Turning Data Center Waste Heat into Energy: A Guide to Organic Rankine Cycle System Design and Performance Evaluation

Abstract

1. Introduction

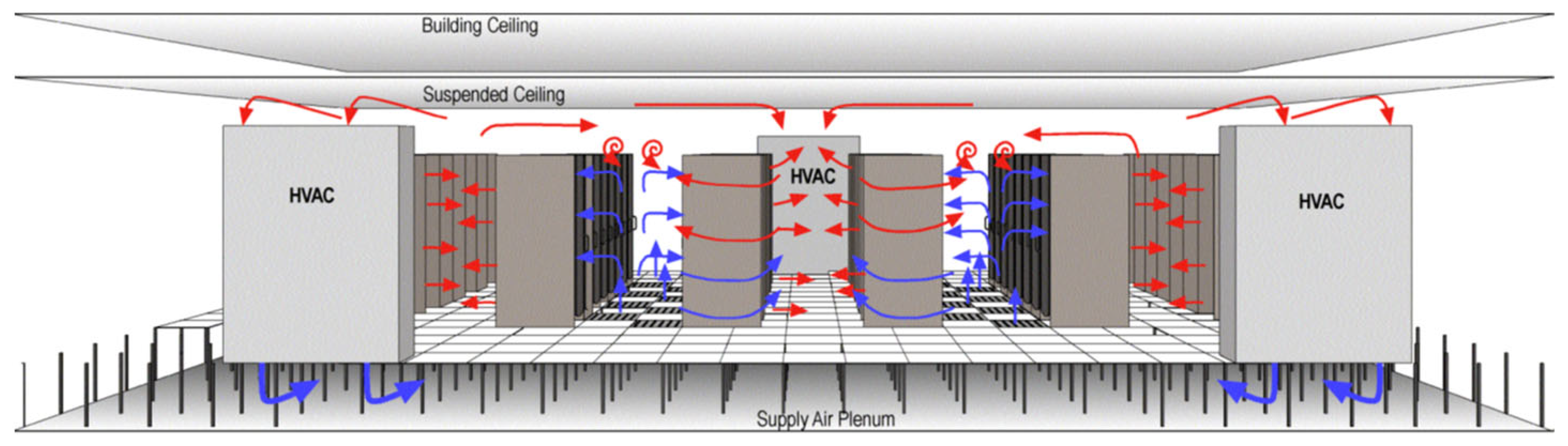

1.1. Background

1.2. Literature Overview

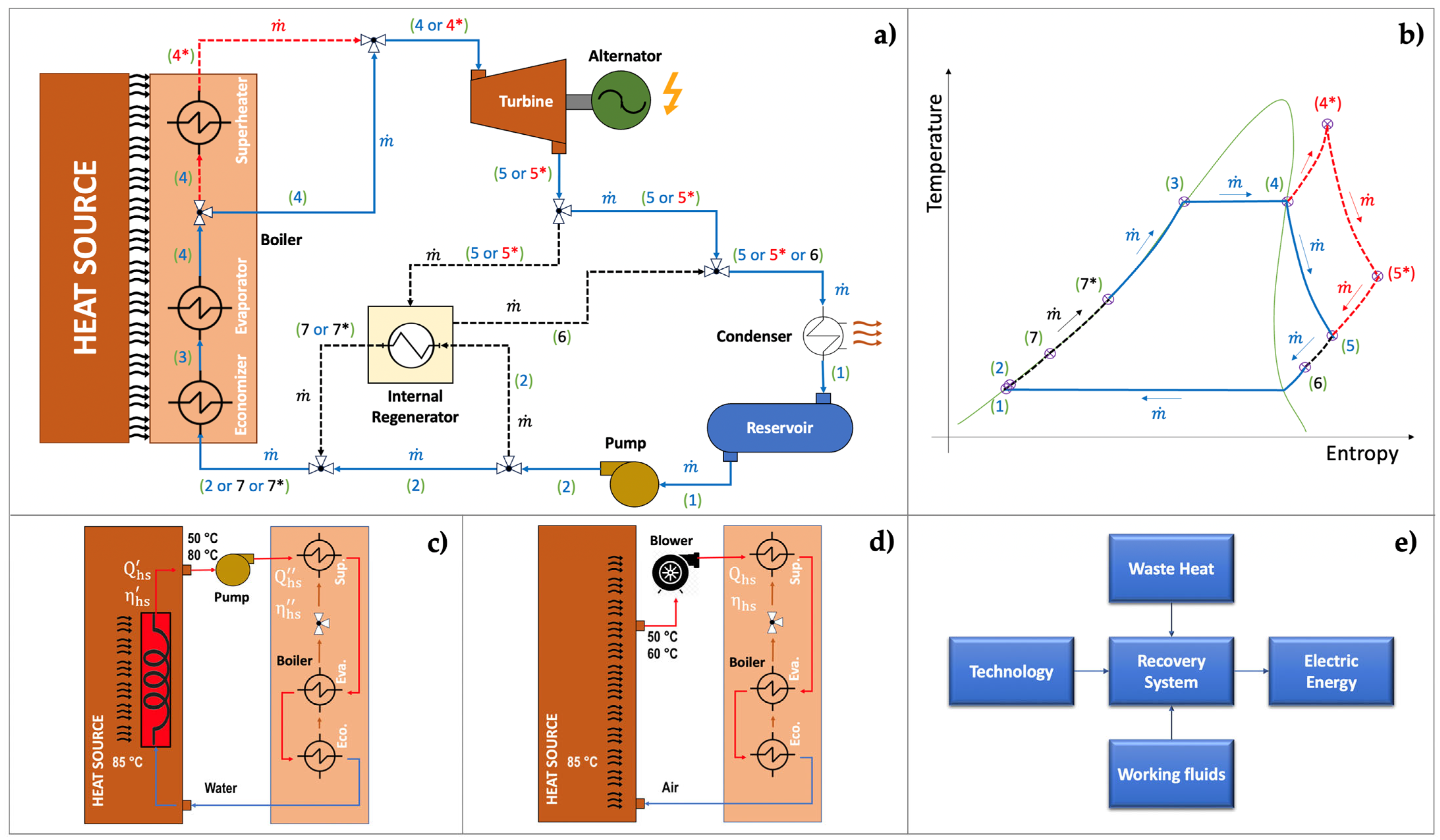

1.3. Contribution

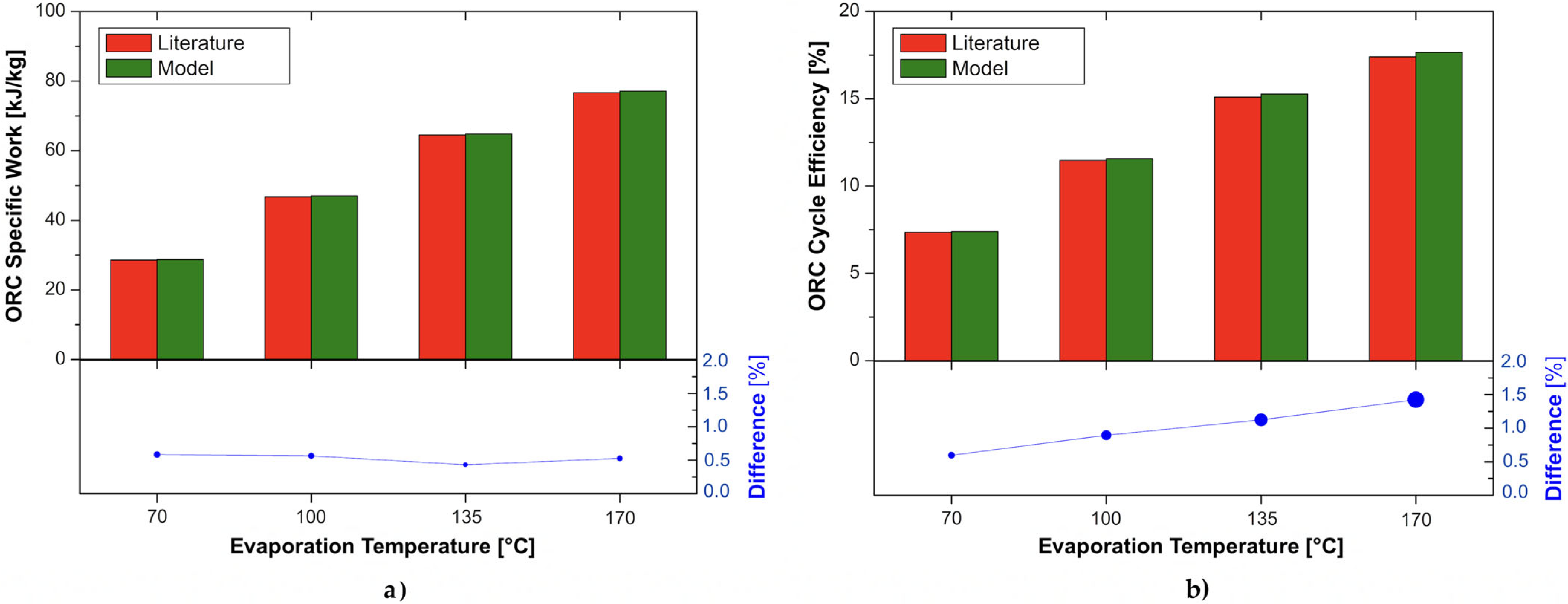

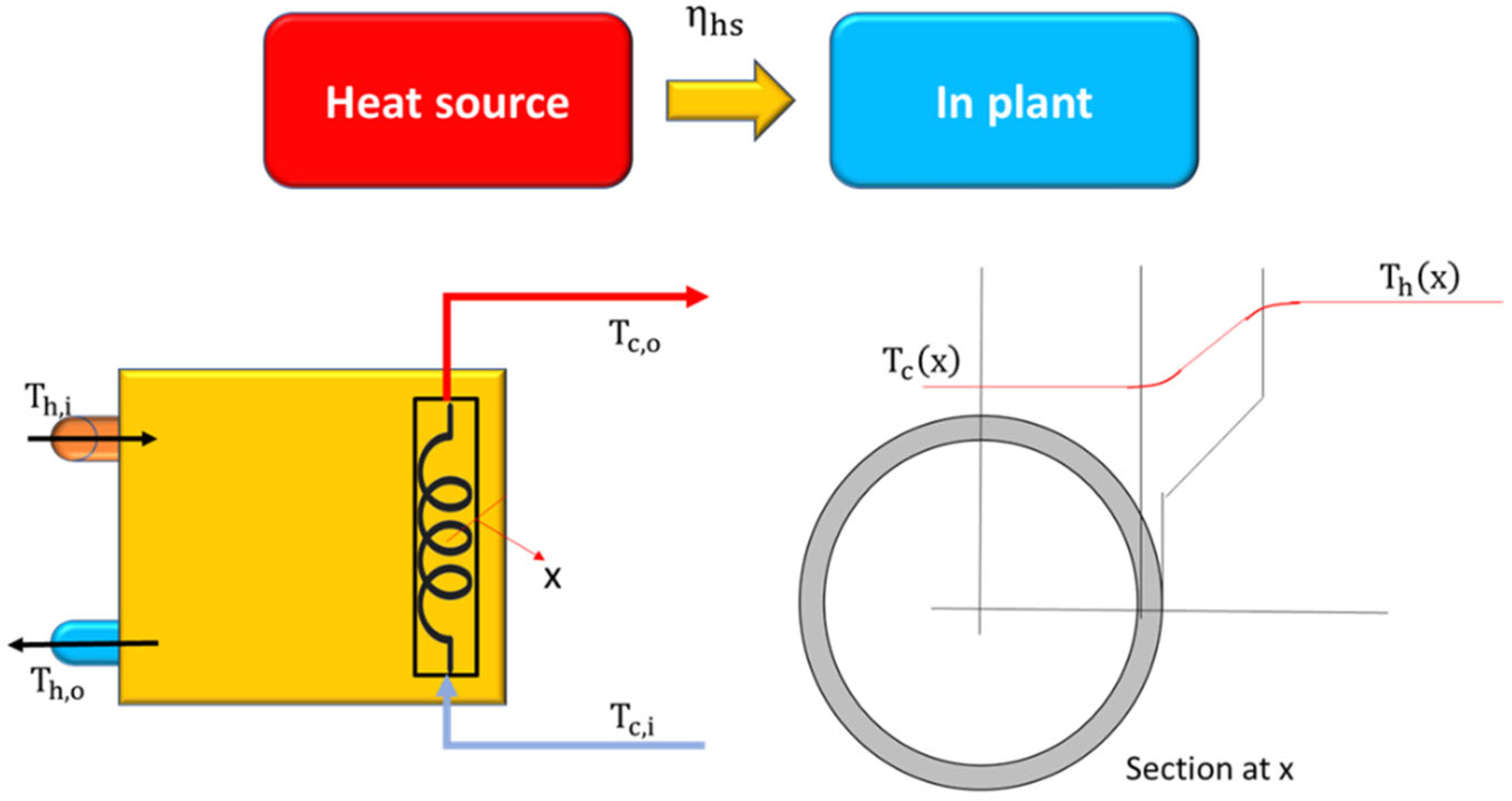

2. Materials and Methods

3. Power Consumption, Heat Fluxes, and Cooling in Data Centers

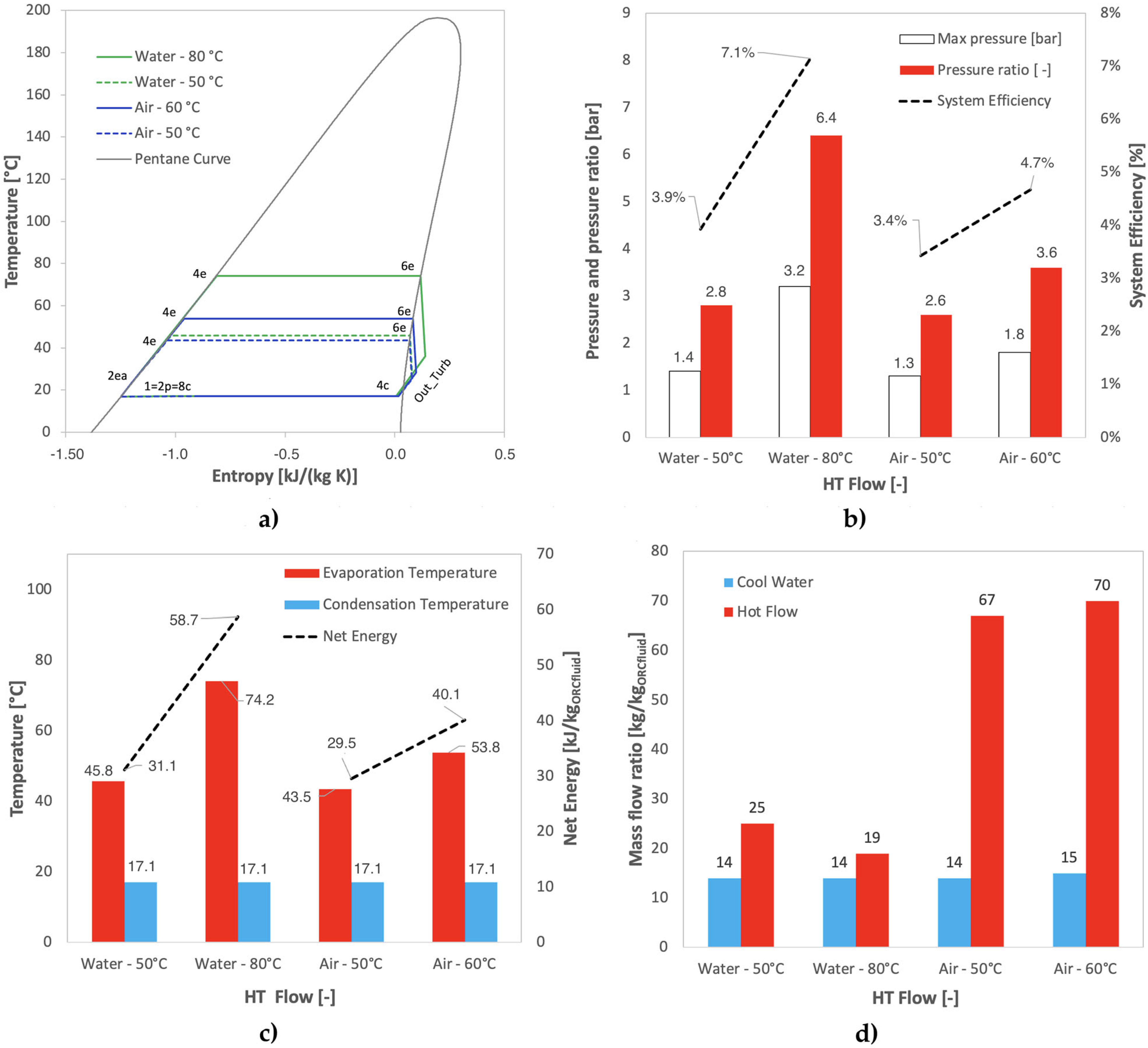

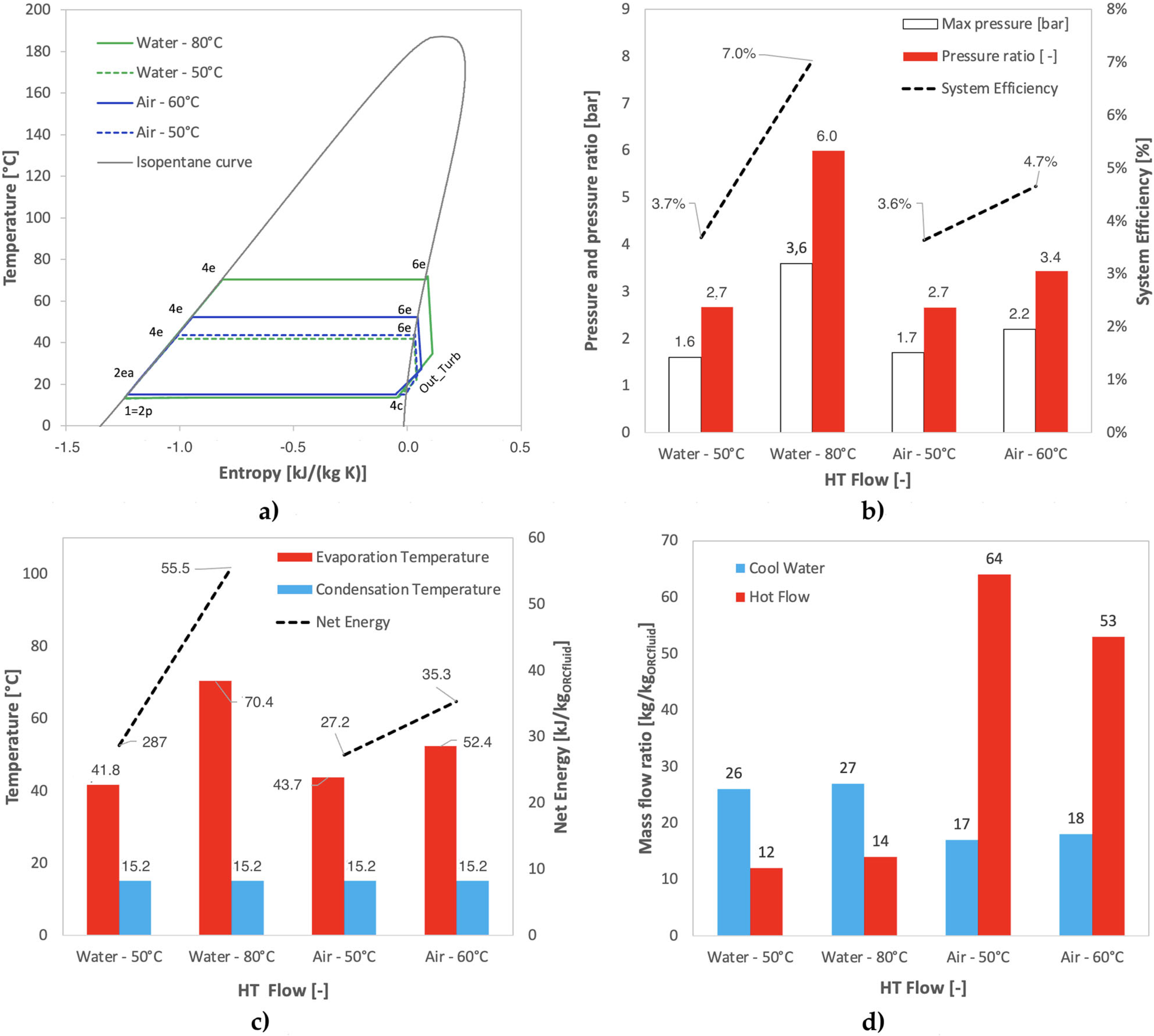

4. Overview of Heat Reuse from Data Centers

5. Waste Heat Recovery (WHR) Based on ORC Technologies

6. Plant Layout and Design Criterion

7. Analysis of Working Fluids for Low-Temperature ORC

8. Application Case

9. Discussion

Guidelines for Further Analysis and Dimensioning

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Acronyms and tags | |

| AI | Artificial intelligence |

| CCHP | Combined cooling, heating, and power |

| CFC | Chlorofluorocarbons |

| CHP | Combined heating and power |

| COND | Condenser |

| COP | Coefficient of performance |

| CRAC | Computer room air conditioning |

| DC | Data center |

| DE-SH | Desuperheater |

| DSC | Differential scanning calorimetry |

| ECO | Economizer |

| EED | Energy Efficiency Directive |

| ERE | Energy reuse effectiveness |

| ERF | Energy reuse factor |

| EVA | Evaporator |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| HFC | Hydrofluorocarbons |

| HT-FLOW | High-temperature flow |

| HVAC | Heating, ventilation, and air conditioning |

| ICT | Information and communication technology |

| IEA | International Energy Agency |

| IT | Information technology |

| IUS | Industry and urban symbiosis |

| L-COOL | Cooler in the liquid phase for ORC |

| LT-AIR | Low-temperature air |

| KPI | Key performance indicators |

| NPV | Net present value |

| ODP | Ozone depletion potential |

| ORC | Organic Rankine cycle |

| PRE-HEAT | Pre-heater |

| PUE | Power usage effectiveness |

| PUMP-ORC | ORC pump |

| PUMP-WA | Water pump |

| SUP-HEAT | Superheater |

| TURBO-EXP | Turbo-expander |

| TLC | Trilateral cycle |

| WHR | Waste heat recovery |

| Symbols | |

| Area (m2) | |

| a | Coefficient (-) |

| b | Coefficient (-) |

| c | Coefficient (-) |

| cp | Specific heat (kJ/kgK) |

| d | Diameter (m) |

| E | Exergy (W) |

| h | Specific enthalpy (kJ/kg) |

| h | Convective heat transfer coefficient (W/m2K) |

| Hm | Pump head (m) |

| L | Width (m) |

| l | Length (m) |

| m | Mass (kg) |

| m | Mass flow rate (kg/s) |

| P | Power (W) |

| p | Pressure (Pa) |

| Q | Thermal power (W) |

| R | Thermal resistance (m2 K/W) |

| r | Radius (m) |

| T | Temperature (°C) |

| t | Time (s) |

| U | Thermal transmittance (W/m2K) |

| v | Velocity (m/s) |

| Ytot | Head losses (m) |

| z | Height (m), pressure, and velocity, respectively. |

| Greek symbols | |

| Δ | Difference |

| δ | Exergy defect (-) |

| λ | Conductive heat transfer coefficient (W/mK) |

| Ψ | Exergy efficiency (-) |

| η | Efficiency (-) |

| Subscripts | |

| aux | Auxiliaries |

| boil | Boiler |

| c | Cold |

| cond | Condenser |

| ch | Chemical |

| cyc | Cycle |

| des | Destruction |

| el | Electric |

| Hot | |

| s | Heat source |

| yd | Hydraulic |

| i | Inlet |

| k | Generic component |

| ki | Kinetic |

| ln | Mean logarithmic |

| m | Mechanical |

| o | Outlet |

| p | Pump |

| po | Potential |

| ph | Physical |

| Q | Thermal |

| reg | Regenerator |

| s | Saturation |

| sys | System |

| t | Turbine |

| 0 | Standard |

References

- Yuan, X.; Liang, Y.; Hu, X.; Xu, Y.; Chen, Y.; Kosonen, R. Waste Heat Recoveries in Data Centers: A Review. Renew. Sustain. Energy Rev. 2023, 188, 113777. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste Heat Recovery Technologies and Applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Ancona, M.A.; Bianchi, M.; Branchini, L.; Pascale, A.D.; Melino, F.; Ottaviano, S.; Peretto, A.; Poletto, C. Experimental and Numerical Investigation of a Micro-ORC System for Heat Recovery from Data Centers. J. Phys. Conf. Ser. 2022, 2385, 012122. [Google Scholar] [CrossRef]

- Braimakis, K.; Karellas, S. Exergy Efficiency Potential of Dual-Phase Expansion Trilateral and Partial Evaporation ORC with Zeotropic Mixtures. Energy 2023, 262, 125475. [Google Scholar] [CrossRef]

- Pereira, J.S.; Ribeiro, J.B.; Mendes, R.; Vaz, G.C.; André, J.C. ORC Based Micro-Cogeneration Systems for Residential Application—A State of the Art Review and Current Challenges. Renew. Sustain. Energy Rev. 2018, 92, 728–743. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 on Energy Efficiency and Amending Regulation (EU) 2023/955 (Recast). Off. J. Eur. Union 2023, L 231, 1–111. [Google Scholar]

- International Energy Agency (IEA). Data Centres and Data Transmission Networks. Available online: https://www.iea.org/energy-system/buildings/data-centres-and-data-transmission-networks (accessed on 16 April 2024).

- Jin, C.; Bai, X.; Yang, C.; Mao, W.; Xu, X. A Review of Power Consumption Models of Servers in Data Centers. Appl. Energy 2020, 265, 114806. [Google Scholar] [CrossRef]

- Rasmussen, N. Guidelines for Specification of Data Center Power Density; White Paper; 2015. Available online: https://www.se.com/id/en/download/document/SPD_NRAN-69ANM9_EN/ (accessed on 15 April 2024).

- Ahmed, K.M.U.; Bollen, M.H.J.; Alvarez, M. A Review of Data Centers Energy Consumption and Reliability Modeling. IEEE Access 2021, 9, 152536–152563. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J. Prediction of Overall Energy Consumption of Data Centers in Different Locations. Sensors 2022, 22, 3704. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Jones, G.F.; Fleischer, A.S. A Review of Data Center Cooling Technology, Operating Conditions and the Corresponding Low-Grade Waste Heat Recovery Opportunities. Renew. Sustain. Energy Rev. 2014, 31, 622–638. [Google Scholar] [CrossRef]

- Oltmanns, J.; Sauerwein, D.; Dammel, F.; Stephan, P.; Kuhn, C. Potential for Waste Heat Utilization of Hot-water-cooled Data Centers: A Case Study. Energy Sci. Eng. 2020, 8, 1793–1810. [Google Scholar] [CrossRef]

- Huang, P.; Copertaro, B.; Zhang, X.; Shen, J.; Löfgren, I.; Rönnelid, M.; Fahlen, J.; Andersson, D.; Svanfeldt, M. A Review of Data Centers as Prosumers in District Energy Systems: Renewable Energy Integration and Waste Heat Reuse for District Heating. Appl. Energy 2020, 258, 114109. [Google Scholar] [CrossRef]

- Zhang, Y.; Shan, K.; Li, X.; Li, H.; Wang, S. Research and Technologies for Next-Generation High-Temperature Data Centers—State-of-the-Arts and Future Perspectives. Renew. Sustain. Energy Rev. 2023, 171, 112991. [Google Scholar] [CrossRef]

- Dayarathna, M.; Wen, Y.; Fan, R. Data Center Energy Consumption Modeling: A Survey. IEEE Commun. Surv. Tutor. 2016, 18, 732–794. [Google Scholar] [CrossRef]

- Wahlroos, M.; Pärssinen, M.; Rinne, S.; Syri, S.; Manner, J. Future Views on Waste Heat Utilization—Case of Data Centers in Northern Europe. Renew. Sustain. Energy Rev. 2018, 82, 1749–1764. [Google Scholar] [CrossRef]

- Katal, A.; Dahiya, S.; Choudhury, T. Energy Efficiency in Cloud Computing Data Centers: A Survey on Software Technologies. Clust. Comput. 2023, 26, 1845–1875. [Google Scholar] [CrossRef] [PubMed]

- Yari, M.; Mehr, A.S.; Zare, V.; Mahmoudi, S.M.S.; Rosen, M.A. Exergoeconomic Comparison of TLC (Trilateral Rankine Cycle), ORC (Organic Rankine Cycle) and Kalina Cycle Using a Low Grade Heat Source. Energy 2015, 83, 712–722. [Google Scholar] [CrossRef]

- Mazhar, A.R.; Shen, Y.; Liu, S. Viability of Low-grade Heat Conversion Using Liquid Piston Stirling Engines. Wiley Interdiscip. Rev. Energy Environ. 2024, 13, e509. [Google Scholar] [CrossRef]

- Lottmann, M.; De Rouyan, Z.; Hasanovich, L.; Middleton, S.; Nicol-Seto, M.; Speer, C.; Nobes, D. Development of a 100-Watt-Scale Beta-Type Low Temperature Difference Stirling Engine Prototype. E3S Web Conf. 2021, 313, 08004. [Google Scholar] [CrossRef]

- Huang, H.; Chen, W. Development of a Compact Simple Unpressurized Watt-level Low-temperature-differential Stirling Engine. Int. J. Energy Res. 2020, 44, 12029–12044. [Google Scholar] [CrossRef]

- Wang, K.; Sanders, S.R.; Dubey, S.; Choo, F.H.; Duan, F. Stirling Cycle Engines for Recovering Low and Moderate Temperature Heat: A Review. Renew. Sustain. Energy Rev. 2016, 62, 89–108. [Google Scholar] [CrossRef]

- Research Institute of Sweden (RISE). Energy Use in Data Centers and Digital Systems; RISE Report 2023: 36; RISE Research Institutes of Sweden: Gothenburg, Sweden, 2023; p. 55. [Google Scholar]

- Vesterlund, M.; Borisová, S.; Emilsson, E. Data Center Excess Heat for Mealworm Farming, an Applied Analysis for Sustainable Protein Production. Appl. Energy 2024, 353, 121990. [Google Scholar] [CrossRef]

- Brännvall, R.; Mattson, L.; Lundmark, E.; Vesterlund, M. Data Center Excess Heat Recovery: A Case Study of Apple Drying. In Proceedings of the 33rd International Conference on Efficiency, Cost, Optimization, Simulation and Enviromental Impact of Energy Systems, Osaka, Japan, 29 June–3 July 2020; pp. 2165–2174. [Google Scholar]

- Yakovlev, I.V.; Avdokunin, N.V. Efficient Use of Waste Heat from Data Centers. Therm. Eng. 2023, 70, 769–776. [Google Scholar] [CrossRef]

- Pärssinen, M.; Wahlroos, M.; Manner, J.; Syri, S. Waste Heat from Data Centers: An Investment Analysis. Sustain. Cities Soc. 2019, 44, 428–444. [Google Scholar] [CrossRef]

- Zhang, C.; Luo, H.; Wang, Z. An Economic Analysis of Waste Heat Recovery and Utilization in Data Centers Considering Environmental Benefits. Sustain. Prod. Consum. 2022, 31, 127–138. [Google Scholar] [CrossRef]

- Araya, S.; Wemhoff, A.P.; Jones, G.F.; Fleischer, A.S. Study of a Lab-Scale Organic Rankine Cycle for the Ultra-Low-Temperature Waste Heat Recovery Associated With Data Centers. J. Electron. Packag. 2021, 143, 021001. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Jones, G.F.; Fleischer, A.S. The Viability of Ultra Low Temperature Waste Heat Recovery Using Organic Rankine Cycle in Dual Loop Data Center Applications. Appl. Therm. Eng. 2017, 126, 393–406. [Google Scholar] [CrossRef]

- Chen, X.; Pan, M.; Li, X.; Zhang, K. Multi-Mode Operation and Thermo-Economic Analyses of Combined Cooling and Power Systems for Recovering Waste Heat from Data Centers. Energy Convers. Manag. 2022, 266, 115820. [Google Scholar] [CrossRef]

- Kanbur, B.B.; Wu, C.; Duan, F. Combined Heat and Power Generation via Hybrid Data Center Cooling-polymer Electrolyte Membrane Fuel Cell System. Int. J. Energy Res. 2020, 44, 4759–4772. [Google Scholar] [CrossRef]

- Yin, X.; Ye, C.; Ding, Y.; Song, Y. Exploiting Internet Data Centers as Energy Prosumers in Integrated Electricity-Heat System. IEEE Trans. Smart Grid 2023, 14, 167–182. [Google Scholar] [CrossRef]

- Wan, J.; Zhou, J.; Gui, X. Sustainability Analysis of Green Data Centers With CCHP and Waste Heat Reuse Systems. IEEE Trans. Sustain. Comput. 2021, 6, 155–167. [Google Scholar] [CrossRef]

- Medeiros, D. DWSIM. 2021. Available online: https://dwsim.org (accessed on 15 March 2024).

- Koomey, J.G. Growth in Data Center Electricity Use 2005 to 2010; Analytics Press: Oakland, CA, USA, 2011. [Google Scholar]

- Little, A.B.; Garimella, S. Waste Heat Recovery in Data Centers Using Sorption Systems. J. Therm. Sci. Eng. Appl. 2012, 4, 021007. [Google Scholar] [CrossRef]

- Abbas, A.M.; Huzayyin, A.S.; Mouneer, T.A.; Nada, S.A. Effect of Data Center Servers’ Power Density on the Decision of Using in-Row Cooling or Perimeter Cooling. Alex. Eng. J. 2021, 60, 3855–3867. [Google Scholar] [CrossRef]

- Balaras, C.A.; Lelekis, J.; Dascalaki, E.G.; Atsidaftis, D. High Performance Data Centers and Energy Efficiency Potential in Greece. Procedia Environ. Sci. 2017, 38, 107–114. [Google Scholar] [CrossRef]

- Sun, K.; Luo, N.; Luo, X.; Hong, T. Prototype Energy Models for Data Centers. Energy Build. 2021, 231, 110603. [Google Scholar] [CrossRef]

- Bramucci, M.; Di Santo, D.; Forni, D. Uso Razionale Dell’energia Nei Centri Di Calcolo; RdS: Rome, Italy, 2010. [Google Scholar]

- Marcinichen, J.B.; Olivier, J.A.; Thome, J.R. On-Chip Two-Phase Cooling of Datacenters: Cooling System and Energy Recovery Evaluation. Appl. Therm. Eng. 2012, 41, 36–51. [Google Scholar] [CrossRef]

- Patel, C.D. A Vision of Energy Aware Computing—From Chips to Data Centers. In Proceedings of the International Symposium on Micro-Mechanical Engineering 2003, Tsuchiura and Tsukuba, Japan, 1–3 December 2003. [Google Scholar]

- Bash, C.E.; Patel, C.D.; Sharma, R.K. Efficient Thermal Management of Data Centers—Immediate and Long-Term Research Needs. HVAC&R Res. 2003, 9, 137–152. [Google Scholar] [CrossRef]

- Ellsworth, M.J.; Iyengar, M.K. Energy Efficiency Analyses and Comparison of Air and Water Cooled High Performance Servers. In Proceedings of the ASME 2009 InterPACK Conference, San Francisco, CA, USA, 19–23 July 2009; ASMEDC; 2009; Volume 2, pp. 907–914. [Google Scholar]

- Campbell, L.; Tuma, P. Numerical Prediction of the Junction-to-Fluid Thermal Resistance of a 2-Phase Immersion-Cooled IBM Dual Core POWER6 Processor. In Proceedings of the 2012 28th Annual IEEE Semiconductor Thermal Measurement and Management Symposium (SEMI-THERM), San Jose, CA, USA, 18–22 March 2012; IEEE: New York, NY, USA, 2012; pp. 36–44. [Google Scholar]

- Hannemann, R.; Marsala, J.; Pitasi, M. Pumped Liquid Multiphase Cooling. In Proceedings of the Electronic and Photonic Packaging, Electrical Systems Design and Photonics, and Nanotechnology, Anaheim, CA, USA, 13–19 November 2004; ASMEDC, 2004; pp. 469–473. [Google Scholar]

- Haywood, A.; Sherbeck, J.; Phelan, P.; Varsamopoulos, G.; Gupta, S.K.S. Thermodynamic Feasibility of Harvesting Data Center Waste Heat to Drive an Absorption Chiller. Energy Convers. Manag. 2012, 58, 26–34. [Google Scholar] [CrossRef]

- Haywood, A.; Sherbeck, J.; Phelan, P.; Varsamopoulos, G.; Gupta, S.K.S. A Sustainable Data Center with Heat-Activated Cooling. In Proceedings of the 2010 12th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Las Vegas, NV, USA, 2–5 June 2010; pp. 1–7. [Google Scholar]

- Vélez, F.; Segovia, J.J.; Martín, M.C.; Antolín, G.; Chejne, F.; Quijano, A. A Technical, Economical and Market Review of Organic Rankine Cycles for the Conversion of Low-Grade Heat for Power Generation. Renew. Sustain. Energy Rev. 2012, 16, 4175–4189. [Google Scholar] [CrossRef]

- Tchanche, B.F.; Lambrinos, G.; Frangoudakis, A.; Papadakis, G. Low-Grade Heat Conversion into Power Using Organic Rankine Cycles—A Review of Various Applications. Renew. Sustain. Energy Rev. 2011, 15, 3963–3979. [Google Scholar] [CrossRef]

- Johnson, I.; Choate, W.; Davidson, A. Waste Heat Recovery. Technology and Opportunities in U.S. Industry; BCS, Inc.: Laurel, MD, USA, 2008. [Google Scholar]

- Martín-González, M.; Caballero-Calero, O.; Díaz-Chao, P. Nanoengineering Thermoelectrics for 21st Century: Energy Harvesting and Other Trends in the Field. Renew. Sustain. Energy Rev. 2013, 24, 288–305. [Google Scholar] [CrossRef]

- Saha, B.K.; Chakraborty, B.; Mondal, J.; Pesyridis, A.; Messini, E.M.B.; Kumar, P. Design and Implementation of a Control Strategy for a Dynamic Organic Rankine Cycle-Based Power System in the Context of Industrial Waste Heat Recovery. Energy Tech. 2023, 11, 2300425. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Fazli, M.; Morad, M.R. A Recent Review of Waste Heat Recovery by Organic Rankine Cycle. Appl. Therm. Eng. 2018, 143, 660–675. [Google Scholar] [CrossRef]

- García-Mariaca, A.; Llera-Sastresa, E.; Moreno, F. Application of ORC to Reduce the Energy Penalty of Carbon Capture in Non-Stationary ICE. Energy Convers. Manag. 2022, 268, 116029. [Google Scholar] [CrossRef]

- Alshammari, F.; Alghafis, A.; Alatawi, I.; Alshammari, A.S.; Alzamil, A.; Alrashidi, A. Potential of Variable Geometry Radial Inflow Turbines as Expansion Machines in Organic Rankine Cycles Integrated with Heavy-Duty Diesel Engines. Appl. Sci. 2023, 13, 12139. [Google Scholar] [CrossRef]

- Semmari, H.; Bouaicha, F.; Aberkane, S.; Filali, A.; Blessent, D.; Badache, M. Geological Context and Thermo-Economic Study of an Indirect Heat ORC Geothermal Power Plant for the Northeast Region of Algeria. Energy 2024, 290, 130323. [Google Scholar] [CrossRef]

- Zinsalo, J.M.; Lamarche, L.; Raymond, J. Performance Analysis and Working Fluid Selection of an Organic Rankine Cycle Power Plant Coupled to an Enhanced Geothermal System. Energy 2022, 245, 123259. [Google Scholar] [CrossRef]

- Bellos, E.; Said, Z.; Lykas, P.; Tzivanidis, C. A Review of Polygeneration Systems with CO2 Working Fluid. Therm. Sci. Eng. Prog. 2022, 34, 101435. [Google Scholar] [CrossRef]

- Javed, S.; Tiwari, A.K. Performance Assessment of Different Organic Rankine Cycle (ORC) Configurations Driven by Solar Energy. Process Saf. Environ. Prot. 2023, 171, 655–666. [Google Scholar] [CrossRef]

- Zhang, Q.; Feng, Y.-Q.; Xu, K.-J.; Liang, H.-J.; Liu, Z.-N.; Zhao, C.-Y.; Wang, Y.-Z.; Sapin, P.; Markides, C.N. Dynamic Behaviour and Performance Evaluation of a Biomass-Fired Organic Rankine Cycle Combined Heat and Power (ORC-CHP) System under Different Control Strategies. Appl. Therm. Eng. 2024, 248, 123236. [Google Scholar] [CrossRef]

- Le Brun, N.; Simpson, M.; Acha, S.; Shah, N.; Markides, C.N. Techno-Economic Potential of Low-Temperature, Jacket-Water Heat Recovery from Stationary Internal Combustion Engines with Organic Rankine Cycles: A Cross-Sector Food-Retail Study. Appl. Energy 2020, 274, 115260. [Google Scholar] [CrossRef]

- Liu, W.; Jin, B.; Wang, D.; Yu, Z. Performance Modeling and Advanced Exergy Analysis for Low-Energy Consumption Data Center with Waste Heat Recovery, Flexible Cooling and Hydrogen Energy. Energy Convers. Manag. 2023, 297, 117756. [Google Scholar] [CrossRef]

- Zhang, S.; Li, L.; Huo, E.; Yu, Y.; Huang, R.; Wang, S. Parameters Analysis and Techno-Economic Comparison of Various ORCs and sCO2 Cycles as the Power Cycle of Lead–Bismuth Molten Nuclear Micro-Reactor. Energy 2024, 295, 131103. [Google Scholar] [CrossRef]

- Chen, W.; Fu, B.; Zeng, J.; Luo, W. Research on the Operational Performance of Organic Rankine Cycle System for Waste Heat Recovery from Large Ship Main Engine. Appl. Sci. 2023, 13, 8543. [Google Scholar] [CrossRef]

- Santos, M.; André, J.; Francisco, S.; Mendes, R.; Ribeiro, J. Off-Design Modelling of an Organic Rankine Cycle Micro-CHP: Modular Framework, Calibration and Validation. Appl. Therm. Eng. 2018, 137, 848–867. [Google Scholar] [CrossRef]

- Wang, T.; Liu, L.; Zhu, T.; Gao, N. Experimental Investigation of a Small-Scale Organic Rankine Cycle under off-Design Conditions: From the Perspective of Data Fluctuation. Energy Convers. Manag. 2019, 198, 111826. [Google Scholar] [CrossRef]

- Bellos, E.; Lykas, P.; Tzivanidis, C. Investigation of a Solar-Driven Organic Rankine Cycle with Reheating. Appl. Sci. 2022, 12, 2322. [Google Scholar] [CrossRef]

- Varshil, P.; Deshmukh, D. A Comprehensive Review of Waste Heat Recovery from a Diesel Engine Using Organic Rankine Cycle. Energy Rep. 2021, 7, 3951–3970. [Google Scholar] [CrossRef]

- Unamba, C.K.; Sapin, P.; Li, X.; Song, J.; Wang, K.; Shu, G.; Tian, H.; Markides, C.N. Operational Optimisation of a Non-Recuperative 1-kWe Organic Rankine Cycle Engine Prototype. Appl. Sci. 2019, 9, 3024. [Google Scholar] [CrossRef]

- Li, Z.; Yu, X.; Wang, L.; Jiang, R.; Yu, X.; Huang, R.; Wu, J. Comparative Investigations on Dynamic Characteristics of Basic ORC and Cascaded LTES-ORC under Transient Heat Sources. Appl. Therm. Eng. 2022, 207, 118197. [Google Scholar] [CrossRef]

- Bahrami, M.; Pourfayaz, F.; Kasaeian, A. Low Global Warming Potential (GWP) Working Fluids (WFs) for Organic Rankine Cycle (ORC) Applications. Energy Rep. 2022, 8, 2976–2988. [Google Scholar] [CrossRef]

- Loni, R.; Najafi, G.; Bellos, E.; Rajaee, F.; Said, Z.; Mazlan, M. A Review of Industrial Waste Heat Recovery System for Power Generation with Organic Rankine Cycle: Recent Challenges and Future Outlook. J. Clean. Prod. 2021, 287, 125070. [Google Scholar] [CrossRef]

- Valencia, G.; Duarte, J.; Isaza-Roldan, C. Thermoeconomic Analysis of Different Exhaust Waste-Heat Recovery Systems for Natural Gas Engine Based on ORC. Appl. Sci. 2019, 9, 4017. [Google Scholar] [CrossRef]

- Daniarta, S.; Kolasiński, P.; Imre, A.R. Thermodynamic Efficiency of Trilateral Flash Cycle, Organic Rankine Cycle and Partially Evaporated Organic Rankine Cycle. Energy Convers. Manag. 2021, 249, 114731. [Google Scholar] [CrossRef]

- Zeynali, A.; Akbari, A.; Khalilian, M. Investigation of the Performance of Modified Organic Rankine Cycles (ORCs) and Modified Trilateral Flash Cycles (TFCs) Assisted by a Solar Pond. Sol. Energy 2019, 182, 361–381. [Google Scholar] [CrossRef]

- Li, T.; Gao, R.; Gao, X. Energy, Exergy, Economic, and Environment (4E) Assessment of Trans-Critical Organic Rankine Cycle for Combined Heating and Power in Wastewater Treatment Plant. Energy Convers. Manag. 2022, 267, 115932. [Google Scholar] [CrossRef]

- Falbo, L.; Perrone, D.; Morrone, P.; Algieri, A. Integration of Biodiesel Internal Combustion Engines and Transcritical Organic Rankine Cycles for waste-heat Recovery in small-scale Applications. Int. J. Energy Res. 2022, 46, 5235–5249. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P. Thermo-Economic Investigation of Solar-Biomass Hybrid Cogeneration Systems Based on Small-Scale Transcritical Organic Rankine Cycles. Appl. Therm. Eng. 2022, 210, 118312. [Google Scholar] [CrossRef]

- Morrone, P.; Algieri, A. Integrated Geothermal Energy Systems for Small-Scale Combined Heat and Power Production: Energy and Economic Investigation. Appl. Sci. 2020, 10, 6639. [Google Scholar] [CrossRef]

- Algieri, A.; Morrone, P. Comparative Energetic Analysis of High-Temperature Subcritical and Transcritical Organic Rankine Cycle (ORC). A Biomass Application in the Sibari District. Appl. Therm. Eng. 2012, 36, 236–244. [Google Scholar] [CrossRef]

- Ziviani, D.; Gusev, S.; Lecompte, S.; Groll, E.A.; Braun, J.E.; Horton, W.T.; Van Den Broek, M.; De Paepe, M. Optimizing the Performance of Small-Scale Organic Rankine Cycle That Utilizes a Single-Screw Expander. Appl. Energy 2017, 189, 416–432. [Google Scholar] [CrossRef]

- Yu, H.; Eason, J.; Biegler, L.T.; Feng, X. Process Integration and Superstructure Optimization of Organic Rankine Cycles (ORCs) with Heat Exchanger Network Synthesis. Comput. Chem. Eng. 2017, 107, 257–270. [Google Scholar] [CrossRef]

- Bianchi, M.; Branchini, L.; De Pascale, A.; Orlandini, V.; Ottaviano, S.; Pinelli, M.; Spina, P.R.; Suman, A. Experimental Performance of a Micro-ORC Energy System for Low Grade Heat Recovery. Energy Procedia 2017, 129, 899–906. [Google Scholar] [CrossRef]

- De La Calle-Arroyo, C.; López-Fidalgo, J.; Rodríguez-Aragón, L.J. Optimal Designs for Antoine Equation. Chemom. Intell. Lab. Syst. 2021, 214, 104334. [Google Scholar] [CrossRef]

- Chitgar, N.; Hemmati, A.; Sadrzadeh, M. A Comparative Performance Analysis, Working Fluid Selection, and Machine Learning Optimization of ORC Systems Driven by Geothermal Energy. Energy Convers. Manag. 2023, 286, 117072. [Google Scholar] [CrossRef]

- Yaïci, W.; Entchev, E.; Talebizadehsardari, P.; Longo, M. Thermodynamic, Economic and Sustainability Analysis of Solar Organic Rankine Cycle System with Zeotropic Working Fluid Mixtures for Micro-Cogeneration in Buildings. Appl. Sci. 2020, 10, 7925. [Google Scholar] [CrossRef]

- Hu, B.; Guo, J.; Yang, Y.; Shao, Y. Selection of Working Fluid for Organic Rankine Cycle Used in Low Temperature Geothermal Power Plant. Energy Rep. 2022, 8, 179–186. [Google Scholar] [CrossRef]

- Pasinato, H.D. Working Fluid Dependence on Source Temperature for Organic Rankine Cycles. J. Energy Resour. Technol. 2020, 142, 012103. [Google Scholar] [CrossRef]

- Yu, H.; Feng, X.; Wang, Y. Working Fluid Selection for Organic Rankine Cycle (ORC) Considering the Characteristics of Waste Heat Sources. Ind. Eng. Chem. Res. 2016, 55, 1309–1321. [Google Scholar] [CrossRef]

- Herath, H.M.D.P.; Wijewardane, M.A.; Ranasinghe, R.A.C.P.; Jayasekera, J.G.A.S. Working Fluid Selection of Organic Rankine Cycles. Energy Rep. 2020, 6, 680–686. [Google Scholar] [CrossRef]

- Babatunde, A.F.; Sunday, O.O. A Review of Working Fluids for Organic Rankine Cycle (ORC) Applications. IOP Conf. Ser. Mater. Sci. Eng. 2018, 413, 012019. [Google Scholar] [CrossRef]

- Hartulistiyoso, E.; Sucahyo, L.; Yulianto, M.; Sipahutar, M. Thermal Efficiency Analysis of Organic Rankine Cycle (ORC) System from Low-Grade Heat Resources Using Various Working Fluids Based on Simulation. IOP Conf. Ser. Earth Environ. Sci. 2020, 542, 012047. [Google Scholar] [CrossRef]

- Dai, X.; Shi, L.; Qian, W. Review of the Working Fluid Thermal Stability for Organic Rankine Cycles. J. Therm. Sci. 2019, 28, 597–607. [Google Scholar] [CrossRef]

- Chauhan, A.; Vaish, R. Fluid Selection of Organic Rankine Cycle Using Decision Making Approach. J. Comput. Eng. 2013, 2013, 105825. [Google Scholar] [CrossRef]

- Darvish, K.; Ehyaei, M.; Atabi, F.; Rosen, M. Selection of Optimum Working Fluid for Organic Rankine Cycles by Exergy and Exergy-Economic Analyses. Sustainability 2015, 7, 15362–15383. [Google Scholar] [CrossRef]

- Algieri, A. Energy Exploitation of High-Temperature Geothermal Sources in Volcanic Areas—A Possible ORC Application in Phlegraean Fields (Southern Italy). Energies 2018, 11, 618. [Google Scholar] [CrossRef]

- Marshall, Z.M.; Duquette, J. A Techno-Economic Evaluation of Low Global Warming Potential Heat Pump Assisted Organic Rankine Cycle Systems for Data Center Waste Heat Recovery. Energy 2022, 242, 122528. [Google Scholar] [CrossRef]

- Faghih, S.; Pourshaghaghy, A. Selecting Working Fluids in Organic Rankine Cycle (ORC) for Waste Heat Applications and Optimal Cycle Parameters for Different Hot Source Temperatures. J. Therm Anal. Calorim. 2022, 147, 13737–13755. [Google Scholar] [CrossRef]

- Biswas, A.; Mandal, B.K. Analysis of Organic Rankine Cycle Using Various Working Fluids for Low-Grade Waste Heat Recovery. In Advances in Clean Energy and Sustainability; Doolla, S., Rather, Z.H., Ramadesigan, V., Eds.; Green Energy and Technology; Springer Nature: Singapore, 2023; pp. 431–441. ISBN 978-981-9922-78-9. [Google Scholar]

- Corigliano, O.; Florio, G.; Fragiacomo, P. Parametric Analysis and Design of a Power Plant to Recover Low-Grade Heat From Data Center Electronics by Using Liquid Nitrogen. J. Energy Resour. Technol. 2023, 145, 121701. [Google Scholar] [CrossRef]

- ISO/IEC 30134-6:2021; Information Technology—Data Centres Key Performance Indicators—Part 6: Energy Reuse Factor (ERF). International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO/IEC 30134-2:2016; Information Technology—Data Centres—Key Performance Indicators—Part 2: Power Usage Effectiveness (PUE). International Organization for Standardization: Geneva, Switzerland, 2016.

- Chen, X.; Wang, X.; Ding, T.; Li, Z. Experimental Research and Energy Saving Analysis of an Integrated Data Center Cooling and Waste Heat Recovery System. Appl. Energy 2023, 352, 121875. [Google Scholar] [CrossRef]

- Ge, Z.; Zhou, Y.; Li, J.; Zhang, X.; Xu, J.; Yang, F. Multi-Objective Optimization and Benefit Evaluation of Heat Pump System for Tobacco Drying Using Waste Heat from Data Center. J. Clean. Prod. 2024, 448, 141623. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Li, H.; Hu, S.; Duan, Y.; Yan, J. Optimal Schemes and Benefits of Recovering Waste Heat from Data Center for District Heating by CO2 Transcritical Heat Pumps. Energy Convers. Manag. 2021, 245, 114591. [Google Scholar] [CrossRef]

- Li, J.; Jurasz, J.; Li, H.; Tao, W.-Q.; Duan, Y.; Yan, J. A New Indicator for a Fair Comparison on the Energy Performance of Data Centers. Appl. Energy 2020, 276, 115497. [Google Scholar] [CrossRef]

- Zhou, X.; Xin, Z.; Tang, W.; Sheng, K.; Wu, Z. Comparative Study for Waste Heat Recovery in Immersion Cooling Data Centers with District Heating and Organic Rankine Cycle (ORC). Appl. Therm. Eng. 2024, 242, 122479. [Google Scholar] [CrossRef]

- Carbon Footprint. 2023 Country Specific Electricity Grid Greenhouse Gas Emission Factors. Available online: https://www.carbonfootprint.com/international_electricity_factors.html (accessed on 30 May 2024).

| Distribution of Heat and Temperatures | Power Loads | |||||

|---|---|---|---|---|---|---|

| Standard Server | Component | Heat Share | Temperature | High performance cluster | Component | Heat Share |

| Microprocessor | 30% | 85 °C | Microprocessors | 63% | ||

| DC/DC conversion | 10% | 50 °C | DC/DC conversion | 13% | ||

| I/O processor | 3% | 40 °C | I/O processor | 10% | ||

| AC/DC conversion | 25% | 55 °C | Memory chips | 14% | ||

| Memory chips | 11% | 70 °C | ||||

| Fans | 9% | 30 °C | ||||

| Disk drives | 6% | 45 °C | ||||

| Motherboard | 3% | 40 °C | ||||

| Other | 3% | - | ||||

| Heat sources and stream | ||||||

| Cooling | Parameter | Value | Cooling | Parameter | Value | |

| Air cooling | Cold aisle (CRAC supply) temperature | 10–32 °C | Water Cooling | Water supply to server | 60–75 °C | |

| Hot aisle (CRAC return) temperature | 50–65 °C | Water rise from server | 2–5 °C | |||

| Temperature rise over servers | 10–20 °C | Flow rate per rack | 840–1680 kg/h | |||

| Air flow rate per rack | 321–4013 m3/h | ΔT from water to lid | 5–18 °C | |||

| Chiller water supply to CRAC | 7–10 °C | Buffer heat exchanger flow rate | 840–1680 kg/h | |||

| Chilled water return from CRAC | 35 °C | Buffer heat exchanger supply temperature | 3–5 °C above ambient | |||

| Two-phase cooling with vapor compressor | Coolant at evaporator | 60–75 °C | Two-phase cooling with liquid pump | Coolant supply to evaporator | 60–75 °C | |

| Coolant at condenser | 90 °C | Coolant exit from evaporator | 75–80 °C | |||

| Condenser cooling fluid inlet | 30 °C | Condenser cooling fluid inlet | 30 °C | |||

| Condenser cooling fluid outlet | 90 °C | Condenser cooling fluid outlet | 45–90 °C | |||

| Summary data | ||||||

| Heat recovery | 70% (max) | |||||

| Power consumption range | 8–15 kW/m2 | |||||

| Component | ORC Configuration with | Power | ||

|---|---|---|---|---|

| Superheater | Regenerator | |||

| Pump | Yes; No | Yes; No | (7) | |

| Boiler | Yes | No | (8) | |

| No | No | (9) | ||

| Yes | Yes | (10) | ||

| No | Yes | (11) | ||

| Turbine | Yes | Yes; No | (12) | |

| No | Yes; No | (13) | ||

| Condenser | Yes | No | (14) | |

| No | No | (15) | ||

| Yes | Yes | (16) | ||

| No | Yes | (17) | ||

| Regenerator | Yes | Yes | (18) | |

| No | Yes | (19) | ||

| Yes; No | No | - | ||

| Code | Name | Ozone Depletion Potential | Global Warming Potential (100-Year) | Boiling Point (0.1 MPa) | Molecular Weight | Critical Temper. | Critical Pressure | Latent Heat | |

|---|---|---|---|---|---|---|---|---|---|

| ODP [-] | GWP [-] | Tb [°C] | MW [g/mol] | Tc [°C] | pc [MPa] | λ [kJ/kg] | |||

| 1 | HC270 | Cyclopropane | 0 | 0 | −32.75 | 42.08 | 125.15 | 5.58 | 366.18 |

| 2 | R21 | Dichlorofluoromethane | 0.01 | 151 | 8.92 | 102.92 | 178.33 | 5.18 | 216.17 |

| 3 | R22 | Chlorofluoromethane | 0.05 | 1810 | −9.10 | 64.48 | 96.15 | 4.99 | 158.46 |

| 4 | R23a | Trifluoromethane | 0 | 14760 | −82.10 | 70.01 | 26.14 | 4.83 | 89.69 |

| 5 | R32 | Difluoromethane | 0 | 675 | −52.15 | 52.02 | 78.11 | 5.78 | 218.59 |

| 6 | R41 | Fluoromethane | 0 | 92 | −78.15 | 34.03 | 44.13 | 5.9 | 270.04 |

| 7 | R116a | Hexafluoroethane | 0 | 12200 | −78.00 | 138.01 | 19.88 | 3.05 | 30.69 |

| 8 | R123 | 2,2-Dichloro-1,1,1-trifluoroet. | 0.02 | 77 | 27.00 | 152.93 | 183.68 | 3.66 | 161.82 |

| 9 | R124 | 2-Chloro-1,1,1,2-tetrafluoroet. | 0.02 | 609 | −12.00 | 136.48 | 122.28 | 3.62 | 132.97 |

| 10 | R125 | Pentafluoroethane | 0 | 3500 | −49.00 | 120.02 | 66.02 | 3.62 | 81.49 |

| 11 | R134a | 1,1,1,2-Tetrafluoroethane | 0 | 1430 | −26.07 | 102.03 | 101.06 | 4.06 | 155.42 |

| 12 | R141b | 1,1-Dichloro-1-fluoroethane | 0.12 | 725 | 32.05 | 116.95 | 204.35 | 4.21 | 215.13 |

| 13 | R142b | 1-Chloro-1,1-difluoroethane | 0.07 | 2310 | −10.00 | 100.5 | 137.11 | 4.06 | 185.69 |

| 14 | R143a | 1,1,1-Trifluoroethane | 0 | 4470 | −47.00 | 84.04 | 72.71 | 3.76 | 124.81 |

| 15 | R152a | 1,1-Difluoroethane | 0 | 140 | −24.65 | 66.05 | 113.26 | 4.52 | 249.67 |

| 16 | R170a | Ethane | 0 | 20 | −88.55 | 30.07 | 32.18 | 4.87 | 223.43 |

| 17 | R218 | Octafluoropropane | 0 | 8830 | −37.00 | 188.02 | 71.87 | 2.64 | 58.29 |

| 18 | R227ea | 1,1,1,2,3,3,3-Heptafluoroprop. | 0 | 3220 | −15.61 | 170.03 | 102.80 | 2.93 | 97.14 |

| 19 | R236ea | 1,1,1,2,3,3-Hexafluoropropan. | 0 | 6300 | 6.19 | 152.04 | 139.29 | 3.5 | 142.98 |

| 20 | R245ca | 1,1,2,2,3-Pentafluoropropane | 0 | 693 | 25.00 | 134.05 | 174.42 | 3.93 | 188.64 |

| 21 | R245fa | 1,1,1,3,3-Pentafluoropropane | 0 | 1030 | 58.80 | 134.05 | 154.05 | 3.64 | 177.08 |

| 22 | R290 | Propane | 0 | 20 | −42.11 | 44.1 | 96.68 | 4.25 | 292.13 |

| 23 | RC318 | Octafluorocyclobutane | 0 | 10250 | −5.85 | 200.03 | 115.23 | 2.78 | 93.95 |

| 24 | R3-1-10 | Decafluorobutane | 8860 | −2.00 | 238.03 | 113.18 | 2.32 | 77.95 | |

| 25 | FC4-1-12 | Dodecafluoropentane | 9160 | 27.85 | 288.03 | 147.41 | 2.05 | 86.11 | |

| 26 | R600 | Butane | 0 | 20 | −0.49 | 58.12 | 151.98 | 3.8 | 336.82 |

| 27 | R600a | Isobutane | 0 | 20 | −12.00 | 58.12 | 134.66 | 3.63 | 303.44 |

| 28 | R601 | Pentane | 0 | 20 | 36.06 | 72.15 | 196.55 | 3.37 | 349 |

| 29 | R601a | Isopentane | 0 | 20 | 27.83 | 72.15 | 187.25 | 3.38 | 343.28 |

| 30 | R717 | Ammonia | 0 | 0 | −33.00 | 17.03 | 132.25 | 11.33 | 1064.38 |

| 31 | R744 | Carbon dioxide | 0 | 1 | −78.45 | 44.01 | 30.98 | 7.38 | 167.53 |

| 32 | R1270 | Propylene | 0 | 20 | 48.00 | 42.08 | 92.42 | 4.66 | 284.34 |

| 33 | Propyne | −23.20 | 40.06 | 129.23 | 5.63 | 431.61 | |||

| 34 | R32 | Difluoromethane | 0 | 675 | −52.00 | 52.02 | 78.11 | 5.782 | 218.59 |

| 35 | R152a | 1,1-Difluoroethane | 0 | 124 | −25.00 | 66.05 | 113.26 | 4.515 | 317.94 |

| Section and Stream | Parameter | Notes |

|---|---|---|

| Heat source | Temperature | 30 °C (pre-heating) 50–60 °C (Air) 50–80 °C (Water) |

| Mover | Blower | |

| ΔT pinch-point | ~10 °C | |

| Mass flow rates | Calibrated through tests | |

| Condensing water | Temperature | 10 °C |

| Mass flow rate | Calibrated through tests | |

| Mover | Pump | |

| ORC fluid | Pentane and isopentane | |

| Mass flow rate | 1 kg/s | |

| Max pressure | Calibrated through tests | |

| Min pressure | Calibrated through tests | |

| Models | Soave–Redlich–Kwong Advanced (air) | |

| Peng–Robinson 1978 Advanced (ORC fluid) | ||

| Steam Tables IAPWS-IF97 (water) | ||

| Data Center (DC) | |

|---|---|

| Location | Beijing (China) |

| IT rooms | 3 |

| IT rooms area [m2] | 1897.2 |

| Racks per room | 340 |

| Power IT equipment [MW] | 12.9 |

| Power auxiliary systems [MW] | 0.97 |

| Cooling system | Water-cooled chillers |

| Chillers COP [-] | 5.5 |

| DC power usage effectiveness [-] | 1.295 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corigliano, O.; Algieri, A.; Fragiacomo, P. Turning Data Center Waste Heat into Energy: A Guide to Organic Rankine Cycle System Design and Performance Evaluation. Appl. Sci. 2024, 14, 6046. https://doi.org/10.3390/app14146046

Corigliano O, Algieri A, Fragiacomo P. Turning Data Center Waste Heat into Energy: A Guide to Organic Rankine Cycle System Design and Performance Evaluation. Applied Sciences. 2024; 14(14):6046. https://doi.org/10.3390/app14146046

Chicago/Turabian StyleCorigliano, Orlando, Angelo Algieri, and Petronilla Fragiacomo. 2024. "Turning Data Center Waste Heat into Energy: A Guide to Organic Rankine Cycle System Design and Performance Evaluation" Applied Sciences 14, no. 14: 6046. https://doi.org/10.3390/app14146046

APA StyleCorigliano, O., Algieri, A., & Fragiacomo, P. (2024). Turning Data Center Waste Heat into Energy: A Guide to Organic Rankine Cycle System Design and Performance Evaluation. Applied Sciences, 14(14), 6046. https://doi.org/10.3390/app14146046