Design and Investigation of a Novel Local Shielding Gas Concept for Laser Metal Deposition with Coaxial Wire Feeding

Abstract

1. Introduction

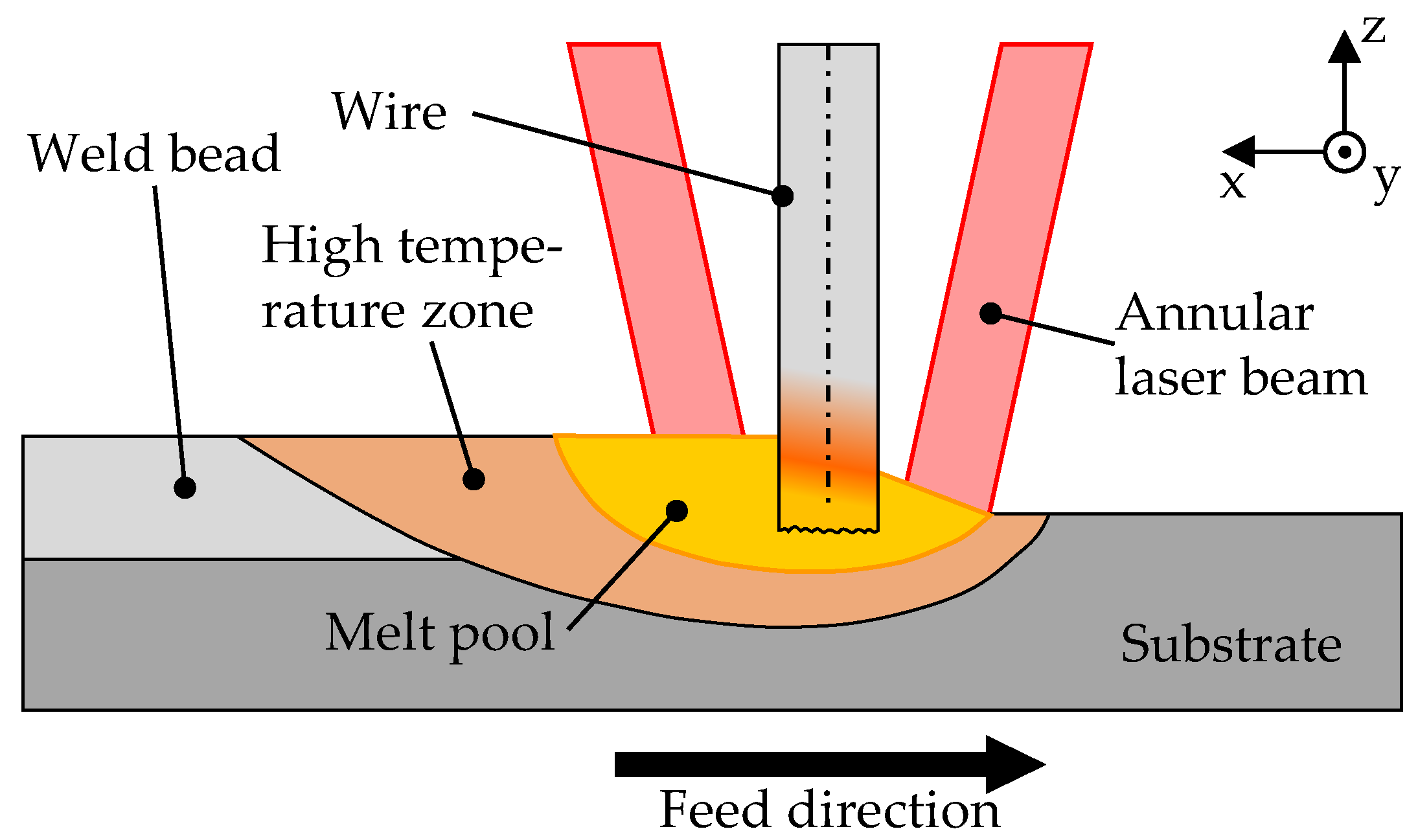

2. Development of a Local Shielding Gas Concept

2.1. Design and Process Requirements

2.2. Computational Simulation Method

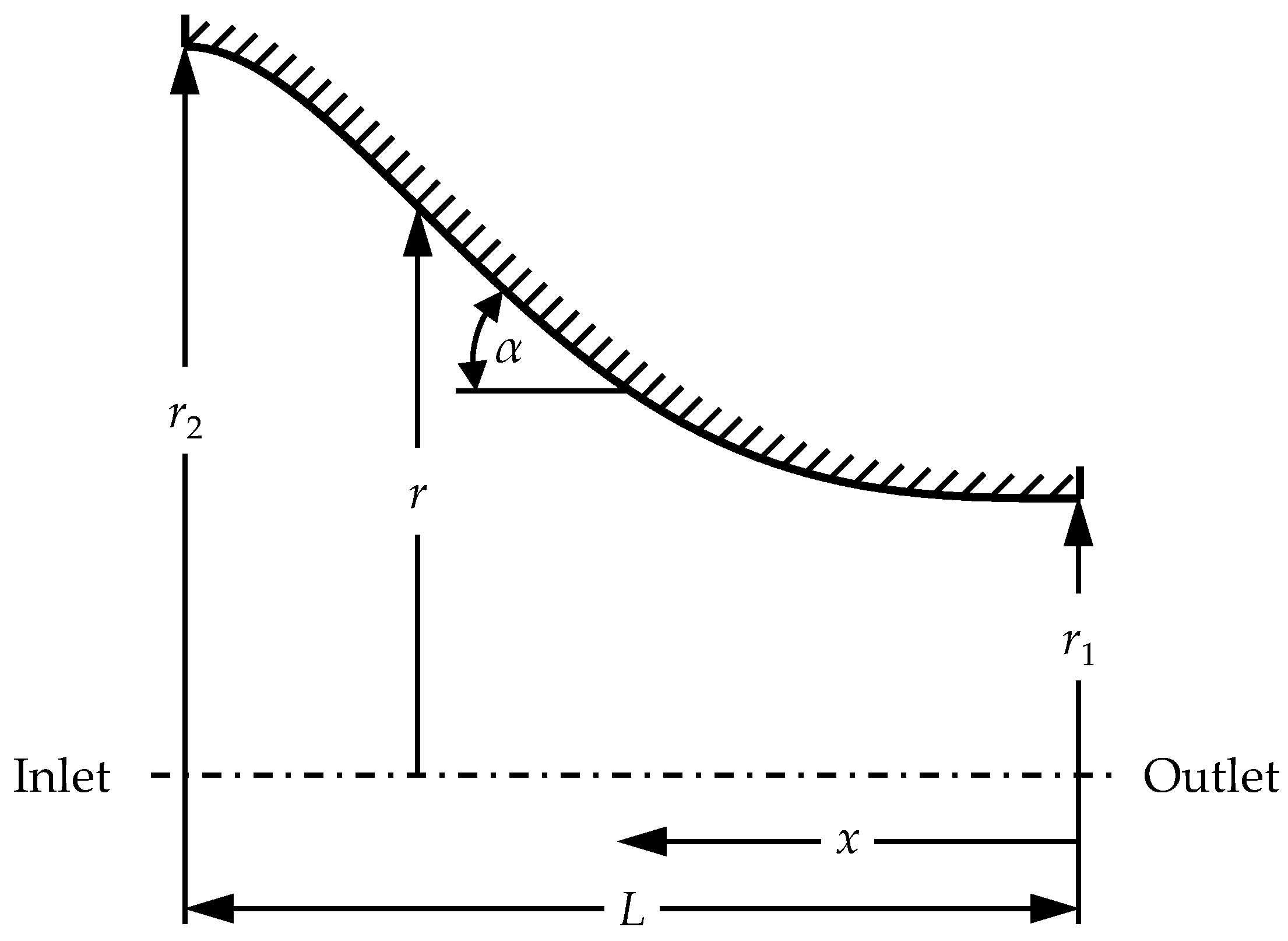

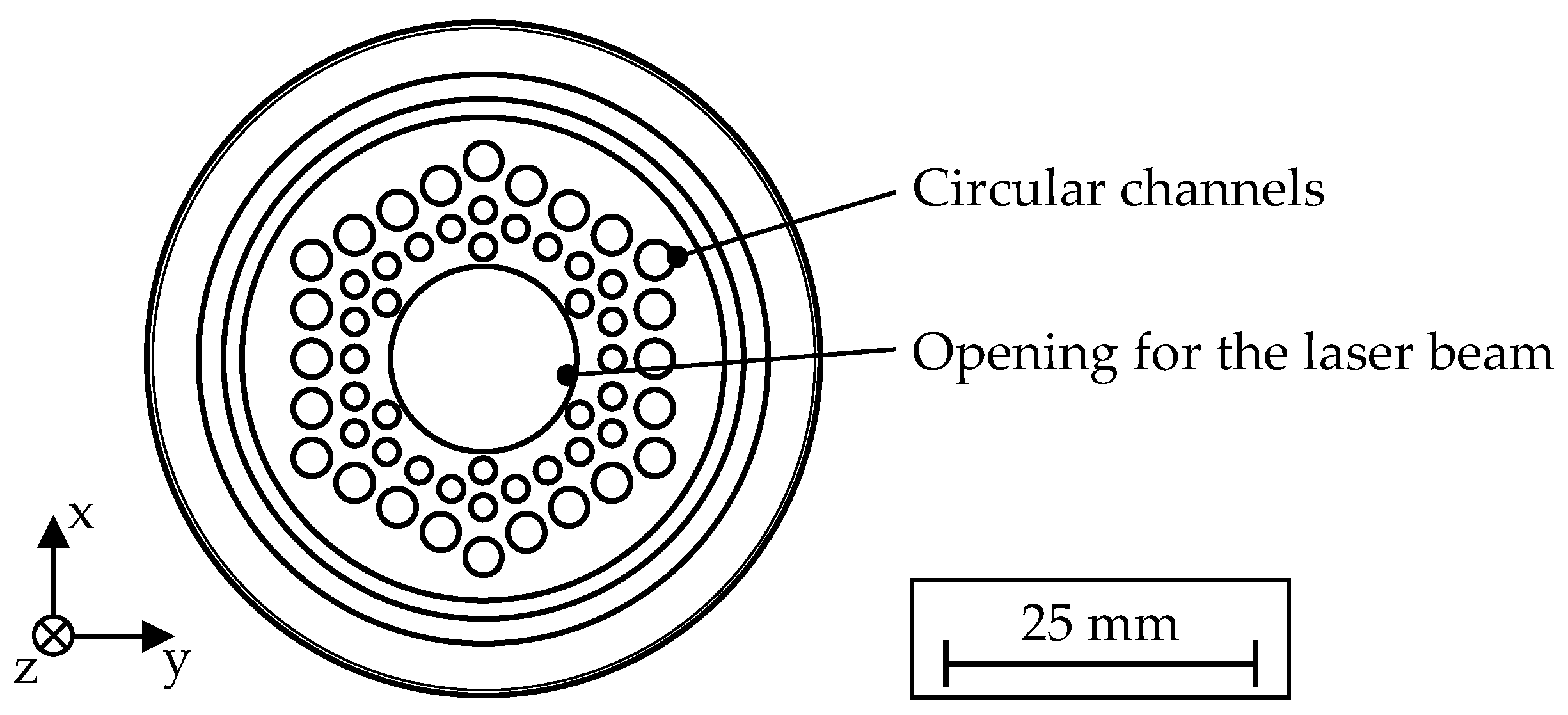

2.3. Design of the Shielding Gas Nozzle Geometry

2.4. Implementation of the Shielding Gas Concept

3. Experimental Procedures

3.1. Materials

3.2. Experimental Setup

3.3. Experimental Procedure

3.4. Characterizations

4. Results and Discussion

4.1. Simulative Evaluation of the Shielding Gas Coverage

4.2. Deposition of Single Weld Beads

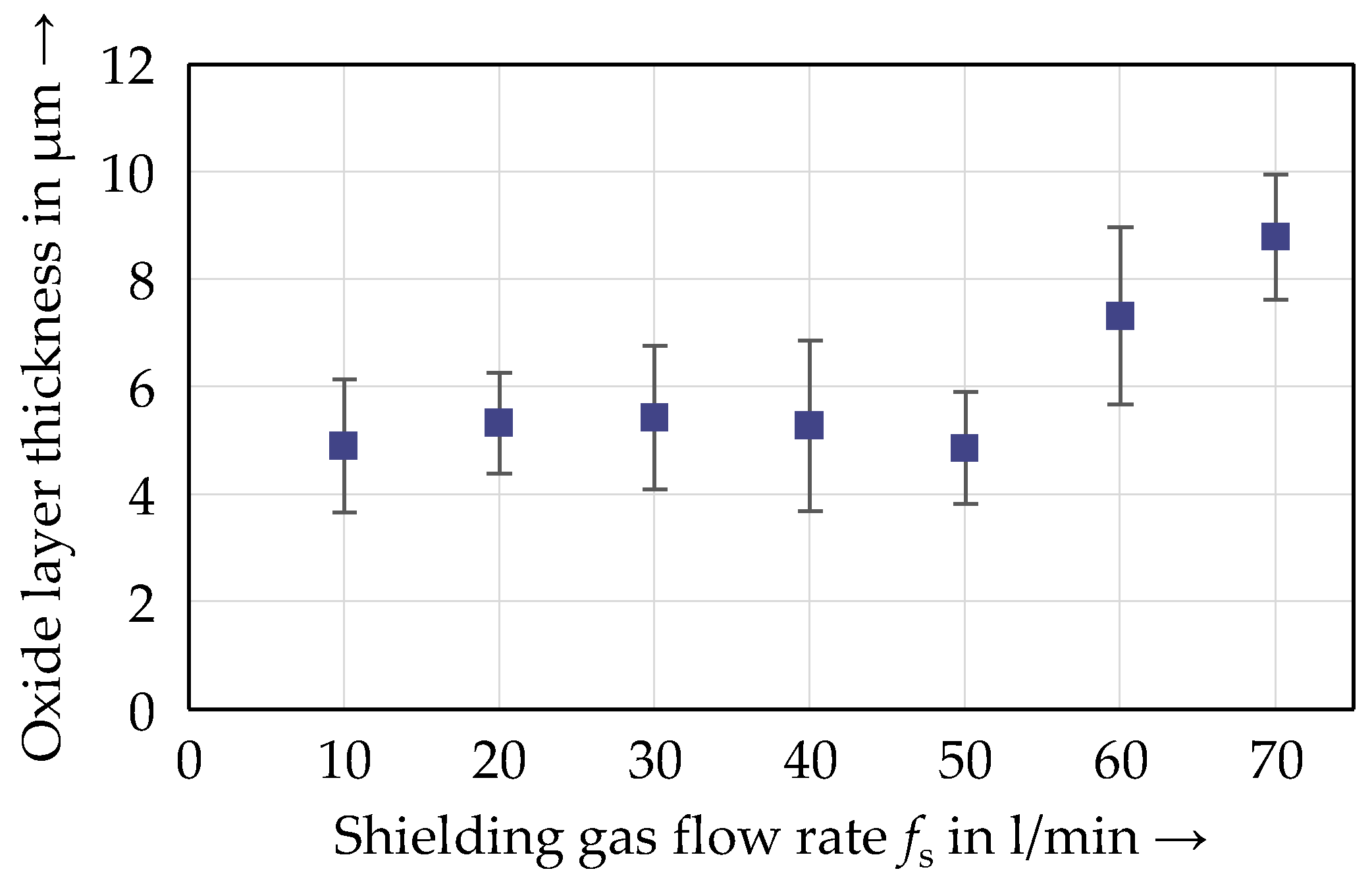

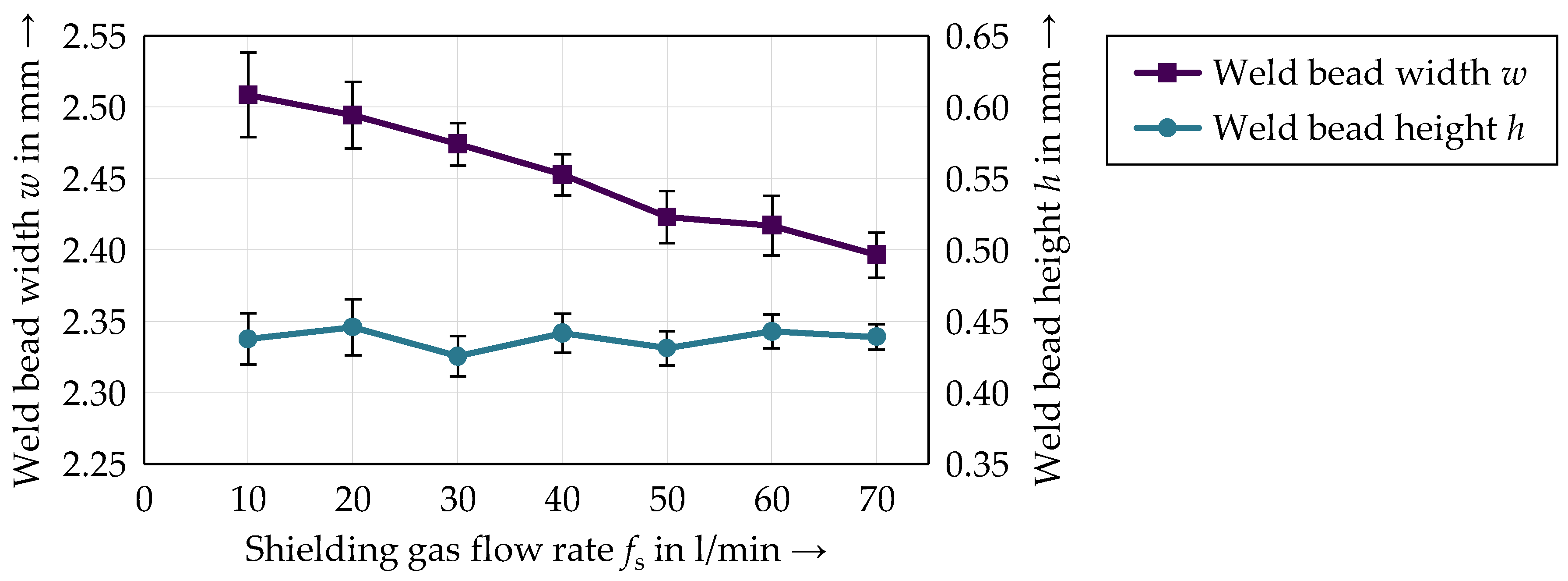

4.3. Influence of the Shielding Gas Flow Rate on the Weld Bead Geometry and the Melt Pool Temperature

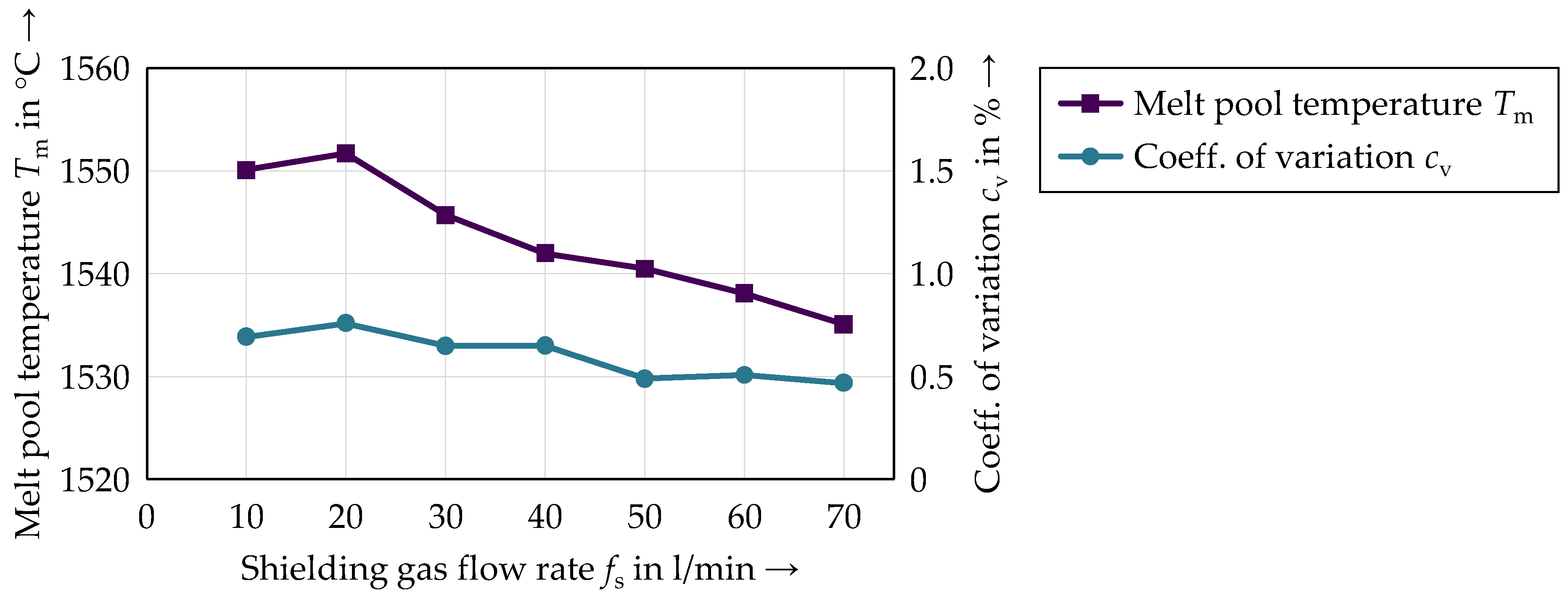

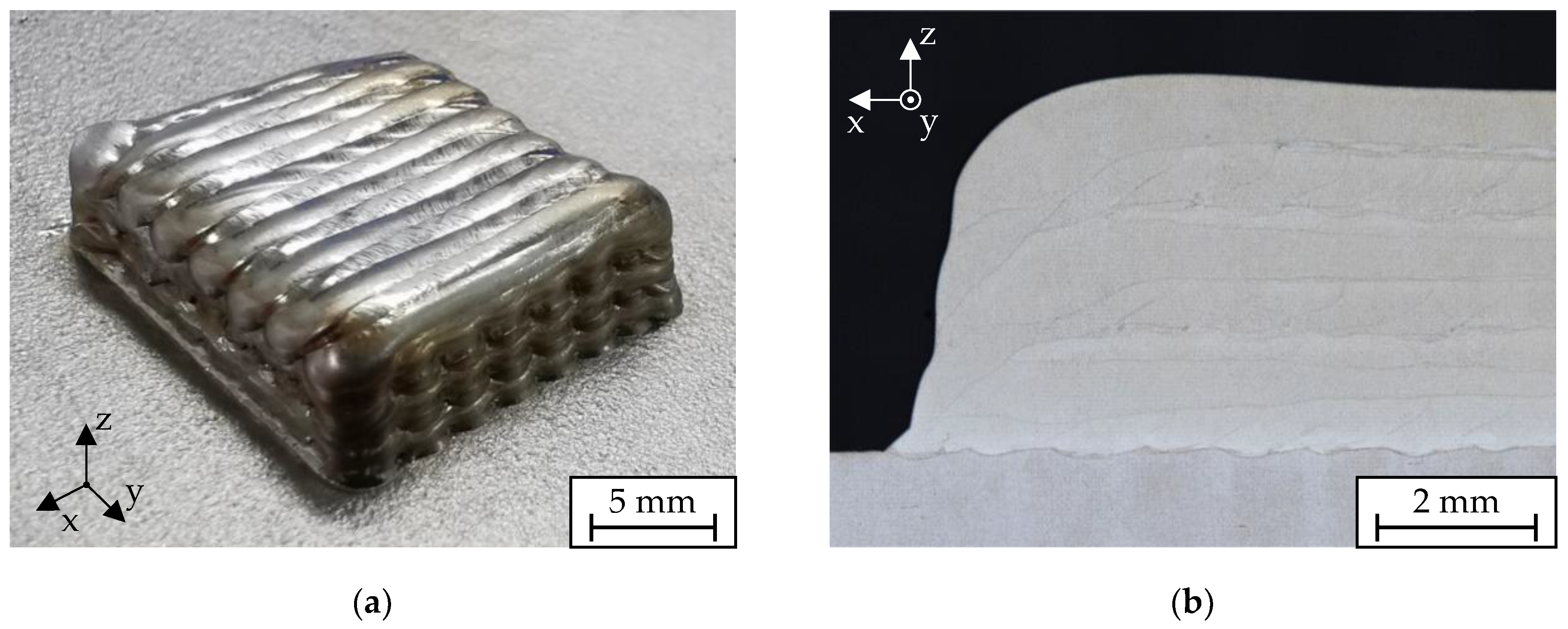

4.4. Build-Up and Characterization of a Solid Cuboid

5. Conclusions

- Using the developed shielding gas concept, an oxide-free deposition was possible for individual weld beads as well as for a solid cuboid.

- The nozzle geometry enables a direction-independent shielding gas coverage with minimal turbulence, thus preventing mixing with the atmosphere.

- Increasing the shielding gas flow rate from 10 l/min to 70 l/min resulted in a 15 K lower melt pool temperature as well as a drop in the weld bead width by approximately 110 µm. This could be attributed to the convective cooling effect of the shielding gas.

- The concept is applicable to many commercially available coaxial wire deposition heads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Dass, A.; Moridi, A. State of the art in directed energy deposition: From additive manufacturing to materials design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Kelbassa, J.; Gasser, A.; Bremer, J.; Pütsch, O.; Poprawe, R.; Henrich Schleifenbaum, J. Equipment and process windows for laser metal deposition with coaxial wire feeding. J. Laser Appl. 2019, 31, 022320-1–022320-7. [Google Scholar] [CrossRef]

- Silze, F.; Schnick, M.; Sizova, I.; Bambach, M. Laser metal deposition of Ti-6Al-4V with a direct diode laser set-up and coaxial material feed. Procedia Manuf. 2020, 47, 1154–1158. [Google Scholar] [CrossRef]

- Lammers, M.; Biester, K.; Schwarz, N.; Hermsdorf, J.; Kaierle, S.; Ahlers, H. Automatic changing of weld deposit for additive manufacturing of hybrid metal-glass components using direct laser deposition. In Proceedings of the Lasers in Manufacturing Conference 2021, Virtual Conference, 21–24 June 2021. [Google Scholar]

- Madarieta-Churruca, M.; Pujana-Astarloa, J.; Garmendia Saez-de-Heredia, I.; Leunda-Arrizabalaga, J. Additive manufacturing of metal components using concentric-wire laser metal deposition. DYNAII 2018, 93, 675–680. [Google Scholar] [CrossRef]

- Kelbassa, J.; Pütsch, O.; Gasser, A.; Biber, A.; Wissenbach, K.; Loosten, P.; Schleifenbaum, J.H. Influence of focal length on the laser metal deposition process with coaxial wire feeding. In Proceedings of the SPIE LASE, San Francisco, CA, USA, 2–7 February 2019; p. 11. [Google Scholar] [CrossRef]

- Motta, M.; Demir, A.G.; Previtali, B. High-speed imaging and process characterization of coaxial laser metal wire deposition. Addit. Manuf. 2018, 22, 497–507. [Google Scholar] [CrossRef]

- Govekar, E.; Jeromen, A.; Kuznetsov, A.; Kotar, M.; Kondo, M. Annular laser beam based direct metal deposition. Procedia CIRP 2018, 74, 222–227. [Google Scholar] [CrossRef]

- Milewski, J.O. Additive Manufacturing of Metals: From Fundamental Technology to Rocket Nozzles, Medical Implants, and Custom Jewelry, 1st ed.; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-58205-4. [Google Scholar]

- Saboori, A.; Piscopo, G.; Lai, M.; Salmi, A.; Biamino, S. An investigation on the effect of deposition pattern on the microstructure, mechanical properties and residual stress of 316L produced by Directed Energy Deposition. Mater. Sci. Eng. A Struct. Mater. 2020, 780, 139179. [Google Scholar] [CrossRef]

- Ruiz, J.E.; Cortina, M.; Arrizubieta, J.I.; Lamikiz, A. Study of the influence of shielding gases on laser metal deposition of Inconel 718 superalloy. Materials 2018, 11, 1388. [Google Scholar] [CrossRef]

- Cheng, D.; Zhang, J.; Shi, T.; Li, G.; Shi, J.; Lu, L.; Fu, G. Microstructure and mechanical properties of additive manufactured Ti-6Al-4V components by annular laser metal deposition in a semi-open environment. Opt. Laser Technol. 2021, 135, 106640. [Google Scholar] [CrossRef]

- Carrozza, A.; Aversa, A.; Mazzucato, F.; Lombardi, M.; Biamino, S.; Valente, A.; Fino, P. An innovative approach on directed energy deposition optimization: A study of the process environment’s influence on the quality of Ti-6Al-4V samples. Appl. Sci. 2020, 10, 4212. [Google Scholar] [CrossRef]

- Iantaffi, C.; Leung, C.L.A.; Chen, Y.; Guan, S.; Atwood, R.C.; Lertthanasarn, J.; Pham, M.-S.; Meisnar, M.; Rohr, T.; Lee, P.D. Oxidation induced mechanisms during directed energy deposition additive manufactured titanium alloy builds. Manuf. Lett. 2021, 1, 100022. [Google Scholar] [CrossRef]

- Klocke, F.; Arntz, K.; Klingbeil, N.; Schulz, M. Wire-based laser metal deposition for additive manufacturing of TiAl6V4: Basic investigations of microstructure and mechanical properties from build up parts. In Proceedings of the SPIE LASE, San Francisco, CA, USA, 28 January 2017. [Google Scholar]

- Valiente Bermejo, M.A.; Thalavai Pandian, K.; Axelsson, B.; Harati, E.; Kisielewicz, A.; Karlsson, L. Microstructure of laser metal deposited duplex stainless steel: Influence of shielding gas and heat treatment. Weld. World 2020, 65, 525–541. [Google Scholar] [CrossRef]

- Harooni, A.; Nasiri, A.M.; Gerlich, A.P.; Khajepour, A.; Khalifa, A.; King, J.M. Processing window development for laser cladding of zirconium on zirconium alloy. J. Mater. Process. Technol. 2016, 230, 263–271. [Google Scholar] [CrossRef]

- Kolsch, N.; Seidel, A.; Finaske, T.; Brueckner, F.; Gumpinger, J.; Bavdaz, M.; Rohr, T.; Ghidini, T.; Leyens, C. Novel local shielding approach for the laser welding based additive manufacturing of large structural space components from titanium. J. Laser Appl. 2020, 32, 22075. [Google Scholar] [CrossRef]

- Arcella, F.G.; Froes, F.H. Producing titanium aerospace components from powder using laser forming. JOM 2000, 52, 28–30. [Google Scholar] [CrossRef]

- Baier, D.; Bachmann, A.; Zaeh, M.F. Towards wire and arc additive manufacturing of high-quality parts. Procedia CIRP 2020, 95, 54–59. [Google Scholar] [CrossRef]

- Vaamonde, E.; Reya, P.; Ariasa, R.M.; Troncosoa, I. Effect of atmosphere conditions on additive manufacturing of Ti4Al6V by coaxial W-DED-LB process. In Proceedings of the Lasers in Manufacturing Conference 2021, Virtual Conference, 21–24 June 2021. [Google Scholar]

- Kisielewicz, A.; Thalavai Pandian, K.; Sthen, D.; Hagqvist, P.; Valiente Bermejo, M.A.; Sikström, F.; Ancona, A. Hot-wire laser-directed energy deposition: Process characteristics and benefits of resistive pre-heating of the feedstock wire. Metals 2021, 11, 634. [Google Scholar] [CrossRef]

- Veiga, F.; Gil Del Val, A.; Suárez, A.; Alonso, U. Analysis of the machining process of Titanium Ti6Al-4V parts manufactured by wire arc additive manufacturing (WAAM). Materials 2020, 13, 766. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Shi, T.; Shi, J.; Cheng, D.; Lu, L.; Shi, S. Experimental investigation on laser metal deposition of Ti-6Al-4V alloy with coaxial local shielding gas nozzle. J. Mater. Eng. Perform. 2020, 29, 7821–7829. [Google Scholar] [CrossRef]

- Kelbassa, I. Qualifizieren des Laserstrahl-Auftragschweißens von BLISKs aus Nickel- und Titanbasislegierungen; Fraunhofer Institute for Laser Technology: Aachen, Germany, 2006. [Google Scholar]

- Bernauer, C.; Merk, T.; Zapata, A.; Zaeh, M.F. Laser metal deposition with coaxial wire feeding for the automated and reliable build-up of solid metal parts. Key Eng. Mater. 2022, 926, 65–79. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Martina, F.; Williams, S.; Wiktorowicz, R.; Palt, M.R. Development of a laminar flow local shielding device for wire + arc additive manufacture. J. Mater. Process. Technol. 2015, 226, 99–105. [Google Scholar] [CrossRef]

- Miyake, R.; Sasahara, H.; Suzuki, A.; Ouchi, S. Wire arc additive and high-temperature subtractive manufacturing of Ti-6Al-4V. Appl. Sci. 2021, 11, 9521. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Thomson-Larkins, J.; St John, D.H.; Dargusch, M.S. Sensitivity of Ti-6Al-4V components to oxidation during out of chamber wire + arc additive manufacturing. J. Mater. Process. Technol. 2018, 258, 29–37. [Google Scholar] [CrossRef]

- Karpagaraj, A.; Siva Shanmugam, N.; Sankaranarayanasamy, K. Experimental investigations and numerical prediction on the effect of shielding area and post flow time in the GTAW of CP Ti sheets. Int. J. Adv. Manuf. Technol. 2019, 101, 2933–2945. [Google Scholar] [CrossRef]

- Mereddy, S.; Bermingham, M.J.; StJohn, D.H.; Dargusch, M.S. Grain refinement of wire arc additively manufactured titanium by the addition of silicon. J. Alloys Compd. 2017, 695, 2097–2103. [Google Scholar] [CrossRef]

- Cortina, M.; Arrizubieta, J.I.; Ruiz, J.E.; Lamikiz, A.; Ukar, E. Design and manufacturing of a protective nozzle for highly reactive materials processing via laser material deposition. Procedia CIRP 2018, 68, 387–392. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Tabernero, I.; Ruiz, J.E.; Lamikiz, A.; Martinez, S.; Ukar, E. Continuous coaxial nozzle design for LMD based on numerical simulation. Phys. Procedia 2014, 56, 429–438. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Shi, S.; Cheng, D. Mass distribution of local shielding gas for laser cladding of titanium alloy in open environment. Chin. J. Laser 2019, 46, 702007. [Google Scholar] [CrossRef]

- Nalam, Y.; Hauser, T.; Peter Breese, P.; Kamps, T.; Küsters, Y.; Hama-Saleh Abdullah, R.; Volpp, J.; Kaplan, A.F.H. Gas flow study for development of a novel shielding gas nozzle for directed energy deposition processes using computational fluid dynamic simulations. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1135, 12016. [Google Scholar] [CrossRef]

- Becker, D.; Boley, S.; Eisseler, R.; Stehle, T.; Möhring, H.-C.; Onuseit, V.; Hoßfeld, M.; Graf, T. Influence of a closed-loop controlled laser metal wire deposition process of S Al 5356 on the quality of manufactured parts before and after subsequent machining. Prod. Eng. Res. Devel. 2021, 15, 489–507. [Google Scholar] [CrossRef]

- Möhring, H.-C.; Becker, D.; Eisseler, R.; Stehle, T.; Reeber, T. Influence of the manufacturing parameters of an AlMg5 wire–based hybrid production process on quality and mechanical properties. Int. J. Adv. Manuf. Technol. 2021, 119, 2445–2460. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Kies, F.; Haase, C. Directed energy deposition of Inconel 718 powder, cold and hot wire using a six-beam direct diode laser set-up. Addit. Manuf. 2021, 47, 102269. [Google Scholar] [CrossRef]

- Pajukoski, H.; Näkki, J.; Thieme, S.; Tuominen, J.; Nowotny, S.; Vuoristo, P. High performance corrosion resistant coatings by novel coaxial cold- and hot-wire laser cladding methods. J. Laser Appl. 2016, 28, 12011. [Google Scholar] [CrossRef]

- Budde, L.; Lammers, M.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Process development for laser hot-wire deposition welding with high-carbon cladding Material AISI52100. In Proceedings of the Lasers in Manufacturing Conference 2021, Virtual Conference, 21–24 June 2021. [Google Scholar]

- Ji, S.; Liu, F.; Shi, T.; Fu, G.; Shi, S. Effects of defocus distance on three-beam laser internal coaxial wire cladding. Chin. J. Mech. Eng. 2021, 34, 45. [Google Scholar] [CrossRef]

- Olson, D.L.; Siewert, T.A.; Liu, S.; Edwards, G.R. ASM Handbook Volume 6: Welding, Brazing, and Soldering, 10th ed.; ASM International: Materials Park, OH, USA, 2000; ISBN 978-0-87170-382-8. [Google Scholar]

- Cattafesta, L.; Bahr, C.; Mathew, J. Fundamentals of wind-tunnel design. Encycl. Aerosp. Eng. 2010, 1–10. [Google Scholar] [CrossRef]

- Kaushik, M. Theoretical and Experimental Aerodynamics; Springer: Singapore, 2019; ISBN 978-981-13-1677-7. [Google Scholar]

- Mehta, R.; Bradshaw, P. Design rules for small low speed wind tunnels. Aeronaut. J. 1979, 83, 443–449. [Google Scholar] [CrossRef]

- Morel, T. Comprehensive design of axisymmetric wind tunnel contractions. J. Fluids Eng. 1975, 97, 225–233. [Google Scholar] [CrossRef]

- Bradshaw, P.; Pankhurst, R.C. The design of low-speed wind tunnels. Prog. Aerosp. Sci. 1964, 5, 1–69. [Google Scholar] [CrossRef]

- Bell, J.; Mehta, R. Contraction Design for Small Low-Speed Wind Tunnels; NASA Contractor Report, NASA CR-177488; NASA: Washington, DC, USA, 1988.

- Jordinson, R. Design of wind tunnel contractions. Aircr. Eng. Aerosp. 1961, 33, 294–297. [Google Scholar] [CrossRef]

- Derbunovich, G.I.; Zemskaya, A.S.; Repik, E.U.; Sosedko, Y.P. Effect of flow contraction on the level of turbulence. Fluid. Dyn. 1987, 22, 289–294. [Google Scholar] [CrossRef]

- Mikhail, M.N. Optimum design of wind tunnel contractions. AIAA J. 1979, 17, 471–477. [Google Scholar] [CrossRef]

- Su, Y.-X. Flow analysis and design of three-dimensional wind tunnel contractions. AIAA J. 1991, 29, 1912–1920. [Google Scholar] [CrossRef]

- Wille, R. Beitraege zur Phaenomenologie der Freistrahlen (Phenomenology of free jets). Zeitschrift Flugwissenschaften 1963, 11, 222–233. [Google Scholar]

- Vagt, J.-D. Bemerkungen zur Auslegung eines Unterschall-Freistrahlwindkanals (Remarks on the design of a subsonic free jet wind tunnel). Zeitschrift Flugwissenschaften 1973, 21, 159–162. [Google Scholar]

- Lechner, C.; Seume, J. Stationäre Gasturbinen (Stationary Gas Turbines), 3rd ed.; Springer Vieweg: Berlin, Germany, 2019; ISBN 978-3-662-56134-8. [Google Scholar]

- Zapata, A.; Bernauer, C.; Hell, M.; Kriz, H.; Zaeh, M.F. Direction-independent temperature monitoring for laser metal deposition with coaxial wire feeding. Procedia CIRP 2022, 111, 302–307. [Google Scholar] [CrossRef]

- Arbo, S.M.; Tomovic-Petrovic, S.; Aunemo, J.; Dahle, N.; Jensrud, O. On weldability of aerospace grade Al-Cu-Li alloy AA2065 by wire-feed laser metal deposition. J. Adv. Join. Process. 2022, 5, 100096. [Google Scholar] [CrossRef]

- Froend, M.; Ventzke, V.; Dorn, F.; Kashaev, N.; Klusemann, B.; Enz, J. Microstructure by design: An approach of grain refinement and isotropy improvement in multi-layer wire-based laser metal deposition. Mater. Sci. Eng. A 2020, 772, 138635. [Google Scholar] [CrossRef]

- Zapata, A.; Bernauer, C.; Stadter, C.; Kolb, C.G.; Zaeh, M.F. Investigation on the cause-effect relationships between the process parameters and the resulting geometric properties for wire-based coaxial laser metal deposition. Metals 2022, 12, 455. [Google Scholar] [CrossRef]

- Fonte, C.P.; Sultan, M.A.; Santos, R.J.; Dias, M.M.; Lopes, J.C.B. Flow imbalance and Reynolds number impact on mixing in confined impinging jets. Chem. Eng. J. 2015, 260, 316–330. [Google Scholar] [CrossRef]

- Teng, Z.; Larsson, I.A.S.; Lundström, T.S.; Marjavaara, B.D. The effect of Reynolds number on jet in asymmetric co-flows: A CFD study. Int. J. Chem. Eng. 2018, 2018, 1572576. [Google Scholar] [CrossRef]

- Akbari, M.; Kovacevic, R. Closed loop control of melt pool width in robotized laser powder–directed energy deposition process. Int. J. Adv. Manuf. Technol. 2019, 104, 2887–2898. [Google Scholar] [CrossRef]

- Bernauer, C.; Zapata, A.; Zaeh, M.F. Toward defect-free components in laser metal deposition with coaxial wire feeding through closed-loop control of the melt pool temperature. J. Laser Appl. 2022, 34, 42044. [Google Scholar] [CrossRef]

- Bernauer, C.J.; Zapata, A.; Kick, L.; Weiss, T.; Sigl, M.E.; Zaeh, M.F. Pyrometry-based closed-loop control of the melt pool temperature in laser metal deposition with coaxial wire feeding. Procedia CIRP 2022, 111, 296–301. [Google Scholar] [CrossRef]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Depositionfor additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

| Parameters | Unit | Adapter | Nozzle |

|---|---|---|---|

| Inlet radius r1 | mm | 47.1 | 18.0 |

| Outlet radius r2 | mm | 18.0 | 7.5 |

| Length L | mm | 61.0 | 30.0 |

| Contraction ratio σ | – | 6.85 | 5.76 |

| Maximum angle αmax | ° | 42.9 | 34.4 |

| Element | Cr | Ni | Mo | Mn | Si | C | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Wire | 18.2 | 12.1 | 2.5 | 1.8 | 0.88 | <0.01 | 0.024 | 0.010 | Bal. |

| Substrate | 17.0–19.0 | 8.0–11.0 | – | ≤2.0 | ≤1.0 | ≤0.07 | ≤0.035 | ≤0.03 | Bal. |

| Parameters | Unit | Single Tracks | Cuboid |

|---|---|---|---|

| Laser power PL | W | 1500 | 1200 |

| Traverse speed vt | m/min | 1.0 | 1.0 |

| Wire feed rate vw | m/min | 1.0 | 1.1 |

| Focal position f | mm | −6 | −6 |

| Shielding gas flow rate fs | l/min | 10–70 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernauer, C.; Meinzinger, L.; Zapata, A.; Zhao, X.F.; Baehr, S.; Zaeh, M.F. Design and Investigation of a Novel Local Shielding Gas Concept for Laser Metal Deposition with Coaxial Wire Feeding. Appl. Sci. 2023, 13, 5121. https://doi.org/10.3390/app13085121

Bernauer C, Meinzinger L, Zapata A, Zhao XF, Baehr S, Zaeh MF. Design and Investigation of a Novel Local Shielding Gas Concept for Laser Metal Deposition with Coaxial Wire Feeding. Applied Sciences. 2023; 13(8):5121. https://doi.org/10.3390/app13085121

Chicago/Turabian StyleBernauer, Christian, Lukas Meinzinger, Avelino Zapata, Xiao Fan Zhao, Siegfried Baehr, and Michael F. Zaeh. 2023. "Design and Investigation of a Novel Local Shielding Gas Concept for Laser Metal Deposition with Coaxial Wire Feeding" Applied Sciences 13, no. 8: 5121. https://doi.org/10.3390/app13085121

APA StyleBernauer, C., Meinzinger, L., Zapata, A., Zhao, X. F., Baehr, S., & Zaeh, M. F. (2023). Design and Investigation of a Novel Local Shielding Gas Concept for Laser Metal Deposition with Coaxial Wire Feeding. Applied Sciences, 13(8), 5121. https://doi.org/10.3390/app13085121