1. Introduction

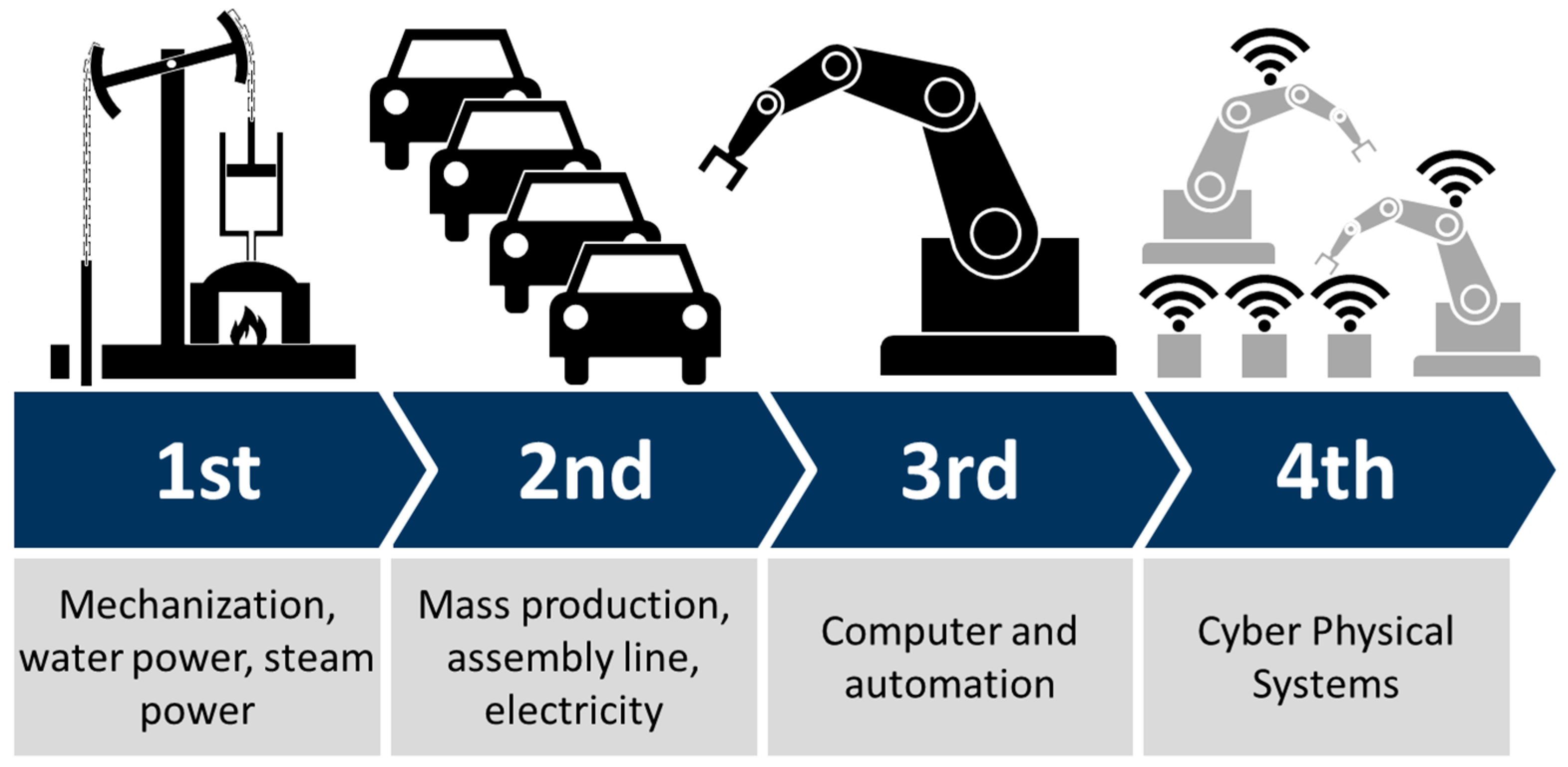

The term “Industry 4.0” indicates the industrial paradigm within which data and information are used through a pervasive system of interconnected digital technologies, aimed at innovating and governing the entire value-creation process along the supply chains. Although Industry 4.0 (

Figure 1) is mainly focused on machinery and automation, its biggest challenge seems to be related to people rather than technology [

1,

2]. Indeed, in general, the employee’s role in the Industry 4.0 era has not changed significantly, but the need for employees able to adapt their working attitude to quick, frequent changes in the whole industry scenario represents a huge problem when it comes to the productive reality and the societal level at large [

3].

Most recently, starting from the Industry 4.0 paradigm, the concept of “Industry 5.0” has been gradually entering our lives and daily practice in several sectors, including, albeit not being limited to, intelligent healthcare, cloud manufacturing, supply chain management, and manufacturing production [

4]. Therefore, Industry 5.0 is defined as a new methodological approach, recently introduced, among others, by the European community, according to which the production paradigm shifted from a strictly profit-driven logic to a logic more centered on people and the environment [

5].

The operational declination of this Industry 5.0 approach within the corporate framework is formalized in the technological support to “the worker” (in general terms, without identifying the professional category), with the final aim of improving their (individual and collective) well-being without distorting the work duties under their responsibility [

6]. Instead of acting on the technological lever with the aim of generating profit (which occurs within the Industry 4.0 paradigm), the Industry 5.0 approach aims to act likewise on the technological lever but, in this case, to increase workers’ well-being by facilitating their work duties, as well as on the environmental working conditions [

7]. Under such premises, the final aim of the Industry 5.0 approach is to indirectly keep the quality of end-products at the same level, together with the related economic results but increase, at the same time, the social sustainability of the workplace (e.g., with reduced working timetables, fairer wages, improved design of working places, better ergonomics of the working instruments, etc.) [

8,

9].

On the one hand, within the main productive sectors of our era, the agrifood/agritech field in general, and the winemaking production chain in particular, have a huge potential as significant flagship fields of application for this concept. In fact, the global wine industry was worth 33 billion EUR in 2022 and provided enormous economic benefits for several countries worldwide through its earnings from exports, employment, and economic growth. More specifically, the global wine production in 2021 was around 250 million hectoliters and, if considering the individual countries, Italy represents one of the most important markets worldwide, both in terms of revenue and exports, with 44.5 million wine hectoliters produced as of 2021, which was ahead of Spain and France, which were on the verge of 35.0 million hectoliters. Other global competitors were the USA, with 24.1 million hectoliters, and Australia, with 14.2 million hectoliters [

10]. In Italy, nowadays, there are 674,000 hectares of surface under vines, 310,000 wine-growing companies (with an average size slightly greater than 2 hectares), and 38,000 winemaking companies, with the small- and medium-sized enterprises (SMEs) representing the real backbone of the Italian wine sector [

11].

On the other hand, the winemaking industry has had many negative impacts on the ecosystem since the start of viticulture. Overall, a comprehensive review of this argument revealed a massive use of water, the generation of organic and inorganic waste streams, a significant use of energy, the emission of greenhouse gases, a large use of chemicals, the suboptimal use of land, and an overall high impact on the ecosystem in general [

12]. For instance, wine production requires huge amounts of freshwater; an Italian study revealed a total water footprint of more than 632.2 L per single 0.75-L bottle, i.e., an impressive quantity that gives a clear idea of the real impact of winemaking on the environment [

13]. Other studies confirm the existence of such an issue also in other countries of the world; for example, an Australian study reports 20 times more water consumption for the production of a single bottle of wine than with best practices [

14], giving a vivid idea of the magnitude of the problem. In addition, the issues related to water concern not only the amount to be used but also its quality in terms of purity. In fact, during the wine production processes, the contamination of surface and groundwater sources can easily occur, both due to the use of chemicals and the inappropriate treatment of wastewater [

15,

16,

17]. Fortunately, later on, best practices in terms of water use and wastewater treatment started being applied [

18], and significant improvements in this regard were already brought by the Industry 4.0 approach [

19].

In addition, due to the continuous harvesting of grapes, vines continually extract nutrients from the soil, depleting it of organic matter and representing a threat to the ecosystem overall. As a consequence, the destruction of local habitats caused by viticulture, the underestimation of soil-depleting compounds, and related questions may significantly impact the relationships between flora and fauna in the areas interested [

20]. Thus, modern approaches are more focused on increasing biodiversity by creating polycultures within the vineyard, partially solving the problem [

21,

22] thanks to technology and higher awareness about what practices can be sustainable or not sustainable [

23].

Furthermore, the use of chemicals (e.g., pesticides, insecticides, and fungicides) to increase the fields’ yields and clean the wine factory facilities [

24] represents a major issue. Indeed, these substances leave residues in the soil and are able to bio-accumulate in the ecosystem. Their impacts are extremely detrimental to the environment in general, especially in this period, which is already characterized by significant efforts by national authorities and national and transnational regulatory agencies to cope with climate-changing scenarios. A novel concept of agricultural sustainability considers the precise, tailored application of chemicals [

25], and the Industry 5.0 application in wine factories is also capable of fostering such good practices.

For all these reasons, the concept of sustainability in the wine sector should integrate many dimensions, considering economics, ecology, and community, to include all the activities performed in fields for the production of grapes and in cellars for winemaking [

26]. Additionally, this emblematic and extremely dynamic sector has been increasingly interested in preserving environmental sustainability, even with alternate outcomes, anyway, becoming an interesting scenario to explore sustainable business model (BM) innovations in greater depth. Indeed, there is a lack of studies dealing with innovative BMs in the wine sector, and, in general, research to date offers only partial views of the winemaking value chain [

27].

In this framework, the environmental sustainability of products has recently gained a growing influence on consumers’ buying decisions, especially in wine markets in the USA and Germany, with this trend expected to increase. This is partially due to consumers’ growing awareness about ethical issues, particularly in the younger generations. For this reason, the responsible consumption of wine, beyond other foods and beverages, has to be considered a growing trend and is expected to attract increasing market portions in the years to come.

Under this light, in recent times, wine companies have been moving towards an increasingly sustainable attitude in terms of business models, technologies, processes, products, strategies, and relationships. Therefore, it is possible to state that sustainability is no longer erroneously seen as a fad, but, rather, has become a real “unavoidable evolutionary paradigm” for companies operating in the sector of food and beverages, particularly in wine production [

28].

Finally, as the wine industry heavily relies on manual labor inputs, the social component of sustainability is highly relevant [

29,

30]. Thus, people’s well-being and quality of life, the educational and work conditions, social benefits, and all the related ethics questions must be accounted for, and this is what drove the team involved in this article to conceive the proposal framework that is outlined here more in-depth.

Despite some scattered applications of the main concepts of Industry 5.0 in the wine industry in recent times [

31,

32], the human component of wine production has been rarely considered, leading to important but somewhat incomplete results. Under such premises, the team of this article dedicated a research project to implementing the Industry 5.0 principles in the Italian winemaking sector, putting the human being at the center of the production process and hence promoting and assessing his well-being at the workplace, as well as the environmental and socio-economic sustainability of the working scenario.

Within the current article,

Section 2 presents the main concepts of partially implementing the Industry 5.0 approach to the Italian winemaking sector, with specific overviews of the single tasks the project is expected to carry out.

Section 3 places the project implementation with reference to the existing solutions according to the scientific literature. Finally,

Section 4 wraps up the main conclusions of the present work.

2. How to Implement the “Industry 5.0” Concepts in the Winemaking Sector: The Italian Experience

The project described here was named “CANTINA 5.0”, as the Italian term “cantina” refers to a wine cellar, i.e., one of the key environments where, traditionally, wine production takes place, and the term “5.0” refers to the implementation and adoption of the “Industry 5.0” approach in such a framework. Under such premises, CANTINA 5.0 aims to apply the main principles of Industry 5.0 to the wine production chain by proposing the adoption of such a paradigm to some SMEs and large factories involved in winemaking, located in two different areas of Italy: (1) the Friuli-Venezia Giulia and Veneto regions (in the north-eastern portion of Italy, latitude 44.9°–46.6° N) and (2) Tuscany region (in the central-western part of Italy, latitude 42.4°–44.3° N). About 800 full-time employees work in the involved companies in these two areas. Beyond the climatic differences (the northernmost area is one of the coldest regions throughout the Italian territory, whereas the central area has a somewhat warmer climate), those areas commonly have completely different attitudes towards winemaking, also related to different cultural roots of the winemaking activity; the former more actively produces white and sparkling wines, whereas the latter is known worldwide for the production of red wines. Both those areas include famous and internationally celebrated protected designation of origin (PDO), protected geographical indication (PGI), and traditional specialty guaranteed (TSG) wines and host both SMEs and large wine factories either operating extensively during the grape harvesting period or working horizontally throughout the year for winemaking. The networking capability of the academic institutions involved in the project with respect to wine factories was ensured by the capillary distribution of university sites (cities of Pisa and Udine) in these activity regions.

Given the peculiarities of the relevant sector, identified in the analysis of the previously described state-of-the-art, the core of the concept implementation lies in the setup of the paradigms of a “human-centric”, “smart”, and “sustainable” wine factory, both from the human and environmental points of view. This is an approach that has never been published in the scientific literature in the past when it comes to the Italian framework of winemaking, to the best of our knowledge. We identified four main dimensions for the implementation of the “5.0” paradigm to the (Italian) winemaking scenario (

Figure 2): (i) the monitoring of the quality of life of wine company employees; (ii) the monitoring of environmental parameters within the working environments used in the wine production; (iii) the assessment of the social and environmental sustainability; and, finally, (iv) the assessment of the quality of wine produced by promoting the “5.0” approach to the whole production chain.

2.1. Monitoring of the Quality of Life of Winemaking Employees

As said, the human side of this approach is pivotal to the success of the overall adoption of the Industry 5.0 principles. Keeping in mind that the “quality of life” of a person is a concept involving lots of different aspects, which, overall, can influence the subjective evaluation of one’s perception of their reality [

33], the assessment of workers’ quality of life will be addressed by two points of view, described here below.

First of all, it is essential to monitor the healthiness (intended by the clinical standpoint, hence based on quantitative parameters) of wine factory workers at their workplace by employing minimally invasive, well-accepted approaches that are eventually compliant with the activities carried out and not interfering with them. Indeed, any possible physical problem can impose on a specific subject habits different from the ones of any perfectly healthy person and, hence, have many repercussions: from the limitation of action possibilities to a resizing of innermost desiderata, to the generation of a sense of inadequacy and exclusion. Therefore, an objective condition/fact can easily give origin to subjective sensations, involving also mental and spiritual aspects. For this reason, it is fundamental to somehow also detect the feelings of the workers, necessarily with qualitative methods, to complete the picture and understand possible misalignments (underestimations and/or overestimations) of their own situation. In this regard, the project foresees monitoring the overall (perception of) well-being of individuals thanks to the administration of structured, validated questionnaires at the very beginning of all the experimentation. Such questionnaires will address possible personal issues like the workers’ perceived anxiety and stress status, the occurrence of possible accidents, safety or health-related problems within or outside the workplace, and an overall self-reported medical anamnesis to be put in relation to the declared overall quality of life of every individual.

As for the implicit physiological parameters acquired from the workers, still bearing in mind the need for minimal obtrusiveness and data minimization, such employees will be equipped with smart wearable sensors, represented by smart bracelets/smart watches (or similar market solutions) [

34,

35] (

Figure 3), or even by smart rings, as the RingConn Smart Ring [

36] (by Guangdong Jiu Zhi Technology Co. Ltd., Zhongshan, China).

Actually, popular solutions available on the market include (albeit not limited to): (i) the Fitbit Sense [

37] (by Fitbit Inc., San Francisco, CA, USA; capable of measuring ECG/heart rate variability, galvanic skin response, sleep phases, oxygen saturation, skin temperature, and respiration rate, with an Android-compatible app), (ii) the Samsung Galaxy Watch 5 [

38] (by Samsung Group, Suwon, Republic of Korea; capable of measuring ECG, heart rate, galvanic skin response, oxygen saturation, and blood pressure, with an Android-compatible app), (iii) the Withings Scanwatch [

39] (by Withings, Issy-les-Moulineaux, France; validated as a medical device, measuring ECG, oxygen saturation, and actigraphy, with an Android-compatible app), and (iv) the Omron Heartguide [

40] (by Omron Corporation, Kyoto, Japan; validated as a medical device, measuring ECG and blood pressure, with an Android-compatible app). An overview of the main physiological parameters that can be monitored with these portable devices can be seen in

Figure 4. Such devices will store data related to the above-referenced parameters and will send such data, through a “wireless bridge” (e.g., the Google Fit App or, eventually, the Apple Health framework, both operating on the mobile phone network), to the CANTINA 5.0 platform for secure data collection. It is worth noting that the wireless connection of these devices with a remote central tool (see

Section 2.5) can be ascribable to the smart technologies able to implement automatic machine-to-machine communication, i.e., not needing human intervention, based on the Internet-of-Things. These technologies are typical of the technological advancement known as “Industry 4.0”, witnessing the continuity and the synergies existing between the “4.0” and the “5.0” steps. Therefore, it is possible to affirm that the 4.0 concepts are completed by “5.0” aspects and have their efficiency increased by the broader meaning attributed to the measurements made with these smart devices in this context.

2.2. Monitoring of Environmental Parameters

Together with the monitoring of physiological parameters, which is useful to provide an overview of the health and well-being status of the employees, environmental parameters need to be checked at the same time. Indeed, sites where wine production occurs often have high concentrations of specific chemical compounds, which are potentially harmful to the health and safety of the employees, at least above certain thresholds. In such a scenario, the wine cellar (

Figure 5) probably represents the cornerstone for such a monitoring approach, as featuring the presence of several compounds, mainly carbon dioxide (CO

2), ethanol (C

2H

6O, often written as EtOH, where Et stands for ethyl), and sulfur dioxide (SO

2), which are all worth continuously monitoring, together with the environmental temperature and humidity, through reliable measurement instruments.

Moreover, volatile organic compound (VOC) emissions, of which winemaking facilities are active sources, cannot be underestimated; VOC emissions analysis is, indeed, a critical aspect of air quality assessment, especially given their potential acute and/or chronic effects on human health. Such a monitoring task can have a two-fold approach: (i) it can be conducted using well-grounded laboratory analyzers, including gas chromatography coupled with mass spectrometry (GC-MS), to perform an accurate, reliable quantification of the different chemical compounds in the air using a non-targeted approach (namely, a full-scan of the air in the wine cellar will be performed, assessing the totality of VOCs employees are exposed to, once a proper environmental air sampling is performed by portable, well-grounded sampling instrumentation) [

41,

42,

43] (

Figure 6) and (ii) using novel Internet-of-Things (IoT)-based devices, which have been progressively entering our daily lives thanks to the significant advancements in technology experienced in the recent period. Some examples of these devices are the “Nicla Sense ME” [

44] (by Arduino s.r.l., Monza, MB, Italy, which can measure air pressure, humidity, temperature, VOCs, VSCs, and various other harmful gases such as CO

2), and the “SmartAir Lamp” [

45] (by Smartme.io s.r.l., Messina, ME, Italy, which can measure the air temperature, pressure, humidity, and VOCs and lights up in different colors depending on the air quality, following the official colors of the Air Quality Index–AQI) [

46].

As such, the laboratory instruments (gas analyzers) will be used as a reference to test the global affordability (absolute and over time) and indicate possible corrections to the readings of the IoT devices [

47], possibly based on cheap and “open” architectures, e.g., the Arduino Mega Rev3 microcontroller [

48] (Arduino s.r.l., Monza, MB, Italy;

Figure 7) or the Raspberry Pi 5 single-board computer [

49] (Raspberry Pi Foundation, Caldecote, UK). Indeed, this second set of devices, in a future perspective of implementation of the results of this project, could constitute an easy and cost-effective way to monitor the safety and healthiness of such workplaces but only if based on reliable calibration curves, to be developed during this project. The data, collected according to the two aforementioned methods, will be stored in a purposely developed IT platform for the project and, subsequently, will be analyzed through dedicated data-processing algorithms, also based on artificial intelligence (AI), when applicable, still considering the critical role of AI when dealing with its environmental sustainability.

Figure 6.

Environmental sampling making use of the headspace solid-phase microextraction (HS-SPME) technique [

50] with portable devices equipped with a polyvalent adsorbing active phase with divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) coating.

Figure 6.

Environmental sampling making use of the headspace solid-phase microextraction (HS-SPME) technique [

50] with portable devices equipped with a polyvalent adsorbing active phase with divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) coating.

2.3. Environmental and Social Sustainability

One of the main pillars of Industry 5.0 is represented by the enhanced attention to environmental and social sustainability. Therefore, to support this aim and strongly believe in the added value of winemaking in an environmentally and socially sustainable way, the whole production chain (“from vine to wine”) will also be monitored in this regard. When it comes to environmental sustainability, tailored questionnaires will be administered to the factories involved in the project. The aim is to monitor their adherence, before and at the end of the production protocol, to best practices in terms of environmental preservation within the whole production chain, with also the possibility to adhere to campaigns like the purchase of carbon credits, promoting the carbon neutral principles.

Such aspects, together with the evaluation of the effectiveness of the current corporate social responsibility (CSR) models, will complement the outlook of the project.

The recent models of CSR involve considering economic, environmental, and social aspects simultaneously. From an environmental perspective, the literature confirms that consumers are increasingly sensitive to the production and packaging of green products, and they are willing to pay a higher price for them [

51,

52]. From a social perspective, respect for the environment and working conditions, both during the cultivation and production phases, plays a central role [

53,

54]. Businesses’ adherence to the principles of social responsibility has helped to strengthen their competitive positioning as well as positively affect profitability [

55].

The adherence to such values, proving the increased attention paid by wineries to the working conditions of their employees, can be certified and communicated to the possible customer. Indeed, the intention of the project is to create a special seal to be placed on the labels of the bottles, awarding the aspects taken into account by the winemaking company (e.g., implementation of a system to monitor the environmental and workers’ health, greater attention to working hours and breaks). This might prove the good practices of the involved producers, and, at the same time, attract possible interested factories in joining such principles, potentially representing a selling-driver into the market, accompanying consumers to a better, more sustainable, and environmentally conscious consumption of wine.

2.4. Wine Quality Assessment

Usually, the quality of wines, as for other foods and beverages, is assessed in a two-fold manner: (i) by means of chemical analysis, with the capability of detecting the chemical composition of the beverage, including through volatilome analysis, from the grapes to the final product [

56,

57], and (ii) using trained panelists that evaluate, based on their experience and expertise, the organoleptic qualities of the wine being tasted [

58]. This second approach is very well grounded in the sensory analysis domain, thought to be reliable as based on the experience of trained judges, and has been recently complemented by the assessment of physiological (hence, implicit) responses of such panelists during a typical tasting session, shedding a light on non-verbal and, often, non-conscious sensory perception towards given compounds and, if possible, decreasing the likelihood of a judgment bias eventually occurring when making use of explicit methods, including sensory sheets and questionnaires.

With the aim to promote the valorization of the wines produced within the Industry 5.0 paradigm, the project will therefore make use of all the above-listed approaches (hence, instrumental tools, sensory panels, and physiological responses) to fully determine the overall quality of produced wine, and certify their fair value, not only from the production chain perspective but also concerning their quality, both chemical and organoleptic/emotional.

Sensorial analysis will be performed by a panel composed of 12 trained assessors (7 females, 5 males) aged between 25 and 63 years, members of the “expert panel” of the DAFE of the University of Pisa. Before the start of the study, all participants will be asked to fill out their informed consent. Each tasting session will involve evaluating a maximum of 8 wines, with judges receiving a sample twice to assess the panelist’s repeatability.

A 220 mL tulip-shaped wine-tasting glass (ISO 3591:1977) [

59] will be used to present approximately 50 mL of each blind-coded sample. Water and breadsticks for palate cleansing will be provided by each judge between two consecutive samples.

The sensory profile will be assessed through a detailed sensory questionnaire with 24 attributes: 16 qualitative (color saturation, purple hues, garnet hues, olfactory intensity, roundness, structure, acidity, alcohol, astringency, bitterness, floral, fruity, vegetal, spicy aromas, off-flavors, persistence); 8 hedonic (attractiveness, finesse, frankness, harmony, retronasal finesse, retronasal frankness, aromatic richness, hedonic level); and 6 emotional (fear, anger, sadness, joy/happiness, disgust and surprise). Each attribute will be evaluated on a 0–9 scale. All ratings will be digitally acquired.

2.5. Data Collection and Analysis and Data Privacy

All the data concerning the health and well-being status of employees, the environmental conditions of wineries and wine cellars, the responses concerning environmental and social sustainability, as well as the results of the wine quality assessment, will be collected in a dedicated IT platform. As such, all the data will be kept confidential and stored on a safe, secure, GDPR-compliant platform (

Figure 8), physically located within the project coordinator’s infrastructure at the institution’s premises. The CANTINA 5.0 IT platform is composed of a cloud-based, modular web app, relying on the Software-as-a-Service (SaaS) paradigm and accessible at various levels thanks to role-based access control (RBAC), thus granting different users different privileges based on the level of interaction they are required to have, according to the project principles. Data stored here will be organized to be easily exported, e.g., on “.csv” files or in other formats, and subsequently analyzed through advanced methods relying on AI principles. All the information retrieved, including the used processing methods and the privacy roles (data controllers, etc.), are specified in dedicated sheets related to the privacy disclaimer that the project partners are distributing to the individuals and representatives of factories taking part in the project, in turn representing an important part of the document package to be submitted to the Ethical Committee in charge for the project assessment.

It is pivotal to acknowledge that data collected with the consent of the interested parties will not be made available to the employer. The data controllers are the three Italian academic institutions composing the project consortium (i.e., the National Research Council of Italy, the University of Pisa, and the University of Udine), since the agreement granted by the interested persons to their employers cannot be considered as free and unconditional, thus legitimate [

60].

Concerning the data collection, a significant matter of concern can be represented by the use of wearable sensors and questionnaires related to the quality of life. In order to preserve, as much as possible, the privacy of workers voluntarily agreeing to participate in the project, beyond the privacy measure mentioned above (i.e., not providing information about data collected to the employer), we decided to keep all data anonymous since the collection, without any name and surname or other data that can lead to the identity of a subject. The questionnaires on the quality of life are also based upon questions that do not include personal information; furthermore, the minimum number of people to be enrolled for the protocol (N = 30) was chosen to be sufficient enough to guarantee a proper statistical analysis for a proof-of-concept study, and allow, at the same time, for the anonymity of workers’ data. All data will be collected in an aggregate manner to safeguard the privacy of employees without compromising the amount of information obtainable from the statistical analysis. In the same way, the results will be shown and commented on in an aggregate manner.

After the analysis phase, participating institutions will be informed about the possible presence of pollutants having the capability to impact the well-being of workers and compromise the environmental sustainability of their production chains. The same way of operating will also be followed when dealing with the results concerning the quality of life of the employees, both if they emerge from the questionnaires and if they derive from the wearable devices. The best practices and/or possible improvement of the current CSR models will be evaluated based on the results obtained in the experimental part, and the factories participating in the project will be informed about them. Finally, data concerning the quality of wines before and after the implementation of the “5.0” approach will be analyzed and compared together to individuate possible improvements or worsening of the products regardless of the overall quality of the harvesting.

3. Discussion

The winemaking industry represents one of the leading sectors worldwide in the food and drink sector. Its importance has risen throughout the decades, so it represents one of the key economic recipients in some specific areas of the globe, including the northern side of the Mediterranean. As such, Italy has always been considered as one of the homelands of winemaking and, together with Spain and France, is still leading global revenues and market pools worldwide in the sector. However, Italy features a very heterogeneous wine production, with different types of wine produced throughout the country, reflecting the important geographical, cultural, and climatic differences that exist among the various productive areas. For example, as of 2022 [

61], Veneto and Apulia have been the two regions with the highest overall wine production; the former has a prevalence of PDO white wines and, in general, PDO and PGI products, and the latter is more largely involved in producing table wine. These specificities also determine important differences in focusing attention on the wine production chain, with different seasonality for grape harvesting and performing care interventions for vineyards, reflecting different scenarios related to the employees’ efforts. Furthermore, different types of producers also feature different working setups, with large companies being organized differently from SMEs in terms of the overall production chain. This contributes to the high fragmentation of the productive tissue that characterizes the Italian territory as far as the wine industry, making the adoption of common strategies to scale up winemaking in a modern framework very difficult, taking into account, at the same moment, the new challenges in terms of environmental, social and economic sustainability.

Just like vineyards, wineries have an important socioeconomic impact and responsibility [

29,

62]. Corporate social responsibility must become part of the wine industry by disclosing its environmental and social impacts [

18,

63].

In such a situation, it appears necessary to rethink the approaches within sustainability research, taking into account–and trying to solve–the main criticisms characterizing wine production in Italy and globally [

12,

13,

14,

15,

16,

17] and at the same time calling for the integration of new, and non-traditional forms of knowledge and new ways of doing research [

64].

To achieve this main goal, the availability of statistically significant, multimodal, multiparametric data is crucial; indeed, this data, properly interpreted, can be used to support decision-making, auditing, and governance. Robust statistics are essential to build up decision support systems and related processes and successfully plan and implement new policies [

65]. Unfortunately, statistics and data collection and management are often looked at as an additional cost and a burden, rather than a valuable tool [

66]; this occurs not only in the winemaking industry but also in other industrial and productive sectors. The lack of proper monitoring, data analysis, and inventories decreases efficiency and increases costs and environmental impact. Detailed metrics on environmental, social, and financial issues can help to implement benchmarking, as well as more efficient management of inputs in vineyards [

67] and wineries [

68].

Information and Communication Technologies have the capability of supporting such actions, and, within this scenario, the CANTINA 5.0 project aims at identifying and comprehensively monitoring the key factors that have a significant impact on the well-being and productivity of operators in the wine supply chain. Furthermore, through a small pilot experience, taking place in two of the most active Italian areas for winemaking, yet quite different from each other, like Friuli-Venezia Giulia/Veneto and Tuscany, it is possible to spread the use of such good practices, enabling their future adoption at a relatively-larger scale.

However, to achieve the goals identified by the project, it is necessary in the first instance to accurately retrieve the factors that affect the well-being of workers in the winemaking sector. Studies focusing on this issue are numerous and often tend to be very dispersed, as they analyze a variety of problems ranging from the safety of the lower limbs [

69] to the impact of overtime working hours on the well-being of workers and their families [

70]. Other studies focus at a macro level on the organizational culture and business management practices [

71] or analyze the impact of management skills and behavior [

72]. What is uncommon to find in literature is a study that addresses these issues in an organized and multidisciplinary manner.

Environmental factors, such as ambient temperature, humidity, and brightness, are strictly related to workers’ welfare [

73,

74], but they also have a strong dependence on some of the wineries’ production activities. As an example, if the thermo-hygrometric conditions in such workplaces are mainly determined by the processes taking place there, rather than being set to the optimal values for personnel, this usually means that some important technical solutions, such as thermal insulation of tanks, are not present and the global energy efficiency of the whole facility is low.

Moreover, emotional (e.g., related to motivation, responsibility), social, physiological, and even psychological factors (e.g., work-related stress) [

75,

76], should be identified to create a more extensive set of indicators useful to all-around monitor the employees’ well-being in the wine industry. To do this, it is essential to start with a broad data collection based on a questionnaire and then, based on the evidence, focus on on-site data collection by using different types of sensors:

environmental sensors capable of measuring the ambient temperature and humidity but also the concentration of some noxious chemicals and gases produced during the different production phases (and the related exposure of workers to these substances);

wearable sensors capable of monitoring the physical health and thermal stress of operators and providing valuable data to intervene promptly when conditions deviate from safe parameters.

In addition, as previously anticipated, the assessment of the produced wines’ quality, resulting from the sensory characterization by panelists, would integrate the analysis, overall providing a complete picture of the whole process of wine production from the harvesting to the table and product quality.

The integration of multidisciplinary approaches and advanced technologies within the CANTINA 5.0 project represents a pioneering step towards the enhancement of the well-being and productivity of workers in the wine supply chain. By meticulously identifying and monitoring the key factors affecting worker welfare, from environmental conditions to psychological aspects, this project aims to set a new benchmark for the evaluation of the social sustainability of this industry. The integration of data coming from an extensive collection, based on questionnaires, and gatherings from precise on-site sensors, delineates a proactive workplace improvement strategy, aimed at enhancing both the work–life quality for operators, and the sustainability and efficiency of winery operations.