Systematic Concept Study of Brayton Batteries for Coupled Generation of Electricity, Heat, and Cooling

Abstract

1. Introduction

1.1. Open vs. Closed Configurations

1.2. Thermal Energy Storage

1.3. Compression and Expansion Machines

1.4. More Complex Concepts

1.5. Conclusions for the SWS-SYS Project

2. Methods

2.1. Boundary Conditions and Assumptions

- Pure electricity generation;

- Pure electricity generation with waste heat integration;

- Coupled generation of electricity and heat;

- Coupled generation of electricity and heat with waste heat integration;

- Coupled generation of electricity and cooling;

- Coupled generation of electricity and cooling with waste heat integration;

- Coupled generation of electricity, heat, and cooling.

- During the summer half-year, the electricity input results from the high solar share between 8 am and 4 pm [34], while in the winter half-year, it is due to the nighttime reduction in electricity demand between 10 pm and 6 am.

- Process waste heat from industry occurs around the clock—both in winter and sum-mer. Here, a temperature level of 90 °C is deliberately chosen, which is typically not utilized because there is no recipient available. Sources include cooling circuits from compressed air generation systems, for example. But also, alkaline electrolysis could be a possible source. [35]

- Process heat also needs to be supplied around the clock. The temperature level of 250 °C is deliberately chosen to be ambitiously high.

- For the supply of cooling, air conditioning of shopping centers and office buildings is chosen as the sink. The time restrictions arise from the usual opening and office hours. The temperature levels for supply and return are taken from [36].

- States according to the ideal gas law;

- No consideration of pressure and heat losses;

- Temperature after compressor of the charging line: 625 or 450 °C;

- Pressure after the turbines: 1 bar;

- Isentropic efficiency of turbomachinery: 0.9;

- Mechanical efficiency of turbomachinery: 0.99;

- Electrical efficiency of motors: 0.97;

- Mechanical efficiency of motors: 0.998;

- Electrical efficiency of generators: 0.99;

- Efficiency of TESs: 0.95;

- Effectiveness of recuperator heat exchangers: 0.9;

- Gradients for the optional heat exchangers for heat input/output: 10 K;

- Ambient temperature: 15 °C.

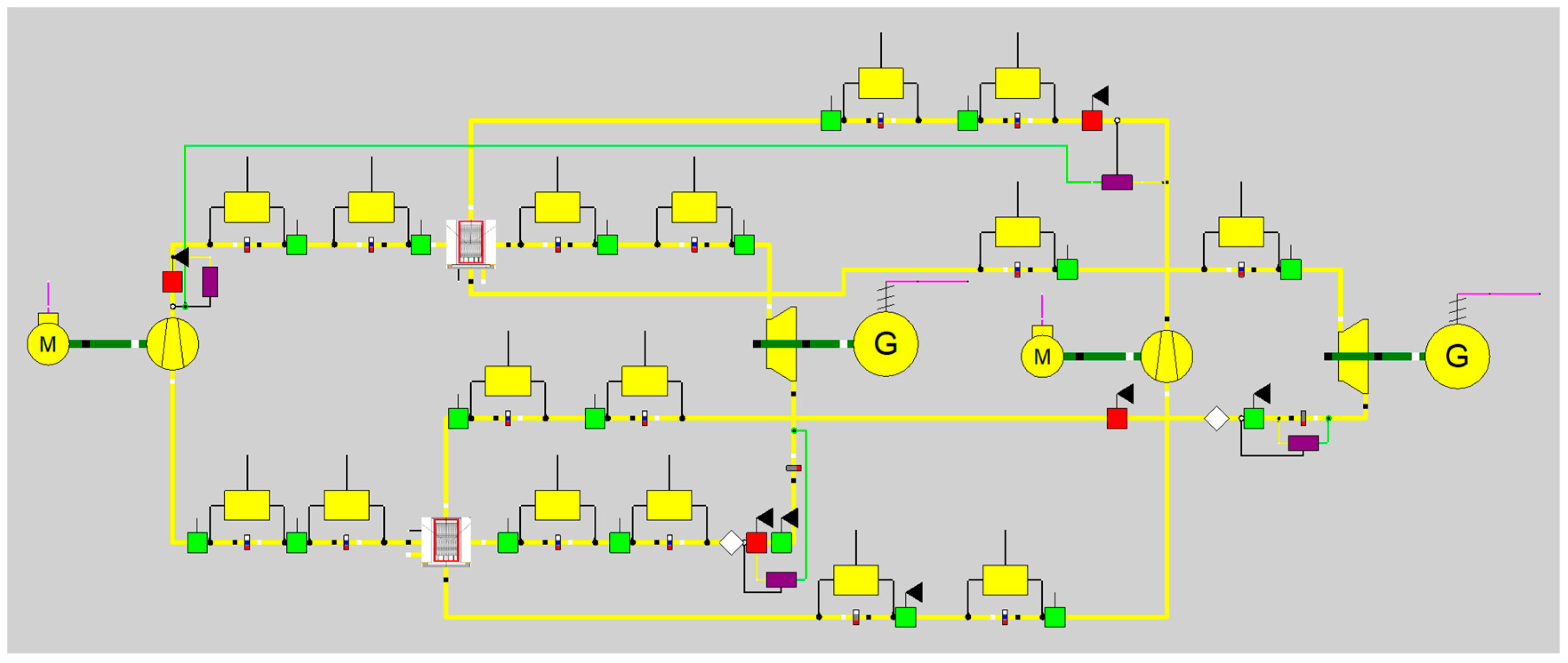

2.2. Design of Suitable System Configurations

- Closed and open cycles.

- Compressor outlet temperature CDT of the charging line (manipulated variable): 450 °C (state of the art for turbo compressors) or 625 °C (a realistically achievable and economically justifiable development stage). The compressor outlet pressure serves as the control variable here. The Ebsilon Professional component 39 (controller with internal target value) is used here.

- Working fluids: air, as well as CO2 and argon for the closed concepts.

- For the air-operated system, variants with a recuperator for transferring the heat from the hot to the cold side of the charging line (and optionally the discharging line) were also considered.

3. Results

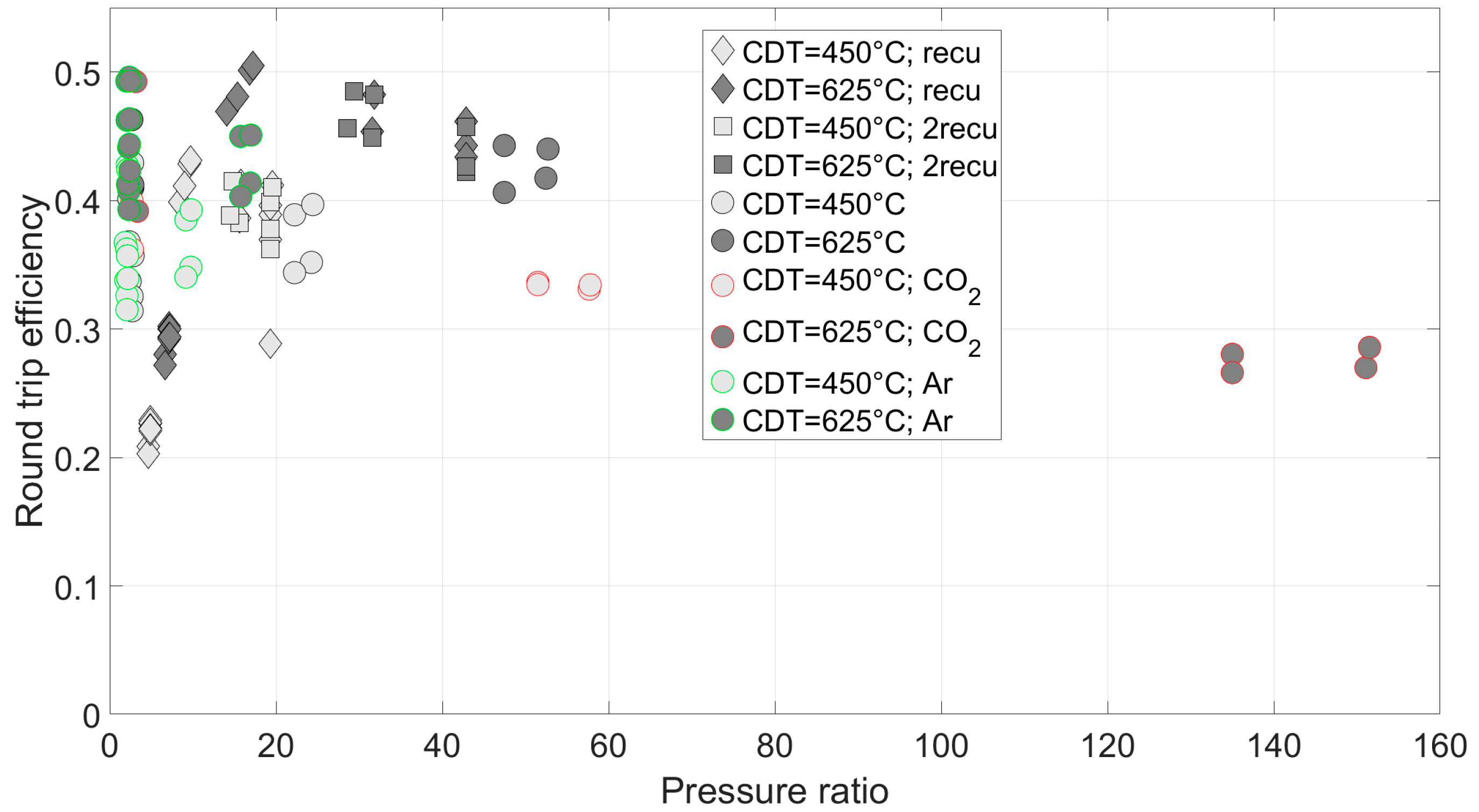

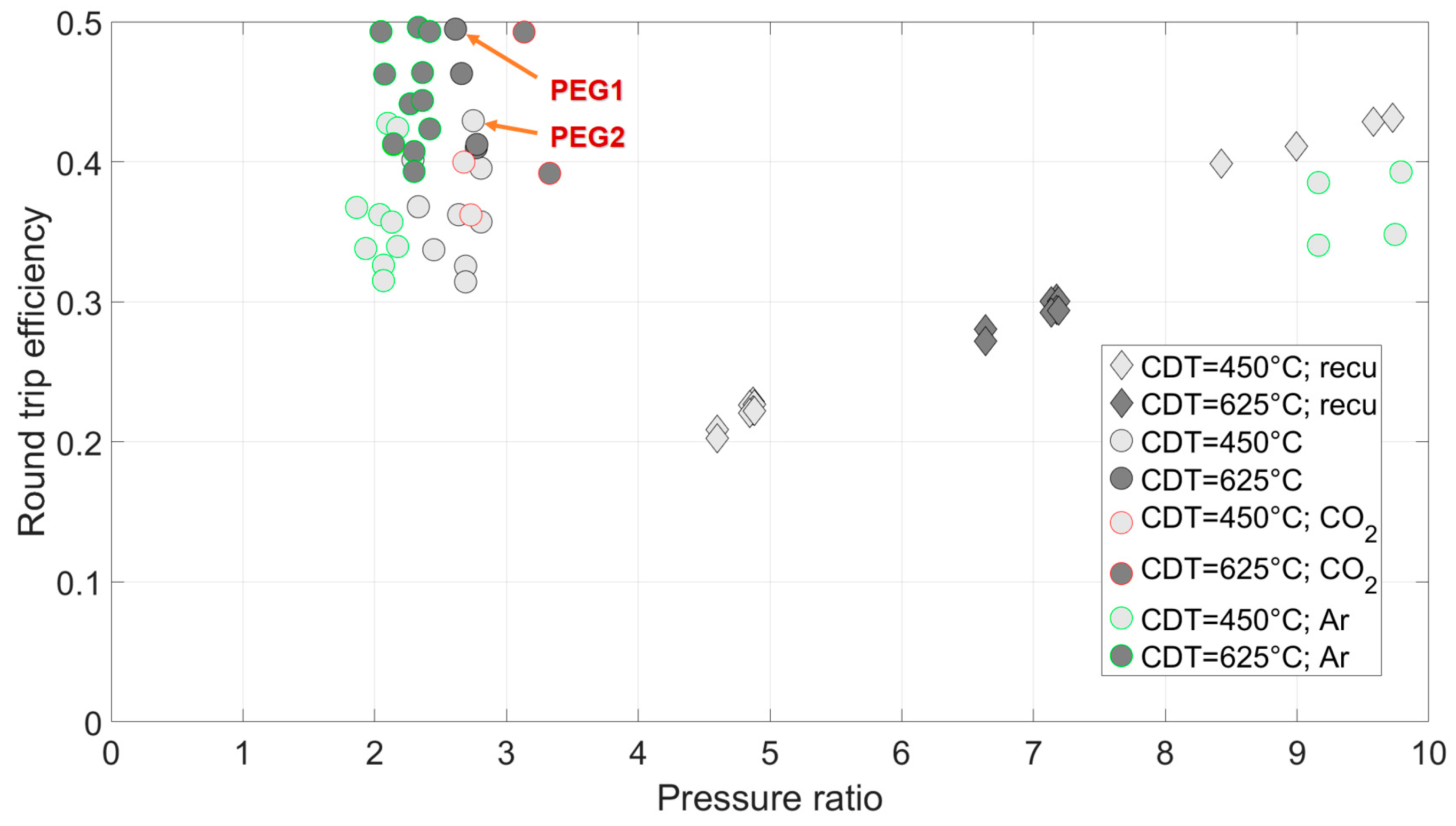

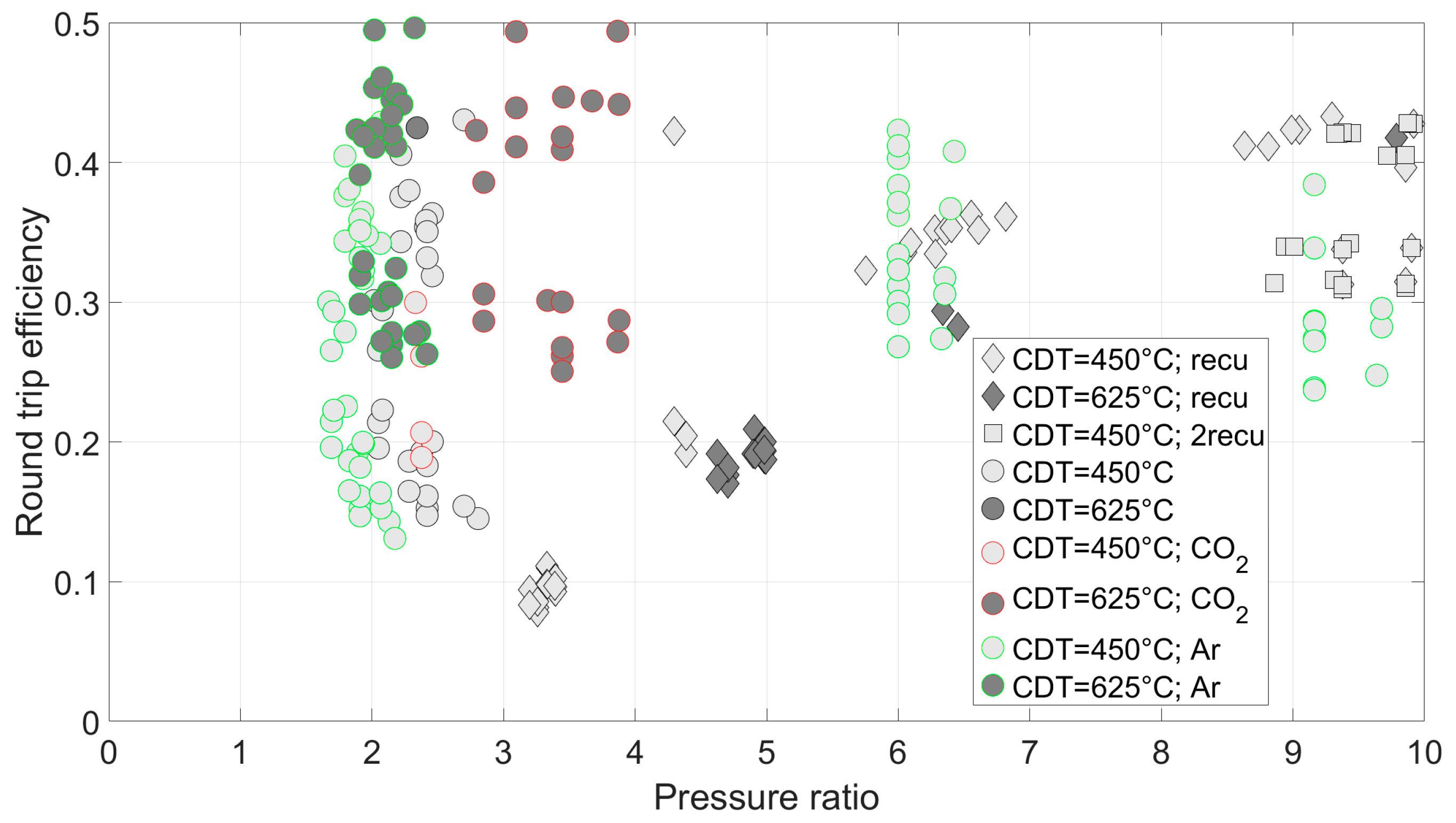

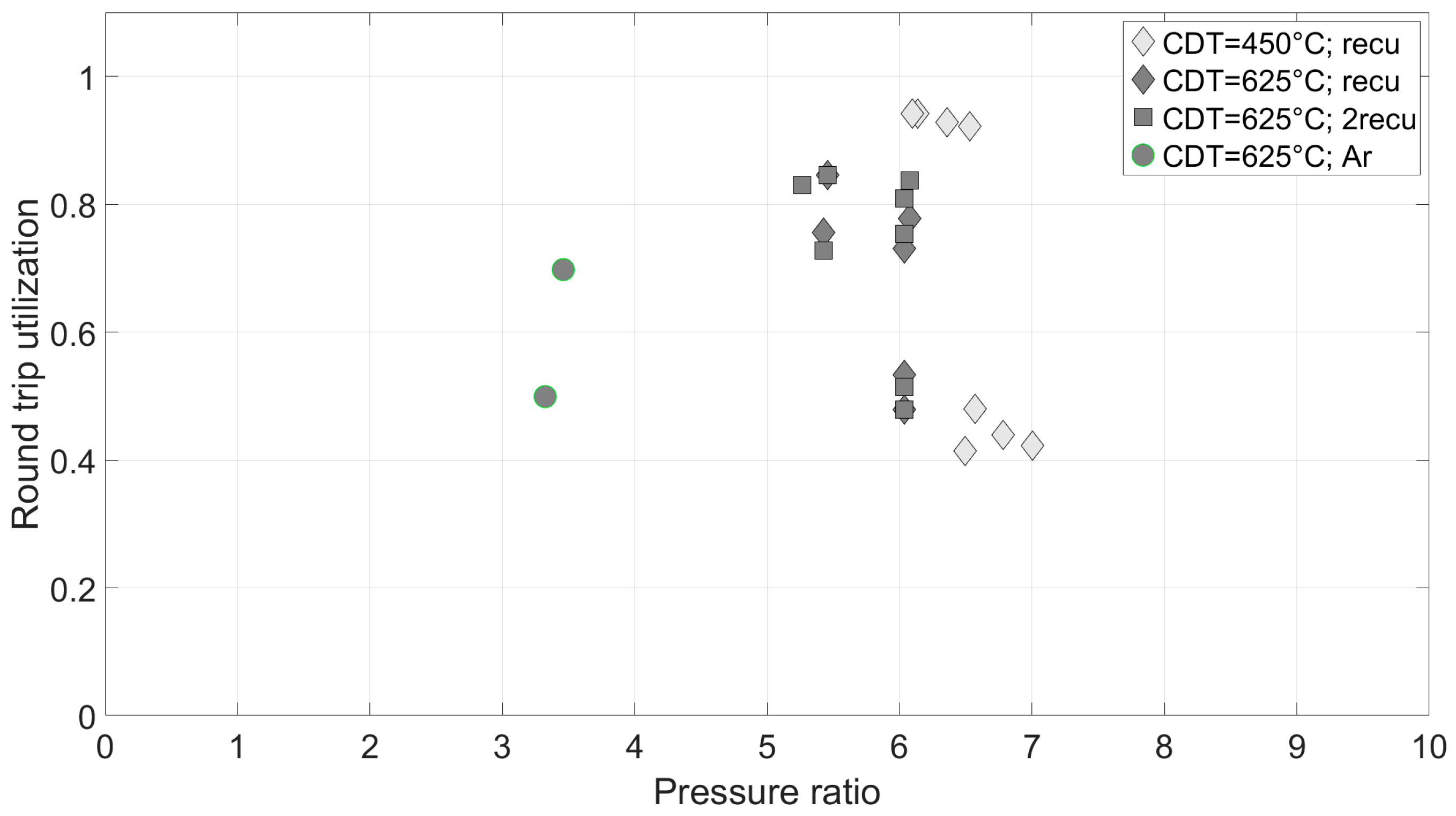

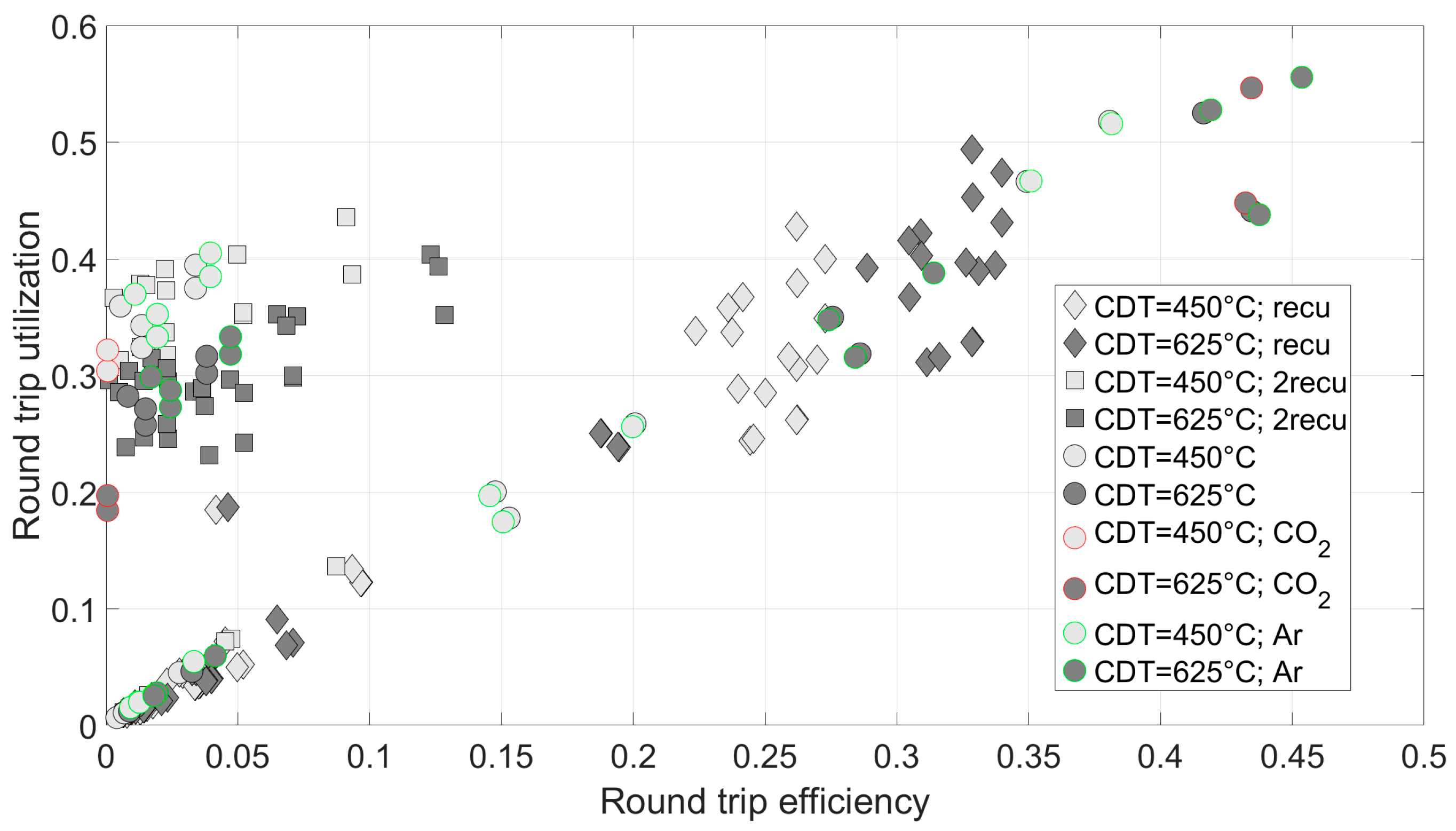

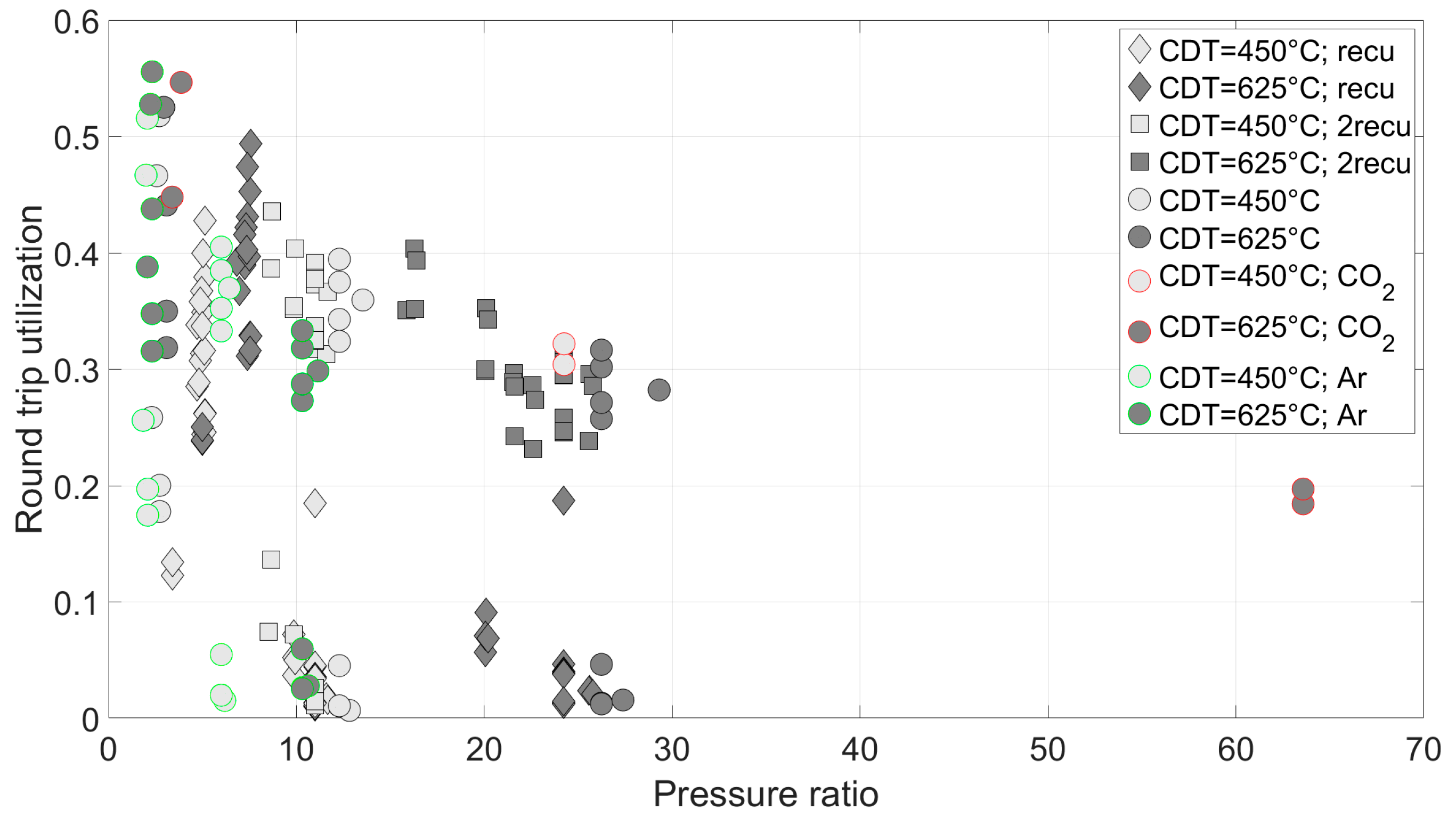

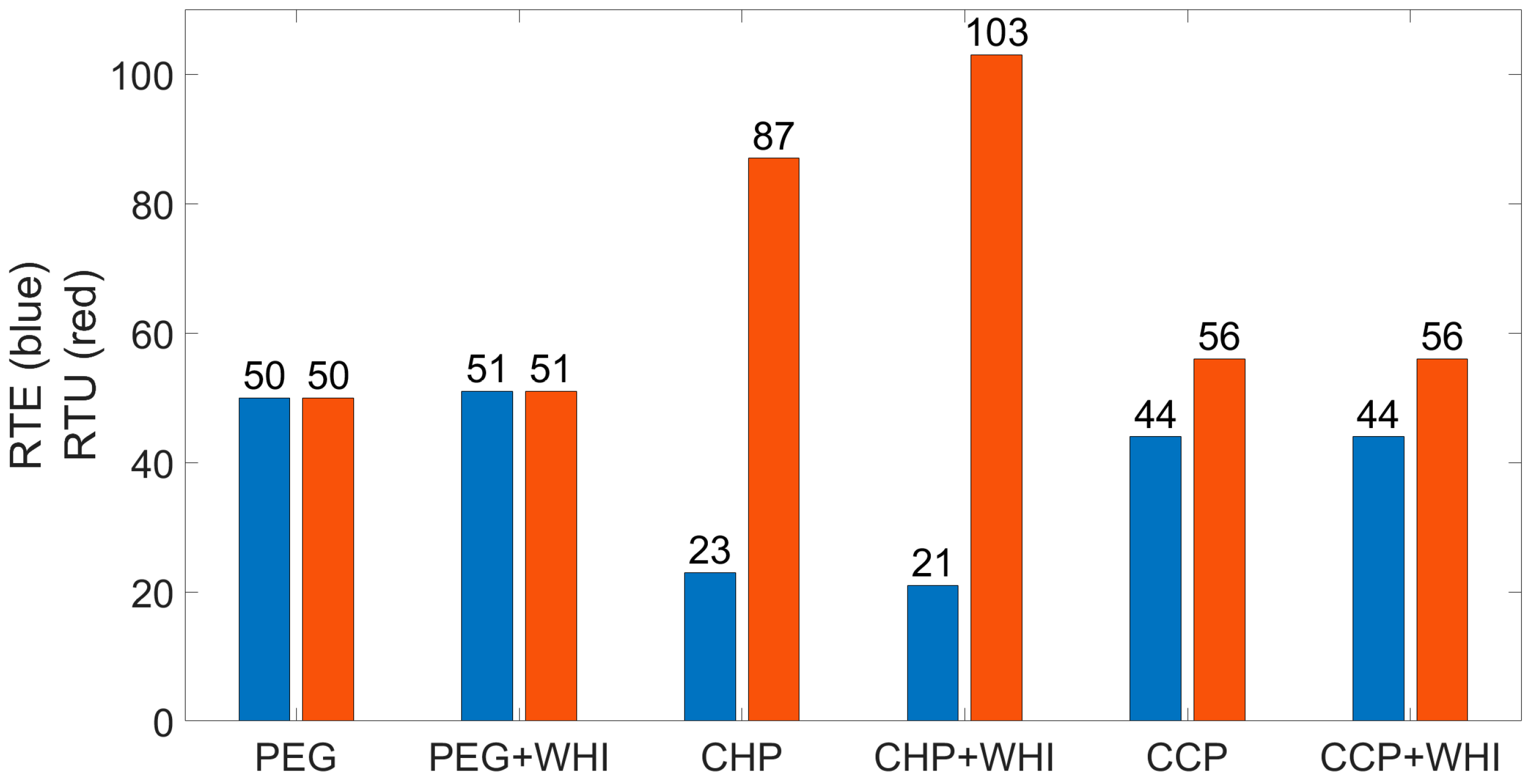

3.1. Power Generation with or without Waste Heat Integration

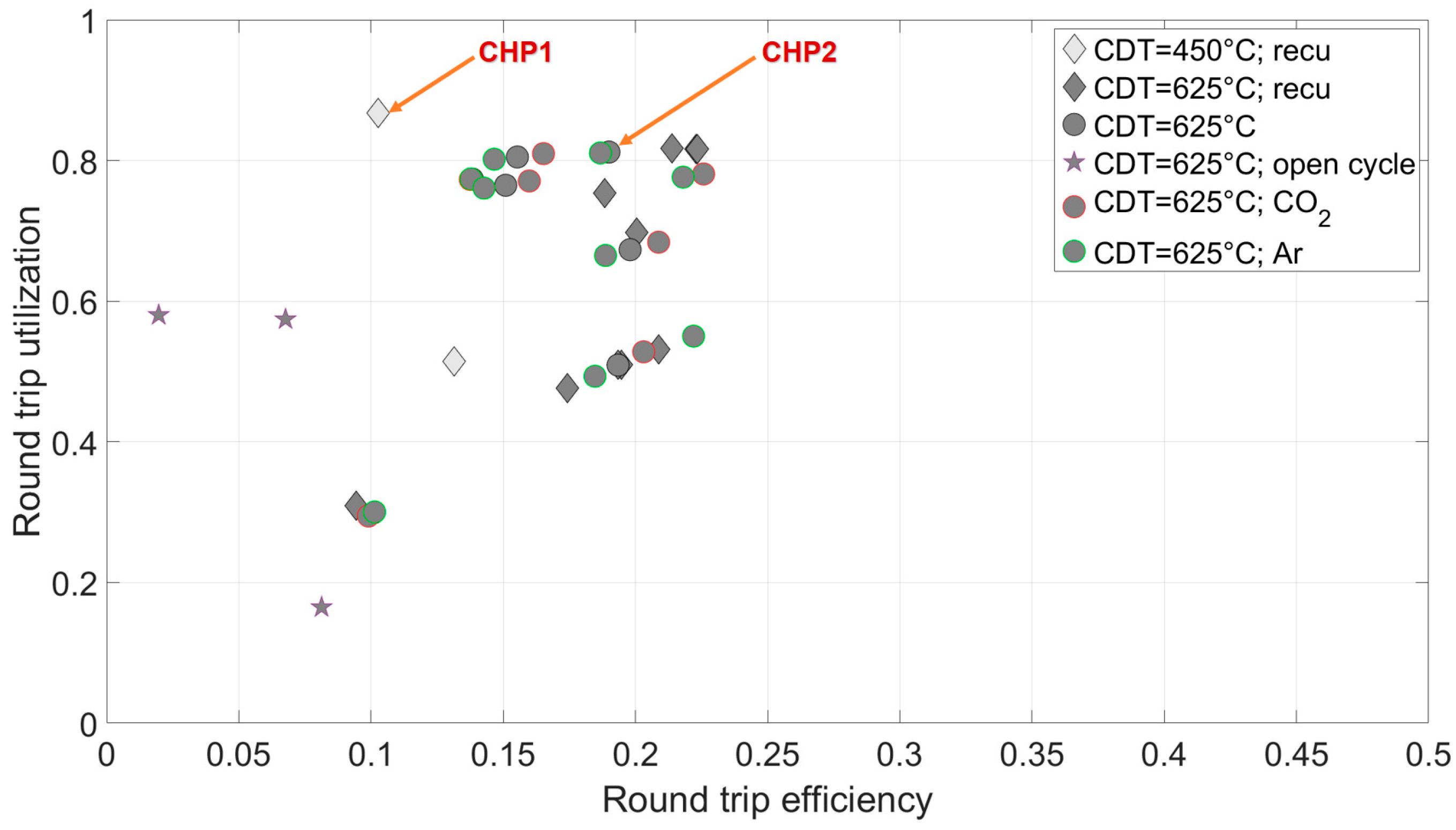

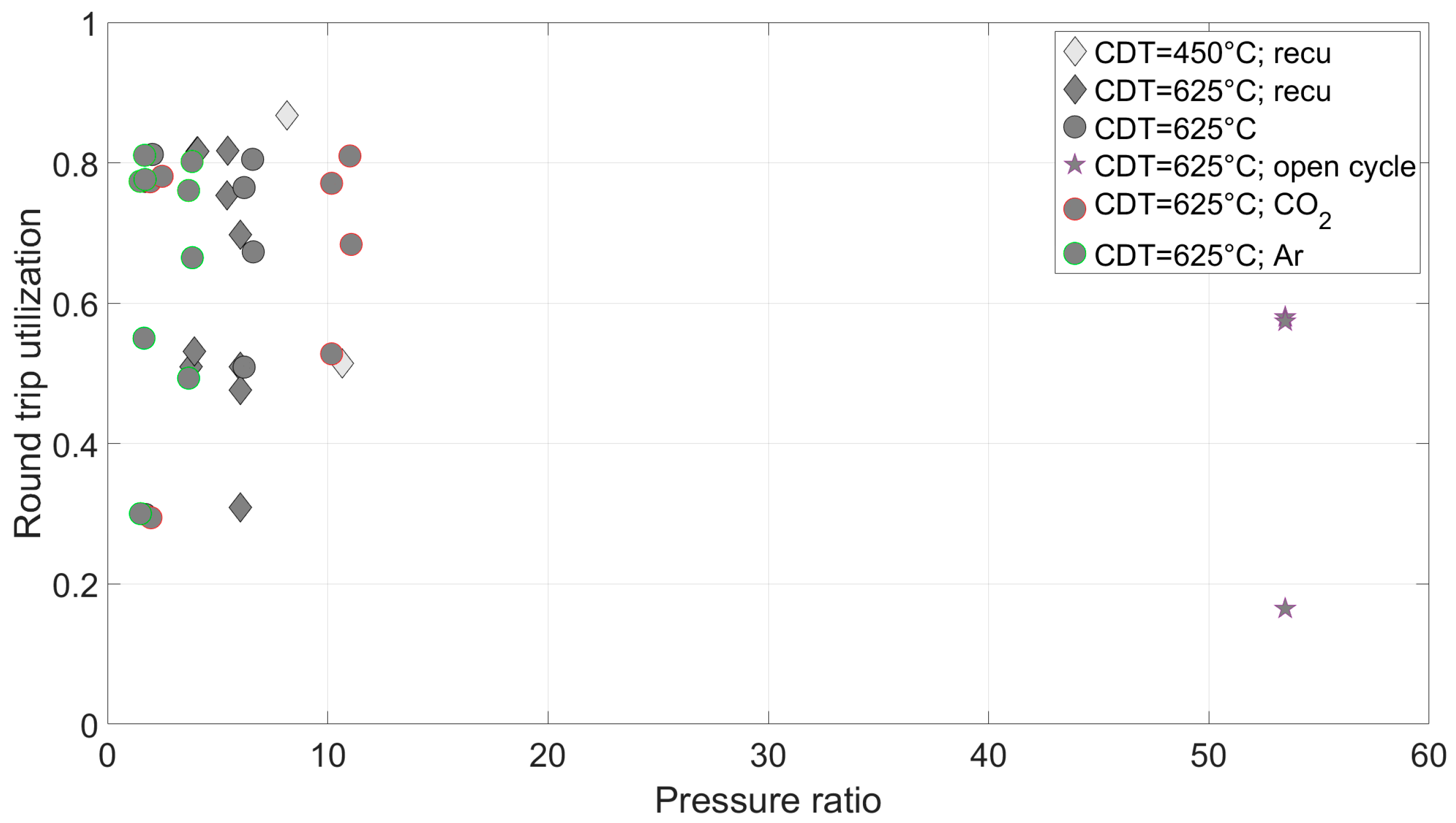

3.2. Coupled Generation of Electricity and Heat with or without Waste Heat Integration

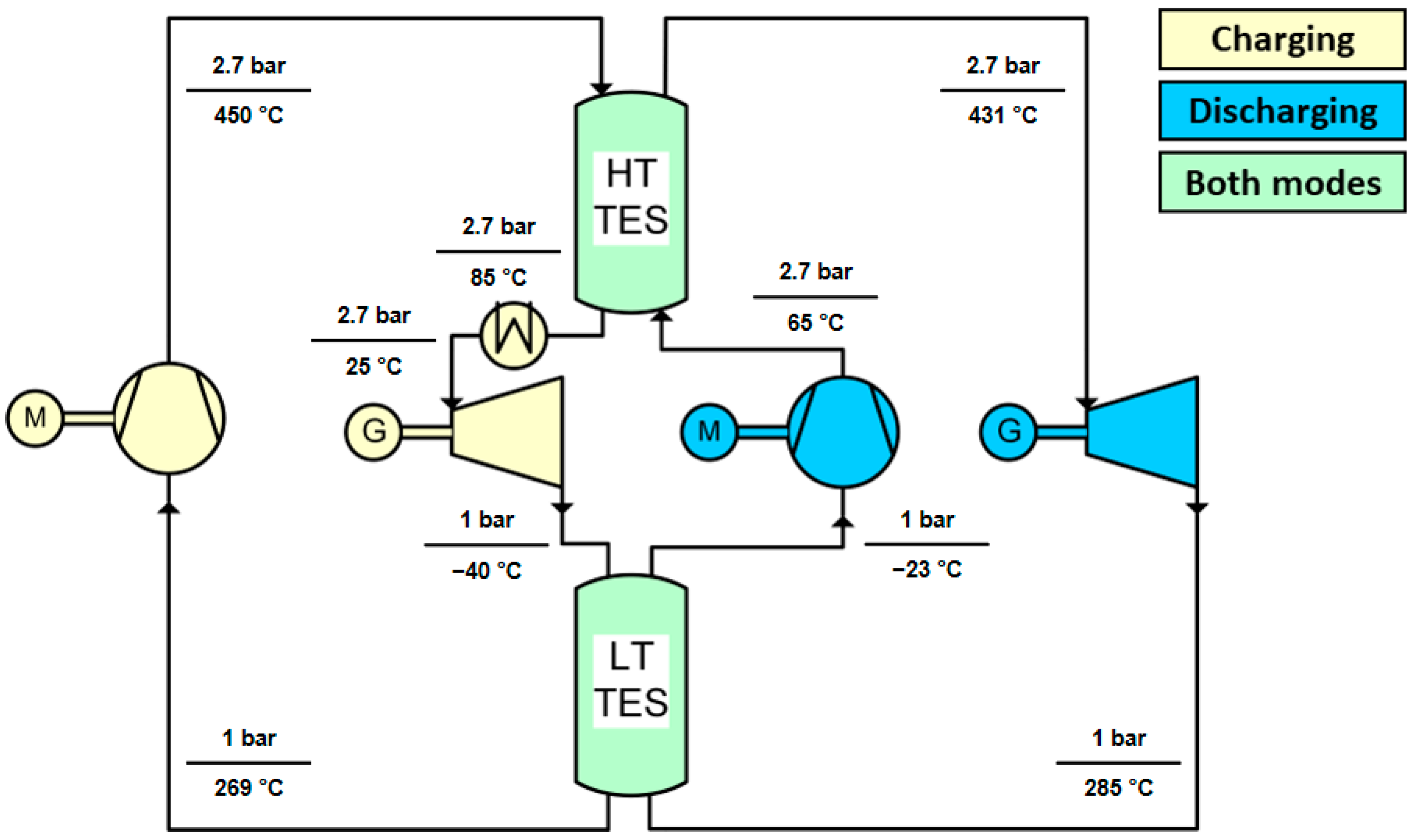

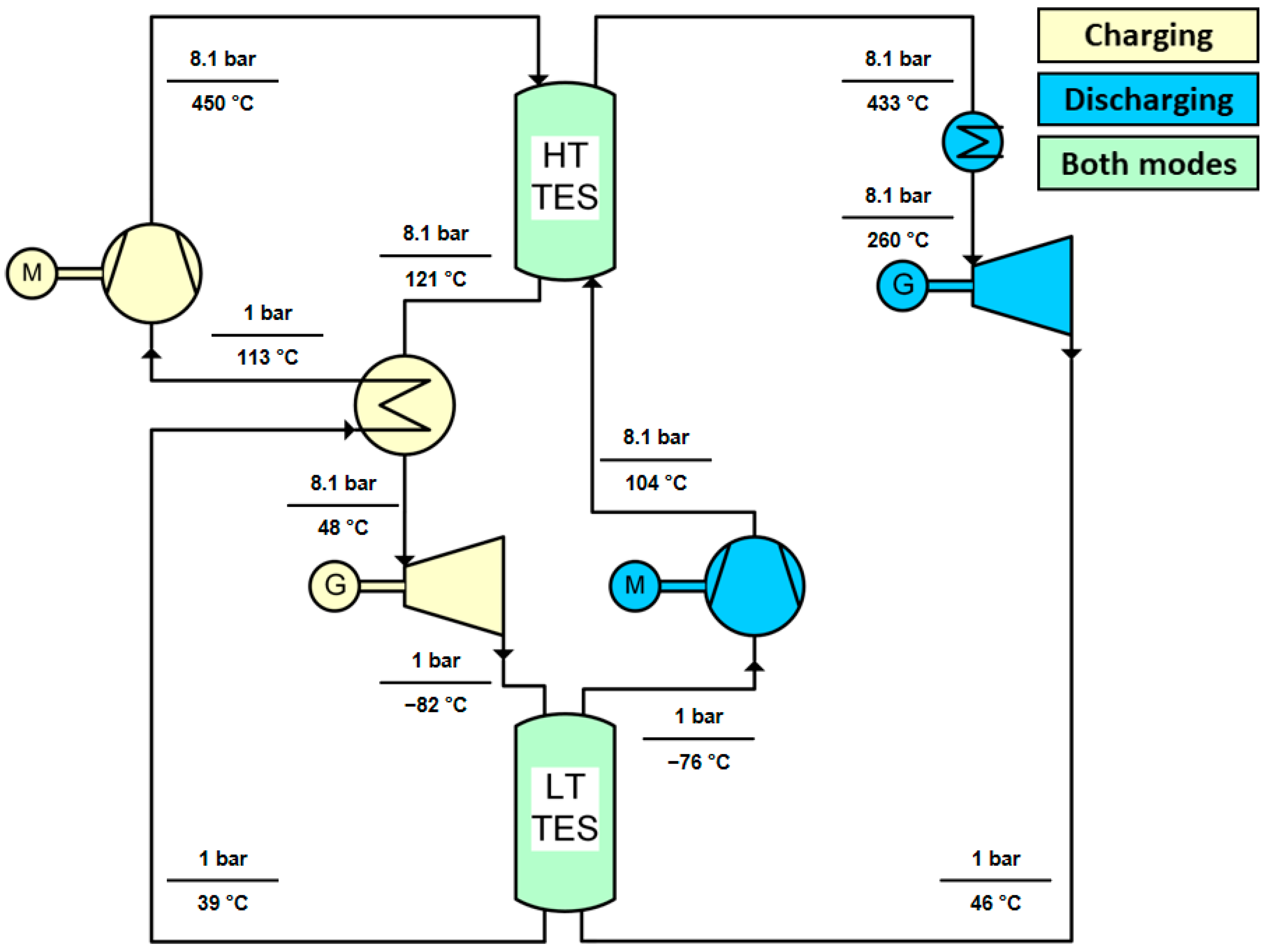

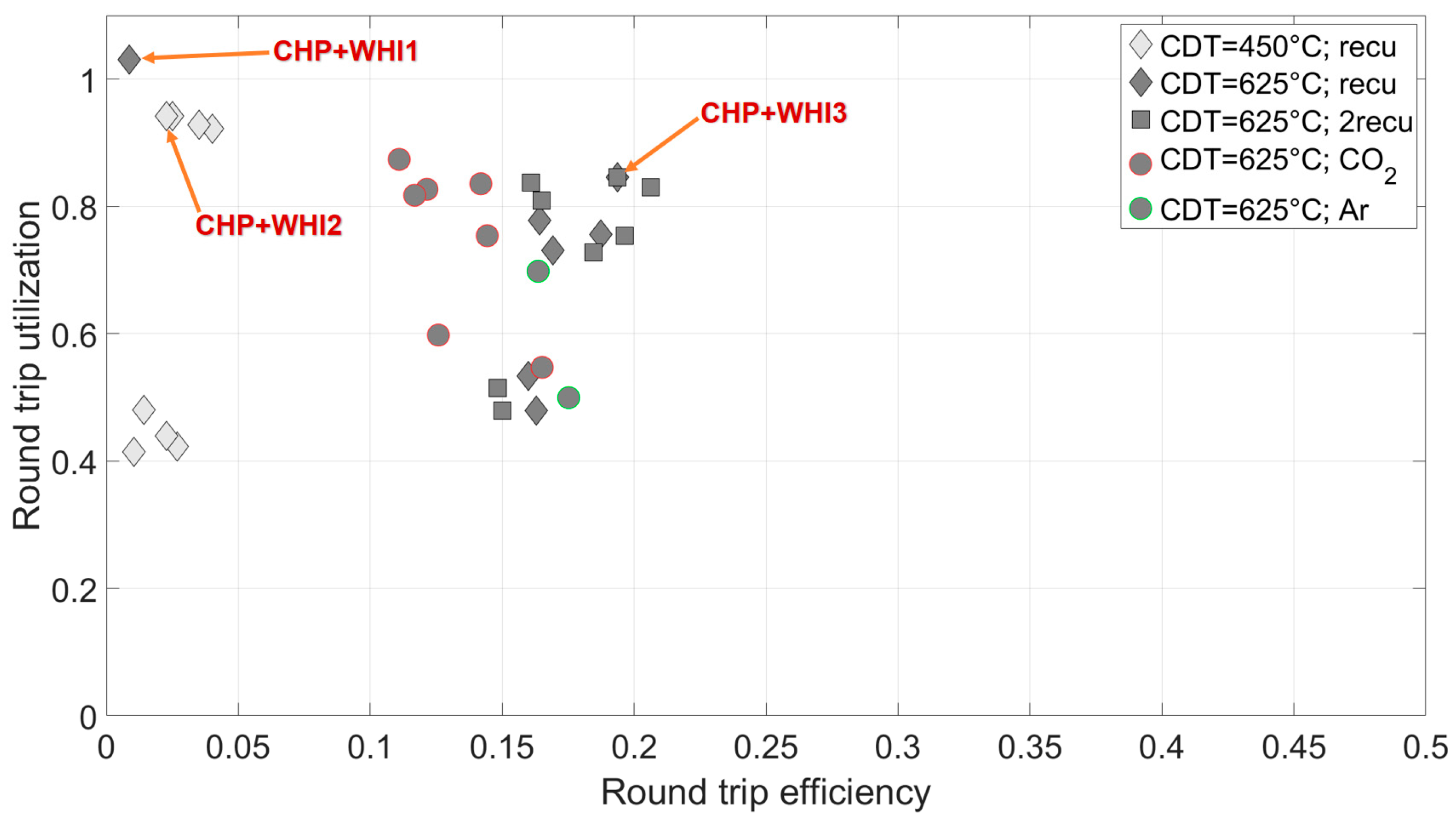

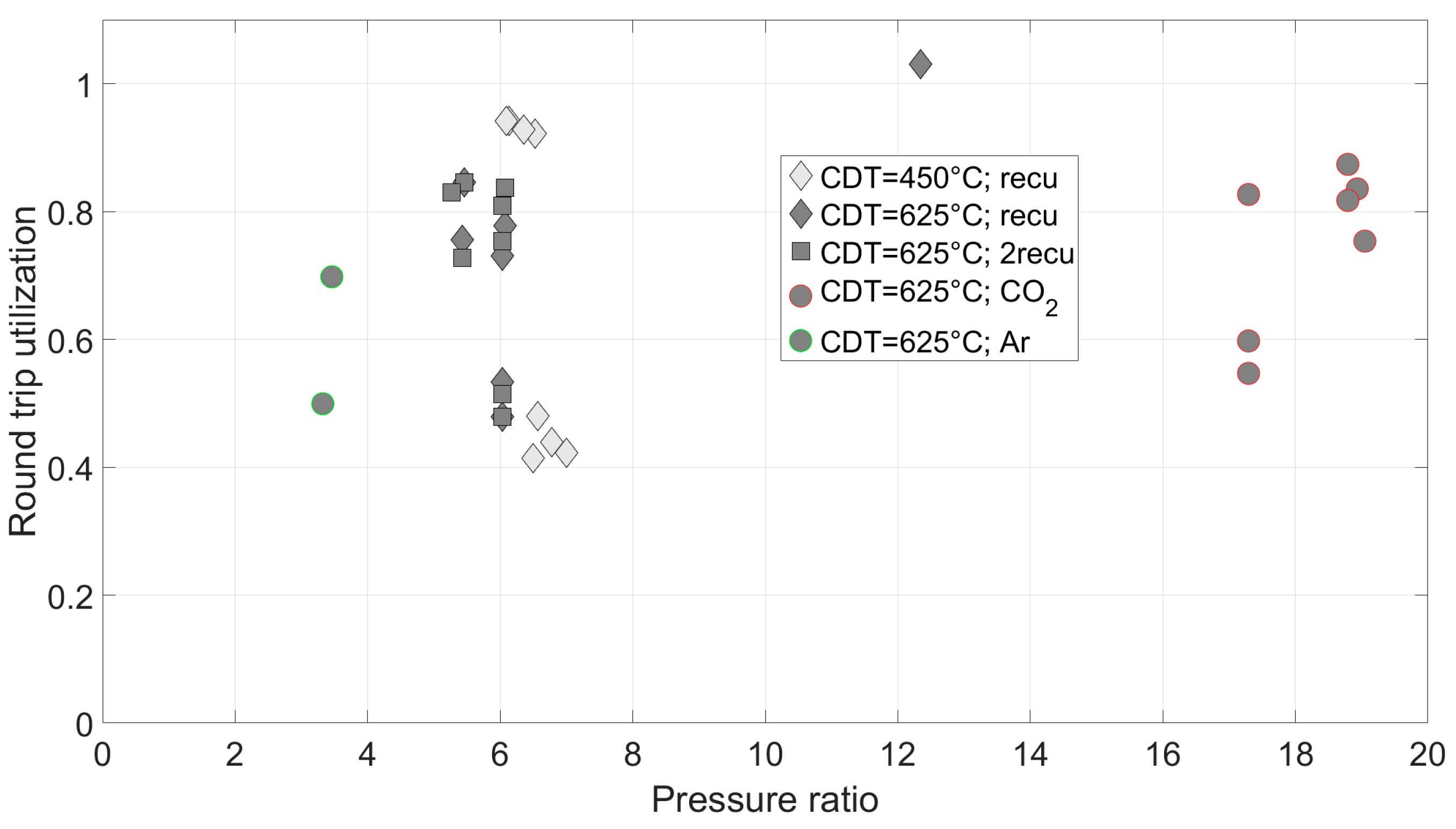

- CHP1: Working fluid is air. Process heat extraction before the turbine in the discharge line. Recuperator in the charge line. ϑmax = 450 °C; RTU = 86.8%; RTE = 10.3%; Π = 8.1. Flowchart: Figure 13.

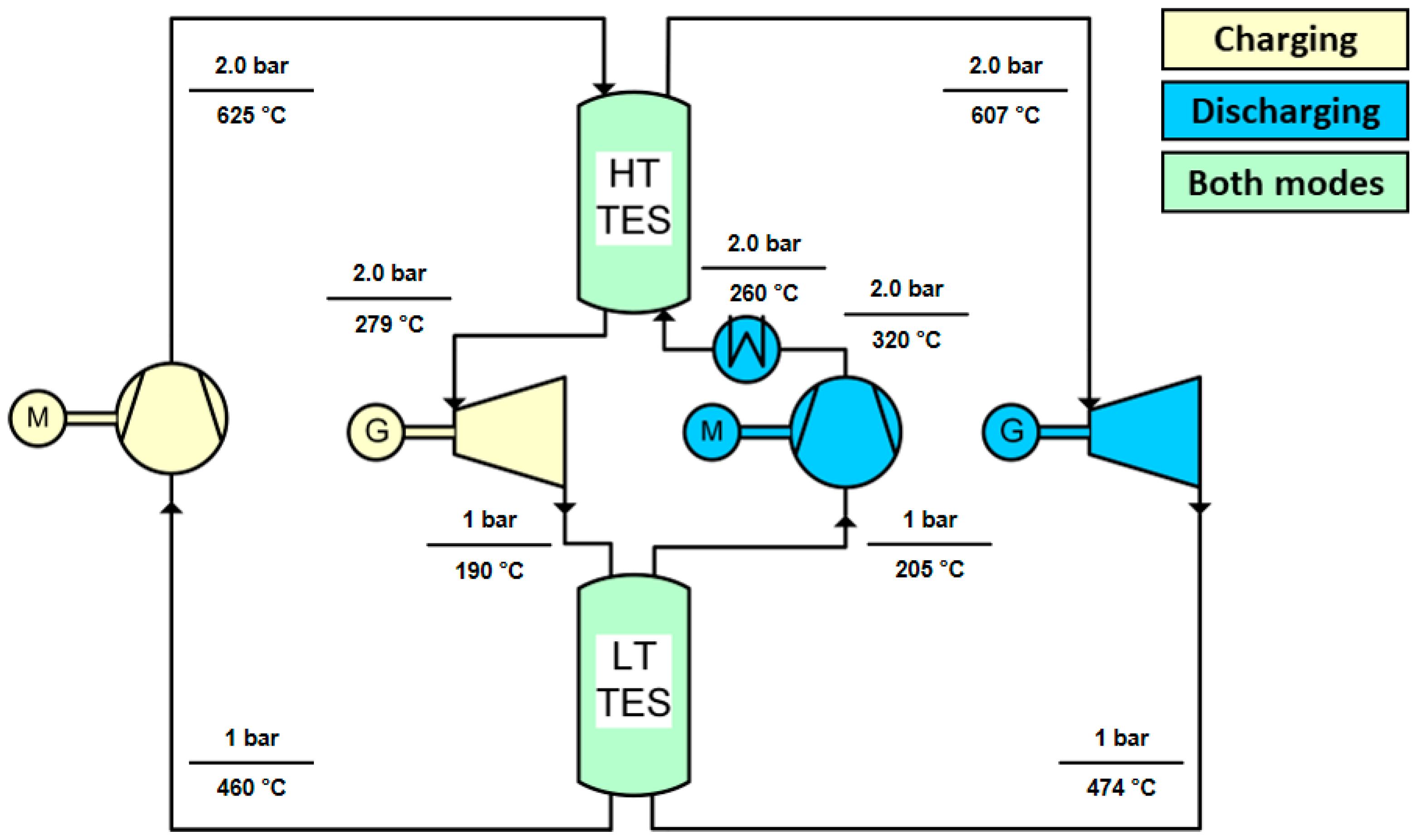

- CHP2: Working fluid is air. Process heat extraction after the compressor in the discharge line. ϑmax = 625 °C; RTU = 81.2%; RTE = 19.0%; Π = 2.0. Flowchart: Figure 14.

- CHP+WHI1: Working fluid is air. Process heat extraction before the turbine in the discharge line. Waste heat integration before the turbine in the charge line. Recuperator in the charge line. ϑmax = 625 °C; RTU = 103.1%; RTE = 0.9%; Π = 12.3. Flowchart: Figure 18.

- CHP+WHI2: Working fluid is air. Process heat extraction before the turbine in the discharge line. Waste heat integration after the low-temperature thermal energy storage (LT-TES) in the charge line. Recuperator in the charge line. ϑmax = 450 °C; RTU = 94.2%; RTE = 2.5%; Π = 6.1. Flowchart: Figure 19.

- CHP+WHI3: Working fluid is air. Process heat extraction after both the compressor and the turbine in the discharge line. Waste heat integration after the turbine in the charge line. Recuperator in the charge line. ϑmax = 625 °C; RTU = 84.6%; RTE = 19.4%; Π = 5.5. Flowchart: Figure 20.

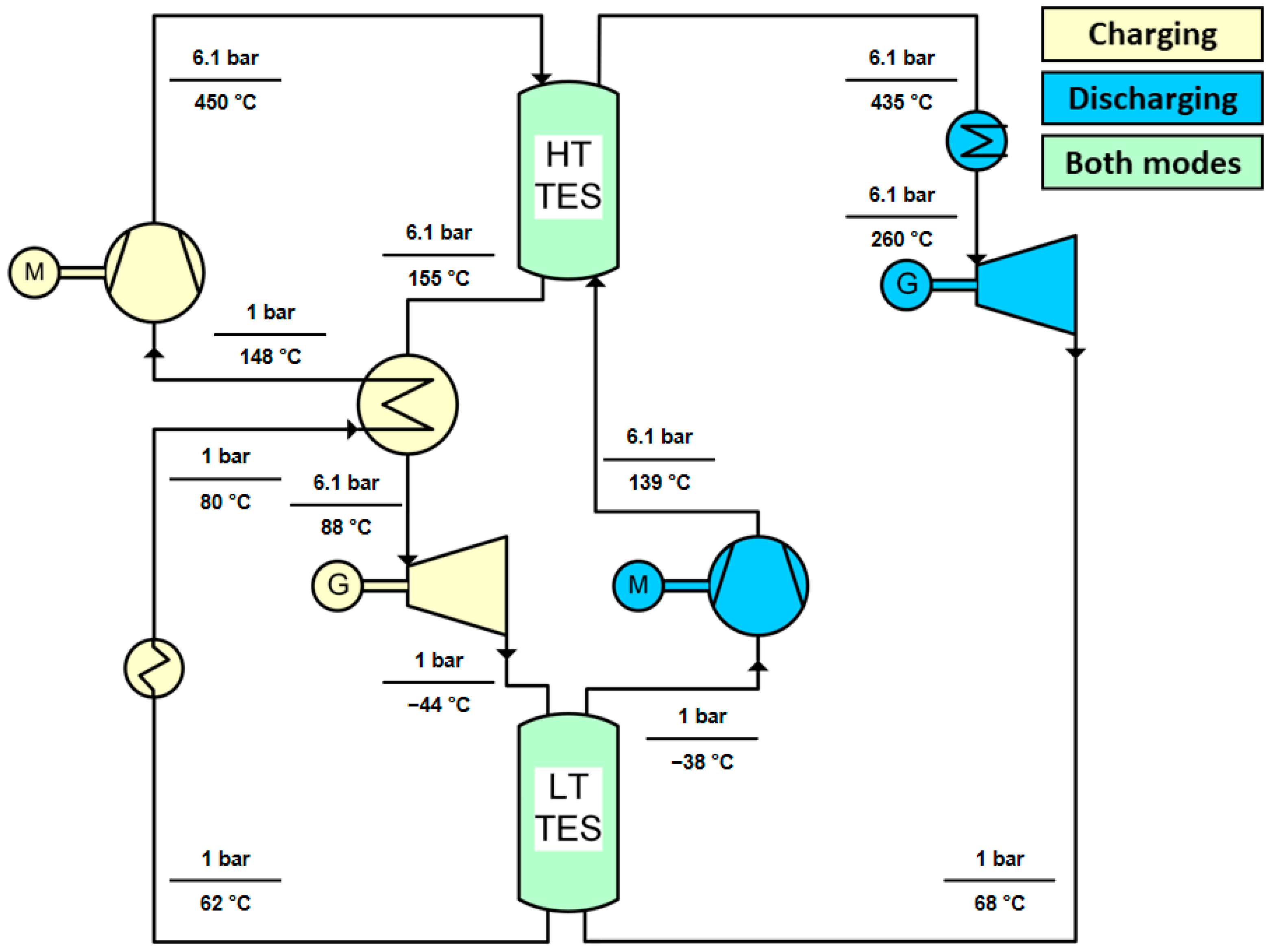

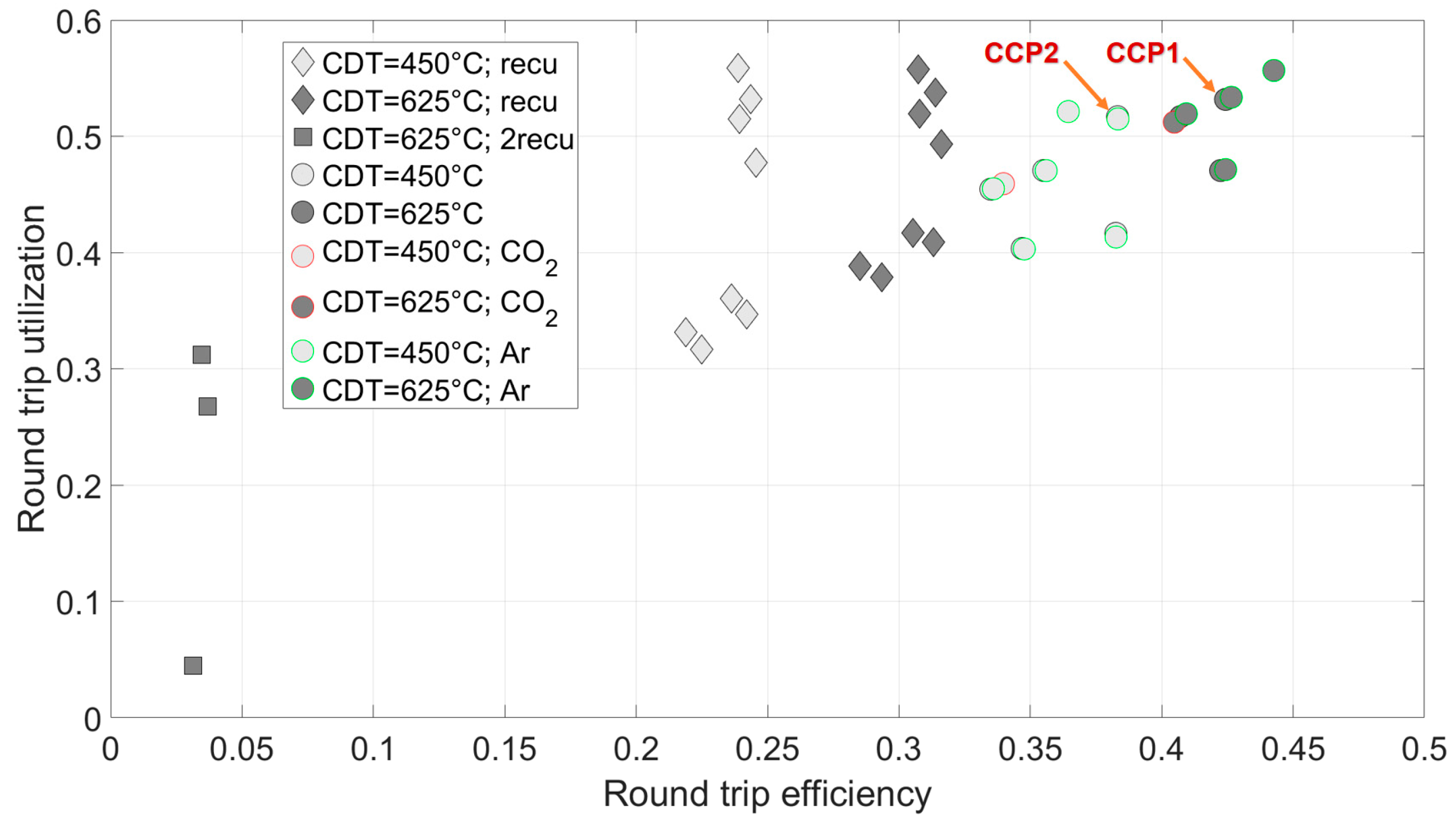

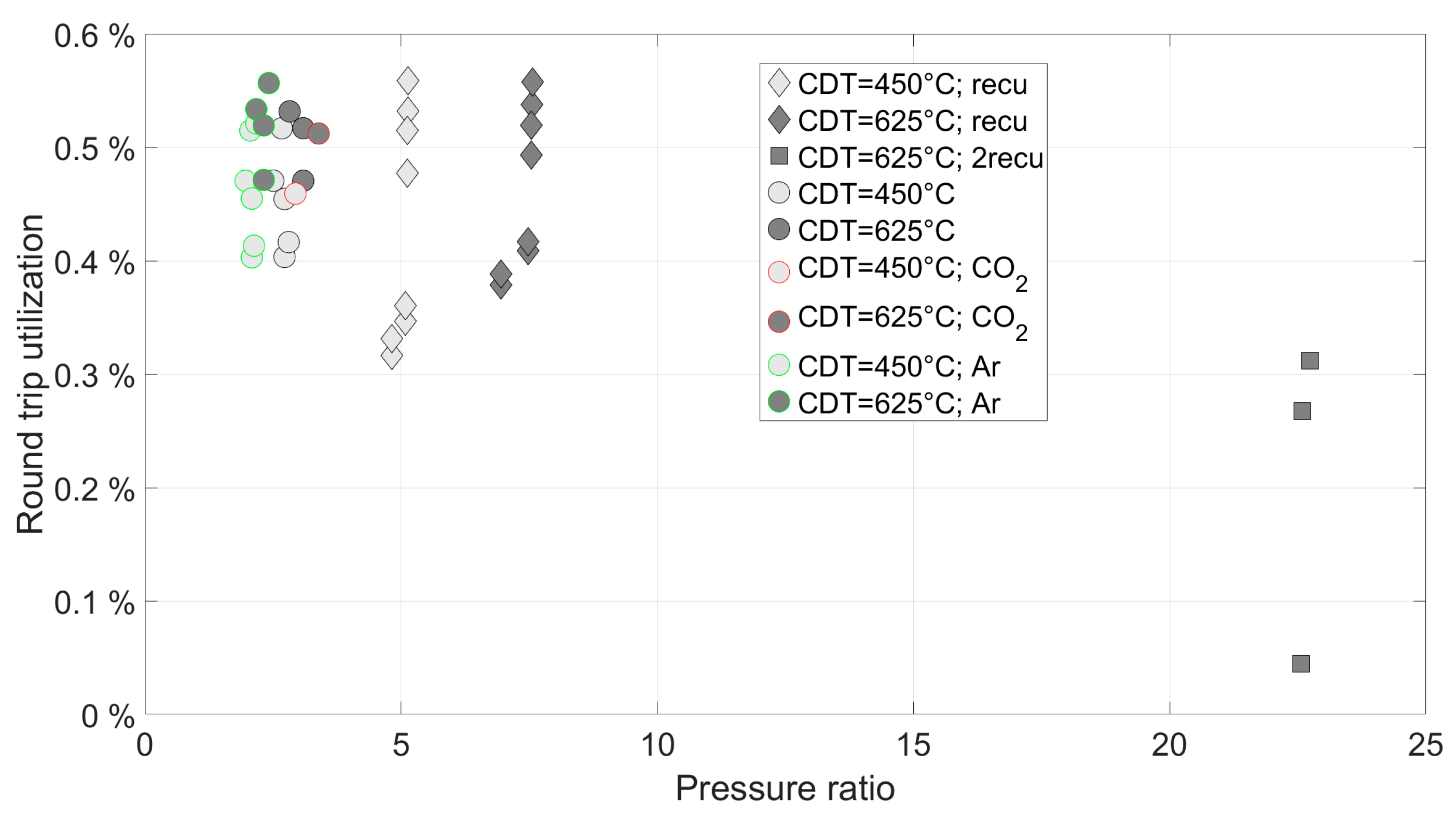

3.3. Coupled Generation of Electricity and Cooling with or without Waste Heat Integration

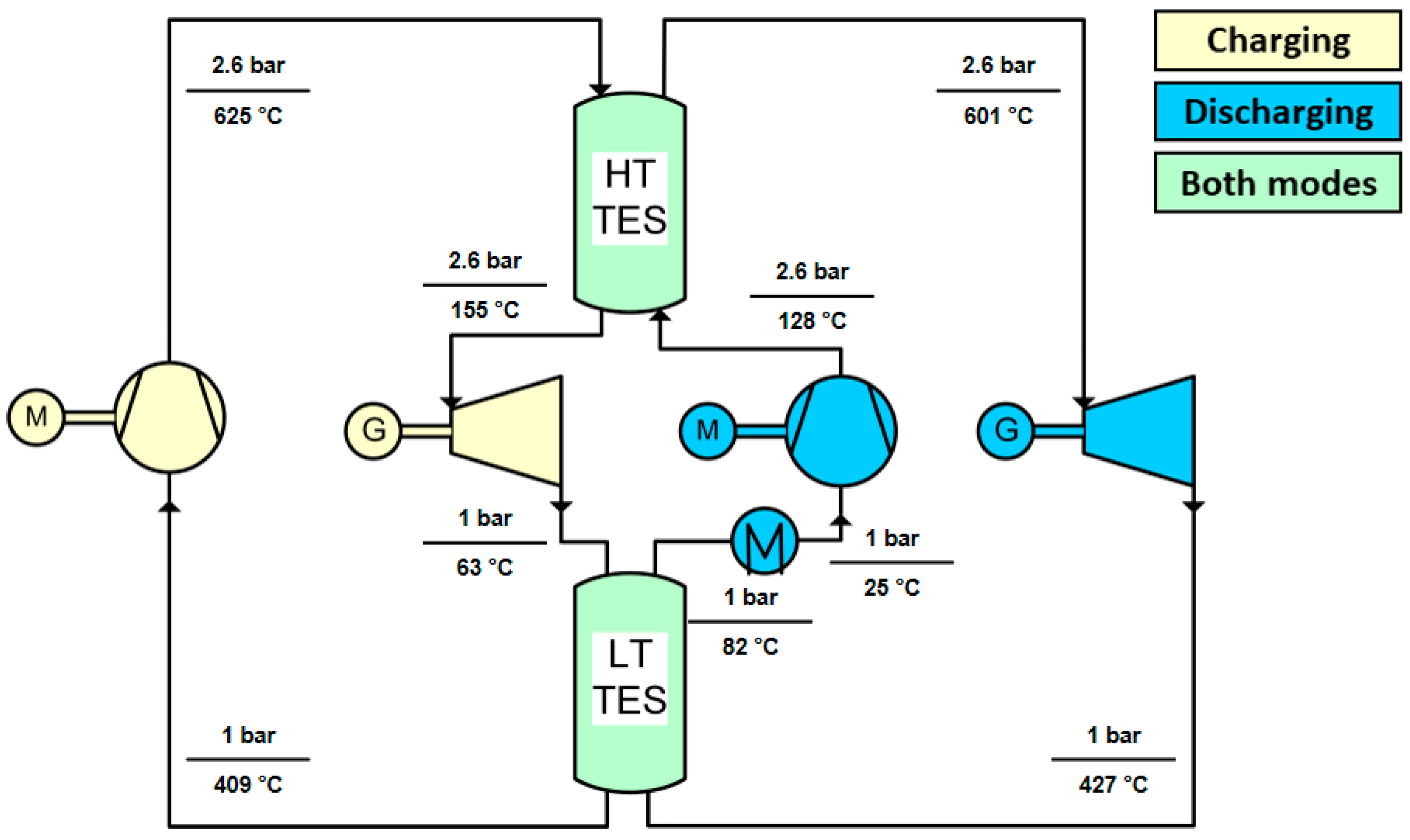

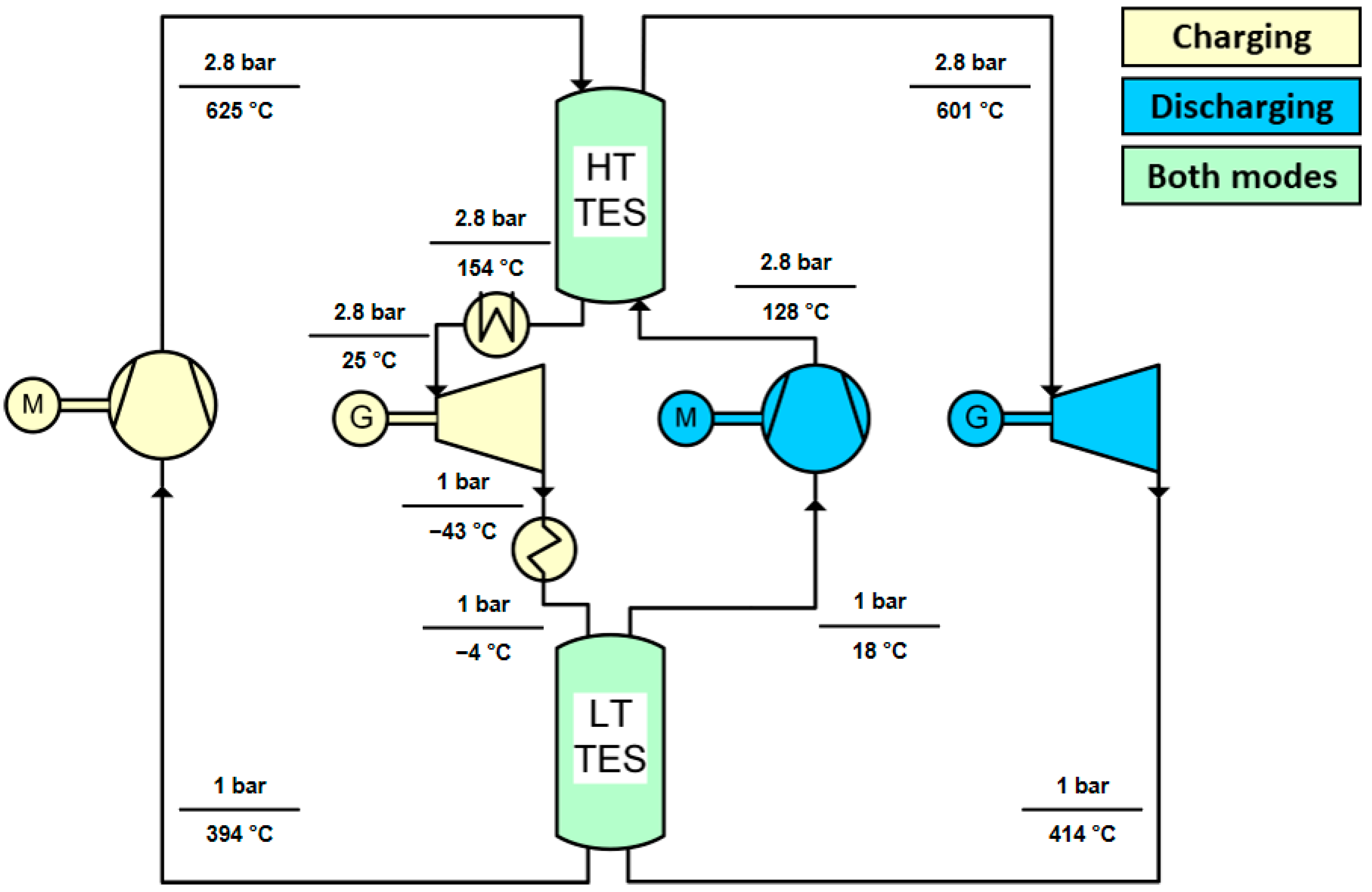

- CCP1: Working fluid air. Cooler before the turbine in the load path. Cooling provision after the turbine in the load path. Cooler before the compressor in the discharge path. ϑmax = 625 °C; RTU = 53.2%; RTE = 42.4%; Π = 2.8. Flow scheme: Figure 24.

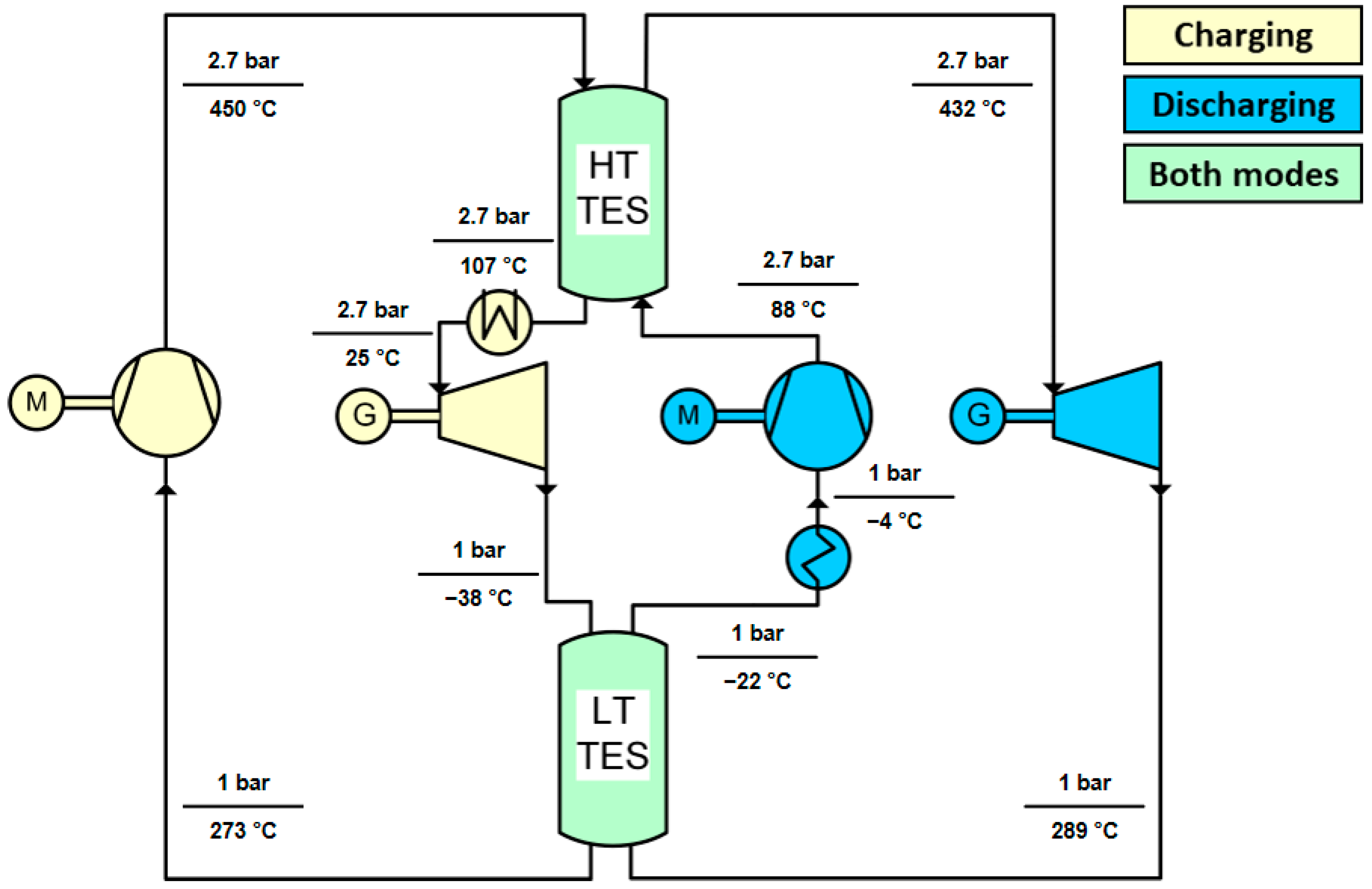

- CCP2: Working fluid air. Cooler before the turbine in the load path. Cooling provision before the compressor in the discharge path. ϑmax = 450 °C; RTU = 51.7%; RTE = 38.3%; Π = 2.7. Flow scheme: Figure 25.

3.4. Coupled Generation of Electricity, Heat, and Cooling

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCP | Combined Cooling and Power |

| CDT | Compressor Discharge Temperature |

| CHP | Combined Heat and Power |

| CO2 | Carbon Dioxide |

| CSP | Concentrated Solar Power |

| HT-TES | High-Temperature Thermal Energy Storage |

| LT-TES | Low-Temperature Thermal Energy Storage |

| ORC | Organic Rankine Cycle |

| PHES | Pumped Heat Storage |

| PTES | Pumped Thermal Electricity Storage |

| RTE | Round Trip Efficiency |

| RTU | Round Trip Utilization |

| SCO2 | Supercritical Carbon Dioxide |

| TES | Thermal Energy Storage |

| WHI | Waste Heat Integration |

References

- Carnot Batteries. Available online: https://iea-es.org/task-36/ (accessed on 28 June 2024).

- Olympios, A.V.; McTigue, J.D.; Farres-Antunez, P.; Tafone, A.; Romagnoli, A.; Li, Y.; Ding, Y.; Steinmann, W.-D.; Wang, L.; Chen, H.; et al. Progress and prospects of thermomechanical energy storage—A critical review. Prog. Energy 2021, 3, 022001. [Google Scholar] [CrossRef]

- Dumont, O.; Frate, G.F.; Pillai, A.; Lecompte, S.; De Paepe, M.; Lemort, V. Carnot battery technology: A state-of-the-art review. J. Energy Storage 2020, 32, 101756. [Google Scholar] [CrossRef]

- Novotny, V.; Basta, V.; Smola, P.; Spale, J. Review of Carnot Battery Technology Commercial Development. Energies 2022, 15, 647. [Google Scholar] [CrossRef]

- Weissenbach, B. Thermischer Kraftspeicher. European Patent EP/0003980 A1, 16 February 1979. [Google Scholar]

- Ruer, J. Installation and Methods for Storing and Recovering Electrical Energy. International Patent WO 2008 148962 A2, 11 December 2008. [Google Scholar]

- MacNaughten, J.; Howes, J.S. Energy Storage. International Patent WO 2009 044139 A2, 09 April 2009. [Google Scholar]

- Smallbone, A.; Jülch, V.; Wardle, R.; Roskilly, A.P. Levelised Cost of Storage for Pumped Heat Energy Storage in comparison with other energy storage technologies. Energy Convers. Manag. 2017, 152, 221–228. [Google Scholar] [CrossRef]

- Laughlin, R.B.; Larochelle, P.; Cizek, N. Systems and Methods for Energy Storage and Retrieval. United States Patent US 2015 0260463 A1, 17 September 2015. [Google Scholar]

- Laughlin, R.B. Adiabatic Salt Energy Storage. United States Patent US 2016 0298455 A1, 13 October 2016. [Google Scholar]

- McTigue, J.D.; Farres-Antunez, P.; Ellingwood, K.; Neises, T.; White, A.J. Pumped Thermal Electricity Storage with Supercritical CO2 Cycles and Solar Heat Input; SolarPACES: Daegu, Republic of Korea, 2019. [Google Scholar]

- The GridScale Technology Explained|Stiesdal. Available online: https://www.stiesdal.com/storage/the-gridscale-technology-explained/ (accessed on 2 May 2024).

- Schneider, G.; Maier, H.; Häcker, J.; Siegele, S. Electricity Storage with a Solid Bed High Temperature Thermal Energy Storage System (HTTES)—A Methodical Approach to Improve the Pumped Thermal Grid Storage Concept. Atlantis Highlights Eng. 2021, 6, 26–33. [Google Scholar]

- White, A.; Parks, G.; Markides, C.N. Thermodynamic analysis of pumped thermal electricity storage. Appl. Therm. Eng. 2013, 53, 291–298. [Google Scholar] [CrossRef]

- Laughlin, R.B. Pumped thermal grid storage with heat exchange. J. Renew. Sustain. Energy 2017, 9, 044103. [Google Scholar] [CrossRef]

- Kim, Y.-M.; Shin, D.-G.; Lee, S.-Y.; Favrat, D. Isothermal transcritical CO2 cycles with TES (thermal energy storage) for electricity storage. Energy 2013, 49, 484–501. [Google Scholar] [CrossRef]

- Thess, A. Thermodynamic Efficiency of Pumped Heat Electricity Storage. Phys. Rev. Lett. 2013, 111, 110602. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Cai, L.; Chen, J.; Zhou, Y. Performance optimization and comparison of pumped thermal and pumped cryogenic electricity storage systems. Energy 2016, 106, 260–269. [Google Scholar] [CrossRef]

- Bortolotti, M. EASE/EERA European Energy Storage Technology Development Roadmap. 2017. Available online: https://www.eera-set.eu/component/attachments/?task=download&id=312 (accessed on 2 May 2024).

- Knödler, P. Thermo-Mechanical Investigations of Packed Beds for High Temperature Heat Storage: Continuum Modeling. Appl. Sci. 2019, 9, 2569. [Google Scholar] [CrossRef]

- McTigue, J.D.; Markides, C.N.; White, A.J. Performance response of packed-bed thermal storage to cycle duration perturbations. J. Energy Storage 2018, 19, 379–392. [Google Scholar] [CrossRef]

- Bruch, A.; Fourmigué, J.F.; Couturier, R. Experimental and numerical investigation of a pilot-scale thermal oil packed bed thermal storage system for CSP power plant. Solar Energy 2014, 105, 116–125. [Google Scholar] [CrossRef]

- Zunft, S.; Krüger, M.; Dreißigacker, V.; Belik, S.; Hahn, J.; Knödler, P. ADELE-ING: Engineering-Vorhaben für die Errichtung der ersten Demonstrationsanlage zur Adiabaten Druckluftspeichertechnik; Öffentlicher Schlussbericht; Deutsches Zentrum für Luft- und Raumfahrt e.V.: Stuttgart, Germany, 2017. [Google Scholar]

- McTigue, J. Analysis and Optimisation of Thermal Energy Storage. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2016. [Google Scholar]

- Zunft, S.; Krüger, M.; Dreißigacker, V.; Mayer, P.-M.; Niklasch, C.; Bertsch, C. Adiabate Druckluftspeicher für die Elektrizitätsversorgung—Der ADELE-Wärmespeicher. In Kraftwerkstechnik; TK Verlag: Dresden, Germany, 2012; Volume 4, pp. 749–757. [Google Scholar]

- Bonk, A.; Braun, M.; Sötz, V.; Bauer, T. Solar Salt—Pushing an old material for energy storage to a new limit. Appl. Energy 2020, 262, 114535. [Google Scholar] [CrossRef]

- Farres-Antunez, P.; Xue, H.; White, A.J. Thermodynamic analysis and optimisation of a combined liquid air and pumped thermal energy storage cycle. J. Energy Storage 2018, 18, 90–102. [Google Scholar] [CrossRef]

- Benato, A. Performance and cost evaluation of an innovative Pumped Thermal Electricity Storage power system. Energy 2017, 138, 419–436. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A. Heat transfer fluid and material selection for an innovative Pumped Thermal Electricity Storage system. Energy 2018, 147, 155–168. [Google Scholar] [CrossRef]

- Chen, L.X.; Hu, P.; Zhao, P.P.; Xie, M.N.; Wang, F.X. Thermodynamic analysis of a High Temperature Pumped Thermal Electricity Storage (HT-PTES) integrated with a parallel organic Rankine cycle (ORC). Energy Convers. Manag. 2018, 177, 150–160. [Google Scholar] [CrossRef]

- Wettstein, H.E. The Potential of GT Combined Cycles for Ultra High Efficiency. In Proceedings of the ASME Turbo Expo 2012, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Seydel, C.G. Thermodynamische Auslegung und Potentialstudien von Heavy-Duty Gasturbinen für kombinierte Gas- und Dampfkraftwerke. Ph.D. Thesis, Ruhr-Universität Bochum, Bochum, Germany, 2014. [Google Scholar]

- Zehner, P. Vier-Quadranten-Charakteristiken Mehrstufiger Axialer Turbinen; VDI-Verlag GmbH: Düsseldorf, Germany, 1980. [Google Scholar]

- Agorameter. Available online: https://www.agora-energiewende.de/daten-tools/agorameter/chart/today/power_generation/29.01.2024/01.02.2024/hourly (accessed on 2 May 2024).

- Sterner, M.; Stadler, I. Energiespeicher—Bedarf, Technologien, Integration; Springer Vieweg: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Krystallas, P.-A. Technische, organisatorische und ökonomische Analyse der Fernkälte am Projekt Fernkälte München. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2018. [Google Scholar]

- Eifler, W.; Schlücker, E.; Spicher, U.; Will, G. Küttner—Kolbenmaschinen; Vieweg+Teubner: Wiesbaden, Germany, 2009. [Google Scholar]

- Ameen, M.T.; Ma, Z.; Smallbone, A.; Norman, R.; Roskilly, A.P. Demonstration system of pumped heat energy storage (PHES) and its round-trip efficiency. Appl. Energy 2023, 333, 120580. [Google Scholar] [CrossRef]

- Theologou, K.; Johnson, M.; Tombrink, J.; Ciganda, J.L.C.; Trebilcock, F.T.; Couvreur, K.; Tassenoy, R.; Lecompte, S. CHESTER: Experimental prototype of a pumped thermal energy storage and management system with thermal integration. Energy Convers. Manag. 2024, 311, 118519. [Google Scholar]

- Malta: Our Solution. Available online: https://www.maltainc.com/solution/ (accessed on 2 May 2024).

| Input/Consumption | Output/Supply | |

|---|---|---|

| Electricity | Duration: 8 h Daytime restrictions: 8–16 h | Duration: 16 h Daytime restrictions: 16–8 h |

| Heat | Waste heat Duration: 24 h Time of day restrictions: none Temperature level: 90 °C | Process heat Duration: 24 h Time of day restrictions: none Temperature level: 250 °C |

| Cold | Air conditioning Duration: 12 h Daytime restrictions: 8–20 h Temperature level: 6 °C (Supply)→ 16 °C (Return) |

| Input/Integration | Output/Delivery | |

|---|---|---|

| Electricity | Duration: 8 h Daytime restrictions: 22–6 h | Duration: 16 h Daytime restrictions: 6–22 h |

| Heat | Waste heat Duration: 24 h Time of day restrictions: none Temperature level: 90 °C | Process heat Duration: 24 h Time of day restrictions: none Temperature level: 250 °C |

| Title 1 | Closed Cycle | Open Cycle | With Recuperator | Working Fluid |

|---|---|---|---|---|

| Pure electricity generation (PEG) | X | X * | Air | |

| X | XX * | Air | ||

| X | Air | |||

| X | Air | |||

| X | CO2 | |||

| X | Argon | |||

| Pure electricity generation with waste heat integration (PEG+WHI) | X | X | Air | |

| X | XX | Air | ||

| X | Air | |||

| X | Air | |||

| X | CO2 | |||

| X | Argon | |||

| Coupled generation of electricity and heat (CHP) | X | X | Air | |

| X | XX | Air | ||

| X | Air | |||

| X | Air | |||

| X | CO2 | |||

| X | Argon | |||

| Coupled generation of electricity and heat with waste heat integration (CHP+WHI) | X | X | Air | |

| X | XX | Air | ||

| X | Air | |||

| X | Air | |||

| X | CO2 | |||

| X | Argon | |||

| Coupled generation of electricity and cooling (CCP) | X | X | Air | |

| X | XX | Air | ||

| X | Air | |||

| X | Air | |||

| X | CO2 | |||

| X | Argon | |||

| Coupled generation of electricity and cooling with waste heat integration (CCP+WHI) | X | X | Air | |

| X | XX | Air | ||

| X | Air | |||

| X | Air | |||

| X | CO2 | |||

| X | Argon | |||

| Coupled generation of electricity, heat, and cooling (CHPC) | X | X | Air | |

| X | XX | Air | ||

| X | Air | |||

| X | Air | |||

| X | CO2 | |||

| X | Argon |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krüger, M. Systematic Concept Study of Brayton Batteries for Coupled Generation of Electricity, Heat, and Cooling. Appl. Sci. 2024, 14, 6073. https://doi.org/10.3390/app14146073

Krüger M. Systematic Concept Study of Brayton Batteries for Coupled Generation of Electricity, Heat, and Cooling. Applied Sciences. 2024; 14(14):6073. https://doi.org/10.3390/app14146073

Chicago/Turabian StyleKrüger, Michael. 2024. "Systematic Concept Study of Brayton Batteries for Coupled Generation of Electricity, Heat, and Cooling" Applied Sciences 14, no. 14: 6073. https://doi.org/10.3390/app14146073

APA StyleKrüger, M. (2024). Systematic Concept Study of Brayton Batteries for Coupled Generation of Electricity, Heat, and Cooling. Applied Sciences, 14(14), 6073. https://doi.org/10.3390/app14146073