Cu(In,Ga)Se2:Te Thin Films for Stoichiometric Compensation by Using Co-Sputtering and Rapid Thermal Annealing †

Abstract

1. Introduction

2. Materials and Methods

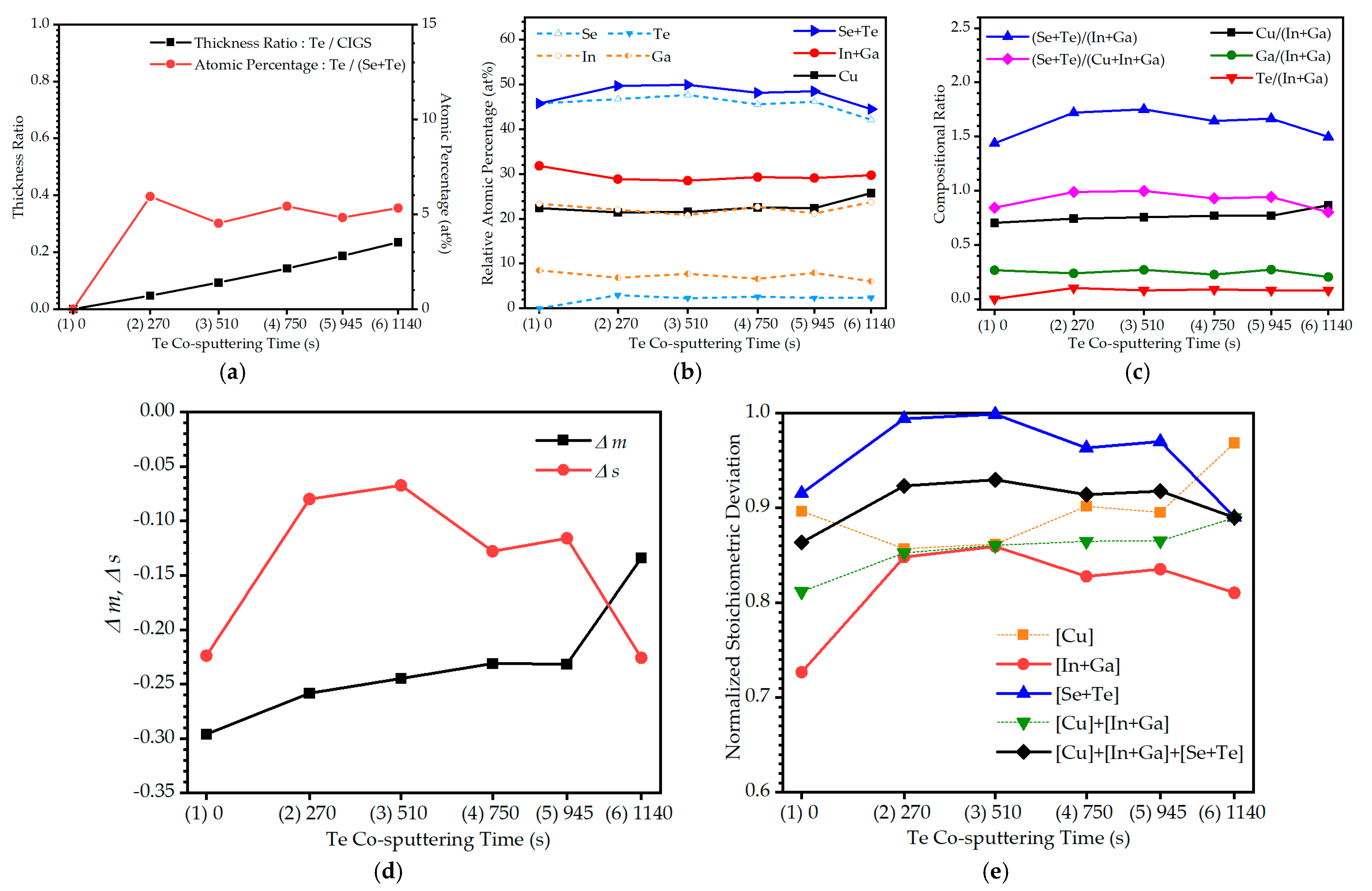

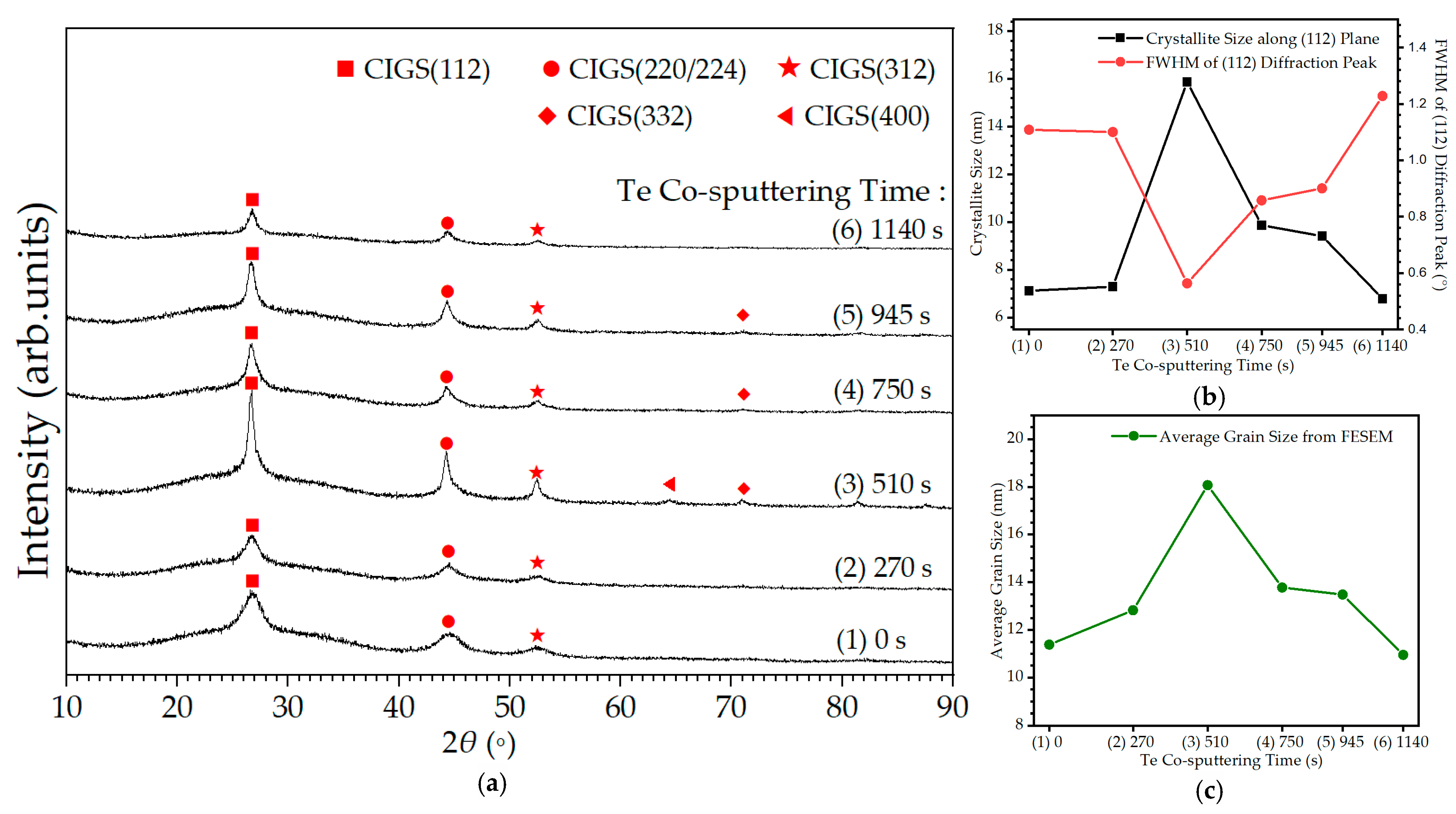

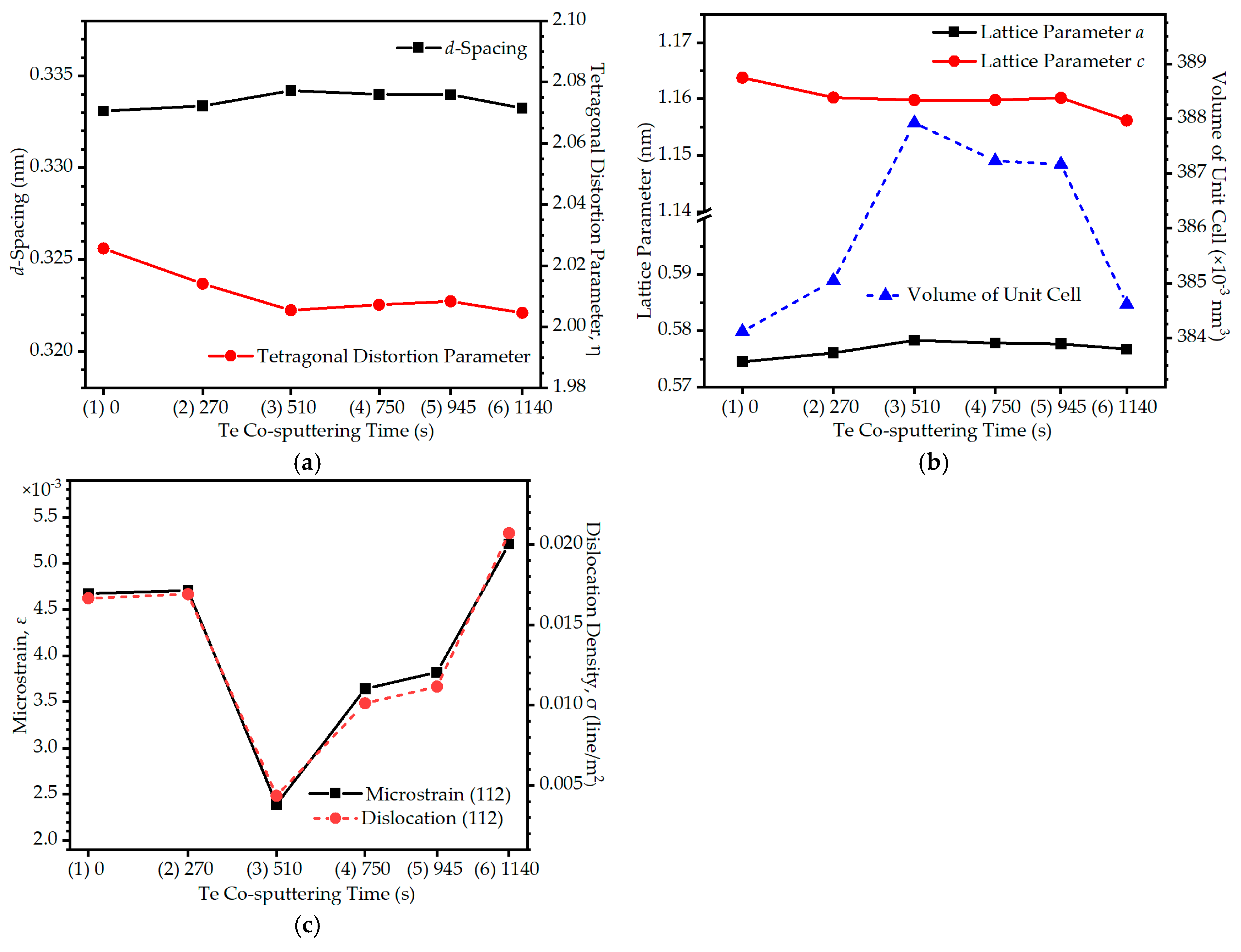

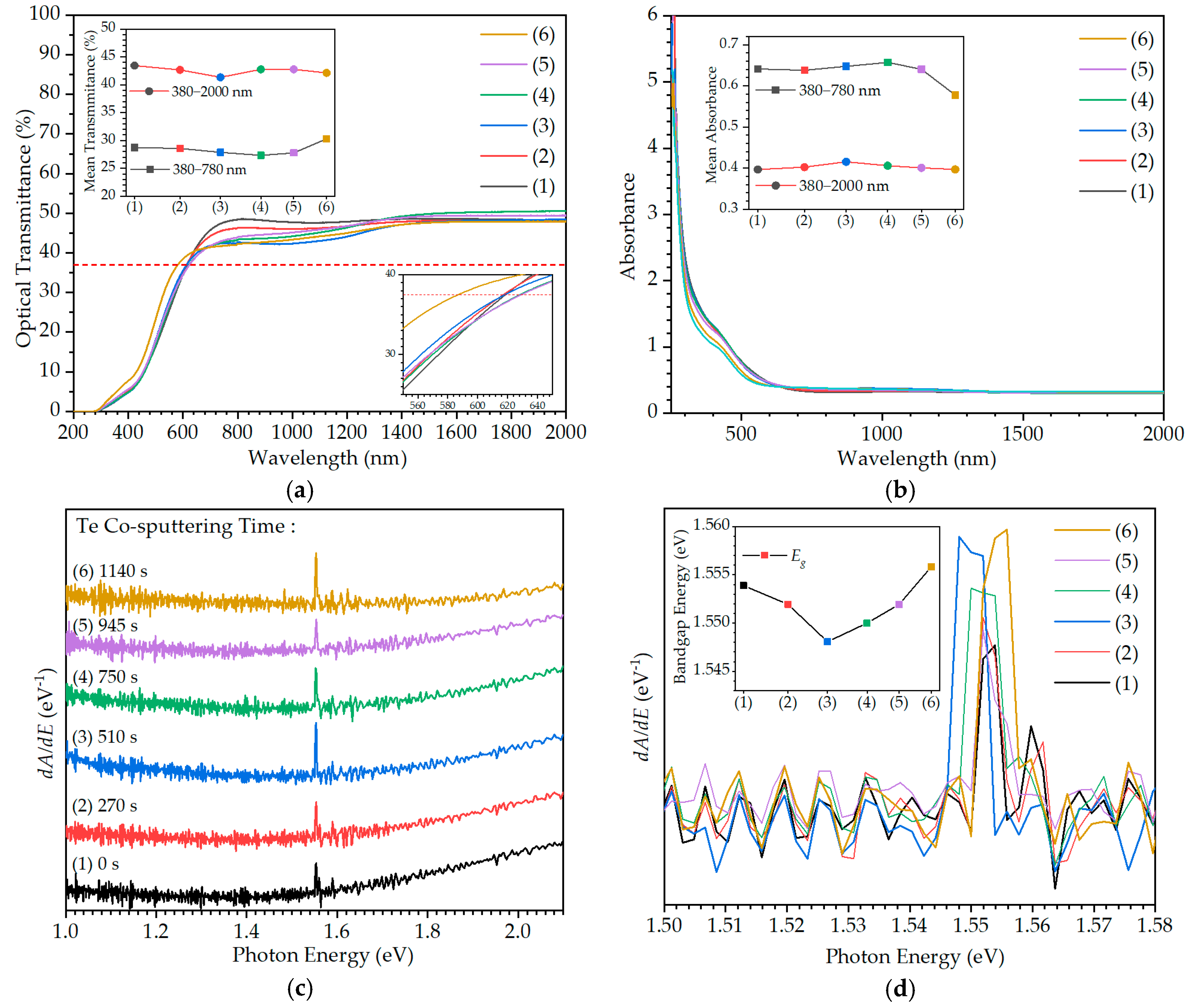

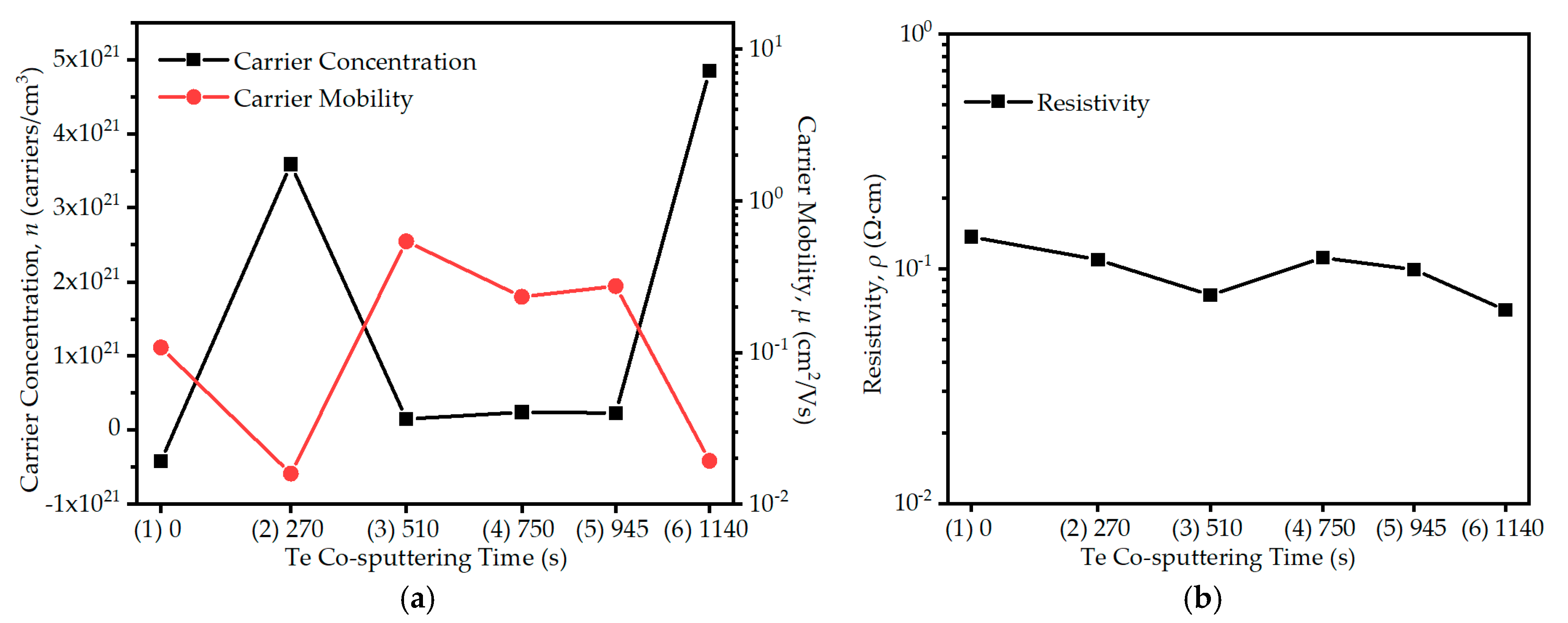

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Atasoy, Y.; Başol, B.M.; Polat, İ.; Tomakin, M.; Parlak, M.; Bacaksız, E. Cu(In,Ga)(Se,Te)2 pentenary thin films formed by reaction of precursor layers. Thin Solid Films. 2015, 592, 189–194. [Google Scholar] [CrossRef]

- Kim, N.-H.; Jun, Y.-K.; Lee, W.-S. Co-Sputtered and Rapid-Thermal-Annealed CIAS Thin Films Using CuSe2/In/Al Triple Targets of Varying In/Al Compositions. J. Nanosci. Nanotechnol. 2016, 16, 1583–1586. [Google Scholar] [CrossRef] [PubMed]

- Teknetzi, I.; Holgersson, S.; Ebin, B. Valuable metal recycling from thin film CIGS solar cells by leaching under mild conditions. Sol. Energy Mater. Sol. Cells 2023, 252, 112178. [Google Scholar] [CrossRef]

- Huang, P.C.; Sung, C.C.; Chen, J.H.; Hsiao, R.C.; Hsu, C.Y. Effect of selenization and sulfurization on the structure and performance of CIGS solar cell. J. Mater. Sci. -Mater. Electron. 2018, 29, 1444–1450. [Google Scholar] [CrossRef]

- Za’abar, F.I.; Yusoff, Y.; Mohamed, H.; Abdullah, S.F.; Zuhdi, A.W.M.; Amin, N.; Chelvanathan, P.; Bahrudin, M.S.; Rahman, K.S.; Samsudin, N.A.; et al. A numerical investigation on the combined effects of MoSe2 interface layer and graded bandgap absorber in CIGS thin film solar cells. Coatings 2021, 11, 930. [Google Scholar] [CrossRef]

- Mabvuer, F.T.; Nya, F.T.; Kenfack, G.M.D.; Laref, A. Lowering Cost Approach for CIGS-Based Solar Cell Through Optimizing Band Gap Profile and Doping of Stacked Active Layers—SCAPS Modeling. ACS Omega 2023, 8, 3917–3928. [Google Scholar] [CrossRef]

- Kim, N.-H.; Oh, S.; Lee, W.S. Non-selenization method using sputtering deposition with a CuSe2 target for CIGS thin film. J. Korean Phys. Soc. 2012, 61, 1177–1180. [Google Scholar] [CrossRef]

- Lin, Y.C.; Lin, Z.Q.; Shen, C.H.; Wang, L.Q.; Ha, C.T.; Peng, C. Cu(In,Ga)Se2 films prepared by sputtering with a chalcopyrite Cu(In,Ga)Se2 quaternary alloy and In targets. J. Mater. Sci. -Mater. Electron. 2011, 23, 493–500. [Google Scholar] [CrossRef]

- Yu, S.; Jiang, J.; Han, S.; Hao, S.; Zhu, Q.; Gong, Y.; Yan, W.; Huang, W.; Xin, H. Structure engineering of solution-processed precursor films for low temperature fabrication of CuIn(S,Se)2 solar cells. Sol. Energy 2021, 220, 796–801. [Google Scholar] [CrossRef]

- Jheng, B.T.; Liu, P.T.; Wu, M.C.; Shieh, H.P. A non-selenization technology by co-sputtering deposition for solar cell applications. Opt. Lett. 2012, 37, 2760–2762. [Google Scholar] [CrossRef]

- Oh, S.; Kim, N.-H. Cigs Thin Films Sputtered by Using Chalcogenide Cuse2 With Multilayer-Stack-Structure and Rapid Thermal Annealing. Chalcogenide Lett. 2014, 11, 71–77. Available online: http://www.chalcogen.ro/71_Oh.pdf (accessed on 27 February 2023).

- Bouchama, I.; Djessas, K.; Saeed, M.A. Physical properties of CuIn0.7Ga0.3Se2 ingot and thin films prepared by one-step rf-magnetron sputtering from single-target material. J. Mol. Struct. 2020, 1217, 128457. [Google Scholar] [CrossRef]

- Kim, N.-H.; Jun, Y.K.; Cho, G.B. Se-loss-induced CIS Thin Films in RTA Process after Co-sputtering Using CuSe2 and InSe2 Targets. J. Electr. Eng. Technol. 2014, 9, 1009–1015. [Google Scholar] [CrossRef]

- Bouabid, K.; Ihlal, A.; Manar, A.; Outzourhit, A.; Ameziane, E.L. Effect of deposition and annealing parameters on the properties of electrodeposited CuIn1− xGaxSe2 thin films. Thin Solid Films. 2005, 488, 62–67. [Google Scholar] [CrossRef]

- Ahmed, E.; Zegadi, A.; Hill, A.E.; Pilkington, R.D.; Tomlinson, R.D.; Dost, A.A.; Ahmed, W.; Leppävuori, S.; Levoska, J.; Kusmartseva, O. The influence of annealing processes on the structural, compositional and electro-optical properties of CuIn0.75Ga0.25Se2 thin films. J. Mater. Sci.-Mater. Electron. 1996, 7, 213–219. [Google Scholar] [CrossRef]

- Do, Q.; Manh, N.T.; Triet, L.N.D.; Choi, Y.; Lee, Y.-W.; Cho, Y.; Lee, K.J.; Cho, N. Controlling the morphology of solution-processed CuIn(SSe)2 absorber layers by film thickness and annealing temperature. Mol. Cryst. Liquid Cryst. 2020, 707, 126–139. [Google Scholar] [CrossRef]

- Desarada, S.V.; Chavan, K.B.; Chaure, N.B. Effect of Different Annealing Techniques on CIGS Deposited Using One-Step Single-Target Sputtering. J. Electron. Mater. 2023, 1–7. [Google Scholar] [CrossRef]

- Singh, H.; Bharti, A.; Kumar, A.; Goyal, N.; Gill, P.S. Crystal Structure Characterization and Morphology of Tellurium Doped Multicomponent Chalcogenide Copper Indium Gallium Diselenide Compound. Mater. Focus 2017, 6, 611–617. [Google Scholar] [CrossRef]

- Fiat, S.; Koralli, P.; Bacaksiz, E.M.; Giannakopoulos, K.P.; Kompitsas, M.; Manolakos, D.E.; Çankaya, G.Ü. The influence of stoichiometry and annealing temperature on the properties of CuIn0. 7Ga0.3Se2 and CuIn0.7Ga0.3Te2 thin films. Thin Solid Films 2013, 545, 64–70. [Google Scholar] [CrossRef]

- Singh, U.P.; Shafarman, W.N.; Birkmire, R.W. Surface sulfurization studies of Cu(InGa)Se2 thin film. Sol. Energy Mater. Sol. Cells 2006, 90, 623–630. [Google Scholar] [CrossRef]

- Kim, S.; Kim, N.-H. Impurity phases and optoelectronic properties of CuSbSe2 thin films prepared by cosputtering process for absorber layer in solar cells. Coatings 2020, 10, 1209. [Google Scholar] [CrossRef]

- Oh, S.; Park, Y.S.; Ko, P.J.; Kim, N.-H. Effects of rapid thermal treatment on properties of magnetron-sputtered NiO thin films for supercapacitor applications. J. Nanosci. Nanotechnol. 2018, 18, 6213–6219. [Google Scholar] [CrossRef] [PubMed]

- Khosroshahi, R.; Dehghani, M.; Tehrani, N.A.; Taghavinia, N.; Bagherzadeh, M. Optimization of selenization process to remove Ga-induced pin-holes in CIGS thin films. Sol. Energy 2022, 236, 175–181. [Google Scholar] [CrossRef]

- Pech, S.; Kim, S.; Kim, N.-H. Magnetron Sputter-Deposited β-Ga2O3 Films on c-Sapphire Substrate: Effect of Rapid Thermal Annealing Temperature on Crystalline Quality. Coatings 2022, 12, 140. [Google Scholar] [CrossRef]

- Erkan, S.; Başol, B.M.; Atasoy, Y.A.; Çiriş, A.; Yüksel, Ö.F.; Bacaksız, E. Cu(In,Ga)Te2 film growth by a two-stage technique utilizing rapid thermal processing. Semicond. Sci. Technol. 2019, 34, 035011. [Google Scholar] [CrossRef]

- Atasoy, Y.; Başol, B.M.; Olğar, M.A.; Tomakin, M.U.; Bacaksız, E. Cu(In,Ga)(Se,Te)2 films formed on metal foil substrates by a two-stage process employing electrodeposition and evaporation. Thin Solid Films 2018, 649, 30–37. [Google Scholar] [CrossRef]

- Kim, N.-H.; Sung, B.S.; Jun, Y.K.; Chung, D.H.; Lee, W.S. Low-temperature, rapid thermal annealing of CIS thin films deposited by using a co-sputtering process with in and CuSe2 targets. J. Korean Phys. Soc. 2015, 66, 1001–1008. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Hill, A.E.; Pilkington, R.D.; Cowpe, J.S.; Hisek, J.; Bagnall, D.M. Single step deposition method for nearly stoichiometric CuInSe2 thin films. Thin Solid Films 2011, 519, 3107–3112. [Google Scholar] [CrossRef]

- Wu, S.; Zhou, L.; Wang, Y.; Xue, Y.; Teng, Y. Effect of Al content on the performance of Cu(In,Al)Se2 powders prepared by mechanochemical process. Mater. Sci. Semicond. Process 2014, 18, 128–134. [Google Scholar] [CrossRef]

- Boonlakhorn, J.; Prachamon, J.; Manyam, J.; Krongsuk, S.; Thongbai, P.; Srepusharawoot, P. Colossal dielectric permittivity, reduced loss tangent and the microstructure of Ca1−xCdxCu3Ti4O12−2yF2y ceramics. RSC Adv. 2021, 11, 16396–16403. [Google Scholar] [CrossRef]

- Shokeen, P.; Jain, A.; Kapoor, A.; Gupta, V. Thickness and Annealing Effects on the Particle Size of PLD Grown Ag Nanofilms. Plasmonics 2016, 11, 669–675. [Google Scholar] [CrossRef]

- Wang, C.-J.; Shei, S.-C.; Chang, S.-J. Novel solution process for synthesis of CIGS nanoparticles using polyetheramine as solvent. Mater. Lett. 2014, 122, 52–54. [Google Scholar] [CrossRef]

- Islam, M.A.; Huda, Q.; Hossain, M.S.; Aliyu, M.M.; Karim, M.R.; Sopian, K.; Amin, N. High quality 1 μm thick CdTe absorber layers grown by magnetron sputtering for solar cell application. Curr. Appl. Phys. 2013, 13, S115–S121. [Google Scholar] [CrossRef]

- Hao, S.; Yu, S.; Liu, X.; Li, B.; Han, S.; Xin, H.; Yan, W.; Huang, W. Effect of K Doping on the Performance of Aqueous Solution-Processed Cu(In,Ga)Se2 Solar Cell. Adv. Energy Sustain. Res. 2022, 3, 2200006. [Google Scholar] [CrossRef]

- Kumar, S.; Asokan, K.; Singh, R.K.; Chatterjee, S.; Kanjilal, D.; Ghosh, A.K. Investigations on structural and optical properties of ZnO and ZnO: Co nanoparticles under dense electronic excitations. RSC Adv. 2014, 4, 62123–62131. [Google Scholar] [CrossRef]

- Kim, N.H.; Yoo, M.H.; Ko, P.J.; Lee, W.S. Deviations from stoichiometry and molecularity in non-stoichiometric Ag-In-Se thin films: Effects on the optical and the electrical properties. J. Korean Phys. Soc. 2016, 69, 1817–1823. [Google Scholar] [CrossRef]

- Marai, A.B.; Belgacem, J.B.; Ayadi, J.B.; Djessas, K.; Alaya, S. Structural and optical properties of CuIn1-xGaxSe2 nanoparticles synthesized by solvothermal route. J. Alloys Compd. 2016, 658, 961–966. [Google Scholar] [CrossRef]

- Goh, K.H.; Haseeb, A.S.M.A.; Wong, Y.H. Physical and electrical properties of thermal oxidized Sm2O3 gate oxide thin film on Si substrate: Influence of oxidation durations. Thin Solid Films 2016, 606, 80–86. [Google Scholar] [CrossRef]

- Rabiei, M.; Palevicius, A.; Monshi, A.; Nasiri, S.; Vilkauskas, A.; Janusas, G. Comparing Methods for Calculating Nano Crystal Size of Natural Hydroxyapatite Using X-ray Diffraction. Nanomaterials 2020, 10, 1627. [Google Scholar] [CrossRef]

- Khallaf, H.; Chai, G.; Lupan, O.; Chow, L.; Park, S.; Schulte, A. Characterization of gallium-doped CdS thin films grown by chemical bath deposition. Appl. Surf. Sci. 2009, 255, 4129–4134. [Google Scholar] [CrossRef]

- Reddy, D.S.; Rao, K.N.; Gunasekhar, K.R.; Reddy, N.K.; Kumar, K.S.; Reddy, P.S. Annealing effect on structural and electrical properties of thermally evaporated Cd1−xMnxS nanocrystalline films. Mater. Res. Bull. 2008, 43, 3245–3251. [Google Scholar] [CrossRef]

- Gu, Y.; Li, X.; Yu, W.; Gao, X.; Zhao, J.; Yang, C. Microstructures, electrical and optical characteristics of ZnO thin films by oxygen plasma-assisted pulsed laser deposition. J. Cryst. Growth 2007, 305, 36–39. [Google Scholar] [CrossRef]

- Chandramohan, S.; Sathyamoorthy, R.; Sudhagar, P.; Kanjilal, D.; Kabiraj, D.; Asokan, K. Optical properties of swift ion beam irradiated CdTe thin films. Thin Solid Films 2008, 516, 5508–5512. [Google Scholar] [CrossRef]

- Sathyamoorthy, R.; Narayandass, S.K.; Mangalaraj, D. Effect of substrate temperature on the structure and optical properties of CdTe thin film. Sol. Energy Mater. Sol. Cells 2003, 76, 339–346. [Google Scholar] [CrossRef]

- Oh, M.S.; Hwang, D.K.; Seong, D.J.; Hwang, H.S.; Park, S.J.; Kim, E.D. Improvement of characteristics of Ga-doped ZnO grown by pulsed laser deposition using plasma-enhanced oxygen radicals. J. Electrochem. Soc. 2008, 155, D599. [Google Scholar] [CrossRef]

- Nicolaou, C.; Zacharia, A.; Delimitis, A.; Itskos, G.; Giapintzakis, J. Single-step growth of high quality CIGS/CdS heterojunctions using pulsed laser deposition. Appl. Surf. Sci. 2020, 511, 145547. [Google Scholar] [CrossRef]

- Mansour, A.M.; Nasr, M.; Saleh, H.A.; Mahmoud, G.M. Physical characterization of 5′,5″-dibromo-o-cresolsulfophthalein (BCP) spin-coated thin films and BCP/p-Si based diode. Appl. Phys. A-Mater. Sci. Process. 2019, 125, 625. [Google Scholar] [CrossRef]

- Kodalle, T.; Greiner, D.; Brackmann, V.; Prietzel, K.; Scheu, A.; Bertram, T.; Reyes-Figueroa, P.; Unold, T.; Abou-Ras, D.; Schlatmann, R.; et al. Glow discharge optical emission spectrometry for quantitative depth profiling of CIGS thin-films. J. Anal. At. Spectrom. 2019, 34, 1233–1241. [Google Scholar] [CrossRef]

- Neumann, H.; Tomlinson, R.D. Relation between electrical properties and composition in CuInSe2 single crystals. Sol. Cells 1990, 28, 301–313. [Google Scholar] [CrossRef]

- Müller, J.; Nowoczin, J.; Schmitt, H. Composition, structure and optical properties of sputtered thin films of CuInSe2. Thin Solid Films 2006, 496, 364–370. [Google Scholar] [CrossRef]

- Kim, N.H.; Ko, P.J.; Cho, G.B.; Park, C.I. Rapid laser annealing of Cu(In,Ga)Se2 thin films by using a continuous wave Nd:YAG laser (λ0 = 532 nm). J. Korean Phys. Soc. 2017, 70, 809–815. [Google Scholar] [CrossRef]

- Suresh, S.; Rokke, D.J.; Drew, A.A.; Alruqobah, E.; Agrawal, R.; Uhl, A.R. Extrinsic Doping of Ink-Based Cu(In,Ga)(S,Se)2-Absorbers for Photovoltaic Applications. Adv. Energy Mater. 2022, 12, 2103961. [Google Scholar] [CrossRef]

- Ou, C.Y.; Som, S.; Lu, C.H.; Gupta, K.K.; Chaurasiya, R. Photovoltaic characteristics and computational simulation of samarium-ion doped Cu(In, Ga)Se2 thin films prepared via a non-vacuum coating process. J. Alloys Compd. 2021, 881, 160377. [Google Scholar] [CrossRef]

- Qiao, J.; Zhao, Y.; Jin, Q.; Tan, J.; Kang, S.; Qiu, J.; Tai, K. Tailoring nanoporous structures in Bi2Te3 thin films for improved thermoelectric performance. ACS Appl. Mater. Interfaces 2019, 11, 38075–38083. [Google Scholar] [CrossRef]

- Shinde, U.P. Hall coefficient, mobility and carrier concentration as a function of composition and thickness of Zn-Te thin films. Adv. Appl. Sci. Res. 2015, 4, 215–220. Available online: https://api.semanticscholar.org/CorpusID:55769927 (accessed on 27 February 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pech, S.; Rou, Y.J.; Kim, S.; Lee, K.-Y.; Kim, N.-H. Cu(In,Ga)Se2:Te Thin Films for Stoichiometric Compensation by Using Co-Sputtering and Rapid Thermal Annealing. Appl. Sci. 2023, 13, 4284. https://doi.org/10.3390/app13074284

Pech S, Rou YJ, Kim S, Lee K-Y, Kim N-H. Cu(In,Ga)Se2:Te Thin Films for Stoichiometric Compensation by Using Co-Sputtering and Rapid Thermal Annealing. Applied Sciences. 2023; 13(7):4284. https://doi.org/10.3390/app13074284

Chicago/Turabian StylePech, Sakal, Yun Ju Rou, Sara Kim, Kang-Yeon Lee, and Nam-Hoon Kim. 2023. "Cu(In,Ga)Se2:Te Thin Films for Stoichiometric Compensation by Using Co-Sputtering and Rapid Thermal Annealing" Applied Sciences 13, no. 7: 4284. https://doi.org/10.3390/app13074284

APA StylePech, S., Rou, Y. J., Kim, S., Lee, K.-Y., & Kim, N.-H. (2023). Cu(In,Ga)Se2:Te Thin Films for Stoichiometric Compensation by Using Co-Sputtering and Rapid Thermal Annealing. Applied Sciences, 13(7), 4284. https://doi.org/10.3390/app13074284