Abstract

The sliding layer created during operation of the expanded graphite–steel combination has had a huge impact on the effectiveness of the friction process, and thus on the sustainable development of society. Knowledge of the factors determining the properties of the sliding layer will make it possible to reduce friction resistance in the future through the proper design and selection of sliding pairs for given applications. This paper studies the effect of the moisture content of expanded graphite on the formation of a sliding layer on a stainless steel surface. The tests were carried out in static contact for 30 s and dynamic contact for 15 and 30 min, for loads of 10, 20, and 30 N and speeds of 25 and 50 mm/s. To determine the changes in surface geometry due to material transfer, the Ra roughness value of the surface of stainless steel samples was measured. In order to realize the purpose of the work and evaluate the effect of moist rings on the resulting sliding layer, the results of the surface roughness of stainless steel samples working with dry and moist graphite rings were compiled. The obtained results show that the presence of water in the stainless steel-expanded graphite friction node affects the formation of a sliding layer. The resulting layer reduces the surface roughness of the cooperating materials and prevents their accelerated wear. After 5 min of work with the water-soaked graphite counter-sample, depending on the applied friction conditions, a reduction in the surface roughness of the stainless steel sample was achieved in the range of 11–18% compared to the initial value. After 30 min of operation, the surface roughness decreased by 3 to 25%. Pilot studies have shown that operating conditions influence the formation of a sliding layer in the stainless steel-expanded graphite tribological contact. This confirms the validity of conducting further research in this area.

1. Introduction

Friction reduction is one of the major problems occurring in cooperating tribological pairs [1,2,3,4]. Many studies suggest that nearly 30% of the world’s energy is expended to overcome friction, and about 60% of mechanical damage is caused by wear [5,6]. Advances in lubrication technology can effectively reduce friction and wear on mechanical parts, also influencing energy efficiency and reducing mechanical failures, thereby greatly facilitating the sustainable development of human society [7]. When two surfaces come into contact, strong adhesive bonds are formed between irregularities, which can increase the coefficient of friction or wear. The solution is to use a lubricant or suitable materials for sliding pairs, which are characterized, for example, by a layered structure with low shear strength. The wear products then formed in the friction process are transferred and accumulated in the irregularities of the mating surfaces, forming a protective sliding layer. This layer improves the load-carrying capacity of the friction node and prevents rapid wear of the mating materials [8,9]. The properties of the resulting layer depend on many factors. These include the type of triboelectric materials used and input parameters such as pressure, speed, or temperature [10,11,12]. A material that has excellent properties for forming a sliding layer is graphite, which has been used as a solid lubricant for decades [13]. The lubricating properties of graphite can be explained by its lamellar structure with weak interlayer bonding, allowing sheets to slide easily horizontally along each other under shear stresses [14,15].

The literature on the effect of operating conditions on the lubricating properties of carbon materials and the ability to form a sliding layer is primarily concerned with carbon, graphene, or graphite-modified plastics [16,17,18,19]. Even though these materials belong to the group of carbon materials, they are characterized by different tribological properties. Hongyun et al. [20] introduced expanded graphite and natural graphite into the friction materials and examined the tribological properties of the obtained composites. The results showed that the expanded graphite composite displayed better lubricity in both the fading and the recovery processes. Meanwhile, PTFE filled with carbon fiber based on polyacrylonitrile (PAN) showed the lowest friction and wear in tests with respect to other fillers. The tribological mechanisms of low friction and wear were attributed to the protective layer formed on both surfaces of the sliding pairs [21]. Wang et al. [16] showed that the amount of friction and wear of a tribological pair is influenced by the amount and size of graphite particles introduced into the plastics. As the size of graphite particles in the plastic increased, the wear rate increased with increasing load. The resulting layer was not durable enough. Large graphite particles were removed from the surface contact zone due to poor interfacial adhesion between graphite and plastic. Studies on the effect of pressures on the polymer–graphite filler friction node have shown that as the pressures increase (0.5, 1 and 1.5 MPa), the value of the coefficient of friction and wear decreases [22]. However, some studies report that at relatively low pressures, the formation of a graphite protective layer is not possible [23,24,25]. Analyzing the effect of speed on the operation of the graphite–stainless steel friction node, it was shown that at higher speeds there was a decrease in the coefficient of friction, which was explained by the formation of a thicker sliding layer [18]. At the same time, the aforementioned studies showed that wear increased with increasing speed. The above studies are confirmed by the authors of the paper [26]. The operating environment is also of great importance for the operation of graphite. Graphite wear changes with an increase or decrease in relative humidity [21,26,27,28,29,30]. In practice, tribological associations in which one of the materials is graphite are widely used in work in the aquatic environment [13,31,32]. Due to the adsorption of water, graphite has good lubricating properties [33]. The adsorbed water molecules on the main sliding planes reduce the adhesion between them and thus reduce the coefficient of friction during their sliding. On the other hand, studies indicate that a larger amount of water in the tribological combination contributes to too rapid wear of the tested surfaces [34]. Water leaches out the resulting wear particles, which are necessary for the formation of a sliding layer [35,36]. According to Hirani and Goilkar [34] and Wang et al. [37], water hinders the formation of a transfer film on the graphite mating surface. It should be noted that in many sealing and bearing applications, the friction pairs are immersed in liquids, and the mechanism of low friction is still not very clear. Somberg et al. [38] studied the effect of graphite as a filler in polymer, which showed that the formation of a sliding layer was hindered when lubricated with water, resulting in lower friction and wear than with pure polymer. The presented research shows that there is no clear answer to the question of how water affects the resulting graphite sliding layer. There is a significant lack of research on the operation of the expanded graphite–stainless steel tribological pair in an aqueous environment. Meanwhile, this pair is widely used in popular piston valves. In this type of valves, a cylindrical piston made of stainless steel moves between graphite sealing rings. The sealed medium is usually water. Practical knowledge indicates that these valves have problems related to frictional resistance and accelerated wear of cooperating parts. To confirm this fact, literature was cited indicating the existence of practical problems related to the reliable operation of the analyzed pair of materials [39,40,41,42,43]. The sliding layer created during operation of the expanded graphite-steel combination affects the effectiveness of the friction process. Knowledge of the factors determining the properties of the sliding layer will make it possible to reduce friction resistance in the future through the proper design and selection of sliding pairs for given applications. The large number of factors affecting graphite transfer means that, it is difficult to determine which of the elementary friction phenomena dominates under specific conditions. The lack of scientific research on the mentioned tribological pair makes it difficult to properly select operating conditions. Therefore, the novelty in the presented research is primarily the set of materials used for the research. Moreover, due to the wide use of expanded graphite in industry, the research performed can be used not only in sealing technology, but also in many other industries. In construction, for example, expanded graphite is a key ingredient in fire-resistant building materials such as fire-resistant coatings, plasterboard, and insulation. In the automotive industry, it is used in battery systems and thermal management materials. It is worth noting that the global expanded graphite market size is estimated at 76.75 kilotons in 2023 and is expected to reach 110.90 kilotons by 2028 [44]. Therefore, it is believed that knowledge of the properties of expanded graphite is crucial for its further development.

The aim of the research was to determine the Influence of working conditions on the formation of a sliding layer in the tribological contact between stainless steel and expanded graphite based on changes in the surface roughness of the samples. The research carried out is of a pilot nature.

2. Materials and Methods

For the study, rings made of expanded graphite were used. This graphite material is used in the construction of technical seals of the highest performance, working mainly in power and industrial installations [13,45]. The graphite rings used in the study were manufactured by a Polish manufacturer of industrial seals and work as stuffing box packing in industrial fittings. The rivet-shaped sample with a tapered head was made of stainless steel AISI 304. This material is used for piston rods operating in valves. Samples characterized by a Ra roughness = 3.21–3.64 µm were selected for testing. The choice of materials with such roughness was dictated by studies performed by Hirani and Goilkar [34] and Jenson et al. [46], according to which surfaces with higher roughness values are more favorable because, as the researchers assessed, they act as microscopic reservoirs of solid lubricants. The friction node analyzed occurs in popular piston valves. In this type of valve, a cylindrical steel piston moves between graphite sealing rings. Information about the tested materials is shown in Table 1.

Table 1.

Information about the sample and counter-sample material.

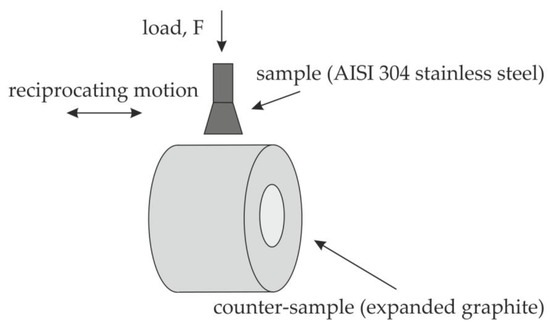

In order to investigate the process of creating the sliding layer, a pin-on-ring station was used (Figure 1). A steel sample in the shape of the tapered head rivet was placed in the upper holder of the mounting plate tribotest. A ring made of expanded graphite was fixedly mounted in the lower handle. The steel sample moved in a reciprocating motion. The solution used enabled the steel sample to move along the graphite ring over a 6-mm-long section with a frequency of 1 to 10 Hz. The drive was transmitted via a belt transmission.

Figure 1.

Scheme of analyzed friction node, based on [47].

The forming layer was identified by measuring the roughness of the steel surfaces of the samples and observing them. Measurements of 2D surface stereometry were made with a ZAISS contact profilometer (ZAISS, Maple Grove, MN, USA) equipped with heads with an induction transducer and SUFORM software by SAJD METROLOGIA (Kielce, Poland), which allows for measurements and analysis of deviations of straightness and surface roughness. The measurements were made by determining the sampling length λc = 0.8 mm, where the measuring length Ln was adequately 5 mm. In the analysis of the roughness results, cut-off filtration was used. The tests were carried out in accordance with PN-EN ISO 21920-3:2022-06 [48], PN-EN ISO 3274:2011 [49].

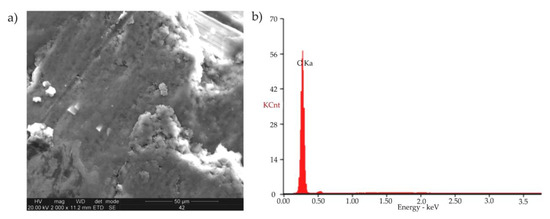

The morphology of the selected samples was performed after the test to assess the chemical composition of the sliding layer. The analysis of the chemical composition of the layer carried out showed that the material from which the layer came into being was coal (Figure 2).

Figure 2.

Microscopic image of a layer formed on a steel surface; (a) microscopic SEM images, (b) EDS spectrum of created layer, based on [50].

The friction surfaces of the samples were examined before mating, after static loading at rest for 30 s, and then after 15 and 30 min of mating operation (Table 2). In order to evaluate the effect of moist graphite rings on the layer formed, tests were performed in the first step for the friction node working dry, that is, the steel sample cooperated with the dry graphite ring. Next, tests were performed for a friction node in which the graphite rings were soaked in water for 24 h before testing. After being removed from the water container, they were dried on tissue paper. In the last step, the obtained results of the surface roughness of samples working with dry and moist graphite rings were compared. The tests were carried out for specific loads and speeds (Table 3).

Table 2.

Operating conditions of the friction node during testing.

Table 3.

Values of load and speed parameters for the tested friction nodes.

In the study, a total of 108 tests were performed. Three repetitions of roughness measurements were performed for each surface. After the roughness measurements, the steel surfaces of the samples were subjected to observational studies using an optical microscopy. Visual assessment was performed using a Nikon Eclipse MA100L (Nikon Instruments Inc., Tokyo, Japan) compact inverted optical microscope. The microscope is designed for a bright field of observation and is equipped with a camera and a computer with dedicated image analysis software. Equipping the microscope with ecological LED lighting ensures stable observation of the sample surface with a uniform color temperature, even at different light intensities. The magnification of 250 and 500 was used in observations. This allowed a preliminary evaluation of the formed sliding layer in dry conditions and after cooperation with moist graphite rings.

3. Results and Discussion

The tests performed involved measurements of the surface roughness of the samples and their observation. The tests were conducted for constant loads and speeds under dry conditions and during the cooperation of the samples with moist rings.

3.1. The Formation of a Sliding Layer on Steel under Dry Friction Conditions

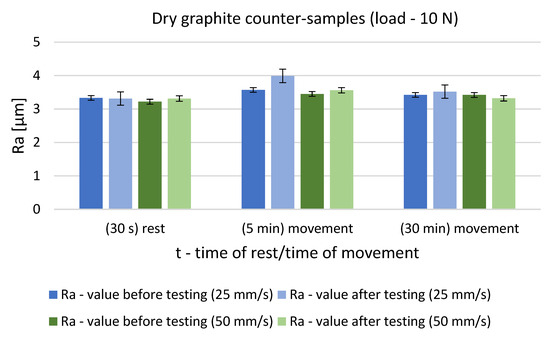

The tests were performed at loads of 10, 20, and 30 N, for speeds of 25 and 50 mm/s. An example of the test run for 10 N and speeds of 25 and 50 mm/s is shown in Figure 3. Tests for 20 and 30 N were performed in the same arrangement.

Figure 3.

Changes in the values of Ra roughness parameters of steel specimens interacting with dry graphite counter-samples (speed 25 and 50 mm/s, load—10 N).

Already during static contact, a change in the surface roughness of the samples was noticeable. This means that particles of expanded graphite had been transferred to the surface of the steel sample. This was noticeable for all loads. As the load increased, a slight decrease in roughness was visible.

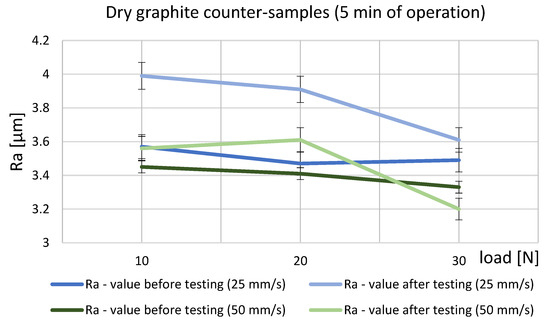

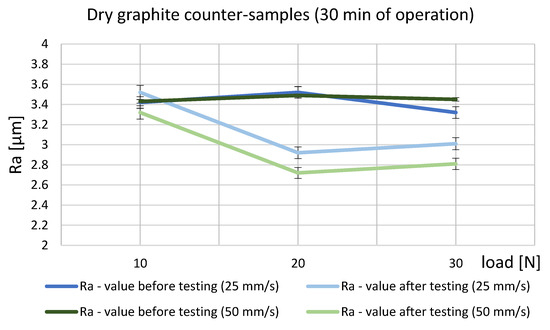

To illustrate the effect of the load on the operation of the friction node under dry conditions for 5 and 30-min cycles, at speeds of 25 and 50 mm/s, the results of the surface roughness of the samples are summarized in Figure 4 and Figure 5.

Figure 4.

Change in the values of the Ra roughness parameters of steel samples working with dry graphite rings in a 5-min cycle under loads of 10, 20, and 30 N and speeds of 25 and 50 mm/s.

Figure 5.

Change in the values of the Ra roughness parameters of steel samples working with dry graphite rings in a 30-min cycle under loads of 10, 20, and 30 N and speeds of 25 and 50 mm/s.

After a 5-min cycle, an increase in surface roughness was noticeable compared to the initial value for all associations. The increase in load contributed to the decrease in roughness.

Analyzing the effect of a 30-min friction node operation on surface roughness, it was noticeable that the roughness of the sample decreased compared to the initial value. A greater decrease in roughness was noted for a speed of 50 mm/s.

3.2. The Formation of a Sliding Layer on Steel under the Conditions of Interaction with Moist Expanded Graphite

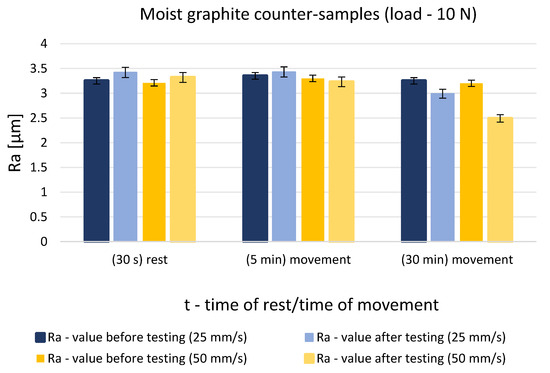

The course of tests for 10 N and speeds of 25 and 50 mm/s during the interaction of steel samples with moist rings is shown in Figure 6. Tests for 20 and 30 N were performed in the same arrangement.

Figure 6.

Changes in the value of the Ra roughness parameter of steel samples mating with moist graphite rings (speed 25 and 50 mm/s, load 10 N).

During static contact between steel samples and moist graphite rings, a change in surface roughness was observed after 30 s of friction node loading. For the initial surface roughness values, an increase in roughness was noted with a 10 N load. With increasing load, a decrease in the surface roughness of the sample was noted. The effect of load on the surface roughness results of samples mated with moist rings for 5 and 30-min cycles, at speeds of 25 and 30 mm/s is shown in Figure 7 and Figure 8.

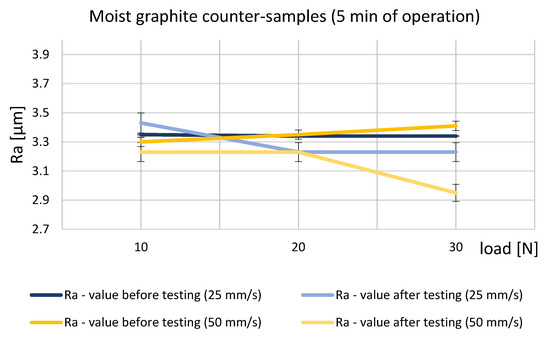

Figure 7.

Change in the values of the Ra roughness parameters of steel samples working with moist graphite rings for 5 min under loads of 10, 20, and 30 N and speeds of 25 and 50 mm/s.

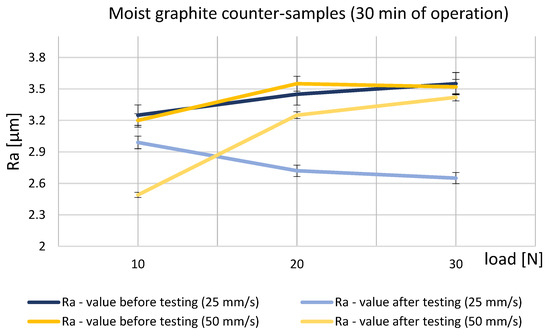

Figure 8.

Change in the values of the Ra roughness parameters of steel samples mated with moist graphite rings for 30 min under loads of 10, 20, and 30 N and speeds of 25 and 50 mm/s.

During the 5-min friction node operation at a speed of 25 mm/s, there was a decrease in surface roughness as the load increased. Increasing the speed to 50 mm/s contributed to a faster and greater decrease in surface roughness.

On the other hand, for a 30-min friction node operation, already at a speed of 25 mm/s there was a significant decrease in roughness as the load increased. Increasing the speed to 50 mm/s contributed to an increase in roughness with increasing load. However, there was no overshoot of the surface roughness value compared to the initial values.

3.3. The Comparative Analysis of Dry and Moist Friction on the Sliding Layer Formation

In order to realize the purpose of the work and evaluate the effect of moist rings on the resulting sliding layer, in the first step the obtained roughness values of steel samples were compared with the initial values (Table 4).

Table 4.

The roughness values of steel samples before and after the tests for all operating conditions.

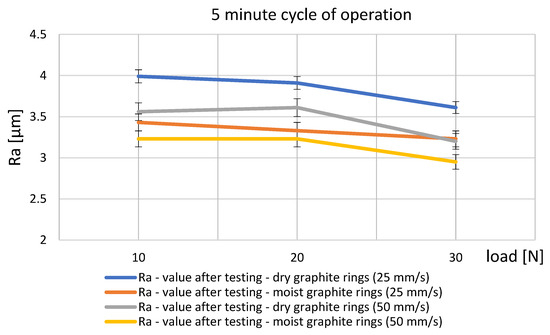

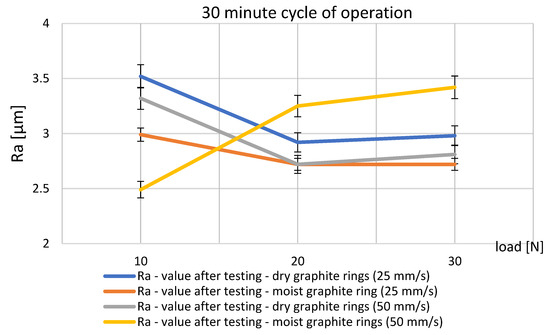

Next, the results of the surface roughness of steel samples, after working with dry and moist graphite rings, were compiled on the charts (Figure 9 and Figure 10). The results of surface roughness tests after conducting two cycles of work—5 and 30 min—are summarized.

Figure 9.

Comparison of the values of the Ra roughness parameter of samples mated with dry and moist rings for a period of 5 min, for loads of 10, 20, and 30 N, at speeds of 25 and 50 mm/s.

Figure 10.

Comparison of the values of the Ra roughness parameter of samples mating with dry and moist rings for a period of 5 min, for loads of 10, 20, and 30 N, at speeds of 25 and 50 mm/s.

For the 5-min cycle, the presence of water in the friction node contributed to a faster and greater decrease in surface roughness with respect to the friction node working dry. This trend was evident for both 25 mm/s and 50 mm/s speeds. The increase in speed contributed to a faster smoothing of the surface.

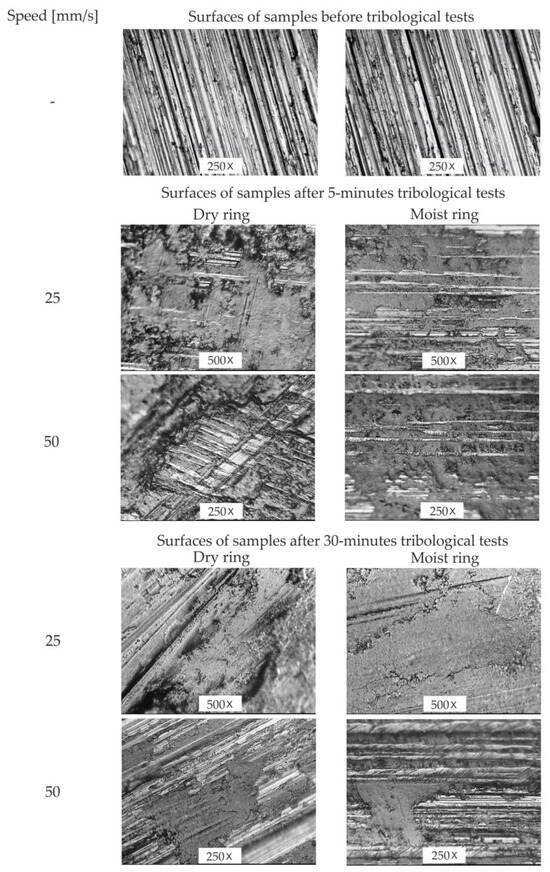

During the 30-min operation of the friction node, the presence of moisture did not clearly affect the results. At a speed of 25 mm/s in the friction node working with soaked samples, there was a significantly greater decrease in roughness than for the friction node working dry. On the other hand, at a speed of 50 mm/s, as the load increased, the presence of moisture affected the increase in the roughness of the counter-sample. This phenomenon was not observed for the dry-running counter-sample, where the surface roughness decreased with increasing load. In order to show the differences in the structure of the emerging layer on the steel sample working with the dry and moist graphite counter-sample, photos of selected surfaces, before and after the experiment, working in 5 and 30-min cycles, at speeds of 25 and 50 mm/s and a load of 30 N are summarized (Figure 11). Observational studies of the surfaces of steel counter-samples confirmed the results obtained while examining the surface roughness that the moisture content of the operation of the tested friction node had a strong influence on the resulting sliding layer. The graphite layer that is formed under dry conditions did not always cover the entire surface of the metal counter-sample. The operating time of the friction node, the set load, and the speed were also significant. After 5 min of operation of steel samples with moist rings, a significant smoothing of the surface was visible, compared to the surface working with dry rings. In turn, after 30 min of work at a speed of 25 mm/s in humid conditions, the greatest smoothing of the steel surface occurred. The steel surface working in dry conditions had an unevenly applied layer of graphite. Imaging studies confirm the results presented in Figure 10 (blue line). The speed increase to 50 mm/s contributed to a greater smoothing of the steel surface cooperating with the dry ring. Expanded graphite filled the irregularities in the surface. The opposite phenomenon was observed when the steel surface operated with a moist ring. Exposed roughness peaks were visible on the surface of the tested sample. The graphite layer did not cover the surface evenly. This phenomenon was also reflected in the surface roughness results of the samples (yellow line—Figure 10).

Figure 11.

Photos of the surfaces of steel samples working with dry and moist graphite counter-samples before and after the experiments (speeds of 25 and 50 mm/s, load of 30 N, magnification 250× and 500×).

A preliminary explanation for the increase in the roughness of the mating surfaces of water-soaked samples at 50 mm/s and a load of 30 N is thermal phenomena. The operation of the friction node under the indicated conditions over an extended period of time contributes to an increase in the temperature of the friction node. This is confirmed by studies [51,52,53]. However, none of the presented studies concern expanded graphite and stainless steel. The adsorbed water in the graphite samples begins to evaporate with the operating time. Up to now, water molecules have provided protection to the emerging graphite layer. Due to the lack of water, the problem of forming a sliding layer and an increase in roughness occurs. The mechanism of the lubricating action of expanded graphite can be explained by the adsorption theory. According to this theory, graphite has good lubricating properties due to water adsorption.

Adsorbed water molecules on the main sliding planes reduce the adhesion between them and thus reduce the coefficient of friction when sliding them. In addition, the adsorbed water functions as a hydrogen and oxygen reservoir for edge passivation of reactive graphene layers on basal planes [54] or in prismatic planes of graphite crystals perpendicular to the sliding direction [55]. However, given the complexity of water activity (density and structure of physisorbed water and chemisorption and reaction of water at the interface under mechanical shear), it is not possible to explain the effect of water sorption by one simple mechanism. Additionally, the previous literature analysis shows that it is important to determine the amount of water necessary to maintain appropriate lubrication conditions. Too much water has an adverse effect on the resulting layer and its smoothness [56]. Therefore, it seems advisable to continue research in the indicated direction.

As part of research, the initial wear mechanism was defined. In the first phase of research, graphite particles transferred as a result of adhesion were anchored at the highest ends of the microcavities. Primary wear products were formed. Then, as a result of the movement, the graphite particles transferred to the metal surface were partially ground. The amount of graphite material on the steel surface increased. After 5 min of operation, the visible grooves of the internal surface were filled with graphite. However, in most cases the steel tops were still visible. This phenomenon was practically unnoticeable after 30 min of association of samples cooperating with wet rings. Wear particles not bound to any surface can be re-adsorbed onto the graphite surfaces or removed from the friction zone.

4. Conclusions

The article describes the research results regarding the formation of a sliding layer during tribological contact between expanded graphite and stainless steel. The tests were carried out under static contact for 30 s and dynamic contact for 15 and 30 min under dry conditions and during the cooperation of the samples with moist rings. The loads of 10, 20, and 30 N and speeds of 25 and 50 mm/s were used. Changes in surface geometry caused by material transfer were determined based on measurements of the Ra surface roughness parameters of stainless steel samples after a friction cycle. It was established that:

- The presence of moisture in the stainless steel-expanded graphite friction node affects the formation of a sliding layer. The resulting layer reduces the surface roughness of the cooperating materials and prevents their accelerated wear. A reduction of the Ra surface roughness parameter of the stainless steel sample was observed for approx. 80% of cases when working with a graphite counter-sample soaked in water, and for approx. 35% of cases when dry working.

- The transfer of graphite material to the surface of the stainless steel sample was observed during static contact of these materials. However, no significant reduction of the Ra surface roughness parameter of the stainless steel sample was observed.

- After 5 min of work with the water-soaked graphite counter-sample, depending on the friction conditions, a reduction of the Ra surface roughness parameter of the stainless steel sample was achieved in the range of 11–18% compared to the initial value. In turn, for dry worked samples, the Ra parameter decreased slightly—by approximately 4%.

- After 30 min of operation, stainless steel samples working with wet expanded graphite were characterized only by a reduction of the Ra surface roughness parameter in the range of 3–25% compared to the initial value. However, the Ra parameter decreased in the range of 5–13% in the case of dry worked samples.

- Pilot studies have shown that operating conditions, i.e., time, load, speed, and humidity, influence the formation of a sliding layer in the tribological contact between stainless steel and expanded graphite. This confirms the validity of conducting further research in this area.

Author Contributions

Conceptualization, A.R.; Methodology, A.R. and G.K.; Software, A.R.; Validation, A.R., K.P. and G.K.; Formal analysis, A.R., K.L. and G.K.; Investigation, A.R., K.P. and G.K.; Resources, A.R.; Data curation, A.R. and K.L.; Writin—original draft, A.R. and K.P.; Writing—review & editing, A.R. and K.L.; Visualization, A.R. and K.P.; Supervision, A.R. and K.L.; Project administration, A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Holmberga, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Holmberga, K.; Anderssona, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Gong, H.; Yu, C.; Zhang, L.; Xie, G.; Guo, D.; Luo, J. Intelligent lubricating materials: A review. Compos. Part B Eng. 2020, 202, 108450. [Google Scholar] [CrossRef]

- Lima, G.A.; Klein, A.N.; Furlan, K.P. Controlling the Solid-State Reaction in Fe-MoS2 Self-Lubricating Composites for Optimized Tribological Properties. Lubricants 2022, 10, 142. [Google Scholar] [CrossRef]

- Zhu, W.; Tan, Y.; Tang, W.; Li, Y.; Tang, Y. Late-model N, B, and P-co-doped carbon dots as additives for friction-reduction and anti-wear. Diam. Relat. Mater. 2023, 139, 110315. [Google Scholar] [CrossRef]

- Nyholm, N.; Espallargas, N. Functionalized carbon nanostructures as lubricant additives—A review. Carbon 2023, 201, 1200–1228. [Google Scholar] [CrossRef]

- Tang, W.; Liu, H.; Zhu, W.; Wei, X. Carbon nitride quantum dots: Towards efficient nano-additives in polyethylene glycol. Carbon 2023, 207, 305–316. [Google Scholar] [CrossRef]

- Khanmohammadi, H.; Wijanarko, W.; Espallargas, N. The role of tribofilm chemical composition on wear of austenitic stainless steel lubricated with water-glycol containing ionic-liquids as additives. Wear 2023, 520–521, 204672. [Google Scholar] [CrossRef]

- Li, L.; Bai, P.; Wen, X.; Zhou, X.; Ma, K.; Meng, Y.; Ding, J.; Tian, Y. Wear mechanism and evolution of tribofilm of ceramic on steel pairs under ester oil lubrication in wide temperature range. J. Mater. Res. Technol. 2023, 27, 6984–6996. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, Q.; Huang, X.; Liu, R.; Zhai, W.; Yang, K. An approximate model for the migration of solid lubricant on metal matrix self-lubricating composites. Tribol. Int. 2016, 93, 104–114. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, J.; Du, S.; Zhang, Y. Test and analysis of the tribofilm and surface state during rolling contact under lubrication condition. Tribol. Int. 2023, 187, 108774. [Google Scholar] [CrossRef]

- Huynh, K.K.; Pham, S.T.; Tieu, A.K.; Collins, S.M.; Lu, C.; Wan, S. Tribo-induced catalytically active oxide surfaces enabling the formation of the durable and high-performance carbon-based tribofilms. Tribol. Int. 2023, 184, 108476. [Google Scholar] [CrossRef]

- Solfitia, E.; Bertoa, F. Mechanical properties of flexible graphite: Review. Procedia Struct. Integr. 2020, 25, 420–429. [Google Scholar] [CrossRef]

- Scharf, T.; Prasad, S. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Li, J.; Peng, Y.; Tang, X.; Liu, B.; Bai, L.; Zhou, K. Hydrogen-passivation modulation on the friction behavior of graphene with vacancy defects under strain engineering. Appl. Surf. Sci. 2022, 579, 152055. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Tian, M. Effect of expanded graphite (EG) dispersion on the mechanical and tribological properties of nitrile rubber/EG composites. Wear 2012, 276–277, 85–93. [Google Scholar] [CrossRef]

- Li, X.; Gao, Y.; Xing, J.; Wang, Y.; Fang, L. Wear reduction mechanism of graphite and MoS2 in epoxy composites. Wear 2004, 257, 279–283. [Google Scholar] [CrossRef]

- He, X.; Kumara, C.; Sulejmanovic, D.; Keiser, J.R.; Gallego, N.; Qu, J. Tribocorrosion of stainless steel sliding against graphite in FLiNaK molten salt. Wear 2023, 522, 204706. [Google Scholar] [CrossRef]

- Tian, X.-L.; Yu, J.-H.; Qiu, L.; Zhu, Y.-H.; Zhu, M.-Q. Structural changes and electrochemical properties of mesoporous activated carbon derived from Eucommia ulmoides wood tar by KOH activation for supercapacitor applications. Ind. Crops Prod. 2023, 197, 116628. [Google Scholar] [CrossRef]

- Jin, H.; Zhou, K.; Ji, Z.; Tian, X.; Chen, Y.; Lu, L.; Ren, Y.; Xu, C.; Duan, S.; Li, J.; et al. Comparative tribological behavior of friction composites containing natural graphite and expanded graphite. Friction 2020, 8, 684–694. [Google Scholar] [CrossRef]

- Chen, Q.; Morita, T.; Sawae, Y.; Fukuda, K.; Sugimura, J. Effects of trace moisture content on tribofilm formation, friction and wear of CF-filled PTFE in hydrogen. Tribol. Int. 2023, 188, 108905. [Google Scholar] [CrossRef]

- Vishal, K.; Rajkumar, K. Dry sliding wear behavior of Poly Ether Ether Ketone (PEEK) reinforced with graphite and synthetic diamond particles. Diam. Relat. Mater. 2022, 130, 109404. [Google Scholar] [CrossRef]

- Adachi, K.; Cho, U.; Sinha, S.K.; Kato, K. Self-Lubrication by Formation of Graphite Films in the Sliding of Silicon Nitride Against Cast Iron. Tribol. Trans. 2008, 44, 41–46. [Google Scholar] [CrossRef]

- Sugishita, J.; Fujiyoshi, S. The effect of cast iron graphites on friction and wear performance: II: Variables influencing graphite film formation. Wear 1981, 68, 7–20. [Google Scholar] [CrossRef]

- Ghasemi, R.; Elmquist, L. A study on graphite extrusion phenomenon under the sliding wear response of cast iron using microindentation and microscratch techniques. Wear 2014, 320, 120–126. [Google Scholar] [CrossRef]

- Hiratsuka, K.; Mariko, R.; Tsutsumi, T. Effects of sliding speed, periodic pauses, and atmospheric moisture content on the wear of graphite against cast iron. Wear 2019, 424–425, 255–260. [Google Scholar] [CrossRef]

- Parsaeian, P.; Van Eijk, M.C.P.; Nedelcu, I.; Neville, A.; Morina, A. Study of the interfacial mechanism of ZDDP tribofilm in humid environment and its effect on tribochemical wear; Part I: Experimental. Tribol. Int. 2017, 107, 135–143. [Google Scholar] [CrossRef]

- Johansson, P.; Marklund, P.; Björling, M.; Shi, Y. Effect of humidity and counterface material on the friction and wear of carbon fiber reinforced PTFE composites. Tribol. Int. 2021, 157, 106869. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, Y.; Guo, F.; Liu, X.; Wang, Y. Friction Characteristics of Impregnated and Non-Impregnated Graphite against Cemented Carbide under Water Lubrication. J. Mater. Sci. Technol. 2017, 33, 1203–1209. [Google Scholar] [CrossRef]

- Lang, H.; Peng, Y.; Zeng, X.; Liu, L.; Zou, K. Effect of relative humidity on the frictional properties of graphene at atomic-scale steps. Carbon 2018, 137, 519–526. [Google Scholar] [CrossRef]

- Jia, J.; Chen, J.; Zhou, H.; Wang, J.; Zhou, H. Friction and wear properties of bronze–graphite compositeunder water lubrication. Tribol. Int. 2004, 37, 423–429. [Google Scholar] [CrossRef]

- Wos, S.; Koszela, W.; Pawlus, P. The effect of graphite surface texturing on the friction reduction in dry contact. Tribol. Int. 2020, 151, 106535. [Google Scholar] [CrossRef]

- Krawiec, S. Kompozycje Smarów Plastycznych i Stałych w Procesie Tarcia Stalowych Węzłów Maszyn; WPW: Wroclaw, Poland, 2011; pp. 38–45. [Google Scholar]

- Hirani, H.; Goilkar, S.S. Formation of transfer layer and its effect on friction and wear of carbon–graphite face seal under dry, water and steam environments. Wear 2009, 266, 1141–1154. [Google Scholar] [CrossRef]

- Briscoe, W.H.; Titmuss, S.; Tiberg, F.; Thomas, R.K.; McGillivary, D.J.; Klein, J. Boundary lubrication under water. Nat. Lett. 2006, 444, 191–194. [Google Scholar] [CrossRef] [PubMed]

- Ilberg, L.; Manis-Levy, H.; Raveh, A.; Lifshitz, Y.; Varenberg, M. Effect of structure of carbon films on their tribological properties. Diam. Relat. Mater. 2013, 38, 79–86. [Google Scholar] [CrossRef]

- Wang, J.; Yan, F.; Xue, Q. Tribological Behaviors of Some Materials in Sea Water. In Advanced Tribology: Proceedings of CIST2008 & ITS-IFToMM2008; Springer: Berlin/Heidelberg, Germany, 2008; pp. 430–432. [Google Scholar] [CrossRef]

- Somberg, J.; Gonçalves, G.; Emami, N. Graphene oxide versus graphite and chemically expanded graphite as solid lubricant in ultrahigh molecular weight polyethylene composites. Tribol. Int. 2023, 187, 108643. [Google Scholar] [CrossRef]

- Masood, E. Power Generation Technologies. In Steam Power Plants, Components. Power Generation Technologies Foundations, Design and Advances; Elsevier: Amsterdam, The Netherlands, 2023; pp. 205–226. [Google Scholar]

- Sotoodeh, K. Valve sealing and packing. In Prevention of Valve Fugitive Emissions in the Oil and Gas Industry; Gulf Professional Publishing: Houston, TX, USA, 2021; pp. 67–91. [Google Scholar]

- Bloch, H.P.; Geitner, F.K. Repair and maintenance of rotating equipment components. In Practical Machinery Management for Process Plants; Elsevier: Amsterdam, The Netherlands, 2019; pp. 449–518. [Google Scholar]

- Zahorulko, A. Experimental investigation of mechanical properties of stuffing box packings. Seal. Technol. 2015, 8, 7–13. [Google Scholar] [CrossRef]

- Roe, M.; Torrance, A.A. The surface failure and wear of graphite seals. Tribol. Int. 2008, 41, 1002–1008. [Google Scholar] [CrossRef]

- Mordor Intelligence. Report Expanded Graphite Market Size & Share Analysis—Growth Trends & Forecasts (2024–2029); Mordor Intelligence: Hyderabad, India, 2024. [Google Scholar]

- Xu, L.; Tang, Z.; Xu, Z.; Xie, C.; Guo, L.; Li, W. High-performance expanded graphite from flake graphite by microwave-assisted chemical intercalation process. J. Ind. Eng. Chem. 2023, 122, 562–572. [Google Scholar]

- Jenson, A.D.; Roy, S.; Sundararajan, S. The evolution of hardness and tribofilm growth during running-in of case carburized steel under boundary lubrication. Tribol. Int. 2018, 118, 1–10. [Google Scholar] [CrossRef]

- Rewolińska, A.; Perz, K.; Kinal, G. Effect of Steel Surface Roughness and Expanded Graphite Condition on Sliding Layer Formation. Materials 2021, 14, 2960. [Google Scholar] [CrossRef] [PubMed]

- PN-EN ISO 21920-3:2022-06; Product Geometry Specifications (GPS)—Geometric Structure of Surfaces: Profile—Part 3: Specification Operators. Polish Committee for Standardization: Warsaw, Poland, 2022.

- PN-EN ISO 3274:2011; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Nominal Characteristics of Contact (Stylus) Instruments. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Rewolińska, A.; Perz, K.; Kinal, G. Graphite expanded as a film-forming material on a steel surface. Tribologia 2017, 5, 81–85. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Conte, M.; Pinedo, B.; Igartua, A. Frictional heating calculation based on tailored experimental measurements. Tribol. Int. 2014, 74, 1–6. [Google Scholar] [CrossRef]

- Zhu, J.; Xie, F.; Dwyer-Joyce, R.S. PEEK Composites as Self-Lubricating Bush Materials for Articulating Revolute Pin Joints. Polymers 2020, 12, 665. [Google Scholar] [CrossRef] [PubMed]

- Restuccia, P.; Ferrario, M.; Righi, M.C. Monitoring water and oxygen splitting at graphene edges and folds: Insights into the lubricity of graphitic materials. Carbon 2020, 156, 93–103. [Google Scholar] [CrossRef]

- Savage, R.H. Graphite lubrication. J. Appl. Phys. 1948, 19, 1–10. [Google Scholar] [CrossRef]

- Morstein, C.E.; Klemenz, A.; Dienwiebel, M.; Moseler, M. Humidity-dependent lubrication of highly loaded contacts by graphite and a structural transition to turbostratic carbon. Nat. Commun. 2020, 13, 5958. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).