The Time Variation Law of Concrete Compressive Strength: A Review

Abstract

1. Introduction

2. Study on Single Factors

2.1. Carbonization

2.2. Freeze–Thaw Cycles

2.3. High and Low Temperature Effect

2.4. Sulfate Attacks

3. Comprehensive Study on Multiple Factors

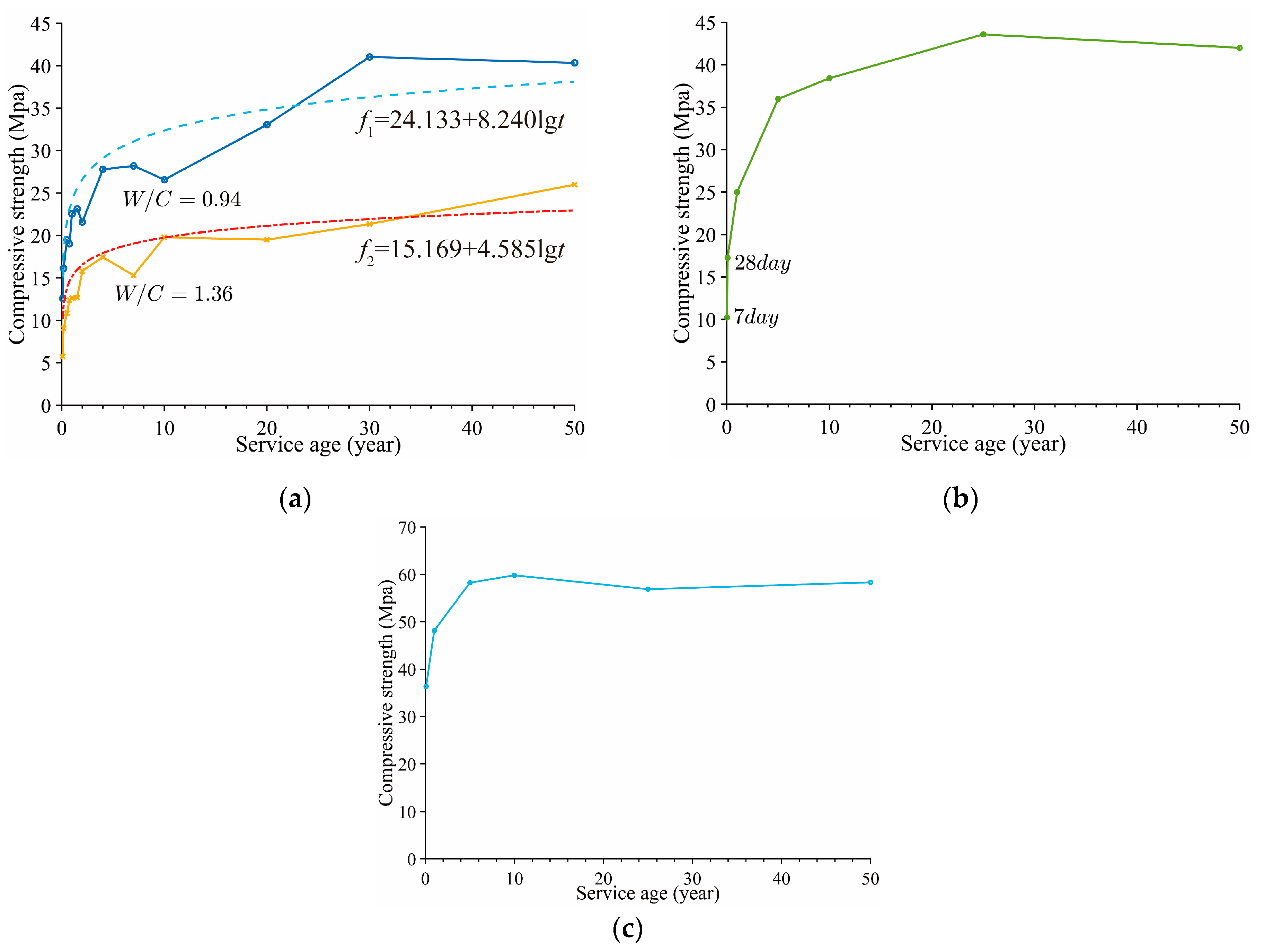

3.1. Statistical Analysis of Laboratory Experimental Data

3.2. Statistical Analysis of Field Test Data

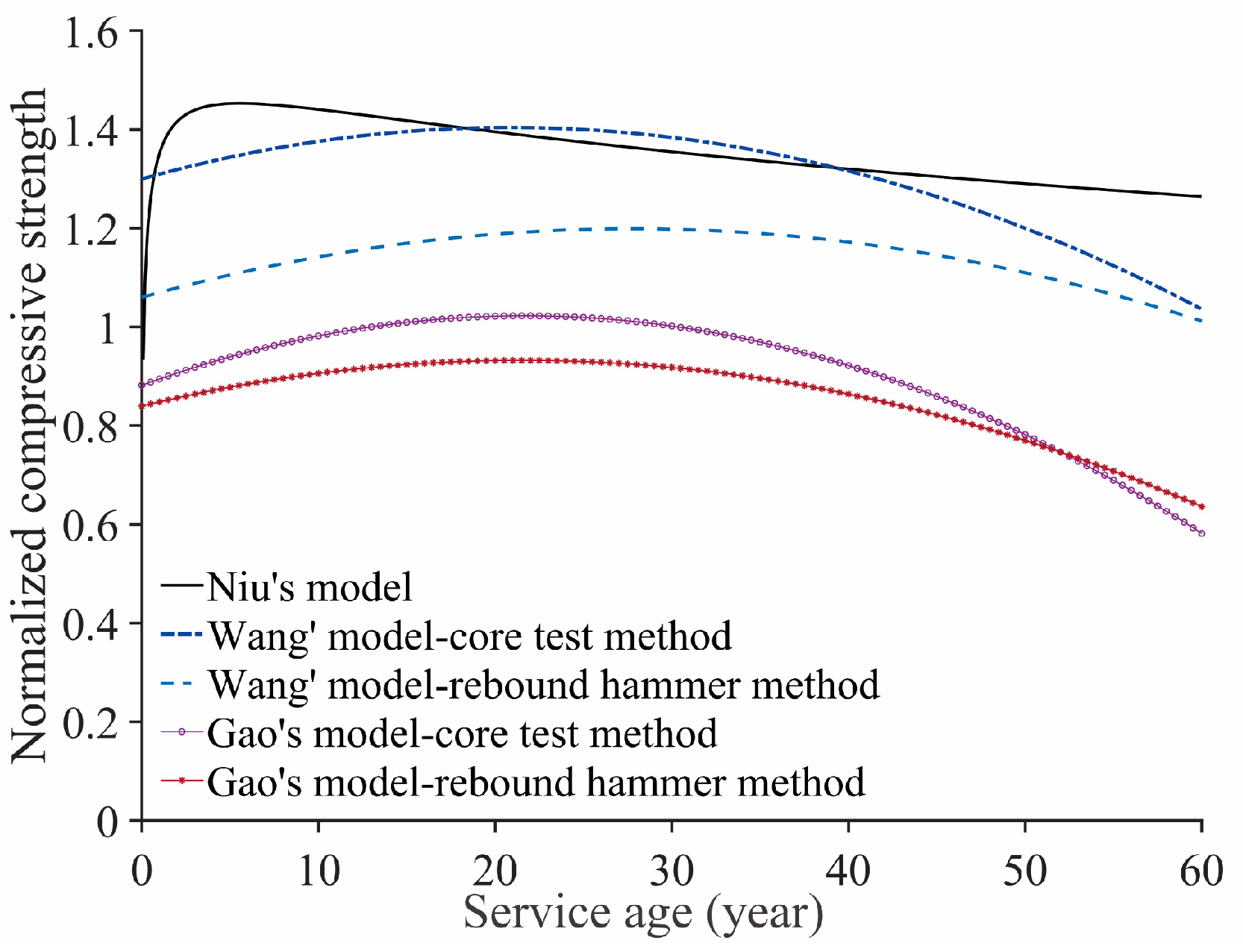

- Niu’s model

- 2.

- Gao’s model

- 3.

- Wang’s model

- 4.

- Comparative analysis of time variation models

4. Study on Internal Factors of Concrete

5. Conclusions and Discussions

- The strength loss of concrete under the coupling effect of multiple factors has been found to be more serious than the single factor. On the whole, the compressive strength of concrete decreased under the action of various factors in the long term. However, the effect of carbonation and sulfate attacks on concrete needs to be divided into two stages, where the compressive strength increases with time in the early stage and gradually decreases in a later stage.

- The compressive strength of concrete first increased and then decreased under long-term variations in existing concrete buildings. Due to different data sources and normalization methods, there are obvious differences in time variation models.

- The compressive strength of concrete is not only influenced by external factors but also internal factors such as cement type and water–cement ratio, and curing conditions also exhibit remarkable influences.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, J.D.; Sabri, M.M.S.; Ulrikh, D.V.; Ahmad, M.; Alsaffar, K.A.M. Predicting the Compressive Strength of the Cement-Fly Ash–Slag Ternary Concrete Using the Firefly Algorithm (FA) and Random Forest (RF) Hybrid Machine-Learning Method. Materials 2022, 15, 4193. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Fouda, R.M.; Abd Elrahman, M.; Youssf, O. Long-Term Performance of Concrete Made with Different Types of Cement under Severe Sulfate Exposure. Materials 2023, 16, 240. [Google Scholar] [CrossRef]

- Gagg, C.R. Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Gartner, E. Industrially interesting approaches to ‘low-CO2’ cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Aïtcin, P.-C. Cements of yesterday and today: Concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Wriggers, P.; Moftah, S.O. Mesoscale models for concrete: Homogenisation and damage behaviour. Finite Elem. Anal. Des. 2006, 42, 623–636. [Google Scholar] [CrossRef]

- Xu, K.; Ren, S.; Song, J.; Liu, J.; Liu, Z.; Sun, J.; Ling, S. Colorful superhydrophobic concrete coating. Chem. Eng. J. 2020, 403, 126348. [Google Scholar] [CrossRef]

- Abu Alfoul, B.; Al Hattamleh, O.; Aldeeky, H. Investigating the effects of disc shaped thumb tacks as a “fiber” reinforcement on various concrete properties. Case Stud. Constr. Mater. 2019, 11, e00257. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled fibers in reinforced concrete: A systematic literature review. J. Clean. Prod. 2019, 248, 119207. [Google Scholar] [CrossRef]

- Said, A.; Zeidan, M.; Bassuoni, M.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Chen, H.G.; Li, X.; Wu, Y.Q.; Zuo, L.; Lu, M.J.; Zhou, Y.S. Compressive Strength Prediction of High-Strength Concrete Using Long Short-Term Memory and Machine Learning Algorithms. Buildings 2022, 12, 302. [Google Scholar] [CrossRef]

- Talavera-Pech, W.; Montiel-Rodríguez, D.; Paat-Estrella, J.; López-Alcántara, R.; Pérez-Quiroz, J.; Pérez-López, T. Improvement in the Carbonation Resistance of Construction Mortar with Cane Bagasse Fiber Added. Materials 2021, 14, 2066. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Dong, X.; Zhang, H.; Deng, M. Research on Deterioration Mechanism of Concrete Materials in an Actual Structure. Adv. Mater. Sci. Eng. 2014, 2014, 306459. [Google Scholar] [CrossRef]

- Basheer, L.; Kropp, J.; Cleland, D.J. Assessment of the durability of concrete from its permeation properties: A review. Constr. Build. Mater. 2001, 15, 93–103. [Google Scholar] [CrossRef]

- Tang, S.W.; Yao, Y.; Andrade, C.; Li, Z.J. Recent durability studies on concrete structure. Cem. Concr. Res. 2015, 78, 143–154. [Google Scholar] [CrossRef]

- Barkhordari, M.S.; Armaghani, D.J.; Mohammed, A.S.; Ulrikh, D.V. Data-Driven Compressive Strength Prediction of Fly Ash Concrete Using Ensemble Learner Algorithms. Buildings 2022, 12, 132. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S.M.A. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502. [Google Scholar] [CrossRef]

- Li, Q.-F.; Song, Z.-M. High-performance concrete strength prediction based on ensemble learning. Constr. Build. Mater. 2022, 324, 126694. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B.C.; Nuti, C. Influence of steel fiber on compressive properties of ultra-high performance fiber-reinforced concrete. Constr. Build. Mater. 2021, 302, 124104. [Google Scholar] [CrossRef]

- Nobile, L. Prediction of concrete compressive strength by combined non-destructive methods. Meccanica 2015, 50, 411–417. [Google Scholar] [CrossRef]

- Shahpari, M.; Bamonte, P.; Mosallam, S.J. An experimental study on mechanical and thermal properties of structural lightweight concrete using carbon nanotubes (CNTs) and LECA aggregates after exposure to elevated temperature. Constr. Build. Mater. 2022, 346, 128376. [Google Scholar] [CrossRef]

- Shang, H.-S.; Song, Y.-P.; Qin, L.-K. Experimental study on strength and deformation of plain concrete under triaxial compression after freeze-thaw cycles. Build. Environ. 2008, 43, 1197–1204. [Google Scholar] [CrossRef]

- Han, N.; Tian, W. Experimental study on the dynamic mechanical properties of concrete under freeze-thaw cycles. Struct. Concr. 2018, 19, 1353–1362. [Google Scholar] [CrossRef]

- Hao, L.; Liu, Y.Z.; Wang, W.J.; Zhang, J.G.; Zhang, Y. Effect of salty freeze-thaw cycles on durability of thermal insulation concrete with recycled aggregates. Constr. Build. Mater. 2018, 189, 478–486. [Google Scholar] [CrossRef]

- Li, Z.Y.; Wang, Z.J. Researches on Concrete Carbonation. Appl. Mech. Mater. 2013, 357–360, 737–742. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, B. Research on the performance of concrete materials under the condition of freeze-thaw cycles. Eur. J. Environ. Civ. Eng. 2013, 17, 860–871. [Google Scholar] [CrossRef]

- Liu, D.Y.; Tu, Y.M.; Shi, P.; Sas, G.; Elfgren, L. Mechanical and durability properties of concrete subjected to early-age freeze–thaw cycles. Mater. Struct. 2021, 54, 1–18. [Google Scholar] [CrossRef]

- Kanaujia, P.; Banerjee, R.; Husain, S.M.A.; Ahmed, S. The Effect of Sulfate Attack on Physical Properties of Concrete. Int. J. Recent Technol. Eng. 2021, 10, 2277–3878. [Google Scholar] [CrossRef]

- Xie, F.; Li, J.P.; Zhao, G.W.; Zhou, P.; Zheng, H.J. Experimental study on performance of cast-in-situ recycled aggregate concrete under different sulfate attack exposures. Constr. Build. Mater. 2020, 253, 119144. [Google Scholar] [CrossRef]

- Ming, F.; Du, C.C.; Liu, Y.H.; Shi, X.Y.; Li, D.Q. Concrete durability under different circumstances based on multi-factor effects. Sci. Cold. Arid. Reg. 2017, 9, 384–391. [Google Scholar] [CrossRef]

- Tao, J.; Yuan, Y.; Taerwe, L. Compressive Strength of Self-Compacting Concrete during High-Temperature Exposure. J. Mater. Civ. Eng. 2010, 22, 1005–1011. [Google Scholar] [CrossRef]

- Husem, M. The effects of high temperature on compressive and flexural strengths of ordinary and high-performance concrete. Fire Saf. J. 2006, 41, 155–163. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Ma, Q.M.; Guo, R.X.; Zhao, Z.M.; Lin, Z.W.; He, K.C. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Zaki, R.A.; AbdelAleem, B.H.; Hassan, A.A.A.; Colbourne, B. Impact resistance of steel fiber reinforced concrete in cold temperatures. Cem. Concr. Compos. 2021, 122, 104116. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, M.; Cui, J. A review on the deterioration of mechanical and durability performance of marine-concrete under the scouring action. J. Build. Eng. 2023, 66. [Google Scholar] [CrossRef]

- Peng, X.; Zhuang, Z.X.; Yang, Q.W. Predictive Modeling of Compressive Strength for Concrete at Super Early Age. Materials 2022, 15, 4914. [Google Scholar] [CrossRef]

- Loo, Y.H.; Chin, M.S.; Tam, C.T.; Ong, K.C.G. A carbonation prediction model for accelerated carbonation testing of concrete. Mag. Concr. Res. 1994, 46, 191–200. [Google Scholar] [CrossRef]

- Krishna, D.A.; Priyadarsini, R.S.; Narayanan, S. Effect of Elevated Temperatures on the Mechanical Properties of Concrete. Procedia Struct. Integr. 2019, 14, 384–394. [Google Scholar] [CrossRef]

- Shen, J.; Xu, Q. Effect of elevated temperatures on compressive strength of concrete. Constr. Build. Mater. 2019, 229, 116846. [Google Scholar] [CrossRef]

- Xie, J.; Li, X.; Wu, H. Experimental study on the axial-compression performance of concrete at cryogenic temperatures. Constr. Build. Mater. 2014, 72, 380–388. [Google Scholar] [CrossRef]

- Jessie, A.; Santhi, A.S. Effect of temperature on compressive strength of steel fibre reinforced concrete. J. Appl. Sci. Eng. 2019, 22, 233–238. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, Q.; Cheng, M. Study on mechanical properties and air-void structure characteristics of hybrid fiber fly ash concrete under sulfate attack. Mater. Res. Express 2021, 8, 105504. [Google Scholar] [CrossRef]

- Cao, D.; Liu, J.; Zhou, Y.L.; Ge, W.J.; Zhang, X. Experimental Study on the Effect of Freeze-Thaw Cycles on Axial Tension and Compression Performance of Concrete after Complete Carbonization. Adv. Civ. Eng. 2021, 2021, 8111436. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, T.; Luo, T.; Zhou, M.; Zhang, K.; Ma, W.W. Study on the Deterioration of Concrete under Dry–Wet Cycle and Sulfate Attack. Materials 2020, 13, 4095. [Google Scholar] [CrossRef]

- Chen, S.; Song, X.; Liu, X. Compressive strength degradation and evolution of failure surfaces in compressively preloaded concrete under freeze-thaw cycles. Mater. Res. Innov. 2015, 19, 433–437. [Google Scholar] [CrossRef]

- Jia, P.; Li, L.; Zhou, J.; Zhang, D.; Guan, Z.W.; Dong, J.F.; Wang, Q.Y. Performance Evolution of Recycled Aggregate Concrete under the Coupled Effect of Freeze–Thaw Cycles and Sulfate Attack. Appl. Sci. 2022, 12, 6950. [Google Scholar] [CrossRef]

- Jiang, L.; Niu, D.T.; Yuan, L.D.; Fei, Q.N. Durability of concrete under sulfate attack exposed to freeze–thaw cycles. Cold Reg. Sci. Technol. 2015, 112, 112–117. [Google Scholar] [CrossRef]

- Wang, R.I.; Zhang, Q.J.; Li, Y. Deterioration of concrete under the coupling effects of freeze–thaw cycles and other actions: A review. Constr. Build. Mater. 2021, 319, 126045. [Google Scholar] [CrossRef]

- Washa, G.W.; Wendt, K.F. Fifty year properties of concrete. ACI Mater. J. 1975, 72, 20–28. [Google Scholar] [CrossRef]

- Withey, M.O. Fifty year compression test of concrete. ACI Mater. J. 1961, 58, 695–712. [Google Scholar] [CrossRef]

- Washa, G.W.; Saemann, J.C.; Cramer, S.M. Fifty-year properties of concrete made in 1937. ACI Mater. J. 1989, 86, 367–371. [Google Scholar] [CrossRef]

- Wood, S.L. Evaluation of the long-term properties of concrete. ACI Mater. J. 1992, 88, 630–643. [Google Scholar] [CrossRef]

- Niu, D.T.; Wang, Q.L. Models of concrete strength changing with time in general air environment. Ind. Constr. 1995, 25, 36–38. (In Chinese) [Google Scholar] [CrossRef]

- Gao, X.L.; Li, J.; Ren, X.D. Probabilistic Model for Long-Term Time-Dependent Compressive Strength of Concrete in Existing Buildings. J. Perform. Constr. Facil. 2018, 32, 4018074. [Google Scholar] [CrossRef]

- Wang, W.N. Research and Prediction of Time Variation Model on the Compressive Strength of Concrete in Existing Buildings. Master’s Thesis, School of Civil Engineering, Shandong Jianzhu University, Jinan, China, 2022. (In Chinese). [Google Scholar] [CrossRef]

- Branson, D.E.; Kripanarayanan, K.M. Loss of prestress, camber and deflection of non-composite and composite prestressed concrete structures. PCI J. 1971, 16, 22–52. [Google Scholar] [CrossRef]

- Abdeldjalil, M.; Chouicha, K. Effect of the Cement-to-Water Ratio and Fractal Granular Model on the Prediction of Concretes Compressive Strength. Int. J. Concr. Struct. Mater. 2022, 16, 43. [Google Scholar] [CrossRef]

- Mckinnie, S.B. Time Dependent Compressive Strength and Modulus of Elasticity of Florida Concrete. Ph.D. Thesis, Department of Civil and Environmental Engineering, Florida State University College of Engineering, Tallahassee, FL, USA, 2004. [Google Scholar]

- Branson, D.E.; Christiason, M.L. Time dependent concrete properties related to design-strength and elastic properties, creep, and shrinkage. Am. Concr. Inst. 1971, 27, 257–278. [Google Scholar] [CrossRef]

- ACI Committee 209. Prediction of creep, shrinkage, and temperature effects in concrete structures. Am. Concr. Inst. 1982, 76, 193–300. [Google Scholar] [CrossRef]

- Chidiac, S.E.; Moutassem, F.; Mahmoodzadeh, F. Compressive strength model for concrete. Mag. Concr. Res. 2013, 65, 557–572. [Google Scholar] [CrossRef]

- Moutassem, F.; Chidiac, S.E. Assessment of concrete compressive strength prediction models. KSCE J. Civ. Eng. 2015, 20, 343–358. [Google Scholar] [CrossRef]

- Liang, M.-T.; Lan, J.-J. Reliability analysis for the existing reinforced concrete pile corrosion of bridge substructure. Cem. Concr. Res. 2005, 35, 540–550. [Google Scholar] [CrossRef]

- Cao, H.F.; Liang, Z.; Peng, X.; Cai, X.; Wang, K.W.; Wang, H.; da Lyu, Z. Research into Carbon Dioxide Curing’s Effects on the Properties of Reactive Powder Concrete with Assembly Unit of Sulphoaluminate Cement and Ordinary Portland Cement. Coatings 2022, 12, 209. [Google Scholar] [CrossRef]

- Talukdar, S.; Banthia, N. Carbonation in concrete infrastructure in the context of global climate change: Development of a service lifespan model. Constr. Build. Mater. 2012, 40, 775–782. [Google Scholar] [CrossRef]

- Caputo, F.; Navarro, C.; De Castro, P.M.S.T. Failure Mechanisms and Damage Modelling for Advanced Materials. Adv. Mater. Sci. Eng. 2017, 2017, 6910685. [Google Scholar] [CrossRef]

- Otieno, M.; Ikotun, J.; Ballim, Y. Experimental investigations on the influence of cover depth and concrete quality on time to cover cracking due to carbonation-induced corrosion of steel in RC structures in an urban, inland environment. Constr. Build. Mater. 2019, 198, 172–181. [Google Scholar] [CrossRef]

- Khunthongkeaw, J.; Tangtermsirikul, S.; Leelawat, T. A study on carbonation depth prediction for fly ash concrete. Constr. Build. Mater. 2006, 20, 744–753. [Google Scholar] [CrossRef]

- Lo, T.Y.; Tang, W.C.; Nadeem, A. Comparison of carbonation of lightweight concrete with normal weight concrete at similar strength levels. Constr. Build. Mater. 2008, 22, 1648–1655. [Google Scholar] [CrossRef]

- Rostami, V.; Shao, Y.X.; Boyd, A.J.; He, Z. Microstructure of cement paste subject to early carbonation curing. Cem. Concr. Res. 2012, 42, 186–193. [Google Scholar] [CrossRef]

- Castellote, M.; Andrade, C.; Turrillas, X.; Campo, J.; Cuello, G.J. Accelerated carbonation of cement pastes in situ monitored by neutron diffraction. Cem. Concr. Res. 2008, 38, 1365–1373. [Google Scholar] [CrossRef]

- Bertos, M.F.; Simons, S.J.R.; Hills, C.D.; Carey, P.J. A review of accelerated carbonation technology in the treatment of cement-based materials and sequestration of CO2. J. Hazard. Mater. 2004, 112, 193–205. [Google Scholar] [CrossRef]

- Liu, D.Y.; Wang, C.; Gonzalez-Libreros, J.; Guo, T.; Cao, J.; Tu, Y.M.; Elfgren, L.; Sas, G. A review of concrete properties under the combined effect of fatigue and corrosion from a material perspective. Constr. Build. Mater. 2023, 369, 130489. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Fardis, M.N.; Vayenas, C.G. Effect of composition, environmental factors and cement-lime mortar coating on concrete carbonation. Mater. Struct. 1992, 25, 293–304. [Google Scholar] [CrossRef]

- Ahmad, S.; Assaggaf, R.A.; Maslehuddin, M.; Al-Amoudi, O.S.B.; Adekunle, S.K.; Ali, S.I. Effects of carbonation pressure and duration on strength evolution of concrete subjected to accelerated carbonation curing. Constr. Build. Mater. 2017, 136, 565–573. [Google Scholar] [CrossRef]

- Lu, B.; He, P.P.; Liu, J.H.; Peng, Z.Y.; Song, B.X.; Hu, X. Microstructure of Portland cement paste subjected to different CO2 concentrations and further water curing. J. CO2 Util. 2021, 53, 101714. [Google Scholar] [CrossRef]

- Ashraf, W. Carbonation of cement-based materials: Challenges and opportunities. Constr. Build. Mater. 2016, 120, 558–570. [Google Scholar] [CrossRef]

- Wang, X.-H.; Val, D.V.; Zheng, L.; Jones, M.R. Carbonation of loaded RC elements made of different concrete types: Accelerated testing and future predictions. Constr. Build. Mater. 2020, 243, 118259. [Google Scholar] [CrossRef]

- Roy, S.K.; Poh, K.B.; Northwood, D.O. Durability of concrete—Accelerated carbonation and weathering studies. Build. Environ. 1999, 34, 597–606. [Google Scholar] [CrossRef]

- Hussain, S.; Bhunia, D.; Singh, S.B. Comparative study of accelerated carbonation of plain cement and fly-ash concrete. J. Build. Eng. 2017, 10, 26–31. [Google Scholar] [CrossRef]

- Idowu, O.; Black, L. The effect of improper curing on properties that may affect concrete durability. Mag. Concr. Res. 2018, 70, 633–647. [Google Scholar] [CrossRef]

- Sanjuán, M.A.; Andrade, C.; Cheyrezy, M. Concrete carbonation tests in natural and accelerated conditions. Adv. Cem. Res. 2003, 15, 171–180. [Google Scholar] [CrossRef]

- Neves, R.; Branco, F.; de Brito, J. Field assessment of the relationship between natural and accelerated concrete carbonation resistance. Cem. Concr. Compos. 2013, 41, 9–15. [Google Scholar] [CrossRef]

- Leemann, A.; Nygaard, P.; Kaufmann, J.; Loser, R. Relation between carbonation resistance, mix design and exposure of mortar and concrete. Cem. Concr. Compos. 2015, 62, 33–43. [Google Scholar] [CrossRef]

- Hanjari, K.Z.; Utgenannt, P.; Lundgren, K. Experimental study of the material and bond properties of frost-damaged concrete. Cem. Concr. Res. 2011, 41, 244–254. [Google Scholar] [CrossRef]

- Krstic, M.; Davalos, J.F.; Rossi, E.; Figueiredo, S.C.; Copuroglu, O. Freeze–Thaw Resistance and Air-Void Analysis of Concrete with Recycled Glass–Pozzolan Using X-ray Micro-Tomography. Materials 2020, 14, 154. [Google Scholar] [CrossRef] [PubMed]

- Medina, C.; de Rojas, M.I.S.; Frías, M. Freeze-thaw durability of recycled concrete containing ceramic aggregate. J. Clean. Prod. 2013, 40, 151–160. [Google Scholar] [CrossRef]

- Gong, F.Y.; Zhi, D.A.; Jia, J.G.; Wang, Z.; Ning, Y.J.; Zhang, B.; Ueda, T. Data-Based Statistical Analysis of Laboratory Experiments on Concrete Frost Damage and Its Implications on Service Life Prediction. Materials 2022, 15, 6282. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Y.; Yang, G.S.; Liu, H. The Influence of Regional Freeze–Thaw Cycles on Loess Landslides: Analysis of Strength Deterioration of Loess with Changes in Pore Structure. Water 2020, 12, 3047. [Google Scholar] [CrossRef]

- Rosenqvist, M.; Oxfall, M.; Fridh, K.; Hassanzadeh, M. A test method to assess the frost resistance of concrete at the waterline of hydraulic structures. Mater. Struct. 2015, 48, 2403–2415. [Google Scholar] [CrossRef]

- Cai, H.; Liu, X. Freeze-thaw durability of concrete: Ice formation process in pores. Cem. Concr. Res. 1998, 28, 1281–1287. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, S.; Alonso, E.; Wang, L.; Xu, L.; Li, Z. Volume changes and mechanical degradation of a compacted expansive soil under freeze-thaw cycles. Cold Reg. Sci. Technol. 2018, 157, 206–214. [Google Scholar] [CrossRef]

- Yang, Z.N.; Lv, J.H.; Shi, W.; Jia, C.; Wang, C.; Hong, Y.; Ling, X.Z. Experimental study of the freeze thaw characteristics of expansive soil slope models with different initial moisture contents. Sci. Rep. 2021, 11, 23177. [Google Scholar] [CrossRef] [PubMed]

- Yun, H.-D. Effect of accelerated freeze–thaw cycling on mechanical properties of hybrid PVA and PE fiber-reinforced strain-hardening cement-based composites (SHCCs). Compos. Part B Eng. 2013, 52, 11–20. [Google Scholar] [CrossRef]

- Zhang, K.; Zhou, J.; Yin, Z.G. Experimental Study on Mechanical Properties and Pore Structure Deterioration of Concrete under Freeze–Thaw Cycles. Materials 2021, 14, 6568. [Google Scholar] [CrossRef] [PubMed]

- Cao, D.F.; Fu, L.Z. Experimental study on the strength of plain concrete after freezing-thawing circumstance. Concrete 2010, 52, 34–40. (In Chinese) [Google Scholar] [CrossRef]

- Shang, H.S.; Song, Y.P. Experimental study of strength and deformation of plain concrete under biaxial compression after freezing and thawing cycles. Cem. Concr. Res. 2006, 36, 1857–1864. [Google Scholar] [CrossRef]

- Malhotra, H.L. The effect of temperature on the compressive strength of concrete. Mag. Concr. Res. 1956, 8, 85–94. [Google Scholar] [CrossRef]

- Vodák, F.; Trtík, K.; Kapičková, O.; Hošková, Š.; Demo, P. The effect of temperature on strength—Porosity relationship for concrete. Constr. Build. Mater. 2004, 18, 529–534. [Google Scholar] [CrossRef]

- Ortiz, J.; Aguado, A.L.; Agulló, L.; García, T. Influence of environmental temperatures on the concrete compressive strength: Simulation of hot and cold weather conditions. Cem. Concr. Res. 2005, 35, 1970–1979. [Google Scholar] [CrossRef]

- ASCE Committee on Fire Protection. Structural Fire Protection; American Society of Civil Engineers: New York, NY, USA, 1992. [Google Scholar] [CrossRef]

- Chang, Y.F.; Chen, Y.H.; Sheu, M.S.; Yao, G.C. Residual stress–strain relationship for concrete after exposure to high temperatures. Cem. Concr. Res. 2006, 36, 1999–2005. [Google Scholar] [CrossRef]

- Anand, N.; Godwin, A. Influence of mineral admixtures on mechanical properties of self-compacting concrete under elevated temperature. Fire Mater. 2016, 40, 940–958. [Google Scholar] [CrossRef]

- Ryshkewitch, E. Compression Strength of Porous Sintered Alumina and Zirconia. J. Am. Ceram. Soc. 1951, 34, 65–68. [Google Scholar] [CrossRef]

- Griffith, A.A., VI. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. Lond. Ser. A 1921, 221, 163–198. [Google Scholar]

- Zhao, G.; Guo, M.; Cui, J.; Li, J.; Xu, L. Partially-exposed cast-in-situ concrete degradation induced by internal-external sulfate and magnesium multiple coupled attack. Constr. Build. Mater. 2021, 294, 123560. [Google Scholar] [CrossRef]

- Yao, M.; Li, J. Effect of the degradation of concrete friction piles exposed to external sulfate attack on the pile bearing capacity. Ocean Eng. 2019, 173, 599–607. [Google Scholar] [CrossRef]

- Zhang, Z.; Jin, X.; Luo, W. Long-term behaviors of concrete under low-concentration sulfate attack subjected to natural variation of environmental climate conditions. Cem. Concr. Res. 2019, 116, 217–230. [Google Scholar] [CrossRef]

- Hu, Y.Y.; Ma, L.L. Effect of Surface Treatment of Polypropylene (PP) Fiber on the Sulfate Corrosion Resistance of Cement Mortar. Materials 2021, 14, 3690. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Mu, R.; Luo, X.; Miao, C. Effect of chloride salt, freeze–thaw cycling and externally applied load on the performance of the concrete. Cem. Concr. Res. 2002, 32, 1859–1864. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Y.M.; Yan, H.D.; Mu, R. Damage and damage resistance of high strength concrete under the action of load and freeze-thaw cycles. Cem. Concr. Res. 1999, 29, 1519–1523. [Google Scholar] [CrossRef]

- Desmettre, C.; Charron, J.P. Water permeability of reinforced concrete subjected to cyclic tensile loading. ACI Mater. J. 2014, 110, 78–87. [Google Scholar] [CrossRef]

- Rahman, M.K.; Al-Kutti, W.A.; Shazali, M.A.; Baluch, M.H. Simulation of Chloride Migration in Compression-Induced Damage in Concrete. J. Mater. Civ. Eng. 2012, 24, 789–796. [Google Scholar] [CrossRef]

- Zhou, J.G.; Wang, G.H.; Liu, P.; Guo, X.F.; Xu, J. Concrete Durability after Load Damage and Salt Freeze–Thaw Cycles. Materials 2022, 15, 4380. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Tang, S.W.; Zhao, G.S.; Chen, E. Comparison of three and one dimensional attacks of freeze-thaw and carbonation for concrete samples. Constr. Build. Mater. 2016, 127, 596–606. [Google Scholar] [CrossRef]

- Zhou, J.G.; Wang, G.H.; Xu, J. Experimental Evaluation of the Concrete Damage and Pore Characteristics under Salt-Freezing Cycles. Materials 2022, 15, 4454. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.H.; Xu, R.H.; Liu, K.; Sun, S.H. Research progress on durability of marine concrete under the combined action of Cl− erosion, carbonation, and dry–wet cycles. Rev. Adv. Mater. Sci. 2022, 61, 622–637. [Google Scholar] [CrossRef]

- Papanikolaou, V.K.; Kappos, A.J. Confinement-sensitive plasticity constitutive model for concrete in triaxial compression. Int. J. Solids Struct. 2007, 44, 7021–7048. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, W.J.; Zhao, Y.G.; Zhang, X.G. Prediction of concrete failure time based on statistical properties of compressive strength. Appl. Sci. 2020, 10, 815. [Google Scholar] [CrossRef]

- Weng, G.Y. Concrete Structure and Masonry Structure; Beijing Institute of Press: Beijing, China, 2018; (In Chinese). [Google Scholar] [CrossRef]

- Lange, D.A. Long-Term Strength Development of Pavement Concretes. J. Mater. Civ. Eng. 1994, 6, 78–87. [Google Scholar] [CrossRef]

- Comite Euro-International Du Beton. CEB-FIP Model Code 1990; Thomas Telford Services Ltd.: London, UK, 1993; pp. 51–52. Available online: https://vdocument.in/ceb-fip-model-code-1990pdf.html?page=1 (accessed on 23 March 2023).

| Literature | Models at Elevated Temperature |

|---|---|

| ASCE Manuals (1992) [102] | |

| Chang et al. (2006) [103] | |

| Krishna et al. (2019) [39] |

| Service Age (Year) | Normalized Compressive Strength |

|---|---|

| 0 | 1.0 |

| 1 | 1.38 |

| 2 | 1.411 |

| 2.5 | 1.347 |

| 3 | 1.41 |

| 5 | 1.5 |

| 7 | 1.336 |

| 10 | 1.53 |

| 12 | 1.344 |

| 17 | 1.351 |

| 20 | 1.58 |

| 24 | 1.40 |

| 25 | 1.56 |

| 30 | 1.35 |

| 45 | 1.21 |

| 60 | 1.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Yue, Q. The Time Variation Law of Concrete Compressive Strength: A Review. Appl. Sci. 2023, 13, 4947. https://doi.org/10.3390/app13084947

Wang W, Yue Q. The Time Variation Law of Concrete Compressive Strength: A Review. Applied Sciences. 2023; 13(8):4947. https://doi.org/10.3390/app13084947

Chicago/Turabian StyleWang, Weina, and Qingxia Yue. 2023. "The Time Variation Law of Concrete Compressive Strength: A Review" Applied Sciences 13, no. 8: 4947. https://doi.org/10.3390/app13084947

APA StyleWang, W., & Yue, Q. (2023). The Time Variation Law of Concrete Compressive Strength: A Review. Applied Sciences, 13(8), 4947. https://doi.org/10.3390/app13084947