Studies on Influence of Chromium Layer on Inner Surface of Steel Tube on Heat Transfer

Abstract

1. Introduction

2. Material and Numerical Methods

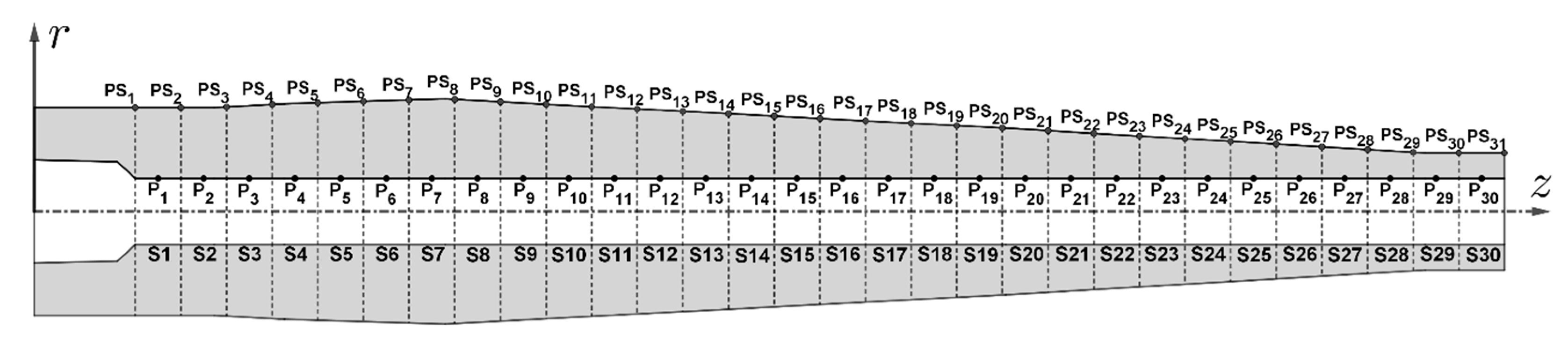

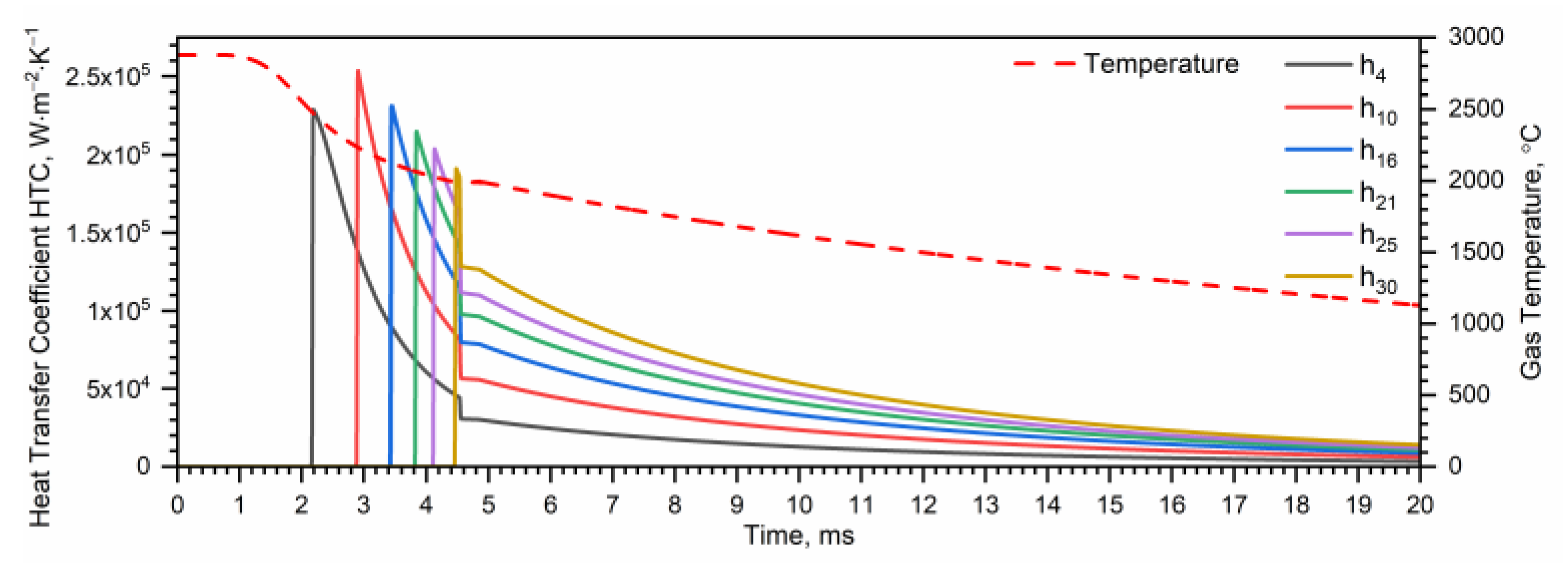

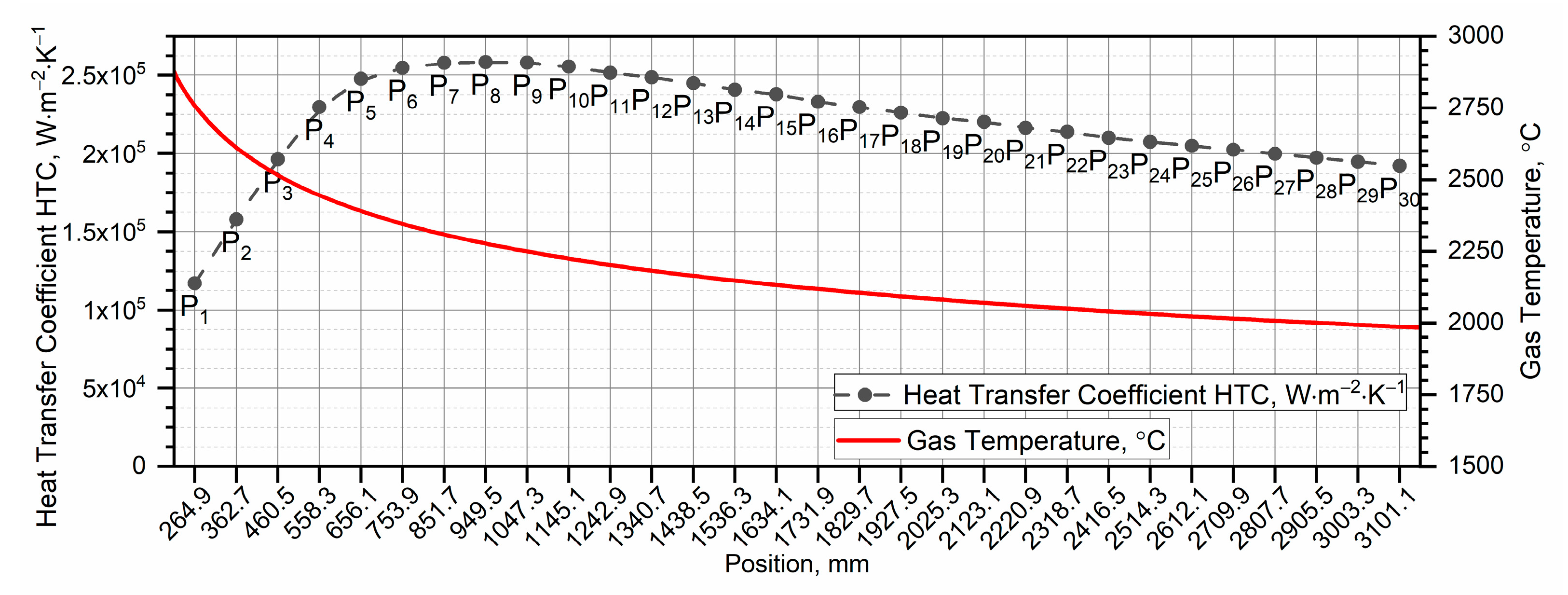

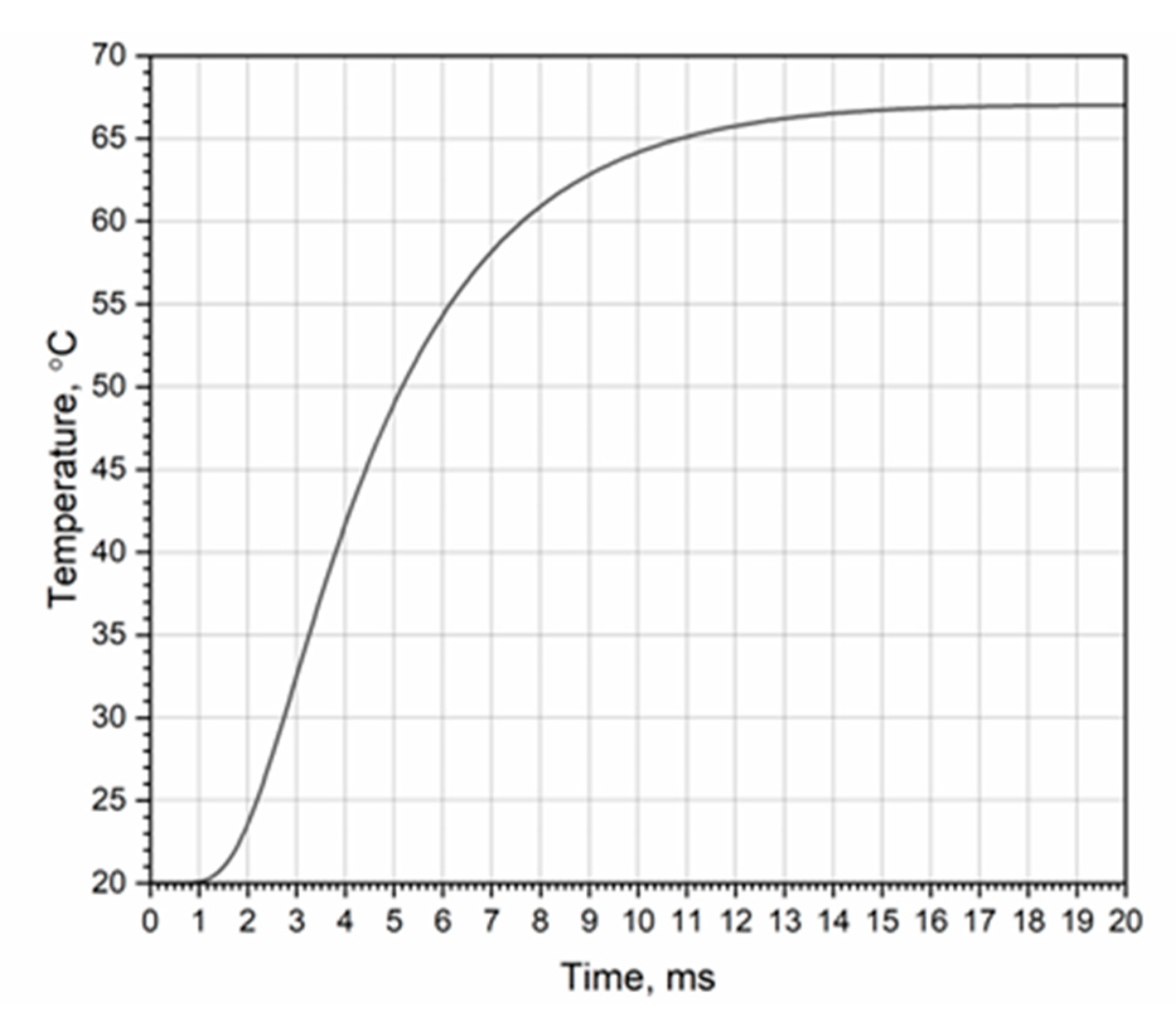

2.1. Heat Transfer Coefficient and Gas Temperature

- when the piston is inside the tube:

- when the tube is open (piston leaves the tube):

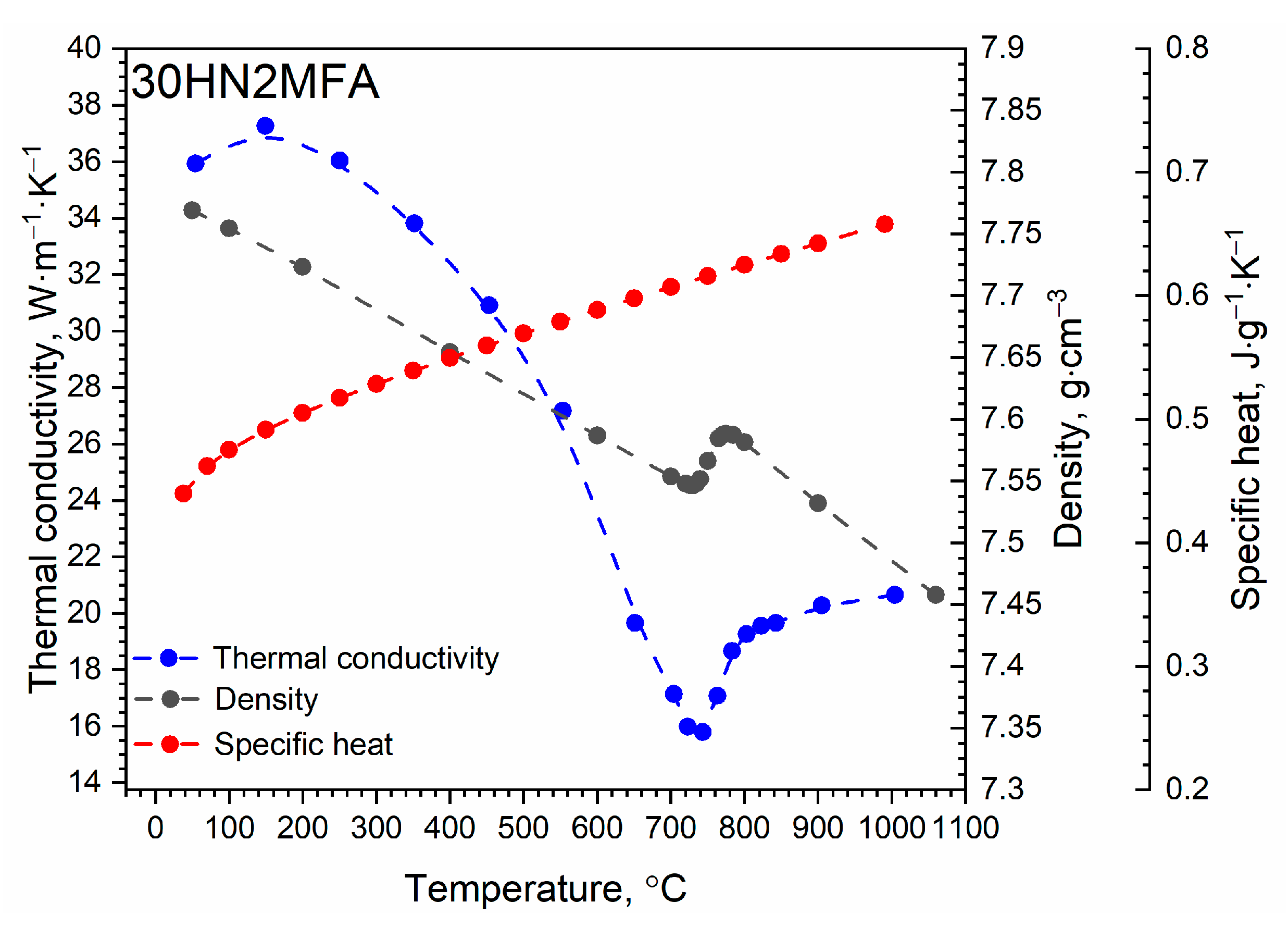

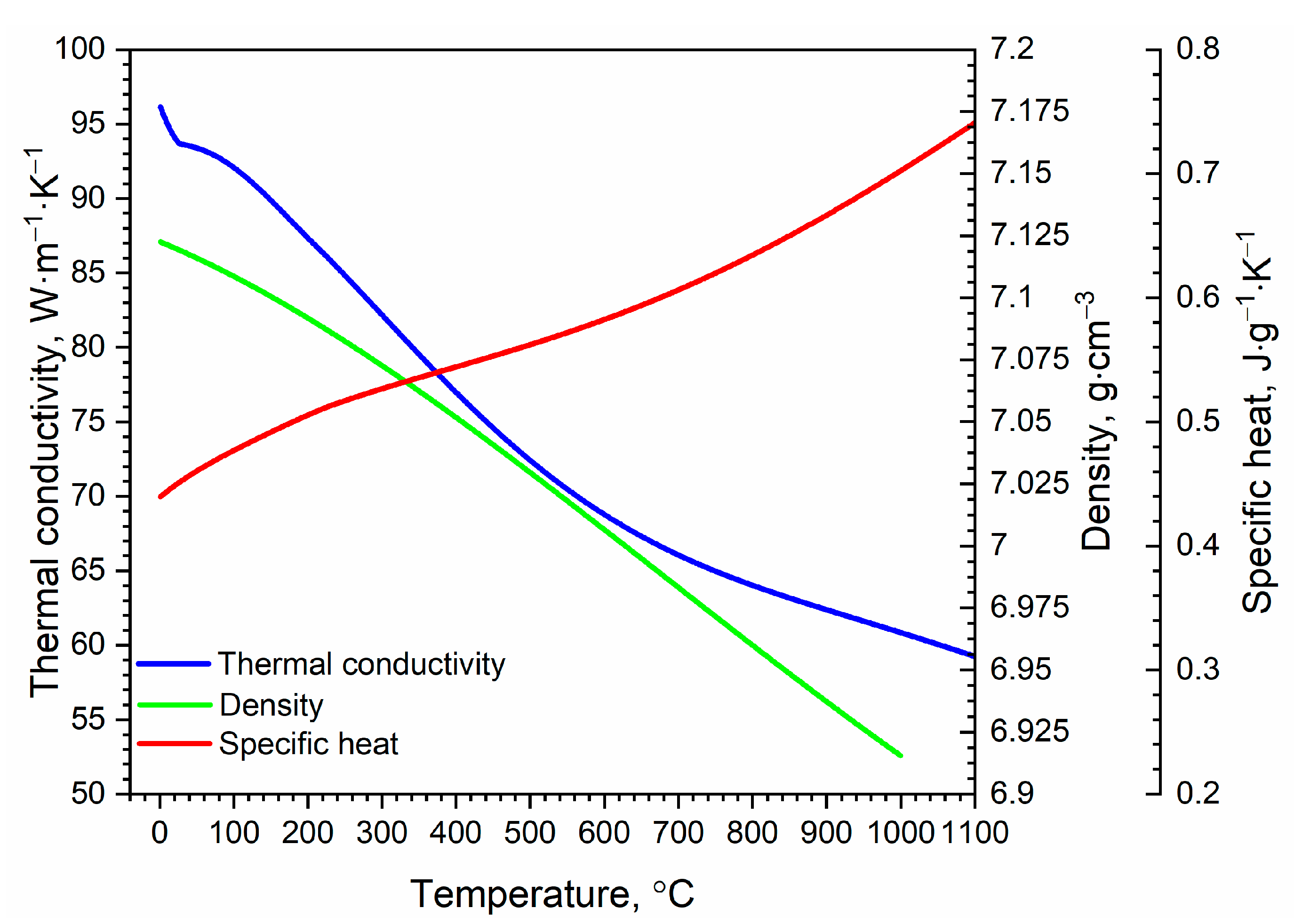

2.2. Thermophysical Properties of Steel and Chromium

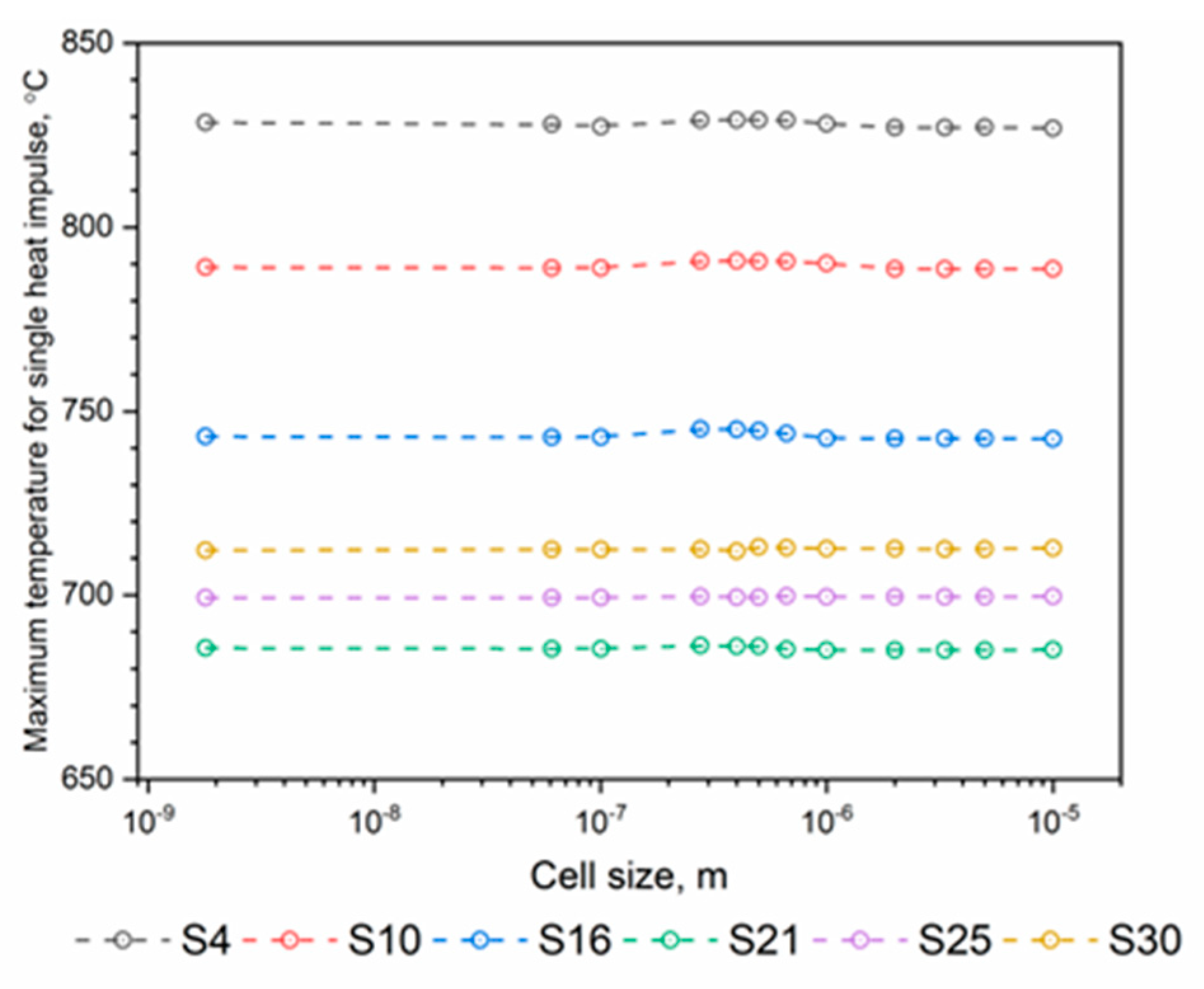

2.3. Initial Boundary Value Problem

- (a)

- in the range —the mesh compaction with a geometric sequence , where n = 25, , and , was performed;

- (b)

- in the range —the equal division into 5 cells was performed;

- (c)

- in the range —the equal division into 5 cells was performed;

- (d)

- in the range —the mesh compaction with a geometric sequence , where n = 9, , and , was performed;

- (e)

- in the range —the mesh compaction with a geometric sequence , where n = 9, , and , was performed;

- (f)

- in the range —the mesh compaction with a geometric sequence , where n = 9, , and , was performed;

- (g)

- in the range —the equal division into 8 cells was performed;

- -

- in case (a)—the compaction of the mesh is due to the large temperature gradient along the thickness of the tube—Figure 8C;

- -

- in case (d)—mesh compaction shortens the calculation time in relation to the uniform mesh;

- -

- in case (e)—the compaction of the mesh is due to the large temperature gradient between Cr—steel interface—Figure 8D;

- -

- in case (f)—mesh compaction shortens the calculation time in relation to the uniform mesh.

3. Numerical Simulation and Results Analysis

3.1. Temperature Distribution in the Tube for a Single Heat Impulse

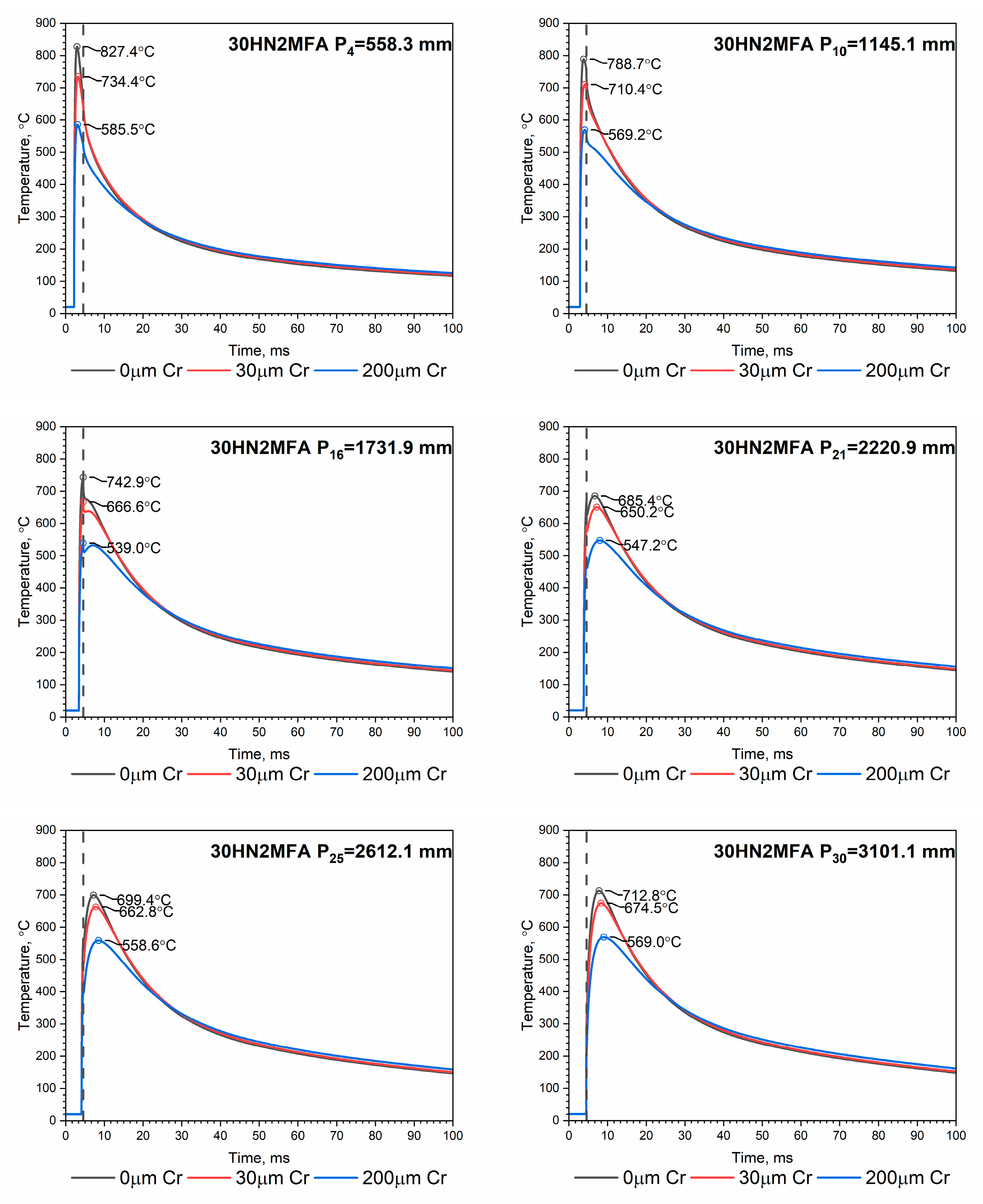

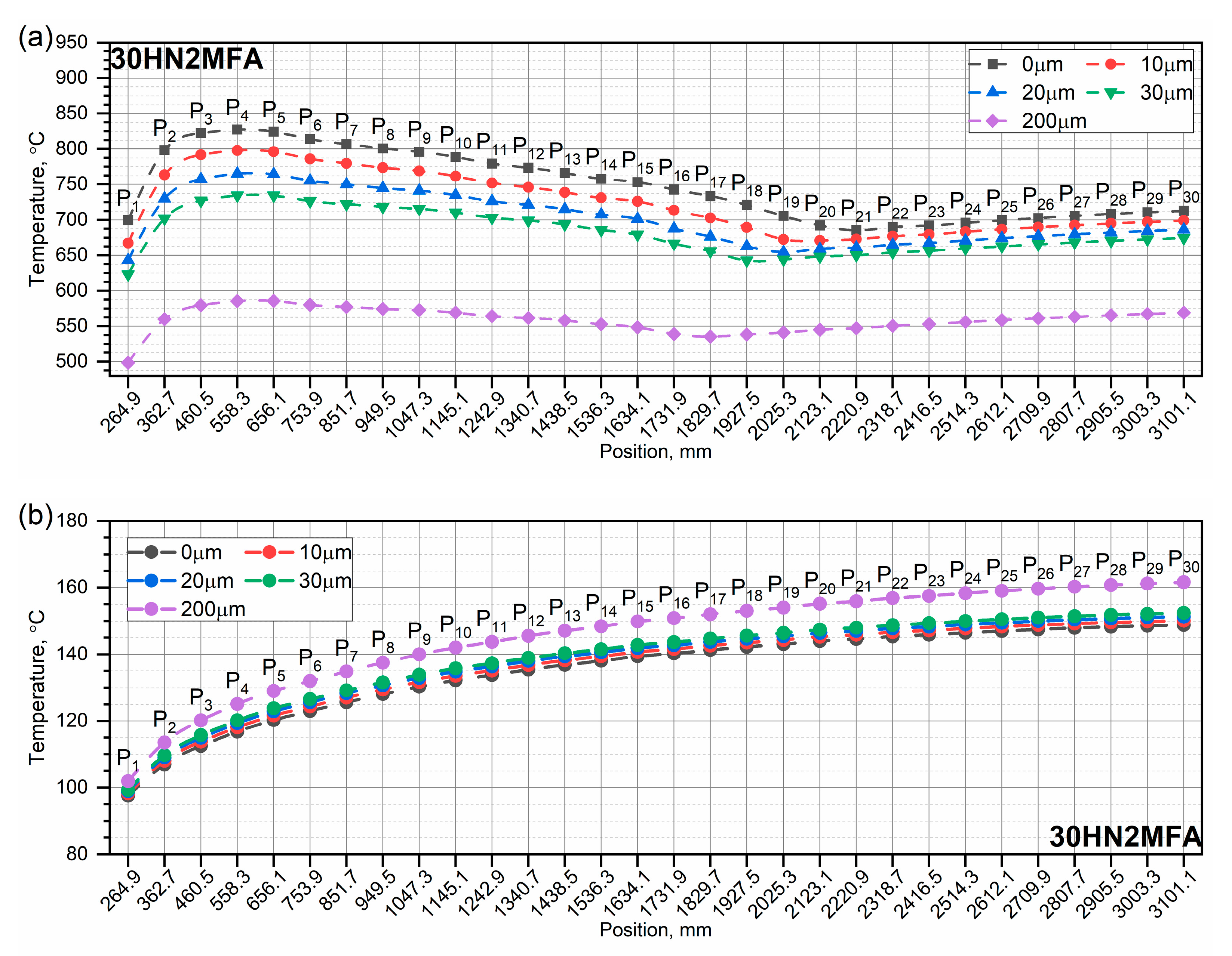

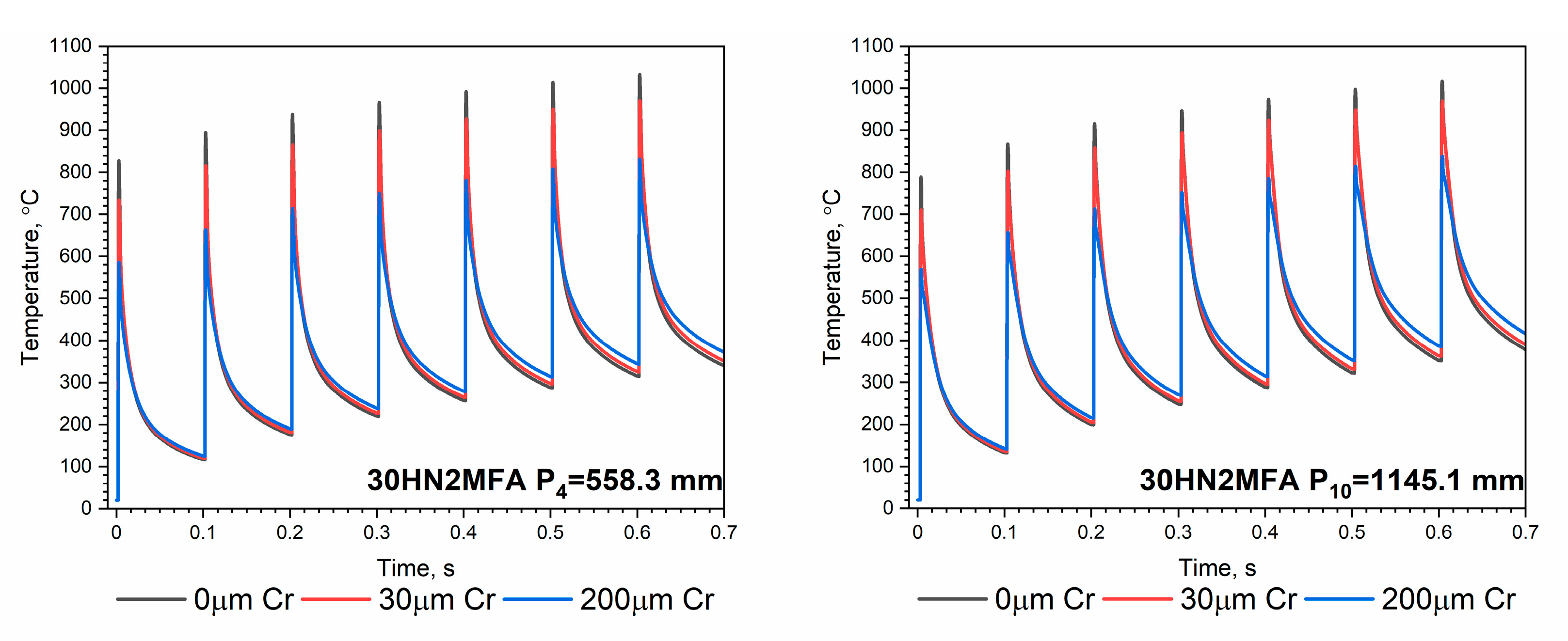

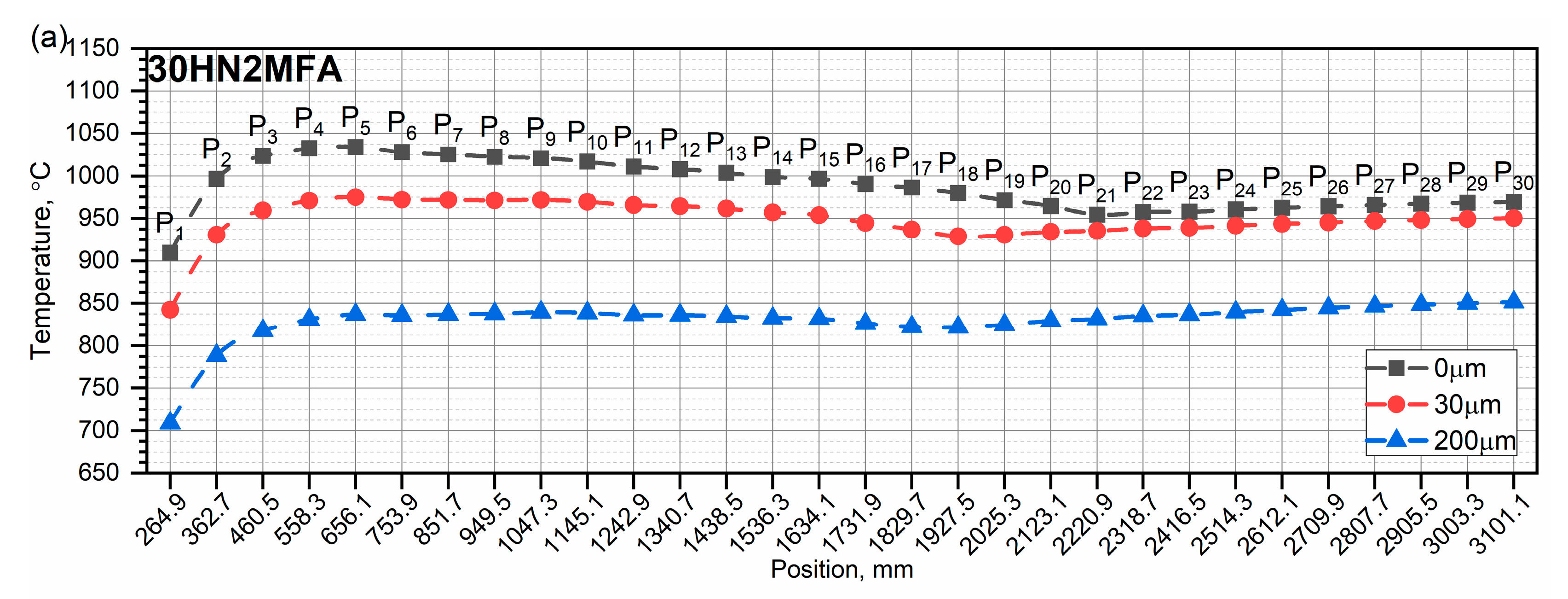

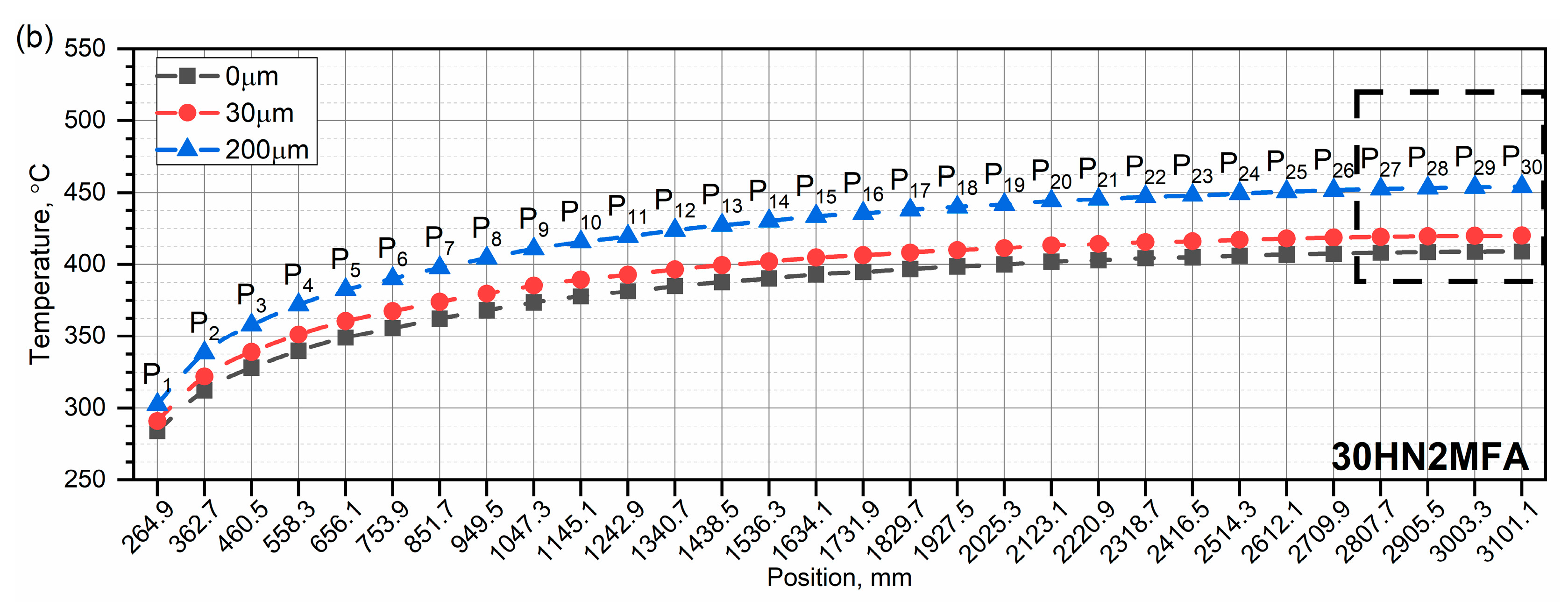

3.2. Temperature Distribution in the Tube for a Series of Seven Heat Impulses

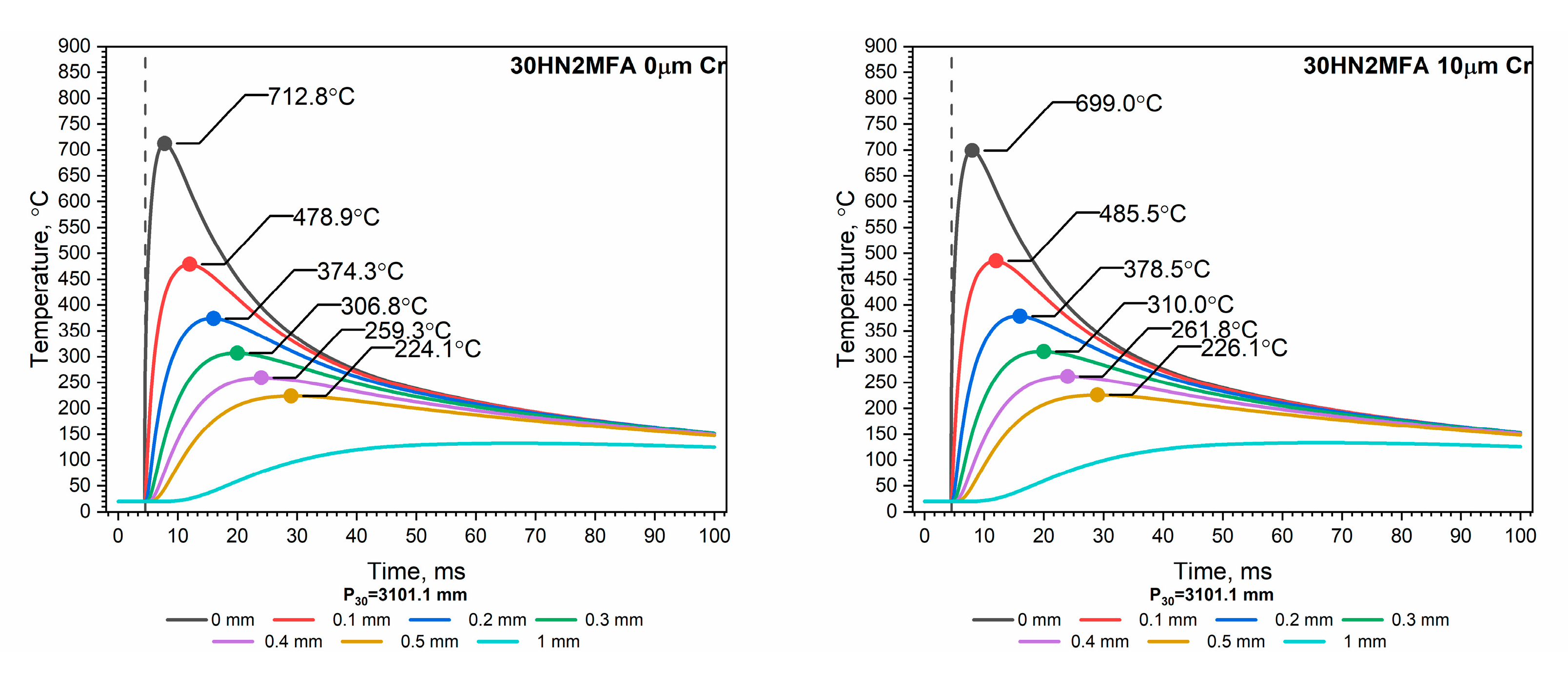

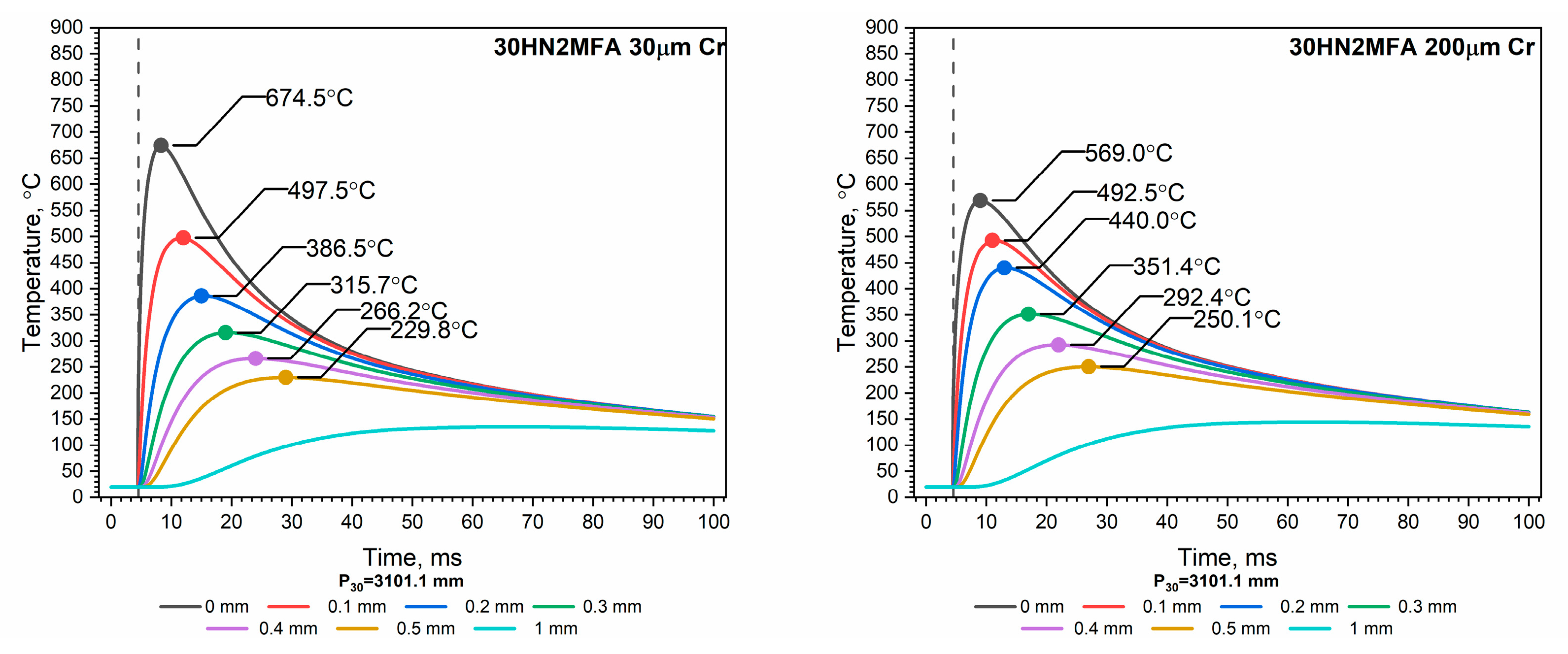

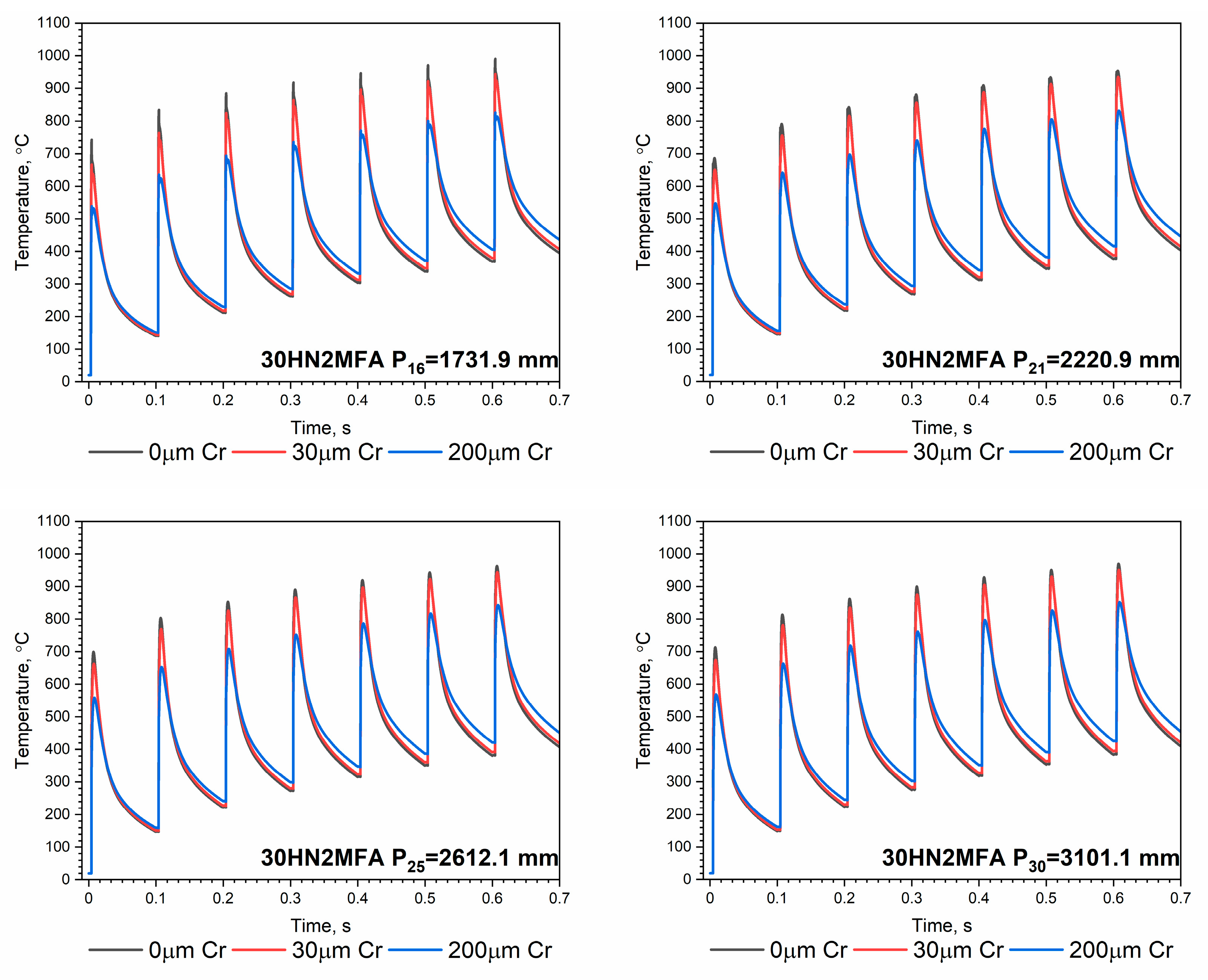

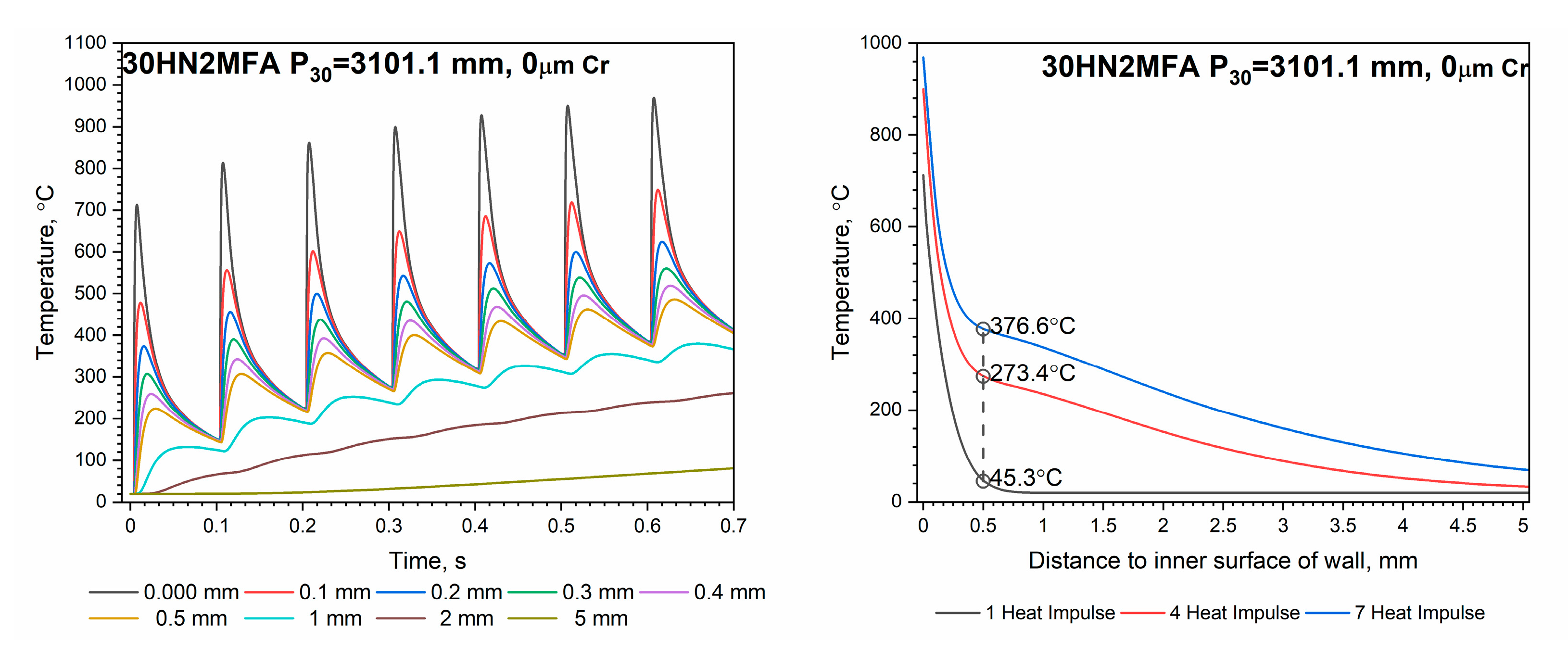

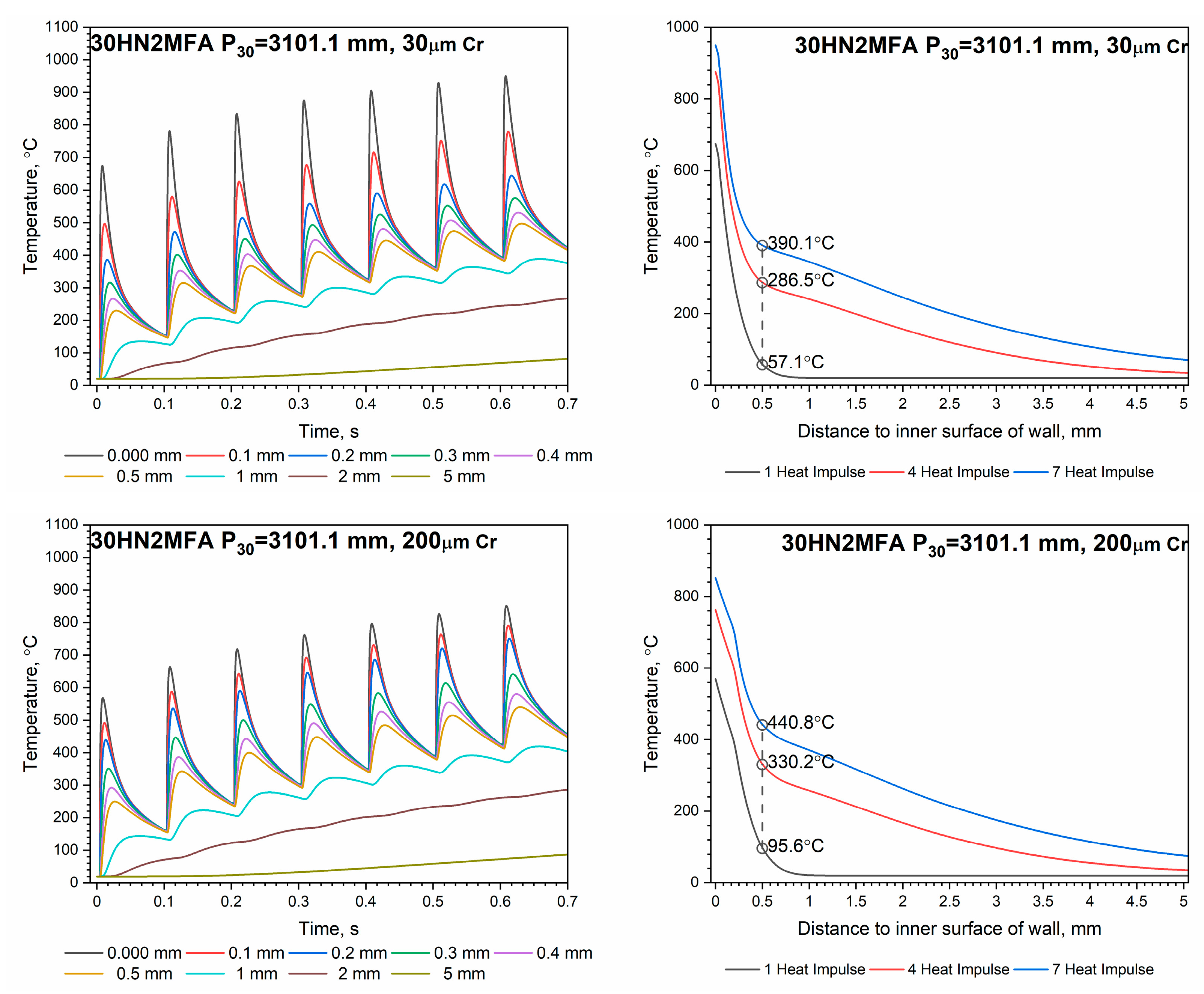

3.3. Temperature Distribution along the Tube Thickness for a Series of Seven Heat Impulses

4. Discussion

5. Conclusions

- (1)

- The calculations of the heat transfer indicate that the division of the tube into 30 zones allows for a reasonable time of several hours to calculate the temperature distribution over the entire length of the tube.

- (2)

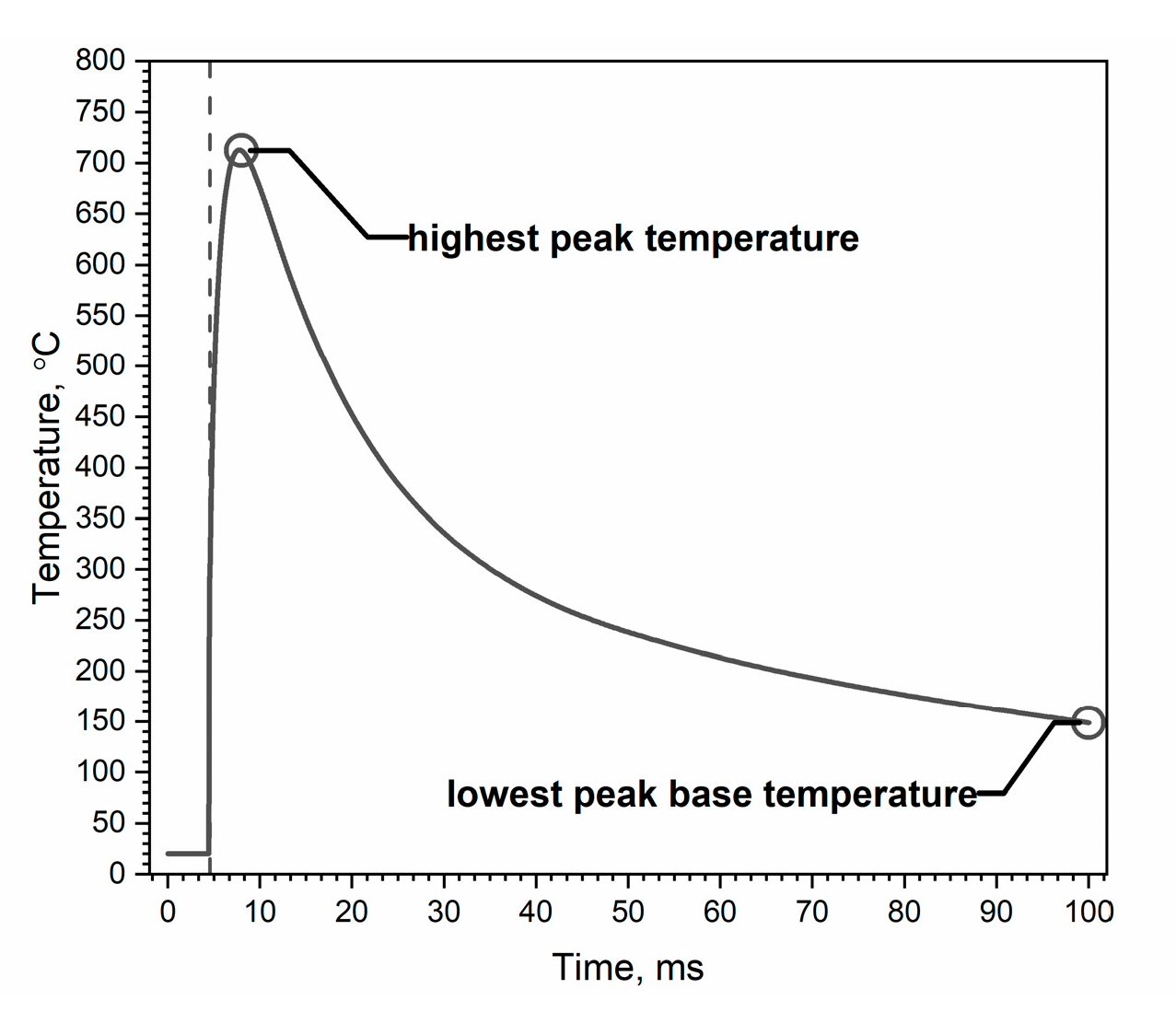

- After the first and subsequent heat impulses, as the thickness of the chrome layer increases, the highest peak temperature in each zone drops, while the temperature inside the steel wall of the tube increases. Such a heat transfer mechanism is related to the high thermal conductivity of chromium. With each subsequent impulse, the lowest peak base temperature of the inner surface of the chrome-plated tube increases relative to the same temperature of the inner surface of the non-chrome-plated tube. Additionally, it can be assumed that the so-called minimum temperature of the peak base is actually the temperature of the tube to a depth of approximately 0.5 mm below its surface.

- (3)

- Already after the first heat impulse, the temperature of the wall at a depth of 0.5 mm below the inner surface is twice as high for a tube with a 200 µm thick chrome coating compared to a tube without this coating. After the fourth heat impulse, the temperature difference stabilizes and amounts to approximately 60 °C and, after the seventh impulse, a little more, i.e., 65 °C.

- (4)

- The presented model of heat transfer calculation in a tube with an inner channel covered with a thin layer of protective material can be used for the analysis of heat engines, internal combustion engines, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sopok, S.; Rickard, C.; Dunn, S. Thermal–chemical–mechanical gun bore erosion of an advanced artillery system part one: Theories and mechanisms. Wear 2005, 258, 659–670. [Google Scholar] [CrossRef]

- Sopok, S.; Rickard, C.; Dunn, S. Thermal–chemical–mechanical gun bore erosion of an advanced artillery system part two: Modeling and predictions. Wear 2005, 258, 671–683. [Google Scholar] [CrossRef]

- Cote, P.J.; Rickard, C. Gas–metal reaction products in the erosion of chromium-plated gun bores. Wear 2000, 241, 17–25. [Google Scholar] [CrossRef]

- Stiefel, L. (Ed.) Gun Propulsion Technology; American Inst. of Aeronautics and Astronautics: Washington, DC, USA, 1988; ISBN 0930403207. [Google Scholar]

- Feng, G.-T.; Zhou, K.-D.; Zhang, Y.-Q.; He, L.; Li, J.-S.; Wang, J. The Study of Gun Barrel’s Two-Dimensional Nonlinear Thermal Conduction. Int. J. Thermophys. 2019, 40, 37. [Google Scholar] [CrossRef]

- Ebihara, W.T.; Rorabaugh, D.T. Mechanisms of Gun-Tube Erosion and Wear. In Gun Propulsion Technology; Stiefel, L., Ed.; American Inst. of Aeronautics and Astronautics: Washington, DC, USA, 1988; pp. 357–376. ISBN 0930403207. [Google Scholar]

- Ahmad, I. The Problem of Gun Barrel Erosion: An Overview. In Gun Propulsion Technology; Stiefel, L., Ed.; American Inst. of Aeronautics and Astronautics: Washington, DC, USA, 1988; pp. 311–356. ISBN 0930403207. [Google Scholar]

- Baracuti, A.J. Wear-Reduction Additives—Role of Propellant. In Gun Propulsion Technology; Stiefel, L., Ed.; American Inst. of Aeronautics and Astronautics: Washington, DC, USA, 1988; pp. 377–412. ISBN 0930403207. [Google Scholar]

- Fikus, B.; Dorochowicz, A.; Surma, Z.; Kijewski, J.; Leciejewski, Z.; Michalski, J.; Trębiński, R. Investigations of Middle-Caliber Anti-Aircraft Cannon Interior Ballistics including Heat Transfer Problem in Estimation of Critical Burst Length. Processes 2022, 10, 607. [Google Scholar] [CrossRef]

- Lawton, B. Thermo-chemical erosion in gun barrels. Wear 2001, 251, 827–838. [Google Scholar] [CrossRef]

- Woodley, C.; Critchley, R.; Wallington, D. QinetiQ Studies on Wear and Erosion in Gun Barrels. Available online: https://www.semanticscholar.org/paper/QinetiQ-Studies-on-Wear-and-Erosion-in-Gun-Barrels-Woodley-Critchley/1e6ebf62df3ecc6b2b064737ee69ce45b659fcdf (accessed on 1 April 2023).

- Mishra, A.; Hameed, A.; Lawton, B. A Novel Scheme for Computing Gun Barrel Temperature History and Its Experimental Validation. J. Press. Vessel. Technol. 2010, 132, 444. [Google Scholar] [CrossRef]

- Dębski, A.; Koniorczyk, P.; Leciejewski, Z.; Preiskorn, M.; Surma, Z.; Zmywaczyk, J. Analysis of Heat Transfer in a 35 mm Barrel of an Anti-Aircraft Cannon. Probl. Mechatron. Armament Aviat. Saf. Eng. 2016, 7, 71–86. [Google Scholar] [CrossRef]

- Koniorczyk, P.; Zmywaczyk, J.; Dębski, A.; Zieliński, M.; Cegła, M. Investigations of thermal diffusivity and thermal expansion for three types of the barrel steel. In Thermophysics 2019: 24th International Meeting of Thermophysics and 20th Conference REFRA, Smolenice, Slovakia, 22–24 October 2019; Koniorczyk, P., Zmywaczyk, J., Dębski, A., Zieliński, M., Cegła, M., Eds.; AIP Publishing: Melville, NY, USA, 2019; p. 20006. [Google Scholar]

- Koniorczyk, P.; Zmywaczyk, J.; Dębski, A.; Zieliński, M.; Preiskorn, M.; Sienkiewicz, J. Investigation of Thermophysical Properties of Three Barrel Steels. Metals 2020, 10, 573. [Google Scholar] [CrossRef]

- Koniorczyk, P.; Sienkiewicz, J.; Zmywaczyk, J.; Dębski, A.; Zieliński, M.; Preiskorn, M. Effect of Microstructure on Thermophysical Properties of Heat-Treated Duplex Steel. Materials 2021, 14, 6043. [Google Scholar] [CrossRef]

- Dębski, A.; Surma, Z.; Koperski, W. Material and Technological Optimization Research in Terms of Increasing the Durability of Small Arms; Military University of Technology: Warsaw, Poland, 2009. [Google Scholar]

- Zhen, W.; Jin, W. Heat Transfer Simulation of Large Caliber Gun Barrel. IOP Conf. Ser. Earth Environ. Sci. 2020, 546, 42039. [Google Scholar] [CrossRef]

- Keith Clutter, J.; Shyy, W. Computation of high-speed reacting flow for gun propulsion applications. Numer. Heat Transf. Part A Appl. 1997, 31, 355–374. [Google Scholar] [CrossRef]

- Wu, Y.-H. Analysis of the Temperature Field of a Gun Tube Based on Thermal-Solid Coupling. RJASET 2013, 5, 4110–4117. [Google Scholar] [CrossRef]

- Akçay, M.; Yükselen, M.A. Unsteady Thermal Studies of Gun Barrels during the Interior Unsteady Thermal Studies of Gun Barrels during the Interior Ballistic Cycle with Non-Homogenous Gun Barrel Material Thermal Characteristics. J. Therm. Sci. Technol. 2014, 34, 75–81. [Google Scholar]

- Ding, C.; Liu, N.; Zhang, X. A mesh generation method for worn gun barrel and its application in projectile-barrel interaction analysis. Finite Elem. Anal. Des. 2017, 124, 22–32. [Google Scholar] [CrossRef]

- Hill, R.; McLeod, L. Methodology for Transient Thermal Analysis of Machine Gun Barrels Subjected to Burst Firing Schedules. Available online: https://nts.com/content/uploads/2017/12/Methodology-for-Transient-Thermal-Analysis-of-Machine-Gun-Barrels-Subjected-to-Burst-Firing-Schedules.pdf (accessed on 1 April 2023).

- Hill, R.D.; Conner, J.M. Transient Heat Transfer Model of Machine Gun Barrels. Mater. Manuf. Process. 2012, 27, 840–845. [Google Scholar] [CrossRef]

- Zieliński, M.; Koniorczyk, P.; Surma, Z.; Zmywaczyk, J.; Preiskorn, M. Numerical Study of Heat Transfer in a Gun Barrel Made of Selected Steels. Energies 2022, 15, 1868. [Google Scholar] [CrossRef]

- Chen, T.-C.; Liu, C.-C.; Jang, H.-Y.; Tuan, P.-C. Inverse estimation of heat flux and temperature in multi-layer gun barrel. Int. J. Heat Mass Transf. 2007, 50, 2060–2068. [Google Scholar] [CrossRef]

- Gu, Z.C.; Lu, H.T.; Wang, S.; Yan, W.M.; Xu, C. Numerical simulation of 3D barrel system based on thermal-structural coupling under continuous firing. J. Phys. Conf. Ser. 2020, 1507, 82052. [Google Scholar] [CrossRef]

- Qu, P.; Li, Q.; Yang, S.F. Temperature Field and Thermal Stress Analysis of Large Caliber Gun Barrel. AMM 2014, 518, 150–154. [Google Scholar] [CrossRef]

- Lee, H.-L.; Yang, Y.-C.; Chang, W.-J.; Wu, T.-S. Estimation of heat flux and thermal stresses in multilayer gun barrel with thermal contact resistance. Appl. Math. Comput. 2009, 209, 211–221. [Google Scholar] [CrossRef]

- Yang, Y.-C.; Lee, H.-L.; Hsu, J.-C.; Chu, S.-S. Thermal Stresses in Multilayer Gun Barrel with Interlayer Thermal Contact Resistance. J. Therm. Stress. 2008, 31, 624–637. [Google Scholar] [CrossRef]

- COMSOL Documentation: Theory for Thermal Contact. Available online: https://doc.comsol.com/6.0/docserver/#!/com.comsol.help.heat/heat_ug_theory.07.01.html (accessed on 22 June 2022).

- Bejan, A.; Kraus, A.D. Heat Transfer Handbook; Wiley: Hoboken, NJ, USA, 2003; ISBN 0471390151. [Google Scholar]

- Zhang, L.; Chen, Z.; Wen, D.; Wang, X.; Zhang, D.; Liang, J. Estimation of the Time-Varying High-Intensity Heat Flux for a Two-Layer Hollow Cylinder. Energies 2018, 11, 3332. [Google Scholar] [CrossRef]

- Ho, C.Y.; Powell, R.W.; Liley, P.E. Journal of Physical and Chemical Reference Data: Thermal Conductivity of the Elements: A Comprehensive Review. Available online: https://srd.nist.gov/JPCRD/jpcrdS1Vol3.pdf (accessed on 22 June 2022).

- McBride, B.J.; Gordon, S.; Reno, M.A. NASA Technical Paper 3287: Thermodynamic Data for Fifty Reference Elements. Available online: https://ntrs.nasa.gov/api/citations/20010021116/downloads/20010021116.pdf (accessed on 22 June 2022).

- Chromium Thermal Properties from Material Properties Database (MPDB) by JAHAM Software. Available online: https://www.jahm.com/demo_version.html (accessed on 22 June 2022).

- Koniorczyk, P.; Zieliński, M.; Sienkiewicz, J.; Zmywaczyk, J.; Dębski, A. Experimental Studies of Thermophysical Properties and Microstructure of X37CrMoV5-1 Hot-Work Tool Steel and Maraging 350 Steel. Materials 2023, 16, 1206. [Google Scholar] [CrossRef]

- Wiśniewski, S.; Wydawnictwo Naukowe PWN. Wymiana Ciepła, 61st ed.; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2017; ISBN 9788301194437. [Google Scholar]

- Corner, J. Theory of the Interior Ballistics of Guns; John Wiley & Sons: New York, NY, USA, 1950. [Google Scholar]

- Serebryakov, M.E. Internal Ballistics of Gun Systems and Solid Rockets; Oborongiz: Moscow, Russia, 1962. [Google Scholar]

- Carlucci, D.E. Ballistics: Theory and Design of Guns and Ammunition, 2nd ed.; CRC Press: Hoboken, NJ, USA, 2013; ISBN 9781466564374. [Google Scholar]

- Fikus, B.; Surma, Z.; Trembiński, R. Preliminary Application Correctness Assessment of Physical Burning Law in Interior Ballistics Phenomena Modeling in Small-Caliber Guns. In Proceedings of the 31st International Symposium on Ballistics, Hyderabad, India, 4–8 November 2019; DEStech Publications, Inc.: Lancaster, PA, USA, 2019. ISBN 978-1-60595-610-7. [Google Scholar]

- Chen, H.; Yue, Z.; Ren, D.; Zeng, H.; Wei, T.; Zhao, K.; Yang, R.; Qiu, P.; Chen, L.; Shi, X. Thermal Conductivity during Phase Transitions. Adv. Mater. 2019, 31, 1806518. [Google Scholar] [CrossRef] [PubMed]

| Number of Zone i | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 |

| 216.0 | 313.8 | 411.6 | 509.4 | 607.2 | 705.0 | 802.8 | 900.6 | 998.4 | 1096.2 | |

| 55.00 | 55.00 | 55.35 | 55.66 | 57.52 | 58.23 | 58.94 | 59.24 | 57.94 | 56.72 | |

| 264.9 | 362.7 | 460.5 | 558.3 | 656.1 | 753.9 | 851.7 | 949.5 | 1047.3 | 1145.1 | |

| Number of Zone i | S11 | S12 | S13 | S14 | S15 | S16 | S17 | S18 | S19 | S20 |

| 1194.0 | 1291.8 | 1389.6 | 1487.4 | 1585.2 | 1683.0 | 1780.8 | 1878.6 | 1976.4 | 2074.2 | |

| 55.47 | 54.21 | 52.93 | 51.70 | 50.44 | 49.18 | 47.93 | 46.67 | 45.41 | 44.16 | |

| 1242.9 | 1340.7 | 1438.5 | 1536.3 | 1634.1 | 1731.9 | 1829.7 | 1927.5 | 2025.3 | 2123.1 | |

| Number of Zone i | S21 | S22 | S23 | S24 | S25 | S26 | S27 | S28 | S29 | S30 |

| 2172.0 | 2269.8 | 2367.6 | 2465.4 | 2563.2 | 2661.0 | 2758.8 | 2856.6 | 2954.4 | 3052.2 | |

| 42.75 | 41.33 | 39.90 | 38.48 | 37.06 | 35.64 | 34.22 | 32.79 | 31.37 | 31.00 | |

| 2220.9 | 2318.7 | 2416.5 | 2514.3 | 2612.1 | 2709.9 | 2807.7 | 2905.5 | 3003.3 | 3101.1 | |

| 3150 | ||||||||||

| mass of piston | m, kg | 0.380 |

| mass of propulsion material | mp, kg | 0.376 |

| cross-sectional area of tube’s hole | s, m2 | 9.98 × 10−4 |

| volume of propulsion material chamber | V0, m3 | 373 × 10−6 |

| total travel of piston in tube | lm, m | 2.9342 |

| coefficient of secondary works of gas | φ | 1.37 |

| “force” of the propulsion material | f, J·kg−1 | 1.071 × 106 |

| covolume of gas | η, m3∙kg−1 | 1.064 × 10−3 |

| ratio of specific heats of gas | γ | 1.2 |

| gas constant | R, J·kg−1·K−1 | 340 |

| density of propulsion material | ρp, kg∙m−3 | 1600 |

| highest peak temperature [°C] | 712.8 | 699.0 | 674.5 | 569.0 |

| lowest temperature of the peak base [°C] | 224.1 | 226.1 | 229.8 | 250.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zieliński, M.; Koniorczyk, P.; Surma, Z. Studies on Influence of Chromium Layer on Inner Surface of Steel Tube on Heat Transfer. Appl. Sci. 2023, 13, 5523. https://doi.org/10.3390/app13095523

Zieliński M, Koniorczyk P, Surma Z. Studies on Influence of Chromium Layer on Inner Surface of Steel Tube on Heat Transfer. Applied Sciences. 2023; 13(9):5523. https://doi.org/10.3390/app13095523

Chicago/Turabian StyleZieliński, Mateusz, Piotr Koniorczyk, and Zbigniew Surma. 2023. "Studies on Influence of Chromium Layer on Inner Surface of Steel Tube on Heat Transfer" Applied Sciences 13, no. 9: 5523. https://doi.org/10.3390/app13095523

APA StyleZieliński, M., Koniorczyk, P., & Surma, Z. (2023). Studies on Influence of Chromium Layer on Inner Surface of Steel Tube on Heat Transfer. Applied Sciences, 13(9), 5523. https://doi.org/10.3390/app13095523