Simulation Study and Engineering Application of Weakening Mine Pressure Behavior in Stope through Ground Fracturing Thick and Hard Rock Strata

Abstract

1. Introduction

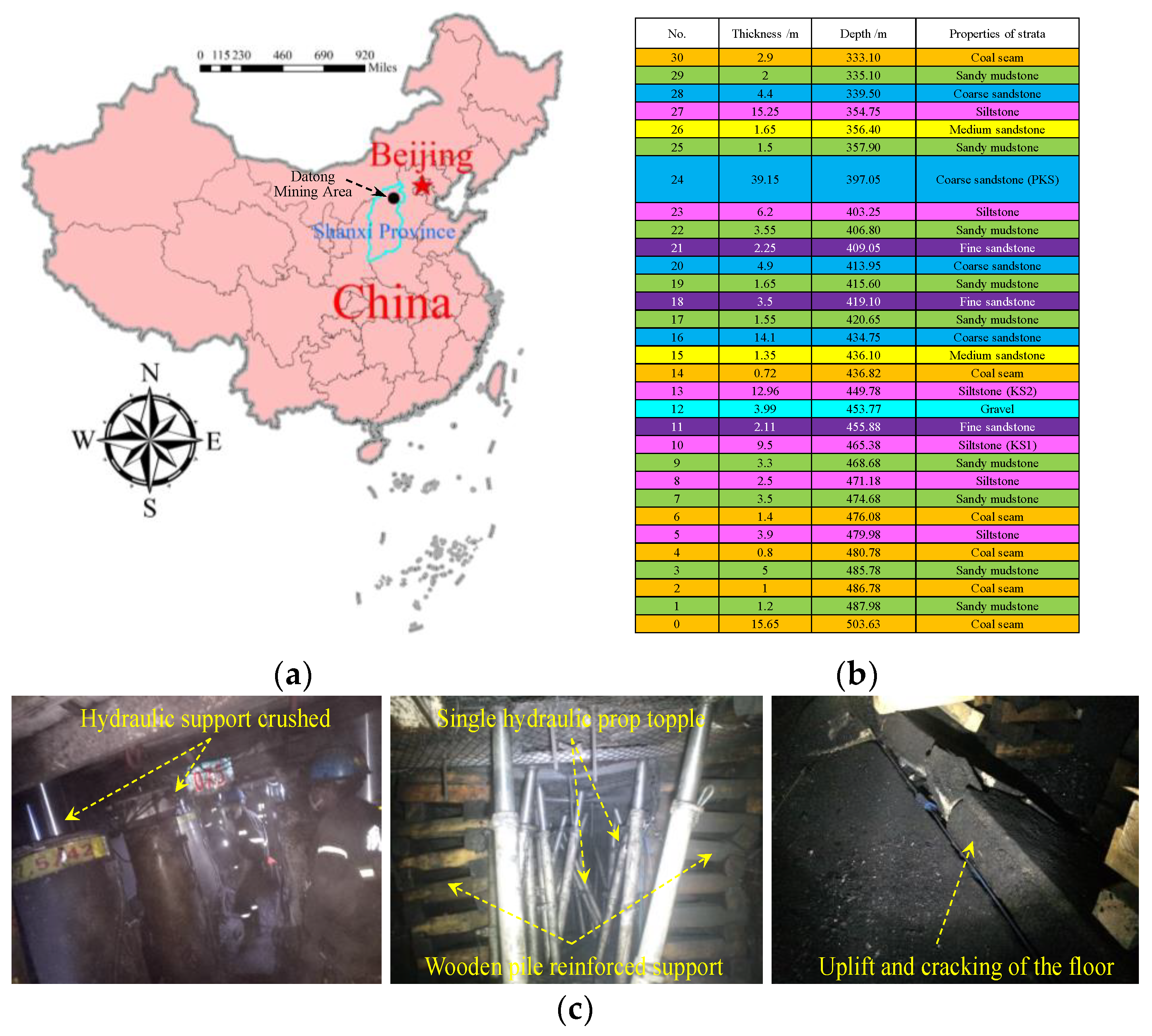

2. Engineering Background

3. Bearing Characteristics of Thick and Hard Strata

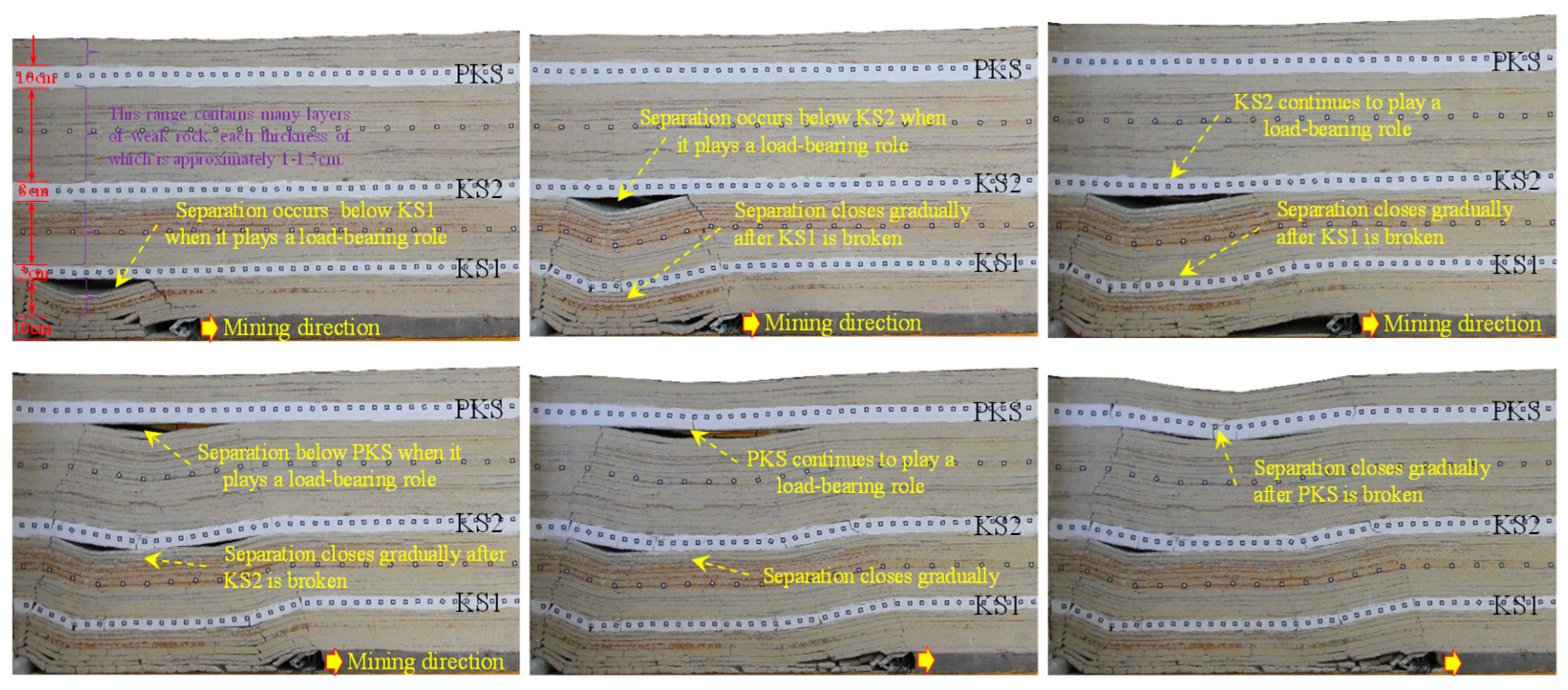

3.1. Influence of Key Strata on Strata Movement

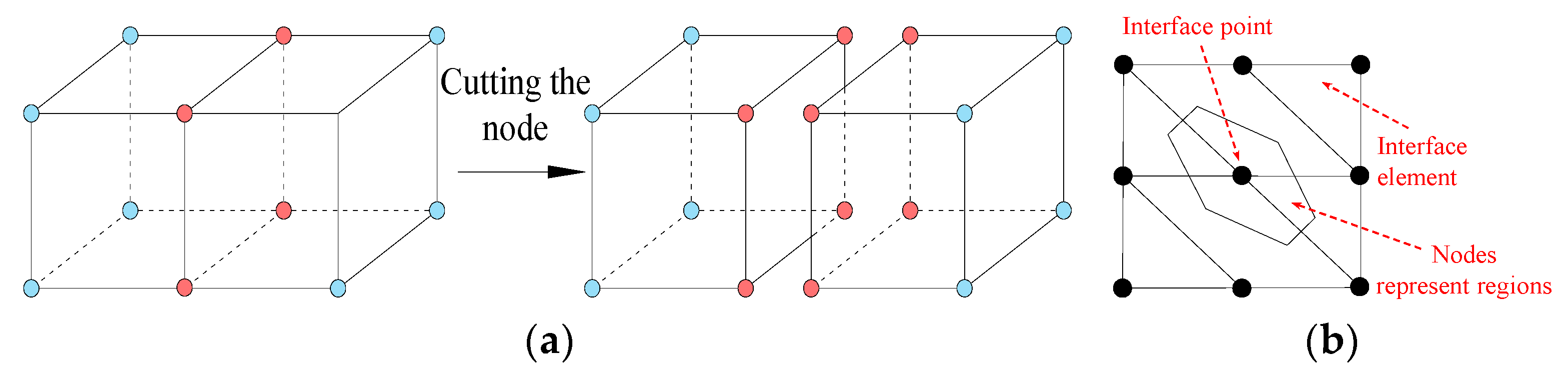

3.2. Key Stratum Fracturing Simulation Methods

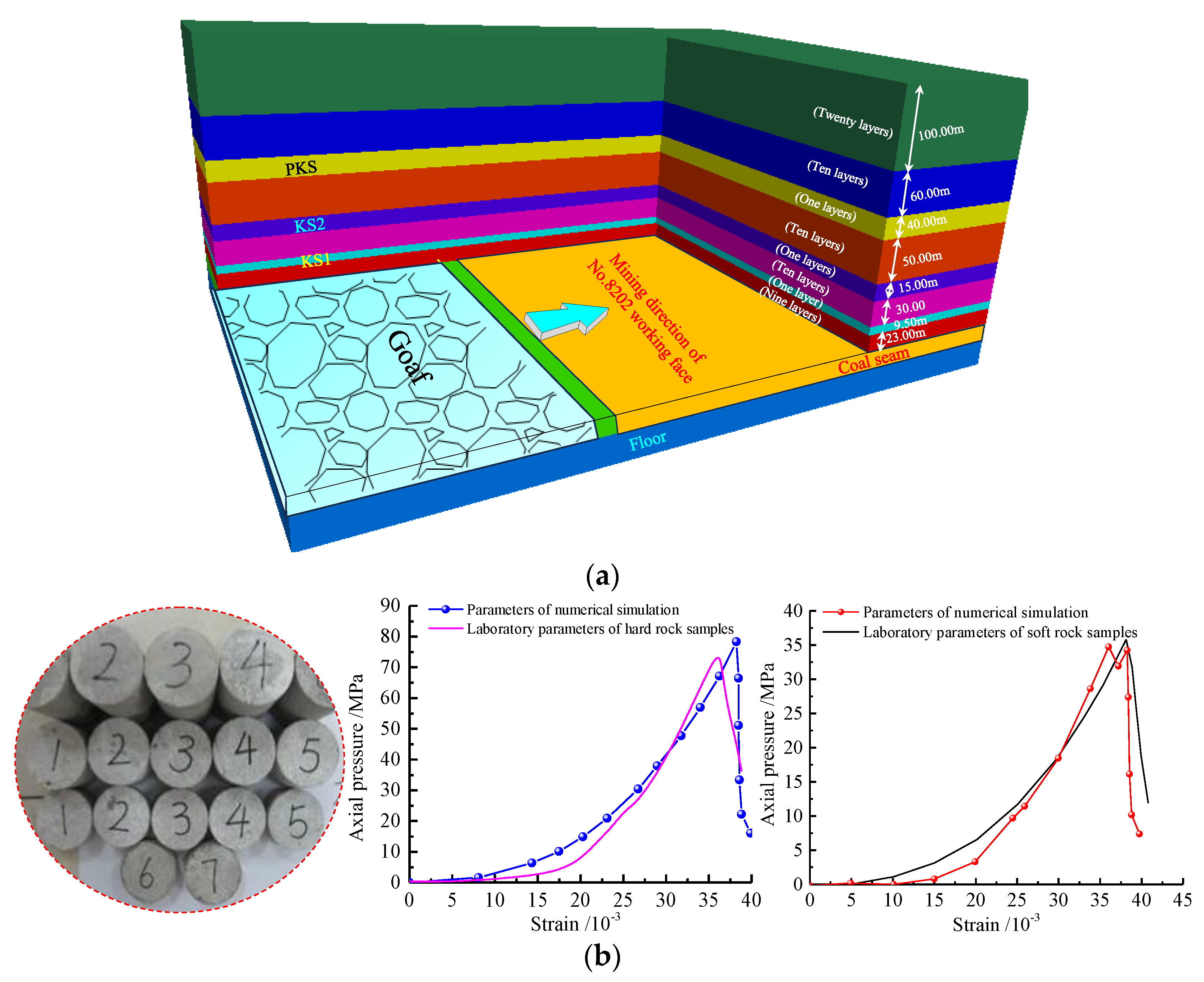

3.3. Numerical Simulation Model

4. Evolution Law of Front Abutment Pressure and Goaf Stress without Fracturing Conditions

5. Weakening Effect of Different Fracturing Schemes on Mining-Induced Stress

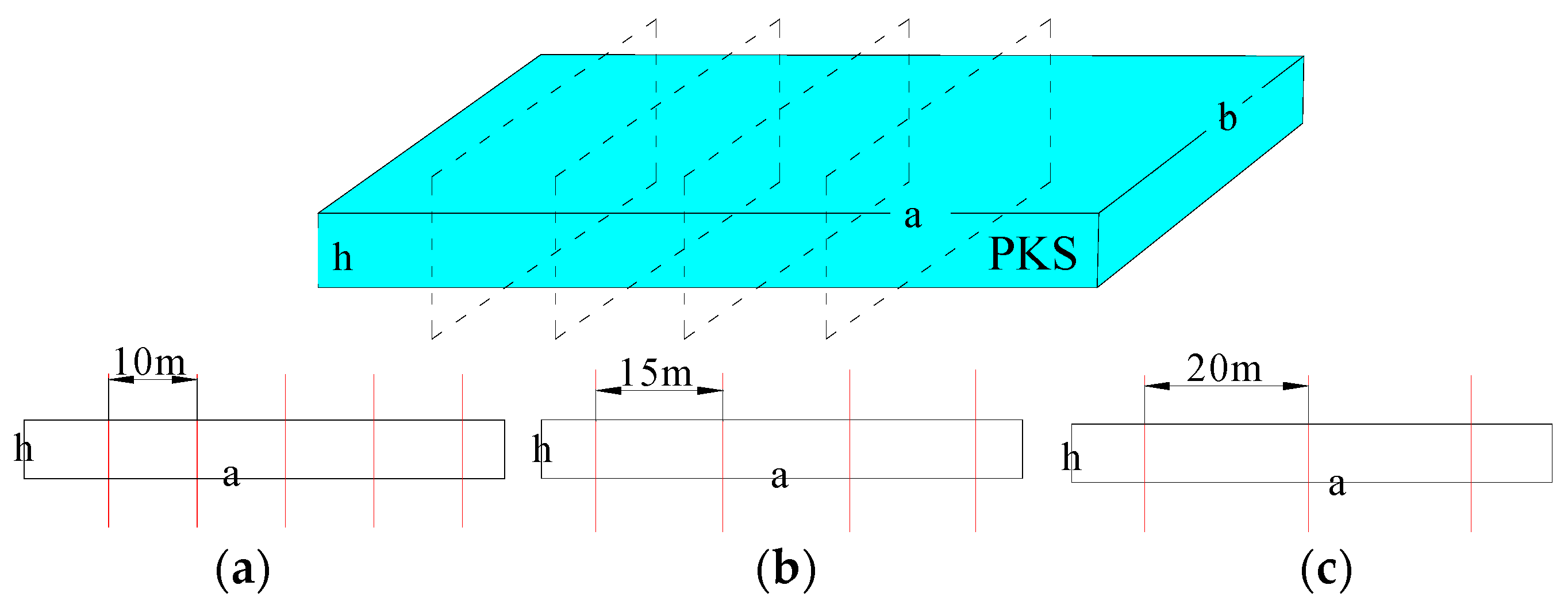

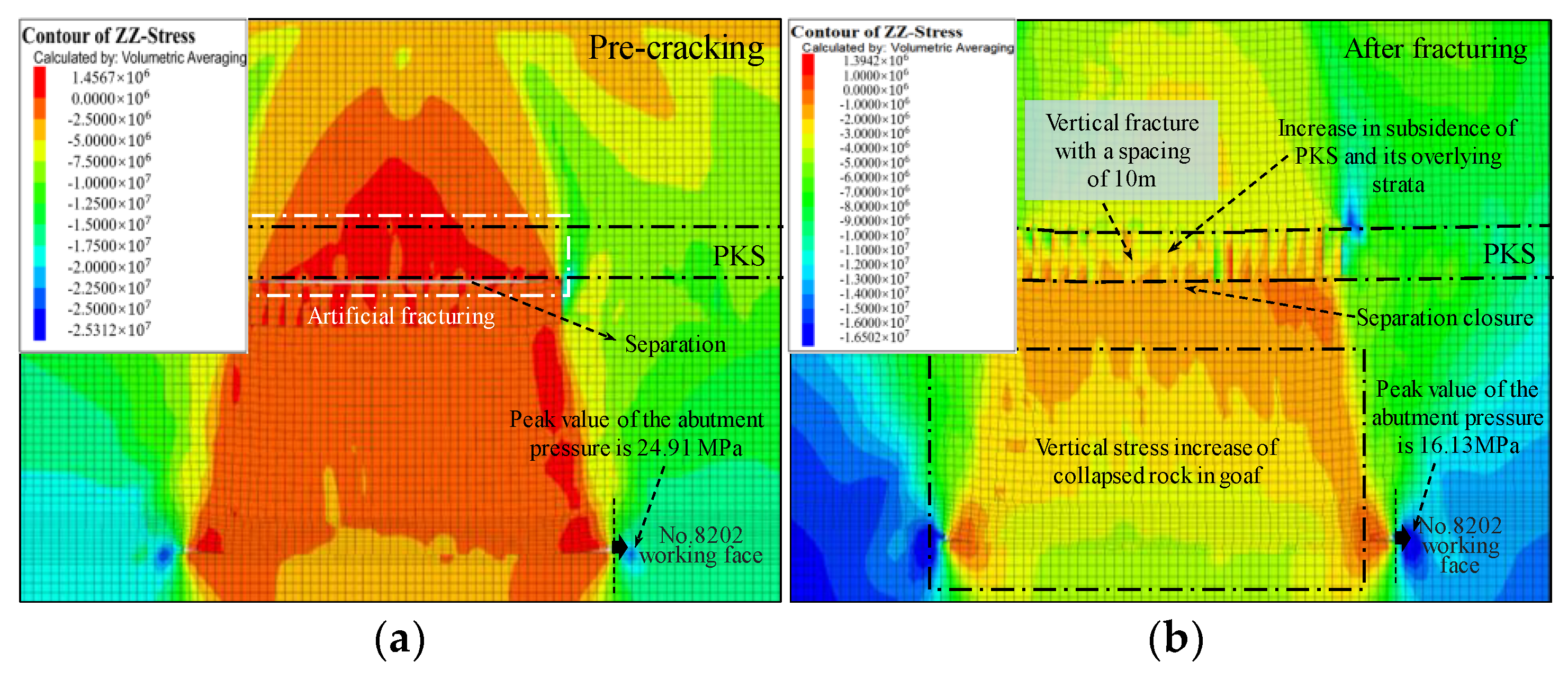

5.1. Vertical Fractures with Different Spacing

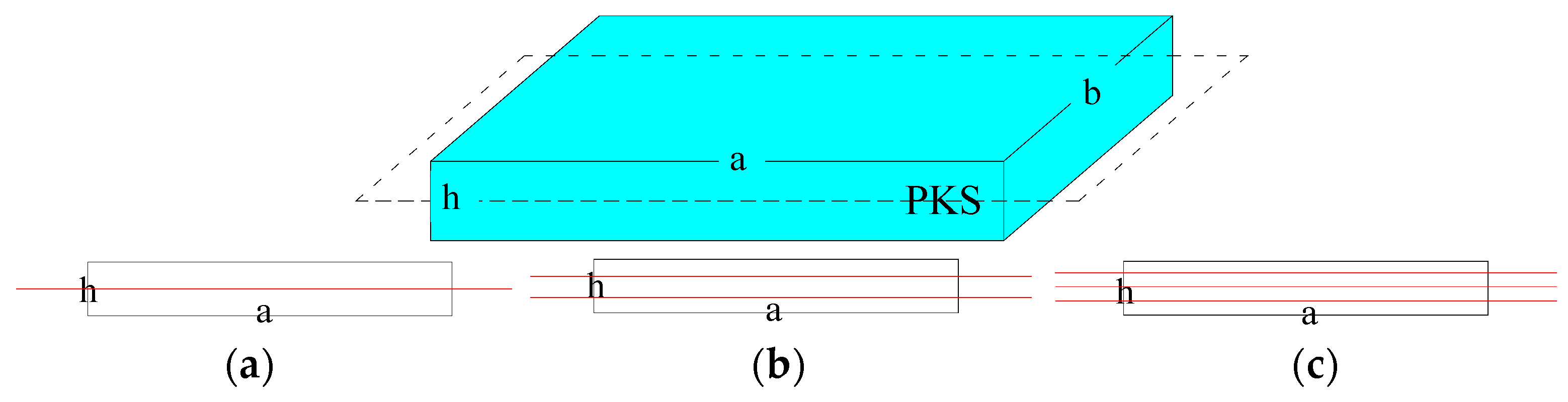

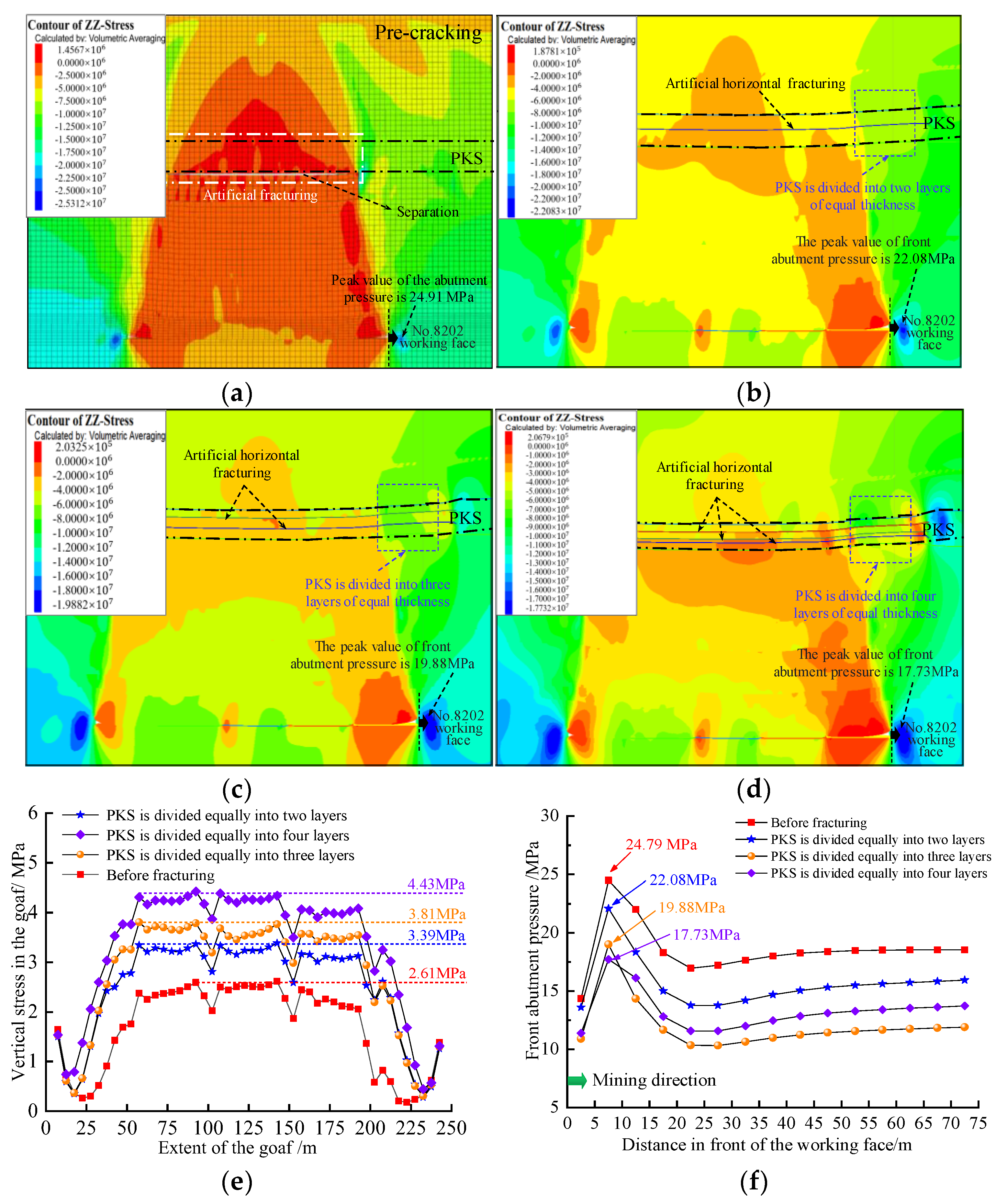

5.2. Horizontal Fractures with Different Layer Thicknesses

6. Physical Simulation for Weakening Mine Pressure by Key Strata Fracturing

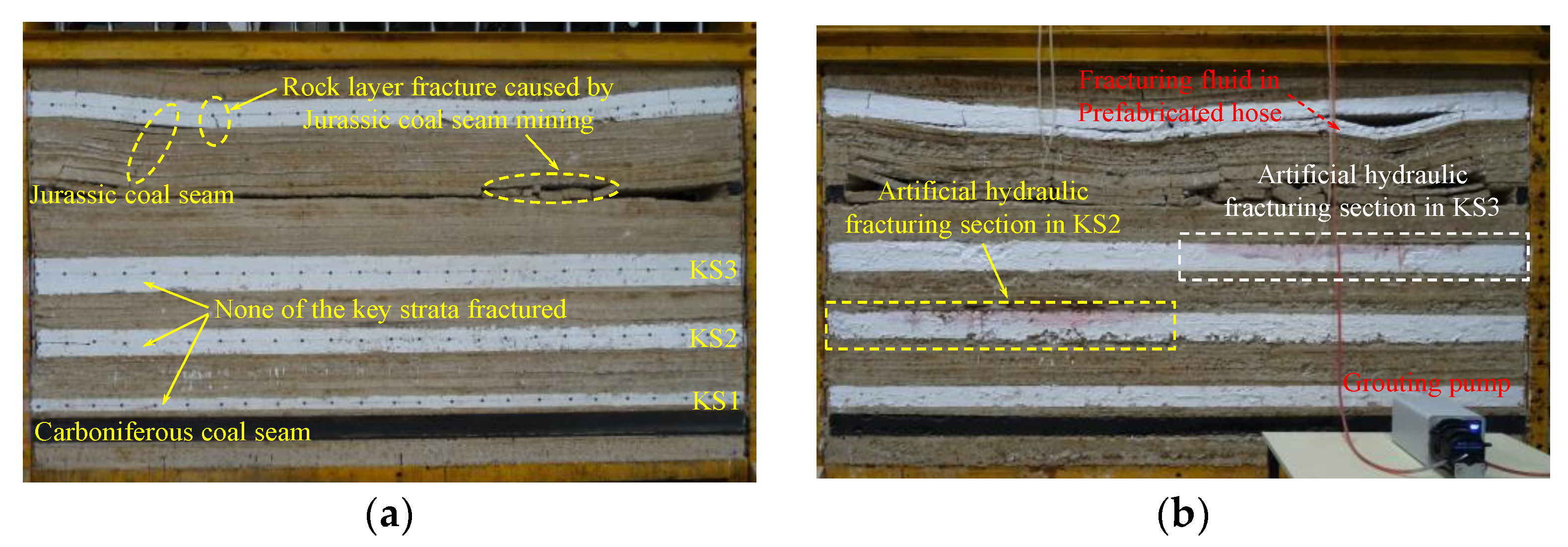

6.1. Physical Simulation Model and Key Strata Fracturing Scheme

6.2. Comparative Analysis of Test Results

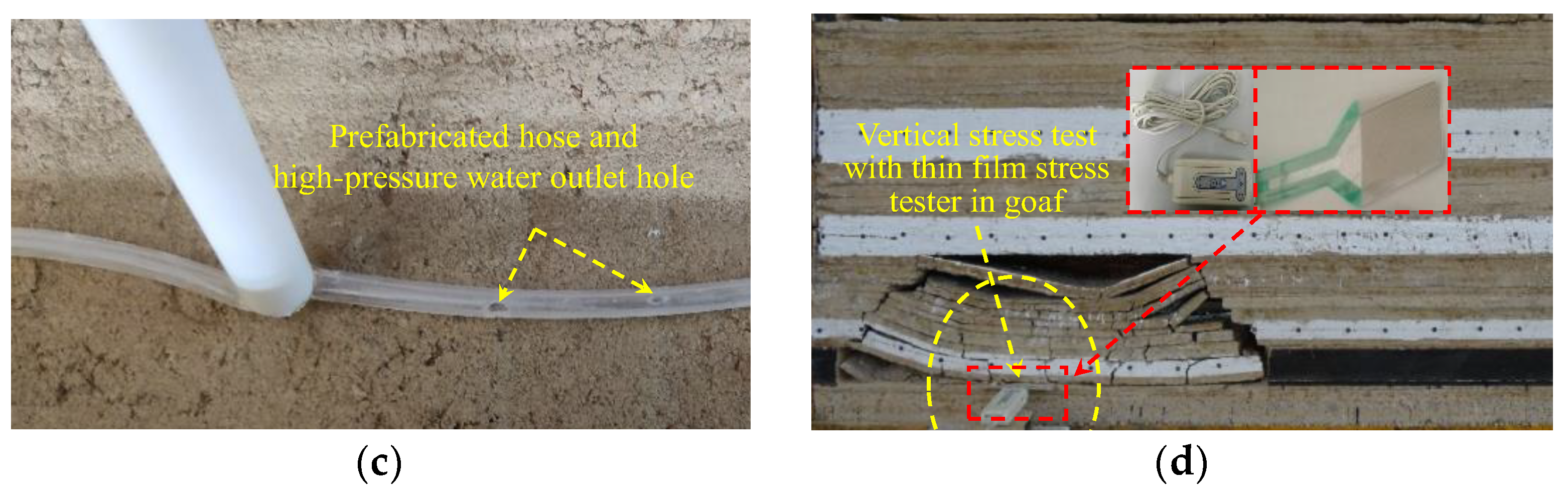

6.2.1. Influence of Hydraulic Fracturing on the Breaking Step of Key Strata

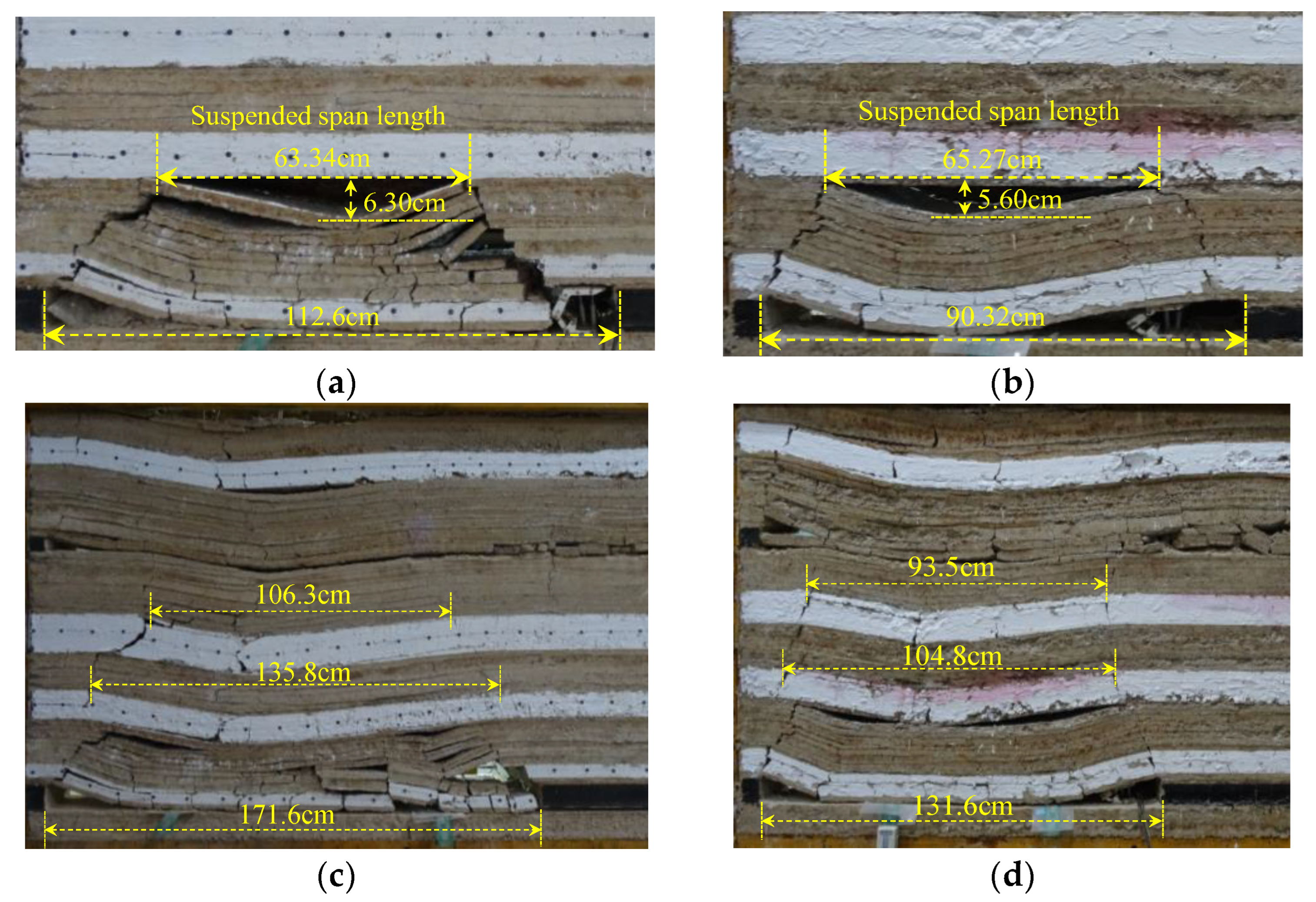

6.2.2. Influence of Hydraulic Fracturing on Goaf Stress

7. Engineering Practices

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balat, M. Status of Fossil Energy Resources: A Global Perspective. Energy Source Part B 2007, 2, 31–47. [Google Scholar] [CrossRef]

- Wu, X.F.; Chen, G.Q. Coal Use Embodied in Globalized World Economy: From Source to Sink Through Supply Chain. Renew. Sustain. Energy Rev. 2018, 81, 978–993. [Google Scholar] [CrossRef]

- Liu, C.; Li, H.M.; Mitri, H. Effect of Strata Conditions on Shield Pressure and Surface Subsidence at a Longwall Top Coal Caving Working Face. Rock Mech. Rock Eng. 2019, 52, 1523–1537. [Google Scholar] [CrossRef]

- Xu, C.; Fu, Q.; Cui, X.Y.; Wang, K.; Zhao, Y.X.; Cai, Y.B. Apparent-Depth Effects of the Dynamic Failure of Thick Hard Rock Strata on the Underlying Coal Mass During Underground Mining. Rock Mech. Rock Eng. 2019, 52, 1565–1576. [Google Scholar] [CrossRef]

- Xu, B.; Jiang, J.Q.; Dai, J.; Zheng, P.Q. Mechanical Derivation and Experimental Simulation of Breaking Angle of Key Strata in Overlying Strata. J. China Coal Soc. 2018, 43, 599–606. (In Chinese) [Google Scholar]

- Zhu, W.B.; Yu, B. Breakage Form and Its Effect on Strata Behavior of Far Field Key Stratum in Large Space Stope. Coal Sci. Technol. 2018, 46, 99–104. (In Chinese) [Google Scholar]

- Jiang, J.Q.; Zhang, P.P.; Qin, G.P.; Xu, B. Analysis of Destabilized Fracture and Microseismic Activity of High-located Main Key Strata. Rock Soil Mech. 2015, 36, 3567–3575. (In Chinese) [Google Scholar]

- Jiang, J.Q.; Zhang, P.P.; Qin, G.P.; Li, F.C.; Xu, B.; Xu, L.N. Fracture Laws of One-side Mined High-position Hard Thick Key Strata and Microseismic Energy Distribution. J. Min. Saf. Eng. 2015, 32, 523–529. (In Chinese) [Google Scholar]

- Yu, B.; Gao, R.; Xia, B.W.; Kuang, T.J. Ground Fracturing Technology and Application of Hard Roof in Large Space. J. China Coal Soc. 2021, 46, 800–811. (In Chinese) [Google Scholar]

- Li, Z.; Xu, J.L.; Ju, J.F.; Zhu, W.B.; Xu, J.M. The Effects of the Rotational Speed of Voussoir Beam Structures Formed by Key Strata on the Ground Pressure of Stopes. Int. J. Rock Mech. Min. Sci. 2018, 108, 67–79. [Google Scholar] [CrossRef]

- Li, Z.; Yu, S.C.; Zhu, W.B.; Feng, G.R.; Xu, J.M.; Guo, Y.X.; Qi, T.Y. Dynamic Loading Induced by the Instability of Voussoir Beam Structure During Mining Below the Slope. Int. J. Rock Mech. Min. Sci. 2020, 132, 104343. [Google Scholar] [CrossRef]

- Kuang, T.J.; Li, Z.; Zhu, W.B.; Xie, J.L.; Ju, J.F.; Liu, J.R.; Xu, J.M. The Impact of Key Strata Movement on Ground Pressure Behaviour in the Datong Coalfield. Int. J. Rock Mech. Min. Sci. 2019, 119, 193–204. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, H.; Jiang, Z.; Feng, G.R.; Cui, J.Q.; Ma, J.K. Research on Failure Criteria and Collapse Height of Roadway Roof Strata Based on Energy Accumulation and Dissipation Characteristics. Energy Sci. Eng. 2021, 9, 2461–2473. [Google Scholar] [CrossRef]

- Gao, R.; Kuang, T.J.; Meng, X.B.; Huo, B.J. Effects of Ground Fracturing with Horizontal Fracture Plane on Rock Breakage Characteristics and Mine Pressure Control. Rock Mech. Rock Eng. 2021, 54, 3229–3243. [Google Scholar] [CrossRef]

- Yu, B.; Gao, R.; Kuang, T.J.; Huo, B.J.; Meng, X.B. Engineering Study on Fracturing High-level Hard Rock Strata by Ground Hydraulic Action. Tunn. Undergr. Space Technol. 2019, 86, 156–164. [Google Scholar] [CrossRef]

- Wang, F.; Xu, J.L.; Xie, J.L. Effects of Arch Structure in Unconsolidated Layers on Fracture and Failure of Overlying Strata. Int. J. Rock Mech. Min. Sci. 2019, 114, 141–152. [Google Scholar] [CrossRef]

- Ji, S.T.; He, H.; Karlovsek, J. Application of Superposition Method to Study the Mechanical Behaviour of Overlying Strata in Longwall Mining. Int. J. Rock Mech. Min. Sci. 2021, 146, 104874. [Google Scholar] [CrossRef]

- Hu, C.S.; Apel, D.; Sudak, L.J.; Liu, W.V.; Chu, Z.Y. Physical Investigation on the Behaviours of Voussoir Beams. J. Rock Mech. Geotech. Eng. 2020, 12, 516–527. [Google Scholar] [CrossRef]

- Newman, D.; Hutchinson, A.J.; Mason, D.P. Tensile Fracture Analysis of a Thin Euler-Bernoulli Beam and the Transition to the Voussoir Model. Int. J. Rock Mech. Min. Sci. 2018, 102, 78–88. [Google Scholar] [CrossRef]

- Ran, Q.C.; Liang, Y.P.; Zou, Q.L.; Hong, Y.; Zhang, B.C.; Liu, H.; Kong, F.J. Experimental Investigation on Mechanical Characteristics of Red Sandstone Under Graded Cyclic Loading and Its Inspirations for Stability of Overlying Strata. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 11. [Google Scholar] [CrossRef]

- Jiang, L.S.; Wu, Q.S.; Wu, Q.L.; Wang, P.; Xue, Y.C.; Kong, P.; Gong, B. Fracture Failure Analysis of Hard and Thick Key Layer and its Dynamic Response Characteristics. Eng. Fail. Anal. 2019, 98, 118–130. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Li, X.H.; Ning, J.G.; Qiu, P.Q. In Situ Investigations into Mining-induced Hard Main Roof Fracture in Longwall Mining: A Case Study. Eng. Fail. Anal. 2019, 106, 14. [Google Scholar] [CrossRef]

- Ning, J.G.; Wang, J.; Jiang, L.S.; Jiang, N.; Liu, X.S.; Jiang, J.Q. Fracture Analysis of Double-layer Hard and Thick Roof and the Controlling Effect on Strata Behavior: A Case Study. Eng. Fail. Anal. 2017, 81, 117–134. [Google Scholar] [CrossRef]

- Yu, M.L.; Zuo, J.P.; Sun, Y.J.; Mi, C.N.; Li, Z.D. Investigation on Fracture Models and Ground Pressure Distribution of Thick Hard Rock Strata Including Weak Interlayer. Int. J. Min. Sci. Technol. 2022, 32, 137–153. [Google Scholar] [CrossRef]

- Ju, Y.; Wang, Y.L.; Su, C.S.; Zhang, D.S.; Ren, Z.Y. Numerical Analysis of the Dynamic Evolution of Mining-induced Stresses and Fractures in Multilayered Rock Strata Using Continuum-based Discrete Element Methods. Int. J. Rock Mech. Min. Sci. 2019, 113, 191–210. [Google Scholar] [CrossRef]

- Liu, J.W.; Liu, C.Y.; Yao, Q.L.; Si, G.Y. The Position of Hydraulic Fracturing to Initiate Vertical Fractures in Hard Hanging Roof for Stress Relief. Int. J. Rock Mech. Min. Sci. 2020, 132, 13. [Google Scholar] [CrossRef]

- Chen, J.C.; Qu, Z.Z.; Zhou, L.; Su, X.P. Numerical Study on the Hydraulic Fracturing Pattern in the Hard Roof in Response to Mining-Induced Stress. Minerals 2023, 13, 308. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Gong, T.; Xia, B.W.; Yu, B.; Huang, F. Target Stratum Determination of Surface Hydraulic Fracturing for Far-Field Hard Roof Control in Underground Extra-Thick Coal Extraction: A Case Study. Rock Mech. Rock Eng. 2019, 52, 2725–2740. [Google Scholar] [CrossRef]

- Wang, W.; Cheng, Y.P.; Wang, H.F.; Liu, H.Y.; Wang, L.; Li, W.; Jiang, J.Y. Fracture Failure Analysis of Hard-thick Sandstone Roof and its Controlling Effect on Gas Emission in Underground Ultra-thick Coal Extraction. Eng. Fail. Anal. 2015, 54, 150–162. [Google Scholar] [CrossRef]

- Shang, X.G.; Zhu, S.T.; Jiang, F.X.; Liu, J.H.; Li, J.J.; Hitch, M.; Liu, H.L.; Tang, S.B.; Zhu, C. Study on Dynamic Disaster Mechanisms of Thick Hard Roof Induced by Hydraulic Fracturing in Surface Vertical Well. Minerals 2022, 12, 1537. [Google Scholar] [CrossRef]

- Jia, Y.Z.; Lu, Z.H.; Liu, H.; Wang, J.H.; Cheng, Y.G.; Zhang, X.W. Fracture Propagation and Morphology Due to Non-Aqueous Fracturing: Competing Roles between Fluid Characteristics and In Situ Stress State. Minerals 2020, 10, 428. [Google Scholar] [CrossRef]

- Jameei, A.A.; Pietruszczak, S. On Hydromechanical Interaction during Propagation of Localized Damage in Rocks. Minerals 2021, 11, 162. [Google Scholar] [CrossRef]

- Gong, X.; Ma, X.H.; Liu, Y.Y.; Li, G.F. Advances in Hydraulic Fracture Propagation Research in Shale Reservoirs. Minerals 2022, 12, 1438. [Google Scholar] [CrossRef]

- Munoz-Ibanez, A.; Herbon-Penabad, M.; Delgado-Martin, J.; Alejano-Monge, L.; Alvarellos-Iglesias, J.; Canal-Vila, J. Hydrostatic, Strike-slip and Normal Stress True Triaxial Hydrofracturing Testing of Blanco Mera Granite: Breakdown Pressure and Tensile Strength Assessment. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 31. [Google Scholar] [CrossRef]

- Saber, E.; Qu, Q.D.; Sarmadivaleh, M.; Aminossadati, S.M.; Chen, Z.W. Propagation of Multiple Hydraulic Fractures in a Transversely Isotropic Shale Formation. Int. J. Rock Mech. Min. Sci. 2023, 170, 105010. [Google Scholar] [CrossRef]

- Pham, C.; Zhuang, L.; Yeom, S.; Shin, H.S. Automatic Fracture Characterization in CT Images of Rocks Using an Ensemble Deep Learning Approach. Int. J. Rock Mech. Min. Sci. 2023, 170, 105531. [Google Scholar] [CrossRef]

- Abousleiman, R.; Sinha, S.; Walton, G. Analysis of the Historic Bondi Pumping Chamber Case Study Using the Adjusted Voussoir Beam Analog. Rock Mech. Rock Eng. 2023, 56, 6357–6374. [Google Scholar] [CrossRef]

- Yiouta-Mitra, P.; Sofianos, A.I. Multi-jointed Stratified Hard Rock Roof Analysis and Design. Int. J. Rock Mech. Min. Sci. 2018, 106, 96–108. [Google Scholar] [CrossRef]

- Shabanimashcool, M.; Li, C.C. Analytical Approaches for Studying the Stability of Laminated Roof Strata. Int. J. Rock Mech. Min. Sci. 2015, 79, 99–108. [Google Scholar] [CrossRef]

- Hadei, M.R.; Veiskarami, A. An Experimental Investigation of Hydraulic Fracturing of Stratified Rocks. Bull. Eng. Geol. Environ. 2021, 80, 491–506. [Google Scholar] [CrossRef]

- Szurgacz, D.; Brodny, J. Analysis of the Influence of Dynamic Load on the Work Parameters of a Powered Roof Support’s Hydraulic Leg. Sustainability 2019, 11, 2570. [Google Scholar] [CrossRef]

- Xuan, D.Y.; Wang, B.L.; Xu, J.L. A Shared Borehole Approach for Coal-bed Methane Drainage and Ground Stabilization with Grouting. Int. J. Rock Mech. Min. Sci. 2016, 86, 235–244. [Google Scholar] [CrossRef]

- Ju, J.F.; Xu, J.L. Surface Stepped Subsidence Related to Top-coal Caving Longwall Mining of Extremely Thick Coal Seam Under Shallow Cover. Rock Mech. Rock Eng. 2015, 78, 27–35. [Google Scholar] [CrossRef]

- Qu, Q.D.; Guo, H.; Khanal, M. Monitoring and Analysis of Ground Movement from Multi-seam Mining. Int. J. Rock Mech. Min. Sci. 2021, 148, 104949. [Google Scholar] [CrossRef]

- Maqsood, Z.; Koseki, J.; Ahsan, M.K.; Shaikh, M.; Kyokawa, H. Experimental study on hardening characteristics and loading rate dependent mechanical behavior of gypsum mixed sand. Constr. Build. Mater. 2020, 262, 119992. [Google Scholar] [CrossRef]

- Mahanta, B.; Singh, T.N.; Ranjith, P.G.; Vishal, V. Experimental investigation of the influence of strain rate on strength; failure attributes and mechanism of Jhiri shale. J. Nat. Gas Sci. Eng. 2018, 58, 178–188. [Google Scholar] [CrossRef]

- Maqsood, Z.; Koseki, J.; Miyashita, Y.; Xie, J.; Kyokawa, H. Experimental study on the mechanical behavior of bounded geomaterials under creep and cyclic loading considering effects of instantaneous strain rates. Eng. Geol. 2020, 276, 105774. [Google Scholar] [CrossRef]

- Wang, H.S.; Wang, J.; Elmo, D.; He, M.C.; Ma, Z.M.; Gao, C.Z. Ground response mechanism of entries and control methods induced by hard roof in longwall top coal caving panel. Eng. Fail. Anal. 2023, 144, 21. [Google Scholar] [CrossRef]

- Gao, R.; Yang, J.X.; Kuang, T.J.; Liu, H.J. Investigation on the Ground Pressure Induced by Hard Roof Fracturing at Different Layers during Extra Thick Coal Seam Mining. Geofluids 2020, 2020, 8834235. [Google Scholar] [CrossRef]

- Mondal, D.; Roy, P.N.S.; Kumar, M. Monitoring the strata behavior in the Destressed Zone of a shallow Indian longwall panel with hard sandstone cover using Mine-Microseismicity and Borehole Televiewer data. Eng. Geol. 2020, 271, 25. [Google Scholar] [CrossRef]

- Gao, R.; Yu, B.; Meng, X.B. Study on the Mechanism of Strong Strata Behavior Influenced by Overlying Coal Pillar and Control Technology of Ground Fracturing. J. Min. Saf. Eng. 2018, 35, 324–331. (In Chinese) [Google Scholar]

| No. | Name | Elastic Modulus E/GPa | Compressive Strength σc/MPa | Tensile Strength σt /MPa | Poisson’s Ratio μ | Cohesion C/MPa | Internal Friction Angle f/° |

|---|---|---|---|---|---|---|---|

| 1 | Coarse sandstone | 23 | 36.83 | 3.9 | 0.24 | 4.1 | 22 |

| 2 | Medium sandstone | 19.5 | 38.6 | 3.7 | 0.25 | 5.1 | 23 |

| 3 | Siltstone | 18.5 | 23.53 | 2.6 | 0.27 | 4.2 | 22 |

| 4 | Fine sandstone | 60 | 90.43 | 12.4 | 0.21 | 8.4 | 25 |

| 5 | Siltstone | 19.1 | 27.63 | 4.2 | 0.22 | 6.1 | 23 |

| 6 | Coal seam | 7.5 | 16.13 | 1.1 | 0.32 | 3.9 | 20 |

| 7 | Mudstone | 5.7 | 25.4 | 2.3 | 0.27 | 3.8 | 21 |

| 8 | Carbonaceous mudstone | 13 | 15.42 | 1.4 | 0.22 | 3.7 | 21 |

| 9 | Sandy mudstone | 10.5 | 32.2 | 2.8 | 0.27 | 5.2 | 22 |

| No. | Name | Sand (kg) | CaCO3 (kg) | Gypsum (kg) |

|---|---|---|---|---|

| 1 | Coarse sandstone | 23.28 | 5.43 | 2.33 |

| 2 | Medium sandstone | 9.10 | 0.46 | 1.06 |

| 3 | Siltstone | 26.25 | 2.63 | 0.90 |

| 4 | Fine sandstone | 14.35 | 0.86 | 2.63 |

| 5 | Siltstone | 23.63 | 2.36 | 2.36 |

| 6 | Coal seam | 21.00 | 2.70 | 0.30 |

| 7 | Mudstone | 17.68 | 2.47 | 1.06 |

| 8 | Carbonaceous mudstone | 9.70 | 1.36 | 0.58 |

| 9 | Sandy mudstone | 20.68 | 3.56 | 2.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Qi, C.; Gao, R.; Yu, B.; Zhu, Y.; Zhang, H.; Zhang, J. Simulation Study and Engineering Application of Weakening Mine Pressure Behavior in Stope through Ground Fracturing Thick and Hard Rock Strata. Appl. Sci. 2024, 14, 415. https://doi.org/10.3390/app14010415

Li Z, Qi C, Gao R, Yu B, Zhu Y, Zhang H, Zhang J. Simulation Study and Engineering Application of Weakening Mine Pressure Behavior in Stope through Ground Fracturing Thick and Hard Rock Strata. Applied Sciences. 2024; 14(1):415. https://doi.org/10.3390/app14010415

Chicago/Turabian StyleLi, Zhu, Chengen Qi, Rui Gao, Bin Yu, Yiran Zhu, Hong Zhang, and Jingyu Zhang. 2024. "Simulation Study and Engineering Application of Weakening Mine Pressure Behavior in Stope through Ground Fracturing Thick and Hard Rock Strata" Applied Sciences 14, no. 1: 415. https://doi.org/10.3390/app14010415

APA StyleLi, Z., Qi, C., Gao, R., Yu, B., Zhu, Y., Zhang, H., & Zhang, J. (2024). Simulation Study and Engineering Application of Weakening Mine Pressure Behavior in Stope through Ground Fracturing Thick and Hard Rock Strata. Applied Sciences, 14(1), 415. https://doi.org/10.3390/app14010415