Study on the Stability and Reasonable Width of Coal Pillars in “Three Soft” Coal Seams Based on a Physical Similarity Simulation Experiment

Abstract

1. Introduction

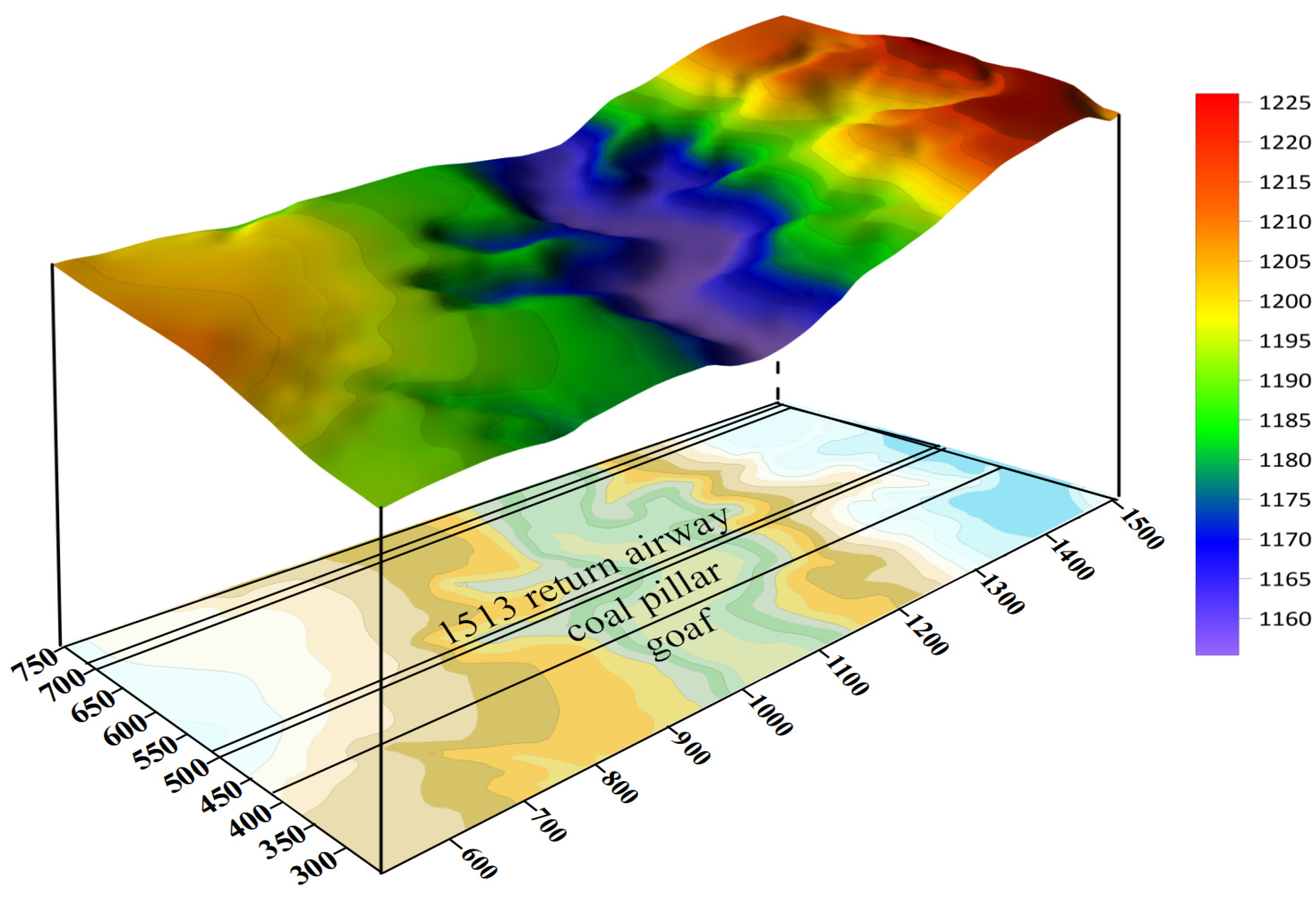

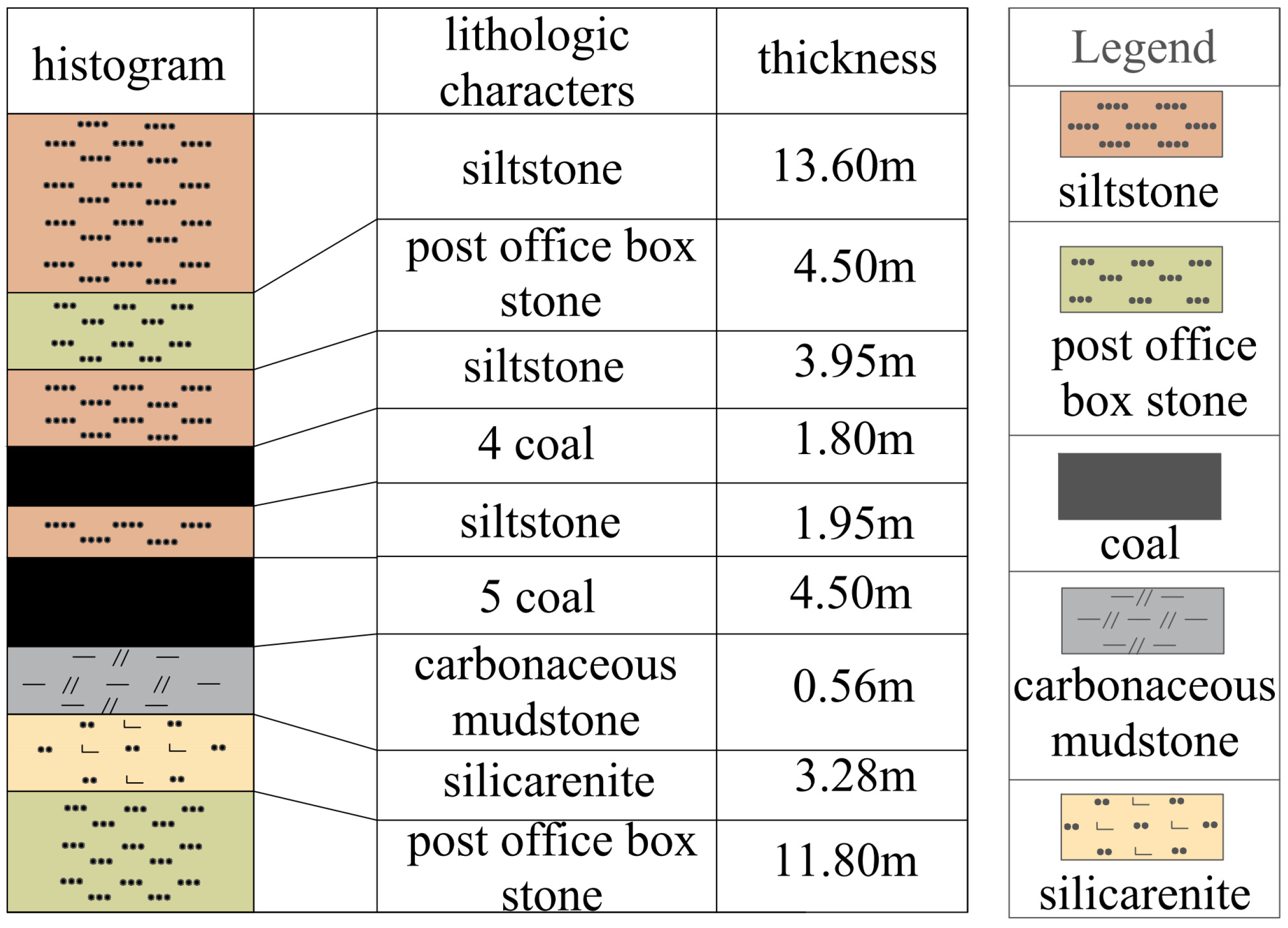

2. Engineering Background

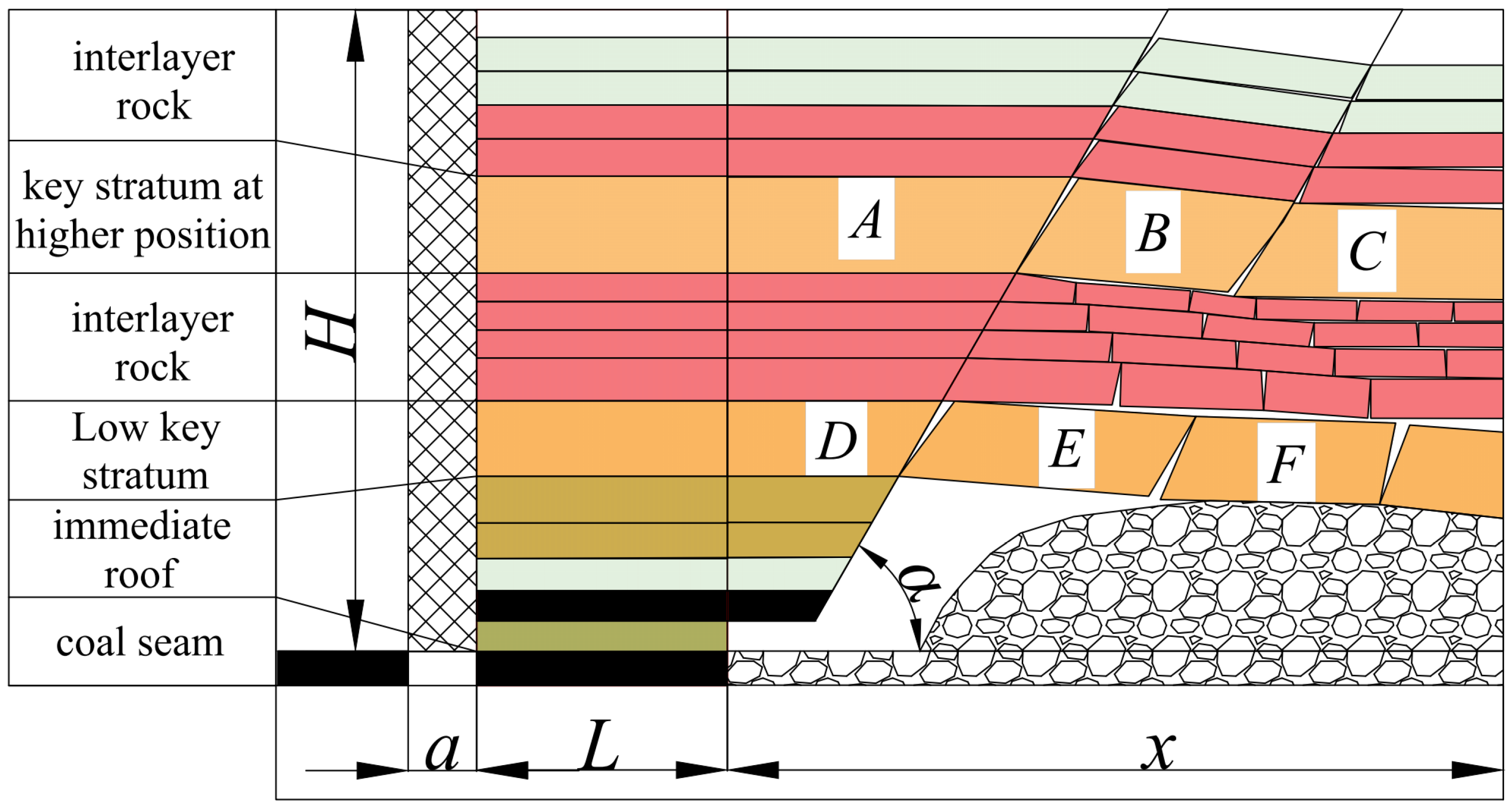

3. Fracture Structure and Stability Analysis of Coal Pillar Overburden Rock

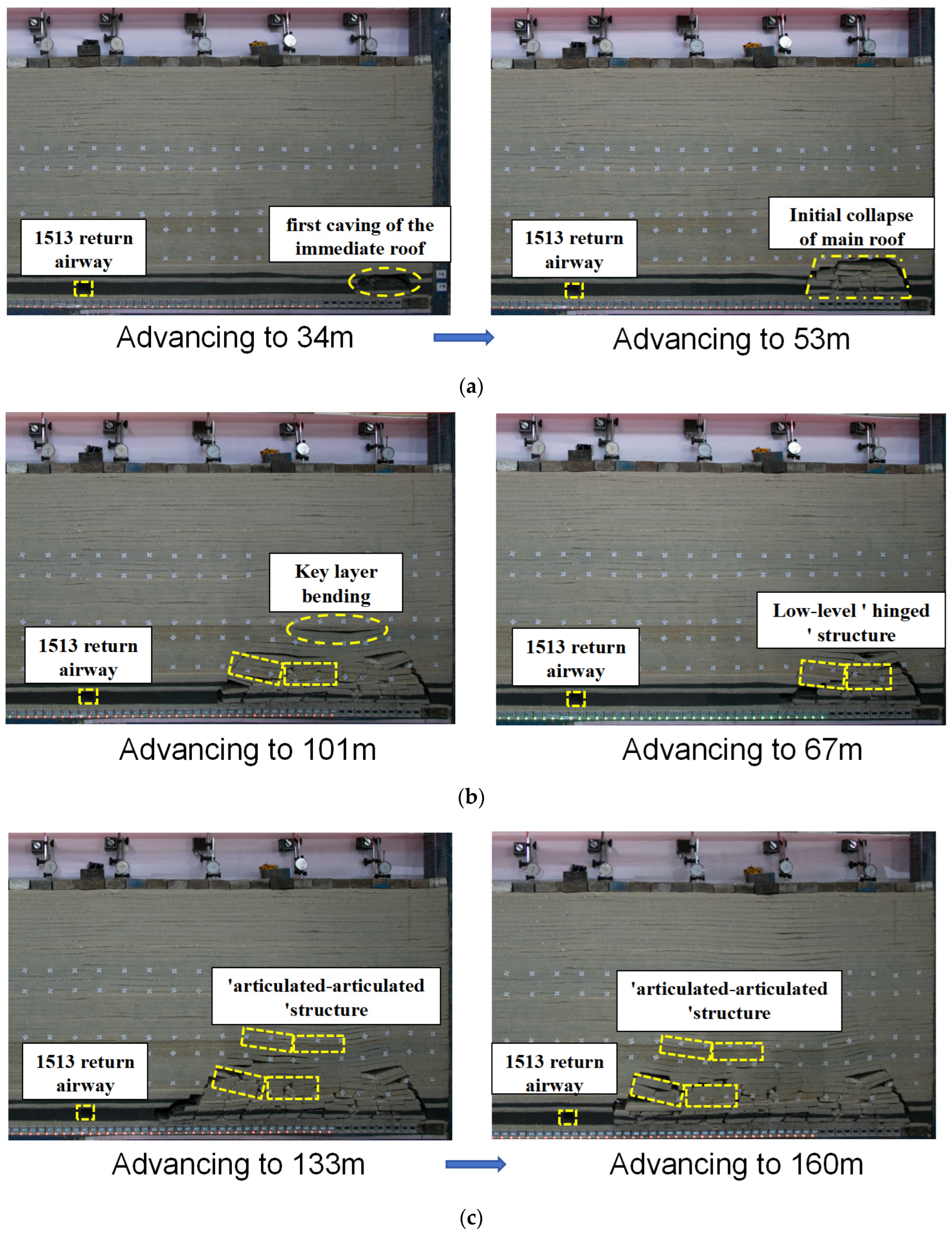

3.1. Physical Simulation Model Design

3.2. Characterization of the Broken Structure of the Coal Pillar Overburden

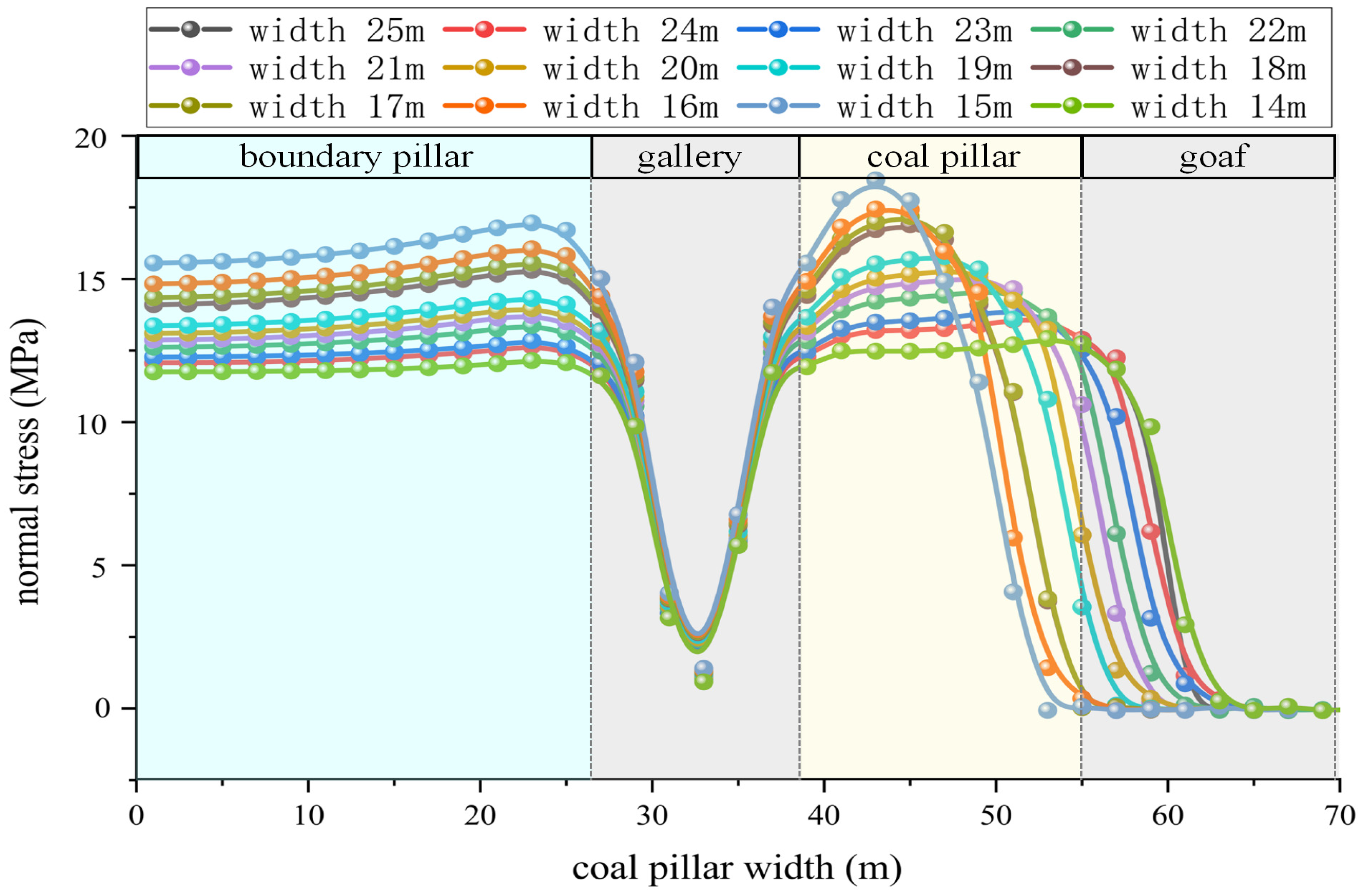

4. Analysis of Coal Pillar Bearing Structure after Coal Seam Mining

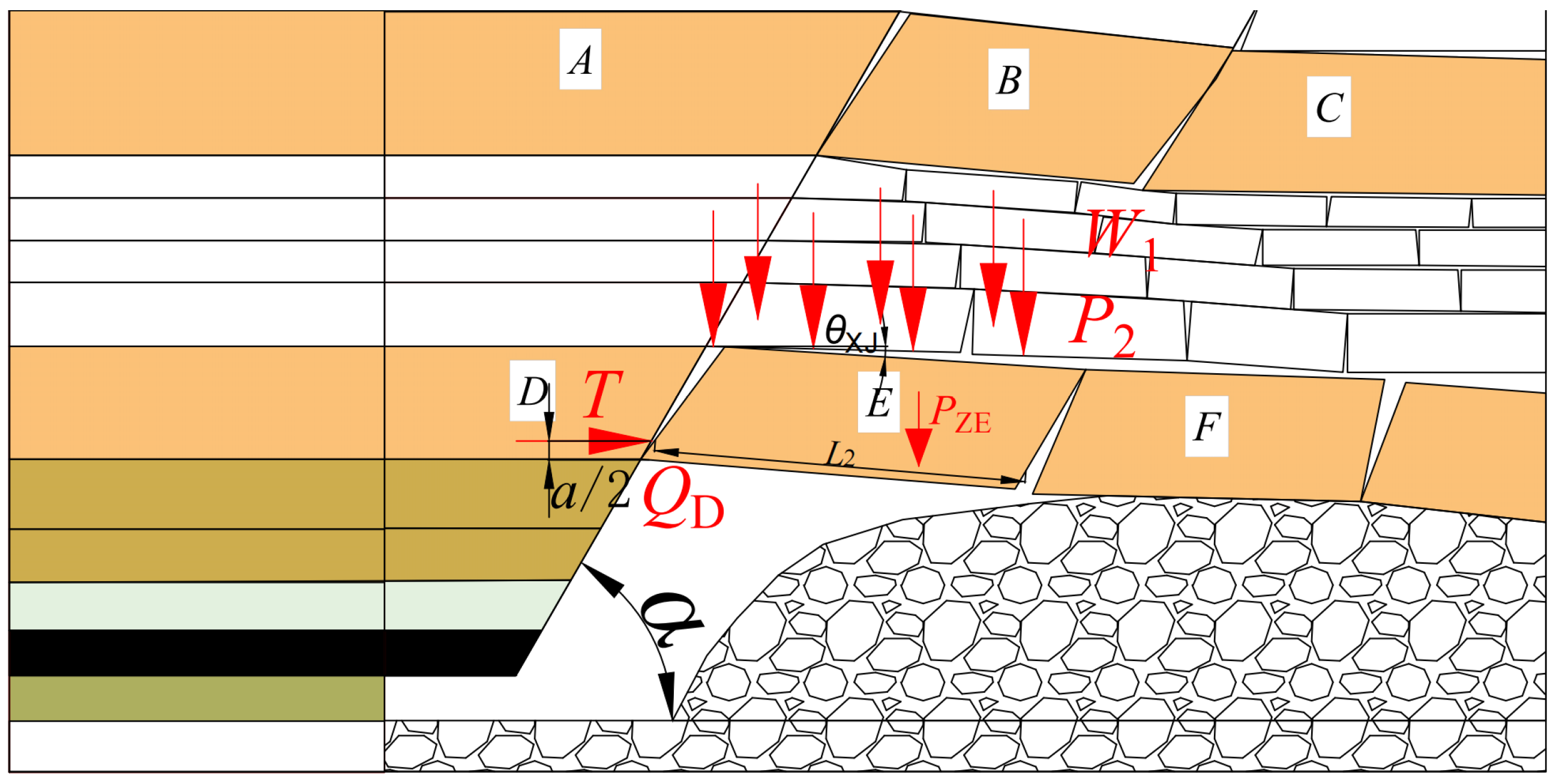

4.1. Mechanical Analysis of High Bearing Structure of Coal Pillar

4.2. Mechanical Analysis of Low Bearing Structure

4.3. Load Calculation of “Hinged-Hinged” Structure in Overlying Strata of Coal Pillar

4.4. Reasonable Width Calculation of Coal Pillar

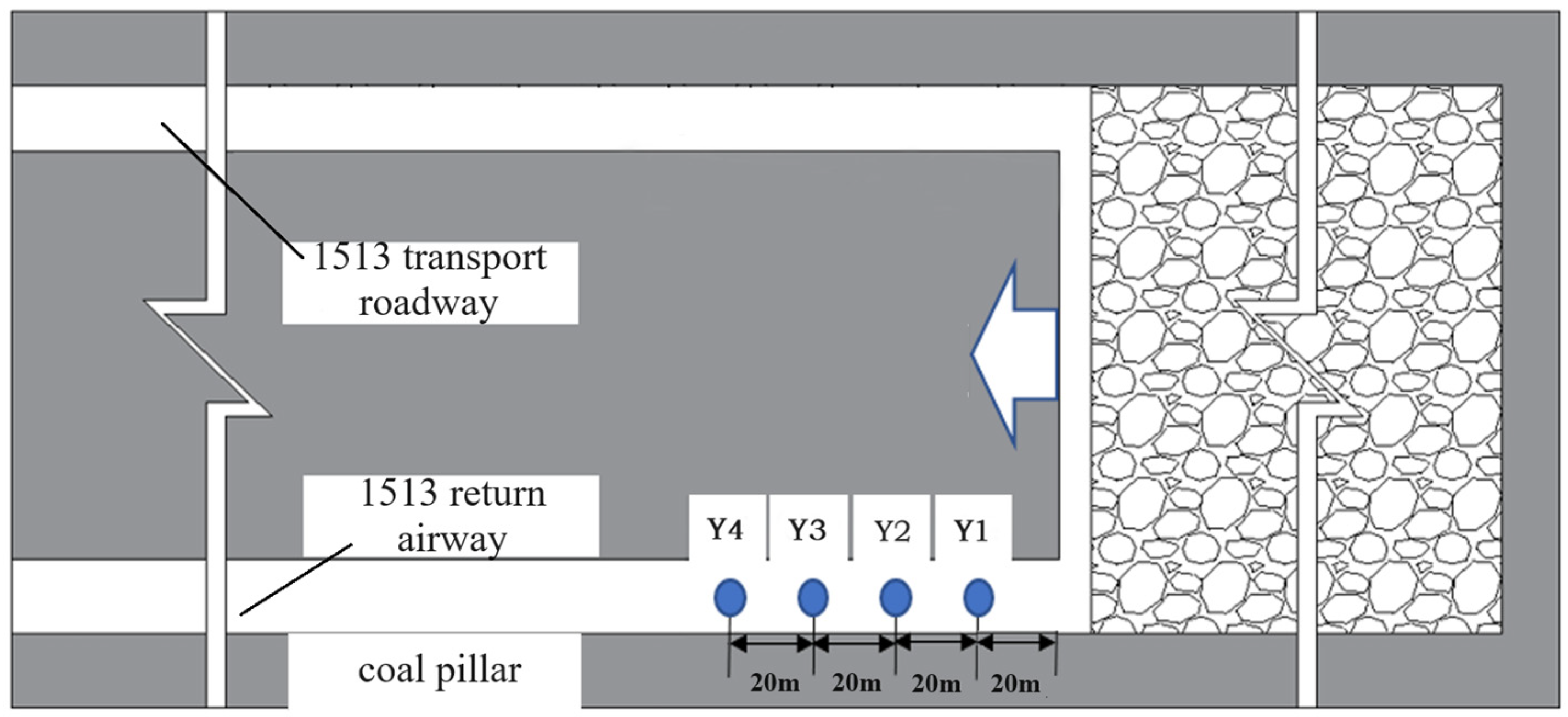

5. Engineering Application

5.1. Roadway Support Parameters

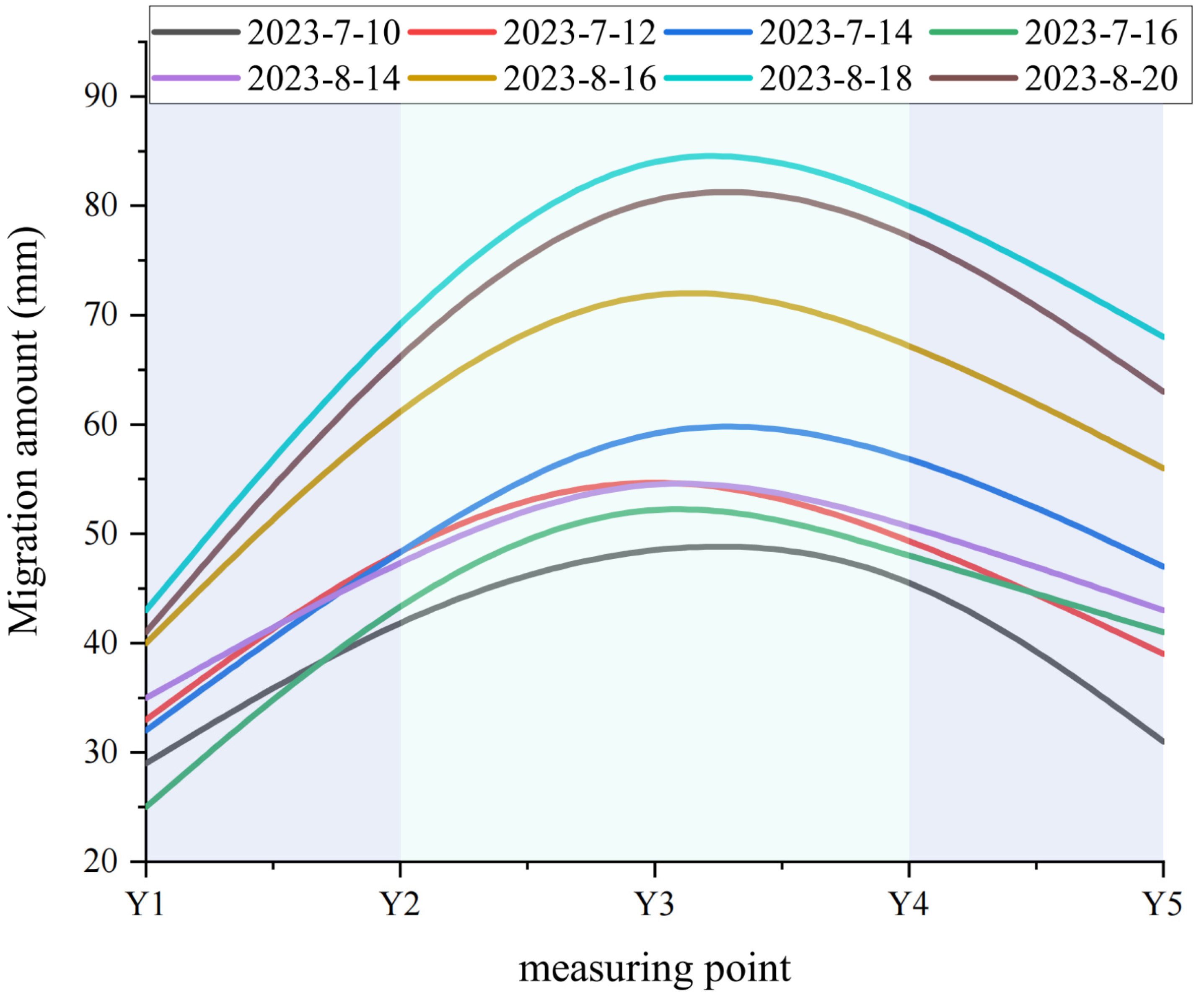

5.2. Filed Monitoring and Analyzing

6. Discussion and Conclusions

- (1)

- Based on the physical similarity model at a scale of 1:100, the experimental results demonstrate that during the reduction of the coal pillar, the overlying bearing layer fractures and forms a “hinged” structure. Consequently, the coal pillar bears an increased load from the overlying strata. As the coal pillar continues to narrow, the upper key stratum also fractures under the influence of mining, resulting in a “hinged-hinged” combination composed of the upper and lower key strata. This combined structure impacts the coal pillar. According to stress data from the floor stress meter, reducing the coal pillar width from 25 m to 14 m significantly increases the stress to 19.4 MPa. Given that the No. 5 coal seam at Anyang Coal Mine is a soft coal seam, an insufficient coal pillar width leads to concentrated stress on the side of the roadway coal pillar, potentially causing significant deformation and the risk of partial collapse. Therefore, the coal pillar width is ultimately determined to be 15 m.

- (2)

- Based on the results of the physical similarity simulation test and the geological conditions of Anyang Coal Mine, a mechanical model of the coal pillar-bearing structure was established. The forces acting on the coal pillar were analyzed using a high and low “hinged” structure model, leading to the development of a “hinged-hinged” combination to calculate the load on the overlying strata. Using the load calculation results of the double “hinged” bearing layer structure and applying Mark Bieniawski’s coal pillar strength calculation formula, the optimal coal pillar width was determined to be 20 m.

- (3)

- Field monitoring data indicate that reducing the coal pillar width from 25 m to 20 m, resulting in significant deformation on the side of the coal pillar in the 1513 return airway. With support strength unchanged, the displacement on both sides increases by 41–42% compared to the original coal pillar width. However, the maximum displacement is observed 40 m to 60 m ahead of the working face, with relatively minor deformation at other locations. Thus, with stable coal pillars, safe production in the mine can be ensured. Additionally, these findings can provide guidance and reference for mines with similar geological conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kang, H.P.; Yi, K. Simulation study on dilatant and rheologic properties of soft rocks surrounding deep roadway and its application. J. China Coal Soc. 2023, 48, 15–33. [Google Scholar] [CrossRef]

- Bai, J.B. Surrounding Rock Control of Gob-Side Entry Driving; China University of Mining and Technology Press: Xuzhou, China, 2006. [Google Scholar]

- Huang, W.P.; Zhao, T.Y.; Jiang, D.H.; Guo, X.S.; Zheng, Y.S.; Wang, X.W. Arrangement of double entry driving with a narrow coal pillar in the middle and stability control technology of surrounding rock. Chin. J. Rock Mech. Eng. 2023, 42, 617–629. [Google Scholar] [CrossRef]

- Zhang, J.P.; Liu, L.M.; Liu, C.X.; Wen, G.C.; Li, Q.H.; Sun, D.L.; Shao, J.; Zhang, J.; Sun, L.Q.; Di, G.Q. Research and application of new prestressed anchor-grouting support for special open-off cut in soft-thick coal seam. J. China Coal Soc. 2021, 46, 3127–3138. [Google Scholar] [CrossRef]

- Gao, Y.B.; Wang, Q.; Yang, J.; Ding, W.B.; Fu, Q.; Xu, X.D. Mechanism of deformation and pressure relief control of dynamic gob-side entry surroundings in fully-mechanized caving mining for extra-thick coal seam. Coal Sci. Technol. 2023, 51, 83–94. [Google Scholar] [CrossRef]

- Sun, L.H.; Yaang, X.D.; Zhang, H.Y.; Li, X.; Yang, B.S. Experimental research on characteristics of deformation and failure of roadway ribs in soft coal seams under strong dynamic pressure and bolt-grouting reinforcement. J. Min. Saf. Eng. 2019, 36, 232–239. [Google Scholar] [CrossRef]

- Wang, G.J.; Jiang, Z.G.; Guo, J.J. Application of numerical simulation to coal mining in seam with soft roof, soft coal and soft floor. Coal Eng. 2019, 36, 232–239. [Google Scholar] [CrossRef]

- Li, C.J.; Liu, Y.X.; Gao, H.B.; Xu, Y.Q.; Qiao, Q.F.; Hou, Z.Q. Overlying strata movement and stress distribution law in the “three-soft”coal seam. J. Xi’an Univ. Sci. Technol. 2015, 35, 187–191. [Google Scholar] [CrossRef]

- Xu, W.; Wang, E.; Liu, Z.; Hou, E.K.; Wang, S.J.; Deng, Z.S. Research on distribution and evolution patterns of abutment pressure in front of the fully-mechanized working face of “three-soft” coal seam isolated island. Prog. Mine Saf. Sci. Eng. II 2014, 2, 949–955. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, R.; Li, S.C.; He, M.C.; Ren, Y.X.; Wang, L.; Ding, G.L.; Sun, H.B.; Jiang, B. Gob side entry failure mechanism and control of bolt-grouting in three soft coal seam. J. China Coal Soc. 2016, 41, 1111–1119. [Google Scholar] [CrossRef]

- Jiang, B.; Li, S.C.; Wang, Q.; Pan, R.; Zhang, R.X.; Ren, Y.X.; Wang, D.C.; Ding, G.L.; Jiang, Z.H. Failure mechanism of three soft coal seam roadway and comparison study on bolt and grouting. J. China Coal Soc. 2015, 40, 2336–2346. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Lai, X.P.; Liu, X.M.; Cui, F. Construction and application of the GRNN model of coal section pillar width prediction in fully mechanized face. J. Xi’an Univ. Sci. Technol. 2019, 39, 209–216. [Google Scholar] [CrossRef]

- Wu, X.; Guo, J.B.; Cui, F.; Wang, Z.Y.; Xu, H.C. PSO-SVM prediction model of coal pillar width in fully mechanized mining face. J. Xi’an Univ. Sci. Technol. 2020, 40, 64–70. [Google Scholar] [CrossRef]

- Wang, K.; Lai, X.P.; Guo, B.; Cui, F. Study on the reasonable section coal pillar width for fully mechanized caving face with hard roof and extra-thick coal seam. Coal Eng. 2019, 51, 43–47. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, S.S.; Li, T.; Huang, X.P.; Yang, T.; Wang, Z.H.; He, Y.F.; Han, J.B. Study on failure characteristics and control of soft rock roadway floor. Coal Sci. Technol. 2023, 51, 21–28. [Google Scholar] [CrossRef]

- Zhang, J.; Li, T.; Gao, S.S.; Huang, X.P.; Wang, L.; Wang, Z.H.; Yan, Y.H. Research on Failure Mechanism and Control of Soft Rock Roadway. Coal Technol. 2023, 42, 1–7. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, F.W.; Yang, T.; Xie, P.; Shen, R.J.; Guo, J.P. Floor heave mechanism and control technique of soft rock roadway in anshan coal mine. Coal Eng. 2019, 51, 37–40. [Google Scholar] [CrossRef]

- Zhi, X.X. Study on the characteristics of strata behavior in shallow seam long wall mining under the room-and-pillar mining goaf. J. China Coal Soc. 2012, 37, 898–902. [Google Scholar] [CrossRef]

- Zhang, J.G.; Cheng, Z.H.; Chen, H.Y.; Yin, S.F.; Chen, L.; Xue, A. Analysis and optimization of remaining width of coal pillars in the section of Yayaomao coal mine. Coal Sci. Technol. 2022, 50, 60–67. [Google Scholar] [CrossRef]

- Cui, F.; Zhang, T.H.; Cheng, X.Q. Research on control of rib spalling disaster in the three-soft coal seam. Shock. Vib. 2021, 2021, 2404218. [Google Scholar] [CrossRef]

- Li, S.B.; Wang, L.; Zhu, C.Q.; Ren, Q.H. Research on mechanism and control technology of rib spalling in soft coal seam of deep coal mine. Adv. Mater. Sci. Eng. 2021, 2021, 2833210. [Google Scholar] [CrossRef]

- Jiang, Z.S.; Guo, W.K.; Xie, S.R. Coal pillar size determination and surrounding rock control for gob-side entry driving in deep soft coal seams. Processes 2023, 11, 2331. [Google Scholar] [CrossRef]

- Qian, M.G.; Shing, P.W.; Xu, J.L. Min Pressure and Rock Formation Control; China University of Mining and Technology Press: Xuzhou, China, 2015. [Google Scholar]

- Xu, Z.L. Elasticity; Higher Education Press: Beijing, China, 2006. [Google Scholar]

- Wang, H. Study on Width Reservation and Stability of Coal Pillar in 421-2 Face of Chenjiashan Coalmine; University of Mining and Technology: Xuzhou, China, 2021. [Google Scholar]

- Guo, L.Q.; Cai, Q.P.; Peng, X.Q. Effect of strength criterion on design of strip coal pillar. Rock Soil Mech. 2014, 35, 777–782. [Google Scholar] [CrossRef]

- Zhang, J.; He, Y.F. Research on the fracture evolution law and combined bearing structureload of shallow buried coal seam group. Coal Sci. Technol. 2023, 51, 65–76. [Google Scholar] [CrossRef]

- Sun, Q. Effect of Overburden Strata Structure on Reasonable Width of Inter Recovery Room Pillar in Mining Close Distance Seam. Master’s Thesis, Taiyuan University Of Technology, Taiyuan, China, 2020. [Google Scholar] [CrossRef]

- Lai, X.P.; Zhang, X.D.; Shan, P.F.; Cui, F.; Liu, B.W.; Bai, R. Study on development law of water-conducting fractures in overlying strata of three soft coal seam mining under thick loose layers. Chin. J. Rock Mech. Eng. 2021, 40, 1739–1750. [Google Scholar] [CrossRef]

| Lithologic Characters | Thickness of Stratum (m) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Force of Cohesion (MPa) | Tensile Strength (MPa) | Angle of Internal Friction (°) | Density (kg·m−3) | Ratio (Sand:Gypsum:Calcium Carbonate) |

|---|---|---|---|---|---|---|---|---|

| kern stone | 8.50 | 7.3 | 5.27 | 4.14 | 3.27 | 32 | 2530 | 7:4:6 |

| post office box stone | 7.80 | 5.6 | 4.38 | 2.91 | 1.37 | 34 | 2460 | 7:2:8 |

| medium grained sandstone | 8.44 | 6.30 | 4.47 | 3.20 | 2.56 | 33 | 2450 | 8:3:7 |

| siltstone | 17.51 | 4.8 | 3.37 | 1.97 | 1.34 | 32 | 2450 | 7:3:7 |

| kern stone | 6.23 | 7.3 | 5.27 | 4.14 | 3.27 | 32 | 2530 | 7:4:6 |

| siltstone | 2.40 | 4.8 | 3.37 | 1.97 | 1.34 | 32 | 2450 | 7:3:7 |

| kern stone | 2.96 | 7.3 | 5.27 | 4.14 | 3.27 | 32 | 2530 | 7:4:6 |

| sandy mudstone | 7.23 | 3.07 | 1.84 | 1.6 | 0.95 | 2 | 2000 | 8:3:7 |

| medium grained sandstone | 6.87 | 6.3 | 4.47 | 3.2 | 2.56 | 33 | 2450 | 8:3:7 |

| siltstone | 6.17 | 4.8 | 3.37 | 1.97 | 1.34 | 32 | 2450 | 7:3:7 |

| sandy mudstone | 4.86 | 3.07 | 1.84 | 1.6 | 0.95 | 2 | 2000 | 8:3:7 |

| siltstone | 5.21 | 4.8 | 3.37 | 1.97 | 1.34 | 32 | 2450 | 7:3:7 |

| post office box stone | 4.69 | 5.6 | 4.38 | 2.91 | 1.37 | 34 | 2460 | 7:2:8 |

| 4 coal | 1.00 | 1.46 | 0.45 | 0.5 | 0.5 | 25 | 1320 | 20:20:1:5 |

| siltstone | 1.95 | 4.8 | 3.37 | 1.97 | 1.34 | 32 | 2450 | 7:3:7 |

| 5 coal | 4.50 | 5.60 | 4.38 | 2.91 | 1.37 | 34 | 2460 | 20:20:1:5 |

| siltstone | 2.91 | 4.8 | 3.37 | 1.97 | 1.34 | 32 | 2450 | 7:3:7 |

| silicarenite | 8.06 | 7.3 | 5.27 | 4.14 | 3.27 | 32 | 2530 | 7:4:6 |

| post office box stone | 2.0 | 5.6 | 4.38 | 2.91 | 1.37 | 34 | 2460 | 7:2:8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, T.; Zhang, Y.; Zhang, J.; Lin, H.; Bao, R.; He, Y.; Yan, Y.; Luo, P.; Wu, H.; Sun, J.; et al. Study on the Stability and Reasonable Width of Coal Pillars in “Three Soft” Coal Seams Based on a Physical Similarity Simulation Experiment. Appl. Sci. 2024, 14, 6127. https://doi.org/10.3390/app14146127

Yang T, Zhang Y, Zhang J, Lin H, Bao R, He Y, Yan Y, Luo P, Wu H, Sun J, et al. Study on the Stability and Reasonable Width of Coal Pillars in “Three Soft” Coal Seams Based on a Physical Similarity Simulation Experiment. Applied Sciences. 2024; 14(14):6127. https://doi.org/10.3390/app14146127

Chicago/Turabian StyleYang, Tao, Yiming Zhang, Jie Zhang, Haifei Lin, Ruoyu Bao, Yifeng He, Yihui Yan, Pengkun Luo, Haohao Wu, Jianping Sun, and et al. 2024. "Study on the Stability and Reasonable Width of Coal Pillars in “Three Soft” Coal Seams Based on a Physical Similarity Simulation Experiment" Applied Sciences 14, no. 14: 6127. https://doi.org/10.3390/app14146127

APA StyleYang, T., Zhang, Y., Zhang, J., Lin, H., Bao, R., He, Y., Yan, Y., Luo, P., Wu, H., Sun, J., & Pang, H. (2024). Study on the Stability and Reasonable Width of Coal Pillars in “Three Soft” Coal Seams Based on a Physical Similarity Simulation Experiment. Applied Sciences, 14(14), 6127. https://doi.org/10.3390/app14146127