1. Introduction

Fires are one of the most critical risks that must be considered in underground mines. Despite significant efforts made in recent years regarding prevention and control systems, the frequency of mine fires does not appear to have decreased. This is likely due to newly introduced materials, the presence of large quantities of fuels, and ever-increasing mechanization [

1,

2]. Among the most serious mining disasters, many are due to fires inside underground mines, possibly accompanied (either preceded or followed) by explosions of various types due to the presence of methane gas or explosive dust. In particular, among the 10 most serious mining disasters in history, 4 were caused or contributed to by a fire inside the underground mine (URL

https://www.amsj.com.au/ (accessed on 5 December 2022)): Benxihu colliery, Liaoning (China), April 1942 (1549 deaths); Laobaidong colliery, Datong (China), May 1960 (682 deaths); Senghenydd Colliery, Caerphilly (Wales, UK), 14 October 1913 (440 deaths); and Wankie Coal Mine, Hwange (Zimbabwe), June 1972 (426 deaths).

The leading cause of the loss of life in a mine fire is found in the miners’ inhalation of toxic gases, mainly carbon monoxide [

3]. In fact, during a fire, the people who are present in the mine must evacuate to a safe place [

4]. However, the path to be taken can also be very long, and the possibility that the fumes or high air temperatures that the personnel on the escape route or in the work site will encounter is not remote.

The analysis of the ventilation of a mine during a fire plays a crucial role.

The flow of air and, therefore, of oxygen that reaches the fire affects its behavior. However, the increase in air temperature and the physical characteristics of the produced gases also modify the ventilation circuit in those relevant zones of the mine.

From an analytical point of view, it is possible to simulate the fire in an underground cavity with a linear development using simplified calculation methods. When knowing, in fact, what thermal power is reached by the fire in a determined time t from the initiation, it is then possible to determine the temperature of the air that is downstream of the fire, as well as the characteristics of the flow (e.g., pressures, speeds, and flow rates). Such a simplified approach is generally applicable to underground voids with a linear or simple development. This can be achieved by introducing certain simplifying assumptions, such as the total absence of heat exchange with the surrounding rock mass.

For the purposes of evaluating, in detail, the evolution of a possible fire and the path of the fumes over time, it is necessary to resort to numerical modeling [

5,

6,

7,

8]. Through doing this, all the influential elements are considered, such as the characteristics and quantities of the combustible materials that are present; the amount and type of produced fumes; the entity of the emitted thermal power; the characteristics of the ventilation circuit; and the type and functioning of the mine fans.

When conducting a numerical model, it is essential to understand the following:

The time required to ensure securing the miners. This should be understood in order to plan the monitoring system, as well as to plan the communication between the safety managers and the workers in the underground levels;

The evolution of the fire and the possible involvement of the mine areas upstream and downstream of it; this information is helpful in guiding the action of emergency teams to rescue people or to fight the fire in order to contain or extinguish it;

The usefulness of a possible intervention with the ventilation system, to enhance the airflow or even to interrupt or reverse it; the choices are challenging to make because they should depend on the knowledge of the chemical–physical and thermodynamic conditions of the fire, as well as an assessment of the position of people and the combustible materials in the mine.

Currently, calculation tools are capable of analyzing all the elements of interest, even in mines with complex ventilation circuits, such as those that are exploited with the room-and-pillar method. Thanks to the calculation speeds reached by modern computers, it is possible to consider various hypotheses on the following:

The location of the fire inside the mine and the ignition typology;

The quantity and characteristics of the combustible materials that are present;

Modifications to the ventilation circuit, such as intervening by interrupting the flow in certain areas of the mine by closing doors, putting up barriers, or by modifying the functioning of the primary fans of the mine.

A detailed study of this type must lead to the definition of the following:

The behavior that miners must adopt inside the mine during a fire;

The information that safety managers must provide for the ventilation system management and for the action of emergency teams;

The maximum quantities and locations of the combustible substances that need to be stored underground;

The monitoring systems of the environmental conditions (e.g., the airflow, temperature, and the air chemical composition in different sections of the mine) in order to be able to identify the start of a fire in time and to control its evolution;

The alarm signals and communications among the people inside the mine, the personnel involved in the functioning of the main facilities of the mine, the safety managers, and the rescue teams;

The safety tools that are necessary for attempting to extinguish the fire or to ensure the breathing of the miners during a fire.

The application of numerical modeling in the analysis of the evolution of a fire in underground mining voids has already been successfully applied in the past [

1,

6,

7,

8]. The same numerical methods were used to understand how the mine ventilation system is able to influence the fire over time. On the other hand, there are no cases in the literature for which numerical modeling has been used to define, in detail, the evacuation plans during an emergency, one which considers the propagation times of the smoke and the fire inside the mine, as well as the routes—with the necessary times—for the escape of the personnel. The safety of the mine, in fact, must be such as to provide all personnel (wherever they operate) with the means to undertake a risk-free escape toward the exit, in the event that a fire develops in any area of the mine. Currently, the development of numerical modeling and the availability of very powerful computers allows one to develop calculations in a dynamic field in an incredibly short time. In addition, the technology is such that the different conditions (such as the entity and position of the fires in a mine) and the evaluation of the results of these calculations are able to be analyzed in detail.

In this work, the phases of analyzing fires and air flows inside a mine using modern numerical calculation programs are reported. An application relating to an underground gypsum quarry in the northwest of Italy is then presented and commented upon, with particular reference to the results that are useful for obtaining information on evacuation plans and emergency management during a possible underground fire. The calculation program that was used (Ventsim) is able to iteratively solve the flow and thermodynamic equations that govern a ventilation circuit, such as taking into account the variation in temperature and the gas composition following the presence of a fire, which can evolve over time in defined points of the circuit. The panels of the mine exploitation and the tunnels/shafts are simulated with one-dimensional elements of the ventilation circuit. These elements possess well-determined geometrical characteristics, which must respect Kirchhoff’s current law in every instance of time that is analyzed during an underground fire.

Numerical modeling was used to verify the most critical conditions that can occur by varying the position and extent of a fire in the studied underground mine, such as taking into account the position of the workers inside it. At the end of this preliminary study, four specific cases were identified, for which it was possible to carry out further investigation; furthermore, the results of these cases will be illustrated and discussed in greater detail.

2. Evaluation of the Environmental Conditions during a Fire by Numerical Modeling of the Ventilation System

Fire dynamics are very complex and they significantly depend on the supply of oxygen and the air speed that reaches and passes through the fire. It implies a considerable increase in air temperatures and, therefore, an increase in the circuit resistances, as well as a change in the specific weight of the air/gases. This interaction between the fire and ventilation must also be carefully analyzed to verify the effects of the fire on the personnel present inside the mine and, in particular, to estimate the time available for a safe escape to internal or external locations, or for extinguishing the fire in its initial phase [

9,

10,

11,

12].

Through the numerical modeling of the ventilation circuits, it is now possible to consider the presence of a localized fire inside the mine by considering all of the following main aspects:

The characteristics of the fire, i.e., the quantity and type of combustible substances present;

The heat transmissibility in the rock, which affects the dispersion of energy toward the rock in the fire area;

The characteristics of the ventilation circuit, such as the shape, section, length, and depth of the underground cavities, as well as the degree of roughness of the side surfaces and the presence of any obstructions or barriers inside the mine;

The characteristics and operating modes of the main fans;

The air temperature and pressure outside the mine (at the circuit entrance and exit);

The temperature gradient of the rock with depth, which affects the transmission of heat to the air inside the mine.

Through numerical modeling, one can consider, in the calculation, the different possible scenarios in order to analyze their effects on the fire dynamics, as well as on the type and quantity of fumes produced, and on the timing of their propagation within the mine; in particular, the following scenarios can be evaluated:

The different locations of the fire inside the mine;

The different type of machine or plant on which the fire is triggered, with a pessimistic forecast of the quantity and type of combustible materials [

13];

The main fans during the fire that will be able to operate either in their standard conditions, with increased power, turn off when the fire is started after a certain period from the ignition, or reverse to change the direction of the airflow inside of the mine and in correspondence with the fire;

The possible turning on of the auxiliary booster fans in certain areas of the mine to help the action of the main fans during a fire;

The introduction or elimination of barriers in the ventilation circuit in order to simulate the closing or opening of doors inside the mine in emergency conditions. In this way, it is possible to simulate the intervention of safety personnel on the ventilation circuit to obtain better environmental conditions during the fire.

From the calculation results, it is then possible to detect the best strategy to contain, mitigate, or even extinguish the fire, thus minimizing damage to people and property. More specifically, it is interesting to determine from the calculation the following values within the ventilation circuit [

14]:

These values are helpful, particularly downstream of the fire (along escape routes that can be used by staff and worksites); their evolution over time is also fascinating.

In this work, the Ventsim 3D program (Ventsim 3D manual) was used in the dynamic configuration (developed by the Building Research Institute) [

15]. This numerical calculation method divides the three-dimensional ventilation circuit into one-dimensional elements (branches) and nodes. Then, through an iterative process based on the Hardy Cross method [

16,

17], a continuous adjustment of the values of the air pressures at the nodes and of the airflow rates within each branch of the network is obtained until the following two conditions are met:

The pressure drop along each branch (i.e., the pressure difference at the two nodes on the branch ends) agrees with the airflow inside it, according to Atkinson’s law [

18,

19,

20]:

The total airflow rate, in mass, in each node—which is obtained by algebraically adding the airflow rates that enter (+) or leave (−) the node through all the branches that are connected to it—must be zero.

A specific module of the program, called VentFIRE, can effectively simulate the presence of a fire inside the ventilation circuit. It can consider the thermal effects of combustion and heat dispersion in the surrounding rock over a certain period of time, as well as the fume propagation and the air flows that occur inside the ventilation circuit. Depending on the fuels present on the considered vehicle, regarding the location of the fire ignition, it is possible to indicate the thermal power values (HRR) that are emitted by the fire over time [

21]. The code is also able to study both the oxygen-rich fire or fuel-rich fire conditions, with the possible consequences emitted by the fire on the thermal powers, as well as on other particular phenomena that can occur inside an airway in the presence of a fire, such as a rollback. With respect to the latter, it is achieved when the smoke from the fire moves upstream on the roof in the opposite direction to the fresh air that feeds the fire and occupies the lower portion of the duct.

The Ventsim program and the VentFIRE module are tried and tested, having been used for many years by researchers around the world to study the problems of mine ventilation and to, more recently, study the effects of fires in underground cavities [

22,

23]. Many studies have been carried out using these calculation tools, making it possible to analyze the conditions of the ventilation system and the evolution of fires. The availability of the measurements made on site and the comparison with the modeling results allowed the validation of the calculation tool [

24,

25,

26,

27].

Furthermore, the same authors of this paper have studied, in detail, the ventilation of the same mine that is under study via the use of the same calculation program (Ventsim), and they were able to successfully compare the results with the in situ measurements [

28].

The advantage of the used program is that it is versatile and precise in its calculations. It is able to consider a substantial number of parameters that can condition the air flow inside mining voids, even in the case of strong perturbations that are due to localized increases in temperature due to a fire.

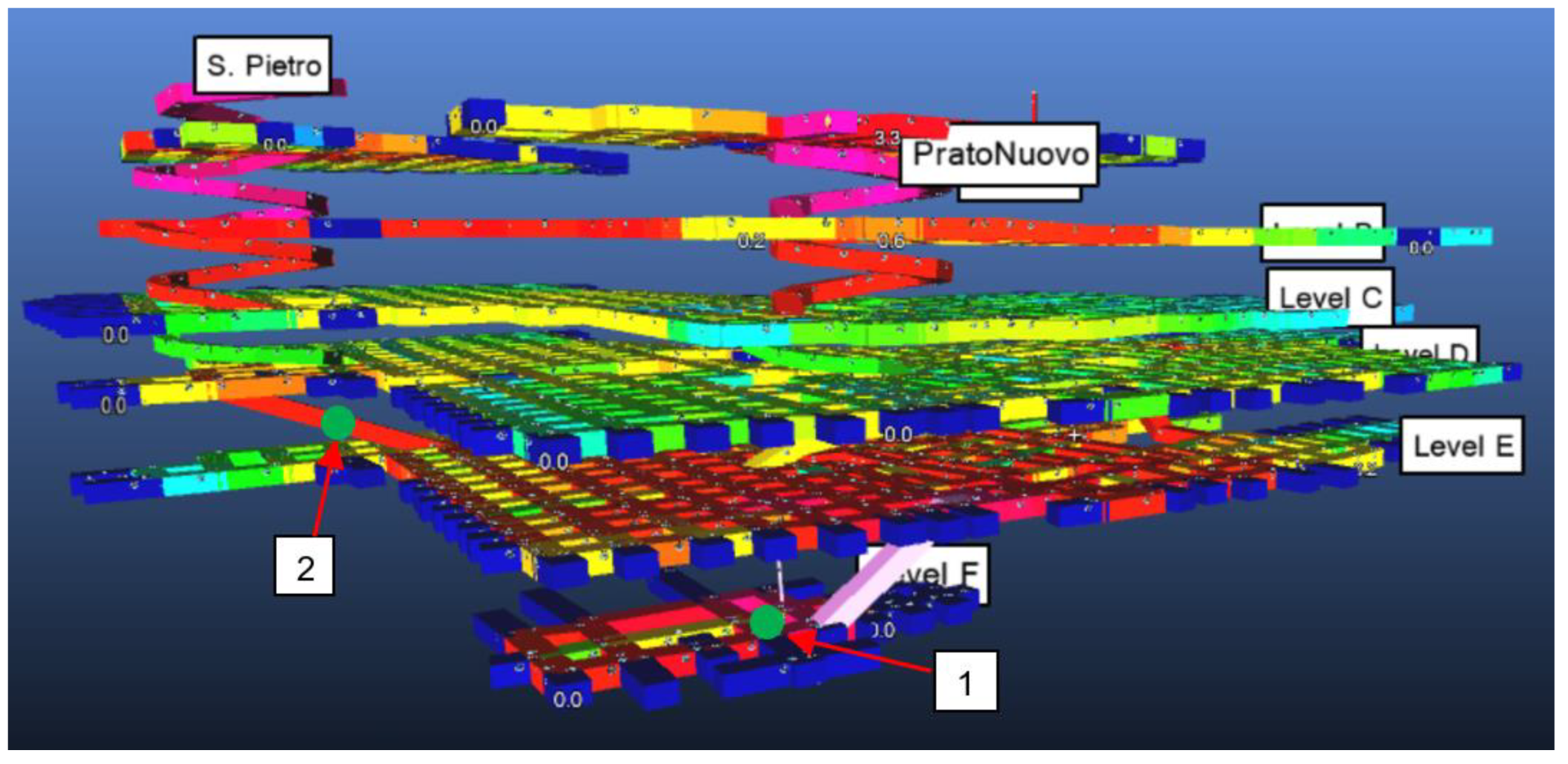

3. The Studied Case of the Murisengo Underground Quarry in Italy

The underground gypsum quarry, which is studied in this work, is located in the northwest of Italy, specifically in the Piedmont Region (

Figure 1). The gypsum extracted from this quarry is mostly used in the construction industry. The adopted exploitation method is the room-and-pillar method, with the use of explosives.

The gypsum formation was formed in the Messinian, approximately 5–7 million years ago, with the evaporation of the water of the Mediterranean Sea, which subsequently confined the gypsum within the lakes, following the lifting of the Earth’s crust in this area. The deposit, which is homogeneous and flattened in shape with a thickness of around 30–40 m and a plant development of a few hundred meters, is covered by incoherent soil and a layer of marl and calcareous sandstone that is of a thickness of approximately 20–30 m.

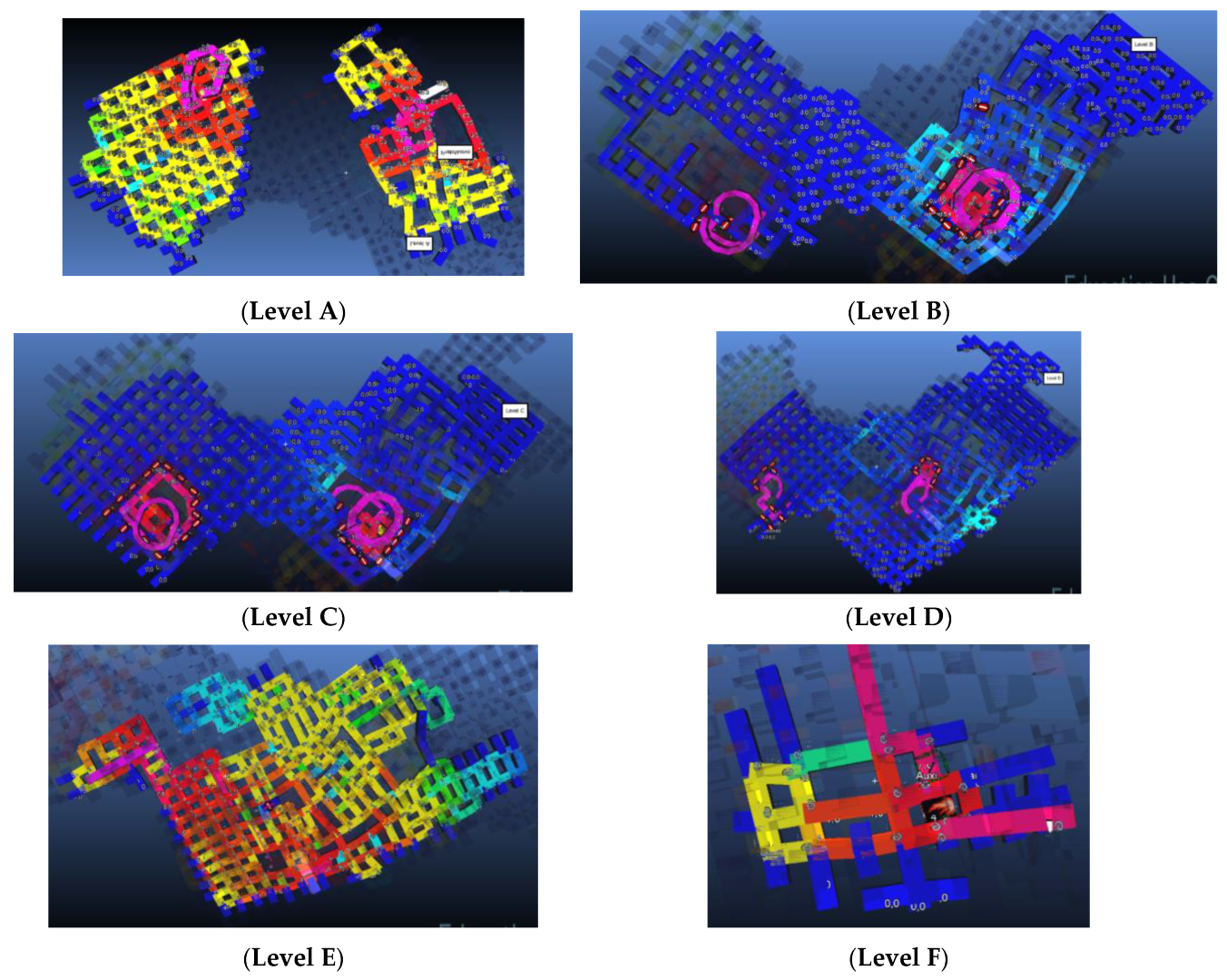

With respect to the aforementioned information, there are six exploiting levels, as outlined in the following:

Level “A”, which has the oldest and most geomechanically unstable portion, which is now depleted;

Level “B”, which connects the two parts of the mine (Prato Nuovo and San Pietro), and is now depleted;

Level “C”, which has outstanding mineralogical characteristics, and is now depleted;

Level “D”, which has an excellent quality gypsum, and is now depleted, but with the possibility of a future expansion;

Levels “E” and “F”, which have an excellent quality gypsum, and are currently active.

Due to the reduced geomechanical characteristics of the gypsum, it is necessary to abandon pillars of considerable size (with a section of 8 m × 8 m) in the deposit. The rooms also have dimensions that are comparable to those of the pillars (

Figure 2). The height of the pillars and rooms is around 8 m. A slab of approximately 4 m is left between one level and another.

The adopted exploitation method involves using machines for drilling blast holes and transporting the broken rock. This method is flexible, allowing a simultaneous attack on multiple faces and a specific adaptation of the dimensions of rooms and pillars to the actual characteristics of the deposit in the various zones of the mine.

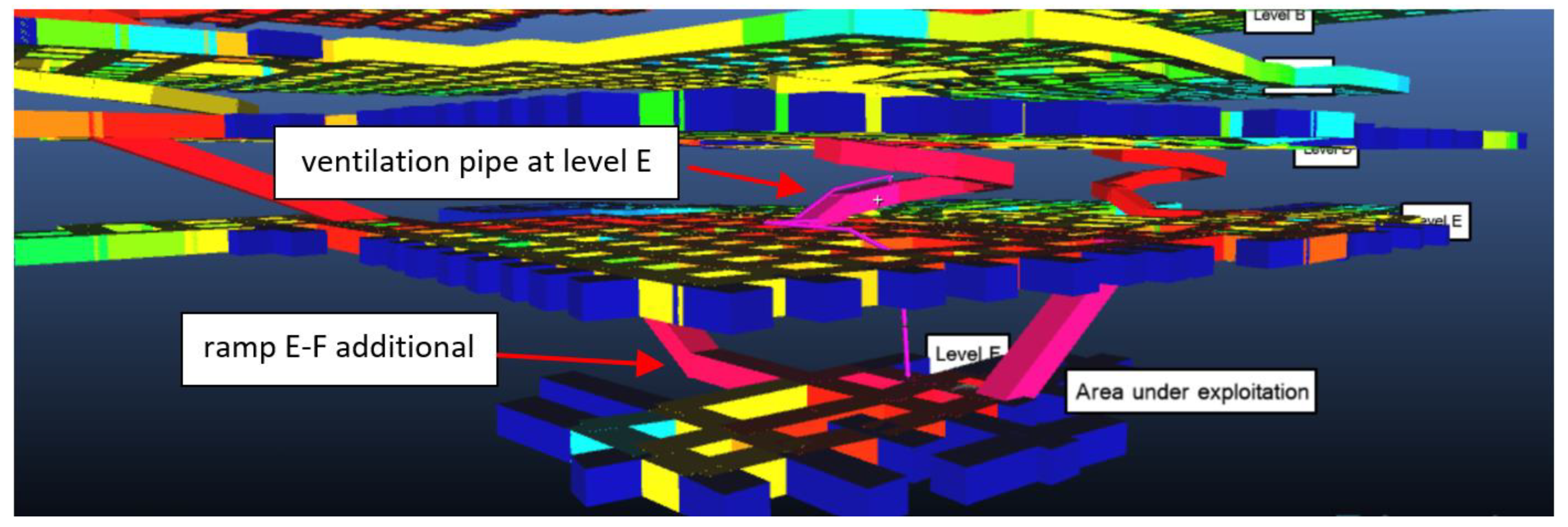

Ventilation in the mine involves the entry of an air flow rate of around 18 m3/s from a lateral ramp called S. Pietro. The ventilation reaches different levels, and the exit of the contaminated air is via a central ramp named Prato Nuovo. Levels B to E connect the two areas of the mine and the two ramps. Level F has only one access point from Level E, with a specific ramp called the E–F ramp. The deeper levels (E and F) are also connected by a small well made in the separation slab, where the main fan is located. This fan sucks in the air from Level F where it arrives through the E–F ramp and sends it to Level E, near the Prato Nuovo ramp, thanks to which the air reaches the outside.

The analysis of the ventilation circuit has highlighted a certain degree of air recirculation in the deepest area of the mine. In addition, the transit of the significant air flows in the more superficial levels (B, C, and D) that are now abandoned. The more superficial levels, therefore, constitute a short circuit in the ventilation, thereby limiting the flow of fresh air that reaches the deepest and most active levels. Due to these aspects, the exhaust gases of diesel vehicles operating underground are removed with a certain difficulty, and their concentration can rise to reach values that are considered inadmissible. For this reason, the following improvements have been made to the ventilation circuit:

An air pipe at the fan’s outlet in order to direct exhausted air toward the Prato Nuovo ramp (i.e., the outlet duct) that crosses Level E;

Barriers at the ramps’ connection zones, with Levels B, C, and D being able to prevent the short circuit in the upper part of the mine;

A second ramp (ramp E–F additional) connecting Levels E and F.

These interventions have shown, from the calculation, an improvement in the efficiency of the ventilation circuit with a considerable supply of fresh air at the lower level (F), as well as a significant reduction in the concentration of toxic gases produced by diesel vehicles operating underground, especially in the active levels (E and F).

4. Fire Scenarios and Emergency Plans

In order to analyze, in detail, what happens inside the mine during a fire to the diesel vehicles present, various numerical models have been developed (

Figure 3,

Figure 4 and

Figure 5). In particular, two hypotheses have been made about the position of the burning vehicle, which are as follows:

In the model, the placements of the fire consider the type of vehicle and the route that it generally travels inside the mine. Among all the possible cases, the positions that can produce the worst conditions for the workers present in the subsoil have been chosen. Various numerical simulations were considered in order to verify the worst condition of the vehicles during the fire phase, both from the point of view of the air temperature and of the concentration of toxic and harmful gases, considering the speed of propagation of the fumes and the time that they take to reach the areas that are dedicated to personnel evacuation.

Furthermore, the current situation of the mine (Case A) and the one that is realized following the three improvement interventions on the ventilation mentioned above (Case B) have been studied. In total, therefore, there were four numerical models developed, which were obtained from the combination of Cases 1 and 2, and Cases A and B, thus: A1, A2, B1, and B2.

In order to define the HRR (heat release rate) trend over time of each of the two hypothesized fires, certain assessments were made on the amount of combustible material that is present on the two considered vehicles (

Table 1). The simulated fires have a total duration of 30 min, with an initial linear growth of the HRR period (5 min), a period of constant HRR (20 min), and a final linear decay period (5 min). The assumed fires in the model correspond to a rapidly growing fire, which represents the worst case scenario in an underground mine. The soot produced by the fire, which varies according to the time, is correlated in Ventsim to the quantity and type of burned fuel, to the emitted thermal power, as well as to the air temperature and composition.

From the numerical calculation, it is possible to detect the trend of air temperatures and the composition of toxic gases over time in the various areas of the mine, with particular reference to the areas where the miners work (active sites) and to the escape routes during the emergency. The Ventsim 5.4 program was used for this study (URL

https://ventsim.com/ (accessed on 5 December 2022)).

The escape routes consist of the two access ramps to the mine: the S. Pietro ramp and the Prato Nuovo ramp. For Case 1 (i.e., a fire in Level F, simulations A1 and B1), both escape routes can be chosen by the staff; however, it should be borne in mind that the Prato Nuovo ramp (the central one) is also the way out for the air and, therefore, for the fumes in the event of an underground fire. In Case 2 (i.e., a fire in the S. Pietro ramp, the lateral one that is used to move the dumpers, simulations A2 and B2), the S. Pietro ramp cannot be used as an escape route due to the presence of the fire. In addition, it is necessary to choose the Prato Nuovo ramp with the risk of the co-presence of fumes and high temperatures together with the staff during the evacuation.

5. Obtained Results by the Numerical Modeling

The results obtained from the numerical calculation are shown below. For each examined case, it was possible to see, over time, the air conditions in the zones (i.e., the E–F ramp and the Prato Nuovo one) where miners can take the emergency route to reach the surface. More specifically, the air temperature and composition were analyzed in order to be able to understand what the available safe time is after which sanitary risks can occur via the miners.

Table 2 shows the minutes, after the ignition of the fire, beyond which the air becomes unbreathable due to a high concentration of toxic gases. These can occur in various specific points of the mine, such as at Level E, from where the exit emergency (Prato Nuovo ramp) starts, as well as on the ramp that connects Levels E and F.

5.1. Case A1 (Current Situation and Fire at Level F)

The simulation of the fire allows one to detect a progressive increase in CO and CO2 values at Level E near the exit of the shaft where the main fan is located. Just a few seconds after the fire has started, the CO values exceed the limit of 25 ppm and CO2 5000 ppm in that area. The area with a high concentration of toxic gases expands considerably over time at Level E, until it invades (after around 8 min) the entire connection area between the E–F ramp and the Prato Nuovo ramp, from which it is possible to reach the surface for workers during the emergency evacuation. After approximately 10 min, even the same E–F ramp is contaminated with toxic gases beyond the admissible levels.

5.2. Case A2 (Current Situation and Fire in the S. Pietro Ramp)

With the assumed fire on a dumper at the S. Pietro ramp, which is between Levels D and E, the diffusion of toxic fumes develops mainly at Level D. There is a progressive expansion of the area with toxic gas concentrations that are higher than the maximum permissible values. After around 12 min from the start of the fire, the concentration of CO exceeds 25 ppm in the Prato Nuovo ramp also (between Levels D and E), which could be used by miners when fleeing active mining sites toward the surface.

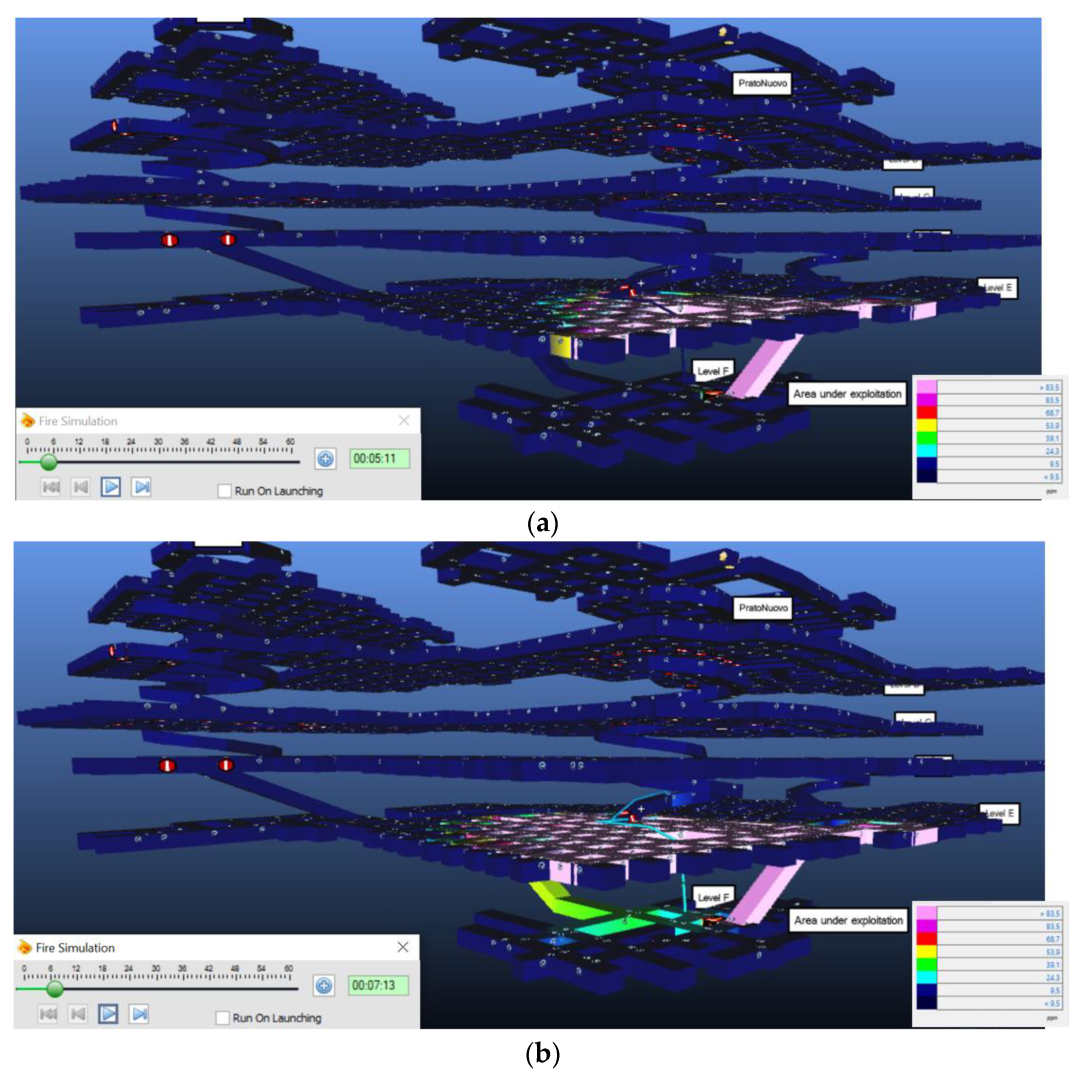

5.3. Case B1 (the Situation with the Advised Improvements to the Ventilation Circuit and Fire at Level F)

With the three interventions that are advised for the improvement of the ventilation circuit (

Section 4), a clear improvement in environmental conditions and in the supply of fresh air in the deeper active levels of the mine (Levels E and F) is achieved. However, with the triggering of a fire in Level F, one of the two access ramps to that level (ramp E–F) immediately reverses the flow of ventilation, thus allowing the fumes to rapidly invade Level E and the area of access around the Prato Nuovo ramp. After only 5 min from the ignition of the fire, dangerous levels of CO invade the access area to the San Pietro ramp, thereby preventing evacuation to the outside from that escape route (

Figure 6a); after 7 min, the second access ramp to Level F also reaches CO concentrations that are incompatible with survival (

Figure 6b). After 8 min, the Prato Nuovo ramp is saturated with the smoke that is produced by the fire. In practice, the advised improvements do not allow better evacuation conditions for miners during the emergency.

5.4. Case B2 (Situation with the Planned Advised Improvements to the Ventilation Circuit and Fire in the S. Pietro Ramp)

With the fire on the San Pietro ramp, the fumes produced tend to slowly invade Level E. However, this leaves the possibility of escape through the Prato Nuovo ramp. Only after approximately 12 min from the start of the fire do the toxic fumes (CO) reach the E–F additional ramp and, subsequently, part of Level F; the CO2 concentrations become dangerous at Level F only after 20 min from the start of the fire. Escape is, however, still always possible through the alternative ramp (ramp E–F) and the Prato Nuovo ramp, where the concentration of the CO never reaches the threshold value of 25 ppm.

6. Discussion

From the developed numerical study, it is possible to detect how, in the current condition of the mine, the available times to safely reach the escape routes can be reduced. This can be achieved to an order of 8–10 min from the start of a fire in the two different hypothesized locations (Cases A1 and A2). Even in the presence of the advised improvements on the ventilation circuit, however, the fire from a loader at Level F would induce very high concentrations of toxic fumes in a short time in all possible directions during the evacuation of the personnel (Case B1). The advised improvements would, however, allow for a possible evacuation of the personnel in adequate times in the event of a dumper fire at the San Pietro ramp (Case B2).

In order to verify the effectiveness of the management of the main fan, in the presence of improvement interventions on the ventilation circuit during a fire from a front loader in Level F, the possible shutdown of the fan (Case B1 second) or its inversion (Case B1 third) have been foreseen. Turning off the fan does not induce significant improvements on the propagation of toxic fumes, nor on the available times for evacuation. Meanwhile, the inversion of the fan allows an increase, even if it is not by much, in the available time for the staff to reach the S. Pietro ramp.

However, after following the advised improvement interventions on the ventilation circuit, it is necessary to pay particular attention to the risk of fire of a diesel vehicle in the deepest active level (Level F). In that case, it would be necessary to signal the immediate evacuation of all personnel toward the San Pietro ramp with a simultaneous reversal of the main fan of the mine.

From the developed numerical study, it was possible to detect how the developed emergency plans, in the presence of improvements to the ventilation circuit inside the mine, would allow the safety of the miners when a fire occurs. This important condition is achieved in the presence of three specific actions that must be undertaken, which are as follows: rapid information to all workers present in the subsoil regarding the presence of a fire, and its position, immediately after it has started; the consequent request to abandon the mine following the pre-established escape route; and the reversal of the mine’s main fan. In order to guarantee the reliability of the emergency plans, it is necessary to have widespread automatic fire detectors available inside the mine, which are capable of signaling the existence, location, and extent of the underground fire to the safety managers.

This study made it possible to demonstrate how today, thanks to the availability of powerful calculators and efficient numerical calculation programs, it is possible to analyze a significant number of cases and identify the most critical ones for the safety of personnel during the development of a fire. The analysis of the results renders it possible to understand whether the time available for a possible escape is sufficient in order to prevent the miners from coming into contact with the fumes that are produced by a possible fire inside the mine.

7. Conclusions

A fire in an underground mine is a major source of risk for workers. In fact, in a confined environment, the fire can evolve very quickly, and the produced toxic fumes can reach the miners in the active site where they operate or along the escape routes to the surface.

The diesel vehicles operating in underground mines use a considerable amount of fuel; it is not uncommon for some anomaly to occur and cause an instance of overheating or a spark to start a fire. The presence of ventilation inside the mine is an aspect that must be properly considered for its effects on the evolution of the fire and on the movement of toxic fumes.

For a detailed analysis of fires in underground mines, it is necessary to use numerical modeling. Thanks to this, it is now possible to study the effects of an underground fire on the environmental conditions in the mine and, in particular, to verify the propagation, over time, of the toxic fumes.

In this paper, different fire scenarios were studied in an underground gypsum mine in northwest Italy. For each of the hypothesized positions of a fire due to a diesel vehicle, it was possible with the Ventsim 5.4 calculation program to evaluate the propagation of toxic fumes (in particular, carbon monoxide and carbon dioxide) and the available time to allow a safe evacuation. For each examined case, the strategies for choosing the escape route and managing the mine’s main fan were evaluated.

The conducted study represents a successful application of sophisticated calculation methods regarding a coupled analysis of ventilation and underground fires in mines. This was conducted as a useful support for the definition of emergency plans that are capable of guaranteeing the safety of personnel in high-risk conditions. In fact, it was possible to identify the suitable escape routes for evacuating personnel for the various assumed fire scenarios, as well as the management strategies that are to be adopted in the event of an emergency. In the event of a front loader fire at the deepest level, i.e., Level F, as an example, it is necessary to deliver an immediate evacuation order to the personnel toward the San Pietro ramp and to immediately reverse the main fan of the mine, thus guaranteeing the abandonment of the deepest levels within the available 6 min.

The evolution of studies and research in this delicate area of mining safety will have to be concerned with the implementation of emergency plans on a probabilistic basis, determining what is the probability of survival for each individual miner when a fire is triggered on a vehicle or plant at a specific point of the mine. These probabilistic studies will have to take into account all the machines or plants that are present in the mine and, therefore, also the probability that a fire will start in a particular area; in the same way, the probability that each individual miner is located in the various possible areas in which they operate must be considered. The probabilistic studies will have to use the same three-dimensional numerical models illustrated in this paper, as well as having to demonstrate that they are able to evaluate the time available to the miners to be able to safely undertake the escape route, specifically before the toxic fumes of the fire make the atmosphere unbreathable.