Abstract

Volatile fatty acids can be used as a cheap carbon source for biotechnological lipid production with oleaginous yeasts, but one factor limiting their large-scale use is their inherent cytotoxicity. Developing a suitable cultivation strategy can help mitigate the adverse effect volatile fatty acids have, since these effects are strongly dependent on concentration and pH. This work shows that, by employing a pH-stat fed-batch approach for the cultivation of Apiotrichum brassicae V134 and Pichia kudriavzevii V194, lipid contents above 56 g/100 g dry cell weight and dry cell weight concentrations above 30 g/L can be reached. Furthermore, volumetric lipid productivities up to 0.29 g/Lh could be achieved using acetic and propionic acid as a sole carbon source. It was also demonstrated that the developed process is robust and scalable. Scale-up to the 500 L scale resulted in a similar lipid yield, dry cell weight (31–37 g/L), and single cell oil content (56 g/100 g dry cell weight–58 g/100 g dry cell weight). The main fatty acid present in the produced lipids was oleic acid (36–43%), but also odd-numbered fatty acids, especially heptadecanoic acid (7–15%), were present. Additionally, different methods for the pretreatment of biomass prior to lipid extraction were assessed, and the iodine value (48), peroxide value (7.3), and acid value (4.3) of the extracted single cell oil were determined.

1. Introduction

Oleaginous yeasts are of biotechnological interest due to their ability to synthesize lipids from various carbon sources. These lipids, called single cell oil (SCO), are accumulated intracellularly as storage compounds for carbon and energy if a limitation of nutrients such as nitrogen or phosphorous prevents growth but carbon is available in excess. Lipid content in the dry biomass of oleaginous yeasts usually ranges from a defined lower limit of 20 g/100 g dry cell weight (DCW) to approximately 70 g/100 g DCW [1]. Research into oleaginous yeasts focuses heavily on five well-known species: Yarrowia lipolytica, Rhodotorula toroluides (previously Rhodosporidium toruloides), Rhodotorula glutinis, Cutaneotrichosporon curvatus (previously Cryptococcus curvatus), and Lipomyces starkeyi account for 90% of publications on oleaginous yeasts since 1950 [2].

For many years, research on oleaginous yeasts has been intertwined with the generation of additional value by producing lipids from materials considered as waste [3,4]. The use of such materials poses various challenges but offers the advantage of being comparably inexpensive. This is an important factor, since substrate costs are reported to be responsible for 50–80% of the costs for microbial lipid production [2]. Another aspect favoring the use of waste-derived substrates for lipid production is the competition between food, feed, and fuel for biomass. While the demand for biofuels and other biomass-based renewable energy forms is ever increasing, the land available for biomass production is limited. This dilemma can be partly overcome by the efficient reuse of waste biomass [5]. The range of substrates investigated in this context includes industrial by-products such as crude glycerol [6,7] and many waste derived materials, such as biomass hydrolysates [8,9,10], food wastes [4], and volatile fatty acids (VFAs) [11,12,13,14].

In particular, the use of VFAs offers several advantages. By employing a shortened anaerobic digestion (AD) process, VFAs can be produced from a range of heterogenous waste streams at low cost [15]. Such waste streams, like biowaste or food waste, are at the moment mainly composted or treated with AD to generate methane [16], but they contain various carbohydrates, proteins, and lipids that can be converted to VFAs during the hydrolysis and acidification stage of AD [13]. The uncomplicated pretreatment of the biomass and low associated costs, as well as a wide range of materials available for AD-based VFA production, make VFAs a promising carbon source for heterotrophic lipid production [2], and calculations suggest that VFA-based lipid production offers a high theoretical lipid yield [17].

VFAs at high concentrations or low pH-values, however, have a cytotoxic effect on the yeasts, since the undissociated, uncharged acids can pass the cell membrane at these conditions and change the intracellular pH [12]. The most common approach to preventing this effect in batch fermentations is using low VFA concentrations [10,18,19,20]. Ultimately, this approach severely limits the volumetric lipid productivity. A way to overcome this hurdle is to implement a fed-batch process with an appropriate feed strategy. In this way, the amount of metabolized VFA can be increased while keeping the VFA concentrations in the reactor at a low level [6].

The present study describes how the use of an acidic VFA feed for pH control (pH-stat fed-batch) can be applied to produce lipids in the two yeast strains Apiotrichum brassicae V134 and Pichia kudriavzevii V194. Both strains were recently identified as promising lipid producers. A screening of natural isolates showed that both strains are able to accumulate lipid contents above 55 g/100 g DCW using acetic acid (HAc) as a carbon source [21]. It was also demonstrated that both strains are not only able to utilize HAc, but also other VFAs such as propionic acid (HPr), butyric acid, valeric acid, and caproic acid [22]. These characteristics make both strains promising candidates for the purpose of the present study. Furthermore, the use of the species Apiotrichum brassicae and Pichia kudriavzevii for the present study allows us to gain further insight into the lipid production potential of these oleaginous yeasts, since the literature on both strains is rather scarce in this context. Apart from the mentioned publications [21,22] and our previous study [23], Apiotrichum brassicae, basionym Trichosporon brassicae Nakase [24], is to the best of our knowledge only once described as a lipid producer [25]. Oleaginous Pichia kudriavzevii strains have previously been described, but either the lipid content [26,27] or the lipid concentration [28] was reported to be rather low.

The aim of this study is to show that both strains can reach comparably high biomass concentrations and lipid contents. It is to be demonstrated that this process is scalable to the 500 L scale, and scale-related problems during fermentation, harvest, and extraction are to be identified. The experiments are performed in already installed bioreactors of various scales and different geometries. Therefore, the intention is not a process engineering type of scale-up employing mathematical models [29]. The chosen approach rather allows us to investigate the robustness of the process and to produce larger quantities of biomass to assess lipid extraction and to characterize the lipids produced in terms of their fatty acid patterns and certain quality parameters. The authors also aim to investigate the effect of different methods for biomass pretreatment prior to lipid extraction in laboratory scale. Subsequently, lipid extraction is to be demonstrated in pilot scale.

2. Materials and Methods

2.1. Yeast Strains

In this study, the oleaginous yeast strains Apiotrichum brassicae V134 and Pichia kudriavzevii V194 were used. These natural isolates were provided by the Centre of Molecular and Environmental Biology, University of Minho (Portugal). DNA sequences of both strains are available in the NCBI GenBank database under the accession numbers MN913458 (V134) and MN913463 (V194) [21].

2.2. Media

A modified yeast extract peptone dextrose medium (YPD) was used for pre-culture preparation. For the cultivation of A. brassicae, the amount of yeast extract (Ohly KAT, Ohly, Hamburg, Germany) was reduced from the original 10 g/L to 3.88 g/L, and the amount of peptone (Casein Peptone E1 19546, Organotechnie, La Courneuve, France) was reduced from the original 20 g/L to 2.53 g/L. The glucose concentration was 20 g/L (Carl Roth, Karlsruhe, Germany). In the case of P. kudriavzevii, the amount of yeast extract was reduced to 5 g/L and the amount of peptone (Soy Peptone E110 19885, Organotechnie, La Courneuve, France) to 1.7 g/L. The respective amounts of yeast extract and peptone were also used during the cultivation of both strains in bioreactors, but no glucose was added to the medium in this case.

2.3. Cultivation in Laboratory Scale

Both strains were first cultivated in a parallel benchtop bioreactor system (DASGIP, Eppendorf, Hamburg, Germany) with a total reactor volume of 1.4 L each. Pre-culture was prepared by inoculating 100 mL of the respective fermentation medium in 300 mL baffled shake flasks with 500 µL of cryo-culture and incubating the flasks in a rotary shaker (130 rpm, 30 °C) for 24 h. This resulted in an inoculum with an OD600 in the range of 25–30. An amount of 40 mL of this pre-culture was used to inoculate 360 mL of fermentation medium. Furthermore, 0.3 g/L of acetic acid (Carl Roth, Karlsruhe, Germany), 0.2 g/L of propionic acid (Sigma-Aldrich, St. Louis, MI, USA), and 100 µL of antifoaming agent (Glanapon DG160, Bussetti, Vienna, Austria) were added at the beginning of all fermentations. During the fermentations, the pH was set to 6.0 by the addition of either 2 M NaOH or a VFA mixture consisting of 150 g/L acetic acid (HAc) and 100 g/L propionic acid (HPr) (ratio HPr/HAc = 0.54 mol/mol), which simultaneously acted as a carbon source feed in a pH-stat fed-batch process. The consumption of VFAs caused an increase in the pH, which was in turn counteracted by the addition of a new VFA feed, thus the VFA concentration and the pH in the reactor could be kept stable. The dissolved oxygen (DO) level was maintained above 20% of the maximum oxygen saturation. This was achieved by controlling oxygen transfer by means of varying the stirrer speed (400 to 1600 rpm). Aeration was kept at a constant rate of 35 L/h throughout the process. The temperature was set to 30 °C. All fermentations in laboratory scale were performed in duplicate.

2.4. Cultivation in Small Pilot Scale

Both strains were subsequently cultivated in a modular 130 L bioreactor (Mavag AG, Neunkirch, Switzerland). The reactor is realized as a mixture of stainless steel and glass modules with a round bottom and a height-to-diameter ratio of 1:0.17. Mixing was achieved by using three six-blade disc agitation elements mounted on a coaxial stirrer shaft. Aeration was provided through a ring sparger placed below the lowest agitation element. The respective medium solutions were sterilized in situ, and, after the initial VFA concentration was set to 1 g/L of HAc and 0.5 g/L HPr, the pH was adjusted to pH 6.0. The starting volume for the fermentation was 45 L, including 1.8 L of pre-culture. The pre-culture was prepared by inoculating two 3 L baffled shake flasks containing 900 mL medium with 5 mL of cryo-culture and incubating them for 27 h at 30 °C in a rotary shaker (130 rpm). This resulted in an inoculum with an OD600 in the range of 20–25. The pH in the reactor was monitored and maintained throughout the fermentation by the addition of 2 M NaOH or a VFA mix composed of 195 g/L HAc and 65 g/L HPr (ratio HPr/HAc = 0.27 mol/mol). The composition of the VFA mixture was changed in comparison to the laboratory scale to better reflect the composition of a VFA mixture derived from the AD of food wastes [16]. The DO setpoint was again kept at 20% of the maximum oxygen saturation. Aeration was controlled using an automated valve in order to maintain the DO setpoint. Airflow increased from 4.3 L/min at the beginning of the fermentation to a maximum of 143.3 L/min. Mixing was provided using a fixed stirrer speed of 200 rpm. Antifoaming agent (10 mL, Glanapon DG160, Bussetti, Vienna, Austria) was added to the reactor prior to the in situ sterilization of the medium. The temperature was maintained at 30 °C. The fermentations were stopped after 65 h (strain V194) and 66 h (strain V134) due to an increase in DO, indicating a decrease in metabolic activity.

2.5. Cultivation in Pilot Scale

For the cultivation of strain V134 in pilot scale, a 1200 L bioreactor was used [30]. The reactor is realized as a double-jacket stainless steel tank with a round bottom and head. The height-to-diameter ratio of the reactor vessel is 1:0.48, and mixing was achieved by using a single six-bladed Rushton turbine impeller mounted on an eccentric stirrer shaft. Aeration was provided through a ring sparger placed below the impeller.

The starting volume for the fermentation was 500 L, including 4.5 L of pre-culture. The pre-culture was prepared by inoculating five 3 L baffled shake flasks containing 900 mL medium with 5 mL of cryo-culture each and incubating them for 27 h at 30 °C in a rotary shaker (130 rpm). This resulted in an inoculum with an OD600 in the range of 20–25. The pH was set to 6.0 with 5 M NaOH and an undiluted VFA mix composed of 76% (v/v) HAc (Donauchem, Vienna, Austria) and 24% (v/v) HPr (Donauchem, Vienna, Austria) (ratio HPr/HAc = 0.27 mol/mol). This concentrated VFA mix was used in pilot scale due to technical reasons. The DO setpoint was again defined at 20% of the maximum saturation. Aeration control was realized in the same way as described for the small pilot scale. In this case, the airflow increased from 16.5 L/min at the beginning of the fermentation to a maximum of 550 L/min. Mixing was provided using a fixed stirrer speed of 250 rpm. Antifoaming agent (50 mL) was added to the reactor prior to the in situ sterilization of the medium. Throughout the fermentation, a temperature of 30 °C was maintained.

2.6. Cell Harvest

Analytical samples were separated into a solid pellet and a cell-free supernatant by centrifugation and washed twice with deionized water. A final harvest of the cells was performed in a two-stage process in small pilot scale. First, the fermentation broth was concentrated using four Al2O3 cross-flow microfiltration membranes (pore size: 0.2 µm, module length: 1000 mm, 7 channels, total filter area: 0.13 m2, Atech, Gladbeck, Germany). The filtration was operated with a centrifugal pump (Hygia Bloc I/20B, GEA Hilge, Bodenheim, Germany) at a constant flow rate of 12 m3/h. The permeate was removed, and the resulting concentrated cell suspension was further concentrated by means of centrifuging for 20 min at 10,000× g in a laboratory centrifuge (Sorvall Lynx 4000, Thermo Fisher Scientific, Waltham, MA, USA). In pilot scale, the cell harvest was performed using a disc-stack centrifuge (Type NA 7-06-067/-576, throughput: 1000–2000 L/h, GEA Westfalia, Oelde, Germany), and the supernatant was discarded. The harvested biomass was frozen at −80 °C, and a part was lyophilized for further processing.

2.7. SCO Extraction

In laboratory scale, an accelerated solvent extraction procedure (ASE 350, DIONEX, Sunnyvale, CA, USA) was used to extract the SCO from lyophilized biomass of strain V134. The extraction was performed at 180 °C using a static extraction time of 5 min per cycle (6 cycles) at a pressure of 10 MPa. A flush volume of 75% of cell volume and a purge time of 90 s were applied. N-Hexane was used for the extraction with a solvent/biomass ratio of 50 mL per g DCW. The resulting extract was vacuum dried in a rotavapor (50 °C, water bath) and the SCO yield was measured gravimetrically.

Since methods for the pretreatment of the biomass are required to improve lipid recovery [31], four approaches for pretreatment prior to ASE extraction were evaluated. Wet biomass was subjected to chemical pretreatment using acid hydrolysis with 8% of H2SO4. The hydrolysis step was performed at 140 °C for 2 h. For mechanical cell disruption, a bead mill with a cylindrical vessel and a capacity of 1 L was used. The ceramic beads had a diameter of 15 mm. Lyophilized biomass was placed in a beaker with grinding beads and kept under orbital rotation overnight at ambient temperature. In an attempt to further improve lipid recovery, bead milling was used in combination with autolysis [32]. To induce autolysis of cells, the bead-milled biomass was mixed with water in a ratio of 1:1 (w/v) and stirred overnight at a temperature of 50 °C.

For the extraction of SCO in larger scale a miniPilot reactor (Büchi, Flawil, Switzerland) with a working volume of 5 L was used. An amount of 250 g lyophilized biomass was placed in the reactor vessel and treated with saturated steam for 5 min. Due to condensation, 1 L of water remained in the vessel. To induce cell lysis in the vessel, the mixture of lyophilized biomass and condensate was maintained at 90 °C for 30 min. Subsequently, the mixture was cooled down to 50 °C, and n-hexane was added to the reactor in a ratio of 1:1 (v/v). The mixture was stirred for another 30 min at 50 °C. The hexane phase was separated and the solvent evaporated until dryness under vacuum pressure.

2.8. Analysis of SCO Properties

Properties of the oil extracted using the miniPilot reactor were analyzed in regard to the iodine value according to the AOAC Official Method 920.159 [33], the peroxide value according to the AOAC Official Method 965.33 [34], and the acid value according to AOAC Official Method 940.28 [35].

2.9. Analysis of Lipid Content and FA Composition

The lipid content of the yeast biomass was determined according to an adapted version of the method described by Meesters et al. [36]. A 10–20 mg sample of freeze-dried yeast biomass was mixed with 2 mL of methanolic H2SO4 (15% v/v) and 2 mL chloroform. Methyl benzoate was used as an internal standard. After cooking this mixture for 2 h at 100 °C, it was cooled down to room temperature and mixed with 1 mL of deionized water to induce phase separation. The aqueous phase was discarded. The organic phase was neutralized and dried with Na2CO3 and Na2SO4, respectively, and analyzed by means of gas chromatography. The injection temperature used was 230 °C, and the split ratio was 50:1. For separation of the resulting fatty acid methyl esters (FAMEs), an HP-88 column (length: 100 m, inner diameter: 250 µm, film thickness 0.2 µm, Agilent, Santa Clara, CA, USA) was used. Hydrogen was used as the carrier gas; the flow was kept constant at 2 mL/min. A flame ionization detector was applied for the detection of FAMEs. Using an external calibration with a 37 component FAME mix (Supelco CRM 47885, Sigma-Aldrich, St. Louis, MO, USA) and the internal standard, FAME amounts were quantified. Furthermore, recovery was determined using a palm oil analytical standard (Sigma-Aldrich, St. Louis, USA).

2.10. Analysis of VFA Concentrations

The VFA concentration was measured in cell-free supernatant by performing HPLC. Samples were diluted to appropriate concentrations and Carrez precipitation was performed to remove proteins. For the column, a CARBOSep COREGEL 87H3 (Transgenomic, San Jose, CA, USA) column kept at 65 °C was used. The system was operated with isocratic elution using 5 mM H2SO4 as a mobile phase at a flow rate of 0.900 mL/min. Refractive index detection and an external calibration were used for quantification.

2.11. Analysis of Nitrogen, Phosphorous Content, and OD600

Nitrogen concentration was determined as Total Kjeldahl Nitrogen (TKN) [37]. TKN was determined from 3 mL of cell-free supernatant for each sample using an AutoKjeldahl Unit K-370 and a Digest Automat K-438 (both Büchi, Flawil, Switzerland). Phosphorous was determined using an LCK350 cuvette test kit (Hach, Loveland, CO, USA). The OD600 of pre-cultures was analyzed using a DR 3900 photometer (Hach, Loveland, CO, USA) blanked against deionized water. The samples were diluted with deionized water so that the measured value was in the range between 0.2 and 1.0 absorbance units.

3. Results

3.1. Cultivation

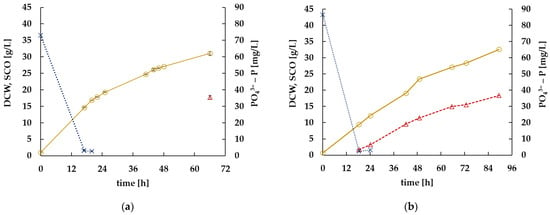

Using a pH-stat fed-batch approach and phosphate limitation (see Figure 1a), DCWs of approximately 30 g/L and an SCO content of approximately 58 g/100 g DCW could be reached in both strains (see Table 1). During the first 18 h of fermentations, phosphate limitation occurred (see Figure 1), inducing lipid production and resulting in volumetric lipid productivities of 0.296 g/Lh (strain V194) and 0.268 g/Lh (V134). The lipid yields (YP/S) reached were approximately 0.17 g SCO produced per g VFA used. In the course of the fermentation, HAc concentrations reached a maximum of 0.9 g/L, while the maximum HPr concentration was 1.3 g/L (Figures S1–S4; Table S1).

Figure 1.

Key parameters for cultivation of A. brassicae V134. Dry cell weight (DCW,  ) and single cell oil (SCO,

) and single cell oil (SCO,  ) are given as concentrations in g/L; the concentration of phosphate (

) are given as concentrations in g/L; the concentration of phosphate ( ) is given as concentration in mg P/L. (a) shows the course of the fermentation process in laboratory scale over 72 h. Cultivations were performed in duplicate. (b) shows the course of a fermentation process in small pilot scale over 96 h.

) is given as concentration in mg P/L. (a) shows the course of the fermentation process in laboratory scale over 72 h. Cultivations were performed in duplicate. (b) shows the course of a fermentation process in small pilot scale over 96 h.

) and single cell oil (SCO,

) and single cell oil (SCO,  ) are given as concentrations in g/L; the concentration of phosphate (

) are given as concentrations in g/L; the concentration of phosphate ( ) is given as concentration in mg P/L. (a) shows the course of the fermentation process in laboratory scale over 72 h. Cultivations were performed in duplicate. (b) shows the course of a fermentation process in small pilot scale over 96 h.

) is given as concentration in mg P/L. (a) shows the course of the fermentation process in laboratory scale over 72 h. Cultivations were performed in duplicate. (b) shows the course of a fermentation process in small pilot scale over 96 h.

Table 1.

Overview of key process parameters for strains A. brassicae V134 and P. kudriavzevii V194 in laboratory scale (400 mL starting volume), small pilot scale (45 L starting volume), and pilot scale (500 L starting volume). Results for laboratory scale are reported as mean values of two fermentation runs ± standard deviation (SD). Pilot scale results each relate to a single fermentation run.

Based on the findings in laboratory scale, the process was adapted to the small pilot scale. While DCWs, SCO contents, and lipid yields were comparable to the laboratory scale results, the volumetric lipid productivity dropped to 0.200 g/Lh in both strains (see Table 1) due to a longer fermentation duration (see Figure 1). HAc concentrations in small pilot scale varied in a range of 0.1 g/L to 2.1 g/L, and HPr concentrations varied in a range of 0.4 g/L to 3.2 g/L (Figures S5 and S6, Table S1).

Given a similar productivity and a slightly higher lipid yield in A. brassicae V134, this strain was chosen for a subsequent scale-up to the pilot scale. HAc concentrations in pilot scale varied in a range of 0.2 g/L to 0.9 g/L, and HPr concentrations varied in a range of 1.5 g/L to 2.4 g/L (Figures S7–S9, Table 1). The lipid yield and SCO content of the biomass were comparable to the smaller scale experiments, reaching 0.18 g/g VFA and 58 g/100 g DCW (see Table 1); however, the SCO concentration was higher, while the volumetric lipid productivity dropped further. The former is explained by the use of concentrated VFAs, eliminating the diluting effect feed addition has on the cell suspension in the smaller scale reactors. The decreased volumetric productivity is again attributed to an increase in fermentation duration by 51 h compared to small pilot scale.

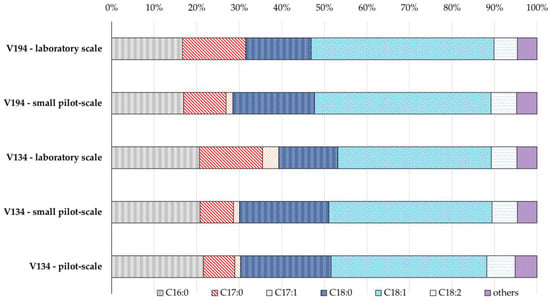

3.2. Fatty acid Spectrum

The fatty acid spectrum of the lipids produced was analyzed at the end of all fermentations (Figures S10–S24, Tables S2 and S3). In general, the share of the individual FAs in the lipids from the two different strains and at different scales was comparable. The highest share of the individual FAs was C18:1, reaching a share of approximately 42% in P. kudriavzevii V194 and approximately 37% in A. brassicae V134. Other FAs represented in larger proportions were C16:0, C18:0, C18:2, and C17:0 (see Figure 2, Table S4).

Figure 2.

Fatty acid spectrum of SCO produced from a mixture of HAc and HPr by P. kudriavzevii V194 and A. brassicae V134 in laboratory scale (starting volume = 400 mL, ratio HPr/HAc = 0.54 mol/mol), small pilot scale (starting volume = 45 L, ratio HPr/HAc = 0.27 mol/mol), and pilot scale for A. brassicae V134 (starting volume = 500 L, ratio HPr/Hac = 0.27 mol/mol).

When comparing the laboratory scale and pilot scale fermentations, a considerable change in the proportion of C17:0 and C18:0 is evident in both strains. This was expected, since a previous study [23] demonstrated that the share of odd-numbered FAs is strongly dependent on the share of HPr provided as a carbon source. Thus, the observed change in the FA spectrum is attributed to the described change of the HPr/HAc ratio in small pilot scale and pilot scale.

3.3. Extraction of SCO

For the assessment of extraction methods, biomass of strain V134 with an SCO content of 48.3 ± 0.5 g/100 g DCW according to analysis was used. ASE under the conditions stated above resulted in an extracted lipid amount of 17.8 ± 0.5 g/100 g DCW. By using a combination of pretreatment methods, the amount of extracted lipids could be increased up to 38.0 ± 0.15 g/100 g DCW (see Table 2). Furthermore, an alternative pretreatment method using acid hydrolysis on non-lyophilized biomass also yielded good results.

Table 2.

Comparison of different biomass pretreatment methods prior to ASE in laboratory scale. Results for laboratory scale are reported as mean values from three extractions each ± standard deviation (SD) values. The different pretreatments form homogeneous groups that are significantly different from each other at the 95% confidence level (LSD).

Bead milling in combination with autolysis was found to be most effective in improving lipid recovery. Due to high costs associated with the implementation of bead milling at large scale, the focus for the larger scale lipid extraction in the miniPilot system was concentrated on the sole use of autolysis [32]. The extraction of biomass in the miniPilot reactor (duplicates) resulted in a recovery of 52 ± 2.9%.

3.4. Analysis of SCO Properties

The lipids extracted in the miniPilot reactor were analyzed with regard to the quality parameters of iodine value, peroxide value, and acid value. The iodine value, which gives information on the saturation of the lipids, was determined to be 48.0 ± 1.2 [38]; the peroxide value is used to monitor lipid oxidation and was 7.28 ± 0.07 [39]; and the acid value, which gives information on the amount of free fatty acids in the lipids, was 4.27 ± 0.43 [40]. The extracted lipids showed a fatty acid distribution of 49.8% saturated fatty acids (SFA), 42.5% monounsaturated fatty acids (MUFA), and 8.2% polyunsaturated fatty acids (PUFA).

4. Discussion

4.1. Cultivation

The present study demonstrates that a SCO production process showing high productivity, SCO content, and biomass concentration, and relying solely on HAc and HPr as carbon sources, can be realized with a pH-stat fed-batch approach. Furthermore, it was shown that the developed process is robust, can be used for different organisms with only minor strain-specific modifications, and can readily be adapted to different scales.

In comparison to other VFA-based processes reported in the literature [8,20,41], both strains showed high DCW concentrations, with the DCWs reached in the present work being more than twice as high. The high DCW concentration is mainly attributed to the cultivation mode, since many values reported in the literature relate to batch cultivation, and the cytotoxic effect of VFAs prevents the use of high initial VFA concentrations, thus limiting the amount of available carbon [20]. When using various modes of fed-batch cultivation, DCWs similar to or above the DCWs reported in this work could be achieved [14,42,43].

Due to high SCO contents and short fermentation durations, the volumetric productivities reported in the present work are above those reported by Fontanille et al. [14] and comparable to the ones reported by Béligon et al. [42]. With 0.51 g/Lh, only Chi et al. [43] were able to achieve substantially higher volumetric productivities than those reported in this work. However, in contrast to the present work, in which a mixture of HAc and HPr was used as a carbon source, the reported productivities were achieved by using only HAc as a carbon source. This is relevant, since the metabolization of HPr is less effective than the metabolization of HAc [19], and the presence of HPr has a substantial effect on the composition of the produced lipids [44]. HPr directly reacts with CoA forming propionyl-CoA that is subsequently used for the synthesis of odd-numbered FAs [19]. Thus, the presence of unusual odd-numbered FAs in the produced SCO is a direct result of the use of HPr as carbon source.

Scale-up to the small pilot scale for both strains resulted in values for DCW, SCO content, and SCO yield (g SCO/g VFA) that were comparable to the laboratory scale results. In contrast, lipid productivity was reduced in both strains, due to longer fermentation times. The process durations were observed to be approximately 23.5 h longer in small pilot scale than in laboratory scale. This increase can be attributed to three factors. For one, the inoculation volume was reduced from 10% of the starting volume in laboratory scale to 4% in the small pilot scale due to technical reasons. For another, the OD600 reached in the pre-culture in laboratory scale could not be achieved in small-pilot scale. This effect is assumed to be a result of a lower oxygen transfer rate (OTR) in the pre-culture due to the geometry of the bigger shake flasks used in the inoculum preparation. Finally, in contrast to laboratory scale, the DO could not be maintained at the setpoint throughout the fermentations (Figures S25–S28). The DO dropped below the setpoint after 6 h (strain V194) or 9 h (strain V134), remaining below the setpoint throughout the fermentations. The unusual geometry of the small pilot scale reactor (height-to-diameter ratio of 1:0.17) may be another factor contributing to decreased oxygen transfer in small pilot scale compared to laboratory scale.

Similar effects were observed when scaling the V134 process further up to the 500 L scale. The SCO content and SCO yield were comparable to the smaller scale processes, but the fermentation duration increased, and lipid productivity decreased. This is explained by a further decrease in the inoculation volume from 4% of the starting volume to 0.9%. Additionally, the DO also dropped and remained below the setpoint after 8 h of fermentation (Figure S29). As in small pilot scale, it is assumed that the geometry of the bioreactor and the configuration of the stirrer resulted in a lower OTR.

In addition to being a potential influence on volumetric lipid productivity, limited oxygen uptake has also been reported to decrease the share of unsaturated fatty acids in the produced SCO [45]. Since there was not a sufficient air supply to maintain the DO setpoint, it is likely that such effects occurred in the described processes. Nevertheless, the ratio of saturated fatty acids (SFAs) to unsaturated fatty acids (UFAs) remained comparable at the different scales (see Figure 2). However, compared to the laboratory scale process an increased proportion of C18:0 in the lipids was observed in the pilot-scale fermentations, while the proportion of C17:0 decreased at approximately the same rate (see Figure 2). Since the ratio SFA/UFA remained essentially constant, and as the presence of HPr has been shown to result in the production of C17:0 fatty acids [23], the described effect can be primarily attributed to the reduction in the HPr/HAc ratio in the feed. While this change complicates the interpretation of the data, the feed was nevertheless adapted to better reflect the composition of actual VFA mixtures derived from the AD of food wastes [16]. Apart from the described effect, the FA composition of the lipids produced at the various scales is quite comparable.

When comparing the DCW, SCO content, and lipid yield, no clear difference between the various scales could be observed. A slight change in the fatty acid pattern is observed, but, as described above, this can be primarily attributed to a deliberate change of the used feed composition. The described limitations regarding aeration are a point that should be addressed in the future, but otherwise, no major challenges in scaling the process could be identified. The decreased productivity in larger scale can potentially be overcome by using customized bioreactors with suitable oxygen transfer and the use of seed fermenters for inoculum preparation. Considering that the three types of bioreactor used for this study differed in their geometries and configurations depending on the scale, the results suggest a robust, scalable fermentation process.

4.2. Extraction of SCO

Methanol and chloroform are the most common solvents used for SCO extraction, but, due to their high costs and their toxicity, they are not well suited for the scale-up of an SCO extraction process. Therefore, hexane was chosen as the solvent for all the extraction trials. The literature, however, suggests that pretreatment of the biomass is necessary, if hexane is used for SCO extraction [46]. The results of the present work confirm this assessment. The lipid recovery, calculated from the extracted lipid amount and the lipid content of the used biomass according to analysis, was only 37% without pretreatment before extraction. While mechanical disruption increased the recovery, the effect was not satisfactory. When combining mechanical disruption with induced autolysis, the recovery could be increased to 79%. This indicates that induced autolysis is a very effective method for the pretreatment of biomass for lipid extraction, which is in line with the literature [47].

Since autolysis proved to be so effective, and bead milling is both energy-intensive and difficult to implement in larger scale [32], the extraction in miniPilot scale was performed without prior bead milling. The drop in lipid recovery from 78% in laboratory scale to 52% in pilot scale is mainly attributed to the difference in extraction conditions used in laboratory and pilot scales. For accelerated solvent extraction, high pressure and temperature were used to facilitate lipid extraction. In comparison, extraction in pilot scale was performed at ambient pressure and moderate temperatures.

4.3. Characterization of the Lipids and Economical Aspects

The extracted SCO was analyzed with regard to various quality parameters. The iodine value of 48 is comparable to tallow, which has an iodine value of 35–48, and palm oil, which has an iodine value of 50–55. The SCO would thus be suited to biodiesel production, where a maximum iodine value of 115 should not be exceeded. Furthermore, the comparably low iodine value of the SCO indicates a good oxidative stability [48]. The peroxide value of 7.3 is quite low, also indicating a high oxidative stability. A comparable vegetable oil would be high oleic sunflower oil [49]. The high acid value of 4.3 indicates a high amount of free fatty acids. Depending on the intended use, this can be problematic, since it may limit the available options for downstream processing. For instance, the efficient alkaline transesterification of the fatty acids requires an acid value below 2, since the free fatty acids and the alkaline catalyst can form soaps [50]. This problem can, however, be addressed by using alternative catalysts for transesterification [51].

The use of waste to produce VFAs, which can subsequently be converted to lipids for the production of biofuels, is in itself a very appealing concept. Due to decarbonization measures, blending regulations, and governmental subsidies, biofuels are still a relevant market. There remains, however, some uncertainty regarding the economic viability of such a process, although it has recently been suggested that VFA-based SCO could potentially compete with vegetable oils [2]. Assuming this calculation proves to be correct, various uses for each FA in the oleochemical industry are conceivable, from surfactants and detergents to lubricants and soaps [52]. Another aspect of potential economic interest is the unusual odd-numbered fatty acids present in the lipids produced. Odd-numbered fatty acids have attracted interest as precursors for fragrances and plasticizers, as plant protection agents, and as active ingredients in medical treatments [53]. Overall, the presented data indicate that the produced SCO is comparably stable to oxidation and suitable for a wide range of applications.

5. Conclusions

The present study was able to demonstrate that both yeast strains, A. brassicae V134 and P. kudriavzevii V194, can reach comparably high values for DCW and lipid contents when they are cultivated using VFAs as a carbon source. It was shown that the pH-stat fed-batch process is robust and can be adapted to pilot scale, resulting in similar values for yield, DCW, SCO content, or fatty acid composition. Apart from constraints regarding oxygen transfer at larger scales, no major issues were observed during scale-up.

In a comparison of methods for the pretreatment of biomass prior to extraction with hexane, induced autolysis turned out to be a very effective method, which was subsequently used to extract lipids from biomass in pilot scale. Based on the values for the tested quality parameters, the extracted lipids were found to be well suited for a wide range of possible applications.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/app13084674/s1, Figure S1: HPLC chromatogram for sample from lab scale cultivation of Apiotrichum brassicae V134; process time: 66h, Reactor: 1, dilution of the sample: 1:5; Figure S2: HPLC chromatogram for sample from lab scale cultivation of Apiotrichum brassicae V134, process time: 66h, Reactor: 2, dilution of the sample: 1:5; Figure S3: HPLC chromatogram for sample from lab scale cultivation of Pichia kudriavzevii V194, process time: 65h, Reactor: 1, dilution of the sample: 1:10; Figure S4: HPLC chromatogram for sample from lab scale cultivation of Pichia kudriavzevii V194, process time: 65h, Reactor: 2, dilution of the sample: 1:10, Figure S5: HPLC chromatogram for sample from small pilot scale cultivation of Apiotrichum brassicae V134, process time: 89h, dilution of the sample: 1:5; Figure S6: HPLC chromatogram for sample from small pilot cultivation of Pichia kudriavzevii V194; process time: 89h, dilution of the sample: 1:5; Figure S7: HPLC chromatogram for sample from pilot scale cultivation of Apiotrichum brassicae V134, process time: 2 h, dilution of the sample: 1:10; Figure S8: HPLC chromatogram for sample from pilot scale cultivation of Apiotrichum brassicae V134, process time: 71h, dilution of the sample: 1:10; Figure S9: HPLC chromatogram for sample from pilot scale cultivation of Apiotrichum brassicae V134, process time: 141h, dilution of the sample: 1:10; Figure S10: GC chromatogram for final sample (141 h) from pilot scale cultivation of Apiotrichum brassicae V134, Sample A; Figure S11: GC chromatogram for final sample (141 h) from pilot scale cultivation of Apiotrichum brassicae V134, Sample B; Figure S12: GC chromatogram for a sample of the chloroform/methyl benzoate mixture used in preparation of analytical samples from pilot scale cultivation of Apiotrichum brassicae V134, Sample A; Figure S13: GC chromatogram for a sample of the chloroform/methyl benzoate mixture used in preparation of analytical samples from pilot scale cultivation of Apiotrichum brassicae V134, Sample B; Figure S14: GC chromatogram for a palm oil sample used as recovery control; sample preparation was the same as biomass samples; determined recovery was used in calculation of SCO content of biomass from pilot scale cultivation of Apiotrichum brassicae V134, Sample A; Figure S15: GC chromatogram for a palm oil sample used as recovery control; sample preparation was the same as biomass samples; determined recovery was used in calculation of SCO content of biomass from pilot scale cultivation of Apiotrichum brassicae V134, Sample B; Figure S16: GC chromatogram for final sample (89h) from small pilot scale cultivation of Pichia kudriavzevii V194, Sample A; Figure S17: GC chromatogram for a sample of the chloroform/methyl benzoate mixture used in preparation of analytical samples from pilot scale cultivation of Pichia kudriavzevii V194, Sample A; Figure S18: GC chromatogram for a sample of the chloroform/methyl benzoate mixture used in preparation of analytical samples from pilot scale cultivation of Pichia kudriavzevii V194, Sample B; Figure S19: GC chromatogram for a sample of the chloroform/methyl benzoate mixture used in preparation of analytical samples from pilot scale cultivation of Pichia kudriavzevii V194, Sample C; Figure S20: GC chromatogram for a sample of the chloroform/methyl benzoate mixture used in preparation of analytical samples from pilot scale cultivation of Pichia kudriavzevii V194, Sample D; Figure S21: GC chromatogram for a palm oil sample used as recovery control; sample preparation was the same as biomass samples; determined recovery was used in calculation of SCO content of biomass from small pilot scale cultivation of Pichia kudriavzevii V194, Sample A; Figure S22: GC chromatogram for a palm oil sample used as recovery control; sample preparation was the same as biomass samples; determined recovery was used in calculation of SCO content of biomass from small pilot scale cultivation of Pichia kudriavzevii V194, Sample B; Figure S23: GC chromatogram for a palm oil sample used as recovery control; sample preparation was the same as biomass samples; determined recovery was used in calculation of SCO content of biomass from small pilot scale cultivation of Pichia kudriavzevii V194, Sample C; Figure S24: GC chromatogram for a palm oil sample used as recovery control; sample preparation was the same as biomass samples; determined recovery was used in calculation of SCO content of biomass from small pilot scale cultivation of Pichia kudriavzevii V194, Sample D; Figure S25: Plot of online DO signal for laboratory scale cultivation of Apiotrichum brassicae V134; Figure S26: Plot of online DO signal for laboratory scale cultivation of Pichia kudriavzevii V194; Figure S27: Plot of online DO signal for during small pilot scale cultivation of Apiotrichum brassicae V134; Figure S28: Plot of online DO signal for small pilot scale cultivation of Pichia kudriavzevii V194; Figure S29: Plot of online DO signal for pilot scale cultivation of Apiotrichum brassicae V134; Table S1: Overview of report values for acetic acid and propionic acid concentrations, dilutions and calculated acetic and propionic acid concentrations in the samples; Table S2: SCO content calculation of biomass from the final sample (141h) of the pilot scale (PS) cultivation of Apiotrichum brassicae V134; Table S3: SCO content calculation of biomass from the final sample (89h) of the small pilot scale (SPS) cultivation of Pichia kudriavzevii V194; Table S4: Raw data of the fatty acid spectrum of SCO produced by strains A. brassicae V134 and P. kudriavzevii V194.

Author Contributions

Conceptualization, L.B. and M.N.; methodology, L.B. and M.N.; investigation, L.B. and L.O.; resources, M.N. and T.D.; data curation, L.B. and L.O.; writing—original draft preparation, L.B.; writing—review and editing, M.N., T.D. and L.O.; visualization, L.B.; supervision, M.N.; project administration, T.D. and M.N.; funding acquisition, T.D. and M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union’s Horizon 2020 research and innovation programme (Call H2020-NMBP-BIO-2016), grant agreement No. 720777.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Essential data are contained within this article. Raw data are available on request from the corresponding author.

Acknowledgments

The authors would like to thank Markus Sadler for his assistance in the pilot scale fermentations and Marcus Pruckner for his help with chemical analytics and the maintenance of equipment.

Conflicts of Interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Papanikolaou, S.; Aggelis, G. Lipids of oleaginous yeasts. Part I: Biochemistry of single cell oil production. Eur. J. Lipid Sci. Technol. 2011, 113, 1031–1051. [Google Scholar] [CrossRef]

- Robles-Iglesias, R.; Naveira-Pazos, C.; Fernández-Blanco, C.; Veiga, M.C.; Kennes, C. Factors affecting the optimisation and scale-up of lipid accumulation in oleaginous yeasts for sustainable biofuels production. Renew. Sustain. Energy Rev. 2023, 171, 113043. [Google Scholar] [CrossRef]

- Moon, N.J.; Hammond, E.G.; Glatz, B.A. Conversion of Cheese Whey and Whey Permeate to Oil and Single-Cell Protein. J. Dairy Sci. 1978, 61, 1537–1547. [Google Scholar] [CrossRef]

- Gallego-García, M.; Moreno, A.D.; González, A.; Negro, M.J. Efficient use of discarded vegetal residues as cost-effective feedstocks for microbial oil production. Biotechnol. Biofuels Bioprod. 2023, 16, 21. [Google Scholar] [CrossRef] [PubMed]

- Muscat, A.; De Olde, E.M.; de Boer, I.; Ripoll-Bosch, R. The battle for biomass: A systematic review of food-feed-fuel competition. Glob. Food Secur. 2020, 25, 100330. [Google Scholar] [CrossRef]

- Poontawee, R.; Limtong, S. Feeding Strategies of Two-Stage Fed-Batch Cultivation Processes for Microbial Lipid Production from Sugarcane Top Hydrolysate and Crude Glycerol by the Oleaginous Red Yeast Rhodosporidiobolus fluvialis. Microorganisms 2020, 8, 151. [Google Scholar] [CrossRef] [PubMed]

- André, A.; Chatzifragkou, A.; Diamantopoulou, P.; Sarris, D.; Philippoussis, A.; Galiotou-Panayotou, M.; Komaitis, M.; Papanikolaou, S. Biotechnological conversions of bio-diesel-derived crude glycerol by Yarrowia lipolytica strains. Eng. Life Sci. 2009, 9, 468–478. [Google Scholar] [CrossRef]

- Gong, Z.; Zhou, W.; Shen, H.; Yang, Z.; Wang, G.; Zuo, Z.; Hou, Y.; Zhao, Z.K. Co-fermentation of acetate and sugars facilitating microbial lipid production on acetate-rich biomass hydrolysates. Bioresour. Technol. 2016, 207, 102–108. [Google Scholar] [CrossRef] [PubMed]

- Ananthi, V.; Siva Prakash, G.; Chang, S.W.; Ravindran, B.; Nguyen, D.D.; Vo, D.-V.N.; La, D.D.; Bach, Q.-V.; Wong, J.; Kumar Gupta, S.; et al. Enhanced microbial biodiesel production from lignocellulosic hydrolysates using yeast isolates. Fuel 2019, 256, 115932. [Google Scholar] [CrossRef]

- Park, G.W.; Chang, H.N.; Jung, K.; Seo, C.; Kim, Y.-C.; Choi, J.H.; Woo, H.C.; Hwang, I. Production of microbial lipid by Cryptococcus curvatus on rice straw hydrolysates. Process Biochem. 2017, 56, 147–153. [Google Scholar] [CrossRef]

- Krikigianni, E.; Matsakas, L.; Rova, U.; Christakopoulos, P.; Patel, A. Investigating the Bioconversion Potential of Volatile Fatty Acids: Use of Oleaginous Yeasts Rhodosporidium toruloides and Cryptococcus curvatus towards the Sustainable Production of Biodiesel and Odd-Chain Fatty Acids. Appl. Sci. 2022, 12, 6541. [Google Scholar] [CrossRef]

- Gao, R.; Li, Z.; Zhou, X.; Bao, W.; Cheng, S.; Zheng, L. Enhanced lipid production by Yarrowia lipolytica cultured with synthetic and waste-derived high-content volatile fatty acids under alkaline conditions. Biotechnol. Biofuels 2020, 13, 3. [Google Scholar] [CrossRef] [PubMed]

- Llamas, M.; Tomás-Pejó, E.; González-Fernández, C. Volatile fatty acids from organic wastes as novel low-cost carbon source for Yarrowia lipolytica. New Biotechnol. 2020, 56, 123–129. [Google Scholar] [CrossRef]

- Fontanille, P.; Kumar, V.; Christophe, G.; Nouaille, R.; Larroche, C. Bioconversion of volatile fatty acids into lipids by the oleaginous yeast Yarrowia lipolytica. Bioresour. Technol. 2012, 114, 443–449. [Google Scholar] [CrossRef]

- Tomás-Pejó, E.; Morales-Palomo, S.; González-Fernández, C. Microbial lipids from organic wastes: Outlook and challenges. Bioresour. Technol. 2021, 323, 124612. [Google Scholar] [CrossRef] [PubMed]

- Velghe, F.; De Wilde, F.; Snellinx, S.; Farahbakhsh, S.; Belderbos, E.; Peral, C.; Wiedemann, A.; Hiessl, S.; Michels, J.; Pierrard, M.-A.; et al. Volatile fatty acid platform-a cornerstone for the circular bioeconomy. FEMS Microbiol. Lett. 2021, 368, fnab056. [Google Scholar] [CrossRef]

- Chakraborty, S. Exploring Volatile Fatty Acids (VFAs) as a Novel Substrate for Microbial Oil Production. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2015. [Google Scholar]

- Huang, X.-F.; Liu, J.-N.; Lu, L.-J.; Peng, K.-M.; Yang, G.-X.; Liu, J. Culture strategies for lipid production using acetic acid as sole carbon source by Rhodosporidium toruloides. Bioresour. Technol. 2016, 206, 141–149. [Google Scholar] [CrossRef]

- Kolouchová, I.; Schreiberová, O.; Sigler, K.; Masák, J.; Řezanka, T. Biotransformation of volatile fatty acids by oleaginous and non-oleaginous yeast species. FEMS Yeast Res. 2015, 15, fov076. [Google Scholar] [CrossRef]

- Fei, Q.; Chang, H.N.; Shang, L.; Choi, J.; Kim, N.; Kang, J. The effect of volatile fatty acids as a sole carbon source on lipid accumulation by Cryptococcus albidus for biodiesel production. Bioresour. Technol. 2011, 102, 2695–2701. [Google Scholar] [CrossRef]

- Miranda, C.; Bettencourt, S.; Pozdniakova, T.; Pereira, J.; Sampaio, P.; Franco-Duarte, R.; Pais, C. Modified high-throughput Nile red fluorescence assay for the rapid screening of oleaginous yeasts using acetic acid as carbon source. BMC Microbiol. 2020, 20, 60. [Google Scholar] [CrossRef]

- Bettencourt, S.; Miranda, C.; Pozdniakova, T.A.; Sampaio, P.; Franco-Duarte, R.; Pais, C. Single Cell Oil Production by Oleaginous Yeasts Grown in Synthetic and Waste-Derived Volatile Fatty Acids. Microorganisms 2020, 8, 1809. [Google Scholar] [CrossRef] [PubMed]

- Burgstaller, L.; Löffler, S.; De Marcellis, L.; Ghassemi, K.; Neureiter, M. The influence of different carbon sources on growth and single cell oil production in oleaginous yeasts Apiotrichum brassicae and Pichia kudriavzevii. New Biotechnol. 2022, 69, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-Z.; Wang, Q.-M.; Göker, M.; Groenewald, M.; Kachalkin, A.V.; Lumbsch, H.T.; Millanes, A.M.; Wedin, M.; Yurkov, A.M.; Boekhout, T.; et al. Towards an integrated phylogenetic classification of the Tremellomycetes. Stud. Mycol. 2015, 81, 85–147. [Google Scholar] [CrossRef] [PubMed]

- Franklin, S.; Decker, S.M.; Wee, J. Fuel and Chemical Production from Oleaginous Yeast. US Patent US 2011/0252696 A1, 2011. [Google Scholar]

- Sankh, S.; Thiru, M.; Saran, S.; Rangaswamy, V. Biodiesel production from a newly isolated Pichia kudriavzevii strain. Fuel 2013, 106, 690–696. [Google Scholar] [CrossRef]

- Bardhan, P.; Gupta, K.; Kishor, S.; Chattopadhyay, P.; Chaliha, C.; Kalita, E.; Goud, V.V.; Mandal, M. Oleaginous yeasts isolated from traditional fermented foods and beverages of Manipur and Mizoram, India, as a potent source of microbial lipids for biodiesel production. Ann. Microbiol. 2020, 70, 27. [Google Scholar] [CrossRef]

- Prabhu, K.; Jayakumar, A.; Sreelakshmi, K.P.; Raha, A.; Maitra, M.; Radha, P. Utilization of microbial oil produced from Pichia kudriavzevii NCIM 3653 using paper mill sludge as an alternative substrate for biodiesel synthesis. Biofuels 2021, 12, 1309–1316. [Google Scholar] [CrossRef]

- Garcia-Ochoa, F.; Gomez, E. Bioreactor scale-up and oxygen transfer rate in microbial processes: An overview. Biotechnol. Adv. 2009, 27, 153–176. [Google Scholar] [CrossRef]

- Schmid, M.T.; Sykacek, E.; O’Connor, K.; Omann, M.; Mundigler, N.; Neureiter, M. Pilot scale production and evaluation of mechanical and thermal properties of P(3HB) from Bacillus megaterium cultivated on desugarized sugar beet molasses. J. Appl. Polym. Sci. 2022, 139, 51503. [Google Scholar] [CrossRef]

- Khot, M.; Raut, G.; Ghosh, D.; Alarcón-Vivero, M.; Contreras, D.; Ravikumar, A. Lipid recovery from oleaginous yeasts: Perspectives and challenges for industrial applications. Fuel 2020, 259, 116292. [Google Scholar] [CrossRef]

- Dong, T.; Knoshaug, E.P.; Pienkos, P.T.; Laurens, L.M. Lipid recovery from wet oleaginous microbial biomass for biofuel production: A critical review. Appl. Energy 2016, 177, 879–895. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists (AOAC). Official Method Number 920.159: Iodine Absorption Number of Oils and Fats; Wijs method; AOAC: Rockville, MD, USA, 2015. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Method Number 965.33: Peroxide Value of Oils and Fats; AOAC: Rockville, MD, USA, 2000. [Google Scholar]

- Association of Official Analytical Chemists (AOAC). Official Method Number 940.28: Fatty Acids (Free) in Crude and Refined Oils; AOAC: Rockville, MD, USA, 2003. [Google Scholar]

- Meesters, P.A.E.P.; Huijberts, G.N.M.; Eggink, G. High-cell-density cultivation of the lipid accumulating yeast Cryptococcus curvatus using glycerol as a carbon source. Appl. Microbiol. Biotechnol. 1996, 45, 575–579. [Google Scholar] [CrossRef]

- Sáez-Plaza, P.; Michałowski, T.; Navas, M.J.; Asuero, A.G.; Wybraniec, S. An Overview of the Kjeldahl Method of Nitrogen Determination. Part I. Early History, Chemistry of the Procedure, and Titrimetric Finish. Crit. Rev. Anal. Chem. 2013, 43, 178–223. [Google Scholar] [CrossRef]

- Kyriakidis, N.B.; Katsiloulis, T. Calculation of iodine value from measurements of fatty acid methyl esters of some oils: Comparison with the relevant American Oil Chemists Society method. J. Am. Oil Chem. Soc. 2000, 77, 1235–1238. [Google Scholar] [CrossRef]

- Zhang, N.; Li, Y.; Wen, S.; Sun, Y.; Chen, J.; Gao, Y.; Sagymbek, A.; Yu, X. Analytical methods for determining the peroxide value of edible oils: A mini-review. Food Chem. 2021, 358, 129834. [Google Scholar] [CrossRef] [PubMed]

- Fernando, S.; Karra, P.; Hernandez, R.; Jha, S. Effect of incompletely converted soybean oil on biodiesel quality. Energy 2007, 32, 844–851. [Google Scholar] [CrossRef]

- Christophe, G.; Deo, J.L.; Kumar, V.; Nouaille, R.; Fontanille, P.; Larroche, C. Production of oils from acetic acid by the oleaginous yeast Cryptococcus curvatus. Appl. Biochem. Biotechnol. 2012, 167, 1270–1279. [Google Scholar] [CrossRef]

- Béligon, V.; Poughon, L.; Christophe, G.; Lebert, A.; Larroche, C.; Fontanille, P. Improvement and modeling of culture parameters to enhance biomass and lipid production by the oleaginous yeast Cryptococcus curvatus grown on acetate. Bioresour. Technol. 2015, 192, 582–591. [Google Scholar] [CrossRef]

- Chi, Z.; Zheng, Y.; Ma, J.; Chen, S. Oleaginous yeast Cryptococcus curvatus culture with dark fermentation hydrogen production effluent as feedstock for microbial lipid production. Int. J. Hydrog. Energy 2011, 36, 9542–9550. [Google Scholar] [CrossRef]

- Llamas, M.; Magdalena, J.A.; González-Fernández, C.; Tomás-Pejó, E. Volatile fatty acids as novel building blocks for oil-based chemistry via oleaginous yeast fermentation. Biotechnol. Bioeng. 2020, 117, 238–250. [Google Scholar] [CrossRef]

- Davies, R.; Holdsworth, J.; Reader, S. The effect of low oxygen uptake rate on the fatty acid profile of the oleaginous yeast Apiotrichum curvatum. Appl. Microbiol. Biotechnol. 1990, 33, 569–573. [Google Scholar] [CrossRef]

- Bonturi, N.; Matsakas, L.; Nilsson, R.; Christakopoulos, P.; Miranda, E.; Berglund, K.; Rova, U. Single Cell Oil Producing Yeasts Lipomyces starkeyi and Rhodosporidium toruloides: Selection of Extraction Strategies and Biodiesel Property Prediction. Energies 2015, 8, 5040–5052. [Google Scholar] [CrossRef]

- Halim, R.; Papachristou, I.; Chen, G.Q.; Deng, H.; Frey, W.; Posten, C.; Silve, A. The effect of cell disruption on the extraction of oil and protein from concentrated microalgae slurries. Bioresour. Technol. 2022, 346, 126597. [Google Scholar] [CrossRef] [PubMed]

- Knothe, G. Structure indices in FA chemistry. How relevant is the iodine value? J. Am. Oil Chem. Soc. 2002, 79, 847–854. [Google Scholar] [CrossRef]

- Bouaid, A.; Martinez, M.; Aracil, J. Long storage stability of biodiesel from vegetable and used frying oils. Fuel 2007, 86, 2596–2602. [Google Scholar] [CrossRef]

- Sahoo, P.K.; Das, L.M.; Babu, M.; Naik, S.N. Biodiesel development from high acid value polanga seed oil and performance evaluation in a CI engine. Fuel 2007, 86, 448–454. [Google Scholar] [CrossRef]

- Atadashi, I.M.; Aroua, M.K.; Abdul Aziz, A.R.; Sulaiman, N. Production of biodiesel using high free fatty acid feedstocks. Renew. Sustain. Energy Rev. 2012, 16, 3275–3285. [Google Scholar] [CrossRef]

- Probst, K.V.; Schulte, L.R.; Durrett, T.P.; Rezac, M.E.; Vadlani, P.V. Oleaginous yeast: A value-added platform for renewable oils. Crit. Rev. Biotechnol. 2016, 36, 942–955. [Google Scholar] [CrossRef]

- Abreu, S.; Park, Y.-K.; Pires de Souza, C.; Vidal, L.; Chaminade, P.; Nicaud, J.-M. Lipid Readjustment in Yarrowia lipolytica Odd-Chain Fatty Acids Producing Strains. Biomolecules 2022, 12, 1026. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).