Two-Parameter Probabilistic Model and Experimental Research on Micron Particle Deposition

Abstract

1. Introduction

2. Particle Deposition Model

2.1. Model Assumptions

- It is assumed that the gas fluid is an incompressible medium, and no temperature change occurs in the study;

- It is assumed that the particles are monodisperse spherical particles of the same diameter with the same physical and chemical properties;

- It is supposed that the influence of particles on the fluid and particles is ignored;

- It is assumed that the work of the adhesion force and the elastic force can be linearly superimposed, and the deposited particles no longer deform when colliding.

2.2. Particle Migration

2.2.1. Mathematical Model of Flow Field

2.2.2. Migration Force of Particulate Matter in Flow Field

2.3. Two-Parameter Particle Probability Deposition Model

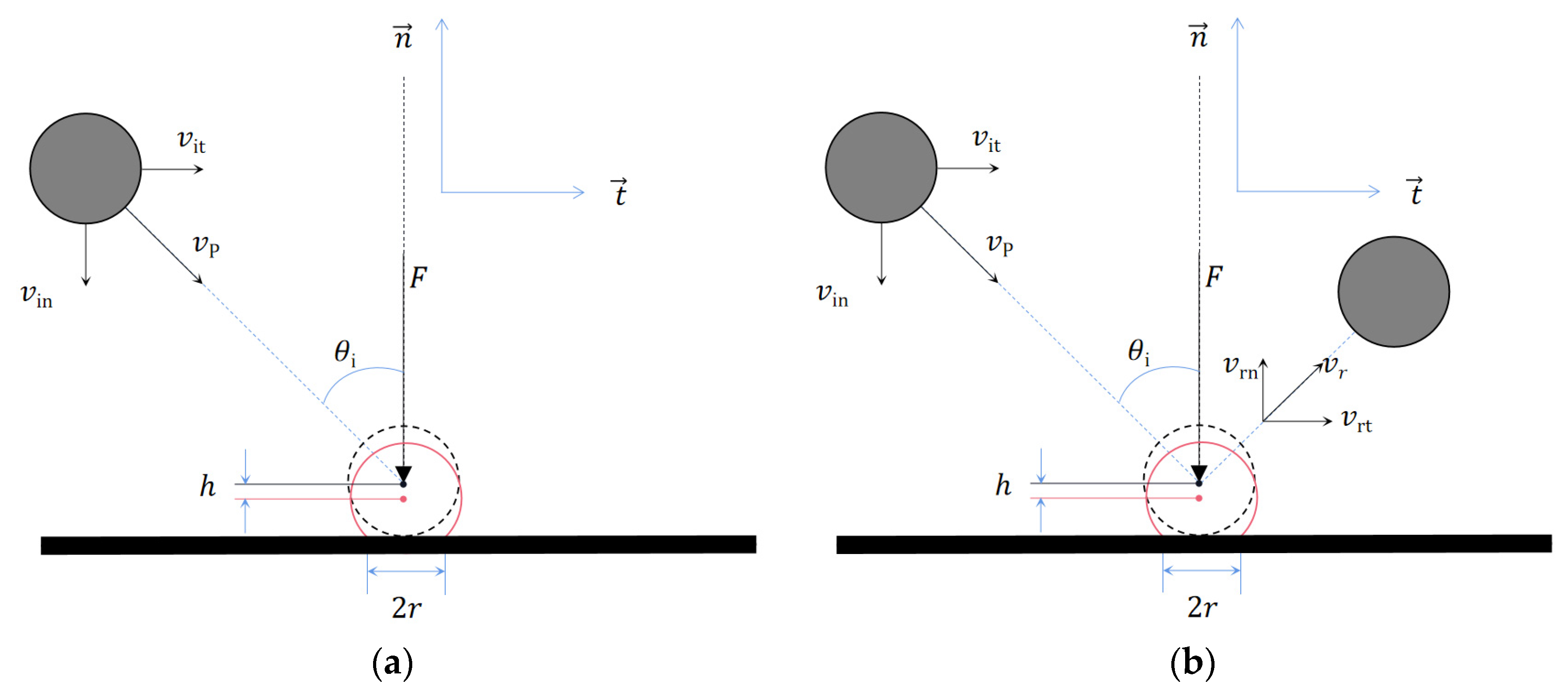

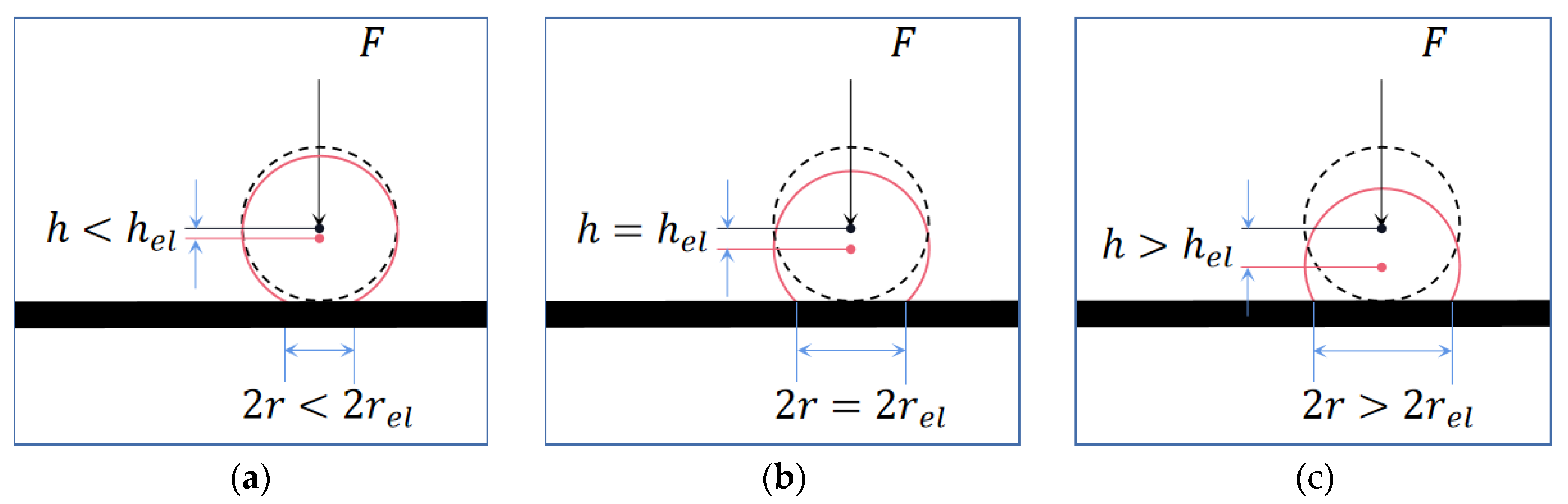

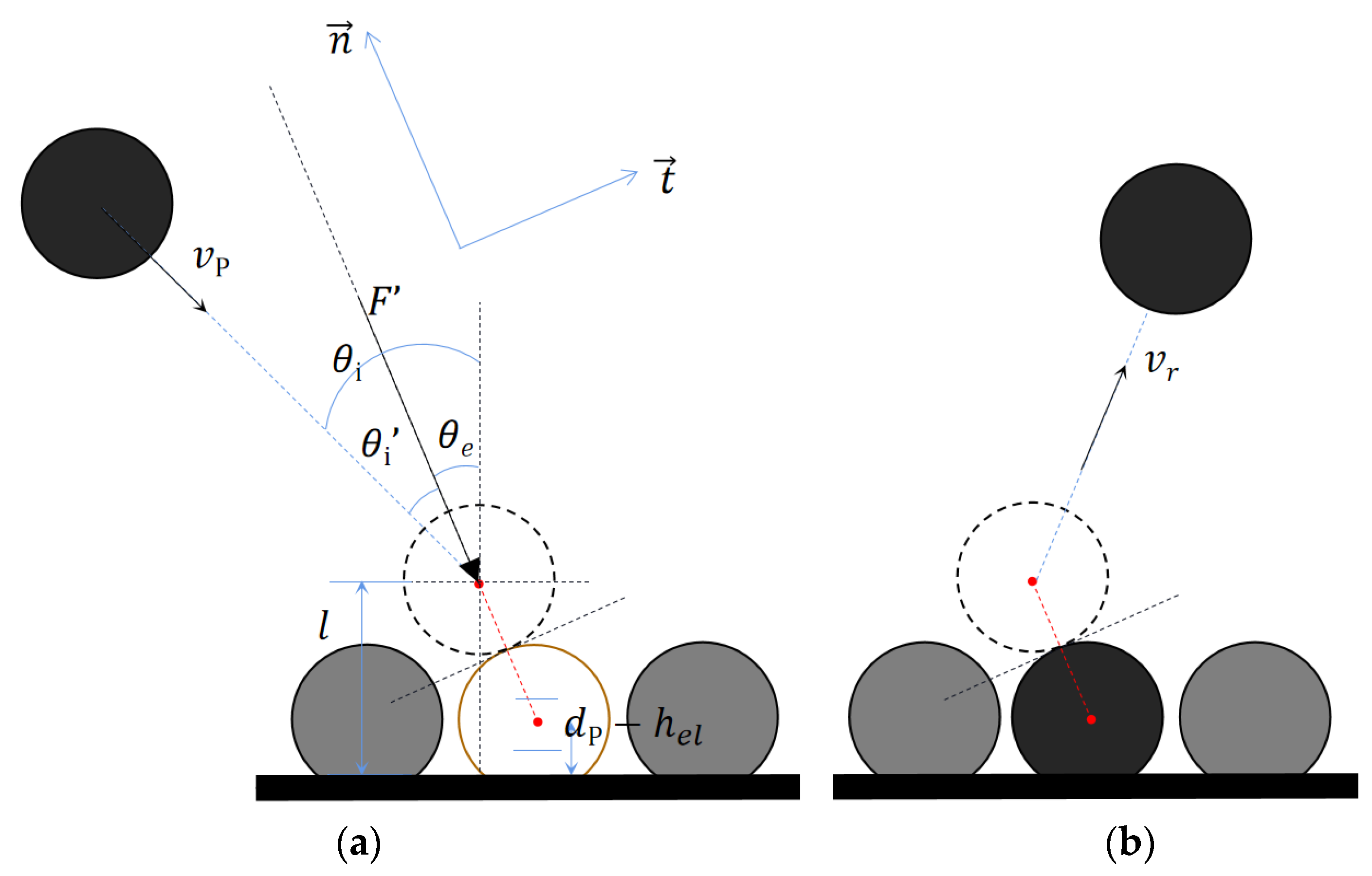

2.3.1. Two-Parameter Determination of Particle Deposition

- If the particle collision angle is less than or equal to the tangential critical collision angle ( ≤ ) and the normal incident velocity of the particle is less than or equal to the normal critical deposition velocity ( ≤ ), the particle will show a wall deposition state ( = 0);

- If the collision angle of the particulate matter is greater than or equal to the tangential critical collision angle ( > ), the particulate matter will show a wall desorbed state ( = 1). If the normal incidence velocity is greater than the normal critical deposition velocity ( > ), the desorption of particles will rebound from the wall surface and return to the continuous-phase fluid. Otherwise, the desorption of particles will be parallel to the wall surface;

- When the collision angle is less than or equal to the tangential critical collision angle ( ≤ ) and the normal incidence velocity is greater than the normal critical deposition velocity ( > ), the particles still exhibit a wall desorption state ( = 1), and the desorption behavior of particles is that they rebound from the wall and return to the continuous-phase fluid.

2.3.2. Determination of Collision Probability of Particle Deposition

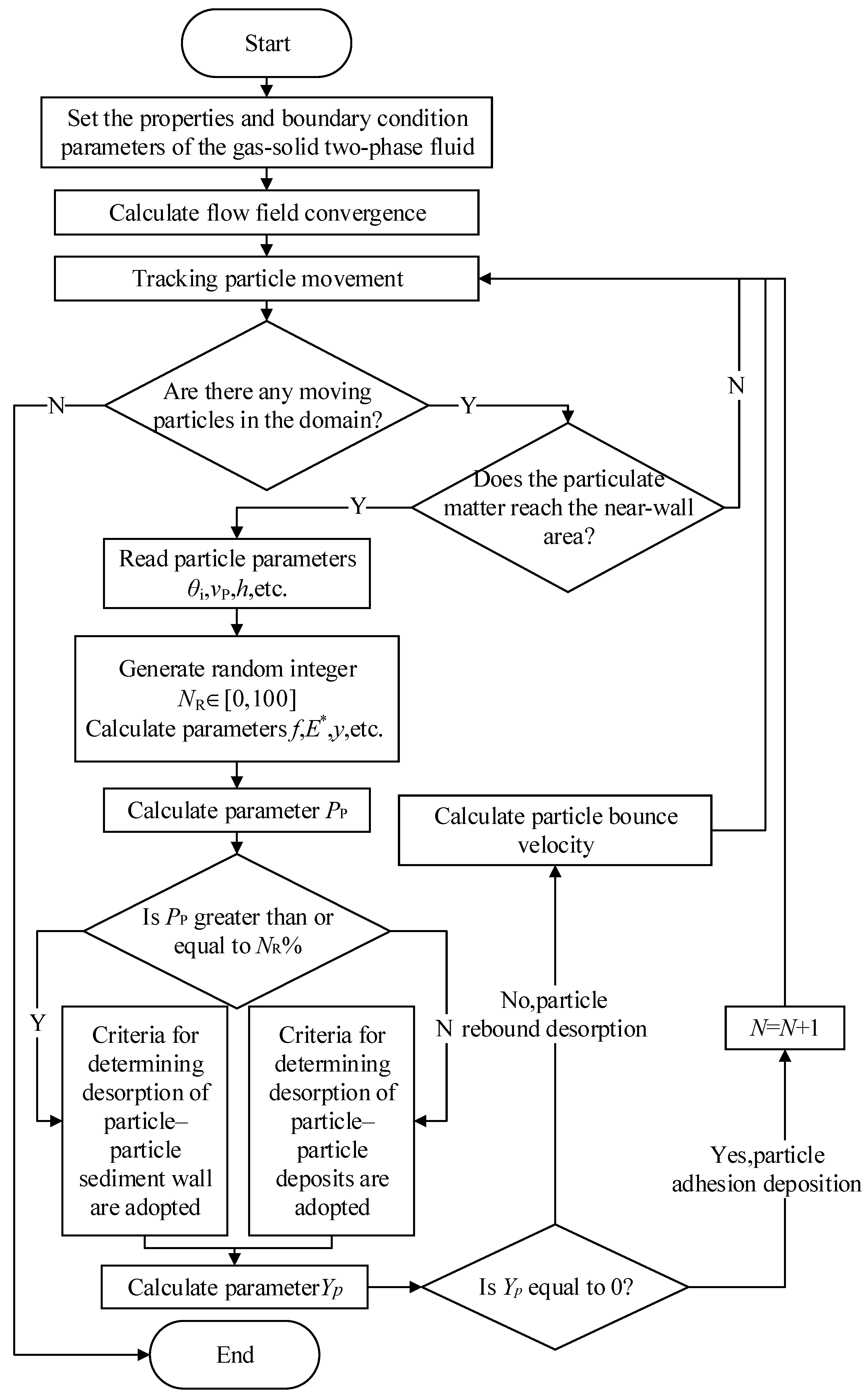

2.3.3. Deposition Calculation Flow of Two-Parameter Particle Probability Deposition

- Start the calculation and set the necessary input parameters, including gas–solid two-phase fluid properties, boundary conditions and other setting parameters, the UDF transmission particle deposition desorbed determination criteria, and other conditional functions;

- According to the input spherical particle force condition function, the Euler–Lagrangian equation is used to calculate the flow field parameters of the gas–solid two-phase particles, and capture the trajectory of the particles in the calculation domain;

- If particulate matter enters the specified near-wall area (the specified near-wall grid), it is considered that the particulate matter will collide with the target surface (particle deposition wall or particle deposition layer); if the particulate matter is not recognized to enter the specified near-wall area (the specified near-wall grid), it is considered that the particulate matter will collide with the target surface (particle deposition wall or particle deposition layer) in the near-wall grid; then continue to track the trajectory of particulate matter in the calculation domain;

- For particles that are about to collide, read the collision angle , particle velocity , particle coordinates, center sinking scale , and other parameters, and calculate the critical stress of the particles , the equivalent Young’s modulus , and the sinking area of the specified unit (grid), and intermediate parameters such as particle number ;

- Call the random function in Fluent to randomly generate an integer greater than or equal to 0 and less than or equal to 100;

- The collision probability coefficient of particulate matter and deposited particles is obtained through the calculated intermediate parameters, and the size of the and values is compared. If , the determination criteria for the deposition and desorbing of the particulate matter–particle deposition wall are used for the particulate matter; otherwise, the determination criteria for the deposition and desorbing of the particulate matter–particle deposition layer are used;

- According to the corresponding criteria, combined with the calculated intermediate parameters, the state coefficient of the particulate matter and particulate matter deposition wall surface is obtained. If = 0, it means that the relationship between the particulate matter and particulate matter deposition wall surface at this time is deposition, and the number of particles accumulated in the area of the specified unit (grid) is value plus 1, and the particles are removed from the calculation domain; otherwise, it means that the relationship between the particulate matter and the deposited wall of the particulate matter is desorbed; calculate the rebound desorbed velocity of the particulate matter, and the particles re-enter the flow field calculation domain at the same time;

- Repeat the calculation step (2) until there are no moving particles in the calculation domain, and reach end the calculation.

3. Results and Discussion

3.1. Particle Migration and Deposition Simulation

3.2. Particle Migration and Deposition Experiment

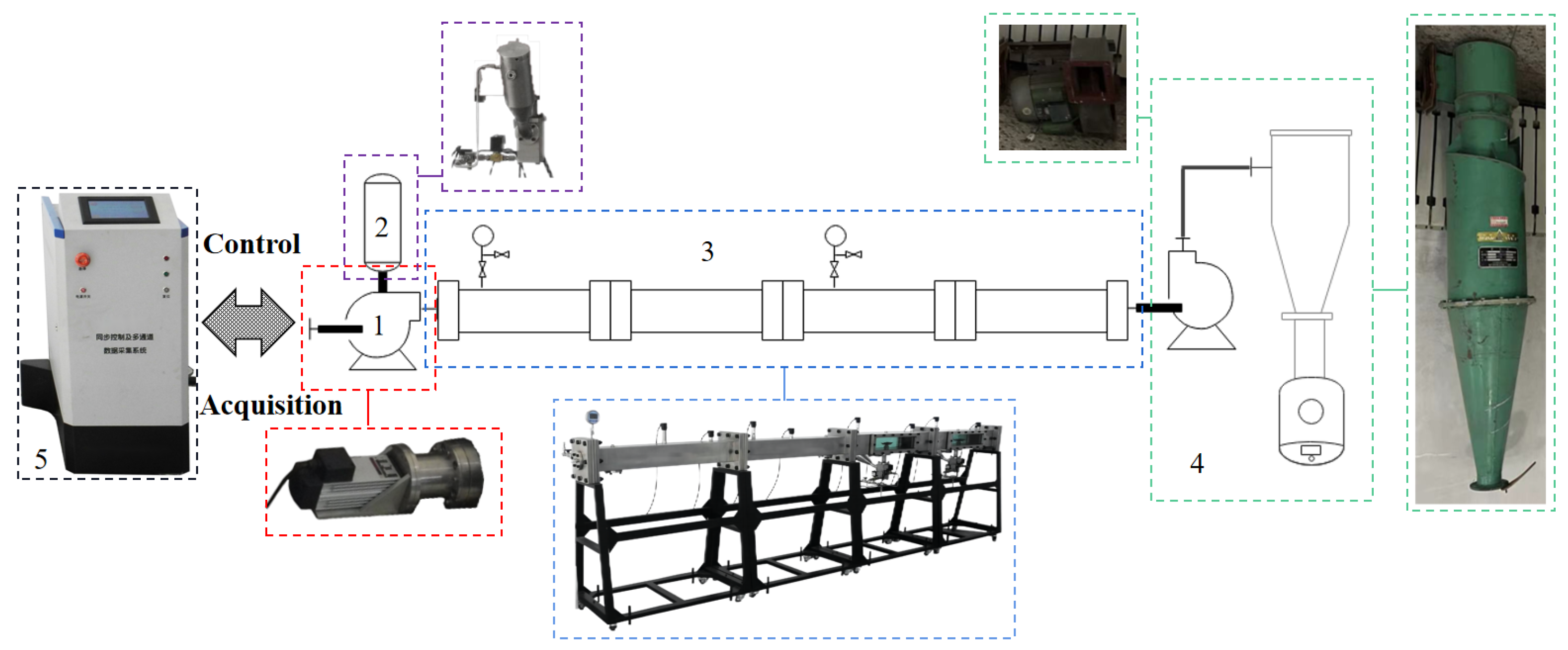

3.2.1. Experimental Platform for Particle Migration and Deposition Simulation

3.2.2. Test Samples

- Cleaning and pretreatment: The experimental samples of silica (SiO2) particles are first dissolved with acetone on the surface of the experimental samples, then washed with deionized water many times to remove the surface stains of the experimental samples, and finally dehydrated with absolute ethanol.

- Drying pretreatment: The silica (SiO2) particle experimental sample is stored in a dark and dry area. Before the experiment, according to the experimental needs, take an appropriate amount of the sample and put it into the drying oven to heat it to 110 °C and dry it for 12 h, and then put it into the dryer for later use, so as to reduce the humidity of the experimental sample and reduce the influence of capillary force between the particles of the experimental sample on the experimental results during the experiment.

- Electrostatic pretreatment: In the storage area where the silica (SiO2) particle experimental sample is located, a suspended ionizing fan is used to remove the electrostatic neutralization in the environmental space, reducing the electrostatic carryover of the experimental samples and reducing the influence of Coulomb force between the experimental sample particles on the experimental results during the experiment.

3.2.3. Experimental Process

- Ensure that the components of the particle migration deposition simulation experimental platform are reliably connected and effectively bonded to the ground;

- When the machine is turned on, the particle migration and deposition simulation experimental platform self-checks the working state, and the ventilation is self-cleaning;

- Open the flow field generator and particle collection system through the software operation of the host computer; the system automatically configures the fan speed according to the set conditions, after the flow field is stable for 3 min, where the wind speed in the particle migration and deposition pipeline is collected through the hot-wire anemometer to meet the experimental setting; if it has been reached, the next experimental process can be carried out; if it is not reached, continue to wait for 5 min and re-measure; if the measured wind speed is still not reached, the experimental conditions need to be re-compared, and the power supply should be turned off and the wind power device and the pipeline interface of the experimental platform should be carefully checked, and step 2 should be repeated to re-start the self-test;

- Open the lid of the particle disperser, put in the pretreated particle samples that meet the quality of the experimental calculation, tighten the lid of the chamber, turn on the gas-phase disturbance through the host computer software, close the disturbance device after a sufficient disturbance, and after a delay of 10 s, the gas–solid two-phase flow mixture is evenly put into the flow field through the deflector, the sensor group collects the simulation data, and the velocity measurement device is triggered synchronously to measure the velocity of the particles and flow field, and the single experiment is completed after the experimental termination condition is reached;

- Carefully take out the sampling plate, clean the pipe, and prepare for the next experiment.

3.3. Simulation Results and Test Results

3.3.1. Particle Concentration Distribution of Simulation Results

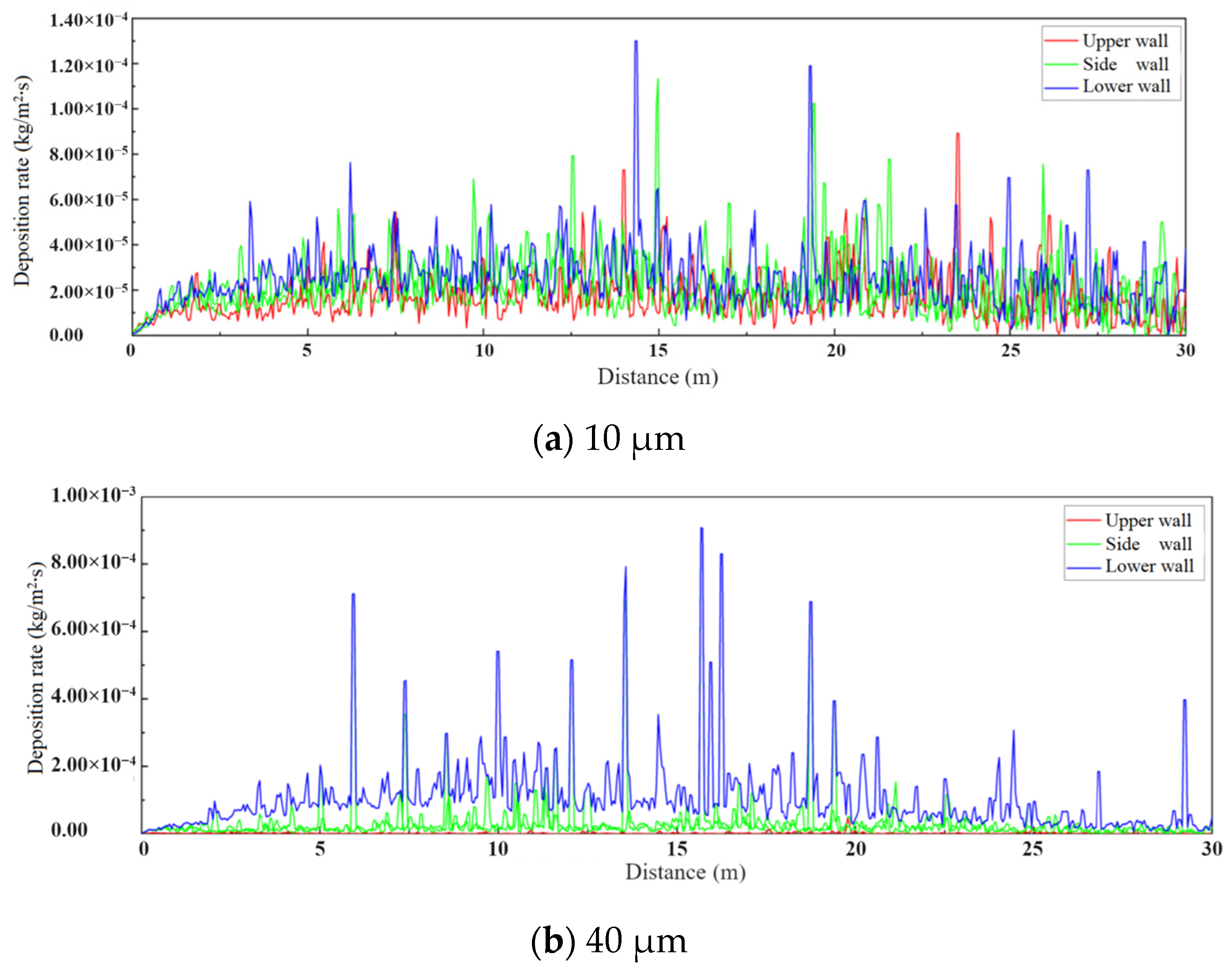

3.3.2. Particle Deposition of Simulation Results

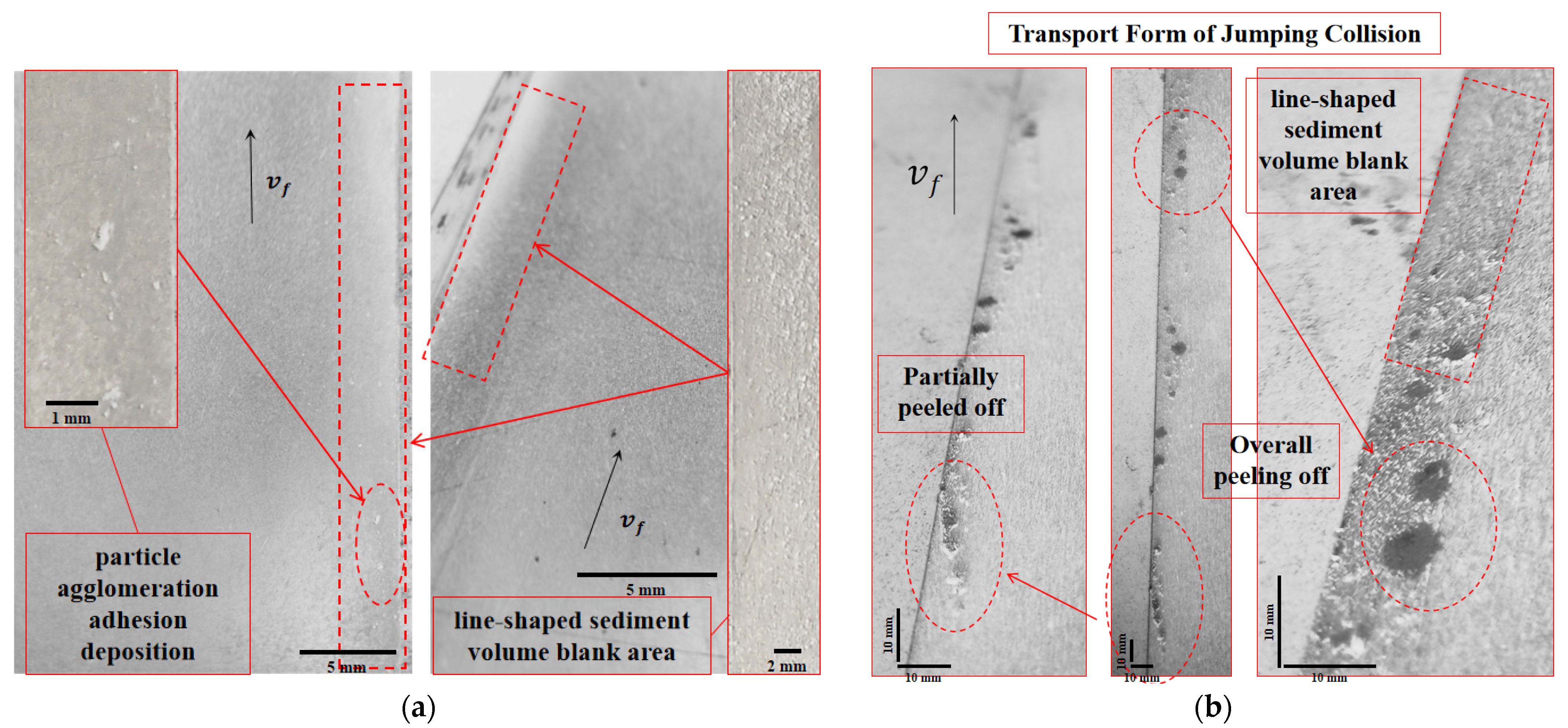

3.3.3. Particle Deposition Morphology of Test Results

3.3.4. Comparison of Simulation Results and Test Results

4. Conclusions

- Combining a mathematical expression of the migration, collision, and deposition of micron particles in the gas pipeline with a simulation of the flow field, a two-parameter particle probability deposition model based on a collision probability coefficient is established, which can show the fouling characteristics of micron particles in the gas pipeline in detail, and an algorithm for the distribution of pollution particles considering the two deposition targets of the pipe wall and sediment layer is presented.

- For 10 μm particles, deposition in the gas transmission pipeline is influenced by turbulent diffusion and presents spot deposition and a random deposition distribution law on each wall of the gas transmission pipeline; 40 μm particle deposition presents flake deposition and concentrates on the lower wall and the two side walls close to the lower wall; for the lower wall, the two-parameter particle probability deposition model simulated a peak deposition efficiency range of (13 D~28 D), and the peak deposition efficiency range of particles in the experimental simulation is (6 D~16 D), which is mainly caused by the difference in the wind field and test samples in the gas transmission pipeline simulation.

- The proposed two-parameter particle probability deposition model is only based on the particle spherical hypothesis, which explores the migration and deposition characteristics of pollutant particles in a long direct gas pipeline, and it still has a large room for improvement in the analysis object and background conditions.

- In the future, based on this model, the deposition law of mixed material and particle-size composite pollution particles under different gas pipeline backgrounds can be explored, and reference suggestions for the gas pipeline selection of different main pollution particles can be given. At the same time, the influence of pipe length, pipe type, and pipe material on the deposition characteristics of composite pollutants can be further studied by simulation and experiment, and optimization suggestions for a standard gas transmission pipeline in different environments are given.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Neauport, J.; Cormont, P.; Lamaignère, L.; Ambard, C.; Pilon, F.; Bercegol, H. Concerning the impact of polishing induced contamination of fused silica optics on the laser-induced damage density at 351 nm. Opt. Commun. 2008, 281, 3802–3805. [Google Scholar] [CrossRef]

- Ling, X.; Wang, G.; Zhao, Y.; Liu, X.; Shao, J. Laser-induced damage of the optical coatings due to organic contamination in vacuum. Appl. Surf. Sci. 2013, 270, 346–351. [Google Scholar] [CrossRef]

- Cheng, X.; Miao, X.; Wang, H.; Qin, L.; Ye, Y.; He, Q.; Ma, Z.; Zhao, L.; He, S. Surface Contaminant Control Technologies to Improve Laser Damage Resistance of Optics. Adv. Condens. Matter Phys. 2014, 2014, 974245. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, W.; Wei, X.; Jing, F.; Sui, Z.; Su, J.; Li, M.; Zhu, Q.; Peng, Z.; He, S.; et al. Preliminary Experimental Results of Shenguang III Technical Integration Experiment Line. In High-Power Lasers and Applications III; SPIE: Bellingham, WA, USA, 2005. [Google Scholar]

- Jiang, W.; Cho, M.K.; Wu, F.; Wang, M.; Wang, B.; Miao, X.; Cheng, X.; Wu, W. Status of cleanliness maintaining in target beam enclosures in SG III facilities and contamination sources analysis. In 7th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Large Mirrors and Telescopes; SPIE: Bellingham, WA, USA, 2014. [Google Scholar]

- Wei, C.; Wang, Y.; Qiu, Y.; Guo, X. Influence of the Sphericity Coefficient on the Deposition Characteristics of Aerosol Particles on the Surface of Photovoltaic (PV) Modules: Numerical Simulation. Appl. Sci. 2023, 13, 8658. [Google Scholar] [CrossRef]

- Aharoni, H.; Ohmi, T.; Oka, M.M.; Nakada, A.; Tamai, Y. Analysis of n + p silicon junctions with varying substrate doping concentrations made under ultraclean processing technology. J. Appl. Phys. 1997, 81, 1270–1288. [Google Scholar] [CrossRef]

- Niu, L.; Liu, H.; Miao, X.; Lv, H.; Yuan, X.; Zhou, H.; Yao, C.; Zhou, G.; Li, Q. Cleaning mechanism of particle contaminants on large aperture optical components by using air knife sweeping technology. In Fourth International Symposium on Laser Interaction with Matter; SPIE: Bellingham, WA, USA, 2017. [Google Scholar]

- Den, W.; Bai, H.; Kang, Y. Organic airborne molecular contamination in semiconductor fabrication clean rooms: A review. J. Electrochem. Soc. 2006, 153, G149. [Google Scholar] [CrossRef]

- Sawamura, F.; Ngu, C.Y.; Hanazaki, R.; Kozuki, K.; Kado, S.; Sakai, M.; Kudo, K. Dry Printing of Ag–Ni Conductive Particles Using Toner-Type Printed Electronics. Appl. Sci. 2022, 12, 9616. [Google Scholar] [CrossRef]

- Choi, K.-M.; Lee, J.-E.; Cho, K.-Y.; Kim, K.-S.; Cho, S.-H. Clean Room Structure, Air Conditioning and Contamination Control Systems in the Semiconductor Fabrication Process. J. Korean Soc. Occup. Environ. Hyg. 2015, 25, 202–210. [Google Scholar] [CrossRef]

- Straka, S.A.; Olson, K.R.; Folgner, K.A.; Ternet, G.K. Effects of vacuum-ultraviolet radiation on the desorption of molecular contaminants. In Optical System Contamination: Effects, Measurements, and Control; SPIE: Bellingham, WA, USA, 2008. [Google Scholar]

- Lignier, H.; Picard, E.; Dubois, S. Controlling surface contamination issues in the fabrication environment of high efficiency crystalline silicon-based homojunction solar cells. Energy Procedia 2017, 124, 745–751. [Google Scholar] [CrossRef]

- Volkov, A.G.; Dyugaeva, N.A.; Kuvyrkin, G.N.; Morozov, A.N. Studying the change in characteristics of optical surfaces of a spacecraft. Cosm. Res. 2017, 55, 124–127. [Google Scholar] [CrossRef]

- Baur, S.D. Cleaning of Operating Rooms as Factor Affecting Clean Room Products. Pharm. Ind. 2010, 72, 1077–1080. [Google Scholar]

- Baxter, R.; Baxter, H.; Campbell, G.; Grant, K.; Jones, A.; Richardson, P.; Whittaker, G. Quantitative analysis of residual protein contamination on reprocessed surgical instruments. J. Hosp. Infect. 2006, 63, 439–444. [Google Scholar] [CrossRef] [PubMed]

- Li, A.; Ahmadi, G. Deposition of aerosols on surfaces in a turbulent channel flow. Int. J. Eng. Sci. 1993, 31, 435–451. [Google Scholar] [CrossRef]

- Uijttewaal, W.S.J.; Oliemans, R.V.A. Particle dispersion and deposition in direct numerical and large eddy simulations of vertical pipe flows. Phys. Fluids 1996, 8, 2590–2604. [Google Scholar] [CrossRef]

- Brooke, J.W.; Kontomaris, K.; Hanratty, T.J.; McLaughlin, J.B. Turbulent deposition and trapping of aerosols at a wall. Phys. Fluids A Fluid Dyn. 1992, 4, 825–834. [Google Scholar] [CrossRef]

- Brooke, J.W.; Hanratty, T.J.; McLaughlin, J.B. Free-flight mixing and deposition of aerosols. Phys. Fluids 1994, 6, 3404–3415. [Google Scholar] [CrossRef]

- Chen, M.; McLaughlin, J.B. A new correlation for the aerosol deposition rate in vertical ducts. J Colloid Interface Sci. 1995, 169, 437–455. [Google Scholar] [CrossRef]

- Mao, S.; Zhou, T.; Liao, Y.; Tang, J.; Liu, X. Particle deposition characteristics of supercritical CO2 in different ribbed tubes. J. Colloid Interface Sci. 2023, 193, 1115–1121. [Google Scholar]

- Sun, J.; Cui, X.; Xu, Z.; Jia, Y.; Wang, J. Molecular Dynamics Simulation of the Deposition Characteristics MgO Particles and Calcium Carbonate Composite Fouling on Copper Heat Transfer Surfaces. Proc. CSEE 2023, 193, 2311–2318. [Google Scholar]

- Yang, J.-H.; Gao, M.; Wang, D.-M.; Dong, W.-H.; Zuo, Q.-R. Lattice Boltzmann simulation of the effect for adding a ghost fluid layer on the simulation accuracy of a sessile droplet on a heated surface. Int. J. Therm. Sci. 2023, 193, 108525. [Google Scholar] [CrossRef]

- Jia, X.; Gan, M.; Williams, R.; Rhodes, D. Validation of a digital packing algorithm in predicting powder packing densities. Powder Technol. 2007, 174, 10–13. [Google Scholar] [CrossRef]

- Sehmel, G.A. particle velocities eddy diffusivities and deposition for isothermal flow and smooth surfaces. Aerosol Sci. 1973, 4, 125–138. [Google Scholar] [CrossRef]

- Zhang, Z.; Qiao, X.; Yang, S.; Jiang, X. Non-Uniform Distribution of Contamination on Composite Insulators in HVDC Transmission Lines. Appl. Sci. 2018, 8, 1962. [Google Scholar] [CrossRef]

- Piskunov, V. Parameterization of aerosol dry deposition velocities onto smooth and rough surfaces. J. Aerosol Sci. 2009, 40, 664–679. [Google Scholar] [CrossRef]

- Rining, D.; Jiejin, C. Experimental Study of Flow Boiling in Layer-by-layer Deposition of SiO2 to Simulate CRUD Layer on Surface of Fuel Cladding. At. Energy Sci. Technol. 2023, 57, 1911–1917. [Google Scholar]

- Yakhot, V.; Orszag, S.A. Renormalization group analysis of turbulence. I. Basic theory. J. Sci. Comput. 1986, 1, 13–51. [Google Scholar] [CrossRef]

- O’Neill, M. A sphere in contact with a plane wall in a slow linear shear flow. Chem. Eng. Sci. 1968, 23, 1293–1298. [Google Scholar] [CrossRef]

- Saffman, P.G. The lift on a small sphere in a slow shear flow. J. Fluid Mech. 1965, 22, 385–400. [Google Scholar] [CrossRef]

- Chen, H.; Ding, W.; Wei, H.; Saxén, H.; Yu, Y. A Coupled CFD-DEM Study on the Effect of Basset Force Aimed at the Motion of a Single Bubble. Materials 2022, 15, 5461. [Google Scholar] [CrossRef]

- Clift, R.; Gauvin, W.H. Motion of entrained particles in gas streams. Can. J. Chem. Eng. 1971, 49, 439–448. [Google Scholar] [CrossRef]

- Zhan, F.; Zhuang, D.; Ding, G.; Tang, J. Numerical model of particle deposition on fin surface of heat exchanger. Int. J. Refrig. 2016, 72, 27–40. [Google Scholar] [CrossRef]

- A Siegel, J.; Nazaroff, W.W. Predicting particle deposition on HVAC heat exchangers. Atmos. Environ. 2003, 37, 5587–5596. [Google Scholar] [CrossRef]

- Derjaguin, B.; Landau, L. Theory of the stability of strongly charged lyophobic sols and of the adhesion of strongly charged particles in solutions of electrolytes. Acta Phys. Chim. Sin. URSS 1941, 14, 662–663. [Google Scholar] [CrossRef]

- Tomeczek, J.; Wacławiak, K. Two-dimensional modeling of deposits formation on platen superheaters. Fuel 2009, 88, 1466–1471. [Google Scholar] [CrossRef]

- Konstandopoulos, A.G. Particle sticking/rebound criteria at oblique impact. J. Aerosol Sci. 2006, 37, 292–305. [Google Scholar] [CrossRef]

| Sample Number | Name | Size | Composition | Purity | Density | Product Batch Number |

|---|---|---|---|---|---|---|

| 1 | Spherical silica particles | 10 μm | SiO2 | 9.99% | 2.32 g/cm3 | KG-24 |

| 2 | Spherical silica particles | 40 μm | SiO2 | 9.99% | 2.32 g/cm3 | KG-22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, C.; Zhou, Z.; Qi, J.; Yang, X. Two-Parameter Probabilistic Model and Experimental Research on Micron Particle Deposition. Appl. Sci. 2024, 14, 6200. https://doi.org/10.3390/app14146200

Niu C, Zhou Z, Qi J, Yang X. Two-Parameter Probabilistic Model and Experimental Research on Micron Particle Deposition. Applied Sciences. 2024; 14(14):6200. https://doi.org/10.3390/app14146200

Chicago/Turabian StyleNiu, Chenchen, Zhen Zhou, Jia Qi, and Xu Yang. 2024. "Two-Parameter Probabilistic Model and Experimental Research on Micron Particle Deposition" Applied Sciences 14, no. 14: 6200. https://doi.org/10.3390/app14146200

APA StyleNiu, C., Zhou, Z., Qi, J., & Yang, X. (2024). Two-Parameter Probabilistic Model and Experimental Research on Micron Particle Deposition. Applied Sciences, 14(14), 6200. https://doi.org/10.3390/app14146200