Effect of Aggregate Type on the Shear Behavior of Reinforced Lightweight Concrete Beams

Abstract

:1. Introduction

2. Research Significance

3. Existing Design Guidelines for Reinforced Lightweight Concrete Beams

4. Experimental Tests

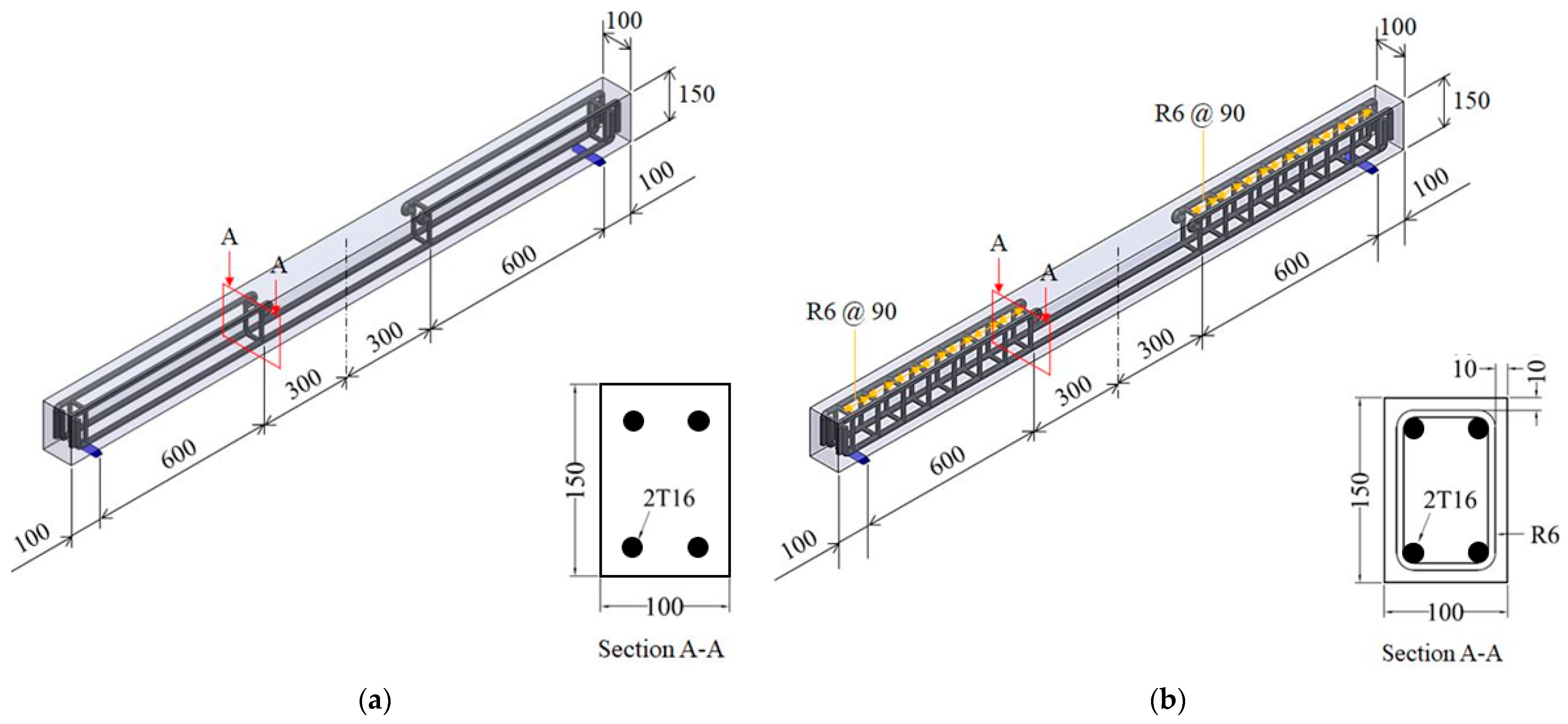

4.1. Test Variables

4.2. Materials and Specimen Preparation

- Pre-soaking lightweight coarse and fine aggregates for over 24 h to ensure adequate water absorption and stability.

- Removing surface water from the aggregates using absorbent cotton towels to achieve SSD conditions.

- Loading all prepared and measured materials into a drum-type mixer in the following sequence: CAs first, then cement and silica fume, and, finally, sand.

- Initiating the mixing process by blending for 60 s with half of the total water to ensure an even distribution of moisture.

- Adding the remaining water along with a high-range water reducer (HRWR) and continuing the mixing for an additional four minutes to achieve the desired consistency and workability of the concrete mix.

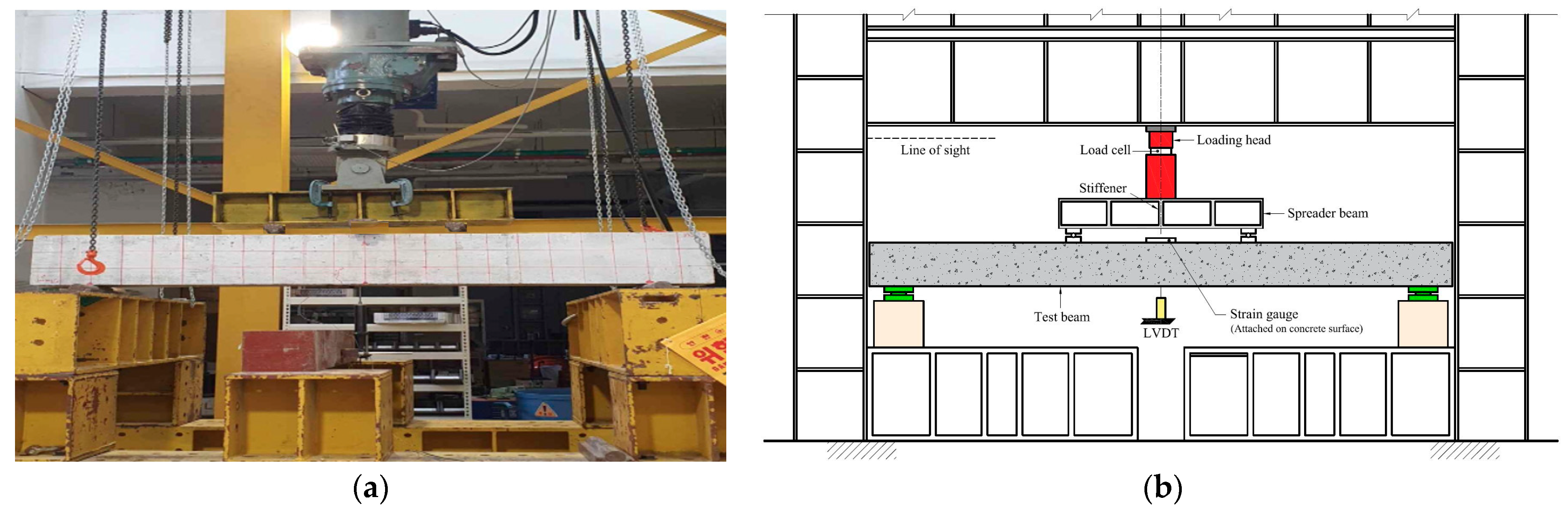

4.3. Testing and Measurements

5. Test Results and Analysis

5.1. Cracking and Failure Behavior

5.2. Applied Load and Mid-Span Deflections

5.3. Cracking and Ultimate Loads

5.4. Measured Strain Values

5.5. Shear Resistance and Comparisons

5.6. Effect of Coarse Aggregate Type on Shear Resistance of RC Beams

6. Limitations and Future Studies

7. Conclusions

- ALWAC beams with stirrups exhibited more extensive and wider flexural cracks compared to NWC beams under the same loading conditions. This difference may be attributed to the lower tensile strength of ALWAC.

- The type of lightweight coarse aggregate selected did not significantly affect the flexural behavior of the RC beams, possibly due to the high a/d ratio adopted in this study.

- ALWAC beams demonstrated structural performance similar to that of NWC beams under identical loading conditions.

- The cracking loads of ALWAC can be estimated through measured concrete strength, with the post-cracking behavior of the beams predominantly influenced by tensile reinforcement.

- All considered design codes underestimated the shear capacity of the tested ALWAC beams, and the shear resistance estimated by EC2 was better matched than that of other methods, although the differences were not statistically significant.

- The developed mix proportions demonstrated consistent results in achieving the desired concrete properties, despite the limited variety of LWAs used. Additionally, beam tests revealed that ALWAC beams exhibited earlier and more extensive cracking compared to NWC beams.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Requirement | ACI 213 [32], ACI 318 [23,24] | BS 8110 [26] | CSA [34] | EC2 [25] | JSCE [35] |

|---|---|---|---|---|---|

| f’c 1 | f’c ≥ 17.0 MPa | Concrete strength classes ≥ LC20/22 | f’c ≥ 20.0 MPa | Not specified | Not specified (less than 60.0 MPa) |

| ρc 2 | 1120–1920 kg/m3 | ρc ≤ 2000 kg/m3 | ρc ≤ 1850 kg/m3 (low density) 1850–2150 kg/m3 (semi-low density) | ρc ≤ 2000 kg/m3 | 1200–1700 kg/m3 (Type I 4) 1600–2100 kg/m3 (Type II 5) |

| λ 3 | 0.75 (ALWAC) 0.85 (LWAC) 1.00 (NWC) | 0.80 | 0.75 (low density) 0.85 (semi-low density) | 0.40 + 0.60ρc/2200 | 0.70 |

References

- Melby, K.; Jordet, E.A.; Hansvold, C. Long-span bridges in Norway constructed in high-strength LWA concrete. Eng. Struct. 1996, 18, 845–849. [Google Scholar] [CrossRef]

- Haug, A.K.; Fjeld, S. A floating concrete platform hull made of lightweight aggregate concrete. Eng. Struct. 1996, 18, 831–836. [Google Scholar] [CrossRef]

- Gerwick, B.C., Jr. Introduction. In Construction of Prestressed Concrete Structures, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1997; pp. 11–52. [Google Scholar]

- Rossignolo, J.A.; Agnesini, M.V.C.; Morais, J.A. Properties of high-performance LWAC for precast structures with Brazilianlightweight aggregates. Cem. Concr. Compos. 2003, 25, 77–82. [Google Scholar] [CrossRef]

- Holm, T.A.; Bremner, T.W. Durability of Structural Lightweight Concrete. Spec. Publ. 1991, 126, 1119–1134. [Google Scholar]

- Mo, K.H.; Ling, T.-C.; Alengaram, U.J.; Yap, S.P.; Yuen, C.W. Overview of supplementary cementitious materials usage in lightweight aggregate concrete. Constr. Build. Mater. 2017, 139, 403–418. [Google Scholar] [CrossRef]

- Cavalline, T.L.; Castrodale, R.W.; Freeman, C.; Wall, J. Impact of Lightweight Aggregate on Concrete Thermal Properties. ACIMater. J. 2017, 114, 945–956. [Google Scholar] [CrossRef]

- Lesovik, R.V.; Botsman, L.N.; Tarasenko, V.N.; Botsman, A.N. Enhancement of sound insulation of floors using light-weight concrete based on nanostructured granular aggregate. ARPN J. Eng. Appl. Sci. 2014, 9, 1789–1793. [Google Scholar]

- Guneyisi, E.; Gesoğlu, M.; Ghanim, H.; Ipek, S.; Taha, I. Influence of the artificial lightweight aggregate on fresh properties and compressive strength of the self-compacting mortars. Constr. Build. Mater. 2016, 116, 151–158. [Google Scholar] [CrossRef]

- He, K.-C.; Guo, R.-X.; Ma, Q.-M.; Yan, F.; Lin, Z.-W.; Sun, Y.-L. Experimental Research on High Temperature Resistance of Modified Lightweight Concrete after Exposure to Elevated Temperatures. Adv. Mater. Sci. Eng. 2016, 2016, 5972570. [Google Scholar] [CrossRef]

- Haque, M.N.; Al-Khaiat, H.; Kayali, O. Strength and Durability of Lightweight Concrete. Cem. Concr. Compos. 2004, 26, 307–314. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Durability of Lightweight Concretes with Lightweight Fly Ash Aggregates. Constr. Build. Mater. 2011, 25, 1430–1438. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z. Oil-Palm by-Products as Lightweight Aggregate in Concrete Mixture: A Review. J. Clean. Prod. 2016, 126, 56–73. [Google Scholar] [CrossRef]

- Kılıç, A.; Atiş, C.D.; Yaşar, E.; Özcan, F. High-Strength Lightweight Concrete Made with Scoria Aggregate Containing Mineral Admixtures. Cem. Concr. Res. 2003, 33, 1595–1599. [Google Scholar] [CrossRef]

- Thomas, M.; Bremner, T. Performance of Lightweight Aggregate Concrete Containing Slag after 25 years in a Harsh Marine Environment. Cem. Concr. Res. 2012, 42, 358–364. [Google Scholar] [CrossRef]

- Chai, L.J.; Shafigh, P.; Bin Mahmud, H. Production of High-Strength Lightweight Concrete Using Waste Lightweight Oil-Palm-Boiler-Clinker and Limestone Powder. Eur. J. Environ. Civ. Eng. 2019, 23, 325–344. [Google Scholar] [CrossRef]

- Mansouri, E.; Manfredi, M.; Hu, J.-W. Environmentally Friendly Concrete Compressive Strength Prediction Using Hybrid Machine Learning. Sustainability 2022, 14, 12990. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Ahmed, S.; Lachemi, M. Lightweight Concrete Incorporating Pumice Based Blended Cement and Aggregate: Mechanical and Durability Characteristics. Constr. Build. Mater. 2011, 25, 1186–1195. [Google Scholar] [CrossRef]

- Chen, S.-H.; Wang, H.-Y.; Jhou, J.-W. Investigating the Properties of Lightweight Concrete Containing High Contents of Recycled Green Building Materials. Constr. Build. Mater. 2013, 48, 98–103. [Google Scholar] [CrossRef]

- Thienel, K.-C.; Haller, T.; Beuntner, N. Lightweight concrete—From basics to innovations. Materials 2020, 13, 1120. [Google Scholar] [CrossRef]

- Gerritse, A. Design considerations for reinforced lightweight concrete. Int. J. Cem. Compos. Light. Concr. 1981, 3, 57–69. [Google Scholar] [CrossRef]

- Ting, T.Z.H.; Rahman, M.E.; Lau, H.H.; Ting, M.Z.Y. Recent development and perspective of lightweight aggregates based self-compacting concrete. Constr. Build. Mater. 2019, 201, 763–777. [Google Scholar] [CrossRef]

- ACI 318-14; Building Code Requirements for Structural Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- ACI 318-11; Building Code Requirements for Structural Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2011.

- Eurocode 2: European Committee for Standardization. Design of Concrete Structures—Part 1–2: General Rules; Structural Fire Design: Brussels, Belgium, 2004. [Google Scholar]

- BS8110-1:1997; British Standards Institution Structural Use of Concrete. BSI: London, UK, 1997.

- Ahmad, S.H.; Xie, Y.; Yu, T. Shear Ductility of Reinforced Lightweight Concrete Beams of Normal Strength and High Strength Concrete. Cem. Concr. Compos. 1995, 17, 147–159. [Google Scholar] [CrossRef]

- Juan, K.Y. Cracking Mode and Shear Strength of Lightweight Concrete Beams. Ph.D. Thesis, National University of Singapore, Singapore, 2011. [Google Scholar]

- Carmo, R.N.F.; Costa, H.; Lourenço, C.; Andrade, D.; Simões, T. Influence of both concrete strength and transverse confinement on bending behaviour of reinforced LWAC beams. Eng. Struct. 2013, 48, 329–341. [Google Scholar] [CrossRef]

- Yang, K.-H.; Ashour, A.F. Modification factor for shear capacity of lightweight concrete beams. ACI Struct. J. 2015, 4, 485–492. [Google Scholar] [CrossRef]

- Bernardo, L.F.; Nepomuceno, M.C.; Pinto, H.A. Flexural ductility of lightweight-aggregate concrete beams. J. Civ. Eng. Manag. 2016, 22, 622–633. [Google Scholar] [CrossRef]

- Sathiyamoorthy, K.; Hossain, K.M.A.; Lofty, A. Shear Resistance of Lightweight Self-Consolidating Concrete Beams. In Proceedings of CSCE 2016 Resilient Infrastructure, London, ON, Canada, 1–4 June 2016. [Google Scholar]

- ACI 213R-14; Guide for Structural Lightweight-Aggregate Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- CSA CAN3-A23.3; Design of Concrete Structures. Canadian Standards Association: Rexdale, ON, Canada, 2004.

- Japan Society of Civil Engineers. Standard Specifications for concrete structures-2007 Materials and Construction. JSCE Guidel. Concr. 2010, 16. [Google Scholar]

- Alqarni, A.S.; Albidah, A.S.; Alaskar, A.M.; Abadel, A.A. The effect of coarse aggregate characteristics on the shear behavior of reinforced concrete slender beams. Constr. Build. Mater. 2020, 264, 120189. [Google Scholar] [CrossRef]

- Herki, B.M.; Khatib, J. Structural behaviour of reinforced concrete beams containing a novel lightweight aggregate. Int. J. Struct. Eng. 2015, 7, 1. [Google Scholar] [CrossRef]

- Li, X.K.; Li, C.Y.; Zhao, M.L.; Yang, H.; Zhou, S.Y. Testing and Prediction of Shear Performance for Steel Fiber Reinforced Expanded-Shale Lightweight Concrete Beams without Web Reinforcements. Materials 2019, 12, 1594. [Google Scholar] [CrossRef]

- Kang, T.H.-K.; Kim, W.; Kwak, Y.-K.; Hong, S.-G. Shear Testing of Steel Fiber-Reinforced Lightweight Concrete Beams without Web Reinforcement. ACI Struct. J. 2011, 108, 553. [Google Scholar]

- Gusella, F.; Orlando, M. Failure analysis and retrofitting of reinforced concrete beams in existing moment resisting frames. Eng. Fail. Anal. 2023, 153, 107601. [Google Scholar] [CrossRef]

- Foraboschi, P. Bending load-carrying capacity of reinforced concrete beams subjected to premature failure. Materials 2019, 12, 3085. [Google Scholar] [CrossRef] [PubMed]

- Tauqir, M.; Qazi, A.U.; Khan, Q.S.; Munir, M.J.; Kazmi, S.M.S. Shear Behavior of Geopolymer Concrete Slender Beams. Buildings 2023, 13, 1191. [Google Scholar] [CrossRef]

- Yang, K.-H.; Sim, J.; Choi, B.; Lee, E. Effect of Aggregate Size on Shear Behavior of Lightweight Concrete Continuous Slender Beams. ACI Mater. J. 2011, 108, 501. [Google Scholar]

- Teo, D.C.L.; Mannan, M.A.; Kurian, J.V. Flexural behaviour of reinforced lightweight concrete beams made with oil palm shell (OPS). J. Adv. Concr. Technol. 2006, 4, 459–468. [Google Scholar] [CrossRef]

- Tang, C.W.; Yen, T.; Chen, H.J. Shear behavior of reinforced concrete beams made with sedimentary lightweight aggregate without shear reinforcement. J. Mater. Civ. Eng. 2009, 21, 730–739. [Google Scholar] [CrossRef]

- Kan, A.; Demirboğa, R. A novel material for lightweight concrete production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C138/C138M-23; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2023.

- Zhang, M.H.; Gjorv, O.E. Mechanical properties of high-strength lightweight concrete. ACI Mater. J. 1991, 88, 240–247. [Google Scholar]

- Hoff, G. High strength lightweight aggregate concrete for artic applications—Part 1–3. In Structural Lightweight Aggregate Concrete Performance; ACI SP-136; Holm, T.A., Vaysburd, A.M., Eds.; ACI: Farmington Hills, MI, USA, 1992. [Google Scholar]

- Roberts-Wollmann, C.L.; Banta, T.; Bonetti, R.; Charney, F. Bearing strength of lightweight concrete. ACI Mater. J. 2006, 103, 459. [Google Scholar]

| Type of Lightweight Coarse Aggregate | Bulk Density (kg/m3) | Particle Density (kg/m3) | 24 h Water Absorption (%) | Maximum Size (mm) | Shape |

|---|---|---|---|---|---|

| Expanded slate | 849 | 1394 | 5.9 | 12 | Angular |

| Expanded clay | 469 | 1449 | 11.9 | 10 | Spherical |

| Normal | 1563 | - | 1.13 | 13 | Angular |

| ID | Length (mm) | Width (mm) | Depth (mm) | Effective Depth, d (mm) | a/d | Longitudinal Reinforcement (mm) | Stirrups Spacing (mm) | Type of Coarse Aggregate |

|---|---|---|---|---|---|---|---|---|

| LNS | 2000 | 100 | 150 | 126 | 4.76 | 16 | - | Expanded slate |

| LSS | 90 | |||||||

| LNC | - | Expanded clay | ||||||

| LSC | 90 | |||||||

| NNN | - | Normal | ||||||

| NSN | 90 |

| ID | OPC | SF | CA | FA | Water | SP | CA Type |

|---|---|---|---|---|---|---|---|

| LNS and LSS | 450 | 50 | 449 | 656 | 180 | 5 | Expanded slate |

| LNC and LSC | Expanded clay | ||||||

| NNN and NSN | Normal |

| Constituent (%) | OPC | SF |

|---|---|---|

| CaO | 61.40 | 1.54 |

| SiO2 | 21.23 | 96.90 |

| Al2O3 | 5.64 | 0.29 |

| Fe2O3 | 3.38 | 0.15 |

| MgO | 2.20 | 0.18 |

| SO3 | 2.25 | – |

| K2O | 1.15 | 0.64 |

| Na2O | 0.11 | 0.16 |

| Cl | 0.06 | – |

| MnO | – | 0.03 |

| P2O5 | - | 0.05 |

| Loss of Ignition | 2.58 | 0.05 |

| ID | f’c | f’sp | ρ | E | First Crack | Inclined Diagonal Crack | Ultimate | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Load | Deflection | Load | Deflection | Load | Deflection | |||||

| (MPa) | (MPa) | (kg/m3) | (GPa) | (kN) | (mm) | (kN) | (mm) | (kN) | (mm) | |

| LNS | 35.04 | 2.87 | 1531 | 17.71 | 14.98 | 2.81 | 30.11 | 6.13 | 32.97 | 8.02 |

| LSS | 10.05 | 1.74 | - | - | 56.89 | 13.01 | ||||

| LNC | 33.79 | 2.79 | 1580 | 17.69 | 14.04 | 2.72 | 26.83 | 5.81 | 32.21 | 9.64 |

| LSC | 11.98 | 2.09 | - | - | 56.56 | 13.61 | ||||

| NNN | 41.28 | 3.13 | 1772 | 22.59 | 15.04 | 3.12 | 33.42 | 7.76 | 33.37 | 7.76 |

| NSN | 14.99 | 2.58 | - | - | 58.54 | 12.76 | ||||

| ID | Maximum Bending Moment, Mu (kNm) | Resistance Bending Moment, Mn (kNm) | Capacity Ratio of Concrete Beams, Mu/Mn |

|---|---|---|---|

| LSS | 17.07 | 16.31 | 1.05 |

| LSC | 16.97 | 16.13 | 1.05 |

| NSN | 17.56 | 17.01 | 1.03 |

| ID | Experimental, Vc | Estimated Values and Percentage Differences (Estimated/Experimental) | ||||

|---|---|---|---|---|---|---|

| ACI 318 [23,24,32] | BS 8110 [26] | CSA [34] | EC2 [25] | JSCE [35] | ||

| kN | kN (%) | kN (%) | kN (%) | kN (%) | kN (%) | |

| LNS | 16.49 | 11.77 (71.39) | 14.54 (88.14) | 14.54 (88.20) | 14.90 (90.37) | 8.52 (51.68) |

| LNC | 16.11 | 11.48 (71.28) | 14.36 (89.13) | 14.28 (88.66) | 14.96 (92.88) | 8.51 (52.81) |

| NNN | 16.69 | 12.71 (76.14) | 19.43 (116.43) | 21.05 (126.11) | 20.40 (122.26) | 13.50 (80.89) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, S.; Kim, M.O. Effect of Aggregate Type on the Shear Behavior of Reinforced Lightweight Concrete Beams. Appl. Sci. 2024, 14, 5992. https://doi.org/10.3390/app14145992

Cho S, Kim MO. Effect of Aggregate Type on the Shear Behavior of Reinforced Lightweight Concrete Beams. Applied Sciences. 2024; 14(14):5992. https://doi.org/10.3390/app14145992

Chicago/Turabian StyleCho, Sanghwan, and Min Ook Kim. 2024. "Effect of Aggregate Type on the Shear Behavior of Reinforced Lightweight Concrete Beams" Applied Sciences 14, no. 14: 5992. https://doi.org/10.3390/app14145992

APA StyleCho, S., & Kim, M. O. (2024). Effect of Aggregate Type on the Shear Behavior of Reinforced Lightweight Concrete Beams. Applied Sciences, 14(14), 5992. https://doi.org/10.3390/app14145992