Influences of Microwave Irradiation on Rock-Breaking Efficiency of a Reduced-Scale TBM Cutter

Abstract

1. Introduction

2. Test Device, Samples, and Test Methods

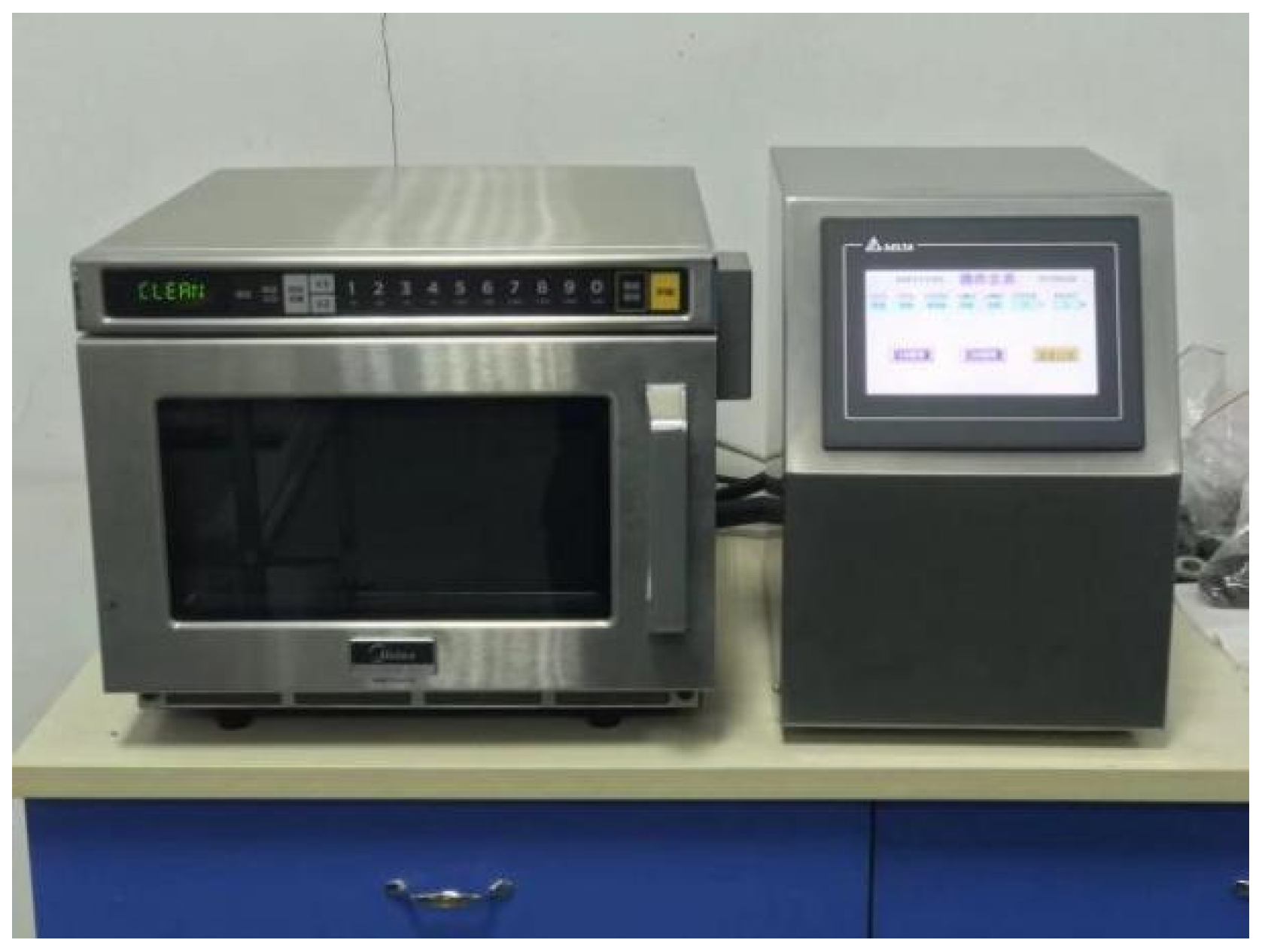

2.1. Test Device

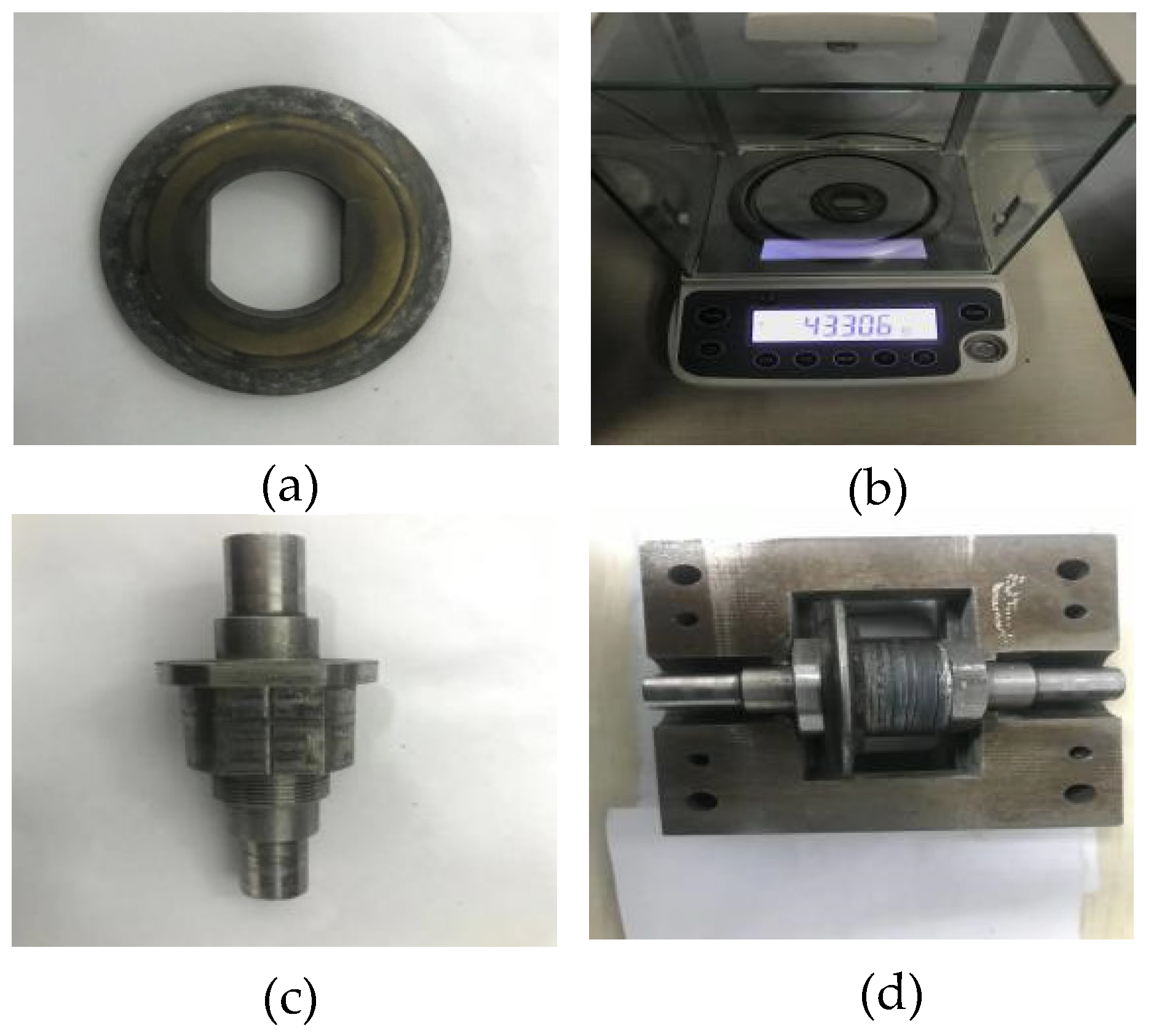

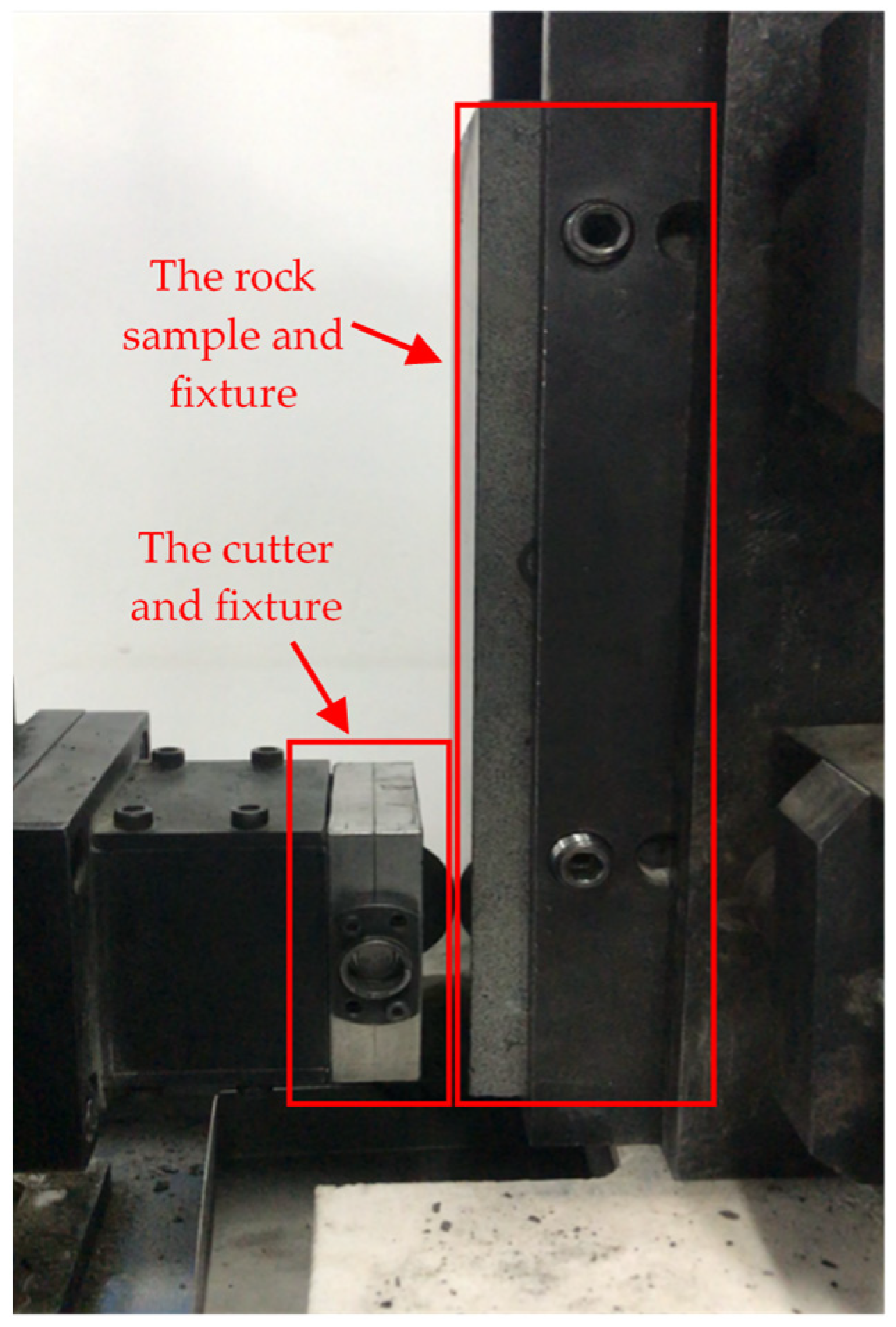

2.2. Samples and Test Methods

3. Test Results and Analysis

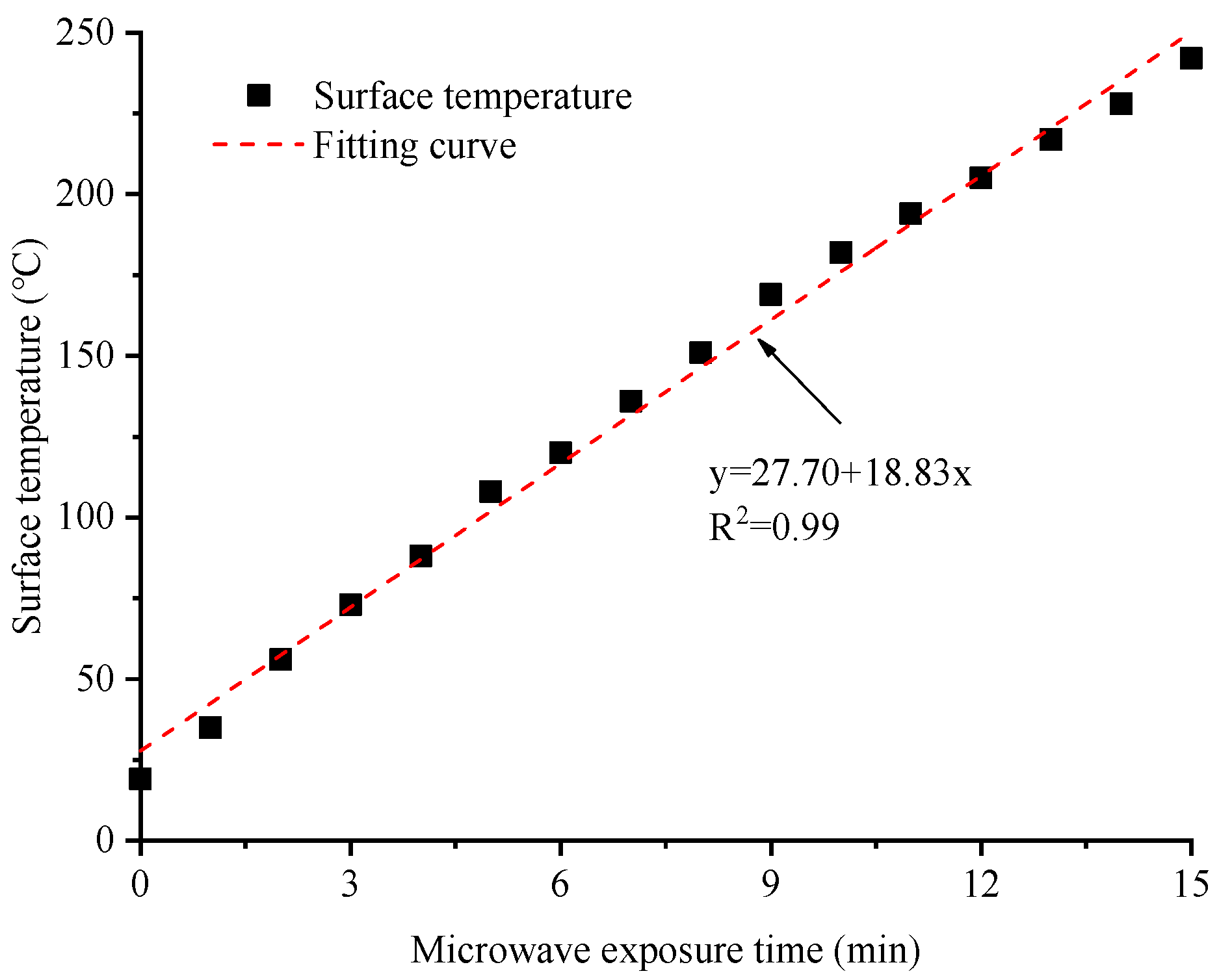

3.1. Microwave Heating Effect

3.2. Cutter Wear

3.3. Cutting and Rock-Breaking Effects

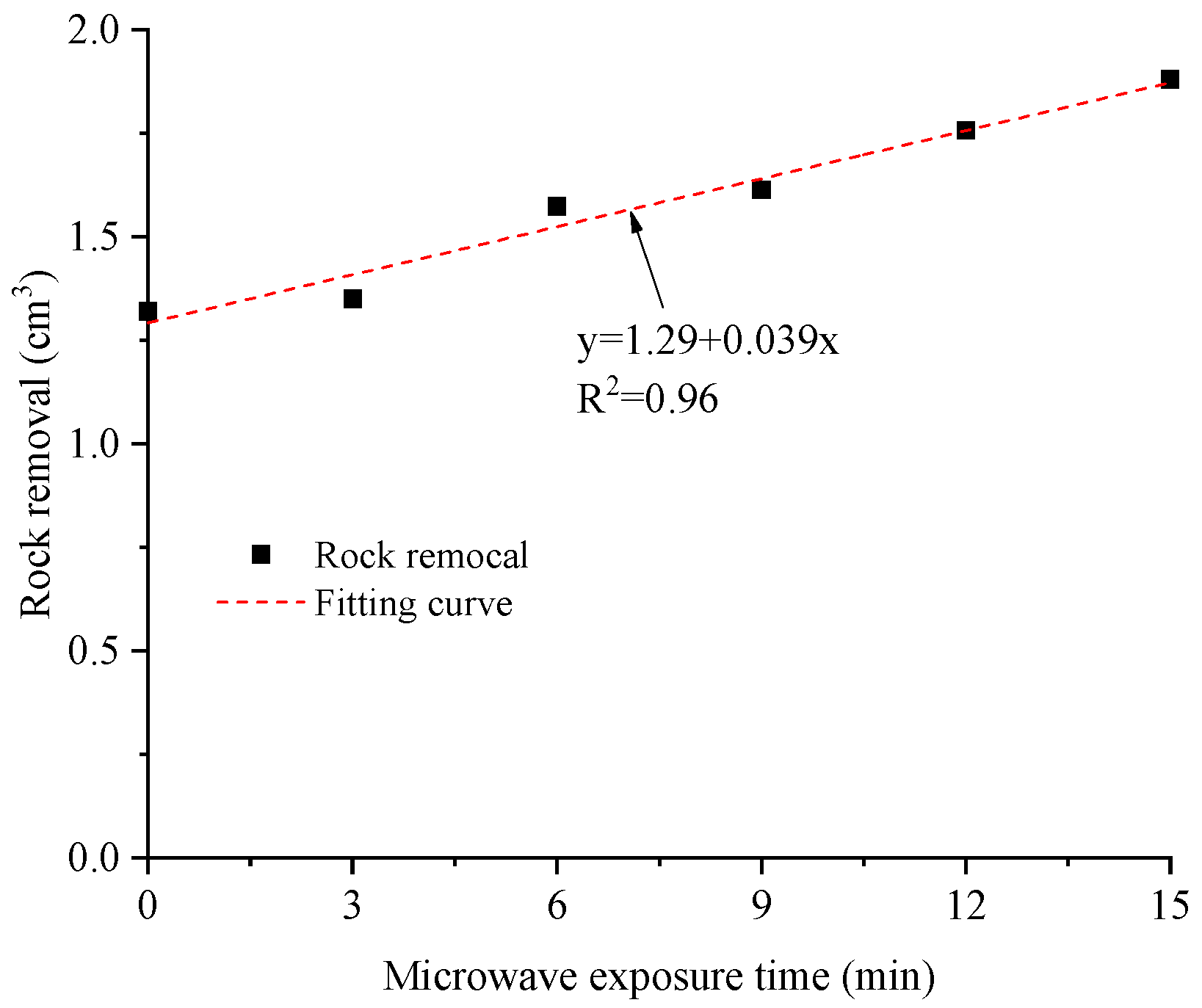

3.4. Rock Removal

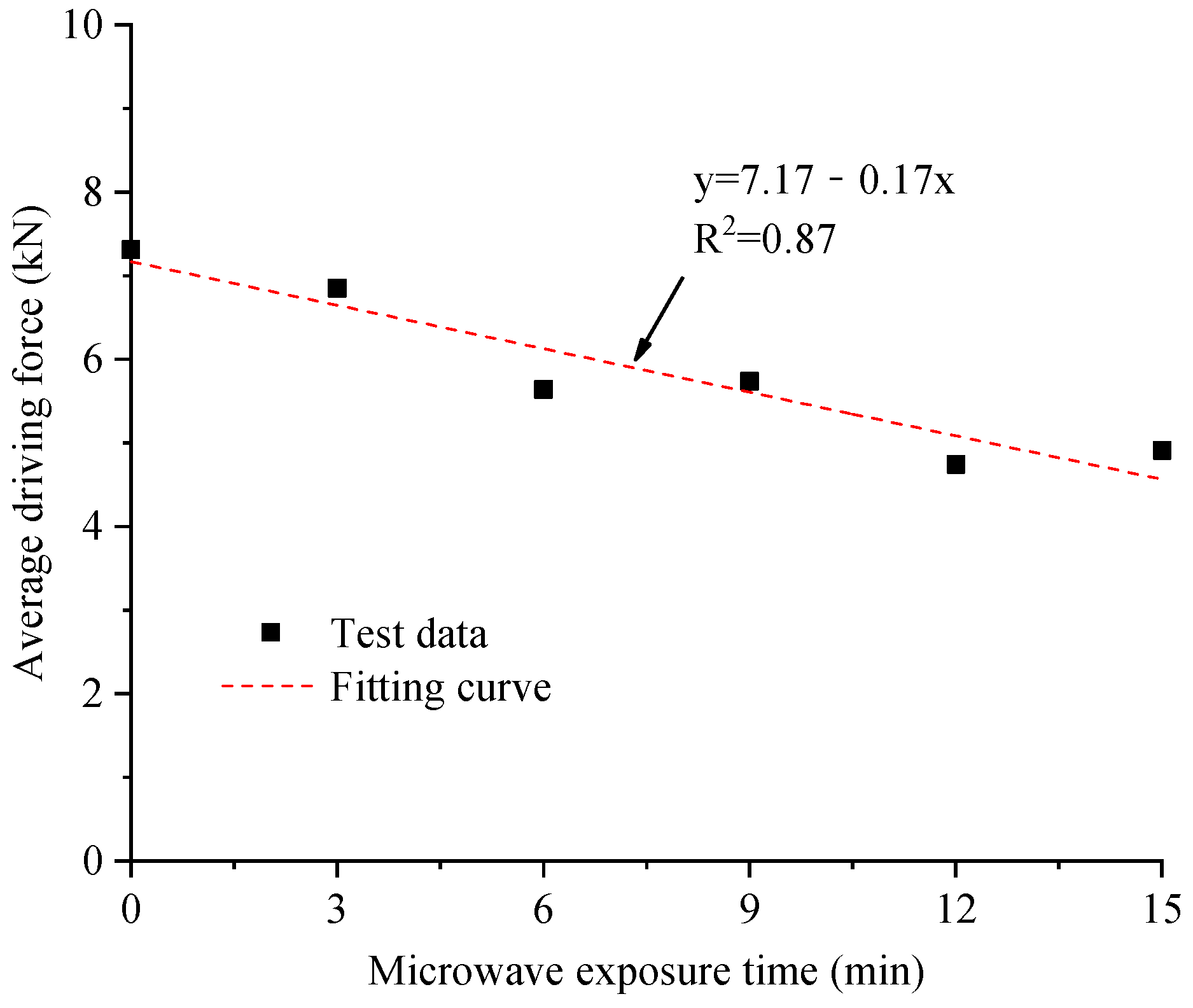

3.5. Cutting Force of the Cutter

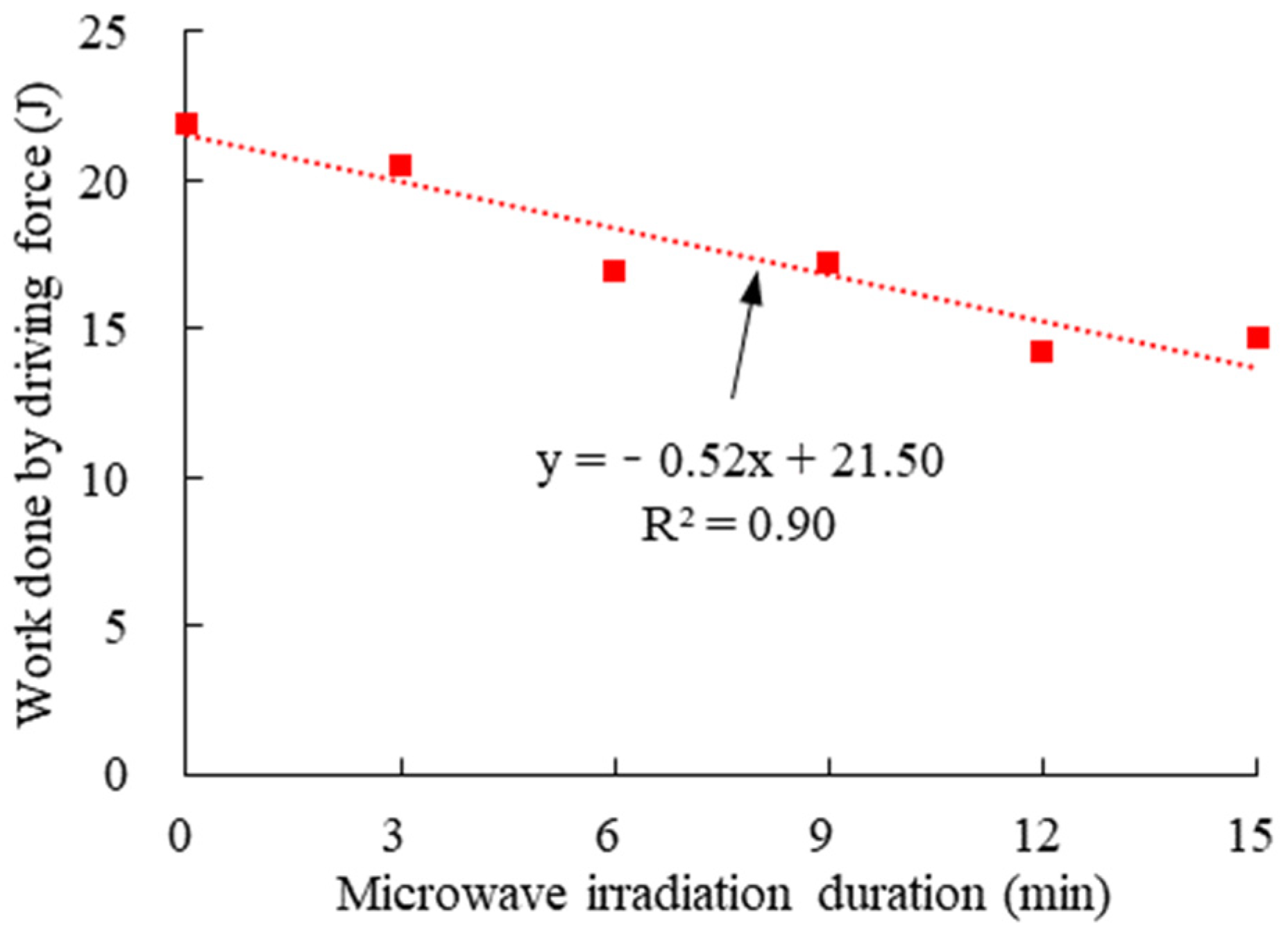

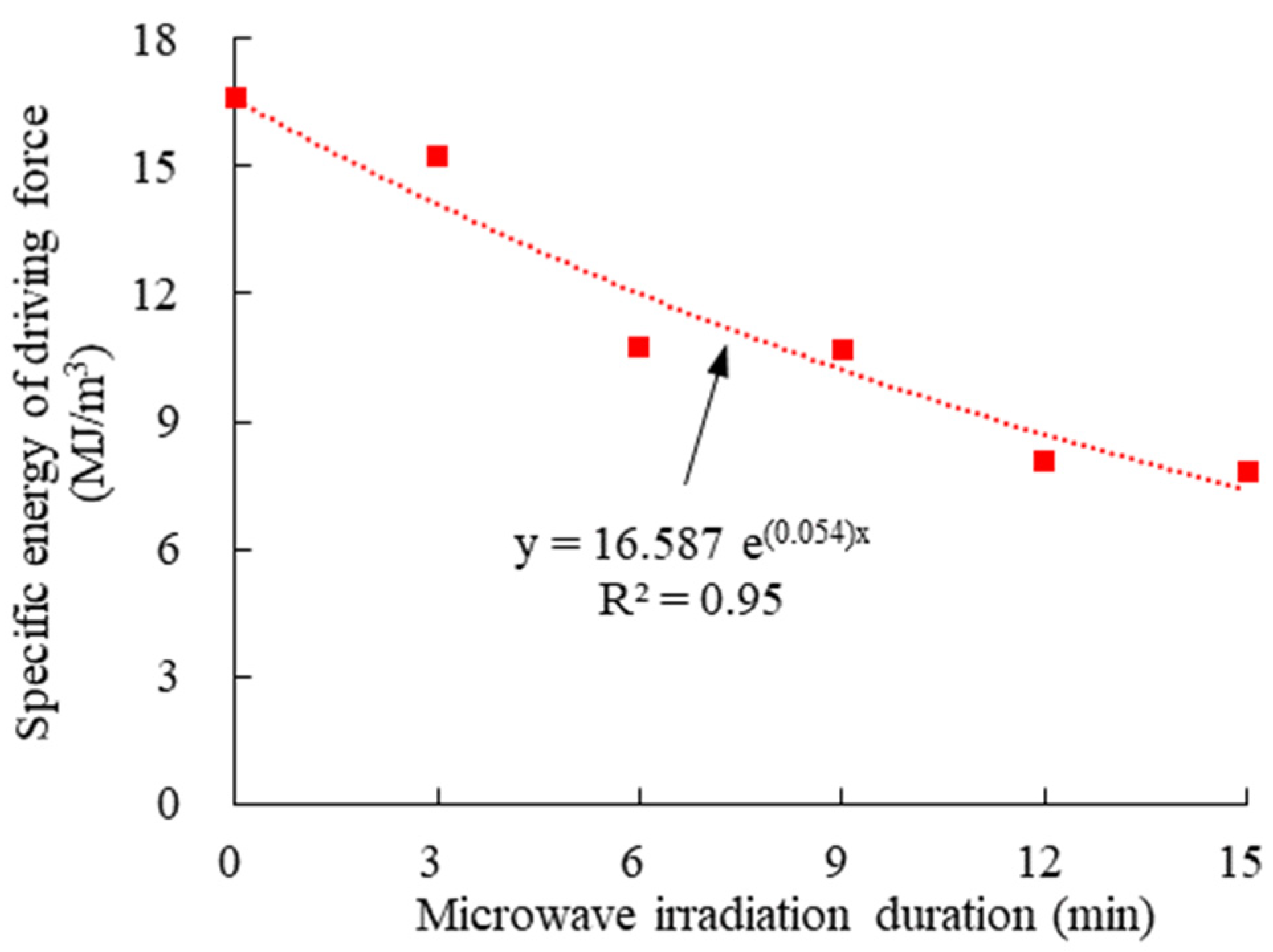

3.6. The Work Done by Cutting Force and the Specific Energy Associated Therewith

4. Discussion

5. Conclusions

- (1)

- Microwave irradiation causes some damage to both the surface and interior of the basalt samples. Under a fixed microwave power input, the wear loss of the reduced-scale TBM cutter is decreased, while the amount of rock removed increases upon prolonged exposure to microwave irradiation. This indicates that microwave irradiation can reduce wear, prolong service life, and increase the amount and rate of rock removal of the cutter.

- (2)

- After microwave irradiation of the rock, the cutting force of the reduced-scale TBM cutter decreases linearly with increasing exposure to microwave irradiation, and the average driving force and the average rolling force separately reduce by 33% and 32% (at most). This suggests that microwave irradiation can reduce the thrust and torque on the cutter head in the TBM tunnelling process.

- (3)

- The work done by the driving force and that done by the rolling force decrease linearly with increasing exposure to microwave irradiation, implying that microwave irradiation can decrease the energy consumption of the TBM cutter. The energy associated with the work done by the driving force is 0.08% of that associated with the work done by the rolling force, suggesting that the energy consumption of the TBM cutter is mainly attributed to the rolling force.

- (4)

- After microwave irradiation of rock, the specific energy of the reduced-scale TBM cutter to reach the same penetration depth constantly decreases with increasing exposure to microwave irradiation. The rock-breaking specific energy decreases with increasing exposure to microwave irradiation in an exponential manner. This indicates that microwave irradiation can reduce the specific energy consumption of the TBM cutter when breaking rock, thus also improving the efficiency of the process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hong, K.R.; Feng, H.H. Development and thinking of tunnels and underground engineering in china in recent 2 years. Tunn. Constr. 2021, 41, 1259–1280. [Google Scholar]

- Entacher, M.; Lorens, S.; Galler, R. Tunnel boring machine performance prediction with scaled rock cutting tests. Int. J. Rock Mech. Min. Sci. 2014, 70, 450–459. [Google Scholar] [CrossRef]

- Rostami, J. Performance prediction of hard rock Tunnel Boring Machines (TBMs) in difficult ground. Tunn. Undergr. Space Technol. 2016, 57, 173–182. [Google Scholar] [CrossRef]

- Evans, I.; Pomeroy, C.D. The Strength, Fracture and Workability of Coal; Elsevier: Amsterdam, The Netherlands, 1966. [Google Scholar]

- Ozdemir, L.; Wang, F.D. Mechanical tunnel boring prediction and machine design. Nasa Sti./Recon. Tech. Rep. N. 1979, 15, 332. [Google Scholar] [CrossRef]

- Sanio, H.P. Prediction of the performance of disc cutters in anisotropic rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1985, 22, 153–161. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Fei, S. The three-dimension model for the rock-breaking mechanism of disc cutter and analysis of rock-breaking forces. Chin. J. Mech. Mech. Engl. Ed. 2012, 28, 8. [Google Scholar] [CrossRef]

- Kotwica, K.; Stopka, G. The Cutting Resistance of Rock Salt in Function of Temperature. New Trends Prod. Eng. 2020, 3, 211–220. [Google Scholar] [CrossRef]

- Makowski, P.; Bednarek, U.; Kotwica, K.; Stopka, G. The Effect of Temperature on Mechnical Properties and Cuttability of Rock Salt. New Trends Prod. Eng. 2019, 2, 384–393. [Google Scholar] [CrossRef]

- Kotwica, K. Atypical and innovative tool, holder and mining head designed for roadheaders used to tunnel and gallery drilling in hard rock. Tunn. Undergr. Space Technol. 2018, 82, 493–503. [Google Scholar] [CrossRef]

- Xia, Y.M.; Xue, J.; Zhou, X.W. Rock fragmentation process and cutting characteristics on shield cutter. J. Cent. South Univ. 2011, 42, 954–959. [Google Scholar]

- Ou, Y.T. Development and Application of Cutting Performance Test Bench for Disk Cutter; Central South University: Changsha, China, 2014. [Google Scholar]

- Han, W.F.; Chen, K.; Li, F.Y.; Zhang, B. Development of composite hob abrasion test bench. Constr. Mech. 2015, 36, 53–56. [Google Scholar]

- Sun, Z.C.; Zhao, H.L.; Hong, K.R.; Chen, K.; Zhou, J.J.; Li, F.Y.; He, R. A practical TBM cutter wear prediction model for disc cutter life and rock wear ability. Tunn. Undergr. Space Technol. 2019, 85, 92–99. [Google Scholar] [CrossRef]

- Chen, T.T.; Dutrizac, J.E.; Haque, K.E.; Wyslouzil, W.; Kashyap, S. Relative transparency of minerals to microwave radiation. Can. Metall. Q. 1984, 23, 349–351. [Google Scholar] [CrossRef]

- Walkiewice, J.W.; Kazonich, G.; Mcgill, S.L. Microwave heating characteristics of selected minerals and compounds. Miner. Metall. Process 1988, 39, 39–42. [Google Scholar]

- Walkiewicz, J.W.; Lindroth, D.P.; Mcgill, S.L. Microwave assisted grinding. IEEE Trans. Ind. Appl. 1991, 27, 239–242. [Google Scholar] [CrossRef]

- Xu, T.; Yuan, Y.; Heap, M.J.; Zhou, G.L.; Perera, M.S.A.; Ranjith, P.G. Microwave-assisted Damage and Fracturing of Hard Rocks and Its Implications for Effective Mineral Resources Recovery. Miner. Eng. 2021, 160, 106663. [Google Scholar] [CrossRef]

- Zheng, Y.L.; He, L. TBM tunneling in extremely hard and abrasive rocks: Problems, Solutions and Assisting Methods. J. Cent. South Univ. 2021, 28, 454–480. [Google Scholar] [CrossRef]

- Lu, G.M.; Zhou, J.J.; Li, Y.H.; Zhang, X.; Gao, W. The influence of minerals on the mechanism of microwave-induced fracturing of rocks. J. Appl. Geophys. 2020, 180, 1–11. [Google Scholar] [CrossRef]

- Hartlieb, P.; Leindl, M.; Kuchar, F.; Antretter, T.; Moser, P. Damage of basalt induced by microwave irradiation. Miner. Eng. 2012, 31, 82–89. [Google Scholar] [CrossRef]

- Hartlieb, P.; Kuchar, F.; Moser, P.; Kargl, H.; Restner, U. Reaction of different rock types to low-power (3.2 kW) microwave irradiation in a multimode cavity. Miner. Eng. 2018, 118, 37–51. [Google Scholar] [CrossRef]

- Hartlieb, P.; Toifl, M.; Kuchar, F.; Meisels, R.; Antretter, T. Thermo-physical properties of selected hard rocks and their relation to microwave-assisted comminution. Miner. Eng. 2016, 91, 34–41. [Google Scholar] [CrossRef]

- Qin, L.K.; Dai, J. Analysis on the growth of different shapes of mineral microcracks in microwave field. Frat. Ed. Integrità Strutt. 2016, 10, 342–351. [Google Scholar]

- Lu, G.M.; Feng, X.T.; Li, Y.H.; Zhang, X. The microwave-induced fracturing of hard rock. Rock Mech. Rock Eng. 2019, 52, 3017–3032. [Google Scholar] [CrossRef]

- Lu, G.M.; Zhou, J.J.; Zhang, L.M.; Gao, W.Y. Experimental investigation on the influence of microwave exposure on the cutting performance of TBM disc cutter cutting of hard rocks. Results Eng. 2021, 12, 100285. [Google Scholar] [CrossRef]

- Lu, G.M.; Feng, X.T.; Li, Y.H.; Zhang, X. Influence of microwave treatment on mechanical behaviour of compact basalts under under different confining pressures. J. Rock Mech. Geotech. Eng. 2020, 12, 213–222. [Google Scholar] [CrossRef]

- Gong, Q.M.; Wu, F.; Duan, L.J. Experimental study on the rock mixed ground under disc cutter by linear cutting. Hazard Control Tunn. Undergr. Eng. 2019, 1, 67–73. [Google Scholar]

- Pan, Y.C.; Liu, Q.S.; Peng, X.X.; Liu, Q.; Liu, J.P.; Huang, X.; Cui, X.Z.; Tao, C. Full-scale linear cutting tests to propose some empirical formulas for TBM disc cutter performance prediction. Rock Mech. Rock Eng. 2019, 52, 4763–4783. [Google Scholar] [CrossRef]

- Hassani, F.; Shadi, A.; Rafezi, H.; Sasmito, A.P.; Ghoreishi-Madiseh, S.A. Energy analysis of the effectiveness of microwave-assisted fragmentation. Miner. Eng. 2020, 159, 106642. [Google Scholar] [CrossRef]

| Serial No. of Cutters | Microwave Power (W) | Increasing Exposure to Microwave Irradiation (min) | The First Cutting Mark (mg) | The Second Cutting Mark (mg) | Total (mg) |

|---|---|---|---|---|---|

| W-5 | 2100 | 0 | 2 | 3 | 5 |

| W-6 | 2100 | 3 | 2 | 2 | 4 |

| W-7 | 2100 | 6 | 2 | 2 | 4 |

| W-8 | 2100 | 9 | 1 | 2 | 3 |

| W-9 | 2100 | 12 | 1 | 2 | 3 |

| W-10 | 2100 | 15 | 1 | 1 | 2 |

| Serial No. of Samples | Increasing Exposure to Microwave Irradiation (min) | Initial State | The First Cutting Mark | The Second Cutting Mark | Rock Debris | Mass of Rock Debris (g) |

|---|---|---|---|---|---|---|

| X-1 | 0 |  |  |  |  | 3.96 |

| X-2 | 3 |  |  |  |  | 4.05 |

| X-3 | 6 |  |  |  |  | 4.72 |

| X-4 | 9 |  |  |  |  | 4.84 |

| X-5 | 12 |  |  |  |  | 5.27 |

| X-6 | 15 |  |  |  |  | 5.64 |

| Exposure time (min) | 0 | 3 | 6 | 9 | 12 | 15 |

| Average driving force (kN) | 7.31 | 6.85 | 5.64 | 5.74 | 4.74 | 4.91 |

| Exposure time (min) | 0 | 3 | 6 | 9 | 12 | 15 |

| Average rolling force (kN) | 0.72 | 0.65 | 0.64 | 0.51 | 0.53 | 0.49 |

| Exposure time (min) | 0 | 3 | 6 | 9 | 12 | 15 |

| Work done (J) | 21.93 | 20.55 | 16.92 | 17.22 | 14.22 | 14.73 |

| Exposure time (min) | 0 | 3 | 6 | 9 | 12 | 15 |

| Work done (J) | 27,000 | 24,375 | 24,000 | 19,125 | 19,875 | 18,375 |

| Exposure time (min) | 0 | 3 | 6 | 9 | 12 | 15 |

| Specific energy (MJ/m3) | 16.61 | 15.22 | 10.75 | 10.67 | 8.09 | 7.84 |

| Exposure time (min) | 0 | 3 | 6 | 9 | 12 | 15 |

| Specific energy (MJ/m3) | 20,455 | 18,056 | 15,254 | 11,854 | 11,314 | 9774 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, G.; Ding, C.; Zhou, J.; Liu, H.; Liu, C. Influences of Microwave Irradiation on Rock-Breaking Efficiency of a Reduced-Scale TBM Cutter. Appl. Sci. 2023, 13, 4713. https://doi.org/10.3390/app13084713

Lu G, Ding C, Zhou J, Liu H, Liu C. Influences of Microwave Irradiation on Rock-Breaking Efficiency of a Reduced-Scale TBM Cutter. Applied Sciences. 2023; 13(8):4713. https://doi.org/10.3390/app13084713

Chicago/Turabian StyleLu, Gaoming, Cong Ding, Jianjun Zhou, Haining Liu, and Chaoyin Liu. 2023. "Influences of Microwave Irradiation on Rock-Breaking Efficiency of a Reduced-Scale TBM Cutter" Applied Sciences 13, no. 8: 4713. https://doi.org/10.3390/app13084713

APA StyleLu, G., Ding, C., Zhou, J., Liu, H., & Liu, C. (2023). Influences of Microwave Irradiation on Rock-Breaking Efficiency of a Reduced-Scale TBM Cutter. Applied Sciences, 13(8), 4713. https://doi.org/10.3390/app13084713