Comparative Study of the Effects of Conventional, Waste, and Alternative Materials on the Geomechanical Properties of Clayey Soil in the Chemical Soil Stabilisation Technique

Abstract

:1. Introduction

2. Materials and Methods Considered in the Research

2.1. Materials Considered in the Research

2.1.1. Natural Clayey Soil

2.1.2. Chemical Stabilisers

- Conventional stabilisers

- Waste materials

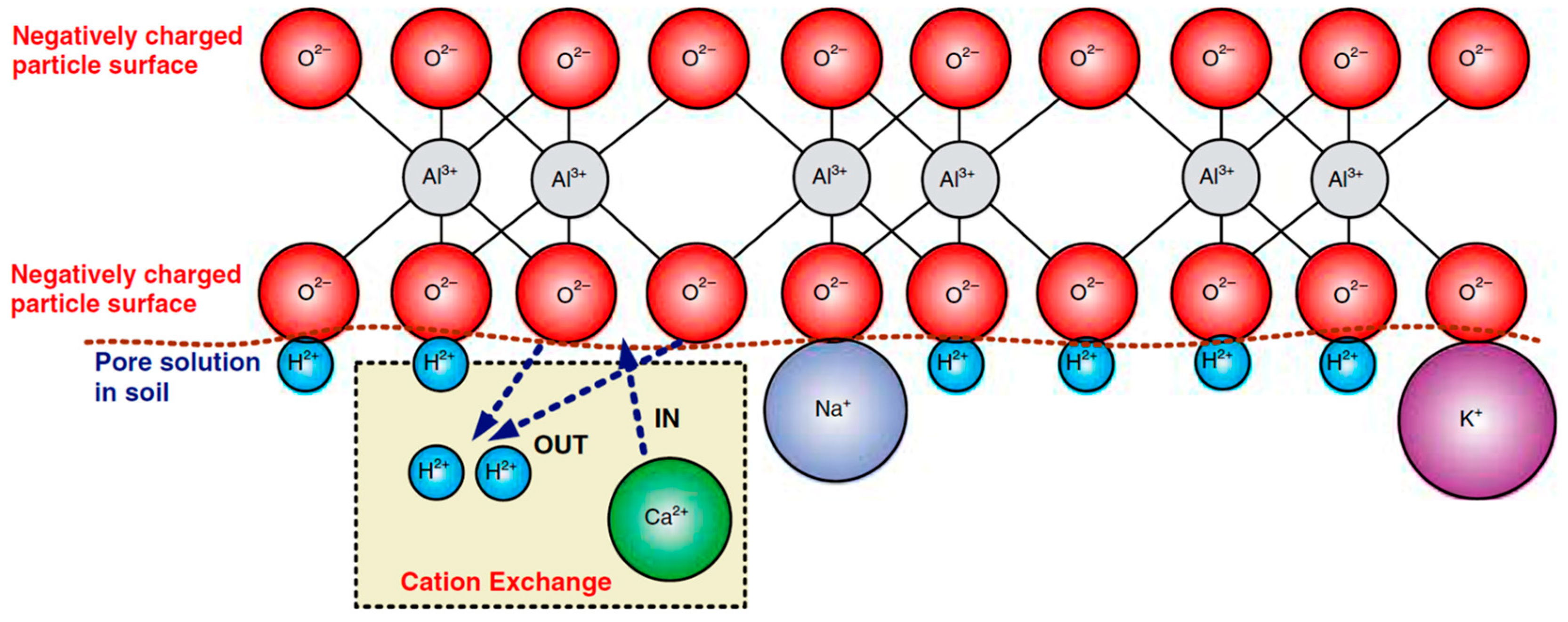

- Alternative chloride-based reagents

2.2. Methods of Experimental Research

3. Research Results—Analysis and Discussion

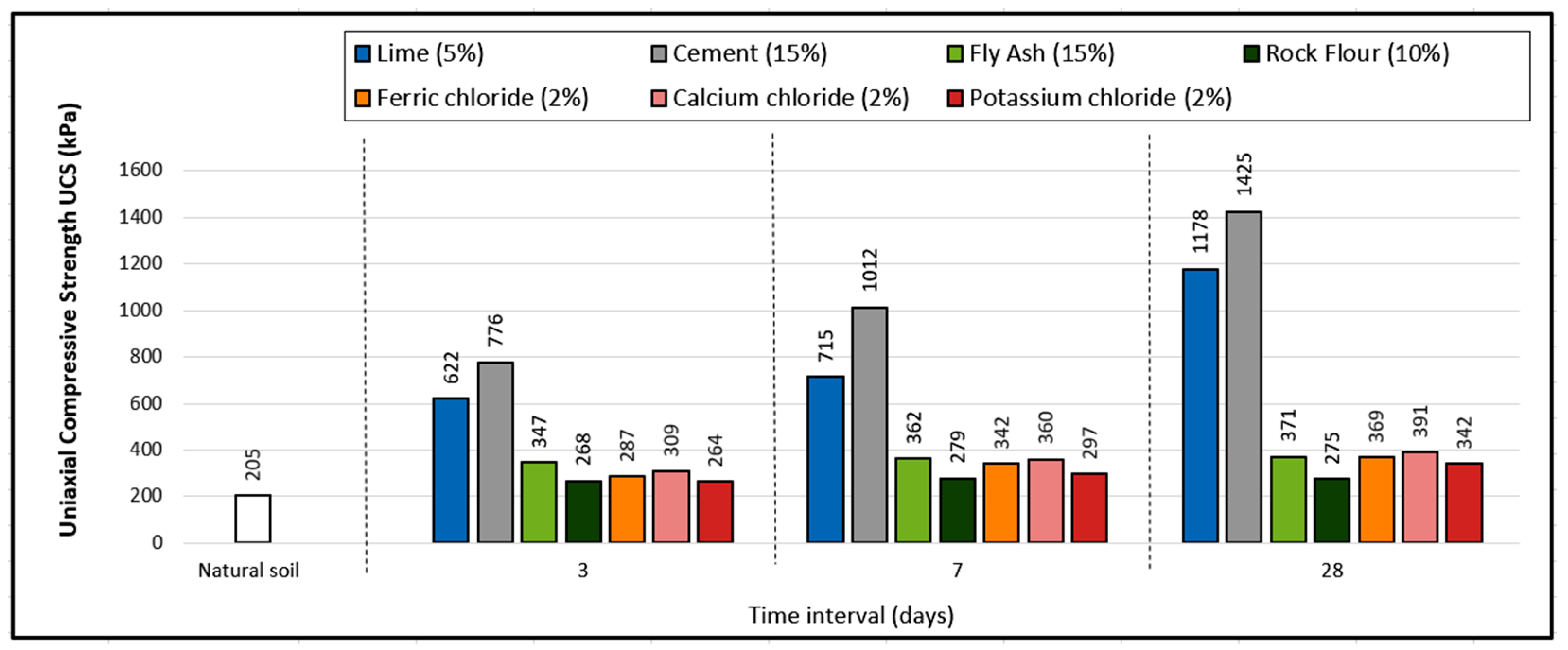

3.1. Uniaxial Compressive Strength (UCS)

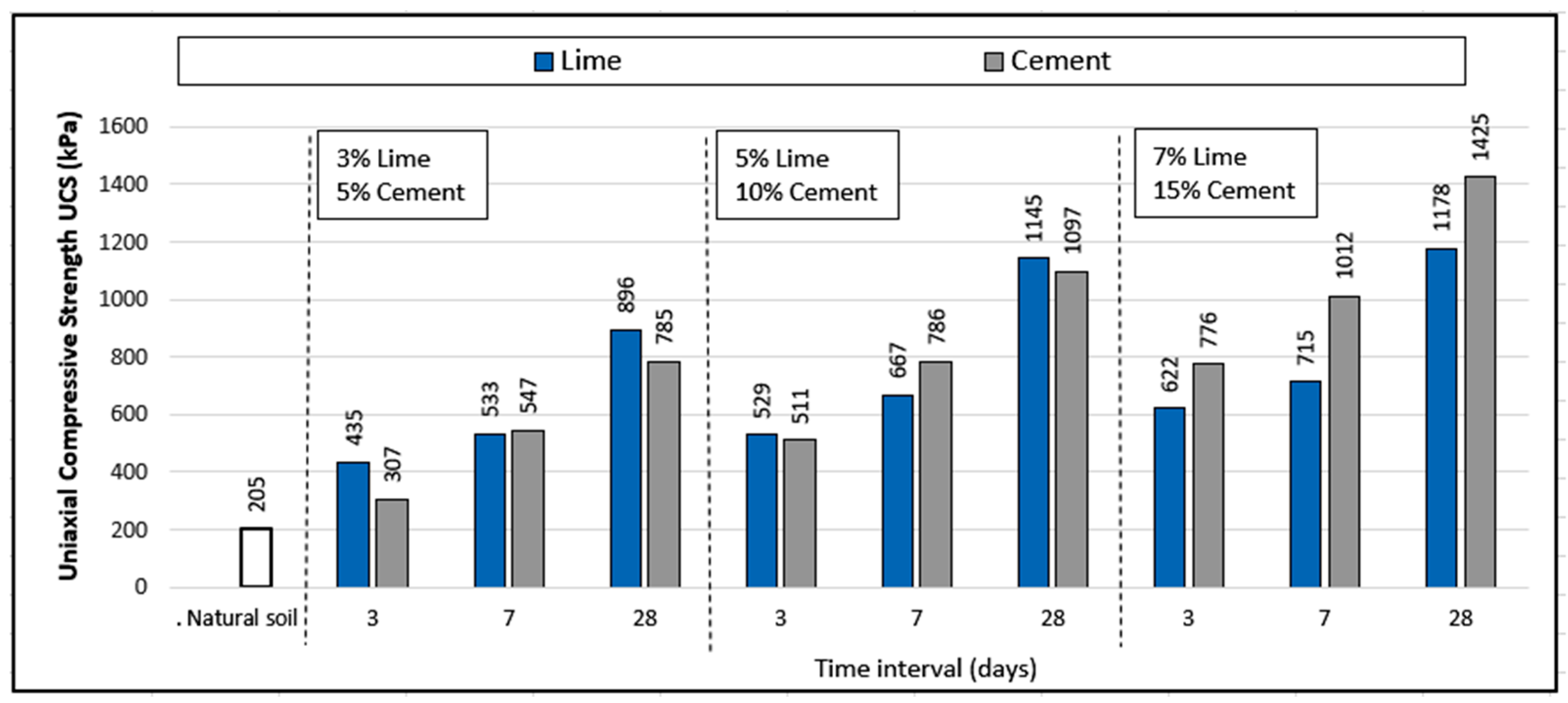

3.1.1. Effects of Conventional Stabilisers on UCS

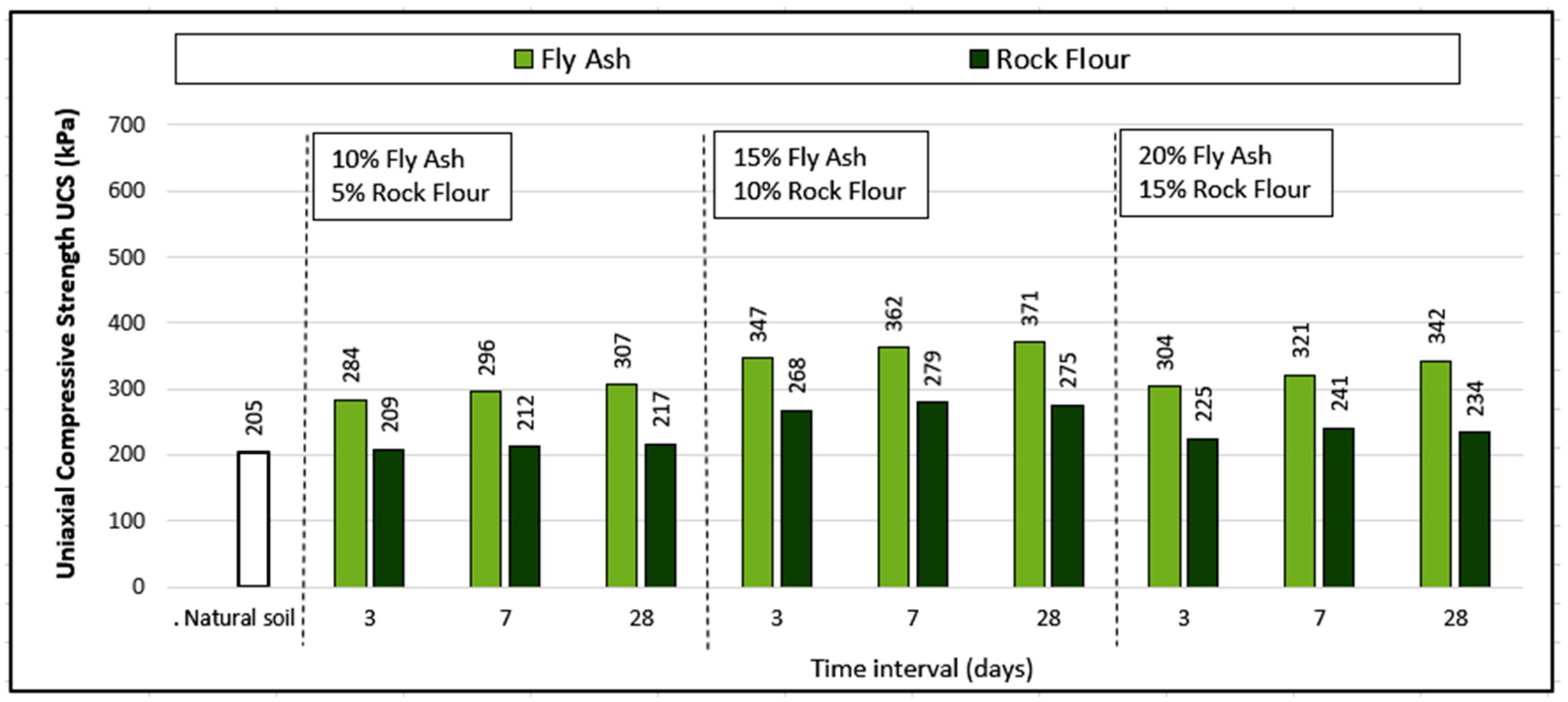

3.1.2. Effects of Waste-Based Stabilisers on UCS

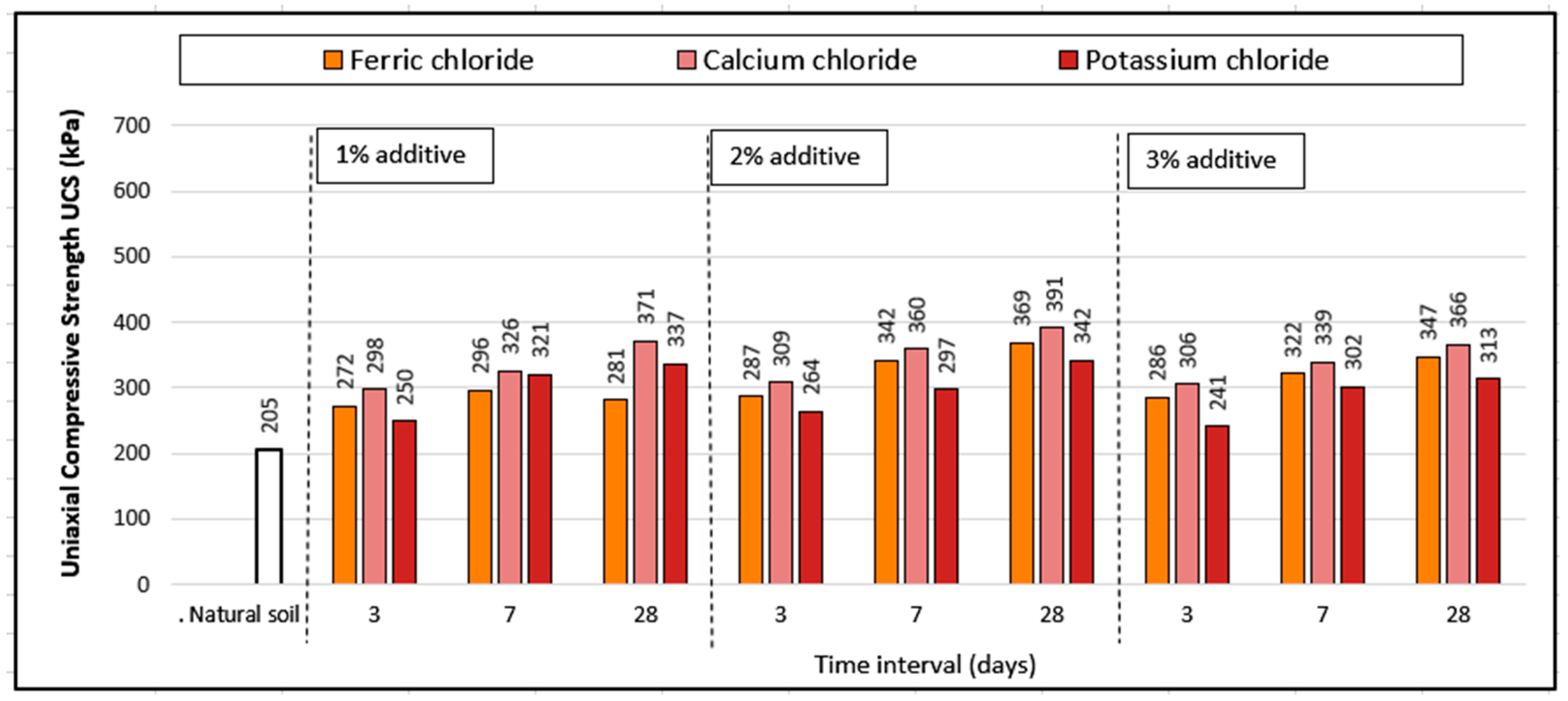

3.1.3. Effects of Alternative Chloride-Based Stabilisers on UCS

3.2. pH Value

3.3. Optimal Stabiliser Content

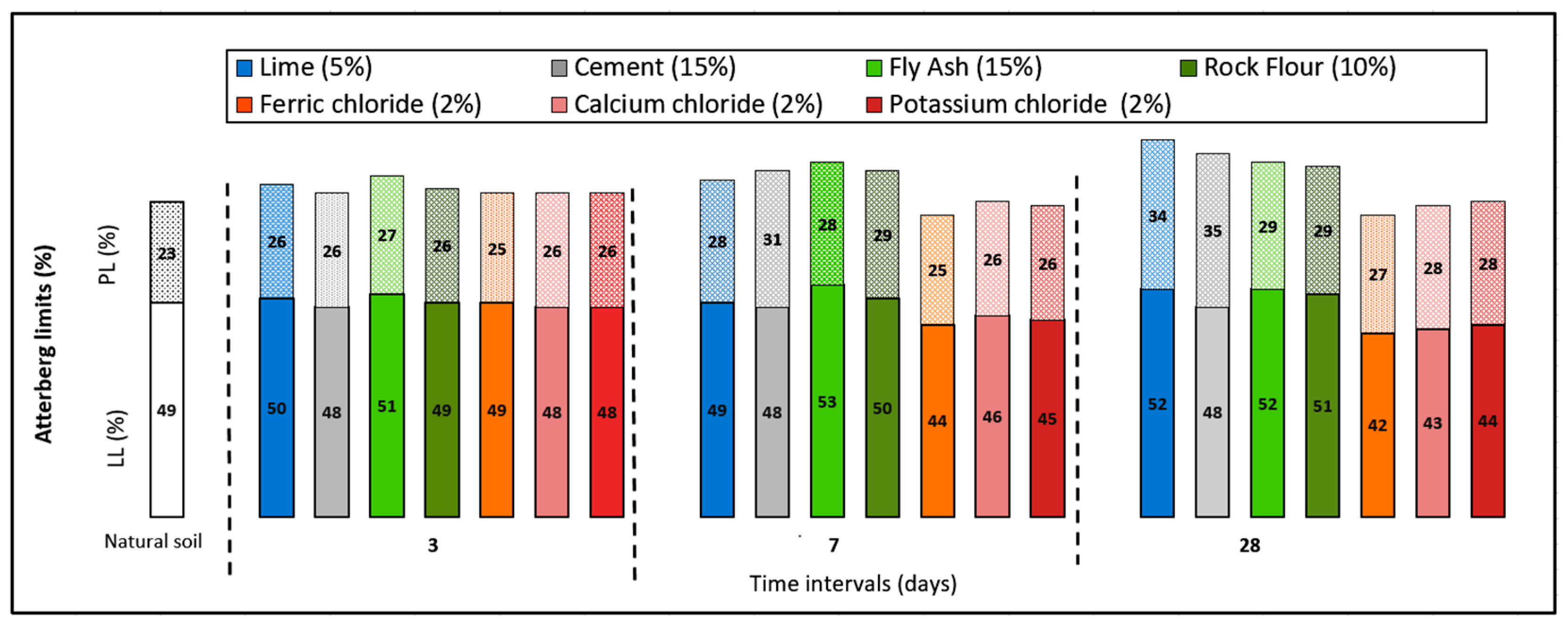

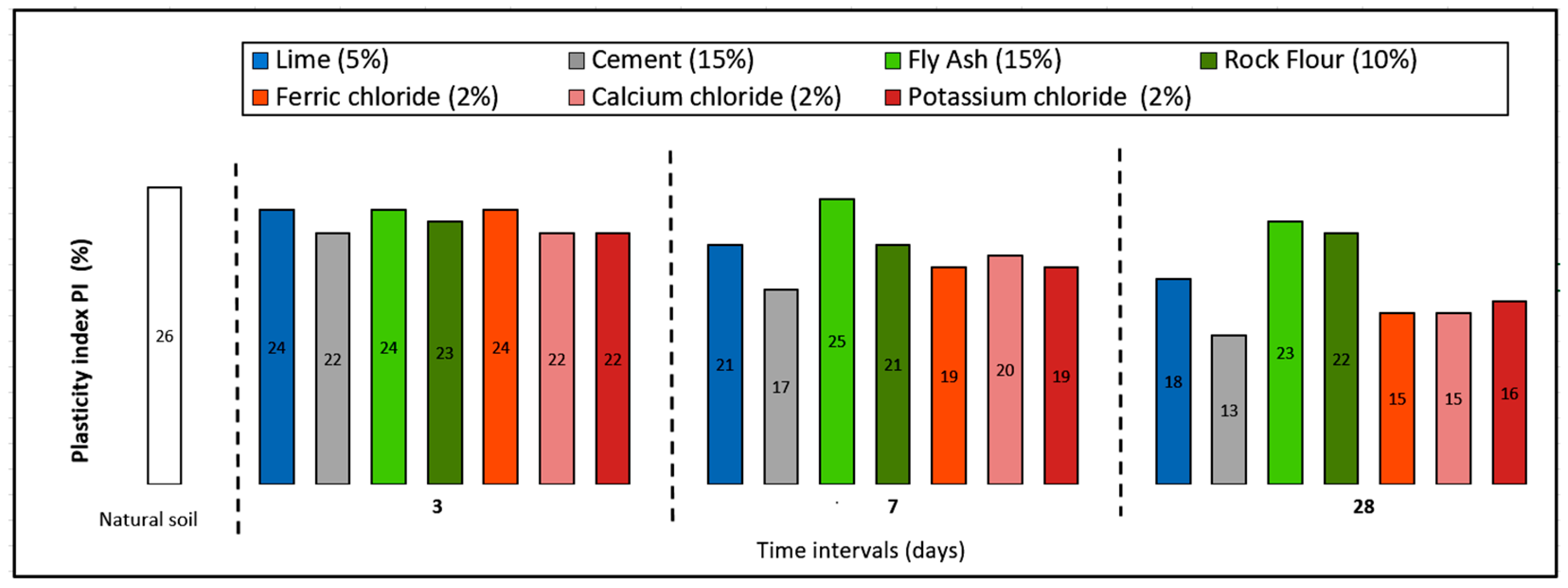

3.4. Atterberg’s Limits (LL and PL) and Plasticity Index (PI)

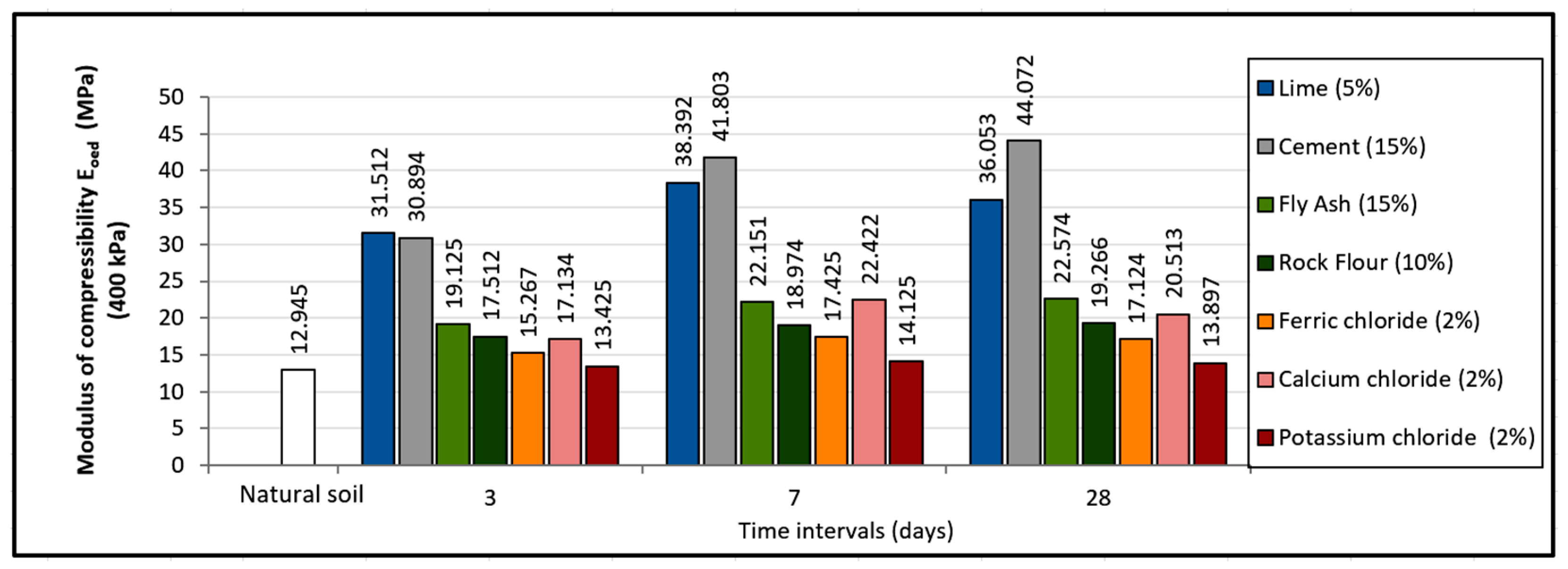

3.5. Modulus of Compressibility (Mv, Eoed)

3.6. California Bearing Ratio (CBR) and Swelling (s)

4. Concluding Remarks

- All the considered stabilisers contributed to the improvement of the uniaxial compressive strength of the clayey soil, among which conventional stabilisers proved to be the most effective.

- The results of the change in pH value revealed that conventional stabilisers are the most successful in reducing soil acidity, a slight increase in the pH value was registered with the addition of waste materials, whereas with the use of chloride the pH value of the natural soil decreased.

- It was determined that the optimal content of stabiliser for the treated clayey soil in the case of applying chlorides attains 2%, in the case of lime is 5%, for rock flour is 10%, with the addition of flying ash is 15%, whereas for cement is found to be higher than the considered 15%, which on the other hand raises the question of the economic justification of the procedure with this binder.

- None of the examined stabilisers contributed to a significant change in the LL value, whereas each of them contributed to an increase in the PL value, which ultimately led to a reduction in the plasticity index of the treated clayey soil.

- The best results in terms of increasing the value of the compressibility modulus were achieved with the addition of conventional stabilisers, although the other considered stabilisers also contributed to the reduced compressibility of the treated soil compared to the natural soil material.

- In the case of all the considered stabilisers, CBR values are higher than 3%, which is of great benefit when it comes to road construction, whereby the greatest improvement was achieved in the case of stabilisation with conventional stabilisers.

- Each of the considered stabilisers contributed to the reduction of soil swelling, whereby the greatest reduction was achieved by the addition of conventional stabilisers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pastor, J.L.; Chai, J.; Sánchez, I. Strength and microstructure of a clayey soil stabilized with natural stone industry waste and lime or cement. Appl. Sci. 2023, 13, 2583. [Google Scholar] [CrossRef]

- Tingle, J.S.; Santoni, R.L. Stabilization of clay soils with nontraditional additives. Transp. Res. Rec. 2003, 1819, 72–84. [Google Scholar] [CrossRef]

- Saygili, G.; Yildirim, Y.; Sahin, H. Stabilization of high sulfate soils with nontraditional additives. In PanAm Unsaturated Soils 2017: Swell-Shrink and Tropical Soils; Hoyos, L.R., McCartney, J.S., Houston, S.L., Likos, W.J., Eds.; American Society of Civil Engineers (ASCE): Washington, DC, USA, 2018; pp. 236–245. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Y. Mechanical and microstructural changes in expansive soils treated with lime and lignin fiber from paper industry. Appl. Sci. 2024, 14, 3393. [Google Scholar] [CrossRef]

- Turkoz, M.; Savas, H.; Acaz, A.; Tosun, H. The effect of magnesium chloride solution on the engineering properties of clay soil with expansive and dispersive characteristics. Appl. Clay Sci. 2014, 101, 1–9. [Google Scholar] [CrossRef]

- Almajed, A.; Dafalla, M.; Shaker, A.A. The combined effect of calcium chloride and cement on expansive soil materials. Appl. Sci. 2023, 13, 4811. [Google Scholar] [CrossRef]

- Latifi, N.; Eisazadeh, A.; Marto, A. Strength behavior and microstructural characteristics of tropical laterite soil treated with sodium silicate-based liquid stabilizer. Environ. Earth Sci. 2013, 72, 91–98. [Google Scholar] [CrossRef]

- Al-Gharbawi, A.S.A.; Najemalden, A.M.; Fattah, M.Y. Expansive soil stabilization with lime, cement, and silica fume. Appl. Sci. 2023, 13, 436. [Google Scholar] [CrossRef]

- Archibong, G.A.; Sunday, E.U.; Akudike, J.C.; Okeke, O.C.; Amadi, C. A review of the principles and methods of soil stabilization. Int. J. Adv. Sci. Technol. 2020, 6, 89–115. [Google Scholar]

- Barman, D.; Dash, S.K. Stabilization of expansive soils using chemical additives: A review. J. Rock. Mech. Geotech. Eng. 2022, 14, 1319–1342. [Google Scholar] [CrossRef]

- Tan, E.H.; Zahran, E.M.M.; Tan, S.J. A review of chemical stabilisation in road construction. IOP Conf. Ser. Mater. Sci. Eng. 2020, 943, 012005. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Kazemi, A.; Javadi, A.A.; Moghadas, M. Stabilisation of a clay soil by injection of different ions. Proc. Inst. Civ. Eng. Ground Improv. 2022, 175, 261–276. [Google Scholar] [CrossRef]

- Verma, H.; Ray, A.; Rai, R.; Gupta, T.; Mehta, N. Ground improvement using chemical methods: A review. Heliyon 2021, 7, 07678. [Google Scholar] [CrossRef] [PubMed]

- Braunović, B. Road Pavements Made of Stabilized Local Material; Građevinska Knjiga: Belgrade, Serbia, 1991. (In Serbian) [Google Scholar]

- Radhakrishnan, G.; Anjan Kumar, M.; Raju, G.V.R.P. Laboratory evaluation of the effects of 3-chloride compounds on the geotechnical properties of an expansive subgrade soil. J. Inst. Eng. India Ser. A 2017, 98, 477–482. [Google Scholar] [CrossRef]

- Bell, F. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Shon, C.S.; Saylak, D.; Mishra, S.K. Combined use of calcium chloride and fly ash in road base stabilization. Transp. Res. Rec. 2010, 2186, 120–129. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- ACAA 2022 CCP Survey Results and Production & Use Charts. Available online: www.acaa-usa.org (accessed on 25 April 2024).

- Kolay, P.K.; Sii, H.Y.; Taib, S.N.L. Tropical peat soil stabilization using class F pond ash from coal fired power plant. Int. J. Civ. Environ. Eng. 2011, 5, 71–75. [Google Scholar]

- Vukićević, M.; Pujević, V.; Marjanović, M.; Jocković, S.; Maraš-Dragojević, S. Stabilization of fine-grained soils with fly ash. Gradjevinar 2015, 67, 761–770. [Google Scholar] [CrossRef]

- Zafirovski, Z.; Markovski, M.; Ognjenovic, S.; Gacevski, V.; Nedevska, I.; Ristov, R. Subbase stabilization with fly ash. Facta Univ. Ser. Archit. Civ. Eng. 2024, 22, 79–88. [Google Scholar] [CrossRef]

- Ene, E.; Okagbue, C. Some basic geotechnical properties of expansive soil modified using pyroclastic dust. Eng. Geol. 2009, 107, 61–65. [Google Scholar] [CrossRef]

- Omowumi, A. Engineering evaluation of lateritic soils of failed highway sections in Southwestern Nigeria. Geosci. Res. 2017, 2, 210–218. [Google Scholar] [CrossRef]

- Gbadamosi, O.S. Improvement of Bearing Capacity of Lateritic Soil for Pavement Subgrade by Addition of Rock Flour. Ph.D. Thesis, Federal University of Technology, Minna, Nigeria, August 2021. [Google Scholar]

- Singh, J.; Singh, U.K.; Singh, R.K. Stabilization of clayey soil using gypsum and calcium chloride. Int. J. Recent Tech. Eng. 2020, 9, 668–673. [Google Scholar] [CrossRef]

- Marto, A.; Latifi, N.; Eisazadeh, A. Effect of non-traditional additives on engineering and microstructural characteristics of laterite soil. Arab. J. Sci. Eng. 2014, 39, 6949–6958. [Google Scholar] [CrossRef]

- Jafer, H.M. Stabilization of soft soils using salts of chloride. J. Babylon Univ. Eng. Sci. 2013, 21, 1546–1554. [Google Scholar]

- Latifi, N.; Marto, A.; Eisazadeh, A. Physicochemical behavior of tropical laterite soil stabilized with non-traditional additive. Acta Geotech. 2016, 11, 433–443. [Google Scholar] [CrossRef]

- Zumrawi, M.M.; Mahjoub, A.M.; Alnour, I.M. Effect of some chloride salts on swelling properties of expansive soil. Univ. Khartoum Eng. J. 2016, 6, 35–41. [Google Scholar] [CrossRef]

- Vinod, B.R.; Shobha, R.; Varun Purad, A.T.; Mansi, S. Analysis of engineering properties of expansive soil treated with ferric chloride and bagasse ash. Int. J. Contemp. Arch. New Arch 2021, 8, 460–467. [Google Scholar]

- Venkaramuthyalu, P.; Ramu, K.; Prasada Raju, G.V.R. Study on performance of chemically stabilized expansive soil. Int. J. Adv. Eng. Tech. 2012, 2, 139–148. [Google Scholar]

- SRPS EN 13286-41:2022; Unbound and Hydraulically Bound Mixtures—Part 41: Test Method for the Determination of the Compressive Strength of Hydraulically Bound Mixtures. Institute for Standardization of Serbia (ISS): Belgrade, Serbia, 2022.

- SRPS EN ISO 14688-2:2018; Geotechnical Investigation and Testing—Identification and Classification of Soil—Part 2: Principles for a Classification. Institute for Standardization of Serbia (ISS): Belgrade, Serbia, 2018.

- SRPS EN ISO 17892-5:2017; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 5: Incremental Loading Oedometer Test. Institute for Standardization of Serbia (ISS): Belgrade, Serbia, 2017.

- SRPS EN 13286-47:2022; Unbound and Hydraulically Bound Mixtures—Part 47: Test Method for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling. Institute for Standardization of Serbia (ISS): Belgrade, Serbia, 2022.

- Ghobadi, M.H.; Abdilor, Y.; Babazadeh, R. Stabilization of clay soils using lime and effect of pH variations on shear strength parameters. Bull. Eng. Geol. Environ. 2014, 73, 611–619. [Google Scholar] [CrossRef]

- Sharma, L.K.; Sirdesai, N.N.; Sharma, K.M.; Singh, T.N. Experimental study to examine the independent roles of lime and cement on the stabilization of a mountain soil: A comparative study. Appl. Clay Sci. 2018, 152, 183–195. [Google Scholar] [CrossRef]

- Eades, J.L.; Grim, R.E. A quick test to determine lime requirements for lime stabilization. In Behavior Characteristics of Lime-Soil Mixtures; Highway Research Board: Washington, DC, USA, 1966; Issue 139, pp. 61–72. Available online: http://onlinepubs.trb.org/Onlinepubs/hrr/1966/139/139-005.pdf (accessed on 13 June 2024).

- Sol-Sánchez, M.; Castro, J.; Ureña, C.; Azañón, J.M. Stabilisation of clayey and marly soils using industrial wastes: pH and laser granulometry indicators. Eng. Geol. 2016, 200, 10–17. [Google Scholar] [CrossRef]

- Seco, A.; del Castillo, J.M.; Espuelas, S.; Marcelino, S.; García, B. Sulphate soil stabilisation with magnesium binders for road subgrade construction. Int. J. Pavement Eng. 2020, 23, 1840–1850. [Google Scholar] [CrossRef]

| Property of Soil | Symbol (Unit) | Value |

|---|---|---|

| Particle Density | Gs (-) | 2.705 |

| Grain Size Distribution | Gravel (%) | 1.2 |

| Sand (%) | 4.9 | |

| Silt (%) | 40.6 | |

| Clay (%) | 53.3 | |

| Coefficient of Uniformity | Cu (-) | 8.0 |

| Coefficient of Curvature | Cc (-) | 2.0 |

| USCS Soil Classification | Symbol (-) | CL |

| Maximum Dry Density | MDD (g/cm3) | 1.903 |

| Optimal Moisture Content | OMC (%) | 18.5 |

| Uniaxial Compressive Strength | UCS (kPa) | 205 |

| Liquid Limit | LL (%) | 49 |

| Plastic Limit | PL (%) | 23 |

| Plasticity Index | PI (%) | 26 |

| pH Value | pH (-) | 9.5 |

| Modulus of Compressibility | Mv (MPa) | 12.945 |

| California Bearing Ratio | CBR (%) | 2.71 |

| Swelling | s (%) | 2.91 |

| Mixture Specimens | Percentage Share of a Stabiliser in the Mixture | ||

|---|---|---|---|

| Soil + Lime | 3% | 5% | 7% |

| Soil + Cement | 5% | 10% | 15% |

| Soil + Rock Flour | |||

| Soil + Fly Ash | 10% | 15% | 20% |

| Soil + Ferric Chloride | 1% | 2% | 3% |

| Soil + Calcium Chloride | |||

| Soil + Potassium Chloride | |||

| Soil Conditions | pH Value | ||||

|---|---|---|---|---|---|

| After 24 h | After 3 Days | After 28 Days | |||

| Soil in natural conditions | 9.5 | 9.5 | 9.5 | ||

| Soil after chemical stabilisation | Lime | 3% | 12.1 | 12.0 | 12.0 |

| 5% | 12.5 | 12.5 | 12.4 | ||

| 7% | 12.8 | 12.8 | 12.7 | ||

| Cement | 5% | 11.6 | 11.6 | 11.6 | |

| 10% | 12.0 | 12.0 | 12.0 | ||

| 15% | 12.4 | 12.4 | 12.4 | ||

| Fly ash | 10% | 11.2 | 11.2 | 11.0 | |

| 15% | 11.6 | 11.3 | 11.3 | ||

| 20% | 12.0 | 11.8 | 11.6 | ||

| Rock flour | 5% | 10.5 | 10.5 | 10.2 | |

| 10% | 10.9 | 10.8 | 10.5 | ||

| 15% | 11.1 | 11.1 | 10.6 | ||

| Ferric chloride | 1% | 9.5 | 9.5 | 9.2 | |

| 2% | 9.4 | 9.4 | 9.2 | ||

| 3% | 9.4 | 9.3 | 9.0 | ||

| Calcium chloride | 1% | 9.2 | 9.2 | 9.2 | |

| 2% | 9.0 | 9.0 | 9.0 | ||

| 3% | 9.0 | 9.0 | 9.0 | ||

| Potassium chloride | 1% | 9.5 | 9.5 | 9.5 | |

| 2% | 9.5 | 9.5 | 9.5 | ||

| 3% | 9.4 | 9.4 | 9.4 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zlatanović, E.; Marinković, N.; Bonić, Z.; Romić, N.; Djorić-Veljković, S.; Cvetković, D.; Djordjević, D. Comparative Study of the Effects of Conventional, Waste, and Alternative Materials on the Geomechanical Properties of Clayey Soil in the Chemical Soil Stabilisation Technique. Appl. Sci. 2024, 14, 6249. https://doi.org/10.3390/app14146249

Zlatanović E, Marinković N, Bonić Z, Romić N, Djorić-Veljković S, Cvetković D, Djordjević D. Comparative Study of the Effects of Conventional, Waste, and Alternative Materials on the Geomechanical Properties of Clayey Soil in the Chemical Soil Stabilisation Technique. Applied Sciences. 2024; 14(14):6249. https://doi.org/10.3390/app14146249

Chicago/Turabian StyleZlatanović, Elefterija, Nemanja Marinković, Zoran Bonić, Nikola Romić, Snežana Djorić-Veljković, Dušan Cvetković, and Dragan Djordjević. 2024. "Comparative Study of the Effects of Conventional, Waste, and Alternative Materials on the Geomechanical Properties of Clayey Soil in the Chemical Soil Stabilisation Technique" Applied Sciences 14, no. 14: 6249. https://doi.org/10.3390/app14146249

APA StyleZlatanović, E., Marinković, N., Bonić, Z., Romić, N., Djorić-Veljković, S., Cvetković, D., & Djordjević, D. (2024). Comparative Study of the Effects of Conventional, Waste, and Alternative Materials on the Geomechanical Properties of Clayey Soil in the Chemical Soil Stabilisation Technique. Applied Sciences, 14(14), 6249. https://doi.org/10.3390/app14146249