Interlayer Shear Sliding Behaviors during the Fracture Process of Thick Sandstone Roof and Its Mechanism Leading to Coal Mine Tremors

Abstract

1. Introduction

2. Experimental Methods

2.1. Specimen Processing and Sensor Placement

2.2. Experimental System

2.3. Experimental Procedure

3. Experimental Results

3.1. Fracture Characteristics of Composite Rock Layer under Bending Loading

3.2. Evolutionary Law of Composite Rock Layer Deformation

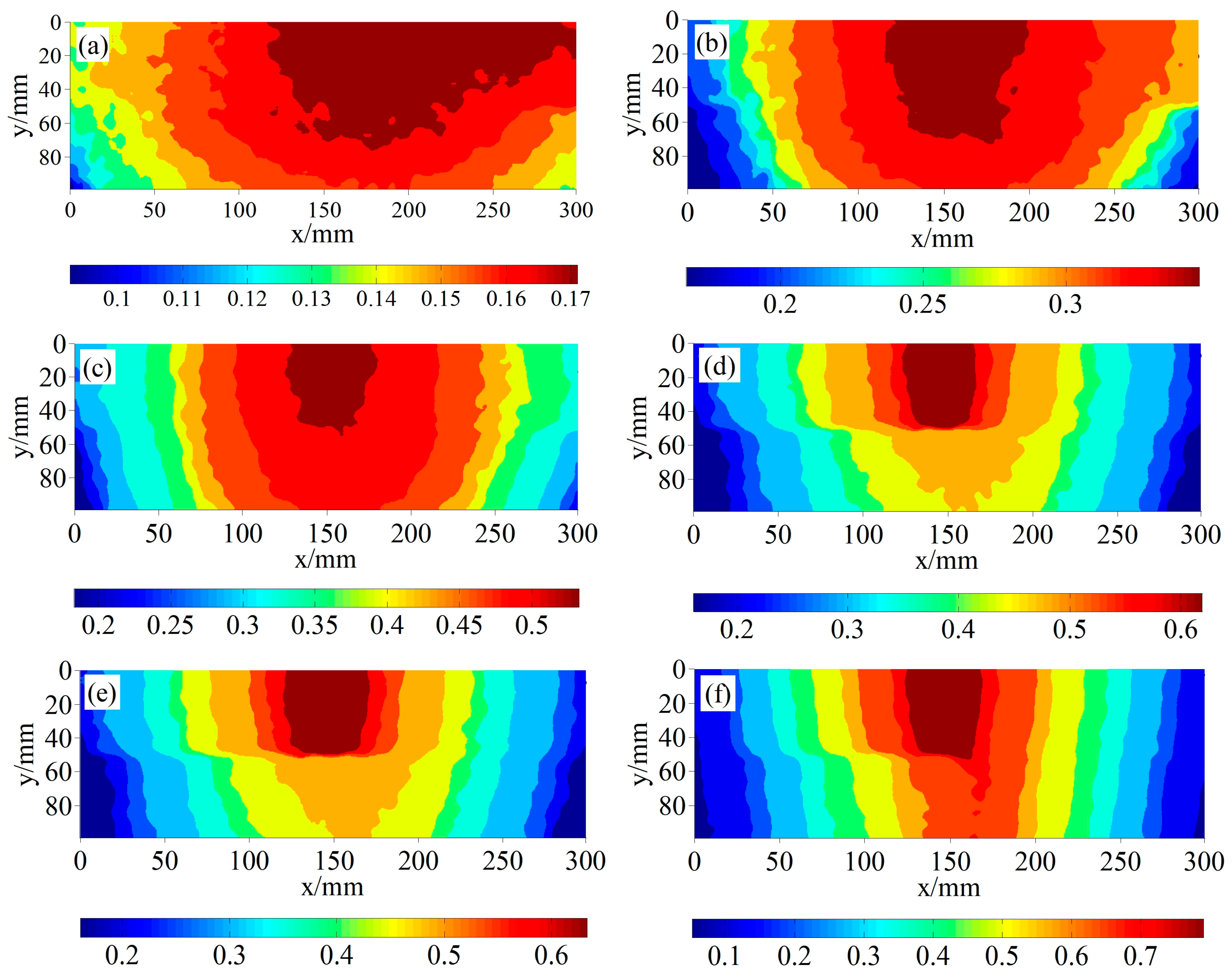

3.2.1. Vertical Deformation

3.2.2. Horizontal Deformation

3.2.3. Shear Deformation

3.3. Characteristics of Interlayer Sliding Acceleration

3.4. Acoustic Emission Characteristics

3.4.1. Acoustic Emission Count and Energy

3.4.2. Damage and Crack Evolution

3.4.3. Acoustic Emission Duration

4. Conditions of Interlayer Shear Slip in Composite Rock Layers and the Possible Mechanism of Mine Tremor

4.1. Interlayer Slip Conditions of Composite Rock Layers

4.2. Fracture Sequence of Composite Rock Layers

4.3. Mechanism of Mine Tremors in Composite Rock Layers

4.4. Coal Mine Tremors and Prevention Cases

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hasegawa, H.S.; Wetmiller, R.J.; Gendzwill, D.J. Induced seismicity in mines in Canada—An overview. Pure Appl. Geophys. 1989, 129, 423–453. [Google Scholar] [CrossRef]

- Li, T.; Cai, M.F.; Cai, M. A review of mining-induced seismicity in China. Int. J. Rock Mech. Min. 2007, 44, 1149–1171. [Google Scholar] [CrossRef]

- Foulger, G.R.; Wilson, M.P.; Gluyas, J.G.; Julian, B.R.; Davies, R.J. Global review of human-induced earthquakes. Earth-Sci. Rev. 2018, 178, 438–514. [Google Scholar] [CrossRef]

- Alber, M.; Fritschen, R. Rock mechanical analysis of a M1 = 4.0 seismic event induced by mining in the Saar District, Germany. Geophys. J. Int. 2011, 186, 359–372. [Google Scholar] [CrossRef]

- Rudziński, Ł.; Cesca, S.; Lizurek, G. Complex Rupture Process of the 19 March 2013, Rudna Mine (Poland) Induced Seismic Event and Collapse in the Light of Local and Regional Moment Tensor Inversion. Seismol. Res. Lett. 2016, 87, 274–284. [Google Scholar] [CrossRef]

- Alvarez-Garcia, I.N.; Ramos-Lopez, F.L.; Gonzalez-Nicieza, C.; Alvarez-Fernandez, M.I.; Alvarez-Vigil, A.E. The mine collapse at Lo Tacón (Murcia, Spain), possible cause of the Torre Pacheco earthquake (2nd May 1998, SE Spain). Eng. Fail. Anal. 2013, 28, 115–133. [Google Scholar] [CrossRef]

- Ford, S.R.; Dreger, D.S.; Walter, W.R. Source Characterization of the 6 August 2007 Crandall Canyon Mine Seismic Event in Central Utah. Seismol. Res. Lett. 2008, 79, 637–644. [Google Scholar] [CrossRef]

- Dong, R.S.; Xu, S.J. A Brief Discussion on Mining Earthquake Disasters—Taking the Taiji Mining Earthquake as an Example. J. Catastrophol. 1990, 65–66. [Google Scholar]

- Zhang, Y.Y.; Wang, T.T.; Su, L.N.; Yang, Y.H.; Hui, S.X. Study on the regional characteristics of the subsidence seismic records in the northern Shaanxi. Acta Seismol. Sin. 2020, 42, 684–696. [Google Scholar] [CrossRef]

- He, W.Z.; Xiang, M.X.; Liu, H.N.; Li, Y.H.; Peng, J. Ground subsidence and its environment problems in Yushenfu mining area. Coal Geol. Explor. 2016, 44, 131–135. [Google Scholar] [CrossRef]

- Bedford, J.D.; Faulkner, D.R.; Lapusta, N. Fault rock heterogeneity can produce fault weakness and reduce fault stability. Nat. Commun. 2022, 13, 326. [Google Scholar] [CrossRef] [PubMed]

- Goebel, T.H.W.; Brodsky, E.E.; Dresen, G. Fault Roughness Promotes Earthquake-Like Aftershock Clustering in the Lab. Geophys. Res. Lett. 2023, 50, e2022GL101241. [Google Scholar] [CrossRef]

- Chen, X.F.; Chitta, S.S.; Zu, X.M.; Reches, Z. Dynamic fault weakening during earthquakes: Rupture or friction? Earth Planet. Sci. Lett. 2021, 575, 117165. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Liu, C.; Zhu, H.Z.; Xie, F.X.; Dou, L.M.; Chen, J.H. Mechanism of rock burst caused by fracture of key strata during irregular working face mining and its prevention methods. Int. J. Min. Sci. Technol. 2019, 29, 889–897. [Google Scholar] [CrossRef]

- Pan, C.; Xia, B.W.; Zuo, Y.J.; Yu, B.; Ou, C.N. Mechanism and control technology of strong ground pressure behaviour induced by high-position hard roofs in extra-thick coal seam mining. Int. J. Min. Sci. Technol. 2022, 32, 499–511. [Google Scholar] [CrossRef]

- Wu, Q.S.; Jiang, J.Q.; Wu, Q.L.; Xue, Y.C.; Kong, P.; Gong, B. Study on the Fracture of Hard and Thick Sandstone and the Distribution Characteristics of Microseismic Activity. Geotech. Geol. Eng. 2018, 36, 3357–3373. [Google Scholar] [CrossRef]

- Du, K.; Li, X.F.; Tao, M.; Wang, S.F. Experimental study on acoustic emission (AE) characteristics and crack classification during rock fracture in several basic lab tests. Int. J. Rock Mech. Min. 2020, 133, 104411. [Google Scholar] [CrossRef]

- Zhang, W.L.; Qu, X.C.; Li, C.; Xu, X.; Zhang, S.L.; Jin, G.D.; Wang, Y.L. Fracture analysis of multi-hard roofs based on microseismic monitoring and control techniques for induced rock burst: A case study. Arab. J. Geosci. 2019, 12, 784. [Google Scholar] [CrossRef]

- Fu, J.H.; Wen, G.G.; Sun, H.T.; Yang, X.L. Study on the shear movement law of overlying strata by slice mining. Energy Sci. Eng. 2020, 8, 2335–2351. [Google Scholar] [CrossRef]

- Alneasan, M.; Behnia, M.; Bagherpour, R. Analytical investigations of interface crack growth between two dissimilar rock layers under compression and tension. Eng. Geol. 2019, 259, 105188. [Google Scholar] [CrossRef]

- Li, Y.J.; Wang, S.T.; Zheng, L.G.; Zhao, S.K.; Zuo, J.P. Evaluation of the fracture mechanisms and criteria of bedding shale based on three-point bending experiment. Eng. Fract. Mech. 2021, 255, 107913. [Google Scholar] [CrossRef]

- Wang, G.B.; Meng, T.; Feng, G.; Ma, L.F.; Yang, W.M.; He, Y.; Zhang, Z.J.; Liang, X.F. Influence of Bedding Strength and Angle on Fracture Characteristics of Sandstone under Three-Point Bending Conditions. Appl. Sci. 2023, 13, 8216. [Google Scholar] [CrossRef]

- Zhen, X.X.; Zang, Z.J.; Wang, R.H.; Li, Z. Influence of slip effect on bending characteristics offrictional laminated beams. Eng. Mech. 2016, 33, 185–193. [Google Scholar] [CrossRef]

- Shabanimashcool, M.; Li, C.C. Analytical approaches for studying the stability of laminated roof strata. Int. J. Rock Mech. Min. 2015, 79, 99–108. [Google Scholar] [CrossRef]

- Sterling, R.L. The Ultimate Load Behavior of Laterally Constrained Rock Beams. In Proceedings of the 21st U.S. Symposium on Rock Mechanics, Rolla, MO, USA, 28–30 May 1980; pp. 80–533. [Google Scholar]

- Chang, X.; Shan, Y.F.; Zhang, Z.H.; Tang, C.A.; Ru, Z.L. Behavior of propagating fracture at bedding interface in layered rocks. Eng. Geol. 2015, 197, 33–41. [Google Scholar] [CrossRef]

- Xiao, Y. Interlaminar shear slip condition of stratified rock mass under bending. In Proceedings of the Second National Engineering Geomechanics Youth Symposium, Beijing, China, 1 March 1992. [Google Scholar]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Determination of the Extent of the Rock Destruction Zones around a Gasification Channel on the Basis of Strength Tests of Sandstone and Claystone Samples Heated at High Temperatures up to 1200 °C and Exposed to Water. Energies 2021, 14, 6464. [Google Scholar] [CrossRef]

- Aldahdooh, M.A.A.; Muhamad Bunnori, N. Crack classification in reinforced concrete beams with varying thicknesses by mean of acoustic emission signal features. Constr. Build. Mater. 2013, 45, 282–288. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, Y.X.; Gao, Y.R.; Zhang, C. Experimental research of influences of bedding and pre-crack directions onfracture characteristics of coal. Chin. J. Rock Mech. Eng. 2022, 41, 433–445. [Google Scholar] [CrossRef]

- Wang, W.; Pan, Y.S.; Xiao, Y.H. Synergistic resin anchoring technology of rebar bolts in coal mine roadways. Int. J. Rock Mech. Min. Sci. 2022, 151, 105034. [Google Scholar] [CrossRef]

- Wang, W.; Pan, Y.S.; Xiao, Y.H. Synergistic mechanism and technology of cable bolt resin anchoring for roadway roofs with weak interlayers. Rock Mech. Rock Eng. 2022, 55, 3451–3472. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Pan, Y.; Zhao, T.; Wang, W.; Xiao, Y.; Song, Y.; Dai, L. Interlayer Shear Sliding Behaviors during the Fracture Process of Thick Sandstone Roof and Its Mechanism Leading to Coal Mine Tremors. Appl. Sci. 2024, 14, 4323. https://doi.org/10.3390/app14104323

Gao X, Pan Y, Zhao T, Wang W, Xiao Y, Song Y, Dai L. Interlayer Shear Sliding Behaviors during the Fracture Process of Thick Sandstone Roof and Its Mechanism Leading to Coal Mine Tremors. Applied Sciences. 2024; 14(10):4323. https://doi.org/10.3390/app14104323

Chicago/Turabian StyleGao, Xuepeng, Yishan Pan, Tongbin Zhao, Wei Wang, Yonghui Xiao, Yimin Song, and Lianpeng Dai. 2024. "Interlayer Shear Sliding Behaviors during the Fracture Process of Thick Sandstone Roof and Its Mechanism Leading to Coal Mine Tremors" Applied Sciences 14, no. 10: 4323. https://doi.org/10.3390/app14104323

APA StyleGao, X., Pan, Y., Zhao, T., Wang, W., Xiao, Y., Song, Y., & Dai, L. (2024). Interlayer Shear Sliding Behaviors during the Fracture Process of Thick Sandstone Roof and Its Mechanism Leading to Coal Mine Tremors. Applied Sciences, 14(10), 4323. https://doi.org/10.3390/app14104323