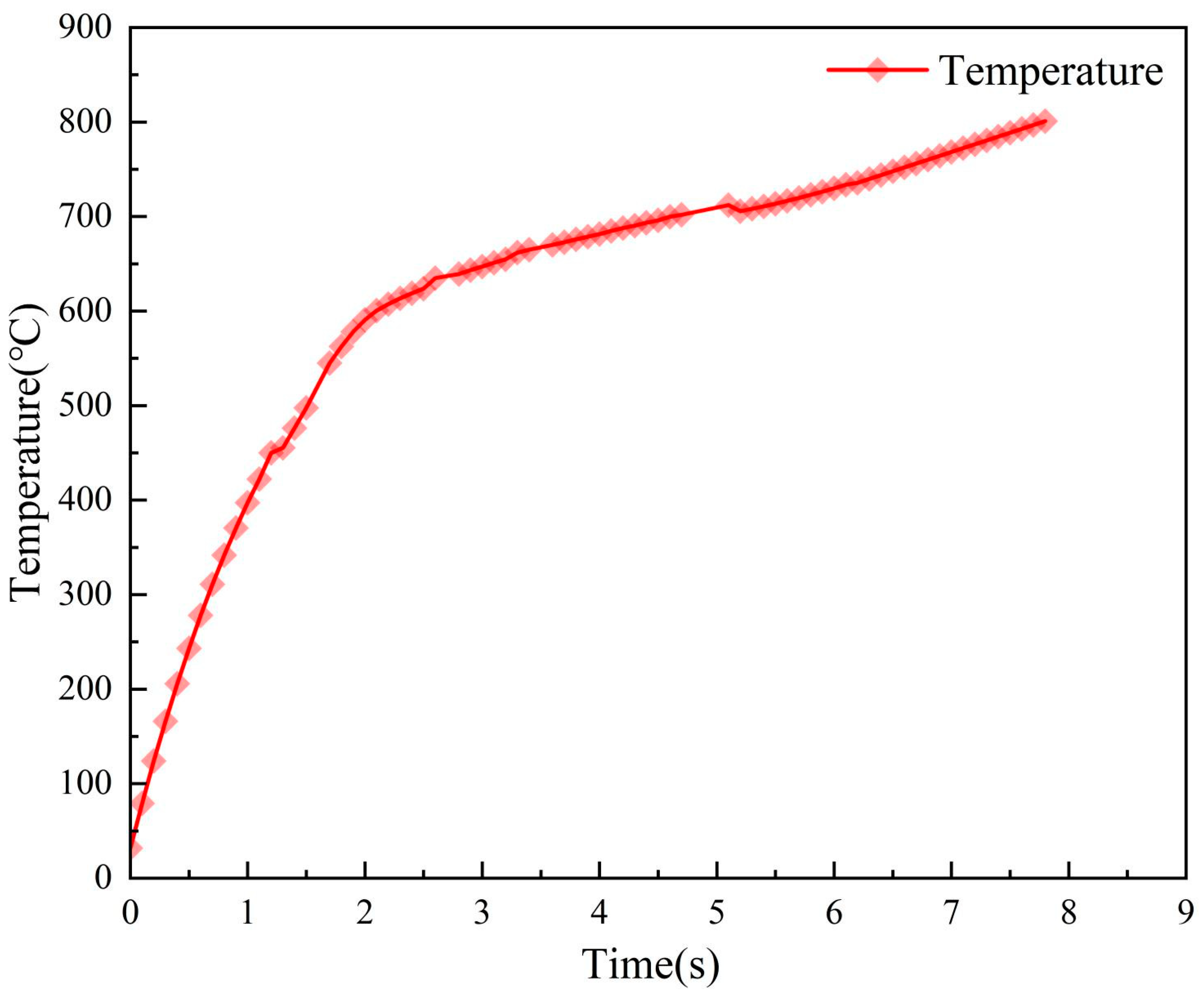

2.1. Experimental Scheme

2.2. Numerical Simulation

3. Results

3.1. Forming Angle Analysis of the Sheet

3.2. Springback and Stress Analysis at Room Temperature

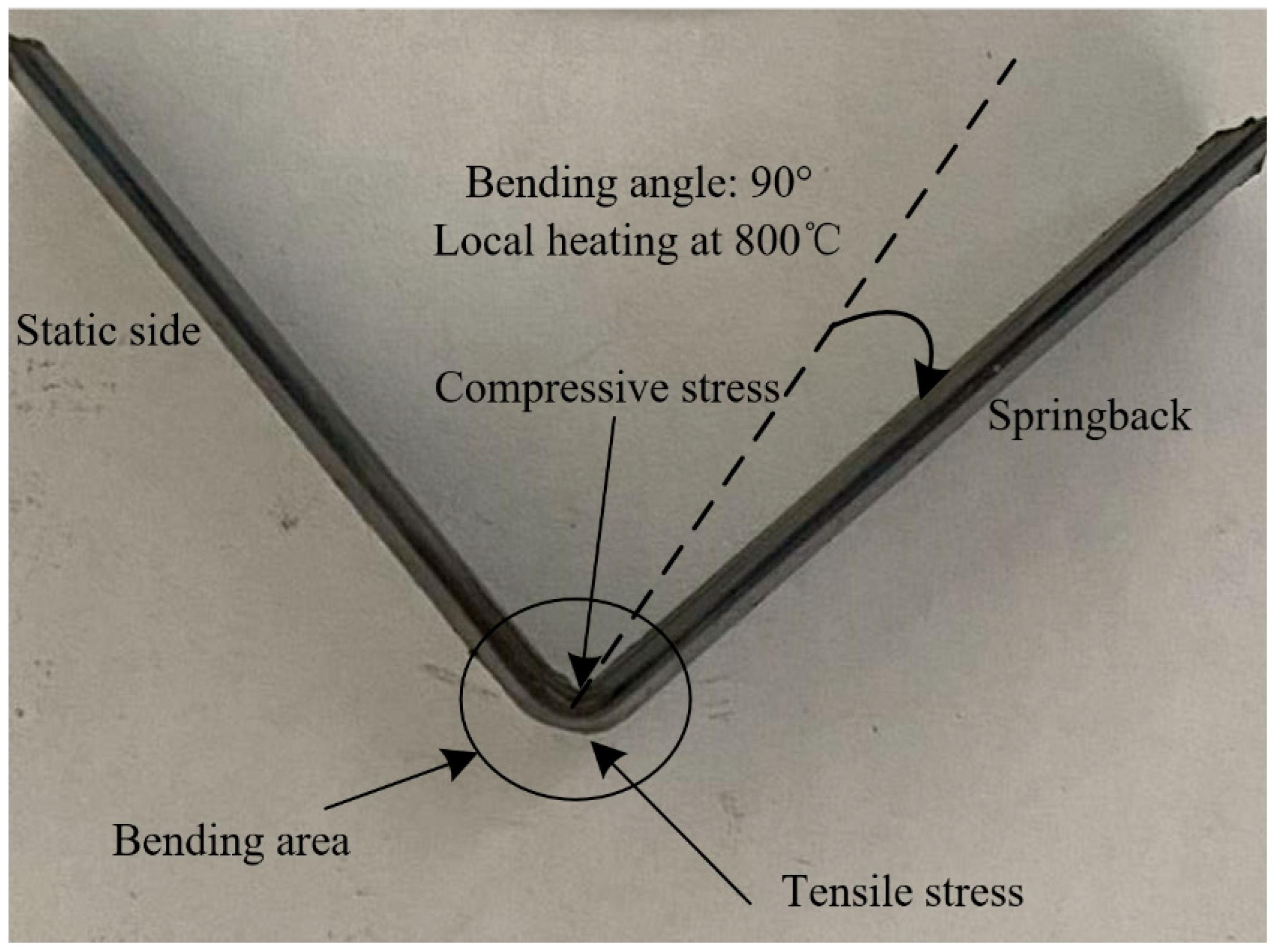

3.3. Springback and Stress Analysis under Local Heating at 800 °C

4. Discussion and Conclusions

- (1)

- The FEA carried out in this study adopts a relatively single VOCE hardening model, and the simulation results obtained and the experimental results still have errors. Researchers can try to use other hardening models (e.g., Hollomon, Ghosh, Swift, etc.) to make comparisons to ensure that the highest simulation accuracy is achieved.

- (2)

- This study only utilizes the finite element simulation of the sheets springback analysis, the analysis method is relatively singular. In the future, the microstructure of the bending place can be studied to further analyze the rebound mechanism.

- (3)

- The bending angle experiments carried out in this study did not analyze the actual springback angle compared with the simulated springback angle. These experiments can be improved in the future to better study the bending springback.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vasanth, S.; Muthuramalingam, T. Application of laser power diode on leather cutting and optimization for better environmental quality measures. Arch. Civ. Mech. Eng. 2021, 21, 54. [Google Scholar] [CrossRef]

- Kim, I.; Lee, C. A study on the machining characteristics of specimens with spherical shape using laser-assisted machining. Appl. Therm. Eng. 2016, 100, 636–645. [Google Scholar] [CrossRef]

- Stepanov, A.; Manninen, M.; Pärnänen, I.; Hirvimäki, M.; Salminen, A. Laser Cutting of Leather: Tool for Industry or Designers? Phys. Procedia 2015, 78, 157–162. [Google Scholar] [CrossRef]

- Gisario, A.; Barletta, M.; Venettacci, S. Improvements in springback control by external force laser-assisted sheet bending of titanium and aluminum alloys. Opt. Laser Technol. 2016, 86, 46–53. [Google Scholar] [CrossRef]

- Valinezhad, M.; Etemadi, E.; Hashemi, R.; Valinezhad, M. Experimental and FE analysis on spring-back of copper/aluminum layers sheet for a L-die bending process. Mater. Res. Express 2019, 6, 1165h4. [Google Scholar] [CrossRef]

- Lee, E.H.; Yang, D.Y.; Yoon, J.W.; Yang, W.H. A manufacturing process using the infrared ray local heating method for seat cross members. Int. J. Adv. Manuf. Technol. 2017, 89, 3299–3305. [Google Scholar] [CrossRef]

- Choi, J.; Lee, J.; Bong, H.J.; Lee, M.G.; Barlat, F. Advanced constitutive modeling of advanced high strength steel sheets for springback prediction after double stage U-draw bending. Int. J. Solids Struct. 2018, 151, 152–164. [Google Scholar] [CrossRef]

- Fei, D.Y.; Hodgson, P. Experimental and numerical studies of springback in air v-bending process for cold rolled TRIP steels. Nucl. Eng. Des. 2006, 236, 1847–1851. [Google Scholar] [CrossRef]

- Bahloul, R.; Ben-Elechi, S.; Potiron, A. Optimisation of springback predicted by experimental and numerical approach by using response surface methodology. J. Mater. Process. Technol. 2006, 173, 101–110. [Google Scholar] [CrossRef]

- Mori, K.; Maki, S.; Tanaka, Y. Warm and hot stamping of ultra high tensile strength steel sheets using resistance heating. Cirp Ann.-Manuf. Technol. 2005, 54, 209–212. [Google Scholar] [CrossRef]

- Mohammadi, A.; Vanhove, H.; Weise, D.; Van Bael, A.; Landgrebe, D.; Duflou, J.R. Influence of global forced-air warming on the bulge formation in shallow sloped SPIF parts. Procedia Eng. 2017, 183, 149–154. [Google Scholar] [CrossRef]

- Ozturk, F.; Toros, S.; Kilic, S. Tensile and Spring-Back Behavior of DP600 Advanced High Strength Steel at Warm Temperatures. J. Iron Steel Res. Int. 2009, 16, 41–46. [Google Scholar] [CrossRef]

- Saito, N.; Fukahori, M.; Minote, T.; Funakawa, Y.; Hisano, D.; Hamasaki, H.; Yoshida, F. Elasto-viscoplastic behavior of 980 MPa nano-precipitation strengthened steel sheet at elevated temperatures and springback in warm bending. Int. J. Mech. Sci. 2018, 146, 571–582. [Google Scholar] [CrossRef]

- Kim, S.; Lee, Y.; Kang, S. Incremental forming of Mg alloy tool at elevated temperatures. J. Mech. Sci. Technol. 2007, 21, 1518–1522. [Google Scholar] [CrossRef]

- Lee, E.H.; Hwang, J.S.; Lee, C.W.; Yang, D.Y.; Yang, W.H. A local heating method by near-infrared rays for forming of non-quenchable advanced high-strength steels. J. Mater. Process. Technol. 2014, 214, 784–793. [Google Scholar] [CrossRef]

- Mohammadi, A.; Vanhove, H.; Van Bael, A.; Duflou, J.R. Towards accuracy improvement in single point incremental forming of shallow parts formed under laser assisted conditions. Int. J. Mater. Form. 2016, 9, 339–351. [Google Scholar] [CrossRef]

- Duflou, J.R.; Callebaut, B.; Verbert, J.; De Baerdemaeker, H. Improved SPIF performance through dynamic local heating. Int. J. Mach. Tools Manuf. 2008, 48, 543–549. [Google Scholar] [CrossRef]

- Göttmann, A.; Diettrich, J.; Bergweiler, G.; Bambach, M.; Hirt, G.; Loosen, P.; Poprawe, R. Laser-assisted asymmetric incremental sheet forming of titanium sheet metal parts. Prod. Eng. 2011, 5, 263–271. [Google Scholar] [CrossRef]

- Bayerl, T.; Brzeski, M.; Martinez-Tafalla, M.; Schledjewski, R.; Mitschang, P. Thermal degradation analysis of short-time heated polymers. J. Thermoplast. Compos. Mater. 2015, 28, 390–414. [Google Scholar] [CrossRef]

- Mori, K.; Maeno, T.; Mongkolkaji, K. Tailored die quenching of steel parts having strength distribution using bypass resistance heating in hot stamping. J. Mater. Process. Tech 2013, 213, 508–514. [Google Scholar] [CrossRef]

- Ambrogio, G.; Filice, L.; Gagliardi, F. Formability of lightweight alloys by hot incremental sheet forming. Mater. Des. 2012, 34, 501–508. [Google Scholar] [CrossRef]

- Fu, X.; Wang, B.; Tang, X.; Ji, H.; Zhu, X. Study on induction heating of workpiece before gear rolling process with different coil structures. Appl. Therm. Eng. 2017, 114, 1–9. [Google Scholar] [CrossRef]

- Wu, J.; Wu, L.; Lei, B.; Gu, Z.; Li, Y.; Cai, G. Research on Thermal Deformation Behavior of 45 Steel Based on Vibration Aging Process. Hot Working Technol. Technol. 2021, 50, 21–24. [Google Scholar]

- Chang, Y.; Tang, X.; Zhao, K.; Hu, P.; Wu, Y. Investigation of the factors influencing the interfacial heat transfer coefficient in hot stamping. J. Mater. Process. Technol. 2016, 228, 25–33. [Google Scholar] [CrossRef]

- Lee, E.H.; Yoon, J.W.; Yang, D.Y. Study on springback from thermal-mechanical boundary condition imposed to V-bending and L-bending processes coupled with infrared rays local heating. Int. J. Mater. Form. 2018, 11, 417–433. [Google Scholar] [CrossRef]

- Zenkour, A.M.; Abbas, I.A. Nonlinear Transient Thermal Stress Analysis of Temperature-Dependent Hollow Cylinders Using a Finite Element Model. Int. J. Struct. Stab. Dyn. 2014, 14, 1450025. [Google Scholar] [CrossRef]

- Lee, E.H.; Yang, D.Y.; Yoon, J.W.; Yang, W.H. Numerical modeling and analysis for forming process of dual-phase 980 steel exposed to infrared local heating. Int. J. Solids Struct. 2015, 75, 211–224. [Google Scholar] [CrossRef]

- Li, K.; Zhao, S.; Zhang, C. Deformation behavior during single-tooth raidal forging of large-scale spline shaft. J. Plast. Eng. 2022, 69–75. [Google Scholar]

- Abbas, I.; Hobiny, A.; Marin, M. Photo-thermal interactions in a semi-conductor material with cylindrical cavities and variable thermal conductivity. J. Taibah Univ. Sci. 2020, 14, 1369–1376. [Google Scholar] [CrossRef]

- En, N.; Civek, T.; Segin, M. Experimental, analytical and parametric evaluation of the springback behavior of MART1400 sheets. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 451. [Google Scholar]

| Composition | C | Si | Mn | Cr | Cu | Ni | Fe |

| Proportion | 0.43 | 0.27 | 0.60 | 0.15 | 0.20 | 0.22 | bal. |

| Temperature (°C) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

| Thermal Conductivity (W·m−1 K−1) | 50.72 | 48.13 | 45.71 | 41.74 | 38.36 | 33.92 | 30.15 | 26.82 |

| Specific Heat Capacity (J·kg−1 K−1) | 381.25 | 404.16 | 412.52 | 459.83 | 509.12 | 555.14 | 604.36 | 659.35 |

| The modulus of Elasticity (MPa) | 2.07 × 105 | 2.02 × 105 | 1.92 × 105 | 1.87 × 105 | 1.69 × 105 | 1.61 × 105 | 1.46 × 105 | 1.32 × 105 |

| σ0 | R0 | R∞ | b |

|---|---|---|---|

| 41.26 | 6.89 | 162.65 | 17.49 |

| 246.79 | −166.72 | 401.87 | 28.75 |

| Outer Mold Rotation Angle (°) | 30 | 40 | 50 | 60 | 70 |

| Bending Angle at 800 °C (°) | 9.49 | 45.75 | 73.83 | 93.73 | 105.44 |

| Bending Angle at Room Temperature (°) | 7.73 | 42.01 | 68.96 | 88.31 | 100.17 |

| Bending Angle (°) | 15 | 30 | 45 | 60 | 75 | 90 |

| Input (°) | 31.58 | 36.42 | 40.93 | 45.83 | 51.85 | 59.73 |

| Bending angle (°) | 15 | 30 | 45 | 60 | 75 | 90 |

| Maximum bending angle (°) | 16.63 | 34.75 | 49.15 | 64.07 | 79.65 | 94.42 |

| Actual bending angle (°) | 15.83 | 33.91 | 48.23 | 63.11 | 78.54 | 93.13 |

| Springback (°) | 0.81 | 0.84 | 0.92 | 0.95 | 1.11 | 1.29 |

| Springback rate | 5.05% | 2.48% | 1.91% | 1.52% | 1.42% | 1.39% |

| Experimental angle (°) | 16.68 | 31.95 | 49.90 | 64.01 | 78.55 | 91.64 |

| Error | 5.39% | 5.78% | 3.47% | 1.43% | 0.01% | 1.6% |

| Bending angle (°) | 15 | 30 | 45 | 60 | 75 | 90 |

| Maximum bending angle (°) | 18.71 | 33.59 | 47.27 | 61.62 | 75.75 | 89.83 |

| Actual bending angle (°) | 15.48 | 30.97 | 45.05 | 59.31 | 73.38 | 87.31 |

| Springback (°) | 3.22 | 2.62 | 2.22 | 2.29 | 2.37 | 2.53 |

| Springback rate | 20.80% | 8.46% | 4.93% | 3.86% | 3.23% | 2.90% |

| Experimental angle (°) | 15.8 | 29.82 | 43.94 | 56.99 | 71.21 | 84.98 |

| Error | 2.06% | 3.71% | 2.47% | 3.91% | 2.96% | 2.65% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Geng, H.; Cao, C.; Arif, A.F.M.; Liu, X.; Yuan, J. Study on L-Bending Springback of 45 Steel Leather Cutting Tool Coupled with Local Induction Heating. Appl. Sci. 2024, 14, 6253. https://doi.org/10.3390/app14146253

Cheng Y, Geng H, Cao C, Arif AFM, Liu X, Yuan J. Study on L-Bending Springback of 45 Steel Leather Cutting Tool Coupled with Local Induction Heating. Applied Sciences. 2024; 14(14):6253. https://doi.org/10.3390/app14146253

Chicago/Turabian StyleCheng, Yuan, Heran Geng, Chao Cao, Abul Fazal M. Arif, Xinhua Liu, and Junfeng Yuan. 2024. "Study on L-Bending Springback of 45 Steel Leather Cutting Tool Coupled with Local Induction Heating" Applied Sciences 14, no. 14: 6253. https://doi.org/10.3390/app14146253

APA StyleCheng, Y., Geng, H., Cao, C., Arif, A. F. M., Liu, X., & Yuan, J. (2024). Study on L-Bending Springback of 45 Steel Leather Cutting Tool Coupled with Local Induction Heating. Applied Sciences, 14(14), 6253. https://doi.org/10.3390/app14146253