Research on Mechanism of Non-Uniform In-Situ Stress Induced Casing Damage Based on Finite Element Analysis

Abstract

1. Introduction

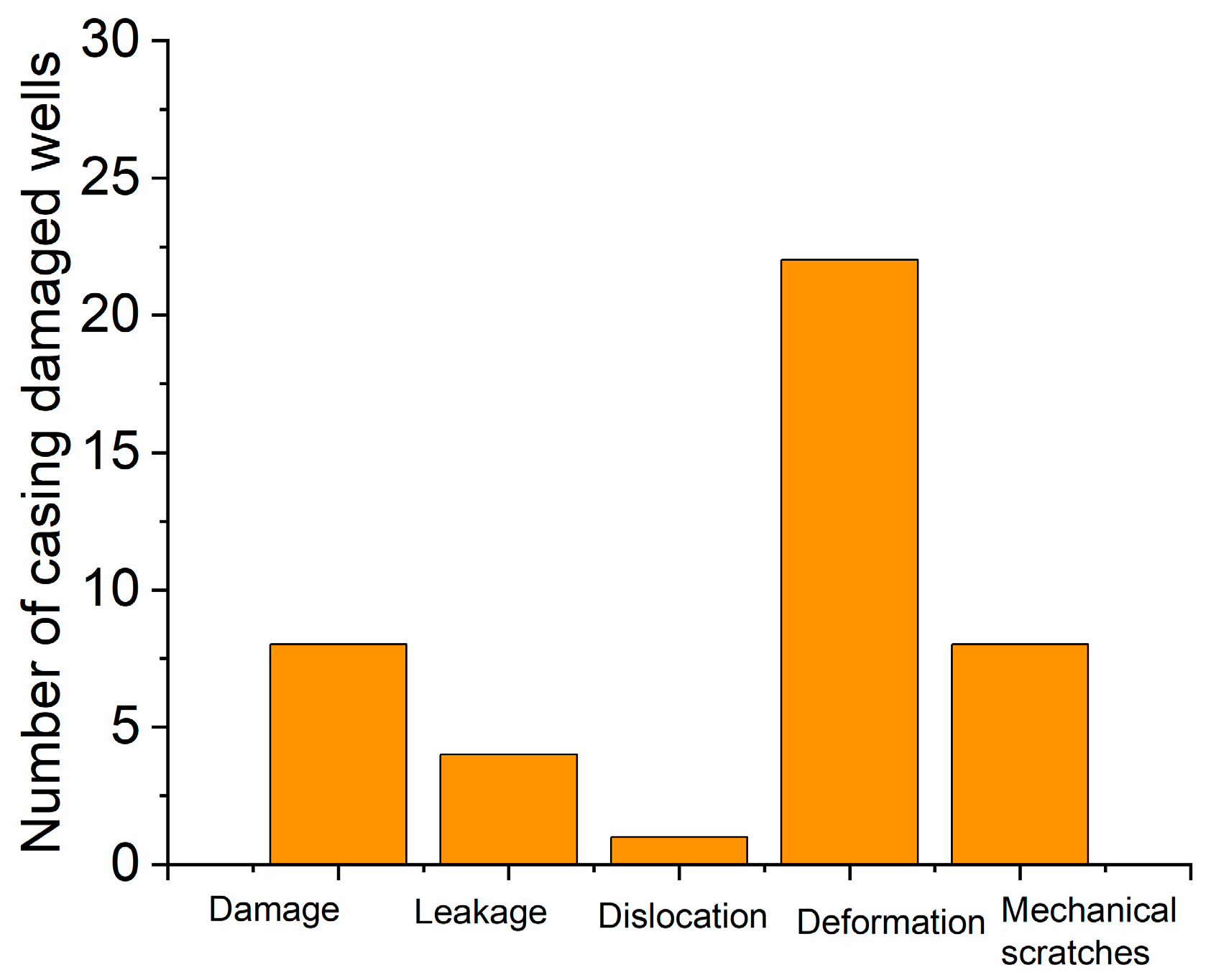

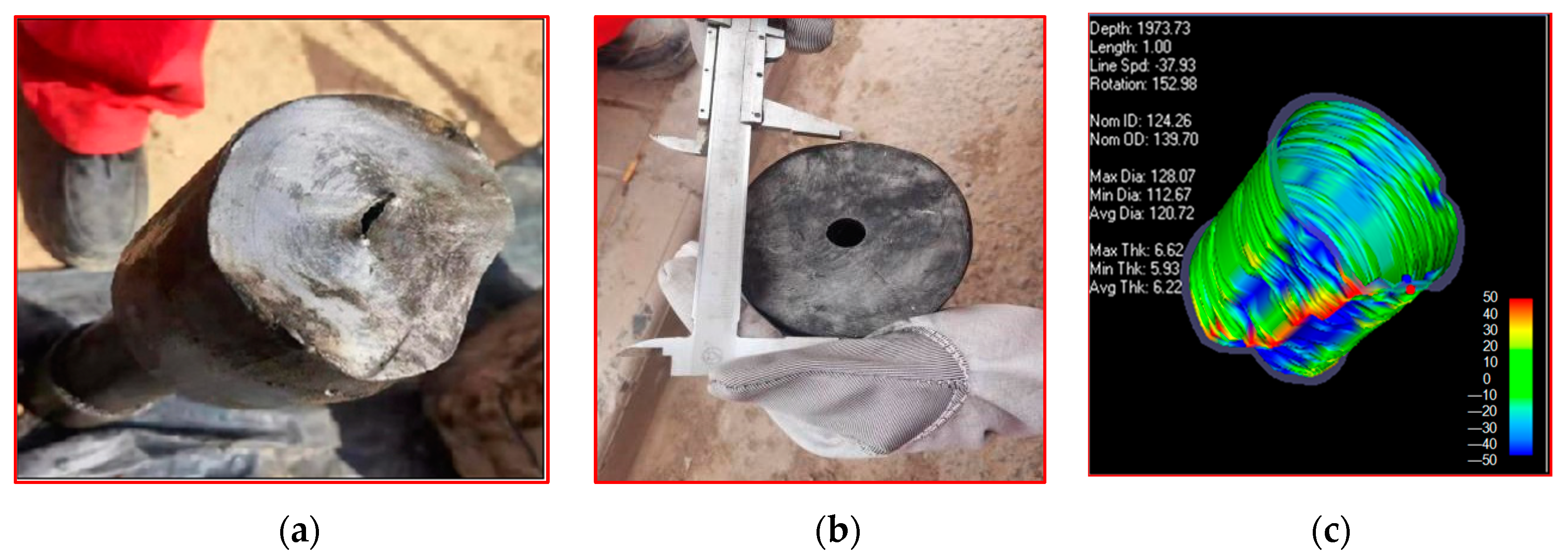

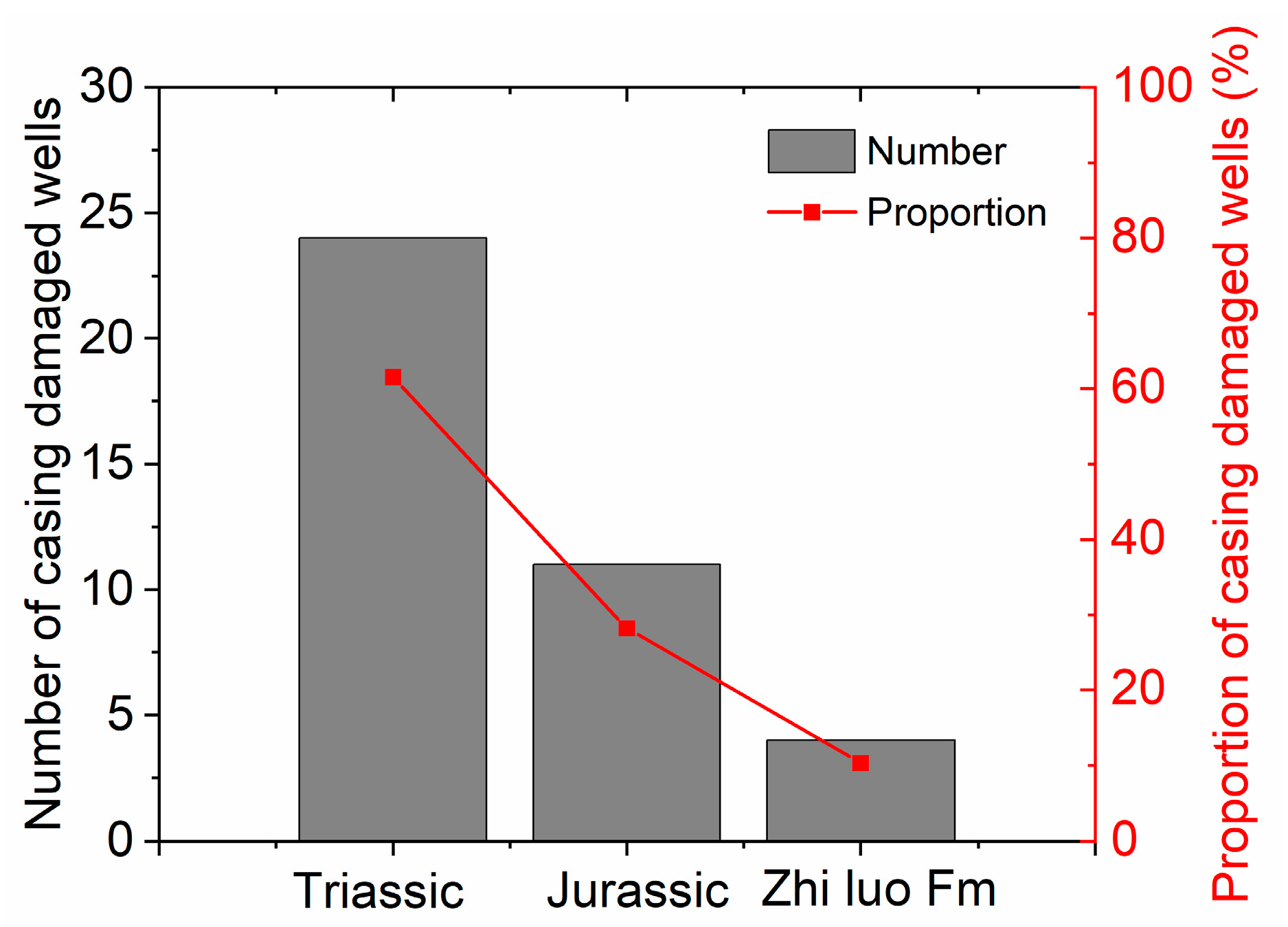

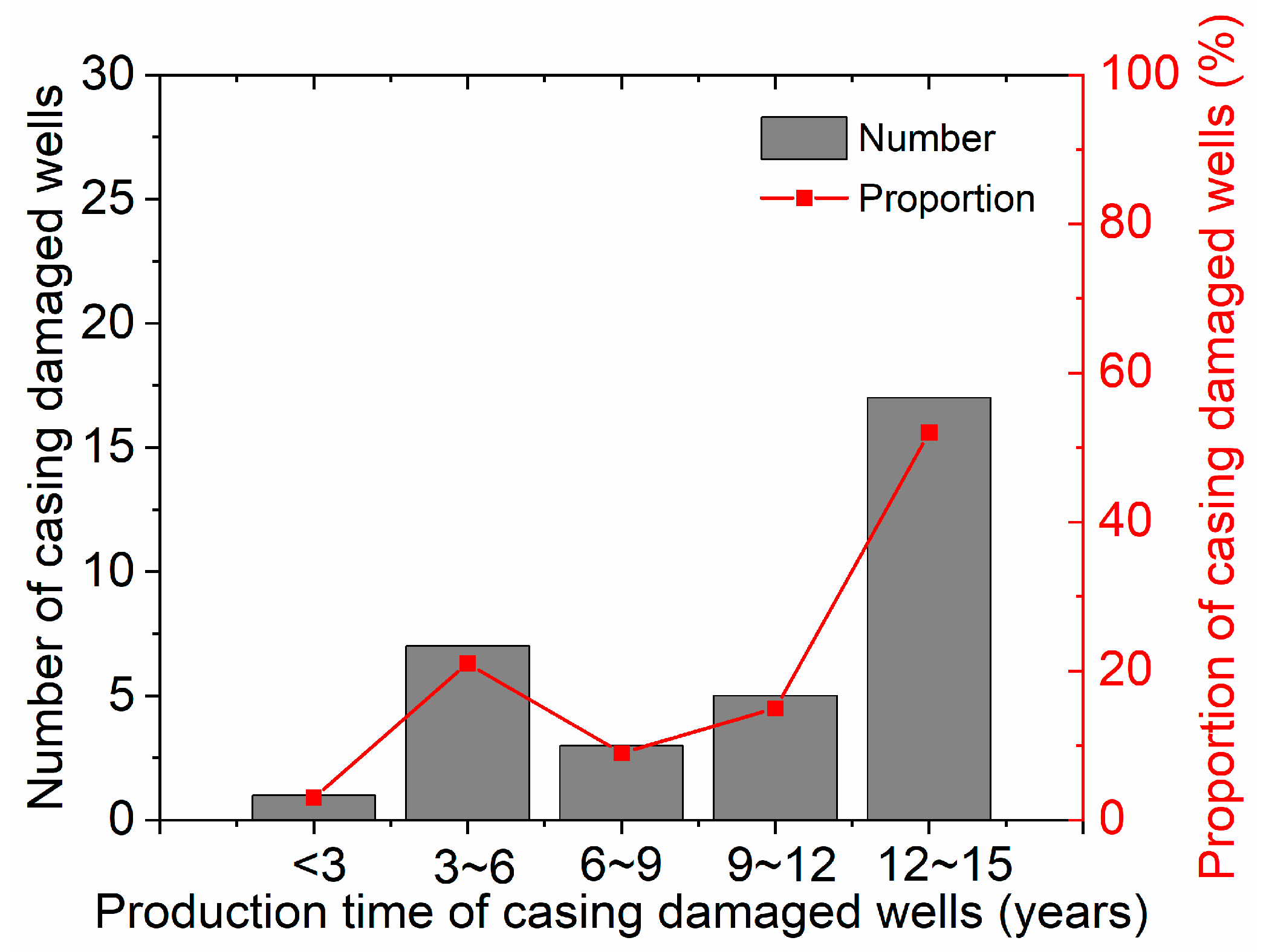

2. Characterization of Casing Damage in the G155 Block

2.1. Block Overview

2.2. Situation of Casing Damage

3. Theoretical Force Analysis of Casing Damaged Wells

3.1. Basic Theory

3.2. Vertical In-Situ Stress Calculation

3.3. Horizontal In-Situ Stress Calculation

3.4. Stress Analysis of Casing Damaged Wells under Uniform In-Situ Stress

3.5. Stress Analysis of Casing Damaged Wells under Non-Uniform In-Situ Stress

4. Finite Element Numerical Simulation of Casing Damage Well

4.1. Finite Element Simulation of Casing Damage Well under Non-Uniform In-Situ Stress

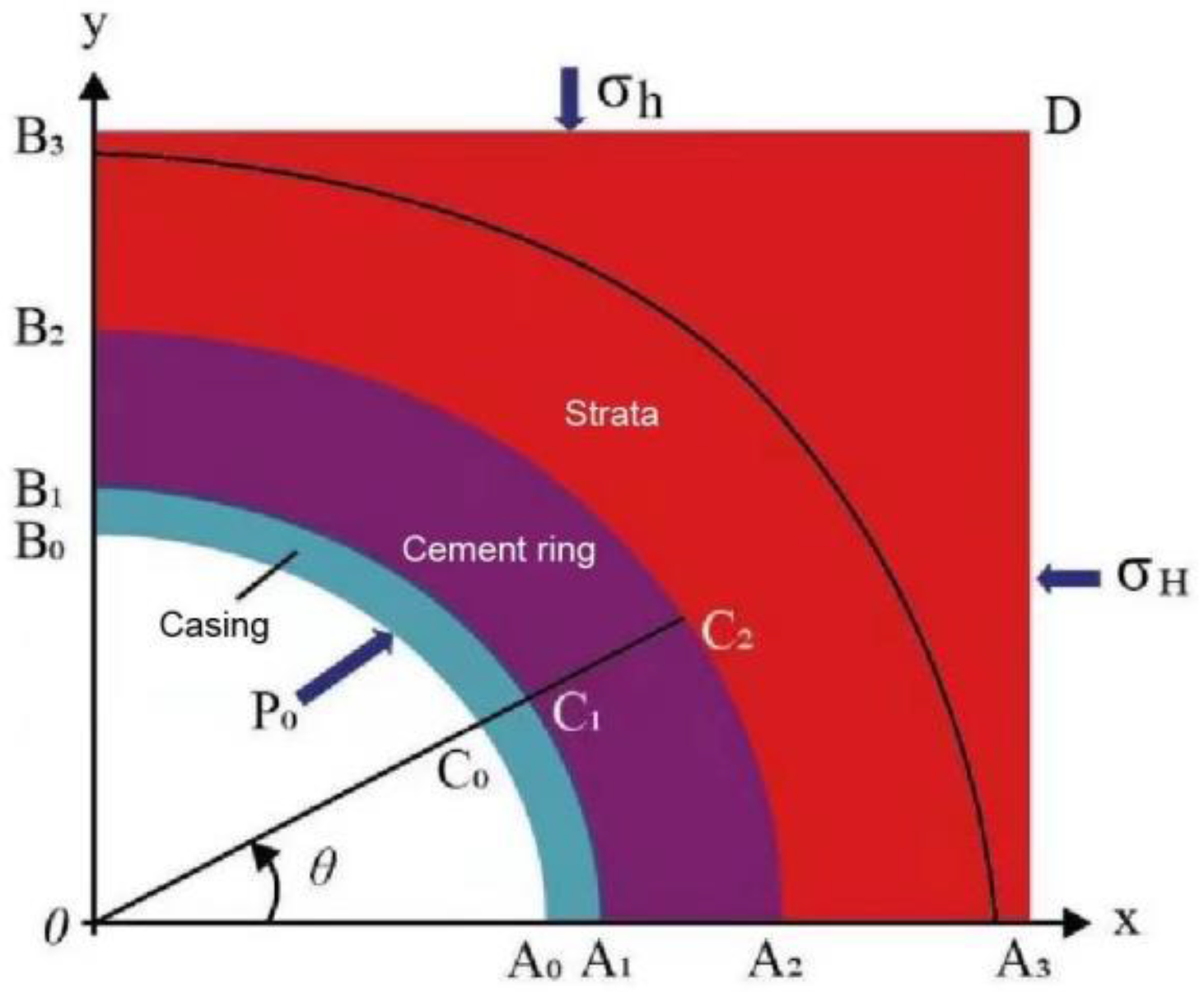

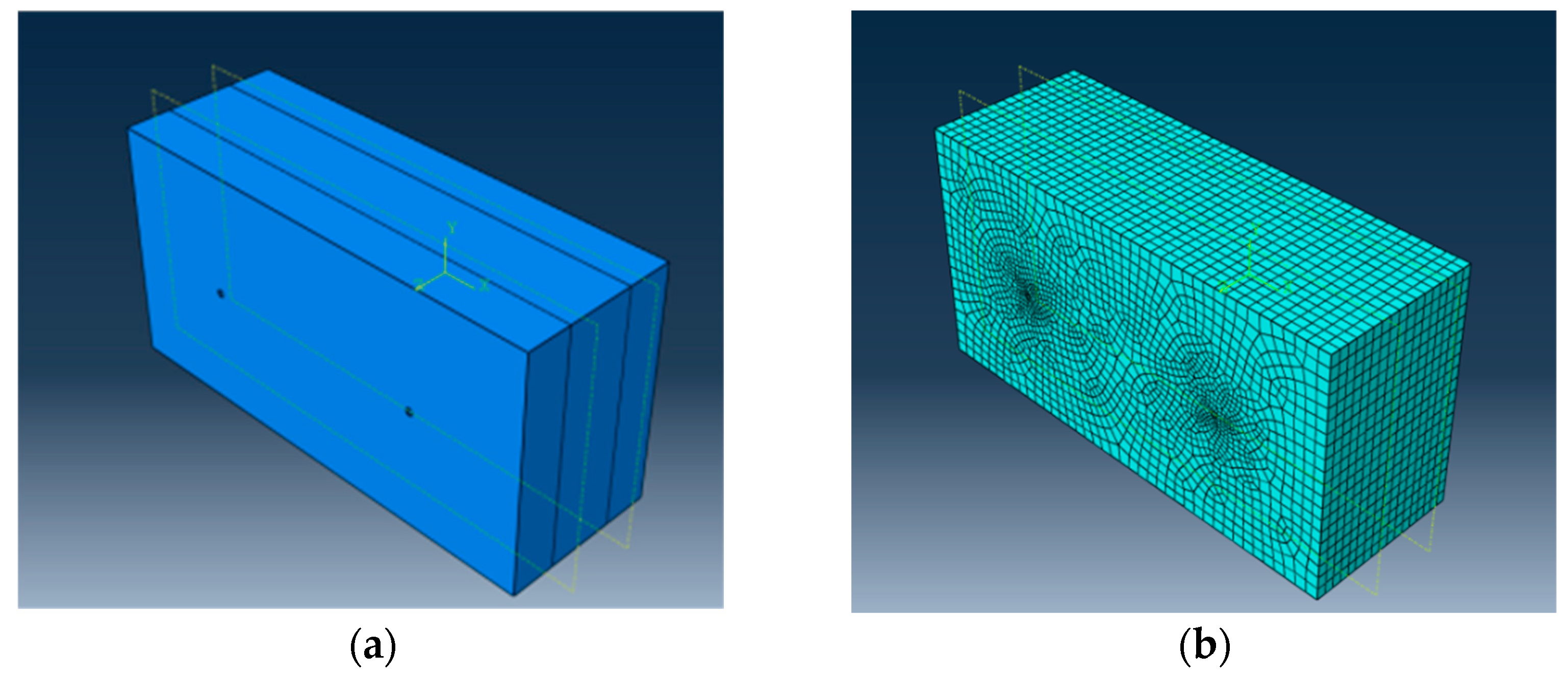

4.1.1. Establishment of a Casing Cement Sheath Formation Combination Model

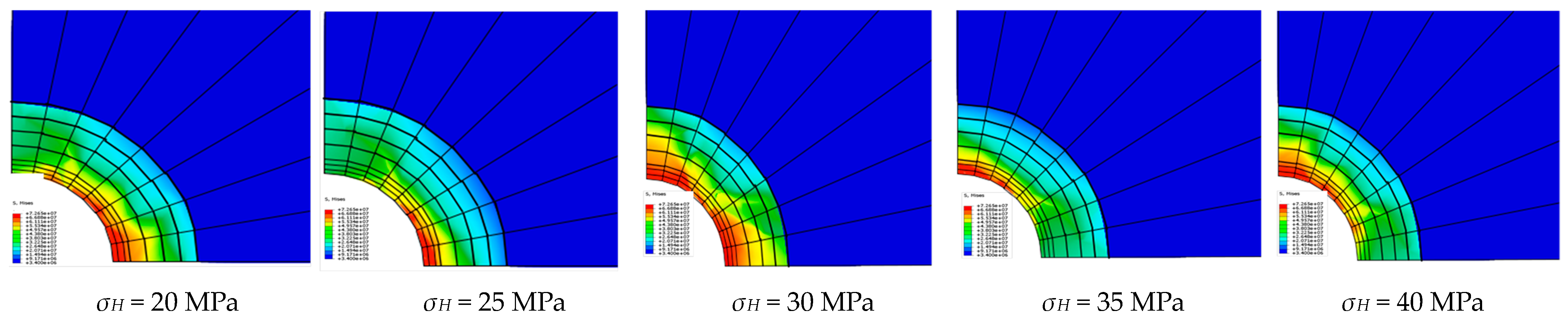

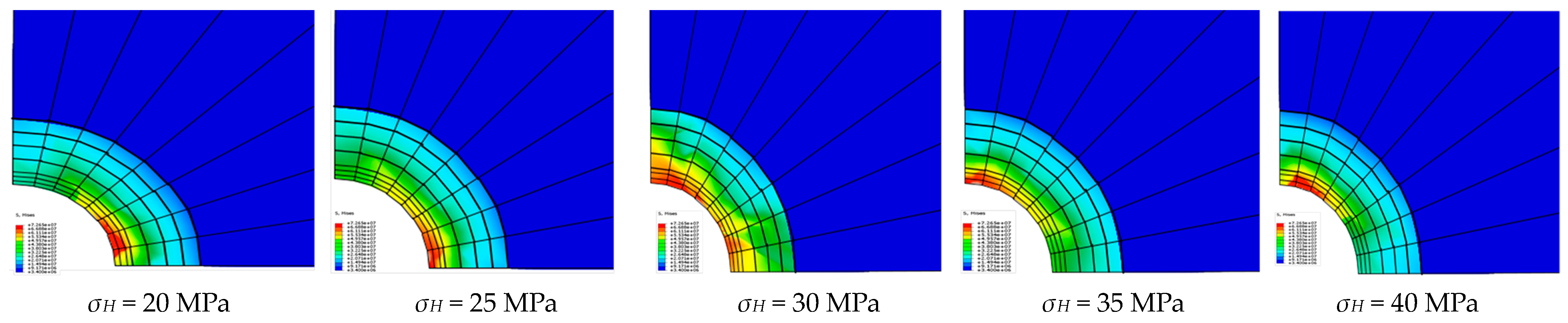

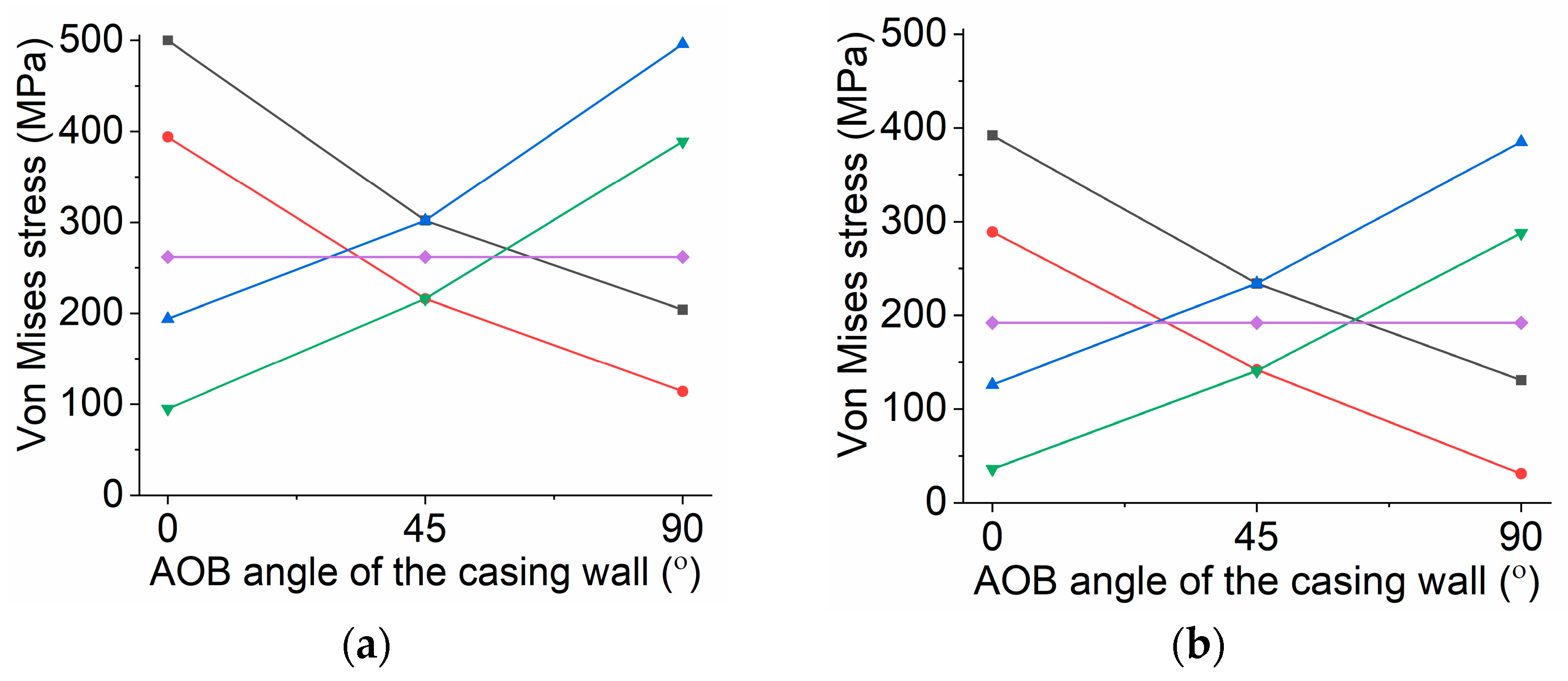

4.1.2. Von Mises Stress Analysis of Casing

4.2. Von Mises Stress Analysis of Casing under Mudstone Creep

4.2.1. Selection of Creep Model

4.2.2. Finite Element Analysis of Casing under Mudstone Creep

- Establishment of finite element model

- 2.

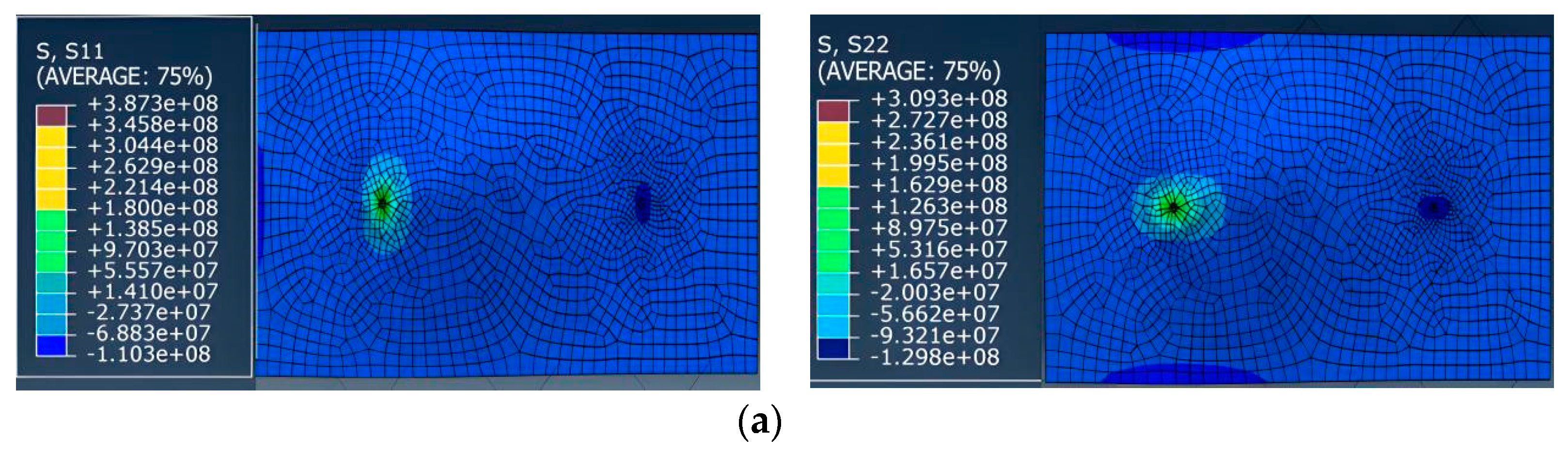

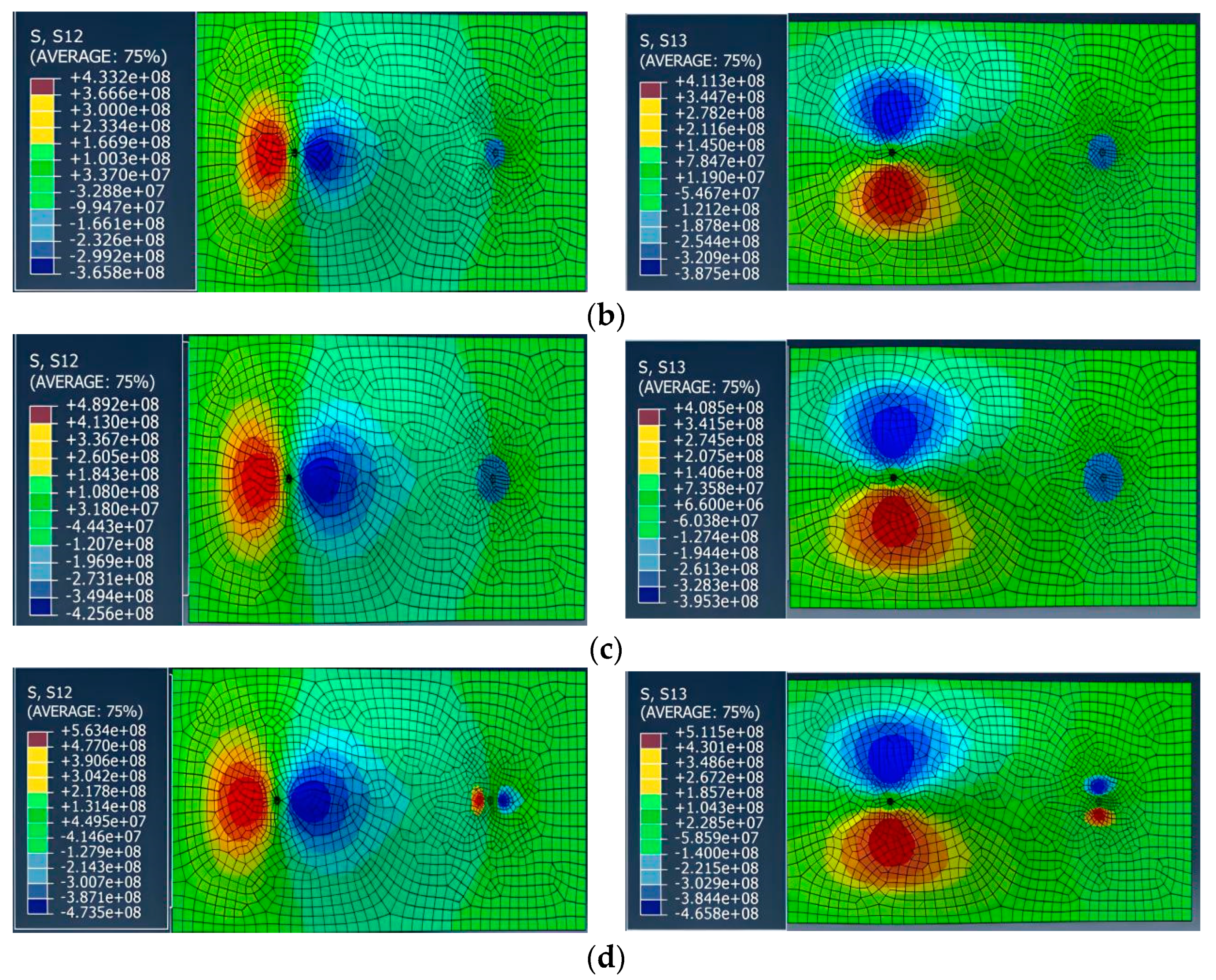

- Normal stress analysis

- 3.

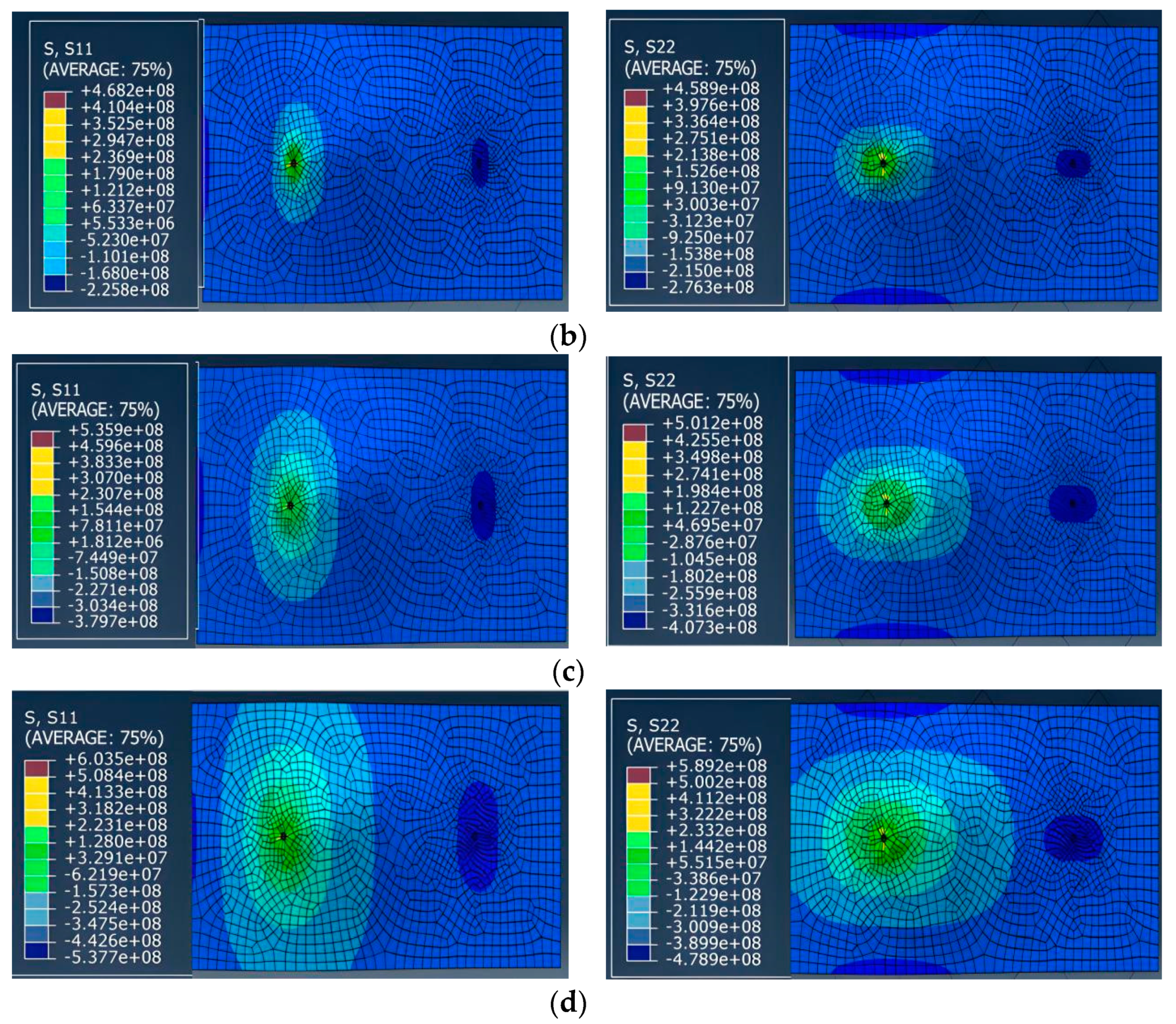

- Shear stress analysis

- 4.

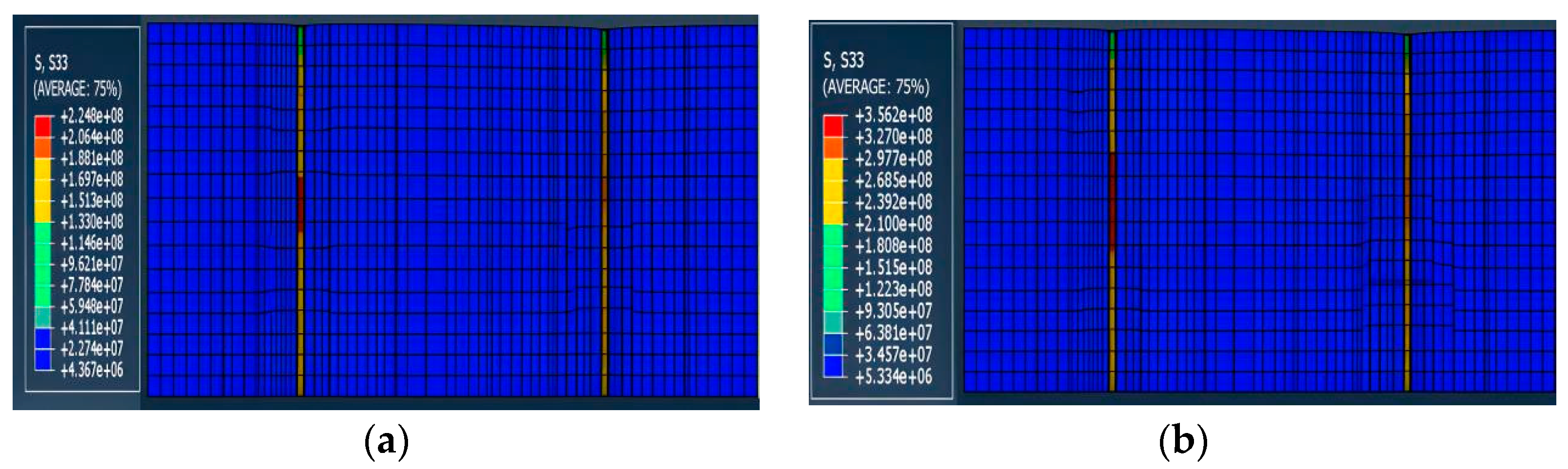

- Vertical stress analysis

- 5.

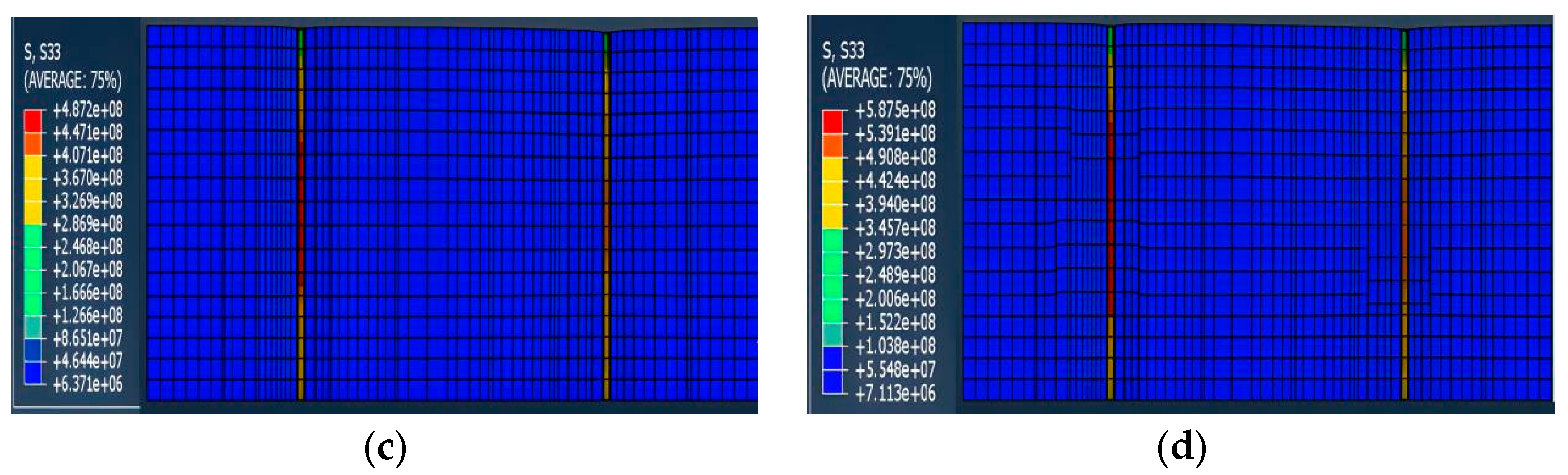

- Von Mises stress analysis

5. Conclusions

- (1)

- Based on the calculation of typical single well fracturing data and the application of the in-situ stress inversion method, the structural stress coefficient of the study area is derived, and the maximum and minimum horizontal in-situ stress calculation formulas are obtained. Theoretical stress analysis is conducted on casing-damaged wells under uniform and non-uniform conditions.

- (2)

- According to the finite element analysis of the casing of X1 and X2 wells under non-uniform in-situ stress conditions at σh = 30 MPa and σH = 20–40 MPa, it can be concluded that the reasons for casing damage in the study area are not only non-uniform in-situ stress but also some other creep additional loads.

- (3)

- Finite element analysis of casing subjected to mudstone creep revealed increased shearing and deformation post-water immersion, causing premature oil well failure over water wells. The equivalent force rose with higher injection production ratios. Ratios above 1.3 led to gradual compression and deformation, exceeding the yield limit, while ratios over 1.6 induced longitudinal stretching. At a ratio of 1.9, shear stress near water wells surpassed the casing’s yield limit, resulting in deformation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, F.; Tang, Q.; Yan, W.; Li, J.; Li, W.; Yang, T.; Lin, L.; Jiang, K.; Wang, K.; Zhang, W. Research on the failure analysis and prediction method of casing deformation under the synergistic effect of sand production and corrosion. Eng. Fail. Anal. 2023, 154, 107706. [Google Scholar] [CrossRef]

- Rodríguez, V.; Guerrero, H.; Alcocer, S.M.; Tapia-Hernández, E. Rehabilitation of heavily damaged beam-column connections with CFRP wrapping and SFRM casing. Soil Dyn. Earthq. Eng. 2021, 145, 106721. [Google Scholar] [CrossRef]

- Kyogoku, T.; Tokimasa, K.; Nakanishi, H.; Okazawa, T. Experimental Study on the Effect of Axial Tension Load on the Collapse Strength of Oilwell Casing. Soc. Pet. Eng. J. 1982, 22, 609–615. [Google Scholar] [CrossRef]

- Lei, W.; Li, Q.; Yang, H.; Wu, T.; Wei, J.; Wang, M. Preferential flow control in heterogeneous porous media by concentration-manipulated rheology of microgel particle suspension. J. Pet. Sci. Eng. 2022, 212, 110275. [Google Scholar] [CrossRef]

- El-Sayed, A.A.H.; Khalaf, F. Resistance of cemented concentric casing strings under nonuniform loading. SPE Drill. Eng. 1992, 7, 59–64. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, Y.; Wang, H.; Yin, H.; Jia, T. Application of numerical simulation in the solid expandable tubular repair for casing damaged wells. Pet. Explor. Dev. 2009, 36, 651–657. [Google Scholar]

- Dusseault, M.B.; Bruno, M.S.; Barrera, J. Casing Shear: Causes, Cases, Cures. SPE Drill. Compl. 2001, 16, 98–107. [Google Scholar] [CrossRef]

- Yan, Y.; Cai, M.; Ma, W.; Zhang, X.; Han, L.; Liu, Y. Research on casing deformation prevention technology based on cementing slurry system optimization. Pet. Sci. 2024, 21, 1231–1240. [Google Scholar] [CrossRef]

- Boade, R.R.; Chin, L.Y.; Siemers, W.T. Forecasting of Ekofisk reservoir compaction and subsidence by numerical simulation. J. Pet. Technol. 1989, 41, 723–728. [Google Scholar] [CrossRef]

- Nordsveen, M.; Nešic, S.; Nyborg, R.; Stangeland, A. A mechanistic model for carbon dioxide corrosion of mild steel in the presence of protective iron carbonate films—Part 1: Theory and Verification. Corrosion 2003, 59, 443–456. [Google Scholar] [CrossRef]

- Kermani, M.B.; Morshed, A. Carbon dioxide corrosion in oil and gas production—A compendium. Corrosion 2003, 59, 659–683. [Google Scholar] [CrossRef]

- Lei, W.; Lu, X.; Liu, F.; Wang, M. Non-monotonic wettability effects on displacement in heterogeneous porous media. J. Fluid Mech. 2022, 942, R5. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, W.; Shu, Z.; Zhao, Q.; Han, L. Failure analysis of casing dropping in shale oil well during large scale volume fracturing. Eng. Fail. Anal. 2020, 118, 104849. [Google Scholar] [CrossRef]

- Yan, W.; Zou, L.; Li, H.; Deng, J.; Ge, H.; Wang, H. Investigation of casing deformation during hydraulic fracturing in high geo-stress shale gas play. J. Pet. Sci. Eng. 2017, 150, 22–29. [Google Scholar] [CrossRef]

- Lian, Z.; Yu, H.; Lin, T.; Guo, J. A study on casing deformation failure during multi-stage hydraulic fracturing for the stimulated reservoir volume of horizontal shale wells. J. Nat. Gas Sci. Eng. 2015, 23, 538–546. [Google Scholar] [CrossRef]

- Peng, S.; Fu, J.; Zhang, J. Borehole casing failure analysis in unconsolidated formations: A case study. J. Pet. Sci. Eng. 2007, 59, 226–238. [Google Scholar] [CrossRef]

- Gholami, R.; Rasouli, V.; Aadnoy, B.; Mohammadnejad, M. Geomechanical and numerical studies of casing damages in a reservoir with solid production. Rock Mech. Rock Eng. 2016, 49, 1441–1460. [Google Scholar] [CrossRef]

- Ispas, I.; Bray, A.R.; Palmer, I.D.; Higgs, N.G. Prediction and evaluation of sanding and casing deformation in a GOM-Shelf well. J. Pet. Technol. 2005, 57, 75–78. [Google Scholar] [CrossRef]

- Wagg, B.; Xie, J.; Solanki, S.; Arndt, S. Evaluating casing deformation mechanisms in primary heavy oil production. In Proceedings of the 1999 SPE International Thermal Operations and Heavy Oil Symposium, Bakersfield, CA, USA, 17–19 March 1999. [Google Scholar]

- Yin, F.; Han, L.; Yang, S.; Deng, Y.; He, Y.; Wu, X. Casing deformation from fracture slip in hydraulic fracturing. J. Pet. Sci. Eng. 2018, 166, 235–241. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, Z.; Chen, J.; Fan, J.; Jiang, D.; Daemen, J.; Li, Y. Physical simulation of construction and control of two butted-well horizontal cavern energy storage using large molded rock salt specimens. Energy 2019, 185, 682–694. [Google Scholar] [CrossRef]

- Cornet, J.S.; Dabrowski, M.; Schmid, D.W. Long term creep closure of salt cavities. Int. J. Rock Mech. Min. Sci. 2018, 103, 96–106. [Google Scholar] [CrossRef]

- Furui, K.; Fuh, G.F.F.; Morita, N. Casing- and screen-failure analysis in highly compacting sandstone fields. SPE Drill. Compl. 2012, 27, 241–252. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, C.; Kannan, L.G.; Rao, K.S.; Ayothiraman, R. Estimation of creep parameters of rock salt from uniaxial compression tests. Int. J. Rock Mech. Min. Sci. 2018, 107, 243–248. [Google Scholar] [CrossRef]

- Ewy, R.T. Wellbore-Stability Predictions by use of a modified lade criterion. SSPE Drill. Compl. 1999, 14, 85–91. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, P. A calculation method for the allowable fracturing injection pressure of preventing casing deformation. Nat. Gas Ind. B 2019, 6, 384–393. [Google Scholar] [CrossRef]

- Ciarlet, P.G. The Finite Element Method for Elliptic Problems; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2002. [Google Scholar]

- Dell’Accio, F.; Di Tommaso, F.; Guessab, A.; Nudo, F. Enrichment strategies for the simplicial linear finite elements. Appl. Math. Comput. 2023, 451, 128023. [Google Scholar] [CrossRef]

- Xi, Y.; Li, J.; Liu, G.; Tao, Q.; Lian, W. A new numerical investigation of cement sheath integrity during multistage hydraulic fracturing shale gas wells. J. Nat. Gas Sci. Eng. 2018, 49, 331–341. [Google Scholar]

- Xi, Y.; Li, J.; Liu, G.; Cha, C.; Fu, Y. Numerical investigation for different casing deformation reasons in Weiyuan-Changning shale gas field during multistage hydraulic fracturing. J. Nat. Gas Sci. Eng. 2018, 163, 691–702. [Google Scholar] [CrossRef]

- Deng, K.; Xie, P.; Yue, Y.; Zeng, D.; Li, Q.; Lin, Y. Study on the effect of interface failure between casing and cement sheath on casing stress under non-uniform in-situ stress. Appl. Math. Model. 2021, 92, 632–652. [Google Scholar]

- Mohammadnejad, T.; Khoei, A.R. An extended finite element method for hydraulic fracture propagation in deformable porous media with the cohesive crack model. Finite Elem. Anal. Des. 2013, 73, 77–95. [Google Scholar] [CrossRef]

- Zhang, Z.; Shao, L.; Zhang, Q.; Zhang, C.; Li, J.; Zeng, D.; Zhong, X.; Hu, J.; Hou, D.; Shi, T. Environmentally assisted cracking performance research on casing for sour gas wells. J. Pet. Sci. Eng. 2017, 158, 729–738. [Google Scholar]

- Meng, H.; Ge, H.; Yao, Y.; Shen, Y.; Wang, J.; Bai, J.; Zhang, Z. A new insight into casing shear failure induced by natural fracture and artificial fracture slip. Eng. Fail. Anal. 2022, 137, 106287. [Google Scholar] [CrossRef]

- Tong, K.; Zhao, J.; Liu, Q.; Zhu, B.; Jin, Q.; Qu, T.; Liu, Q.; Cong, S. Analysis and investigation of the leakage failure of a casing used in a shale gas well. Eng. Fail. Anal. 2022, 131, 105891. [Google Scholar] [CrossRef]

| Media Type | Elastic Modulus, E (104 MPa) | Poisson Ratio, μ (-) | Density, ρ (g/cm3) | Cohesion, τ (MPa) | Internal Friction Angle, φ (°) |

|---|---|---|---|---|---|

| Casing | 21.2 | 0.30 | 7.8 | / | / |

| Cement sheath | 3.2 | 0.23 | 2.4 | 9 | 24 |

| Sandstone | 1.32 | 0.25 | 2.2 | 10 | 28 |

| Media Type | Density (g/cm3) | Elastic Modulus (104 Mpa) | Poisson Ratio (-) |

|---|---|---|---|

| Casing | 7.8 | 21.2 | 0.30 |

| Cement sheath | 2.4 | 3.2 | 0.23 |

| Sandstone | 2.2 | 1.32 | 0.25 |

| Mudstone | 2.5 | 0.21 | 0.24 |

| Producing Pressure Difference (MPa) | Injection Pressure (MPa) | Injection-Production Ratio |

|---|---|---|

| 10 | 15.5 | 1.0 |

| 10 | 15.5 | 1.3 |

| 10 | 15.5 | 1.6 |

| 10 | 15.5 | 1.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.; Li, M.; Liu, N.; Zhang, T.; Su, J. Research on Mechanism of Non-Uniform In-Situ Stress Induced Casing Damage Based on Finite Element Analysis. Appl. Sci. 2024, 14, 5987. https://doi.org/10.3390/app14145987

Wu T, Li M, Liu N, Zhang T, Su J. Research on Mechanism of Non-Uniform In-Situ Stress Induced Casing Damage Based on Finite Element Analysis. Applied Sciences. 2024; 14(14):5987. https://doi.org/10.3390/app14145987

Chicago/Turabian StyleWu, Tianjiang, Mei Li, Nana Liu, Tao Zhang, and Junwei Su. 2024. "Research on Mechanism of Non-Uniform In-Situ Stress Induced Casing Damage Based on Finite Element Analysis" Applied Sciences 14, no. 14: 5987. https://doi.org/10.3390/app14145987

APA StyleWu, T., Li, M., Liu, N., Zhang, T., & Su, J. (2024). Research on Mechanism of Non-Uniform In-Situ Stress Induced Casing Damage Based on Finite Element Analysis. Applied Sciences, 14(14), 5987. https://doi.org/10.3390/app14145987