Abstract

Condition-based maintenance of a machine tool spindle unit is known to reduce the total cost of operation in a manufacturing environment. However, standard vibration monitoring thresholds, which are based only on average vibration energy levels, do not account for the machine’s dynamics, such as dynamic stiffness and damping ratios, which, ultimately, control the final quality of a machined workpiece. In this study, a new mechanical device is proposed for the estimation of spindle dynamics characteristics through measurement of the frequency response function (FRF) of the spindle. The device is simple, robust in a manufacturing environment, small, and requires no power source. The new device is shown to be comparable in performance to conventional impact hammer testing, with the advantage of being fully automated and capable of dynamic assessment on a rotating spindle. Such a device allows a machine tool operator to routinely monitor the stiffness and damping ratios of the spindle unit and make informed maintenance decisions based on meaningful changes in operating conditions that impact production.

1. Introduction

1.1. Background

Condition-based maintenance (CBM), the practice of driving maintenance decisions using condition monitoring data, has been proposed as an advanced maintenance strategy enabled by Industry 4.0 initiatives to reduce the overall costs of equipment ownership and improve the productivity of manufacturing enterprises [1]. However, reports from McKinsey & Company indicate that many CBM initiatives fall short of these promised goals and report little measurable impact [2]. Unsuccessful advanced maintenance programs tend to place too much emphasis on the technology, rather than the high-impact root-cause problems of the machine [3].

In the context of CNC milling operations, the roles of the machine tool spindle unit are to (1) facilitate the precision rotation of the tool at the commanded speed and (2) to transmit the required forces and energy to the cutting zone for metal removal [4]. The ability of a spindle to accomplish these tasks is fundamentally governed by the dynamic characteristics of the spindle’s modes, that is, the mass, stiffness, and damping properties of the system. Experimental modal analysis provides a means to directly measure these dynamic characteristics by describing how a system vibrates in response to an input excitation force.

Industry-standard spindle monitoring procedures do not outline methods for the modal characterization of machine tool spindle units. For example, the standard ISO 10816, which describes methods for evaluating the mechanical vibrations of rotating machines, considers only the vibration magnitude root mean square level [5]. Similarly, standard ISO/TR 17243, which is specifically tailored to the monitoring of machine tool spindle vibration, also only considers the average magnitude and neglects the frequency domain analysis, tracking of dynamic characteristics, or machining performance metrics for maintenance decision making [6]. This is despite the existence of established techniques for the modal analysis of machine tool spindle units. The pioneering works concerned with the modal analysis of machine tools for metal cutting were established by Tlusty and Polacek [7] and Tobias and Fiswick [8] in the 1950s. Another study established the groundwork for the powerful prediction of machine tool performance such as chatter stability in metal cutting processes [9]. Modal analysis has found additional usage outside of chatter prediction, such as by Altintas and Cao, who used the technique to model and predict the behavior of a machine tool spindles unit and optimize spindle design for maximum dynamic stiffness [10]. Given that the connection between modal analysis and spindle performance has been established for decades, why has the field of machine condition monitoring and CBM not capitalized on this knowledge to drive impactful maintenance decisions?

Jardaine et al. established that successful CBM is predicated on the ability to acquire machine condition data at regular intervals for processing and maintenance decision making [11]. Before using modal analysis for CBM applications, the problem of frequency response function (FRF) data collection must be overcome. When compared to conventional vibration monitoring practices currently used by CBM programs, the collection of FRF data is more difficult as it requires collection of both the input excitation forces and the vibration response [12]. Conventional methods for experimental modal analysis include the use of either an impact hammer or a shaker to excite the mechanical system with an impulse, a transient sine-sweep, or a random excitation [13]. However, both of these devices require specialized equipment and a skilled operator to perform the test, which presents a challenge when trying to implement this type of data collection in a wide scale CBM operation. New methods of FRF data collection are needed if CBM is to be enhanced by the tracking of modal characteristics.

1.2. Advanced Methods for Modal Analysis Data Collection

The challenge of applying modal analysis techniques for machine tools is an active research problem as demonstrated by the recent review conducted by Iglesias et al. on a series of emerging technologies aimed at the assessment of machine tool dynamics [12]. The authors found that while many new methods show promise, they suffered from being too situationally specific, requiring a complex experimental setup and, generally, being more time-consuming to perform than conventional methods. Vogl and Donmez developed a prototype spindle condition estimation device that uses a solenoid-driven mass to apply an impulse force to the housing of a machine tool spindle. Notable features of this design are the integration of two accelerometers and a force sensor into the device and a magnetic base, which allows the small device to be portable and attached to the spindle housings of different machines [14]. Bediz et al. used a custom-made impact hammer excitation system which used a double-notch flexure actuated by an electromagnet to reliably excite frequencies up to 20 kHz in miniature ultra-high-speed spindles. The resultant vibrations from the spindle were measured using two mutually perpendicular laser Doppler vibrometers [15]. Wiederkehr et al. developed a novel method to excite micromilling tools by shooting ball bearings at the tool using compressed air; then, tool deflections were measured using a contactless eddy current sensor. The limitations of this setup were that direct measurement of the impact force was not possible and the force imparted by the ball was modeled using finite element simulations based on geometry, mass, and velocity data for each ball bearing [16].

Noncontact methods that excite the spindle have also been explored, such as the electromagnetic system designed by Tlalolini et al., which applies a noncontact force to the tip of an HSK standard tool [17]. The system can apply both a static magnetic force and sinusoidal forces through pulse-width-modulated control signals in perpendicular x and y directions. While the system was successfully demonstrated to measure the FRF of static and rotating spindles, the electromagnetic shaker is large and takes up valuable table space in the machine tool that would have significant implications on the productivity of the operation in a continuous monitoring application.

Finally, research has been conducted on instrumented machine tools that use sweep milling force excitation to estimate the FRF using cutting forces as the input excitation. Iglesias et al. used a table-mounted dynamometer and a dynamometric tool holder to measure the cutting forces and response of the spindle with three mutually perpendicular accelerometers [18]. The FRF generated by the cutting force excitation agreed with both the hammer impact testing and shaker tests. On the one hand, this method is useful because measurements could in theory be collected during the actual cutting operation, and the resulting FRF would most accurately describe the specific cutting dynamics under consideration. On the other hand, Iglesias notes that to solve the three-dimensional system of equations, a minimum of three independent cutting tests must be performed by modifying the cutting condition. This limitation may be in opposition to the constraints of the actual cutting operation in practice and, therefore, limits the usage of the method. Furthermore, the table-mounted dynamometer suffers from the same space limitations as previously described.

On the basis of a review of the current state of the art, the common pitfalls of FRF data collection equipment making FRF tracking unsuitable for CBM are as follows:

- Stationary test equipment is complex and takes up valuable space on the machine table.

- Portable test equipment requires the attention of a skilled operator, which is not scalable for repetitive data collection tasks.

- Tests are time-consuming to perform.

- Tests interfere with production cycles.

These drawbacks limit the ability of machine tool owners to track the dynamic characteristics of their spindles, which are known to be strong predictors of final part quality. The aim of this research work was to provide a practical means of collecting FRF data from machine tool spindle units in production. To this end, three goals were developed for this research program: (1) develop and characterize a device to impart reliable excitation forces into a static or dynamic spindle unit; (2) establish a programmed FRF data collection test cycle that can acquire modal data from the spindle while having a minimal impact on production schedules; and (3) demonstrate that the new method is comparable to conventional impact-testing methods. The new method should be applied so that CNC machine tool owners and operators can monitor the dynamic characteristics of the spindle unit for enhancement of CBM practices.

The remainder of the article is structured as follows: Section 2 describes the experimental apparatus used for data collection, contains a detailed description of the proposed mechanical impulse generator (IG), and describes the modal analysis calculations used to characterize the spindle. Section 3 documents the results from the tests. Section 4 highlights the implications of the results in the broader context of the analysis of CBM and dynamic analysis of machine tool systems. Finally, Section 5 provides a summary of the findings.

2. Materials and Methods

The research program was divided into three tests. First, the IG was constructed and the resultant force profile of the IG was validated through experimentation. Second, the performance of the IG was compared against a conventional impulse hammer for the purpose of a modal analysis of a static CNC machine tool spindle. Third, the functionality of the IG was demonstrated in a modal analysis test for the dynamic spindle.

2.1. Testing Methods

2.1.1. Validation of the Mechanical Impulse Generator

Characterization of the force produced by the IG was conducted by repeatedly impacting the force plate dynamometer with the IG and recording the result. The IG was mounted vertically in the chuck of the CNC machine and driven into the force plate in the z axis at a constant feed rate of 1000 mm/min. Once an impact was triggered, the machine feed was halted for a period of 1.5 s to allow the force response to decay. After this period, the feed direction was reversed to the starting position and subsequent trials were repeated. Fifty trials were recorded for the IG sampled at 51,200 Hz. To compare the results, the force hammer was also used to strike the force plate for 50 trials, and both the force plate measurement and impact hammer measurements were recorded. After the initial characterization of the IG the dynamometer was no longer required for FRF generation.

2.1.2. Static Spindle Test

The performance of the IG was compared against the conventional hammer through three impulse response test conditions for the static spindle. Condition 1 was experimental control. In this condition the operator used the manual force hammer to strike the tool tip in the x direction, and the free vibrations of the spindle were measured. Condition 2 investigated any effect of tool tip contact that the IG might impart on the analysis. In this test, the tool was brought into contact with the IG in the loaded position before performing the manual hammer test as in Condition 1. Note that because of space limitations, the operator needed to strike the tool from the symmetric +x direction. Condition 3 was the automated tap test cycle using the IG. The tool was positioned in line with the IG and then the machine axis was driven at a constant feed rate of 1000 mm/min until impact occurred. Once an impact was triggered, the machine feed was halted for a period of 1.5 s to allow for the vibration response to decay. After this period, the feed direction was reversed to the starting position and subsequent trials were repeated. Fifty individual tap tests were conducted for each condition for statistical assessment. The readings from the force plate dynamometer were monitored during each test to ensure that the force generated by the IG did not exceed a safe limit for the machine (500 N); however, the force plate data were not used for the FRF calculation.

2.1.3. Dynamic Spindle Test

The final test examined the performance of the IG on a rotating spindle. In this test, three spindle speeds were selected ranging the entire spindle range: 240, 1000, and 10,000 RPM. The static spindle test from Condition 3 was also used in this comparison as a control. The procedures for this test were otherwise identical to Condition 3 of the static test.

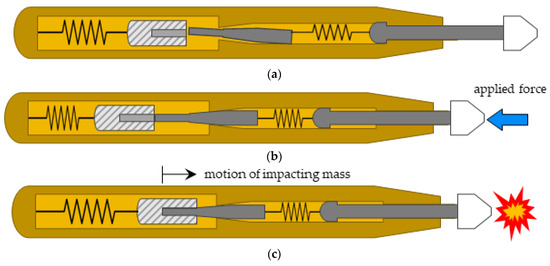

2.2. Mechanical Impulse Generator

The design of the mechanical IG, shown in Figure 1, was based upon an automatic center punch. The IG consisted of four components: (1) housing; (2) impacting mass; (3) tapered pin; and (4) impact tip. Two springs were used to drive the impact and to automatically reset the device between cycles. During operation of the IG, the linear motion of the CNC table is used to activate the impact. The tool is positioned to press against the tip, and the preload springs are compressed, as seen in Figure 1b. At maximum compression, the tapered pin slips into a matching hole in the impact mass, and the mass begins to rapidly accelerate under the force of the preload spring. The impact of the mass imparts a pulse through to the tip which is translated to the tool and excites the spindle system, as seen in Figure 1c. The IG automatically resets itself after an impact is generated to achieve repeated tests, as seen in Figure 1a.

Figure 1.

Schematic cross-section of the mechanical IG showing the principles of operation. (a) Uncompressed position of the IG. (b) Compression of IF as force is applied to the tip. (c) Actuation of the IG causing impulse at the tip.

The design was selected to address the practical challenges with continual spindle FRF monitoring, which were identified during the literature review. In contrast to many of the other solutions proposed in literature, the presented design is low cost, can be completely actuated by the CNC controller, requires minimal space on the CNC table, does not require power, and is not sensitive to the coolant and chips present in the manufacturing environment. Most notably, the proposed design is robust because of the simplicity of the mechanical components used.

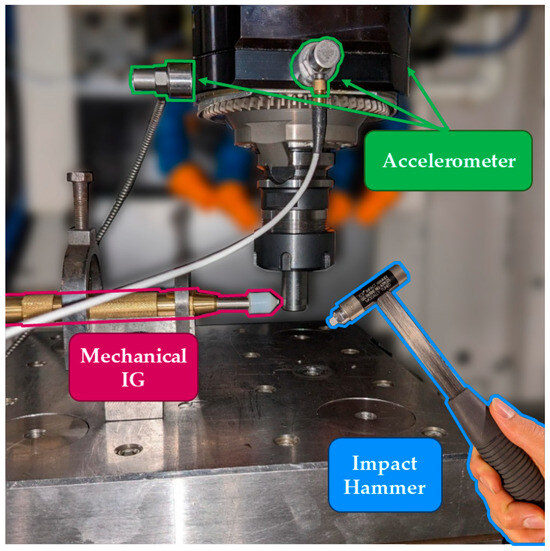

2.3. Experimental Setup

Experimentation was conducted using the setup shown in Figure 2. The CNC machining center used during experimentation was the FANUC Robodrill D14SiA (Mississauga, ON, Canada), loaded with a standard BT30 tool holder. The tool holder held a 16 mm cylindrical carbide rod as a simulated tool. Impact forces from the IG were measured using a Kistler 9255C multicomponent dynamometer (Mississauga, ON, Canada) mounted to the table of the CNC machine.

Figure 2.

Experimental setup for the study completed on a three-axis CNC vertical milling center.

The forces from the IG were compared against a conventional PCB Piezotronics 086C01 impulse hammer (Depew, NY, USA). Spindle vibrations were measured with accelerometers at three locations on static locations of the spindle housing. Two Kistler 8702B K-Shear-type single axis accelerometers (Mississauga, ON, Canada) were mounted at the static part of the spindle housing to record accelerations in the machine +x and +y directions. A redundant third PCB Piezotronics 352A21 (Depew, NY, USA) single-axis accelerometer was also included to measure accelerations in the machine −x direction for verification and error checking. Data acquisition was performed by a National Instruments NI-9234 data acquisition card at a sampling frequency of 51,200 Hz. Finally, the saved time-series data was exported to MATLAB R2023b for experimental modal analysis.

2.4. Experimental Modal Analysis

Time-series data collected from experimentation was used for experimental modal analysis following the established techniques such as those described in the works of Altintas [19] and Schmitz [20]. For brevity, only the relevant definitions and equations are described in this article, and the interested reader is directed to the reference material for comprehensive coverage on the subject.

2.4.1. Frequency Response Function

Force and acceleration signals were used to calculate the inertance FRF for the spindle using the cross-spectrum method. For the input force time-series, , and output accelerometer time-series, , the frequency response function was calculated as in the following Equation (1).

where the cross-spectrum, , of the acceleration and force signals is defined as in the following Equation (2).

where and denote the discrete Fourier transform of the acceleration and force signals and respectively; denotes the complex conjugate of . Similarly, the auto-spectrum of the force and acceleration signals are defined as in the following Equations (3) and (4), respectively.

2.4.2. Coherence

The quality of the FRF was assessed based on the coherence value calculated at each frequency for a series of repeated tap tests. If individual tap test trials are conducted for the same system, the coherence value for those trials is defined as in the following Equation (5).

where the horizontal bar indicates the averaging operator across the trials, as defined in the following Equation (6).

When the coherence is unity, the vibration output is described by a linear relationship with the input force, which indicates a high quality of the measurement, while a coherence value of zero indicates that the output vibration and the input force are completely unrelated, which is an indication of low-quality measurement.

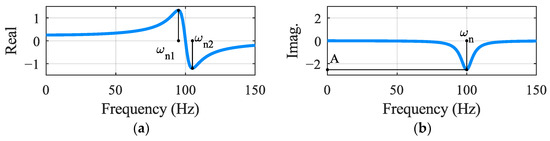

2.4.3. Modal Characterization

The modal characteristics of the spindle were extracted from the FRF using the peak picking method applied to the real and imaginary plots of the FRF. For each mode in the plotted FRF, four features were identified to determine the modal characteristics. The modal frequency, , identified by the minima in the imaginary plot; the two frequencies and , identified by the maxima and minima in the real plot; and the magnitude , identified by the value of the imaginary plot at . An illustration of these features for a single degree of freedom modal model is shown in Figure 3.

Figure 3.

Pedagogical diagram of the FRF for a single degree-of-freedom system with important features for the modal characterization indicated: (a) real component with indicated features and ; (b) imaginary component with indicated features and .

The damping ratio for the identified mode is calculated as in the following Equation (7).

The modal stiffness is calculated as in the following Equation (8).

Finally, the modal mass is calculated as in the following Equation (9).

3. Results

3.1. Validation of the Mechanical Impulse Generator

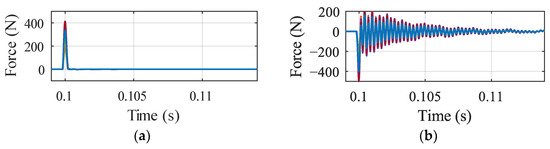

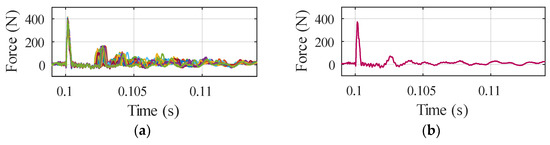

The results of 50 tap trials for the conventional impact hammer are shown in Figure 4a, while the corresponding results collected from the force plate dynamometer are shown in Figure 4b. The force hammer produced a range of impulse magnitudes. The lowest recorded peak force was 175 N, while the largest was 414 N. This spread was due to the manual operation of the hammer.

Figure 4.

Measured force signal from 50 manual conventional hammer strikes: (a) hammer signal time-series; (b) force plate time-series. Each colored line in the chart depicts an individual impact trial.

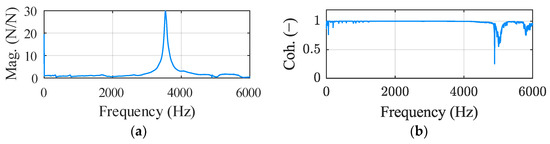

The force plate signal displayed a clear oscillation after the initial impulse due to the system dynamics, which are unrelated to the IG. To reduce the impact of these unrelated dynamics, the transfer function between the hammer and force plate was calculated using the FRF methods described in Section 2.4. Figure 5a shows the magnitude plot of the transfer function, while Figure 5b shows the coherence plot calculated for the 50 trials, which displayed values near unity up to 5000 Hz. The transfer function displayed a characteristic peak at 3538 Hz, which corresponded to the period of oscillations of 0.28 ms observed in Figure 4b.

Figure 5.

Transfer function for the force plate response: (a) magnitude plot; (b) coherence plot.

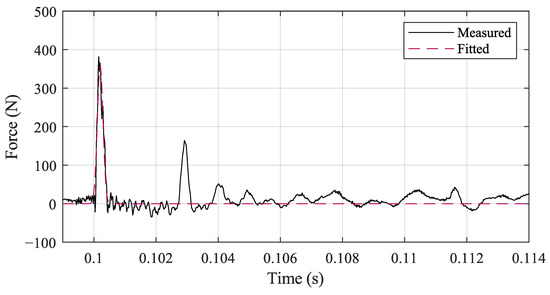

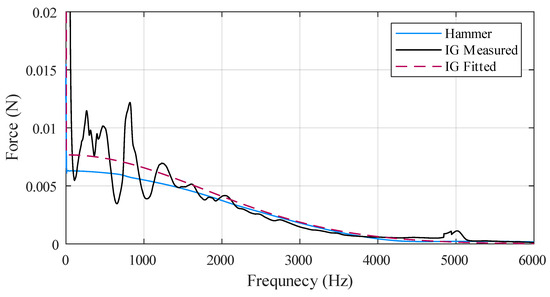

The force plate response from 50 IG trials was collected, and the transfer function in Figure 5 was used to reduce the effect of the force plate dynamics. Figure 6 shows the measured impulse for a single trial of the IG. Some undesirable oscillation was observed in the measured force signal beyond the initial impulse; however, these effects were lessened through averaging over 50 trials. Further discussion of these oscillations is found in Section 4.1 of this article. A smooth and symmetric curve was needed to model the physical characteristics of the impulse. Some authors have suggested a truncated sine to represent the impulse [19], which can be generated by convolving an appropriate cosine function with a square window. However, the square window truncation is known to introduce artifacts in the frequency domain after applying the Fourier transform. In this article, the impulse was modeled with the Gaussian function shown in Equation (10), since it preserves the smoothness and symmetrical properties of the truncated sine while also avoiding the frequency domain problems resulting from the truncation.

In Equation (10), the independent variable is the time in seconds, and the constants and characterize the magnitude and duration of the impulse. Fitting was accomplished using the MATLAB Curve Fitting Toolbox 23.2.

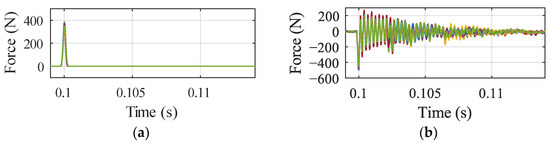

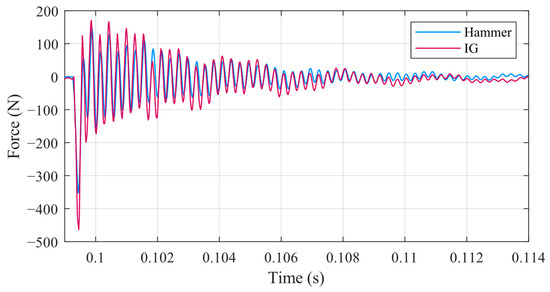

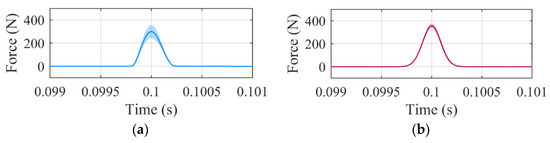

Figure 7a shows the IG results across 50 trials for the fitted Gaussian impulse and in Figure 7b for the direct force plate measurements. The IG was found to produce a reliable impulse at 360 N, which is comparable to the average hammer force of 300 N. The impulse duration for both devices was also found to be comparable. The average force plate response for 50 trials from the hammer and the IG are shown in Figure 8. Both time-series showed close agreement with one another.

Figure 7.

Measured force signal from 50 impulses from the IG: (a) fitted Gaussian impulse time-series; (b) force plate time-series. Each colored line in the chart depicts an individual impact trial. Each colored line in the chart depicts an individual impact trial.

Figure 8.

Average magnitude measured by the force plate for 50 trials from the conventional hammer and the IG.

Figure 6.

Impulse magnitude measured by the force plate after applying the transfer function to reduce the effect of force plate dynamics. A single trial is plotted of the force generated using the IG. A Gaussian impulse was fitted to the force plate data to characterize each impulse.

Figure 9 shows a comparison of the impulses from the conventional hammer and the fitted impulses of the IG across 50 trials each. The shaded regions in Figure 9 indicate the maximum range of the results recorded in the 50 trials. An advantage of the IG is observed in the reliable impact force produced by the mechanical device. A comparison of the two methods indicates that the IG produced a more consistent impact force compared to the conventional hammer. Since the results from the initial characterization of the IG were consistent, the input force profile of the IG was assumed to be constant in the following analysis, and the force plate measurements were not needed for FRF estimation. Impacts of this assumption are discussed further in Section 4.1.

Figure 9.

Maximum variation in the input force magnitudes over 50 trials: (a) conventional hammer; (b) mechanical IG device. The solid line indicates the average force across 50 trials, while the shaded region indicates one standard deviation of the force values over the 50 trials.

3.2. Static Spindle Test

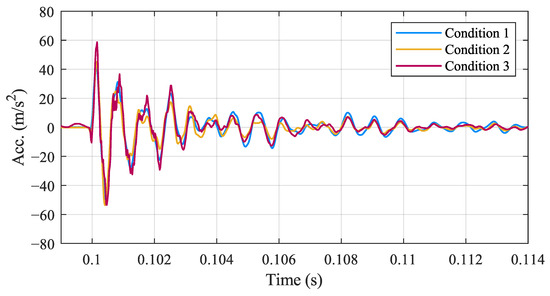

The average time-series accelerometer data from the −x axis accelerometer is shown in Figure 10 for 50 tap test trials under each of the three static test conditions. The acceleration profiles displayed strong agreement across the static test conditions.

Figure 10.

Average time-series accelerometer data recorded from 50 trials for each of the three static spindle test conditions.

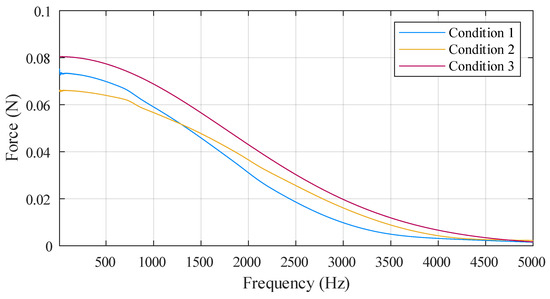

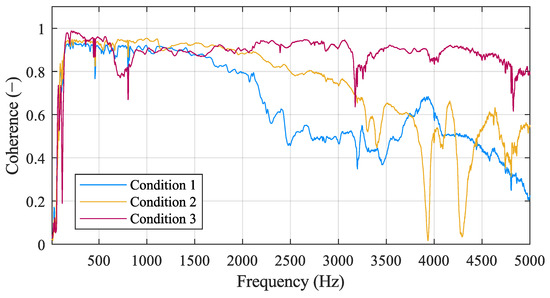

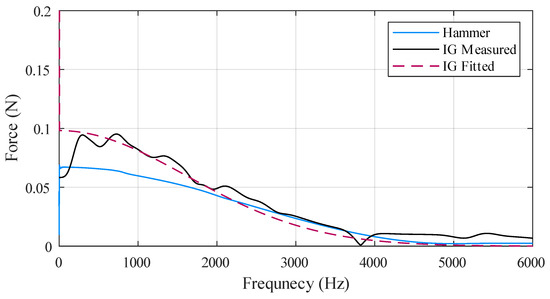

Figure 11 shows the average input force spectrum for each test condition. Beyond the range of 2000 Hz, the magnitude of the input spectrum decays below 50% of the peak value. Degrading coherence was also observed beyond 2000 Hz, as shown in Figure 12. The results beyond the 2000 Hz range were not considered reliable and have been neglected from further analysis. Low coherence values were also observed below the 100 Hz range; however, no significant modal content was evident in this region.

Figure 11.

Comparison of the average input force spectrum recorded from 50 trials for each of the three static spindle test conditions.

Figure 12.

Comparison of the coherence value recorded from 50 trials for each of the three static spindle test conditions.

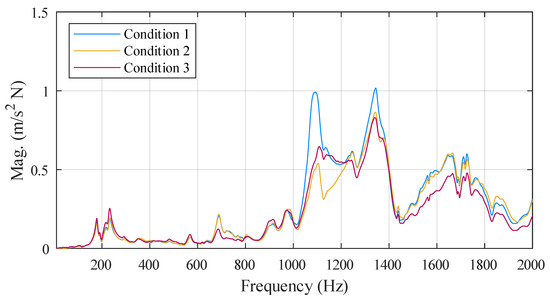

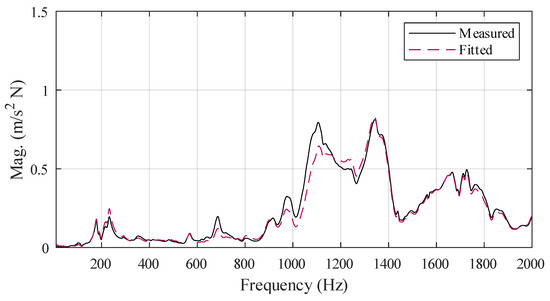

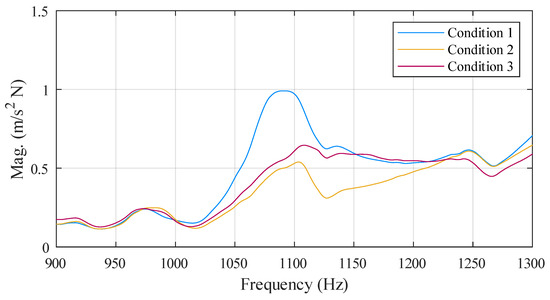

The magnitude plot for the three FRFs is shown in Figure 13. Close agreement is observed in the FRFs calculated for each of the three conditions in the first half of the frequency range up to 1000 Hz. Beyond this range, the results show some minor deviations in magnitude, with similar overall trends. The FRF peak at 1080 Hz displayed the most notable difference among the tests. The freely vibrating tool of Condition 1 displayed a high magnitude peak at this frequency, while the tool–IG contact found in Condition 2 and Condition 3 displayed a notably lower magnitude. However, Condition 2 and Condition 3 both show good agreement with one another, which suggests that the tool–IG contact is the cause of this difference and not the method of applying the force. Further discussion on the effect of this contact is found in Section 4 of this article.

Figure 13.

Average magnitude plot of the FRF recorded from 50 trials for each of the three static spindle test conditions.

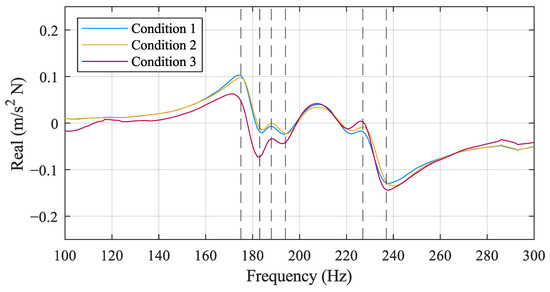

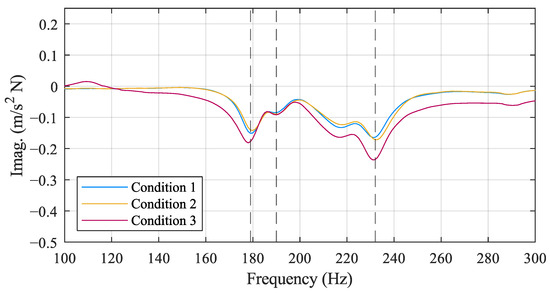

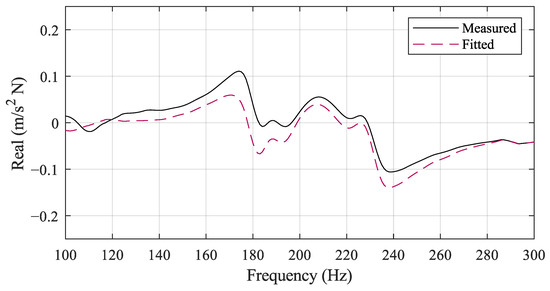

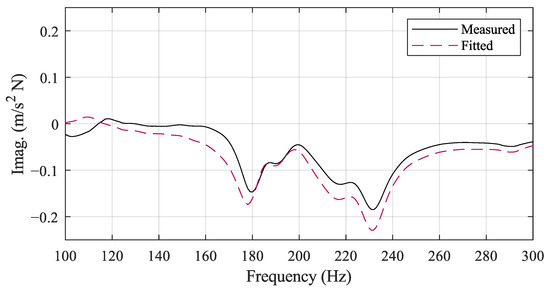

The real and imaginary components of the FRFs were considered to determine modal characteristics of the static spindle. A detailed view of the real and imaginary components of the FRF between 100 and 300 Hz is shown in Figure 14 and Figure 15, respectively. The peak picking method was used to identify the modal characteristics at 180, 190, and 230 Hz to illustrate the capability for the tracking of spindle dynamics. Table 1 summarizes the characteristics for the three modes calculated using Equations (7)–(9). Close agreement was observed across the three conditions, with the largest differences observed in the stiffness parameters for the three modes. These results demonstrate the capacity of the proposed system to accurately track the modal characteristics of a machine tool spindle unit with comparable accuracy to the conventional impact hammer test.

Figure 14.

Detailed view of the real components of the FRF for each of the three static spindle test conditions. Dashed lines indicate critical features for modal characterization.

Figure 15.

Detailed view of the imaginary components of the FRF for each of the three static spindle test conditions. Dashed lines indicate critical features for modal characterization.

Table 1.

Comparison of the identified modal characteristics for three peaks identified in the 100–300 Hz range of the static spindle test.

3.3. Dynamic Spindle Test

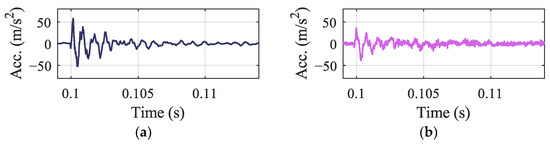

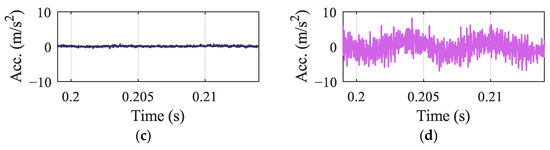

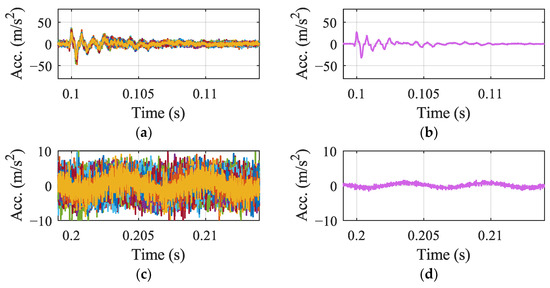

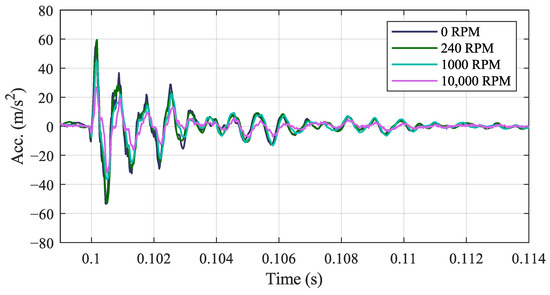

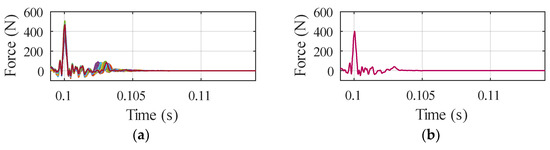

The dynamic spindle test presented additional challenges due to the vibrations produced by the rotating spindle. The x axis vibration time-series of a single trial of the 0 RPM and 10,000 RPM test immediately at impact from the IG are shown in Figure 16a,b for comparison. At high speed, a harmonic oscillation corresponding to the spindle rotational speed was observed in the acceleration signal. After the vibration response from the IG decayed, the harmonic component remained in the acceleration signal, as observed in Figure 16c,d, which displays a detailed view of the same signals 0.1 s later. Averaging the acceleration signal from 50 trials had a significant reduction on this noise, while retaining the characteristic response from the input of the IG. The averaging approach is illustrated in Figure 17 for the 10,000 RPM trial. Figure 18 shows a comparison of the average accelerometer signal collected from all 50 impact tests performed at each of the spindle speeds. The results are similar to the static spindle tests; however, the magnitude of the vibration response tended to decrease as the spindle speed increased. A discussion of the spindle speed effect on the vibration dynamics can be found in Section 4.5. The FRF was calculated for each trial for an in-depth investigation.

Figure 16.

Comparison of the acceleration response of a single trial for the static and dynamic spindles: (a) during the impulse from the IG at 0 RPM; (b) during the impulse from the IG at 10,000 RPM; (c) after the vibration decay at 0 RPM; (d) after the vibration decay at 10,000 RPM.

Figure 17.

Illustration of the averaging method for noise reduction at 10,000 RPM: (a) acceleration response signal for 50 trials during an impulse from the IG; (b) average of 50 trials, which retains the overall shape of the responses; (c) acceleration response signal for 50 trials; (d) average of 50 trials showing a reduced signal noise. Each colored line in the chart depicts an individual impact trial, while the pink color is reserved for the averaged value.

Figure 18.

Average accelerometer signal for each spindle speed recorded in the dynamic spindle test.

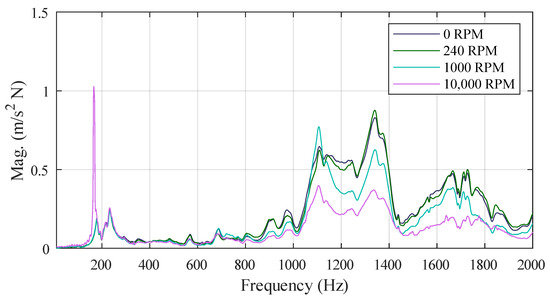

The magnitude plot for the dynamic FRFs is shown in Figure 19. Similar to the static tests, close agreement was observed between the FRFs in the range up to 1000 Hz. One notable exception is the spike in magnitude at 167 Hz observed in the 10,000 RPM case corresponding to the spindle speed. The FRF magnitude tended to decrease in the range beyond 1000 Hz, with the exception of the 1000 RPM trial near 1100 Hz. At 1080 Hz, the 1000 RPM trial was the only speed at which the magnitude of this peak exceeded the static trial.

Figure 19.

Average magnitude plot of the FRF recorded from 50 trials for each of the dynamic spindle test conditions.

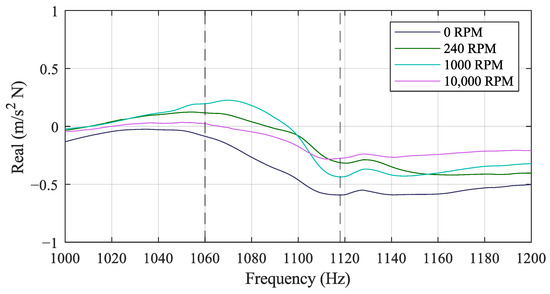

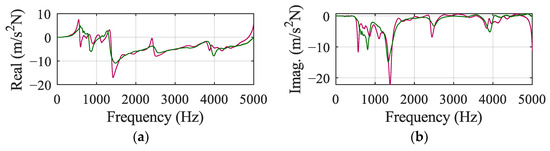

The real and imaginary components of the FRF for each speed were considered in the range for characterization of the modes in this region. Figure 20 shows the real component for the FRF in the dynamic spindle tests, while Figure 21 shows the imaginary components. The modal characteristics are listed in Table 2 for each spindle speed.

Figure 20.

Detailed view of the real component of the FRF for each of the dynamic spindle test conditions. Dashed lines indicate the critical feature for modal characterization.

Figure 21.

Detailed view of the imaginary component of the FRF for each of the dynamic spindle test conditions. Dashed lines indicate the critical feature for modal characterization.

Table 2.

Comparison of the identified modal characteristics for the peak identified in the 1000–1200 Hz range of the dynamic spindle test.

4. Discussion

4.1. Practical Usage of the IG Device

The force plate dynamometer in this experiment was used to characterize the input force profile of the IG. However, it should be noted that the force plate dynamometer suffers from many of the same drawbacks of the other FRF measurement devices discussed in Section 1, namely, the need for a skilled operator, the large table space required, and the high cost of the device. For these reasons, the force plate dynamometer is not practical in a production environment and should not be used in practice to measure the output force from the IG. Instead, the output force spectrum of the IG can be assumed to be constant given that it was found to produce a very reliable input force, as shown in Section 3.1.

It remains to be demonstrated that this assumption does not compromise the validity of the computed FRF or modal characteristics. This result can be observed in Figure 22, which shows the average magnitude plot of the FRF for 50 trials, calculated using both the directly measured force plate input and the assumed force input, which were characterized by the Gaussian impulse.

Figure 22.

Average magnitude plot of the FRF recorded from 50 trials for the static spindle test condition for the directly measured input force and the assumed input force fitted to the Gaussian impulse.

The two FRF curves show close agreement over the considered range. Furthermore, the modal characteristics extracted from the real and imaginary components of the FRF were compared for both methods. Detailed views of the real and imaginary components are shown in Figure 23 and Figure 24, respectively. Table 3 shows the modal characteristics, which were calculated based on these FRF results.

Figure 23.

Detailed view of the real components of the FRF for each of the directly measured and Gaussian-fitted static spindle test conditions.

Figure 24.

Detailed view of the imaginary component of the FRF for each of the directly measured and Gaussian-fitted static spindle test conditions.

Table 3.

Comparison of the identified modal characteristics for the three peaks identified in the 100–300 Hz range of the static spindle test.

These results indicate that while some characteristics of the input force profile from the IG must be assumed in practical usage, the resultant modal characteristics, which were calculated from the FRF, were not significantly affected by this assumption. As a result, the modal characteristics of the spindle can still be monitored with sufficient accuracy. The validity of this assumption is the key factor that enables the proposed method to be used for practical FRF data collection for CBM tasks.

4.2. Oscillations Observed in the IG Force Profile

The simple mechanical design of the IG has many benefits, which were explored in Section 2.2. However, as was observed from the force plate measurements, as shown in Figure 6, the IG displayed some undesirable characteristics related to the selection of the springs and impact mass in the device. The force plate measurements collected from all 50 validation trials with the IG are shown in Figure 25a, while the average of these measurements is shown in Figure 25b. In the force plot, there were two features that deviated from the Gaussian impulse, which was expected from the IG: (1) a high-frequency oscillation observed near the initial impulse and (2) a low-frequency series of undulations that rippled after the initial impulse. The spectrum of the input force for the hammer signal, the IG collected from the force plate, and the Gaussian-fitted impulse from the IG were plotted, as shown in Figure 26, for the frequency analysis. In this plot, the high-frequency content from the IG signal was located near 5000 Hz, beyond the range of the results discussed in this study. The low-frequency undulations appeared as a broad band of spectral content in the range from 0 to 1000 Hz. The fitted impulse does capture the overall shape of the impulse resulting from the IG, which is supported by the agreement of the FRF plots observed in Figure 13. Judicious selection of the spring and mass elements inside the IG is expected to reduce the presence of these low-frequency effects, while the selection of materials is expected to be a valid method to dampen the high-frequency oscillations.

Figure 25.

Input force magnitudes recorded on the force plate from the mechanical IG: (a) all 50 impact trials; (b) average result of 50 trials. Each colored line in the chart depicts an individual impact trial.

Figure 26.

Spectrum comparison of the input force for the conventional hammer, the IG force plate measurements, and the Gaussian impulse fitted to the force plate measurements.

The design of the IG was refined to enhance the force profile of the device and make it match more closely with the expected Gaussian impulse. Three adjustments were made to the design. First, the tolerance between the housing and the plunger of the impact tip was changed from a free-running clearance fit to a tighter locational clearance fit. This tolerancing change allowed for the free movement of the plunger without any perceivable play in the device, which could cause undesired undulations from excessive looseness. Second, a longer spring was selected to ensure that the impacting mass never came out of contact with the spring. The loss of contact caused an abrupt change in dynamics of the spring–mass system, which should be avoided. With the longer spring, there was always a small amount of preload stored in the system to avoid this problem. Third, viscous oil was added inside the housing of the IG to dampen vibrations of the mass after the initial impact.

The validation results following the procedures were repeated following the same procedures as defined in Section 2.1.1 for the refined IG. The new input force magnitude for 50 trials is shown in Figure 27a, and the average results of the 50 trials are shown in Figure 27b. The average magnitude of the impulse increased from 360 to 410 N due to the increased preload from the longer spring. The undulations following the initial impulse were observed to be less significant in the redesigned IG.

Figure 27.

Input force magnitudes recorded on the force plate for the mechanical IG after redesign of the internal components: (a) all 50 impact trials; (b) average result of 50 trials. Each colored line in the chart depicts an individual impact trial.

The force spectrum of the refined IG is shown in Figure 28. The results indicate that the design changes to the IG improved the force profile, which corresponded more closely to the Gaussian impulse as intended. Further optimizations may be possible to improve the spectral response at very low frequencies; however, it is noted by Munoa et al. that the critical frequencies related to spindle and tool performances range between 0.5 and 10 kHz [21]. For this reason, it is not expected that improvements in the low-frequency range will have a significant effect on the results.

Figure 28.

Spectrum comparison of the input force from the redesigned IG collected directly from the force plate and the Gaussian impulse fitted to the force plate measurements.

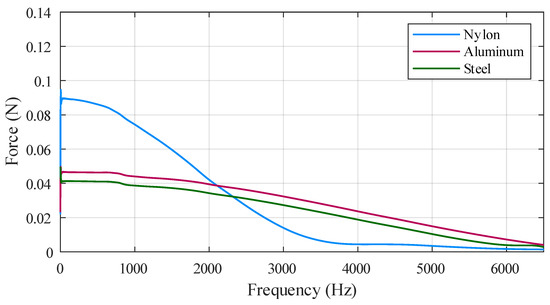

4.3. Impact Tip Material Selection

The IG was able to excite frequencies up to 2000 Hz, as observed in the spectrum plot shown in Figure 11 and Figure 26. While this range was acceptable for the CNC machine considered in the present study, very stiff machines could have critical frequencies that exist at higher ranges. In this study, nylon was selected as the impact tip material for the IG to provide a fair comparison to the conventional impact hammer; however, other materials can be used. To illustrate the effect of the material selection on the excitation frequency, the power spectrum of three different tip materials for the conventional impact hammer is shown in Figure 29. It was observed that the harder metallic tips exhibited a more flat, broad frequency excitation compared to the soft nylon tip as expected. The metallic tips were found to excite frequencies as high as 5000 Hz, more than double the range of the nylon tip. This result suggests that the IG could be fitted with interchangeable impact tips to generate the desired frequency response for a given application. This technique of using interchangeable impact tips is commonly found in commercial products to a similar effect [22].

Figure 29.

Comparison of the force spectrum for three different impact tip materials showing that harder tips excited a broader range of higher frequencies compared to the softer tip material.

4.4. Contact Effects at Tool Tip

In Figure 13, a change in the FRF magnitude was observed between Condition 1, in which the tool tip was freely vibrating, and Conditions 2 and 3, in which the tool was in contact with the impact tip of the IG. A detailed view of this reduction in magnitude is displayed in Figure 30, which suggests that the contact of the tool with the IG caused an increase in stiffness and damping. These findings agree with the existing results found in the literature [23]. However, the underlying mechanism for these effects remains to be described by a comprehensive theory. The results of this study demonstrate that the proposed automated impulse response test is sensitive enough to observe the changes in dynamics due to tool tip contact and may provide a means for researchers to collect experimental data necessary to test new theories.

Figure 30.

A drop in magnitude observed between the free vibration tool tip in Condition 1 and the tool–IG tip contact in Conditions 2 and 3 during the static spindle test.

4.5. Speed Dependent Dynamics

The modal characterization of the dynamic spindle test listed in Table 2 suggests a speed-dependent relationship with the modal characteristics of the spindle. The existence of this relationship is well established in the literature; however, much of the nuance in this relationship remains to be explored. In a review by Iglesias et al., the most important speed-related dependency in the spindle, as identified by the authors, is concerned with bearing stiffness effects [12]. To understand bearing stiffness effects, it is first noted that increased axial preload in angular contact bearings increases the dynamic stiffness of machine tool spindle units [24,25,26]. Increased spindle speed causes increased centrifugal forces on the rolling elements, resulting in an increase in the contact angle and decrease in the effective axial preload. Therefore, it has been proposed that increased spindle speed should result in a reduction in dynamic stiffness of the spindle. However, increased spindle speed also causes a temperature increase due to friction. The increased temperature differential is proposed to conversely cause an increased preload in the bearings, resulting in increased dynamic stiffness [27]. From the results shown in Table 2, the root cause of the apparent increase in stiffness observed for the 10,000 RPM case is not obvious, and future investigative work should be conducted. While the relationship between the modal parameters of a spindle unit and the spindle speed is rich in complexity, this study demonstrated that the characteristics can be estimated from a rotating spindle using the proposed method. The ability of this mechanical IG and the automated test routine to observe these speed-dependent modal characteristics of the spindle suggests that the approach used in this study may have applications beyond spindle-condition monitoring, such as cutting parameter optimization.

4.6. Application to Spindle Maintenance Decision Making

The majority of this article focused on the characterization of the IG for FRF data collection. However, it remains to be demonstrated how CNC machine tool owners and operators can monitor the dynamic characteristics of the spindle unit for enhancement of CBM practices.

Methods for spindle health assessment based on FRF data have seen development in recent literature. Vogl and Donmez proposed a method for spindle health assessment based on FRF measurements and known bearing fault frequency characteristics, which outperformed conventional vibration monitoring methods [14]. Ritou et al. presented method to describe spindle health based on changes in stiffness and damping characteristics using numerical models and a series of spindle failure experiments. In this work, the author was able to directly link spindle dynamics to cutting performance [28]. While these works both show an improved capacity for maintenance decision making compared to conventional methods, they remain isolated examples of usage. As discussed in Section 1, a significant challenge with the development of FRF-based tools for effective maintenance decision making is that it is more difficult to collect FRF data compared to more popular direct vibration monitoring methods. As a result, there is less FRF data available to conclusively demonstrate these benefits.

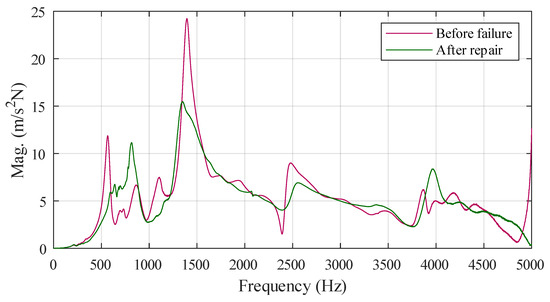

To further motivate the usage of FRF monitoring for spindle maintenance decision making, a case study was conducted by the author on production machine tools used at an automotive engine plant. In this case study, a fleet of 10 machine tool spindles of identical design were monitored periodically every six months during scheduled downtime activities so as not to impact production. The same run-out bar tool was used in the spindle during each measurement. All tests were conducted on a static spindle using the conventional impact hammer with the nylon tip as described in Section 2.1.2. A photograph of the data collection tools used in this case study is shown in Figure 31. Over the five-year period of monitoring this fleet of machines, only one exhibited a spindle failure. While the first nine machines displayed consistent FRF characteristics, the tenth machine showed significant changes prior to the failure.

Figure 31.

Photograph of the manual impact hammer, accelerometer, and run-out bar tool used in the case study during data collection.

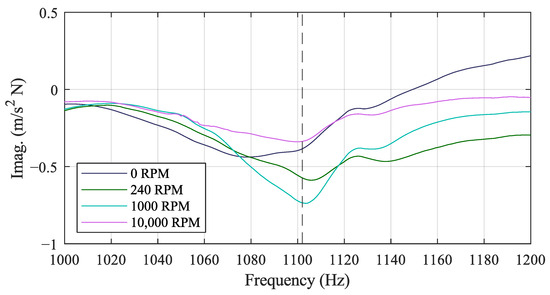

Figure 32 shows a comparison of two FRF measurements taken from the failed machine before and after the spindle repair. The most significant changes were observed in the two dominant modes of the system located near 1400 and 600 Hz.

Figure 32.

Comparison of the FRF magnitudes collected from the same machine tool spindle unit five months before a failure occurred and immediately after repair.

The real and imaginary components of the FRF, as shown in Figure 33, were considered to determine the characteristics, as previously described. An analysis of the modal characteristics near 600 and 1400 Hz showed that after the repair the spindle unit displayed larger damping coefficients at these modes. A comparison of the modal characteristics is shown in Table 4. The two most notable changes evident in the modal parameters were the shift in frequency for Mode 1 from 569 to 808 Hz after the repair and the increase in damping for both modes. These indicators suggest that the dynamics were not stable and that this spindle was at an increased risk of failure in the future. As a result, the maintenance staff observed this machine closely and began the procedures for procuring a replacement spindle unit.

Figure 33.

Components of the FRF from the same spindle five months before a failure occurred (red) and immediately after a repair (green): (a) real component; (b) imaginary component.

Table 4.

Comparison of the modal characteristics for the two dominant modes from the case study spindle five months before failure and immediately after the repair.

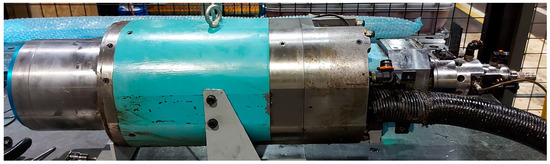

More severe problems with the spindle followed the changes observed in the FRF. In this case, the change in spindle FRF was observed five months prior to the failure of the spindle. At the point of failure, high torque warnings were intermittently observed from the CNC controller, which prompted service of the spindle. The spindle was removed from the CNC machine, as shown in Figure 34, and the high torque warnings were attributed to a failed support bearing at the rear of the spindle, as shown in Figure 35. The early knowledge of an impending spindle problem allowed the maintenance staff to order and procure a replacement spindle ahead of the failure. This preemptive maintenance decision, which was motivated by the FRF data, greatly reduced the maintenance downtime when the spindle ultimately failed. Downtime savings were achieved since the replacement spindle was already at the facility and ready for installation at the time of failure, and the maintenance staff were prepared for this service. This maintenance resource planning avoided significant costs to the production facility, the most notable savings were related to lost productivity.

Figure 34.

The problematic spindle unit was removed from the CNC machine tool after high torque warnings were received from the controller.

Figure 35.

High torque warnings were attributed to a damaged support bearing after a complete tear-down investigation was performed: (a) spindle rotor removed from the housing; (b) damaged rear support bearing.

This case study demonstrates two key aspects of FRF-based maintenance decision making. Firstly, modal characteristics were used to identify spindles with changing dynamics, and this knowledge provided an early warning for impending failure events. Secondly, cost savings were realized by taking a proactive approach to maintenance planning, which was motivated by the FRF data collected on this fleet of spindles.

5. Conclusions

While CBM programs for machine tools have promised reduced failures and downtime costs, the end results do not generally measure up to this ideal. One reason for this shortcoming is that standard vibration monitoring criteria, such as ISO 10816 and ISO/TR 17243, neglect important dynamic characteristics of the machine, such as natural frequency, dynamic stiffness, and damping ratios, in favor of vibration RMS magnitude values, which are easier to collect.

In this article a mechanical impulse generator was designed and fabricated to assist in the collection of FRF data from machine tool spindle units. This device is small, robust, requires no power for operation, and can collect data from both static and rotating spindles without endangering the machine tool operator. For the purposes of modal analysis, the performance of this device was found to be comparable to results obtained through conventional impact hammer testing. An automated data collection protocol was implemented in a CNC machining center using this new device and G-code programs to collect FRF data from the spindle. The automated protocol enables the routine monitoring of the spindle dynamics characteristics, which is valuable for CBM programs but is often too costly to collect on a regular basis.

The limitations of the impulse generator are observed through some undesirable characteristics in the input force spectrum. The device is capable of exciting frequencies up to 2000 Hz, however some stiff machine tool spindles may have natural frequencies beyond this range. Furthermore, the spectrum was observed to have harmonic components, which must be accounted for in the analysis. Higher frequencies were shown to be excited by the selection of a harder material for the impact tip. Harmonic oscillations were shown to be mitigated by selecting spring and mass parameters to push the oscillations outside of the measurement range, or the effects were suppressed by the material selection to dampen undesired oscillations.

A case study was conducted over a five-year period on a fleet of CNC machine tools in an automotive engine production facility. The FRFs and modal characteristics of these spindles were periodically monitored throughout the case study using the methods outlined in this article. An early warning of spindle failure was detected through modal analysis, and cost saving maintenance decisions were able to be made based on the data available from FRF monitoring.

The automatic test routine for modal analysis of machine tool spindle units presented in this article affords opportunities for enhanced data collection for condition monitoring tasks, condition-based maintenance, and dynamic assessment of machine tools.

Author Contributions

Conceptualization, P.C.; methodology, P.C.; software, P.C.; validation, P.C.; formal analysis, P.C.; investigation, P.C.; resources, S.C.V.; data curation, P.C.; writing—original draft preparation, P.C.; writing—review and editing, J.M.D.; visualization, P.C.; supervision, S.C.V.; project administration, S.C.V.; funding acquisition, S.C.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Thomas, D.S. The Costs and Benefits of Advanced Maintenance in Manufacturing. 2018. Available online: https://www.nist.gov/publications/advanced-maintenance-manufacturing-costs-and-benefits (accessed on 9 May 2024). [CrossRef]

- Decaix, G.; Gentzel, M.; Luse, A.; Neise, P.; Thibert, J. A Smarter Way to Digitize Maintenance and Reliability. 2021. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/a-smarter-way-to-digitize-maintenance-and-reliability (accessed on 9 May 2024).

- Breidenthal, J.; O’Sullivan, E. Industrial Analytics: Maintenance Gains without Adoption Pains. 2019. Available online: https://www.bain.com/globalassets/noindex/2019/bain_brief_industrial_analytics.pdf (accessed on 9 May 2024).

- Abele, E.; Altintas, Y.; Brecher, C. Machine tool spindle units. CIRP Ann. Manuf. Technol. 2010, 59, 781–802. [Google Scholar] [CrossRef]

- BS ISO 10816-1:1996; Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Non-Rotating Parts. ISO: Geneva, Switzerland, 1995.

- ISO/TR 17243-1; Machine Tool Spindles—Evaluation of Machine Tool Spindle Vibrations by Measurements on Spindle Housing: Part 1: Spindles with Rolling Element Bearings and Integral Drives Operating at Speeds between 600 min−1 and 30,000 min−1. ISO: Geneva, Switzerland, 2014.

- Tlusty, J.; Polacek, M. Beispiele der Behandlung der Selbsterregten Schwingung der Werkzeugmaschinen, FoKoMa; Hanser Verlag: Munich, Germany, 1957. [Google Scholar]

- Tobias, S.A.; Fiswick, W. Theory of Regenerative Machine Tool Chatter. Engineer 1958, 205, 199–205. Available online: https://www.vibraction.fr/images/stories/Documents/1erePresentationLobesTobias.pdf (accessed on 9 May 2024).

- Altintas, Y.; Weck, M. Chatter stability of metal cutting and grinding. CIRP Ann. Manuf. Technol. 2004, 53, 619–642. [Google Scholar] [CrossRef]

- Altintas, Y.; Cao, Y. Virtual Design and Optimization of Machine Tool Spindles. CIRP Ann. 2005, 54, 379–382. [Google Scholar] [CrossRef]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Iglesias, A.; Taner Tunç, L.; Özsahin, O.; Franco, O.; Munoa, J.; Budak, E. Alternative experimental methods for machine tool dynamics identification: A review. Mech. Syst. Signal Process 2022, 170, 1–19. [Google Scholar] [CrossRef]

- Schwartz, B.; Richardson, M. Experimental modal analysis. In CSI Reliabilty Week; Vibrant Technology: Jamestown, CA, USA, 1999; pp. 1–12. [Google Scholar] [CrossRef]

- Vogl, G.W.; Donmez, M.A. A defect-driven diagnostic method for machine tool spindles. CIRP Ann. Manuf. Technol. 2015, 64, 377–380. [Google Scholar] [CrossRef] [PubMed]

- Bediz, B.; Arda Gozen, B.; Korkmaz, E.; Burak Ozdoganlar, O. Dynamics of ultra-high-speed (UHS) spindles used for micromachining. Int. J. Mach. Tools Manuf. 2014, 87, 27–38. [Google Scholar] [CrossRef]

- Wiederkehr, P.; Wilck, I.; Siebrecht, T. Determination of the dynamic behaviour of micro-milling tools at higher spindle speeds using ball-shooting tests for the application in process simulations. CIRP Ann. 2020, 69, 97–100. [Google Scholar] [CrossRef]

- Tlalolini, D.; Ritou, M.; Rabréau, C.; Le Loch, S.; Furet, B. Modeling and characterization of an electromagnetic system for the estimation of Frequency Response Function of spindle. Mech. Syst. Signal Process 2018, 104, 294–304. [Google Scholar] [CrossRef]

- Iglesias, A.; Munoa, J.; Ramírez, C.; Ciurana, J.; Dombovari, Z. FRF Estimation through Sweep Milling Force Excitation (SMFE). Procedia CIRP 2016, 46, 504–507. [Google Scholar] [CrossRef][Green Version]

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design, 2nd ed.; Cambridge University Press: Cambridge, UK, 2012; ISBN 9781107001480. [Google Scholar]

- Schmitz, T.L.; Smith, K.S. Machining Dynamics; Springer: Boston, MA, USA, 2009. [Google Scholar] [CrossRef]

- Munoa, J.; Beudaert, X.; Dombovari, Z.; Altintas, Y.; Budak, E.; Brecher, C.; Stepan, G. Chatter suppression techniques in metal cutting. CIRP Ann. Manuf. Technol. 2016, 65, 785–808. [Google Scholar] [CrossRef]

- TM-ImpactHammers-0823. PCB Piezotronics; Amphenol Corporation: New York, NY, USA, 2023; pp. 1–12. Available online: https://www.pcb.com/sensors-for-test-measurement/impact-hammers (accessed on 9 May 2024).

- Jensen, S.A.; Shin, Y.C. Stability Analysis in Face Milling Operations, Part 2: Experimental Validation and Influencing Factors. ASME J. Manuf. Sci. Eng. 1999, 121, 606–614. [Google Scholar] [CrossRef]

- Lin, C.W.; Tu, J.F.; Kamman, J. An integrated thermo-mechanical-dynamic model to characterize motorized machine tool spindles during very high speed rotation. Int. J. Mach. Tools Manuf. 2003, 43, 1035–1050. [Google Scholar] [CrossRef]

- Chen, J.S.; Hwang, Y.W. Centrifugal force induced dynamics of a motorized high-speed spindle. Int. J. Adv. Manuf. Technol. 2006, 30, 10–19. [Google Scholar] [CrossRef]

- Cao, H.; Holkup, T.; Altintas, Y. A comparative study on the dynamics of high speed spindles with respect to different preload mechanisms. Int. J. Adv. Manuf. Technol. 2011, 57, 871–883. [Google Scholar] [CrossRef]

- Rusu, F.; Tudose, C.; Tudose, L. A new proof of rule of thumb regarding clearance variation with temperature in two tapered rolling bearings in O-arrangement. Acta Tech. Napoc. 2013, 56, 789–794. [Google Scholar]

- Ritou, M.; Rabréau, C.; Le Loch, S.; Furet, B.; Dumur, D. Influence of spindle condition on the dynamic behavior. CIRP Ann. 2018, 67, 419–422. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).