A Novel Technosol Formulation for Sustainable Landfill Top Covers Using Non-Hazardous Wastes

Abstract

1. Introduction

2. Materials and Methods

2.1. Selection and Characterization of Waste Materials

2.2. Technosol Formulation

2.3. Geotechnical Testing Methods

3. Results and Discussion

3.1. Physico-Chemical Properties and Mineral Constituents of Waste Materials

3.2. Geotechnical Properties

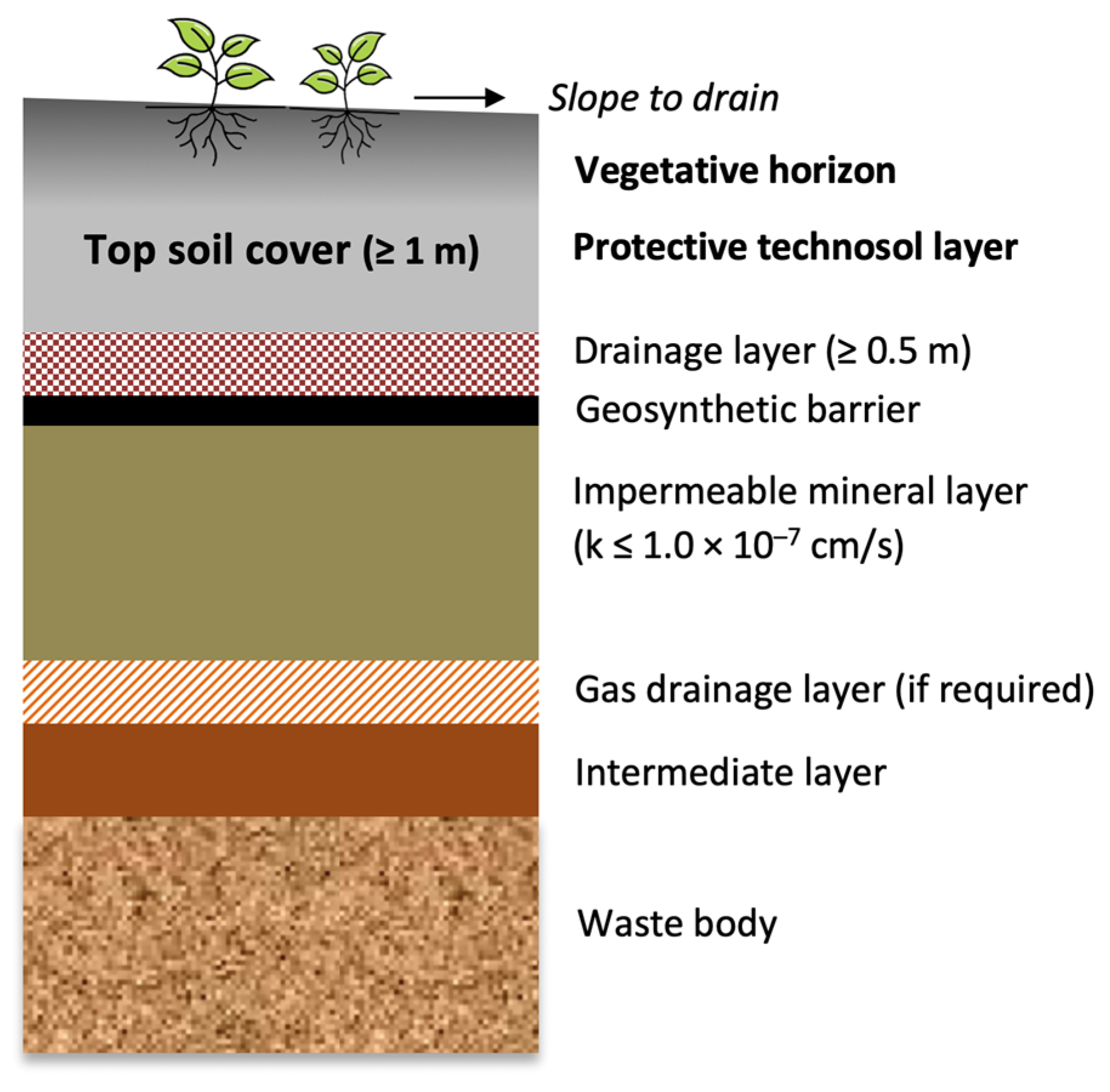

3.3. Vegetative Landfill Cap

4. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Daniel, D.E. Geotechnical Practice for Waste Disposal; Springer: Dordrecht, The Netherlands, 1993. [Google Scholar]

- Cossu, R.; Garbo, F. Landfill covers: Principles and design. In Solid Waste Landfilling. Concepts, Processes, Technologies; Cossu, R., Stegmann, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 649–676. [Google Scholar]

- Ng, C.W.W.; Guo, H.W.; Xue, Q.A. Novel environmentally friendly vegetated three-layer landfill cover system using construction wastes but without a geomembrane. Indian Geotech. J. 2021, 51, 460–466. [Google Scholar] [CrossRef]

- Koerner, R.M.; Daniel, D.E. Final Covers for Solid Waste Landfills and Abandoned Dumps; American Society of Civil Engineers Press: Reston, VA, USA, 1997. [Google Scholar]

- Elshorbagy, W.A.; Mohamed, A.M.O. Evaluation of using municipal solid waste compost in landfill closure caps in arid areas. Waste Manag. 2000, 20, 499–507. [Google Scholar] [CrossRef]

- Hyun, J.; Kim, M.G. Field testing of conversion of sewage sludge to daily landfill cover material. J. Mater. Cycles Waste Manag. 2012, 14, 14–18. [Google Scholar] [CrossRef]

- Andreas, L.; Diener, S.; Lagerkvist, A. Steel slags in a landfill top cover–experiences from a full-scale experiment. Waste Manag. 2014, 34, 692–701. [Google Scholar] [CrossRef] [PubMed]

- Aziz, H.A.; Yik, W.C.; Ramli, H.; Amr, S.S.A. Investigations on the hydraulic conductivity and physical properties of silt and sludge as potential landfill capping material. Int. J. GEOMATE 2016, 23, 1989–1993. [Google Scholar]

- Berger, K.; Groengroeft, A.; Gebert, J. 20 years performance measurements of a landfill cover system with components constructed from pre-treated dredged sediments. Waste Manag. 2019, 100, 230–239. [Google Scholar] [CrossRef] [PubMed]

- Cevikbilen, G.; Basar, H.M.; Karadogan, U.; Teymur, B.; Dagl, S.; Tolun, L. Assessment of the use of dredged marine materials in sanitary landfills: A case study from the Marmara sea. Waste Manag. 2020, 113, 70–79. [Google Scholar] [CrossRef] [PubMed]

- Séré, G.; Schwartz, C.; Ouvrard, S.; Sauvage, C.; Renat, J.C.; Morel, J.L. Soil Construction: A step for ecological reclamation of derelict lands. J. Soils Sediments 2008, 8, 130–136. [Google Scholar] [CrossRef]

- Ruiz, F.; Cherubin, M.R.; Ferreira, T.O. Soil quality assessment of constructed Technosols: Towards the validation of a promising strategy for land reclamation, waste management and the recovery of soil functions. J. Environ. Manag. 2020, 276, 111344. [Google Scholar] [CrossRef]

- Fabbri, D.; Pizzol, R.; Calza, P.; Malandrino, M.; Gaggero, E.; Padoan, E.; Ajmone-Marsan, F. Constructed Technosols: A strategy toward a circular economy. Appl. Sci. 2021, 11, 3432. [Google Scholar] [CrossRef]

- Kumpiene, J.; Desogus, P.; Schulenburg, S.; Arenella, M.; Renella, G.; Brännvall, E.; Lagerkvist, A.; Andreas, L.; Sjöblom, R. Utilisation of chemically stabilized arsenic-contaminated soil in a landfill cover. Environ. Sci. Pollut. Res. 2013, 20, 8649–8662. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.; Uchimura, T. Effect of material composition on geotechnical properties—Study on synthetic municipal solid waste. Geotechnics 2023, 3, 397–415. [Google Scholar] [CrossRef]

- Mohajerani, A.; Lound, S.; Liassos, G.; Kurmus, H.; Ukwatta, A.; Nazari, M. Physical, mechanical and chemical properties of biosolids and raw brown coal fly ash, and their combination for road structural fill applications. J. Clean Prod. 2017, 166, 1–11. [Google Scholar] [CrossRef]

- Sabour, M.R.; Derhamjani, G.; Akbari, M.; Hatami, A.M. Global trends and status in waste foundry sand management research during the years 1971–2020: A systematic analysis. Environ. Sci. Pollut. Res. 2021, 28, 37312–37321. [Google Scholar] [CrossRef] [PubMed]

- Ozkan, H.; Kabay, N. Manufacture of sintered aggregate using washing aggregate sludge and ground granulated blast furnace slag: Characterization of the aggregate and effects on concrete properties. Constr. Build. Mater. 2022, 342, 128025. [Google Scholar] [CrossRef]

- Kahle, M.; Kleber, M.; Jahn, R. Review of XRD-based quantitative analyses of clay minerals in soils: The suitability of mineral intensity factors. Geoderma 2002, 109, 191–205. [Google Scholar] [CrossRef]

- Fernández-Caliani, J.C.; Fernández-Landero, S.; Giráldez, M.I.; Hidalgo, P.J.; Morales, E. Unveiling a Technosol-based remediation approach for enhancing plant growth in an iron-rich acidic mine soil from the Rio Tinto Mars analog site. Sci. Total Environ. 2024, 922, 171217. [Google Scholar] [CrossRef] [PubMed]

- EN 12457-4; Characterization of Waste–Leaching–Compliance Test for Leaching of Granular Waste Materials and Sludges, Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size below 10 mm (without or with Size Reduction). European Committee for Standardization: Brussels, Brussels, 2002.

- British Environment Agency. Earthworks in Landfill Engineering: LFE4. Design, Construction and Quality Assurance of Earthworks in Landfill Engineering; British Environment Agency: Almondsbury/Bristol, UK, 2014.

- Li, Y. Handbook of Geotechnical Testing. Basic Theory, Procedures and Comparison of Standards; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- ASTM D6913/D6913M; Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM D2487-17e1; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM D4546-2; Standard Test Methods for One-Dimensional Swell or Collapse of Soil. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D1883-21; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM: West Conshohocken, PA, USA, 2021.

- ISO 17892-11; Geotechnical Investigation and Testing. Laboratory Testing of Soil. Part 11: Permeability Tests. International Organization for Standardization: Geneva, Switzerland, 2019.

- ASTM D3080/D3080M-11; Standard Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions. ASTM: West Conshohocken, PA, USA, 2011.

- Svensson, P.D.; Hansen, S. Intercalation of smectite with liquid ethylene glycol—Resolved in time and space by synchrotron X-ray diffraction. Appl. Clay Sci. 2010, 48, 358–367. [Google Scholar] [CrossRef]

- Siddique, R.; Kaur, G.; Rajor, A. Waste foundry sand and its leachate characteristics. Resour. Conserv. Recycl. 2010, 54, 1027–1036. [Google Scholar] [CrossRef]

- Miguel, R.E.; Ippolito, J.A.; Porta, A.A.; Banda, R.B.; Dungan, R.S. Use of standardized procedures to evaluate metal leaching from waste foundry sands. J. Environ. Qual. 2013, 42, 615–620. [Google Scholar] [CrossRef]

- Ross, S.M. Sources and forms of potentially toxic metals in soil-plant systems. In Toxic Metals in Soil-Plant Systems; Ross, S.M., Ed.; Wiley: Chichester, UK, 1996; pp. 3–25. [Google Scholar]

- Fernández-Caliani, J.C. Rare-earth element and stable isotope signatures of kaolin from a Pliocene lateritic weathering profile at mid-latitude region (Andalusia, Spain): Implications for paleoweathering and paleoclimatic reconstructions. Catena 2018, 167, 160–170. [Google Scholar] [CrossRef]

- Fernández-Caliani, J.C.; Cantano, M. Intensive kaolinization during a lateritic weathering event in South-West Spain. Mineralogical and geochemical inferences from a relict paleosol. Catena 2010, 80, 23–33. [Google Scholar] [CrossRef]

- Anlauf, R.; Rehrmann, P. Effect of compaction on soil hydraulic parameters of vegetative landfill covers. Geomaterials 2012, 2, 29–36. [Google Scholar] [CrossRef]

- Domingues, L.G.F.; Ferreira, G.C.S.; Pires, M.S.G. Waste foundry sand used to cover organic waste in landfills. J. Mater. Cycles Waste Manag. 2022, 24, 378–385. [Google Scholar] [CrossRef]

- Qian, X.; Koerner, R.M.; Gray, D.H. Geotechnical Aspects of Landfill Design and Construction; Prentice Hall: New Jersey, NJ, USA, 2002. [Google Scholar]

- Abichou, T.; Benson, C.; Edil, T. Foundry green sands as hydraulic barriers: Laboratory study. J. Geotech. Geoenviron. Eng. 2000, 126, 1174–1183. [Google Scholar] [CrossRef]

- Abichou, T.; Benson, C.; Edil, T. Foundry green sands as hydraulic barriers: Field study. J. Geotech. Geoenviron. Eng. 2002, 128, 206–215. [Google Scholar] [CrossRef]

- McBride, M.B. Processes of heavy and transition metal sorption by soil minerals. In Interactions at the Soil-Colloid-Soil Solution Interface; Bolt, G.H., De Boodt, M.F., Hayes, M.H.B., McBride, M.B., De Strooper, E.B.A., Eds.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1991; pp. 149–175. [Google Scholar]

- Jackson, T.A. The biochemical and ecological significance of interactions between colloidal minerals and trace elements. In Environmental Interactions of Clays; Parker, A., Rae, F.E., Eds.; Springer: Berlin/Heidelberg, Germany, 1998; pp. 93–205. [Google Scholar]

- World Health Organization. Guidelines for Drinking-Water Quality, 4th ed.; incorporating the first and second addenda; World Health Organization: Geneva, Switzerland, 2022. [Google Scholar]

| Material Properties and Constituents | Waste Material | ||

|---|---|---|---|

| Waste Foundry Sand (WFS) | Washing Aggregate Sludge (WAS) | Composted Biosolids (CBS) | |

| Physico-chemical parameters | |||

| pH (in water) | 10.31 ± 0.04 | 6.24 ± 0.26 | 7.5 ± 0.16 |

| Electrical cond. (mS cm−1) | 0.77 ± 0.01 | 0.24 ± 0.02 | 3.2 ± 0.3 |

| Mineral composition and organic matter content (wt %) | |||

| Bulk sample | Quartz (65–70) Clay minerals (20–25) Feldspars (<5) Calcite (<5) | Clay minerals (7–80) Quartz (15–20) Feldspars (<5) Goethite (<5) | Organic matter (54) |

| Clay fraction | Smectite (75–80) Mica (5–10) Quartz (<5) Feldspars (<5) Calcite (<5) | Kaolinite (70–75) Mica (20–25) Smectite (<5) Quartz (<5) | |

| Chemical composition | |||

| Plant macronutrients (wt %) | |||

| N | - | - | 2.6 |

| P | 0.008 | 0.037 | 4.2 |

| K | 0.23 | 1.23 | 1.21 |

| Ca | 0.35 | 0.07 | 6.7 |

| Mg | 0.33 | 0.23 | 1.30 |

| S | 0.04 | 0.04 | - |

| Potentially toxic trace elements (mg kg−1) | |||

| As | 3 | 36 | - |

| Cd | <0.3 | <0.3 | <0.6 |

| Co | <1 | 9 | <10 |

| Cr | 13 | 58 | 33 |

| Cu | 10 | 19 | 161 |

| Mn | 138 | 82 | 642 |

| Ni | 5 | 33 | <20 |

| Pb | 10 | 33 | 46 |

| Zn | 30 | 42 | 458 |

| Geotechnical Parameter | Waste Foundry Sands (WFS) | Washing Aggreg. Sludge (WAS) | Mixture 90:10 (WFS/WAS) | Mixture 80:20 (WFS/WAS) | Mixture 70:30 (WFS/WAS) |

|---|---|---|---|---|---|

| Fine-grained fraction 1 (%) | 17.5 | 89.4 | 20.6 | 26.4 | 34.8 |

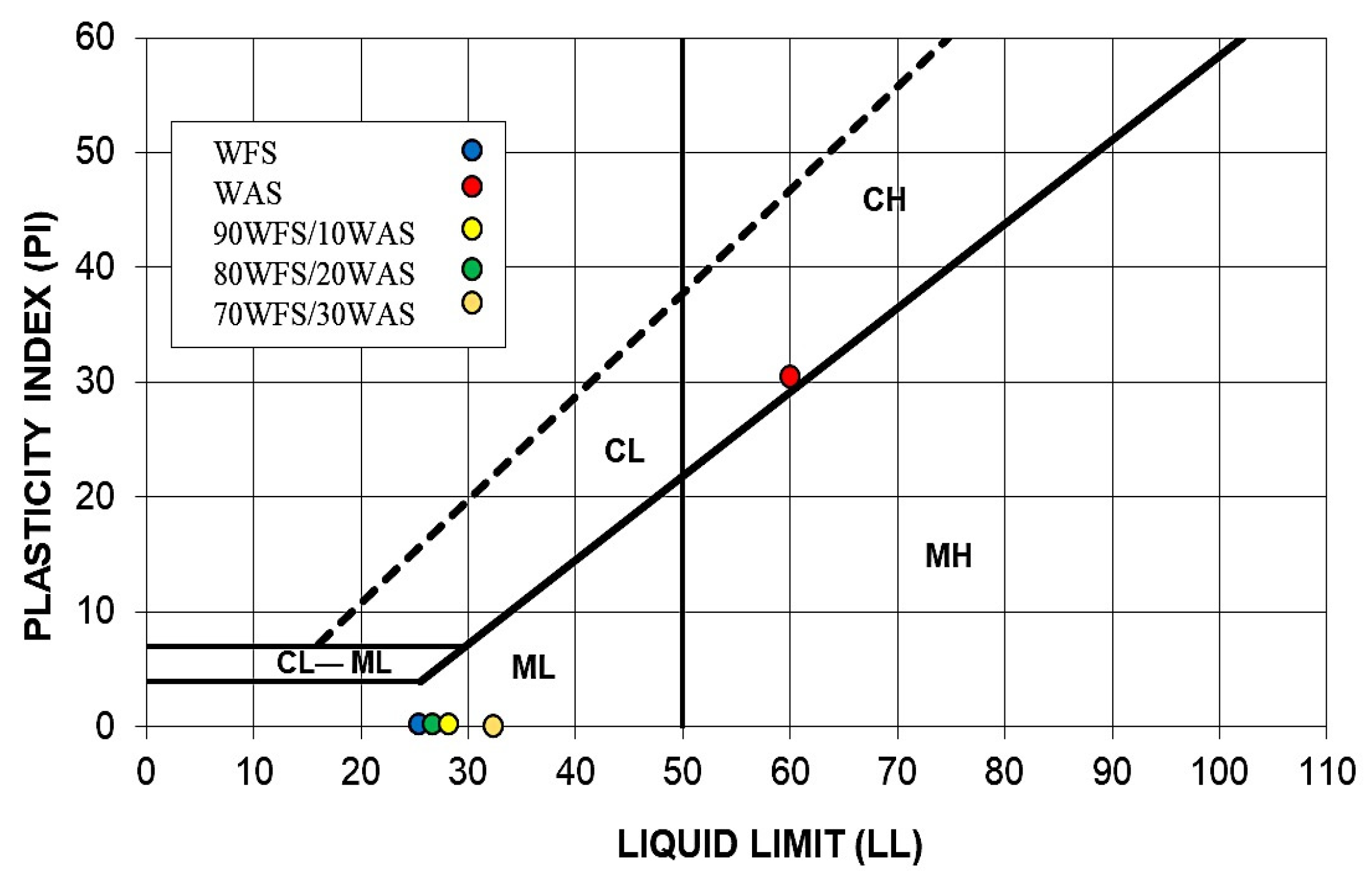

| Liquid limit (LL) | 26 | 60 | 28 | 27 | 33 |

| Plastic limit (PL) | no plastic | 29 | no plastic | no plastic | no plastic |

| Plasticity index (PI) | 0 | 31 | 0 | 0 | 0 |

| USCS classification 2 | ML | CH | ML | ML | ML |

| Optimum moisture content (%) | 13.40 | 26.95 | 13.57 | 15.36 | 15.45 |

| Maximum dry density (g/cm3) | 1.74 | 1.50 | 1.77 | 1.75 | 1.74 |

| Relative density of particles (G) | 2.50 | 2.58 | 2.47 | 2.50 | 2.50 |

| Void ratio | 0.44 | 0.72 | 0.40 | 0.46 | 0.46 |

| Free swelling (%) | 0 | 0.25 | 0 | 0 | 0 |

| Swelling pressure (kPa) | 0 | 0 | 0 | 0 | 0 |

| CBR index | - | - | 23.2 | 8.4 | - |

| CBR swelling (%) | - | - | 0.58 | 0.76 | - |

| Permeability coefficient (cm/s) | - | - | 1.48 × 10−6 | 1.00 × 10−6 | - |

| Cohesion (kPa) | - | - | 40 | - | - |

| Friction angle (ϕ, degree) | - | - | 30 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-Caliani, J.C.; Álvarez-Lozano, J.; García-Navarro, E.; Fernández-Landero, S.; Cantero, C.; Giráldez, M.I. A Novel Technosol Formulation for Sustainable Landfill Top Covers Using Non-Hazardous Wastes. Appl. Sci. 2024, 14, 6166. https://doi.org/10.3390/app14146166

Fernández-Caliani JC, Álvarez-Lozano J, García-Navarro E, Fernández-Landero S, Cantero C, Giráldez MI. A Novel Technosol Formulation for Sustainable Landfill Top Covers Using Non-Hazardous Wastes. Applied Sciences. 2024; 14(14):6166. https://doi.org/10.3390/app14146166

Chicago/Turabian StyleFernández-Caliani, Juan Carlos, Julia Álvarez-Lozano, Encarnación García-Navarro, Sandra Fernández-Landero, Cristóbal Cantero, and María Inmaculada Giráldez. 2024. "A Novel Technosol Formulation for Sustainable Landfill Top Covers Using Non-Hazardous Wastes" Applied Sciences 14, no. 14: 6166. https://doi.org/10.3390/app14146166

APA StyleFernández-Caliani, J. C., Álvarez-Lozano, J., García-Navarro, E., Fernández-Landero, S., Cantero, C., & Giráldez, M. I. (2024). A Novel Technosol Formulation for Sustainable Landfill Top Covers Using Non-Hazardous Wastes. Applied Sciences, 14(14), 6166. https://doi.org/10.3390/app14146166