Integrated Path Tracking Controller of Underground Articulated Vehicle Based on Nonlinear Model Predictive Control

Abstract

1. Introduction

- A stepper motor provides torque to drive a hydraulic steering valve and control the articulated angle or angular speed [21];

- A proportional directional control valve (DCV) controls flow into the steering cylinder so that controls the articulated angular speed [22]. However, the proportional DCV usually has a dead zone [20], resulting in small articulated angular speeds not being achieved. Furthermore, when the oil pump is powered by the engine, the engine speed and the opening of the valve port will jointly affect the articulated angular speed, increasing the control difficulty;

- A motor controls the variable displacement pump (VDP) to manage the flow into the steering cylinder, so that controls the articulated angular speed. Compared to the DCV-controlled system, the response time of the pump-controlled actuation system is slower [23];

- Based on solution 3, a variable frequency drive (VFD) is applied to control the speed of an electric motor. Therefore, the flow entering into cylinders can be directly controlled either by the pump’s displacement or by the motor’s variable speed [24].

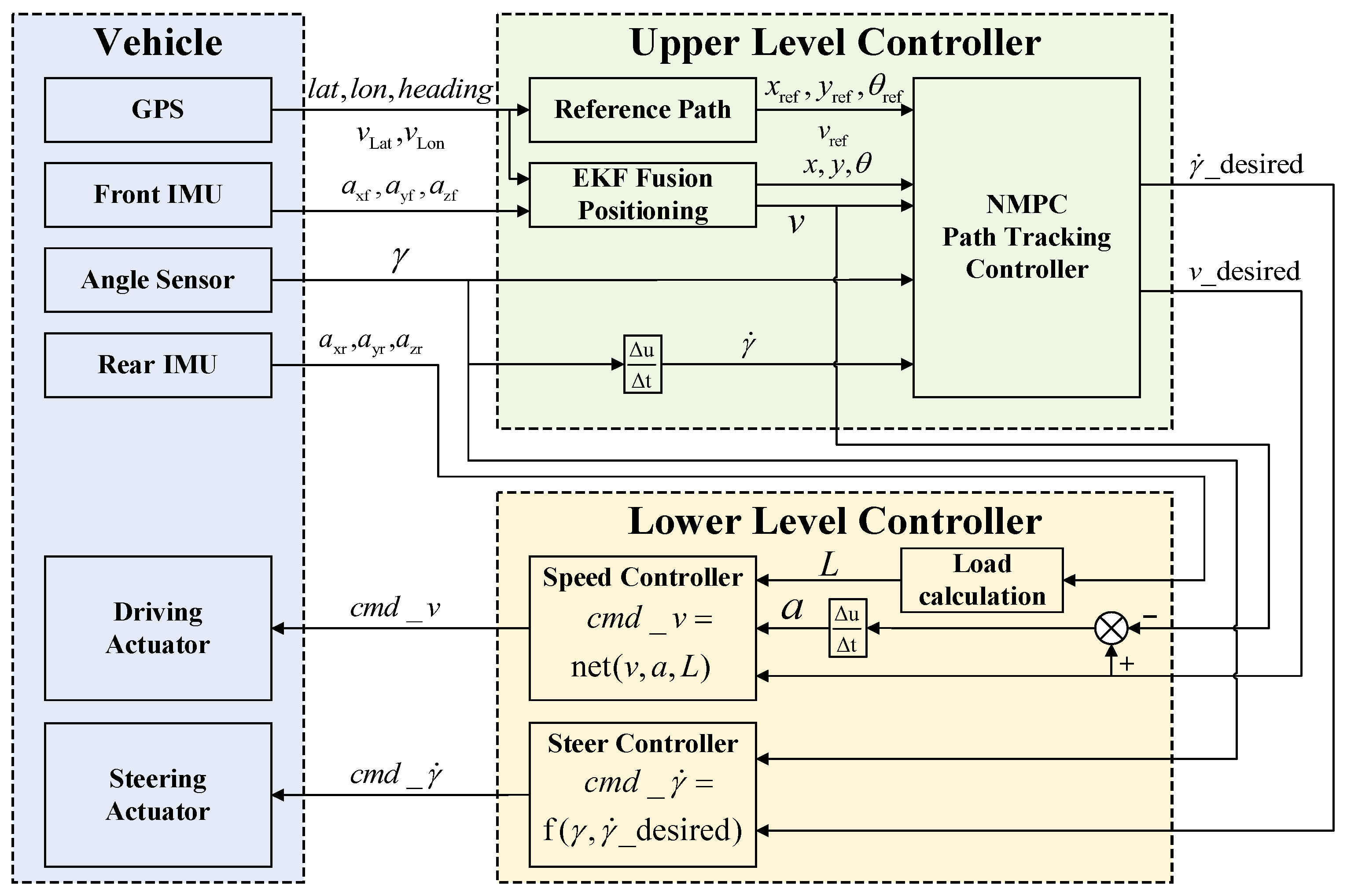

2. Upper-Level Controller

2.1. Nonlinear Model-Predictive Control

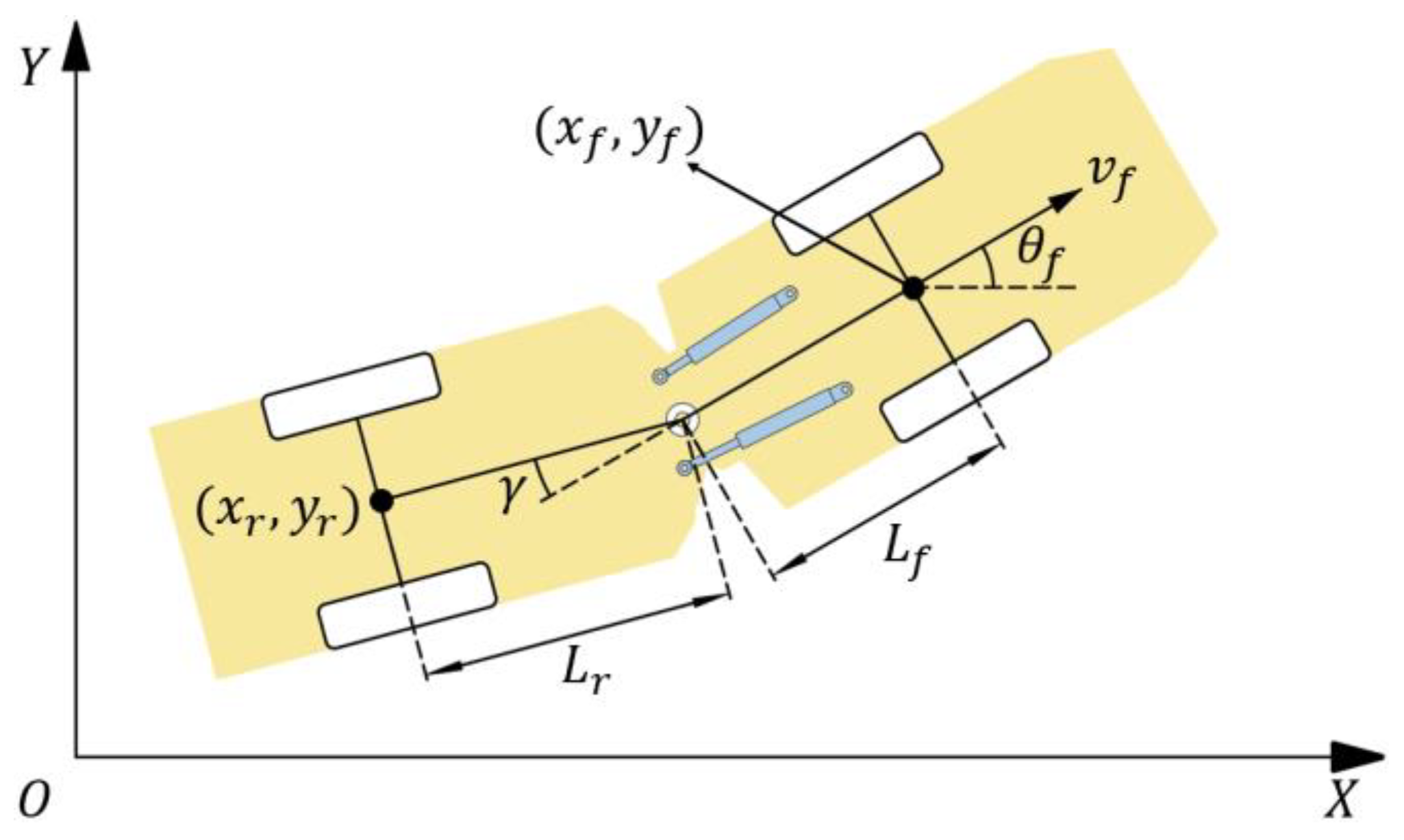

2.2. Predictive Model

2.3. Controller Design

3. Lower-Level Controller

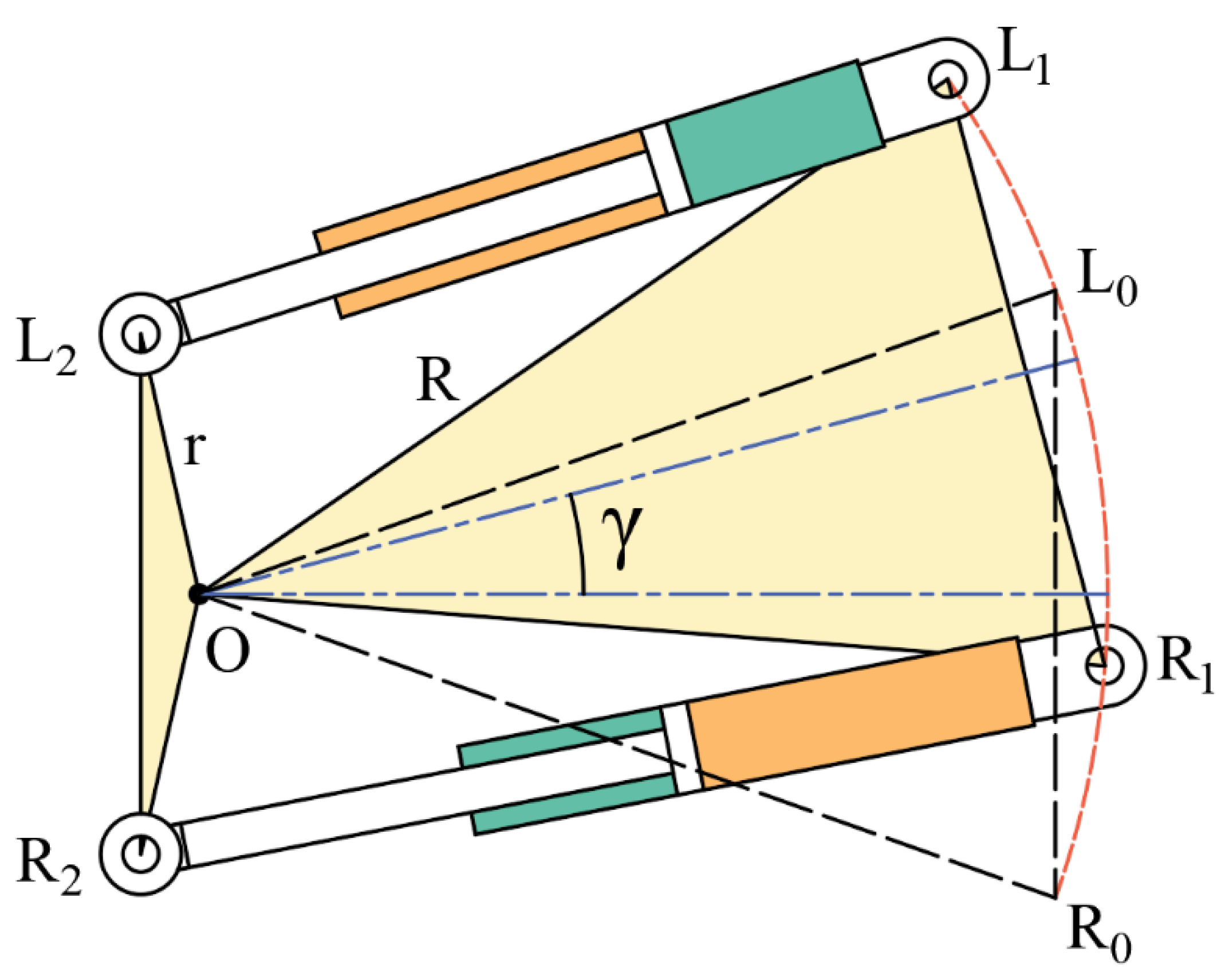

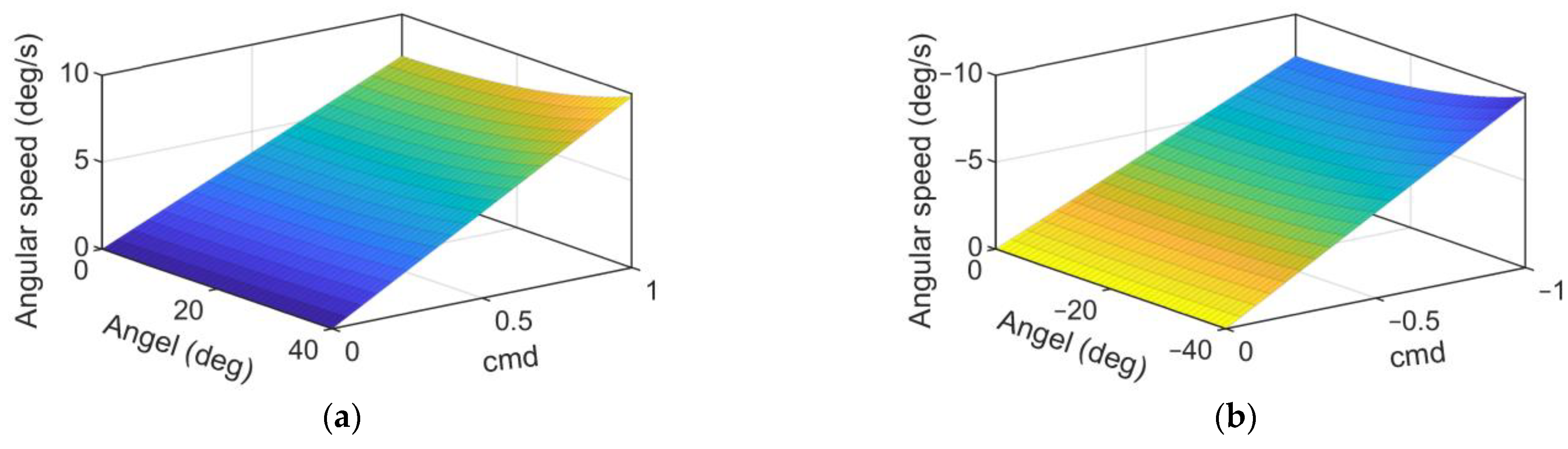

3.1. Steering Controller

Controller Design

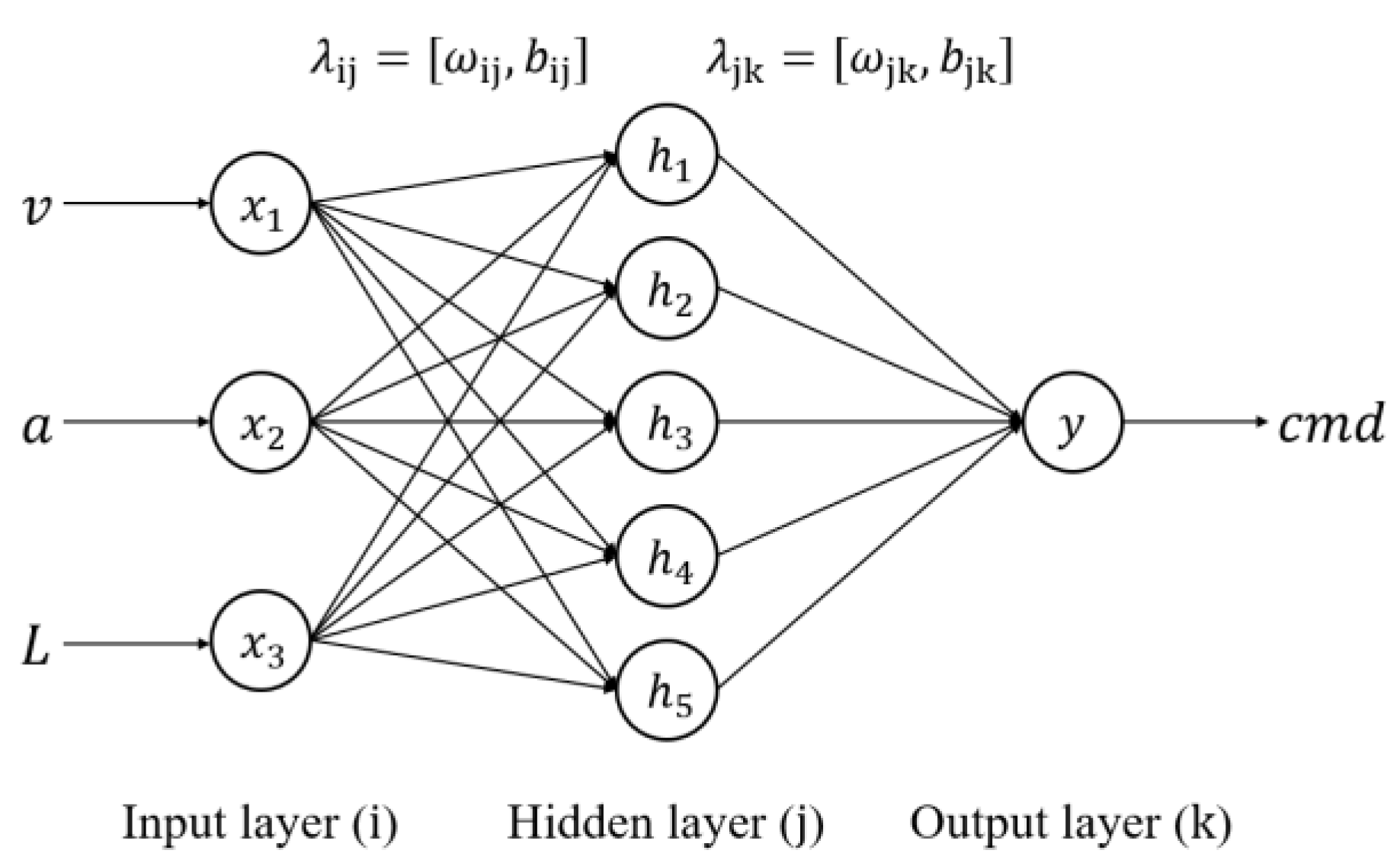

3.2. Driving Controller

3.2.1. Controller Design

- Load: no-load (), half-load (), full-load ().

- Throttle commands:

- a.

- Fixed: ;

- b.

- Varying (5 seconds step): , .

3.2.2. Data Preprocessing

3.2.3. Training

| Algorithms 1: The neural network training process. |

| Input: training set (control command: engine throttle opening) Input: training set (speed, acceleration) Input: parameters , the learning rate , the number of iterations |

| 1: for to do |

| 2: calculate for a small batch (number of samples ) |

| 3: calculate by back-propagation |

| 4: |

| 5: update the parameters |

| 6: end for |

| 7: Return ; return the trained parameters |

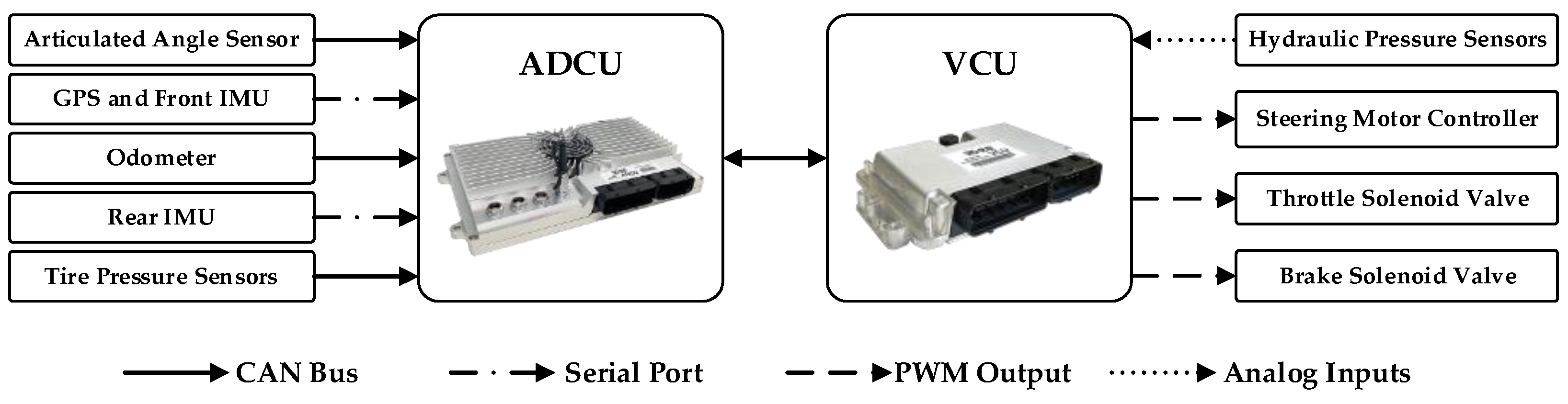

4. Experimental Vehicle

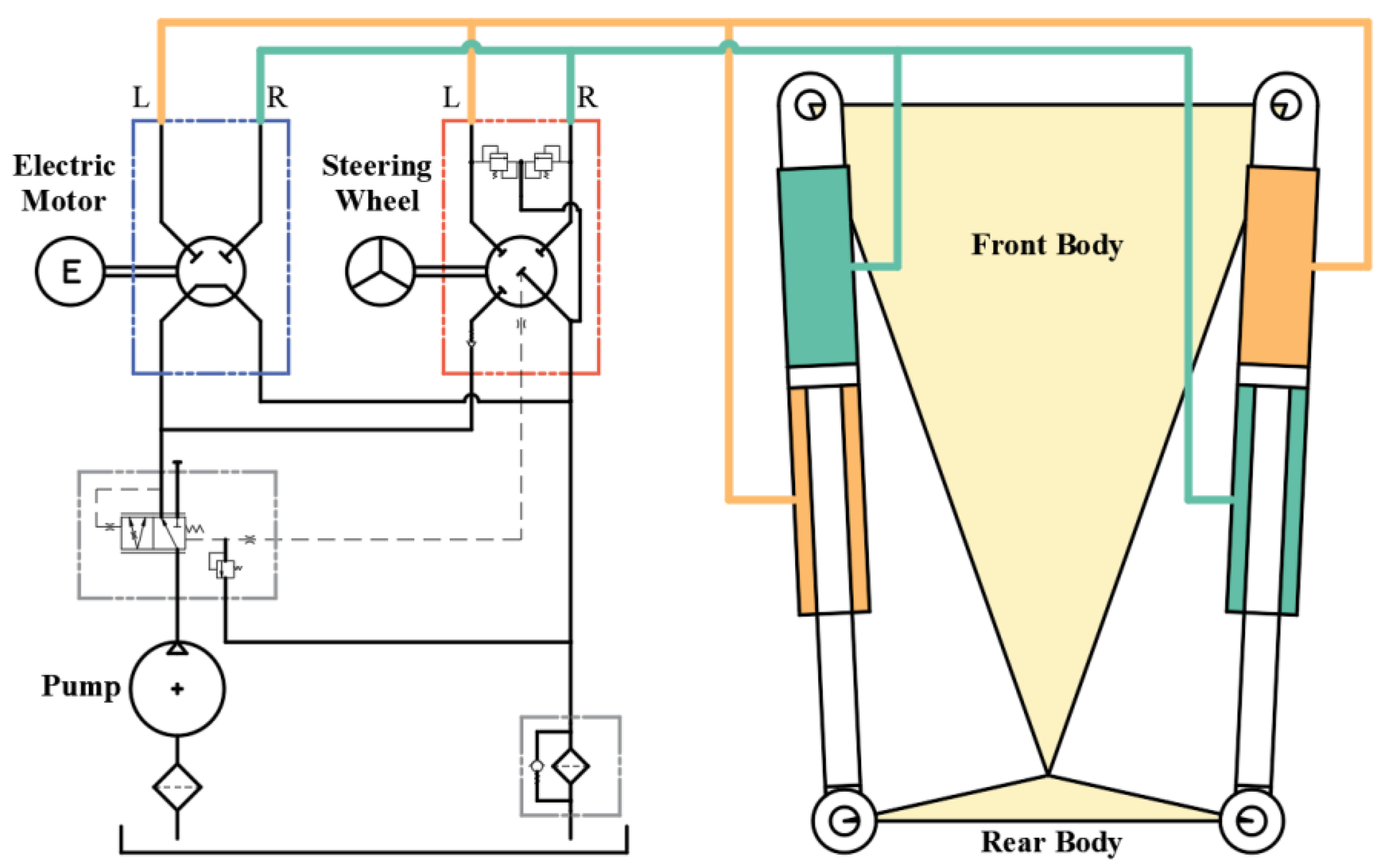

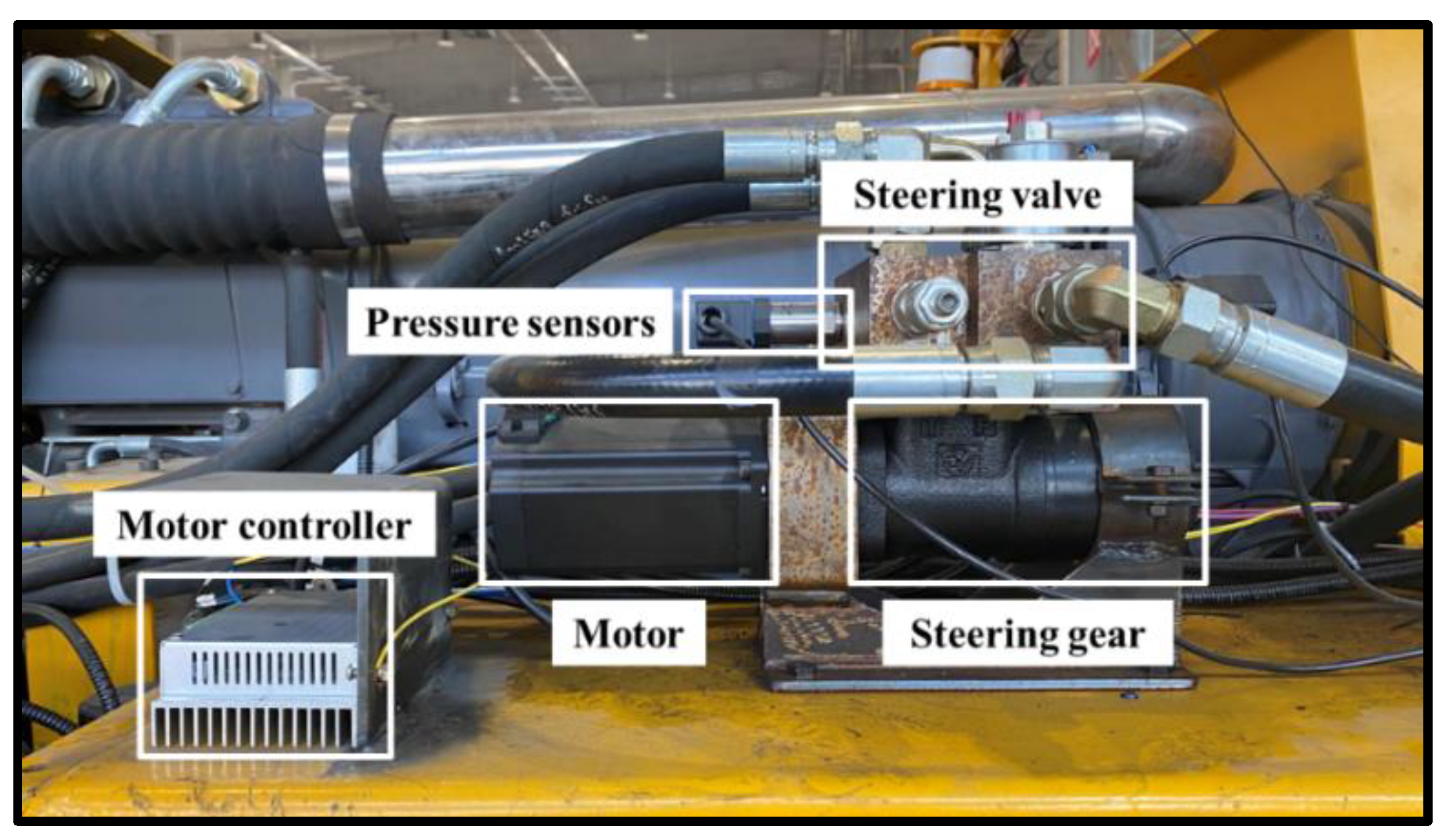

4.1. Steering-by-Wire System

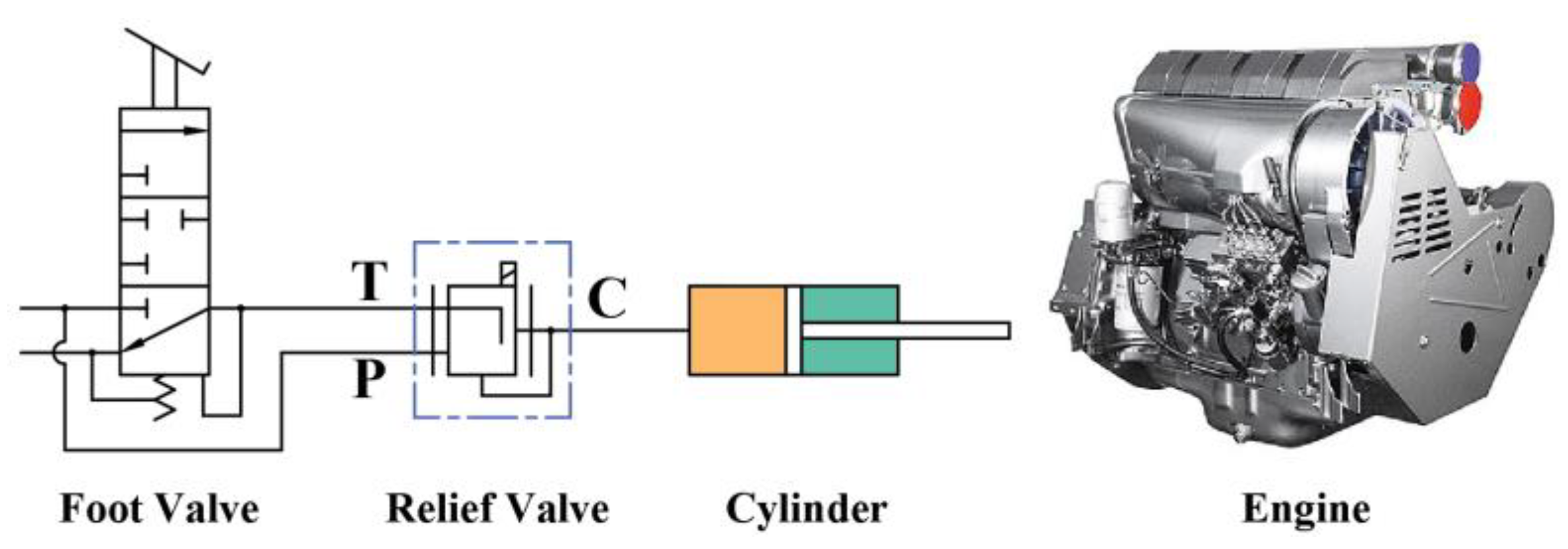

4.2. Driving-by-Wire System

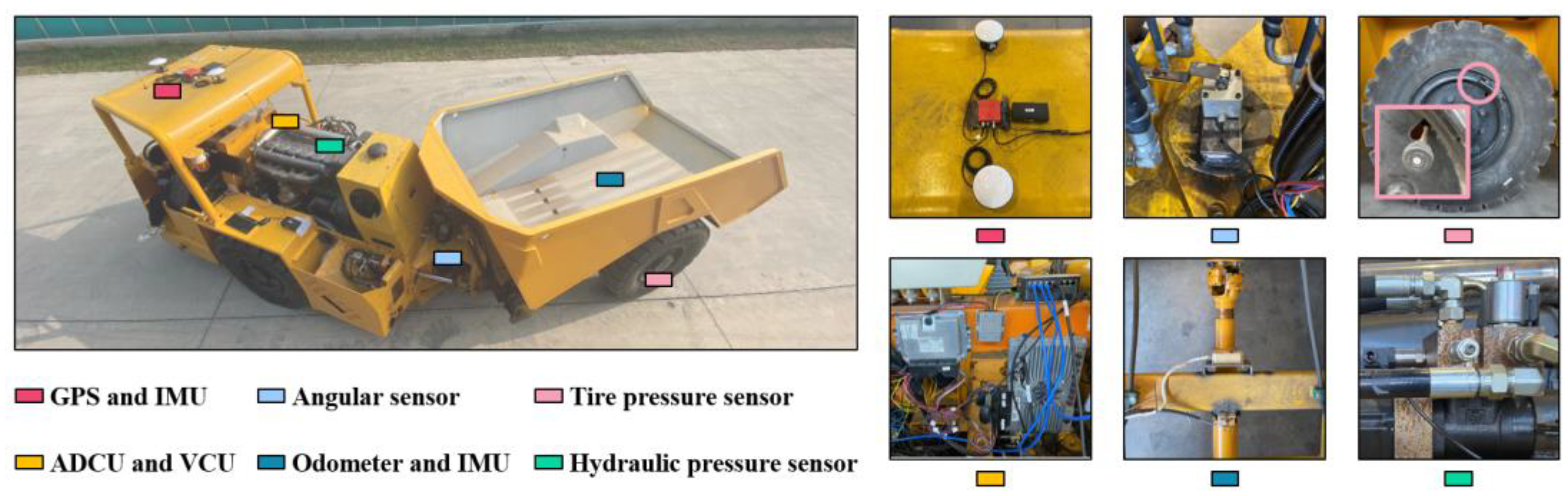

4.3. Sensors and Controllers

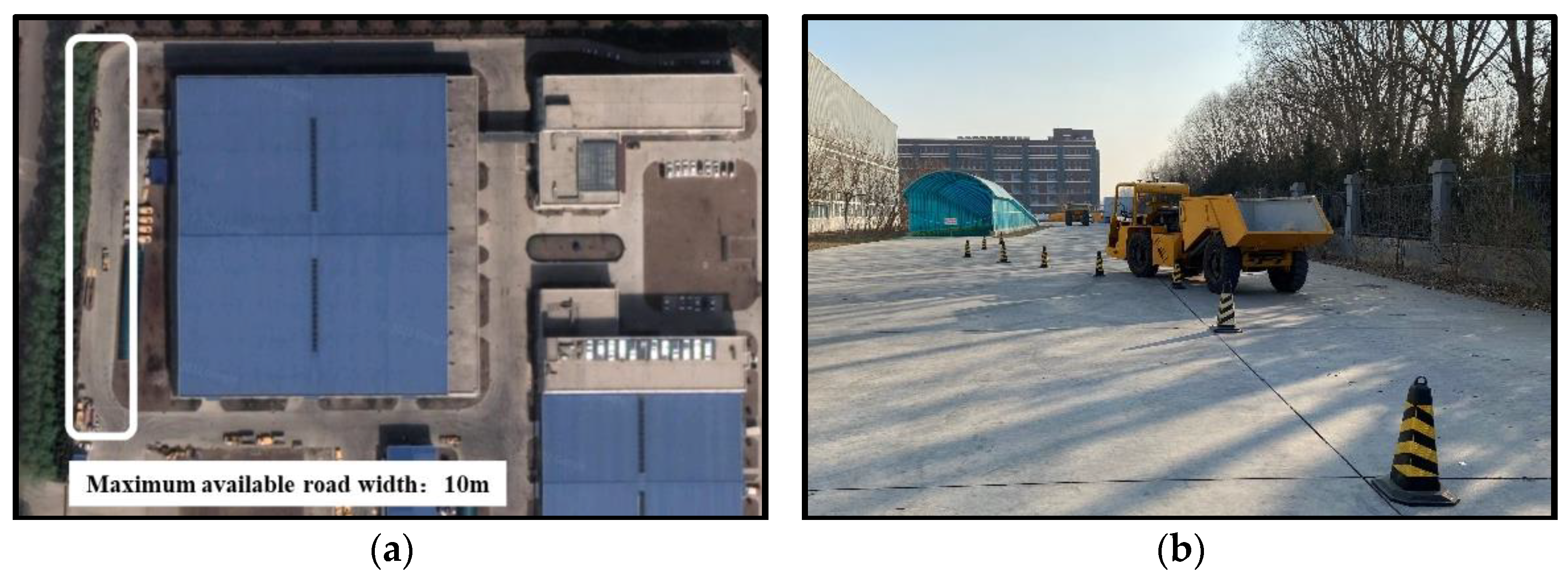

5. Field Testing

5.1. Lower-Level Controller Verification

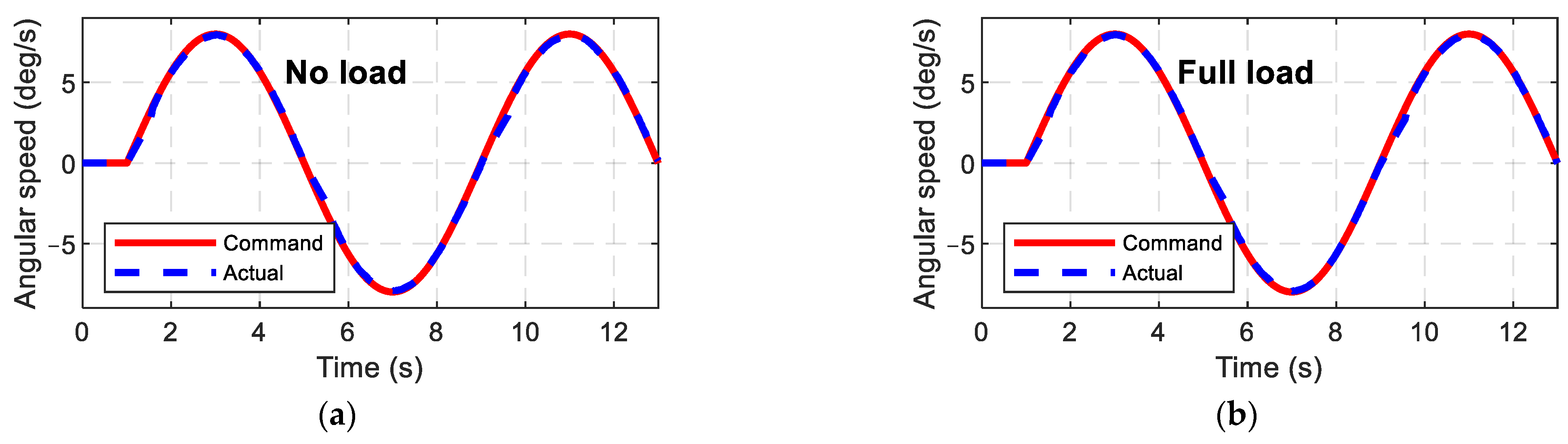

5.1.1. Steering Controller Verification

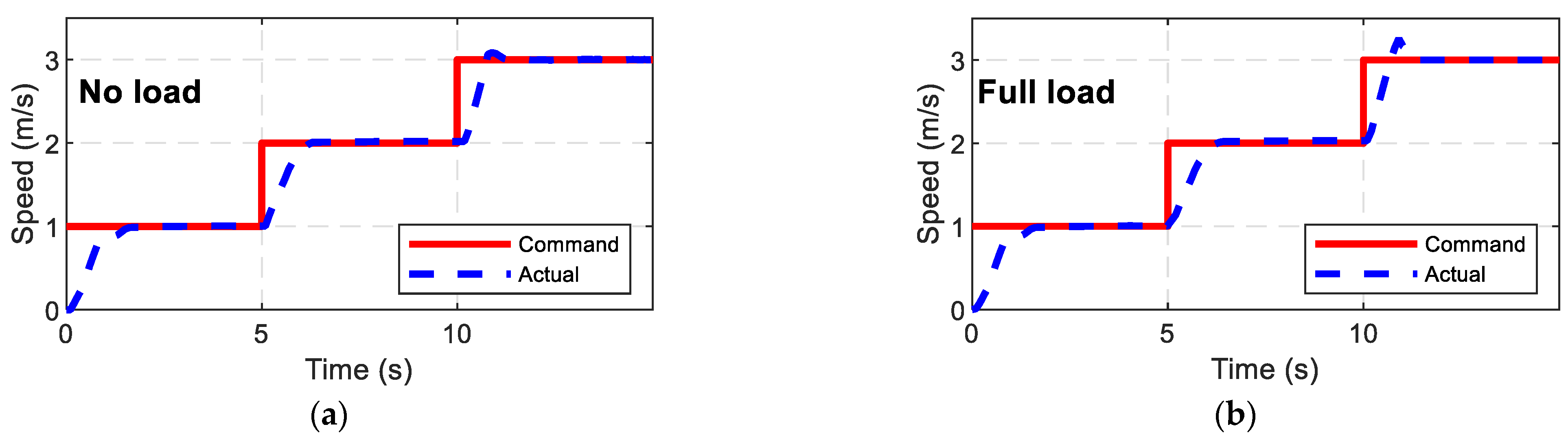

5.1.2. Driving Controller Verification

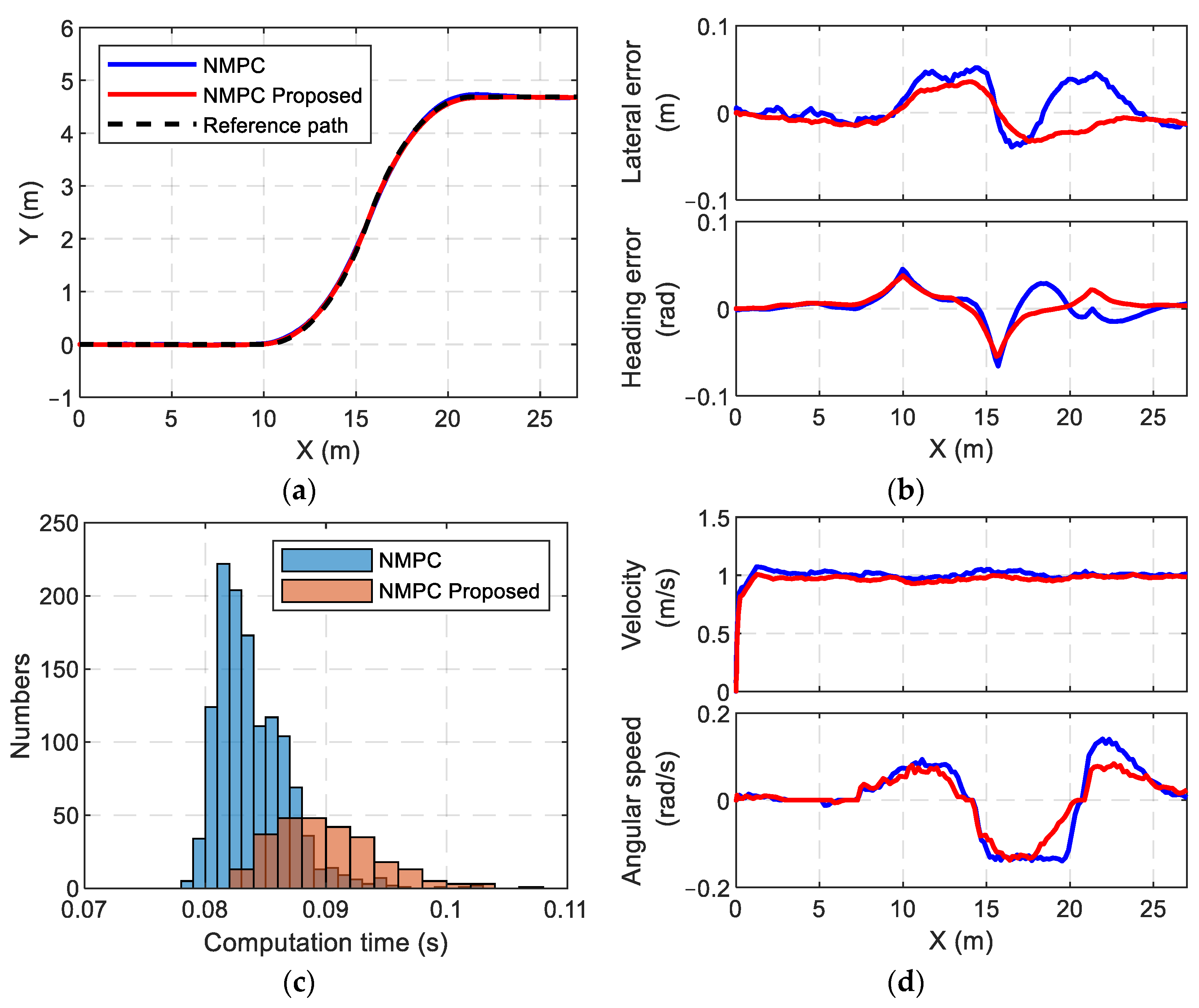

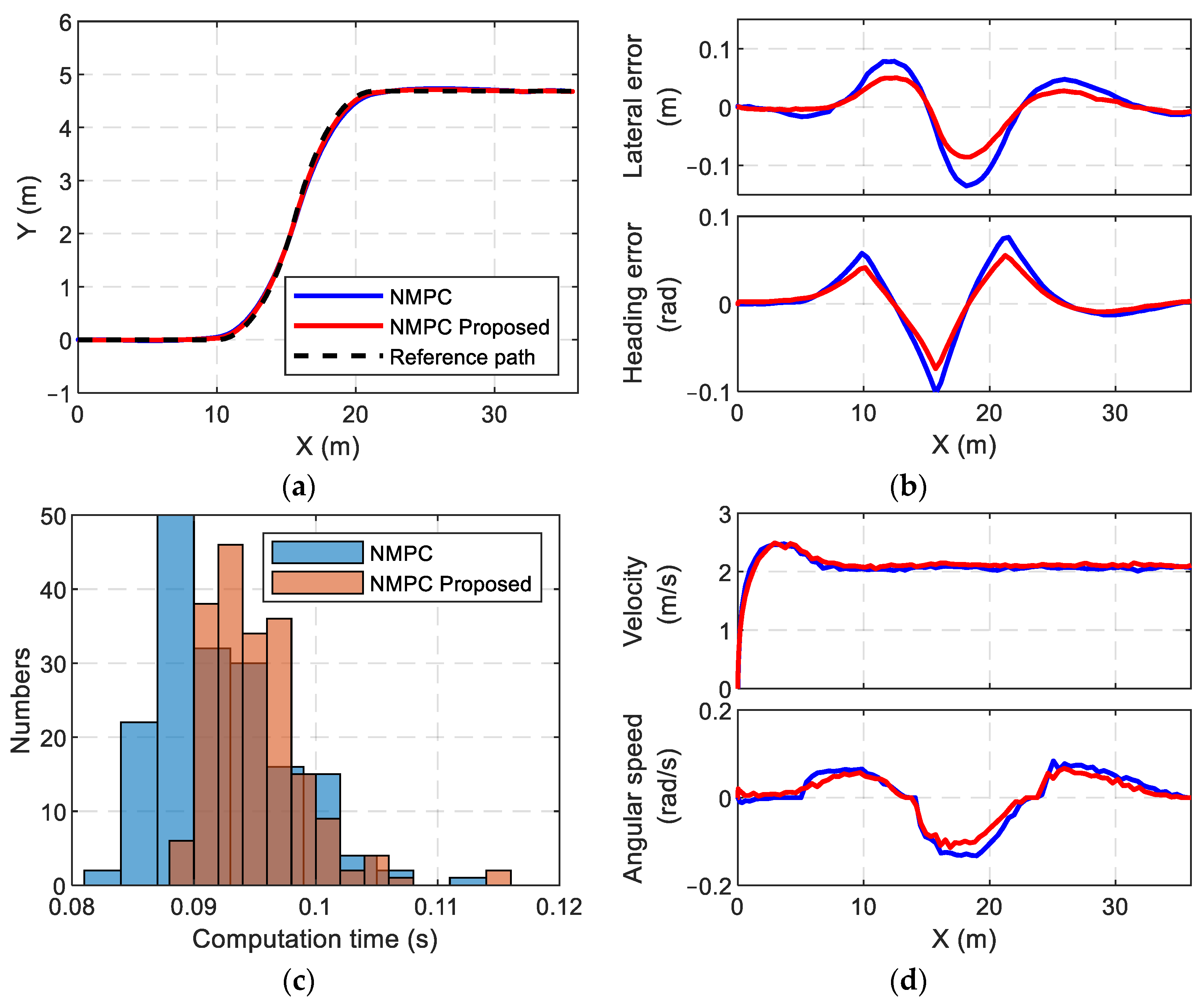

5.2. Integrated Path Tracking Controller Testing

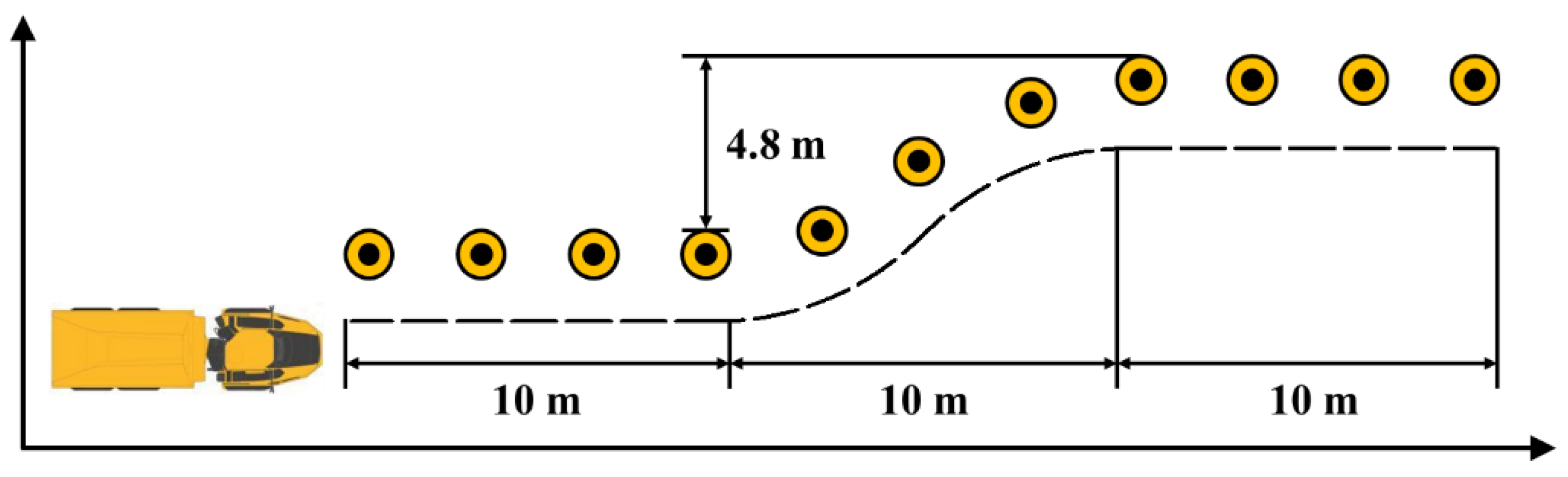

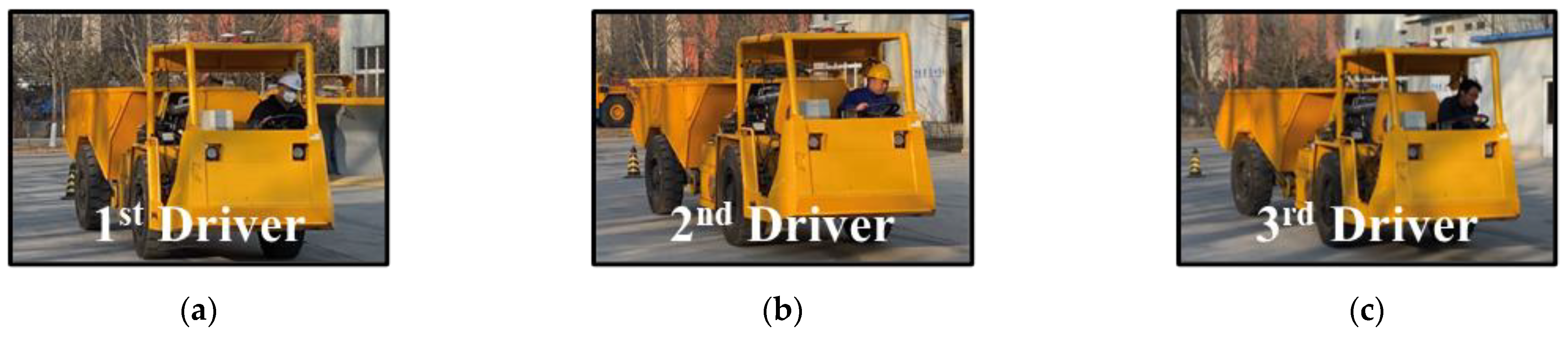

5.2.1. Pre-Experiment

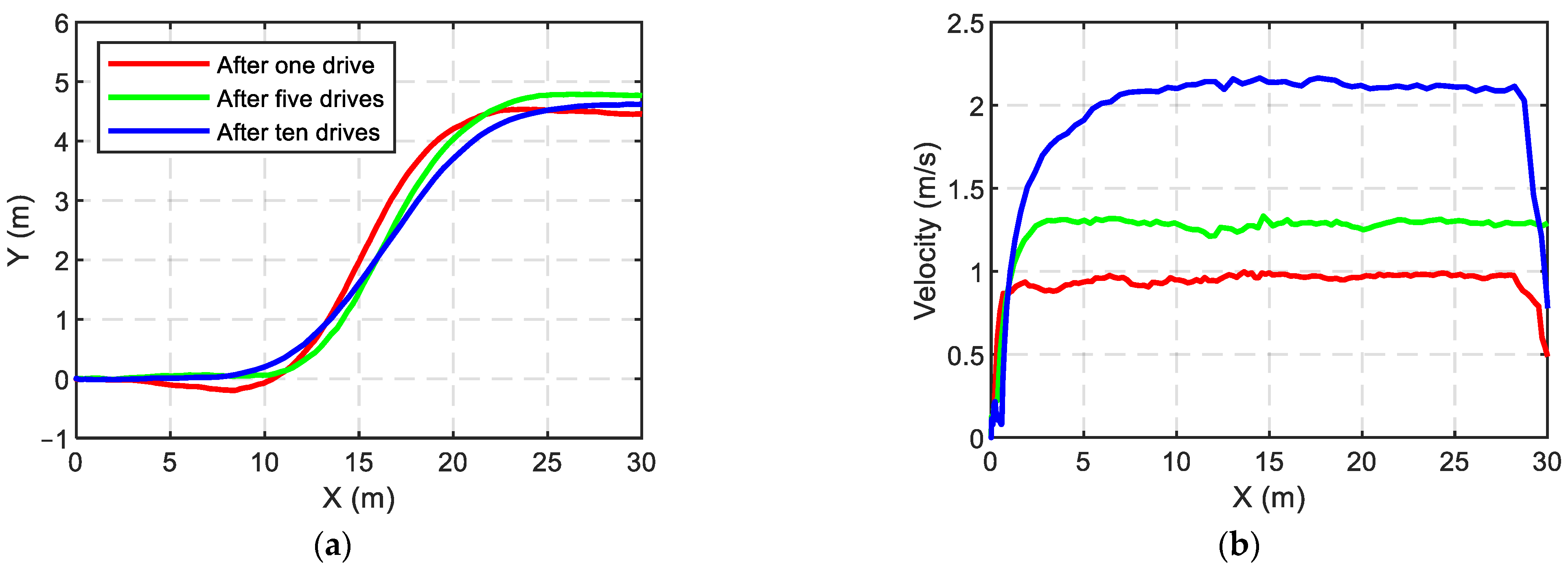

5.2.2. Tracking Result

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Altafini, C. Why to use an articulated vehicle in underground mining operations? In Proceedings of the 1999 IEEE International Conference on Robotics and Automation (Cat. No. 99CH36288C), Detroit, MI, USA, 10–15 May 1999; pp. 3020–3025. [Google Scholar]

- Rowduru, S.; Kumar, N.; Kumar, A. A critical review on automation of steering mechanism of load haul dump machine. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2020, 234, 160–182. [Google Scholar] [CrossRef]

- Cai, M.; Xue, D.; Ren, F. Current status and development strategy of metal mines. Chin. J. Eng. 2019, 41, 417–426. [Google Scholar]

- Cai, M.; Li, P.; Tan, W.; Ren, F. Key Engineering Technologies to Achieve Green, Intelligent, and Sustainable Development of Deep Metal Mines in China. Engineering 2021, 7, 1513–1517. [Google Scholar] [CrossRef]

- Ardiny, H.; Witwicki, S.; Mondada, F. Construction automation with autonomous mobile robots: A review. In Proceedings of the 2015 3rd RSI International Conference on Robotics and Mechatronics (ICROM), Tehran, Iran, 7–9 October 2015; pp. 418–424. [Google Scholar]

- Amer, N.H.; Zamzuri, H.; Hudha, K.; Kadir, Z.A. Modelling and control strategies in path tracking control for autonomous ground vehicles: A review of state of the art and challenges. J. Intell. Robot. Syst. 2017, 86, 225–254. [Google Scholar] [CrossRef]

- Xu, S.; Peng, H. Design, analysis, and experiments of preview path tracking control for autonomous vehicles. IEEE Trans. Intell. Transp. Syst. 2019, 21, 48–58. [Google Scholar] [CrossRef]

- Yao, Q.; Tian, Y.; Wang, Q.; Wang, S. Control strategies on path tracking for autonomous vehicle: State of the art and future challenges. IEEE Access 2020, 8, 161211–161222. [Google Scholar] [CrossRef]

- Rokonuzzaman, M.; Mohajer, N.; Nahavandi, S.; Mohamed, S. Review and performance evaluation of path tracking controllers of autonomous vehicles. IET Intell. Transp. Syst. 2021, 15, 646–670. [Google Scholar] [CrossRef]

- Ji, J.; Khajepour, A.; Melek, W.W.; Huang, Y. Path planning and tracking for vehicle collision avoidance based on model predictive control with multiconstraints. IEEE Trans. Veh. Technol. 2016, 66, 952–964. [Google Scholar] [CrossRef]

- Falcone, P.; Borrelli, F.; Asgari, J.; Tseng, H.E.; Hrovat, D. Predictive active steering control for autonomous vehicle systems. IEEE Trans. Control Syst. Technol. 2007, 15, 566–580. [Google Scholar] [CrossRef]

- Gong, J.; Xu, W.; Jiang, Y.; Liu, K.; Guo, H.; Sun, Y. Multi-constrained model predictive control for autonomous ground vehicle trajectory tracking. J. Beijing Inst. Technol. 2015, 24, 441–448. [Google Scholar]

- Bai, G.; Meng, Y.; Liu, L.; Luo, W.; Gu, Q.; Liu, L. Review and comparison of path tracking based on model predictive control. Electronics 2019, 8, 1077. [Google Scholar] [CrossRef]

- Matschek, J.; Bäthge, T.; Faulwasser, T.; Findeisen, R. Nonlinear predictive control for trajectory tracking and path following: An introduction and perspective. In Handbook of Model Predictive Control; Springer: Cham, Switzerland, 2019; pp. 169–198. [Google Scholar]

- Andersson, J.A.; Gillis, J.; Horn, G.; Rawlings, J.B.; Diehl, M. CasADi: A software framework for nonlinear optimization and optimal control. Math. Program. Comput. 2019, 11, 1–36. [Google Scholar] [CrossRef]

- Nayl, T.; Nikolakopoulos, G.; Gustfsson, T. Switching model predictive control for an articulated vehicle under varying slip angle. In Proceedings of the 2012 20th Mediterranean Conference on Control & Automation (MED), Barcelona, Spain, 3–6 July 2012; pp. 890–895. [Google Scholar]

- Nayl, T.; Nikolakopoulos, G.; Gustafsson, T. A full error dynamics switching modeling and control scheme for an articulated vehicle. Int. J. Control Autom. Syst. 2015, 13, 1221–1232. [Google Scholar] [CrossRef]

- Dou, F.; Huang, Y.; Liu, L.; Wang, H.; Meng, Y.; Zhao, L. Path planning and tracking for autonomous mining articulated vehicles. Int. J. Heavy Veh. Syst. 2019, 26, 315–333. [Google Scholar] [CrossRef]

- Bai, G.; Liu, L.; Meng, Y.; Luo, W.; Gu, Q.; Ma, B. Path tracking of mining vehicles based on nonlinear model predictive control. Appl. Sci. 2019, 9, 1372. [Google Scholar] [CrossRef]

- Gao, L.; Jin, C.; Liu, Y.; Ma, F.; Feng, Z. A Novel Model-Based Steering Control for Hydra-Power Articulated Steering Vehicles. In Proceedings of the BATH/ASME 2020 Symposium on Fluid Power and Motion Control, Virtual, 9–11 September 2020; ASME: New York, NY, USA, 2020; p. V001T001A006. [Google Scholar]

- Nelson, F.W.; Pickett, T.D. Vehicle Guidance System with a Stepper Motor. US9834248B2, 15 January 2016. [Google Scholar]

- Liu, J.; Tan, J.; Mao, E.; Song, Z.; Zhu, Z. Proportional directional valve based automatic steering system for tractors. Front. Inf. Technol. Electron. Eng. 2016, 17, 458–464. [Google Scholar] [CrossRef]

- Daher, N.; Ivantysynova, M. Energy analysis of an original steering technology that saves fuel and boosts efficiency. Energy Convers. Manag. 2014, 86, 1059–1068. [Google Scholar] [CrossRef]

- Jangnoi, T.; Pinsopon, U. Velocity control of electro-hydraulic pump control system using gear pump. Int. J. Innov. Comput. Inf. Control 2018, 14, 2307–2323. [Google Scholar]

- Liu, W.; Xia, X.; Xiong, L.; Lu, Y.; Gao, L.; Yu, Z. Automated vehicle sideslip angle estimation considering signal measurement characteristic. IEEE Sens. J. 2021, 21, 21675–21687. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, J.; Zhang, W.; Zeng, J. Feedback linearization control for path tracking of articulated dump truck. TELKOMNIKA Telecommun. Comput. Electron. Control 2015, 13, 922–929. [Google Scholar] [CrossRef]

- Borrelli, F.; Bemporad, A.; Morari, M. Predictive Control for Linear and Hybrid Systems; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Zhu, F.; Ma, L.; Xu, X.; Guo, D.; Cui, X.; Kong, Q. Baidu apollo auto-calibration system-an industry-level data-driven and learning based vehicle longitude dynamic calibrating algorithm. arXiv 2018, arXiv:1808.10134. [Google Scholar]

- Haddoun, A.; Benbouzid, M.E.H.; Diallo, D.; Abdessemed, R.; Ghouili, J.; Srairi, K. Modeling, analysis, and neural network control of an EV electrical differential. IEEE Trans. Ind. Electron. 2008, 55, 2286–2294. [Google Scholar] [CrossRef]

| Major Parameters | Unit | Value |

|---|---|---|

| Overall vehicle mass | Kg | 7400 |

| Maximum load capacity | Kg | 7000 |

| Maximum folding angle | deg | ±42 |

| Length from front axle to articulated center | mm | 1620 |

| Length from rear axle to articulated center | mm | 1923 |

| Inside steering radius | mm | 3955 |

| Outer steering radius | mm | 5850 |

| Tire rolling radius | mm | 519 |

| Wheelbase | mm | 1322 |

| Engine | DEUTZ-F6L914 | |

| Integrated torque converter transmission: | DANA-1201FT20000 | |

| Parameters | Value |

|---|---|

| 20 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, N.; Zhang, W.; Yang, J. Integrated Path Tracking Controller of Underground Articulated Vehicle Based on Nonlinear Model Predictive Control. Appl. Sci. 2023, 13, 5340. https://doi.org/10.3390/app13095340

Sun N, Zhang W, Yang J. Integrated Path Tracking Controller of Underground Articulated Vehicle Based on Nonlinear Model Predictive Control. Applied Sciences. 2023; 13(9):5340. https://doi.org/10.3390/app13095340

Chicago/Turabian StyleSun, Nan, Wenming Zhang, and Jue Yang. 2023. "Integrated Path Tracking Controller of Underground Articulated Vehicle Based on Nonlinear Model Predictive Control" Applied Sciences 13, no. 9: 5340. https://doi.org/10.3390/app13095340

APA StyleSun, N., Zhang, W., & Yang, J. (2023). Integrated Path Tracking Controller of Underground Articulated Vehicle Based on Nonlinear Model Predictive Control. Applied Sciences, 13(9), 5340. https://doi.org/10.3390/app13095340