Experimental Thrust and Specific Impulse Analysis of Pulsed Detonation Combustor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Model

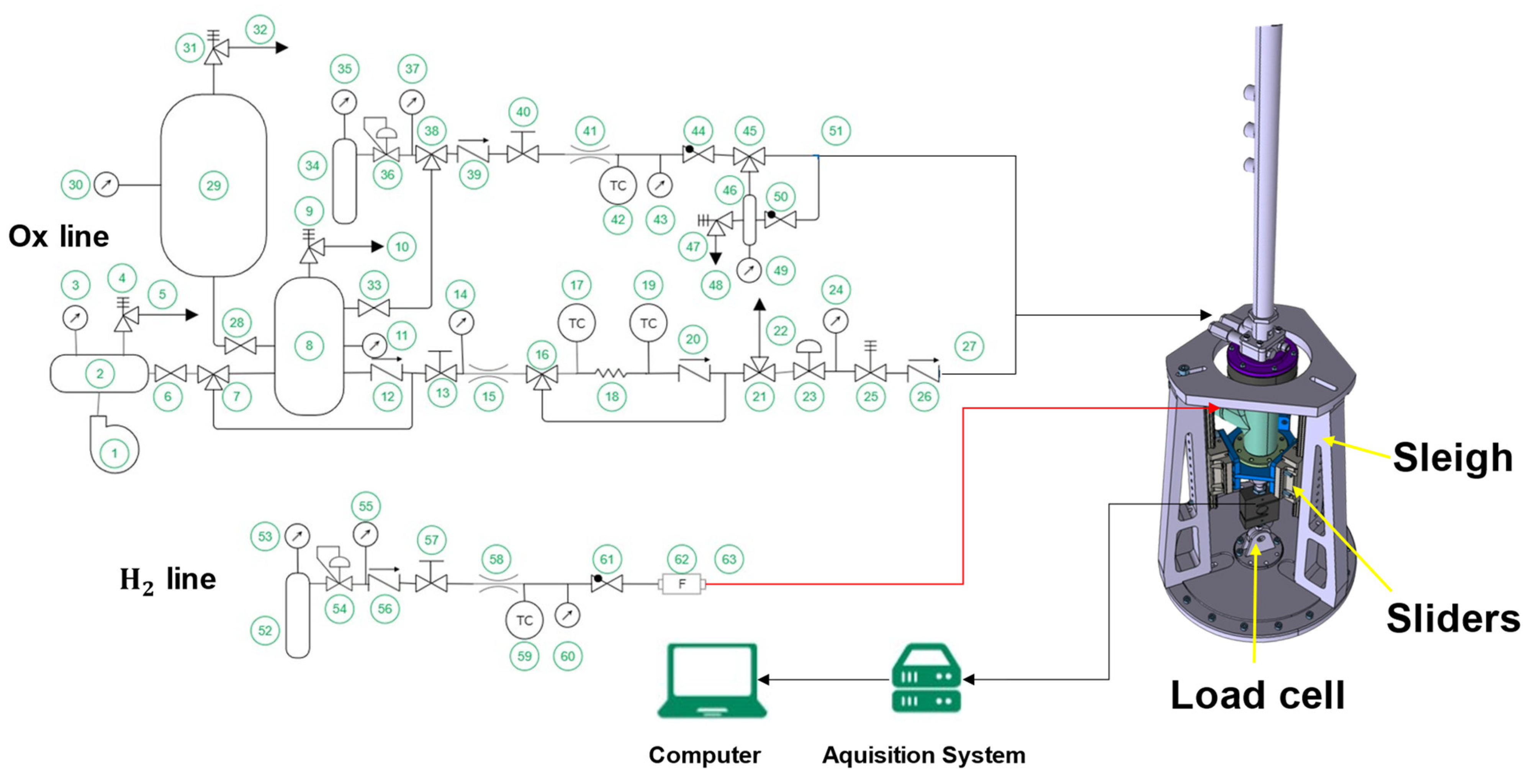

2.2. Experimental Setup

2.3. Test Conditions

2.4. Data Processing

3. Results and Discussions

3.1. Hydrogen/Air Mixture

3.1.1. Time-Average Thrust

3.1.2. Time-Averaged Total Specific Impulse

3.1.3. Time-Averaged Fuel Specific Impulse

3.2. Hydrogen/Oxygen Mixture

3.2.1. Time-Averaged Thrust

3.2.2. Time-Averaged Total Specific Impulse

3.2.3. Time-Averaged Fuel Specific Impulse

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The European Green Deal. 2019. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 7 May 2024).

- EU Negotiators Secure Agreement at COP28 to Accelerate the Global Transition Away from Fossil Fuels and Triple Renewables and Double Energy Efficiency this Decade. 13 December 2023. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_23_6591 (accessed on 16 December 2023).

- Koff, B.L. Gas Turbine Technology Evolution: A Designer’s Perspective. J. Propuls. Power 2004, 20, 577–595. [Google Scholar] [CrossRef]

- Gulen, S.C. Pressure gain combustion advantage in land-based electric power generation. J. Glob. Power Propuls. Soc. 2017, 1, 288–302. [Google Scholar] [CrossRef]

- Cuciumita, C.F.; Cuciuc, T.; Porumbel, I. Evaluation of the Cycle Averaged Performances of a Pulsed Detonation Engine Based on Thermodynamic Cycle Computations. GT 2016-57310. In Proceedings of the ASME TURBO EXPO 2016: Turbomachinery Technical Conference and Exposition, GT2016, Seoul, Republic of Korea, 13–17 June 2016. [Google Scholar]

- Eidelman, S.; Grossmann, W.; Lottati, I. Review of Propulsion Applications and Numerical Simulations of the Pulsed Detonation Engine Concept. J. Propuls. Power 1991, 7, 857–865. [Google Scholar] [CrossRef]

- Helman, D.; Shreeve, R.; Eidelman, S. Detonation pulse engine. In Proceedings of the 22nd Joint Propulsion Conference, Huntsville, AL, USA, 13–15 May 1986. [Google Scholar]

- Kailasanath, K. Review of Propulsion Applications of Detonation Waves. AIAA J. 2000, 38, 1698–1708. [Google Scholar] [CrossRef]

- Wolanski, P. Detonative propulsion. Proc. Combust. Inst. 2013, 34, 125–158. [Google Scholar] [CrossRef]

- Buyakofu, V.; Matsuoka, K.; Matsuyama, K.; Kawasaki, A.; Watanabe, H.; Matsuo, A.; Funaki, I.; Nakata, D.; Uchiumi, M.; Habu, H.; et al. Flight Demonstration of Pulse Detonation Engine Using Sounding Rocket S-520-31 in Space. J. Spacecr. Rocket. 2023, 60, 181–189. [Google Scholar] [CrossRef]

- Roy, G.; Frolov, S.; Borisov, A.; Netzer, D. Pulse detonation propulsion: Challenges, current status and future perspective. Prog. Energy Combust. Sci. 2004, 30, 545–672. [Google Scholar] [CrossRef]

- Carter, J.D.; Lu, F.K. Experiences in Testing of a Large-Scale, Liquid-Fueled, Air-Breathing, Pulse Detonation Engine. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011. [Google Scholar]

- Wang, K.; Fan, W.; Lu, W.; Chen, F.; Zhang, Q.; Yan, C. Study on a liquid-fueled and valveless pulse detonation rocket engine without the purge process. Energy 2014, 71, 605–614. [Google Scholar] [CrossRef]

- Li, J.-L.; Fan, W.; Chen, W.; Wang, K.; Yan, C.-J. Propulsive performance of a liquid kerosene/oxygen pulse detonation rocket engine. Exp. Therm. Fluid Sci. 2011, 35, 265–271. [Google Scholar] [CrossRef]

- Baklanove, D.; Gvozdeva, L.; Scherbak, N. Pulsed detonation combustion chamber for PDE. In High-Speed Deflagration and Detonation: Fundamentals and Control; ELEX-KM Publishers: Moscow, Russia, 2001; pp. 239–250. [Google Scholar]

- Frolov, S.M.; Smetanyuk, V.A.; Aksenov, V.S.; Koval’, A.S. Deflagration-to-Detonation Transition in Crossed-Flow Fast Jets of Propellant Components. Dokl. Phys. Chem. 2017, 476, 153–156. [Google Scholar] [CrossRef]

- Matsuoka, K.; Taki, H.; Kawasaki, A.; Kasahara, J.; Watanabe, H.; Matsuo, A.; Endo, T. Semi-valveless pulse detonation cycle at a kilohertz-scale operating frequency. Combust. Flame 2019, 205, 434–440. [Google Scholar] [CrossRef]

- Cojocea, A.V.; Cuciuc, T.; Porumbel, I.; Gall, M.; Gherman, B.; Crunțeanu, D.E. Experimental investigations of hydrogen fuelled pulsed detonation combustor. In Proceedings of the ASME Turbo Expo 2022 Turbomachinery Technical Conference and Exposition GT2022, Rotterdam, The Netherlands, 13–17 June 2022. [Google Scholar]

- Shepherd, J.; Database, D. 2002. Available online: https://shepherd.caltech.edu/detn_db/html/db.html (accessed on 12 May 2024).

- Peraldi, O.; Knystautas, R.; Lee, J.H. Criteria for transition to detonation in tubes. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1988; Volume 21, pp. 1629–1637. [Google Scholar]

- Kasahara, J.; Hirano, M.; Matsuo, A.; Daimon, Y.; Endo, T. Thrust Measurement of a Multicycle Partially Filled Pulse Detonation Rocket Engine. J. Propuls. Power 2009, 25, 1281–1290. [Google Scholar] [CrossRef]

- Matsuoka, K.; Takagi, S.; Kasahara, J.; Matsuo, A.; Funaki, I. Validation of Pulse Detonation Operation in Low-Ambient-Pressure Environment. J. Propuls. Power 2018, 34, 116–124. [Google Scholar] [CrossRef]

- Buyakofu, V.; Matsuoka, K.; Matsuyama, K.; Kawasaki, A.; Watanabe, H.; Itouyama, N.; Goto, K.; Ishihara, K.; Noda, T.; Kasahara, J.; et al. Development of an S-Shaped Pulse Detonation Engine for a Sounding Rocket. J. Spacecr. Rocket. 2022, 59, 850–860. [Google Scholar] [CrossRef]

- Wang, Y.-Q.; Fan, W.; Yan, C.-J.; Qin, H.-Q.; Xie, K.-C.; Wang, W. Performance Measurements of a Kerosene-Oxygen Pulse Detonation Rocket Engine at the Frequencies of 35–40Hz. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Denver, CO, USA, 3 August 2009. [Google Scholar]

- Wang, K.; Fan, W.; Lu, W.; Zhang, Q.; Chen, F.; Yan, C.; Xia, Q. Propulsive performance of a pulse detonation rocket engine without the purge process. Energy 2015, 79, 228–234. [Google Scholar] [CrossRef]

- Zhang, B. Enhancing detonation propulsion with jet in cross-flow: A comprehensive review. Prog. Aerosp. Sci. 2024, 101020. [Google Scholar] [CrossRef]

- Bogoi, A.; Cuciuc, T.; Cojocea, A.V.; Gall, M.; Porumbel, I.; Hrițcu, C.E. Experimental Pressure Gain Analysis of Pulsed Detonation Engine. Aerospace 2024, 11, 465. [Google Scholar] [CrossRef]

- SGA|Strain Gauge Amplifier. Available online: https://www.micronmeters.com/product/sga-strain-gauge-amplifier (accessed on 15 May 2024).

- Pegg, R.J.; Couch, B.D.; Hunter, L.G. Pulse detonation engine air induction system analysis. In Proceedings of the AIAA Paper 96-2918, AIAA Meeting Papers on Disc, Lake Buena Vista, FL, USA, 1–3 July 1996. [Google Scholar]

- Cutler, A.D. Parametric Study of High Frequency Pulse Detonation Tubes. In Proceedings of the AIAA Paper 2008-4691, Hartford, CT, USA, 21–23 July 2008. [Google Scholar]

- Wang, K.; Fan, W. Efforts on High Frequency PDE. J. Propuls. Power 2017, 33, 17–28. [Google Scholar] [CrossRef]

- Matsuoka, K.; Muto, K.; Kasahara, J.T. Development of High-Frequency Pulse Detonation Combustor Without Purging Material. J. Propuls. Power 2017, 33, 43–50. [Google Scholar] [CrossRef]

- Schwinn, K.; Gejji, R.; Kan, B.; Sardeshmukh, S.; Heister, S.; Slabaugh, C.D. Self-sustained, high-frequency detonation wave generation in a semi-bounded channel. Combust. Flame 2018, 193, 384–396. [Google Scholar] [CrossRef]

- Di Cara, D.M.; Schneider, D.; Searle, T.; Villace, V.F.; Cohen, O. (Eds.) Innovative Propulsion Cross-Cutting Initiative. In Proceedings of the ESA-TECMP-WP-2023-001844, Amsterdam, The Netherlands, 28–30 June 2023; pp. 41–48. [Google Scholar]

| Factor | Level 1 | Level 2 | Level 3 | Level 4 | |

|---|---|---|---|---|---|

| 1 | Exhaust pipe length | 200 mm | 300 mm | 400 mm | 500 mm |

| 2 | Spark plug frequency | 100 Hz | 150 Hz | 233 Hz | 350 Hz |

| 3 | Hydrogen supply pressure | 5.5 bara | 7 bara | 8.5 bara | 10 bara |

| 4 | Oxidant supply pressure | 9 bara | 7.5 bara | 6 bara | 4.5 bara |

| 0 | 1 | 2 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cojocea, A.V.; Porumbel, I.; Gall, M.; Cuciuc, T. Experimental Thrust and Specific Impulse Analysis of Pulsed Detonation Combustor. Appl. Sci. 2024, 14, 5999. https://doi.org/10.3390/app14145999

Cojocea AV, Porumbel I, Gall M, Cuciuc T. Experimental Thrust and Specific Impulse Analysis of Pulsed Detonation Combustor. Applied Sciences. 2024; 14(14):5999. https://doi.org/10.3390/app14145999

Chicago/Turabian StyleCojocea, Andrei Vlad, Ionuț Porumbel, Mihnea Gall, and Tudor Cuciuc. 2024. "Experimental Thrust and Specific Impulse Analysis of Pulsed Detonation Combustor" Applied Sciences 14, no. 14: 5999. https://doi.org/10.3390/app14145999

APA StyleCojocea, A. V., Porumbel, I., Gall, M., & Cuciuc, T. (2024). Experimental Thrust and Specific Impulse Analysis of Pulsed Detonation Combustor. Applied Sciences, 14(14), 5999. https://doi.org/10.3390/app14145999