The Effect of the Temperature–Humidity Coupling Cycle on the Performance of Styrene Butadiene Styrene Polymer-Modified Asphalt Mastic

Abstract

1. Introduction

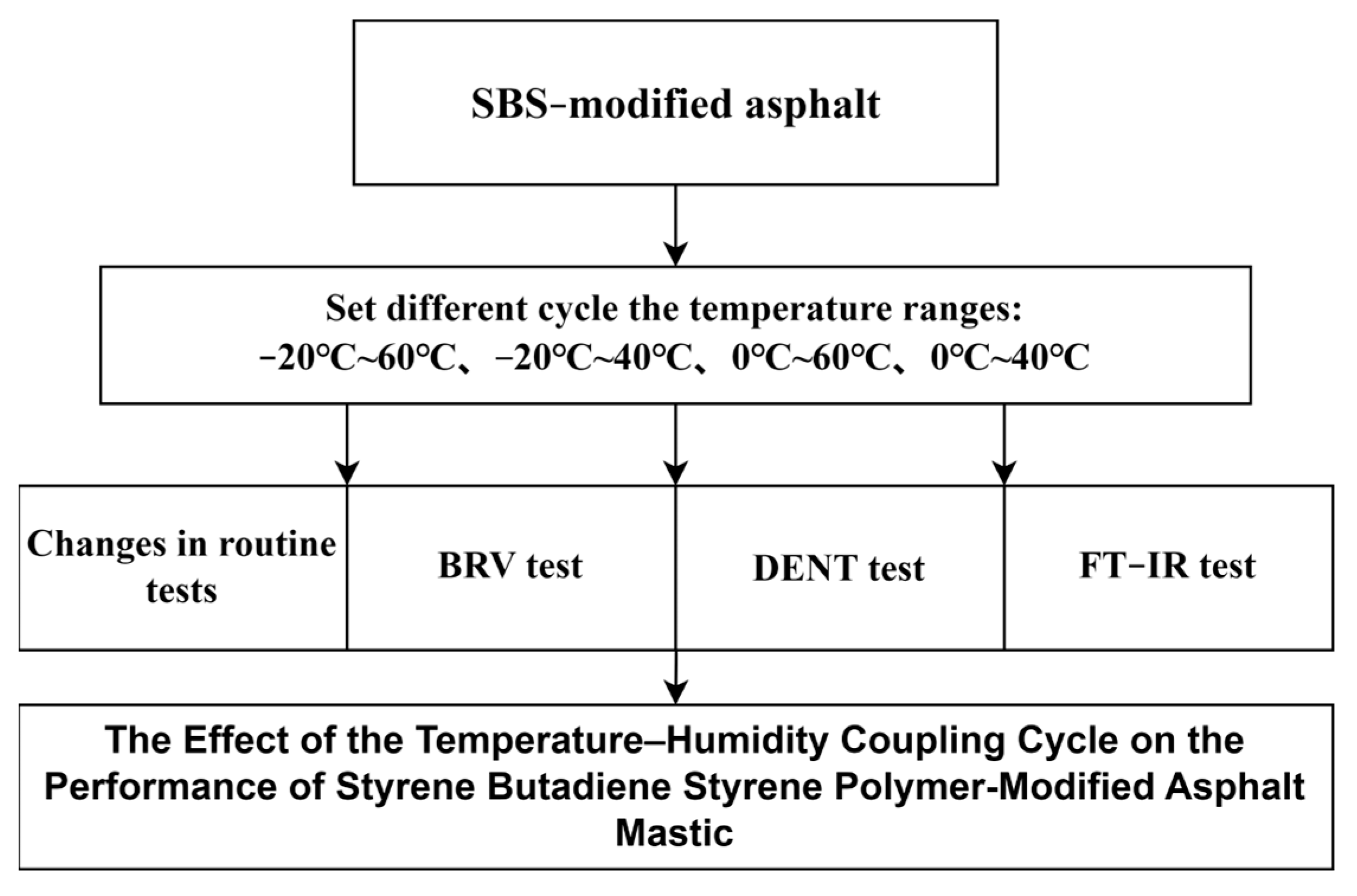

2. Materials and Methods

2.1. Raw Materials

2.2. Asphalt Mastic Sample Preparation

2.3. Temperature and Humidity Coupling Cycle Test

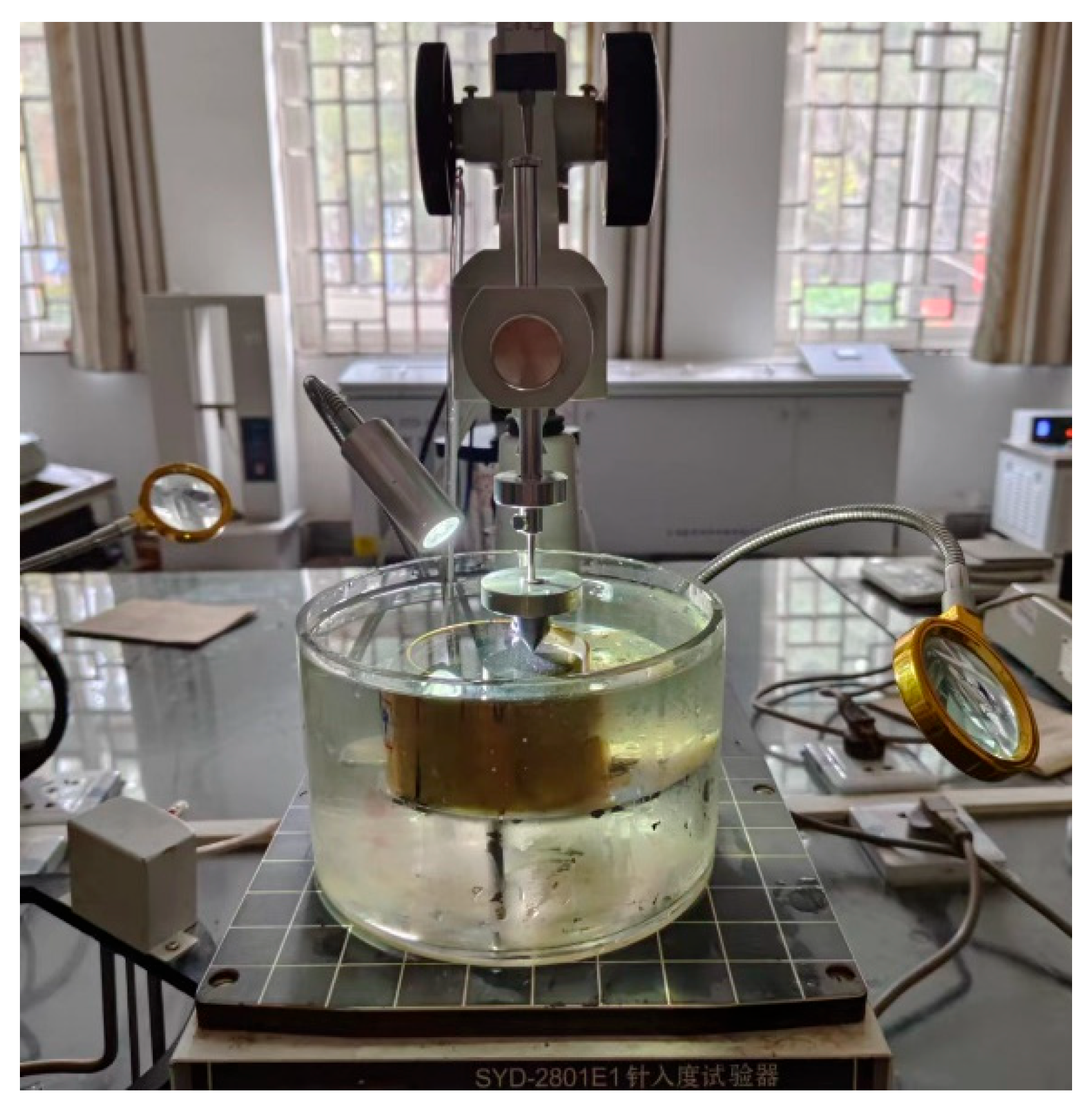

2.4. General Tests

2.5. Brinell’s Rotational Viscosity

2.6. Fourier Infrared Spectroscopy Test

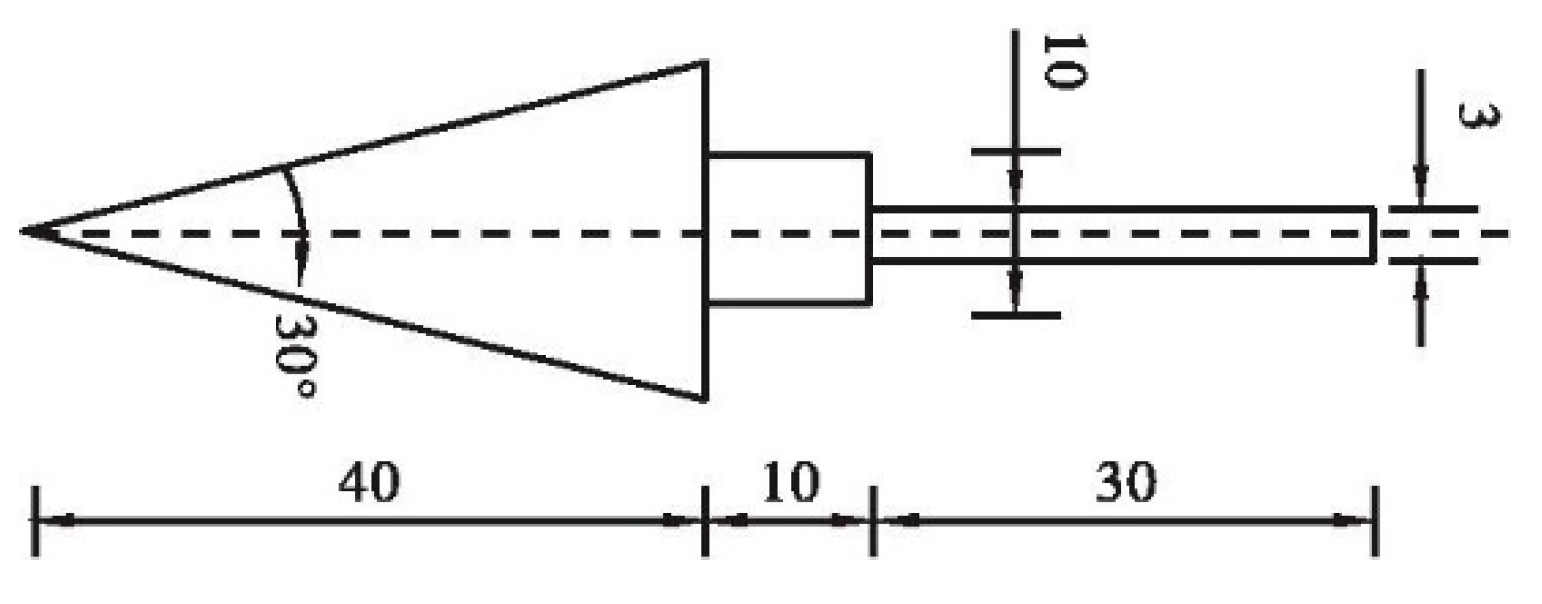

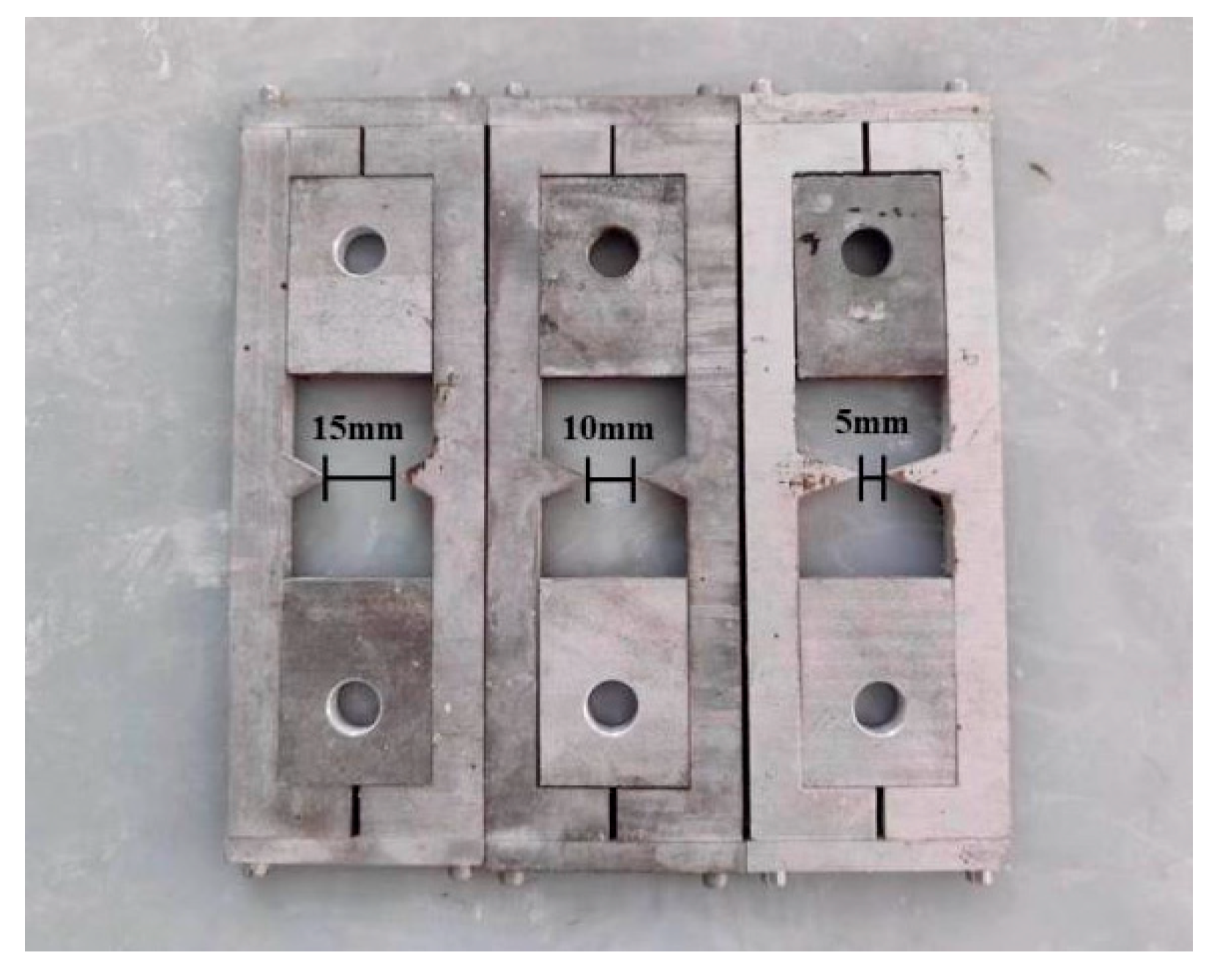

2.7. Double-Edge-Notched Tension Testing (DENT)

3. Analysis of Test Results

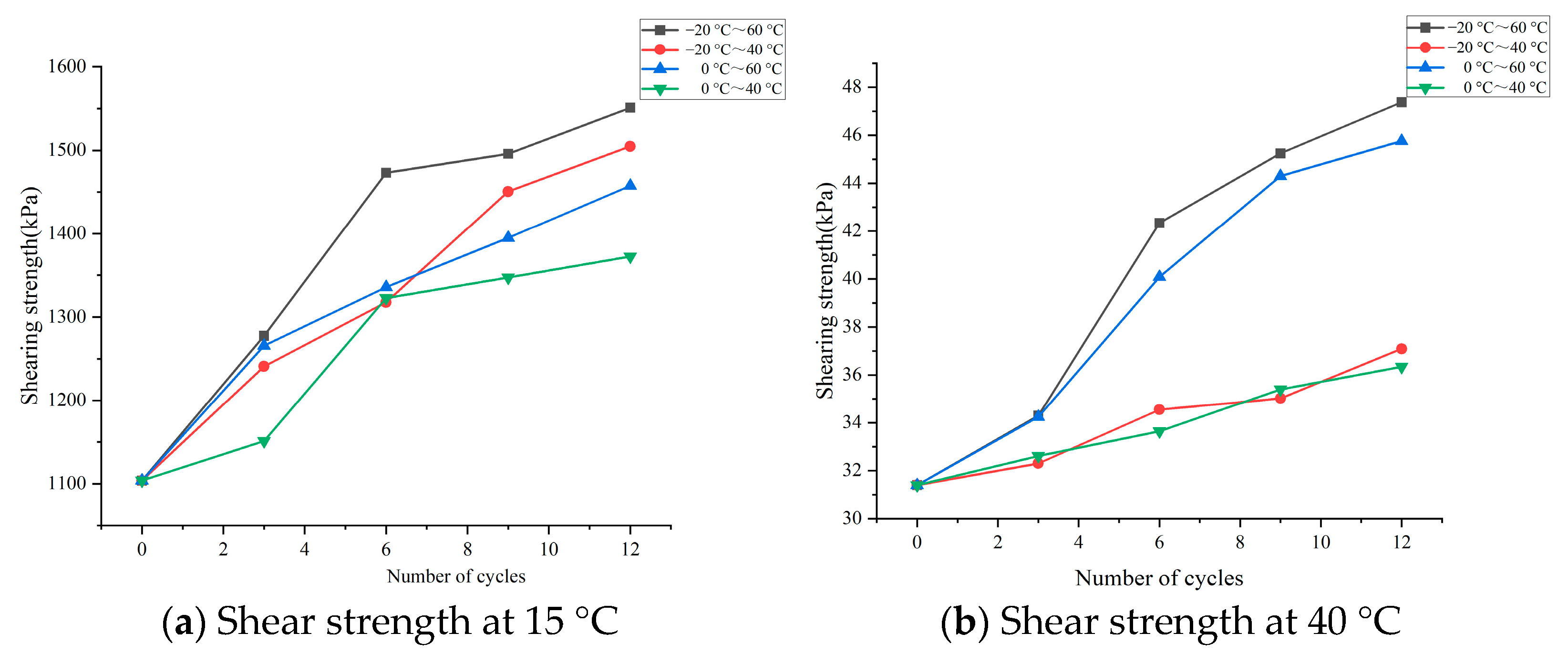

3.1. Conventional Test

3.1.1. Penetration

3.1.2. Softening Point

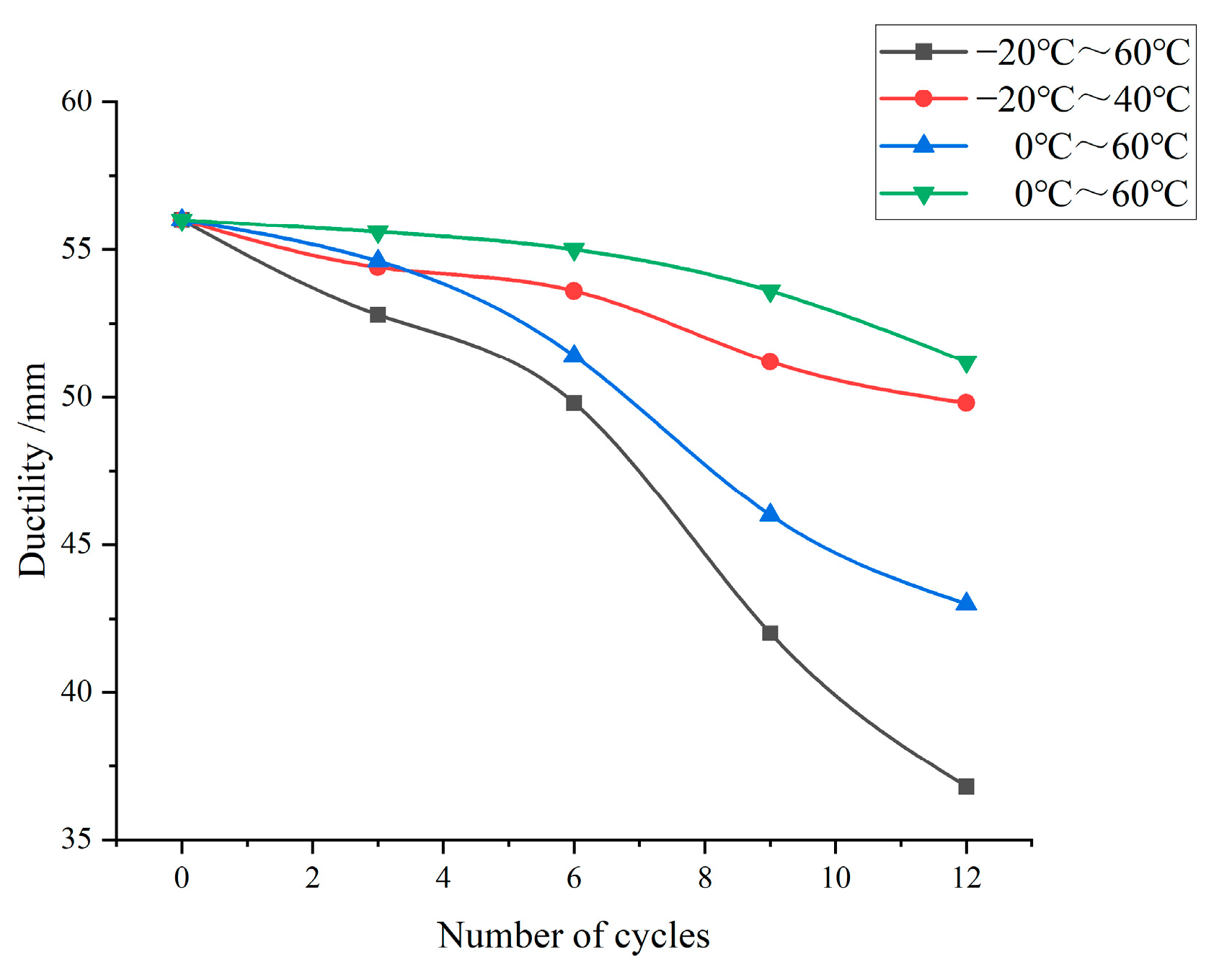

3.1.3. Ductility

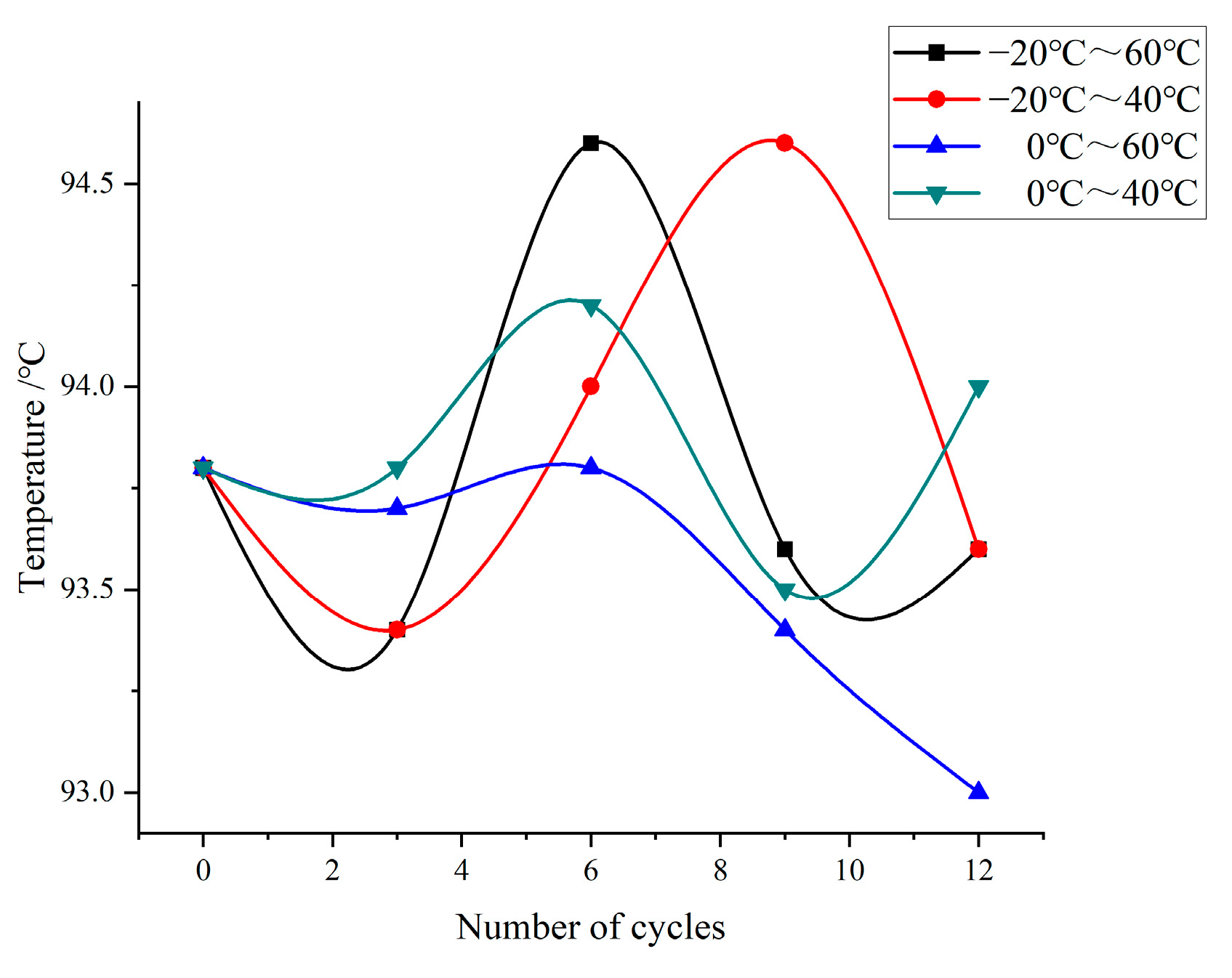

3.2. Bostwick Rotary Viscosity Test

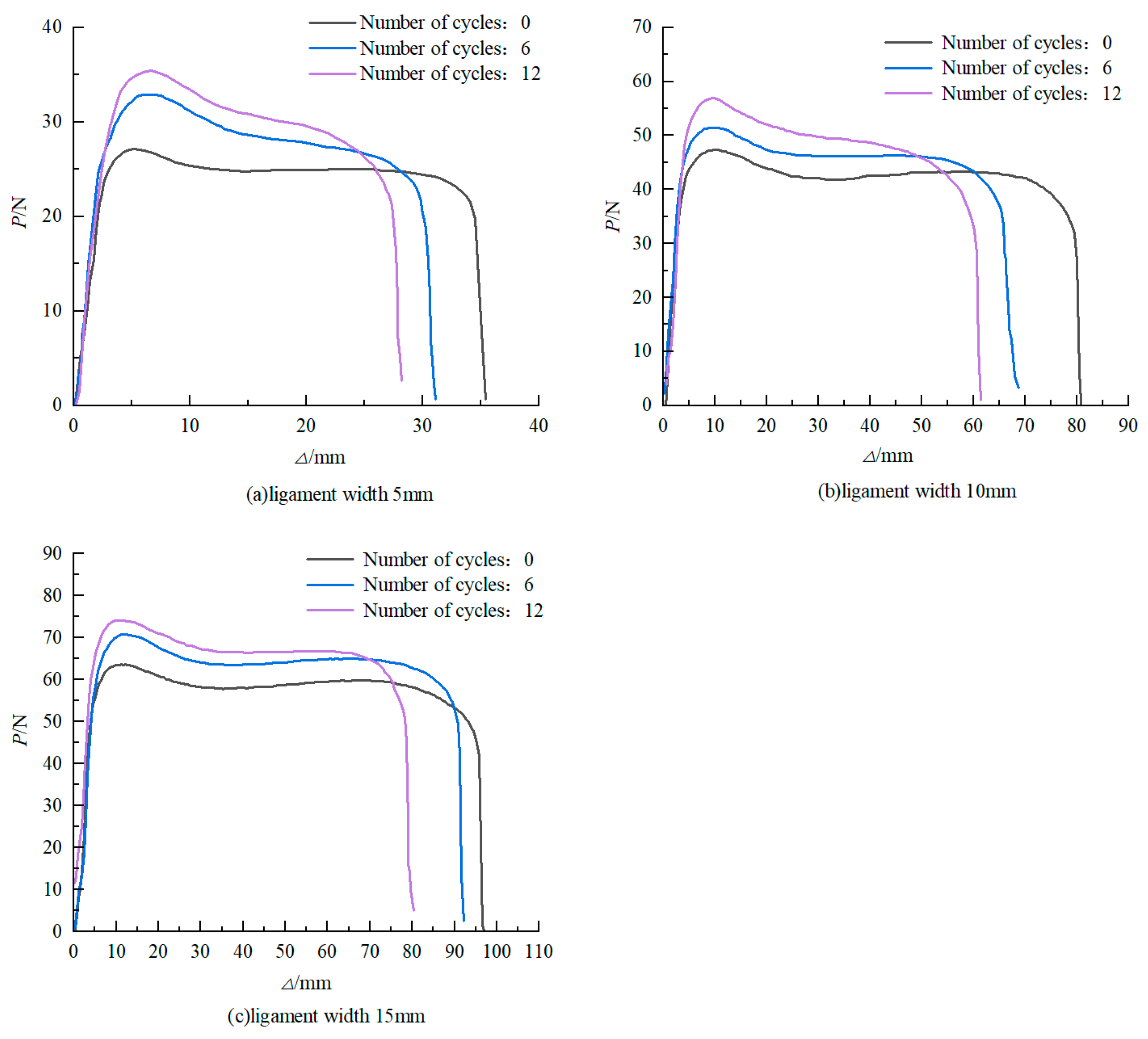

3.3. The Force–Displacement Curves for SBS-Modified Asphalt Mastic for Different Numbers of Cycles

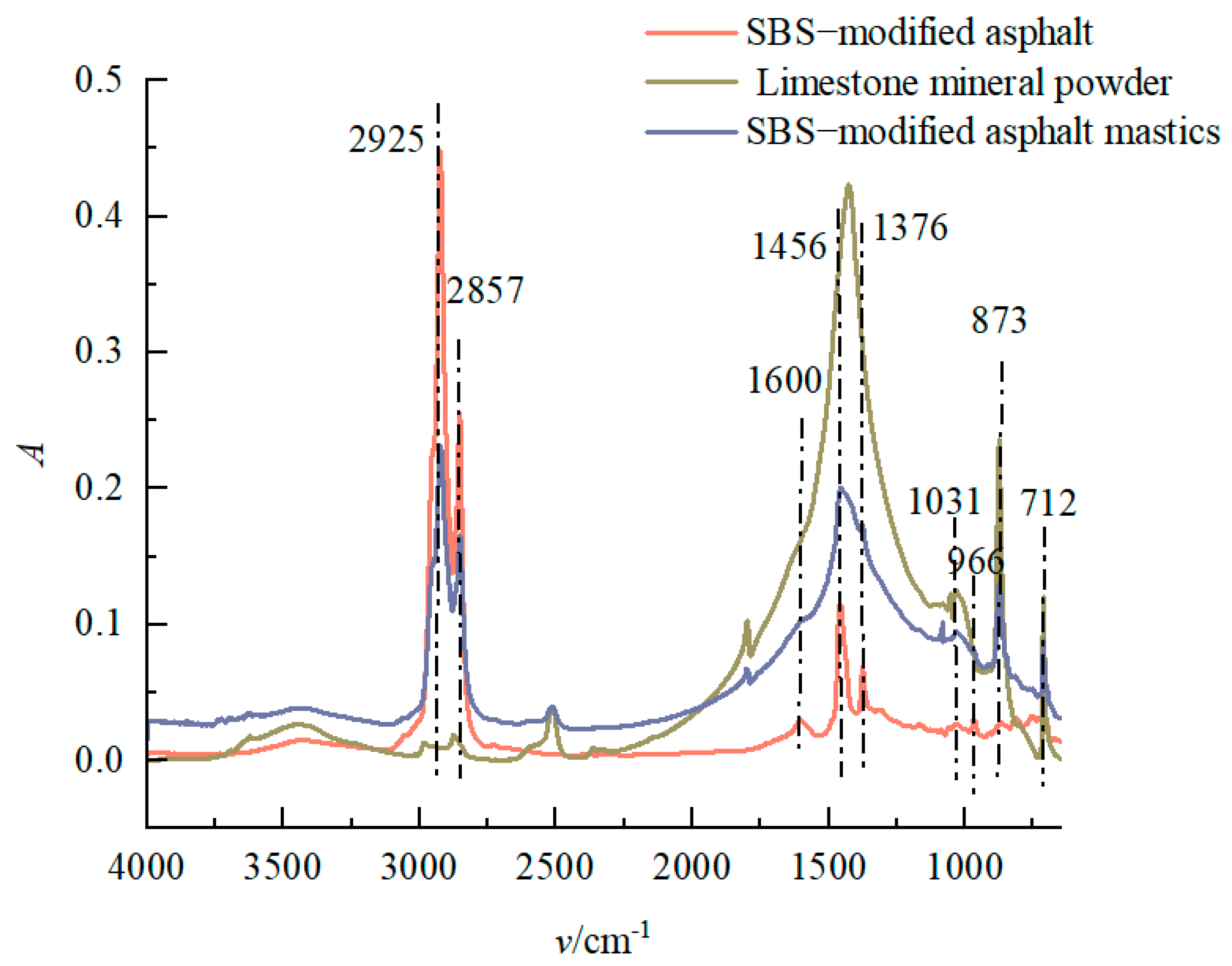

3.4. Changes in Chemical Composition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, D.; Zheng, Y.; Yuan, G.; Guo, H.; Zhou, Q.; Qian, G.; Liang, B. Comparative analysis of rheological and microscopic performance of SBS modified asphalt based on field aging and laboratory aging. Fuel 2023, 352, 128933. [Google Scholar] [CrossRef]

- Wang, F.; Xiao, Y.; Cui, P.; Lin, J.; Li, M.; Chen, Z. Correlation of asphalt performance indicators and aging degrees: A review. Constr. Build. Mater. 2020, 250, 118824. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, J.; Wang, T.; Xu, S.; Hu, C.; Duan, W. Evaluation of ultraviolet aging resistance of bitumen modified with isobutyltriethoxysilane surface organic grafted LDH. Constr. Build. Mater. 2020, 241, 118016. [Google Scholar] [CrossRef]

- Chen, M.; Geng, J.; Chen, H.; Luo, M. Effect of water aging on the fatigue performance of asphalt binders using the linear amplitude sweep. Constr. Build. Mater. 2021, 304, 124679. [Google Scholar] [CrossRef]

- Gong, Y.; Xu, J.; Chang, R.; Yan, E.-H. Effect of water diffusion and thermal coupling condition on SBS modified asphalts’ surface micro properties. Constr. Build. Mater. 2020, 273 (Suppl. S1), 121758. [Google Scholar] [CrossRef]

- Wei, C.; Duan, H.; Zhang, H.; Chen, Z. Influence of SBS modifier on aging behaviors of SBS-modified asphalt. J. Mater. Civ. Eng. 2019, 31, 04019184. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Zaumanis, M.; Mazza, E.; Partl, M.N.; Poulikakos, L.D. Effect of ageing on the mechanical and chemical properties of mastic from RAP treated with bio-based rejuvenators. Compos. Part B Eng. 2018, 141, 174–181. [Google Scholar] [CrossRef]

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci. 2015, 224, 72–112. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Gao, J.; You, Z.; Yang, X. High temperature performance of SBS modified bio-asphalt. Constr. Build. Mater. 2017, 144, 99–105. [Google Scholar] [CrossRef]

- Xiao, Y.; Chang, X.; Yan, B.; Zhang, X.; Yunusa, M.; Yu, R.; Chen, Z. SBS morphology characteristics in asphalt mastic and their relation with viscoelastic properties. Constr. Build. Mater. 2021, 301, 124292. [Google Scholar] [CrossRef]

- Zhou, L.; Huang, W.; Sun, L.; Lv, Q.; Lin, P.; Zhang, X.; Liu, L. Analysis of quantification and mechanism of SBS modifier in SBS-modified asphalt. J. Mater. Civ. Eng. 2021, 33, 04021158. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.; Yang, X. Low-temperature performance of SBS modified asphalt mixture in high altitude and cold regions. Int. J. Pavement Res. Technol. 2019, 12, 33–42. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.; You, Z.; Gao, J.; Irfan, M. Performance test on Styrene-Butadiene-Styrene (SBS) modified asphalt based on the different evaluation methods. Appl. Sci. 2019, 9, 467. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, H.; Zhang, D.; Chen, Z. Influence of base asphalt and SBS modifier on the weathering aging behaviors of SBS modified asphalt. J. Mater. Civ. Eng. 2018, 30, 04017306. [Google Scholar] [CrossRef]

- Lopes, M.; Zhao, D.; Chailleux, E.; Kane, M.; Gabet, T.; Petiteau, C.; Soares, J. Characterisation of ageing processes on the asphalt mixture surface. Road Mater. Pavement Des. 2014, 15, 477–487. [Google Scholar] [CrossRef]

- Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Understanding the bitumen ageing phenomenon: A review. Constr. Build. Mater. 2018, 192, 593–609. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, P. Effect of polymer modification on the ageing properties of asphalt mastics: Chemical and morphological investigation. Constr. Build. Mater. 2019, 205, 633–641. [Google Scholar] [CrossRef]

- Ding, Y.; Li, D.; Zhang, H.; Deng, M.; Mao, X.; Cao, X. Investigation of aging behavior of asphalt under multiple environmental conditions. J. Mater. Civ. Eng. 2022, 34, 04021419. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, H.; Wang, W.; Liang, J. Rheological evolution mechanisms of asphalt binder and mastic under freeze-thaw cycles. Constr. Build. Mater. 2023, 372, 130780. [Google Scholar] [CrossRef]

- Fernández-Gómez, W.D.; Rondón Quintana, H.; Reyes Lizcano, F. A review of asphalt and asphalt mixture aging: Una revisión. Ing. E Investig. 2013, 33, 5–12. [Google Scholar] [CrossRef]

- Sulyman, M.; Sienkiewicz, M.; Haponiuk, J. Asphalt pavement material improvement: A review. Int. J. Environ. Sci. Dev. 2014, 5, 444. [Google Scholar] [CrossRef]

- JTG F40-2004; Highway Science Research Institute of the Ministry of Transportation Technical Specification for Construction of Asphalt Pavement on Highways. People’s Transportation Press: Beijing, China, 2009.

- JTG E42-2005; Unit: Highway Science Research Institute of the Ministry of Transportation Test Code for Aggregate in Highway Engineering. People’s Transportation Publishing House: Beijing, China, 2005.

- Wang, L.; Ma, H.; Wang, T.; Peng, H. Factors and technical standards affecting the properties of limestone mineral powder on asphalt mastic. J. Harbin Inst. Technol. 2022, 54, 7–16. [Google Scholar]

- JTG E20-2011; Ministry of Transport Standard Test Methods of Asphalt and Asphalt Mixtures for Highway Engineering. People’s Transportation Publishing House: Beijing, China, 2011.

- Guo, Q.; Li, Y.; Hu, J.; Li, X.; Gao, Y. The influence of temperature and humidity environment on the low-temperature mechanical properties of asphalt mixtures. Highw. Transp. Technol. 2022, 39, 10–16. [Google Scholar] [CrossRef]

- Feng, X.; Chen, W.; Li, W. Road performance and modification mechanism of coal gangue powder asphalt mastic modified with silane coupling agent. J. Build. Mater. 2020, 23, 1121–1129, 1152. [Google Scholar] [CrossRef]

- TP 113–15; Determination of Asphalt Mastic’s Resistance to Ductile Failure Using Double-Edge-Notched Tension (DENT) Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- Sengoz, B.; Isikyakar, G. Evaluation of the properties and microstructure of SBS and EVA polymer modified bitumen. Constr. Build. Mater. 2008, 22, 1897–1905. [Google Scholar] [CrossRef]

- Li, N.; Zhao, X.; Sun, J.; Zhang, C.; Geng, J. Aging kinetics of rubber asphalt based on apparent viscosity. Synth. Rubber Ind. 2016, 39, 229–233. [Google Scholar] [CrossRef]

- Chen, Y.; Zheng, W.; Xu, S.; Tebaldi, G.; Su, Y.-M. Characteristics of mineral fillers and their effects on mastic fracture resistance at intermediate temperature 20 °C. Constr. Build. Mater. 2022, 323, 126568. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, H.; Yang, H.; Li, Y.; Yu, L.; Zhao, S. Research on surface morphology characteristics and micro-damage mechanism of asphalt mastic based on charge transfer principle. Constr. Build. Mater. 2023, 391, 131686. [Google Scholar] [CrossRef]

- Nian, T.; Li, P.; Wei, X.; Wang, P.; Li, H.; Guo, R. The effect of freeze-thaw cycles on durability properties of SBS-modified bitumen. Constr. Build. Mater. 2018, 187, 77–88. [Google Scholar] [CrossRef]

- Luo, S.; Tian, J.; Liu, Z.; Lu, Q.; Zhong, K.; Yang, X. Rapid determination of styrene-butadiene-styrene (SBS) content in modified asphalt based on Fourier transform infrared (FTIR) spectrometer and linear regression analysis. Measurement 2020, 151, 107204. [Google Scholar] [CrossRef]

- Zhao, Y.; Gu, F.; Xu, J.; Jin, J. Analysis of aging mechanism of SBS polymer modified asphalt based on Fourier transform infrared spectrum. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 1047–1052. [Google Scholar] [CrossRef]

| Properties | Experimental Value | Normative Value | Test Method |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s)/0.1 mm | 46.1 | 40~60 | T 0604 |

| Softening point/°C | 85.6 | ≥60 | T 0606 |

| Ductility (5 °C, 5 cm/min)/cm | 24.6 | ≥20 | T 0605 |

| Properties | Experimental Value | Normative Value | Test Method | |

|---|---|---|---|---|

| Apparent density/(g∙cm−3) | 2.706 | ≥2.50 | T 0352 | |

| Water content/% | 0.4 | ≤1 | T 0332 | |

| Hydrophilic coefficient | 0.4 | <1 | T 0353 | |

| Mineral powder plasticity index (%) | 2.8 | <4 | T 0354 | |

| Particle range | <0.6 mm passage rate/% | 100 | 100 | T 0351 |

| <0.15 mm passage rate/% | 91.6 | 90~100 | T 0351 | |

| <0.075 mm passage rate/% | 81.7 | 75~100 | T 0351 | |

| Temperature Range | 15 °C Shear Strength Increment | 40 °C Shear Strength Increment |

|---|---|---|

| −20~60 °C | 47.54% | 50.9% |

| −20~40 °C | 36.32% | 18.1% |

| 0~60 °C | 32.05% | 45.7% |

| 0~60 °C | 24.35% | 15.7% |

| Temperature Range | Number of Cycles | Relational Regression Model | Coefficient of Determination R2 | p | Eη/(kJ∙mol−1) |

|---|---|---|---|---|---|

| −20~60 °C | 0 | y = 3923.8x − 8.67418 | 0.990 | 0.0003 | 75.13 |

| 3 | y = 3965.9x − 8.74436 | 0.993 | 0.0001 | 75.94 | |

| 6 | y = 3978.1x − 8.73747 | 0.994 | 0.0001 | 76.17 | |

| 9 | y = 4011.8x − 8.79068 | 0.995 | 0.0001 | 76.81 | |

| 12 | y = 4062.6x − 8.88664 | 0.994 | 0.0001 | 77.79 | |

| −20~40 °C | 0 | y = 3923.8x − 8.67418 | 0.990 | 0.0003 | 75.13 |

| 3 | y = 3941.0x − 8.69152 | 0.996 | 0.0001 | 75.46 | |

| 6 | y = 3955.1x − 8.6973 | 0.999 | 0.0001 | 75.73 | |

| 9 | y = 3983.2x − 8.74042 | 0.999 | 0.0001 | 76.27 | |

| 12 | y = 4005.6x − 8.77071 | 0.999 | 0.0001 | 76.7 | |

| 0~60 °C | 0 | y = 3923.8x − 8.67418 | 0.990 | 0.0003 | 75.13 |

| 3 | y = 3945.7x − 8.69562 | 0.997 | 0.0000 | 75.55 | |

| 6 | y = 3964.8x − 8.7142 | 0.998 | 0.0000 | 75.91 | |

| 9 | y = 3981.6x − 8.73365 | 1.000 | 0.0000 | 76.24 | |

| 12 | y = 4010.3x − 8.78018 | 0.999 | 0.0000 | 76.79 | |

| 0~40 °C | 0 | y = 3923.8x − 8.67418 | 0.990 | 0.0003 | 75.13 |

| 3 | y = 3939.0x − 8.68776 | 0.997 | 0.0000 | 75.42 | |

| 6 | y = 3944.9x − 8.68674 | 0.999 | 0.0000 | 75.53 | |

| 9 | y = 3964.4x − 8.71990 | 0.998 | 0.0000 | 75.91 | |

| 12 | y = 3981.5x − 8.74841 | 0.998 | 0.0000 | 76.23 |

| Number of Temperature and Humidity Coupling Cycles | we/(kJ∙m−2) | R2 | CTOD/(mm) |

|---|---|---|---|

| 0 | 17.673 | 0.9962 | 17.03 |

| 6 | 13.330 | 0.9728 | 11.99 |

| 12 | 11.501 | 0.9984 | 9.57 |

| Temperature Cycle Interval | Uncycled | −20~60 °C | −20~40 °C | 0~60 °C | 0~40 °C |

|---|---|---|---|---|---|

| IB | 0.00686 | 0.00282 | 0.00435 | 0.00385 | 0.00548 |

| 0.01632 | 0.03171 | 0.02495 | 0.02454 | 0.02499 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Su, Y.; Tan, B.; Fan, Y.; Zhang, W. The Effect of the Temperature–Humidity Coupling Cycle on the Performance of Styrene Butadiene Styrene Polymer-Modified Asphalt Mastic. Appl. Sci. 2024, 14, 5047. https://doi.org/10.3390/app14125047

Ma C, Su Y, Tan B, Fan Y, Zhang W. The Effect of the Temperature–Humidity Coupling Cycle on the Performance of Styrene Butadiene Styrene Polymer-Modified Asphalt Mastic. Applied Sciences. 2024; 14(12):5047. https://doi.org/10.3390/app14125047

Chicago/Turabian StyleMa, Chao, Youliang Su, Bo Tan, Yuzhu Fan, and Wanzhen Zhang. 2024. "The Effect of the Temperature–Humidity Coupling Cycle on the Performance of Styrene Butadiene Styrene Polymer-Modified Asphalt Mastic" Applied Sciences 14, no. 12: 5047. https://doi.org/10.3390/app14125047

APA StyleMa, C., Su, Y., Tan, B., Fan, Y., & Zhang, W. (2024). The Effect of the Temperature–Humidity Coupling Cycle on the Performance of Styrene Butadiene Styrene Polymer-Modified Asphalt Mastic. Applied Sciences, 14(12), 5047. https://doi.org/10.3390/app14125047