An Experimental Study on Ice Accretion under Bridge Cable in Different Conditions

Abstract

1. Introduction

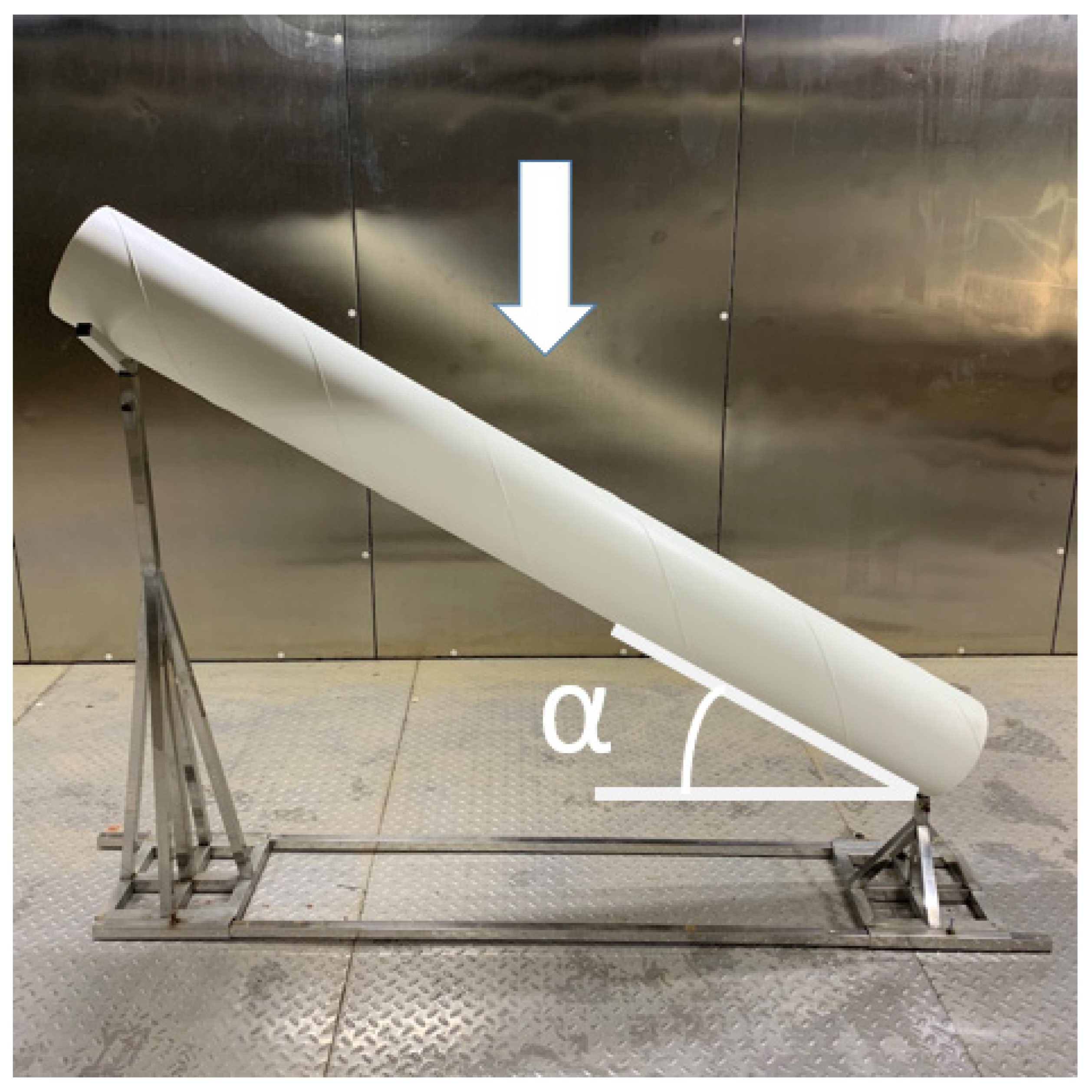

2. Materials and Methods

3. Results and Discussion

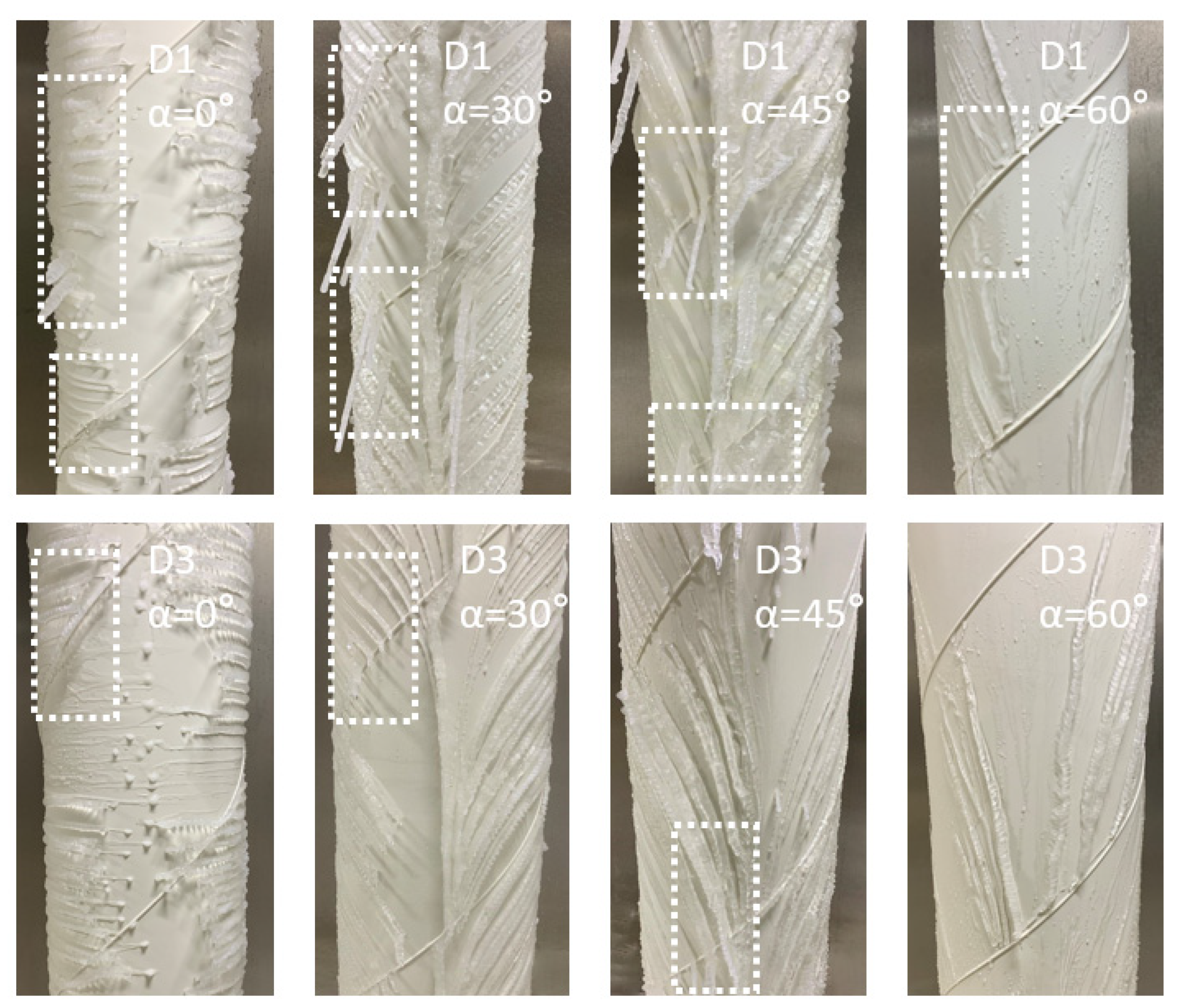

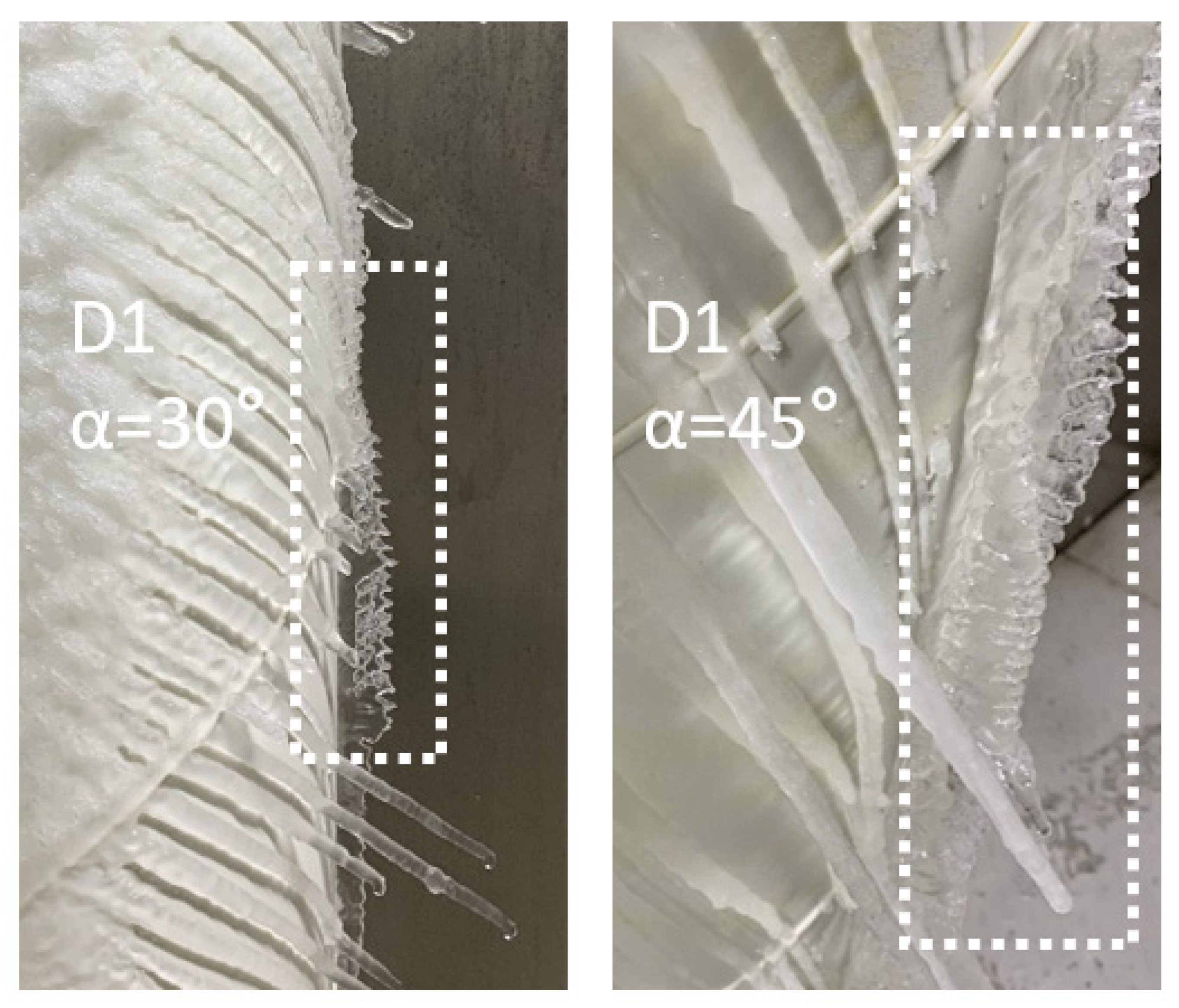

3.1. Formation of Ice on the Surface of the Cable

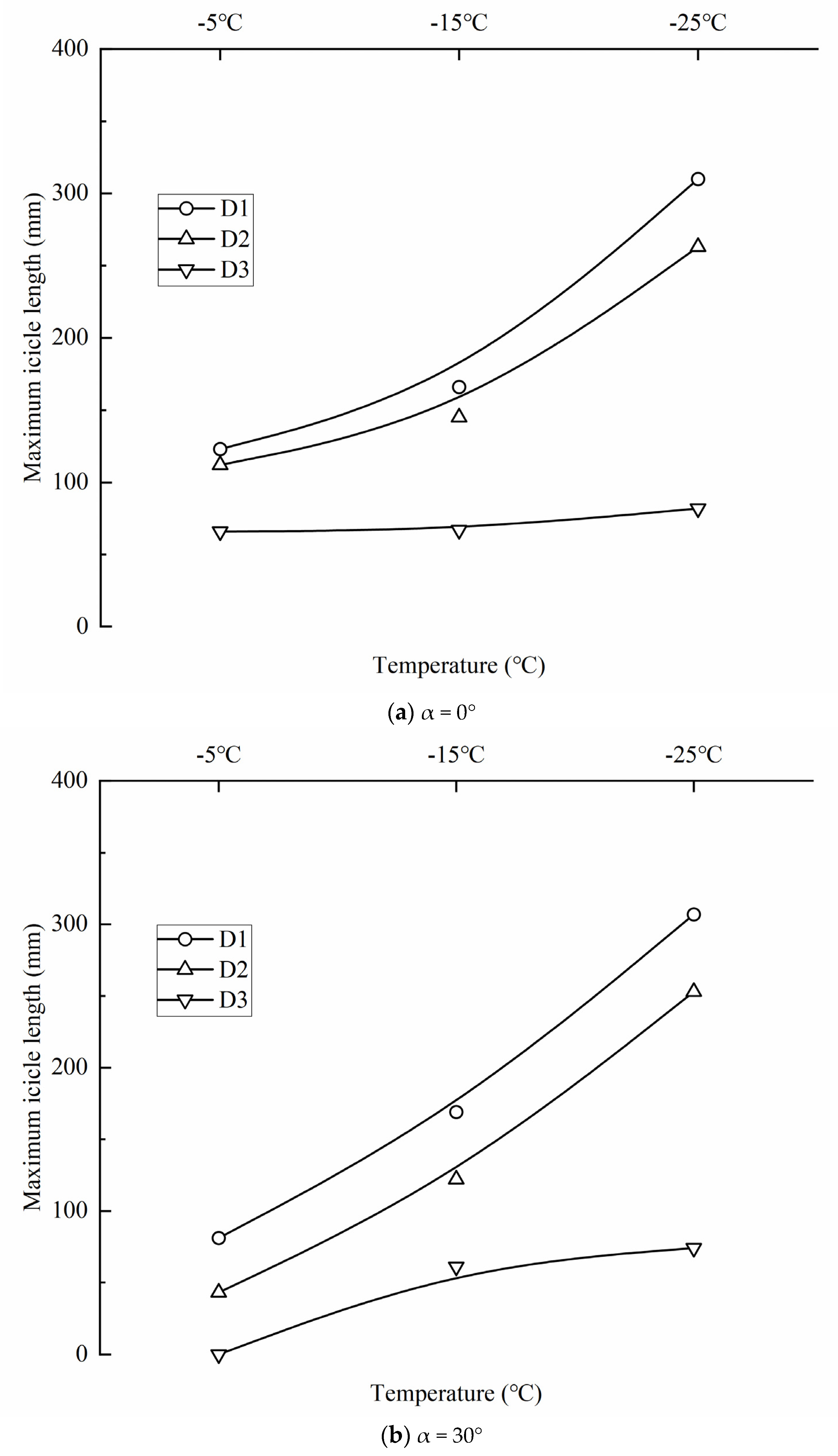

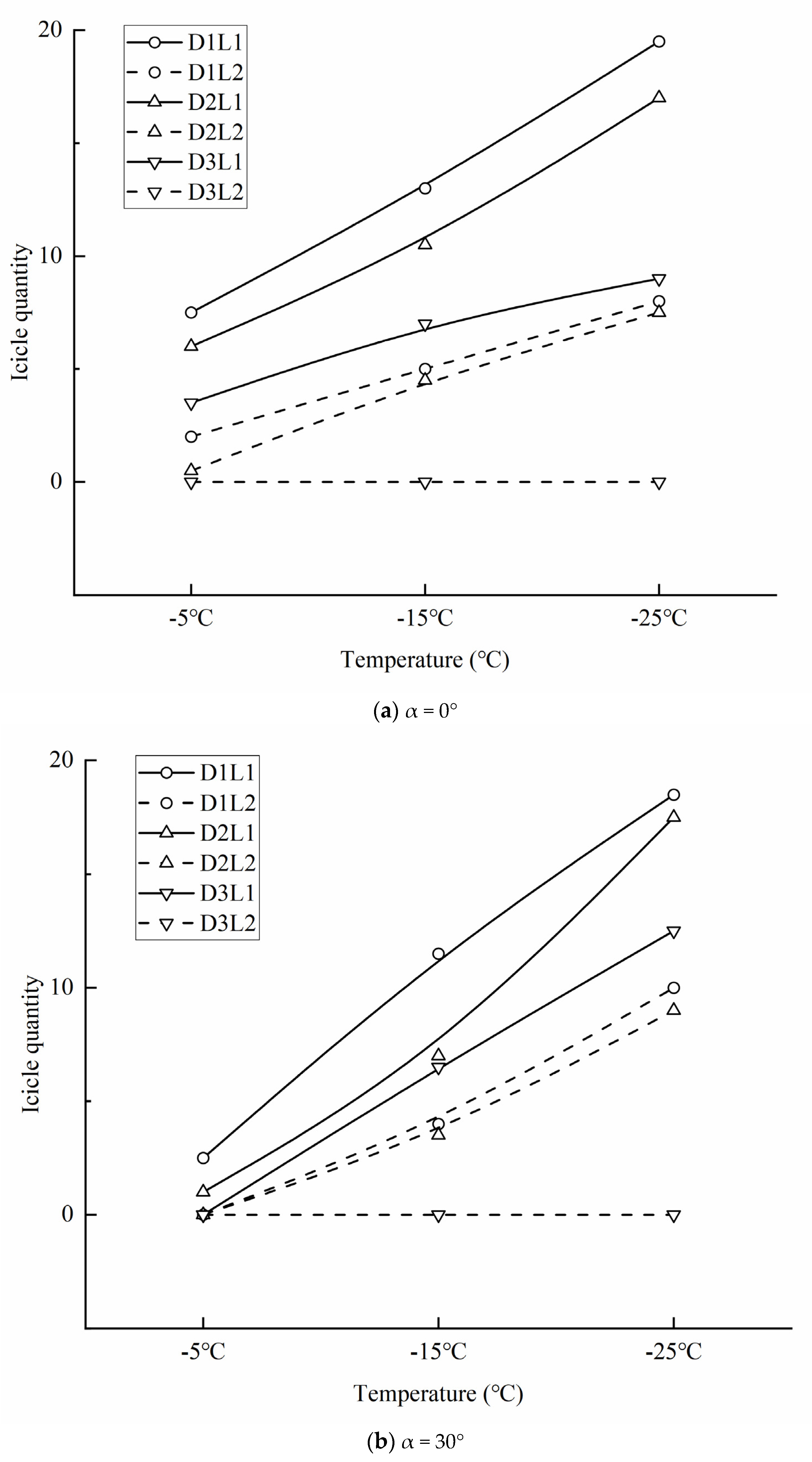

3.2. The Effect of Temperature on Bottom Icing Conditions

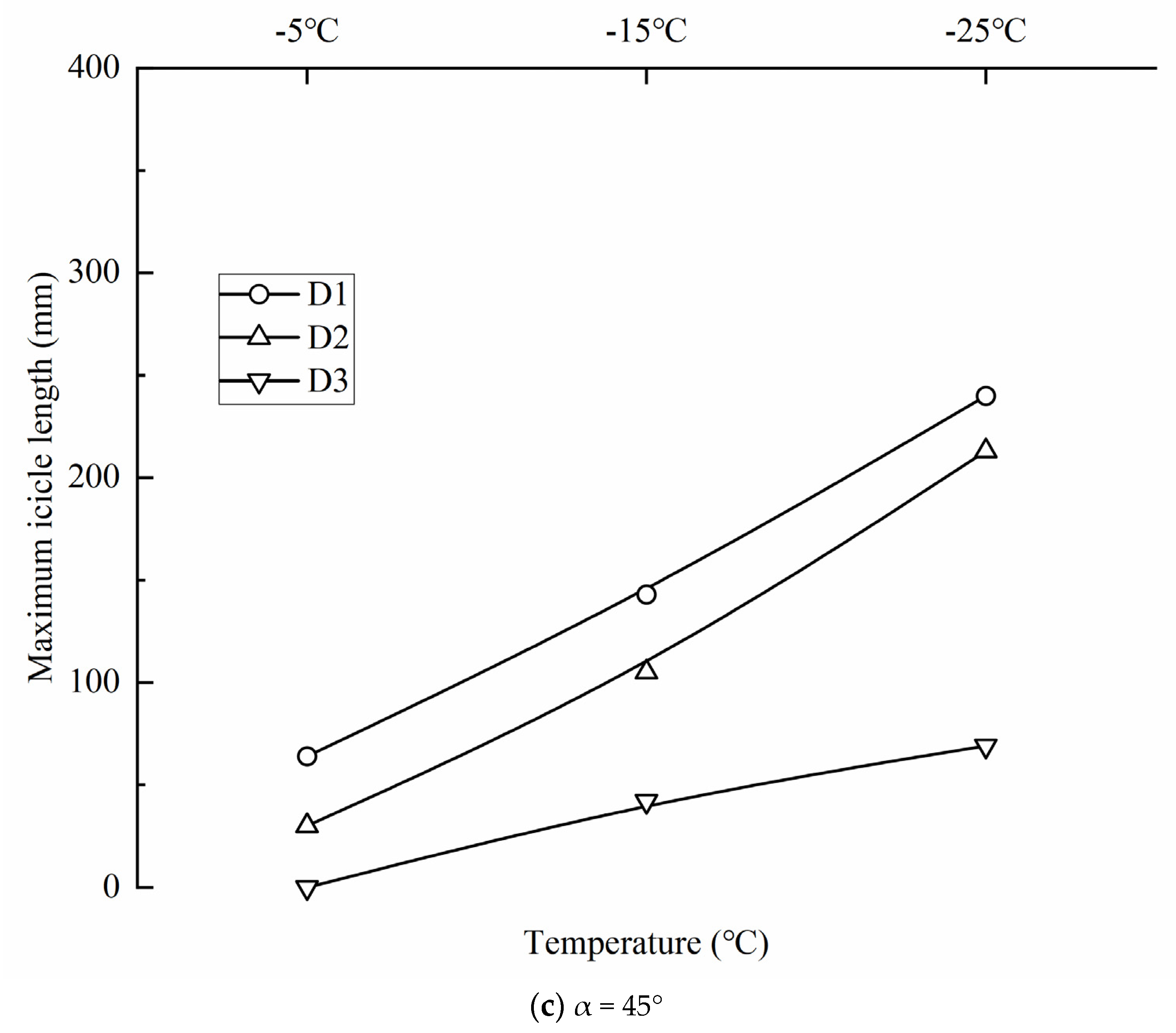

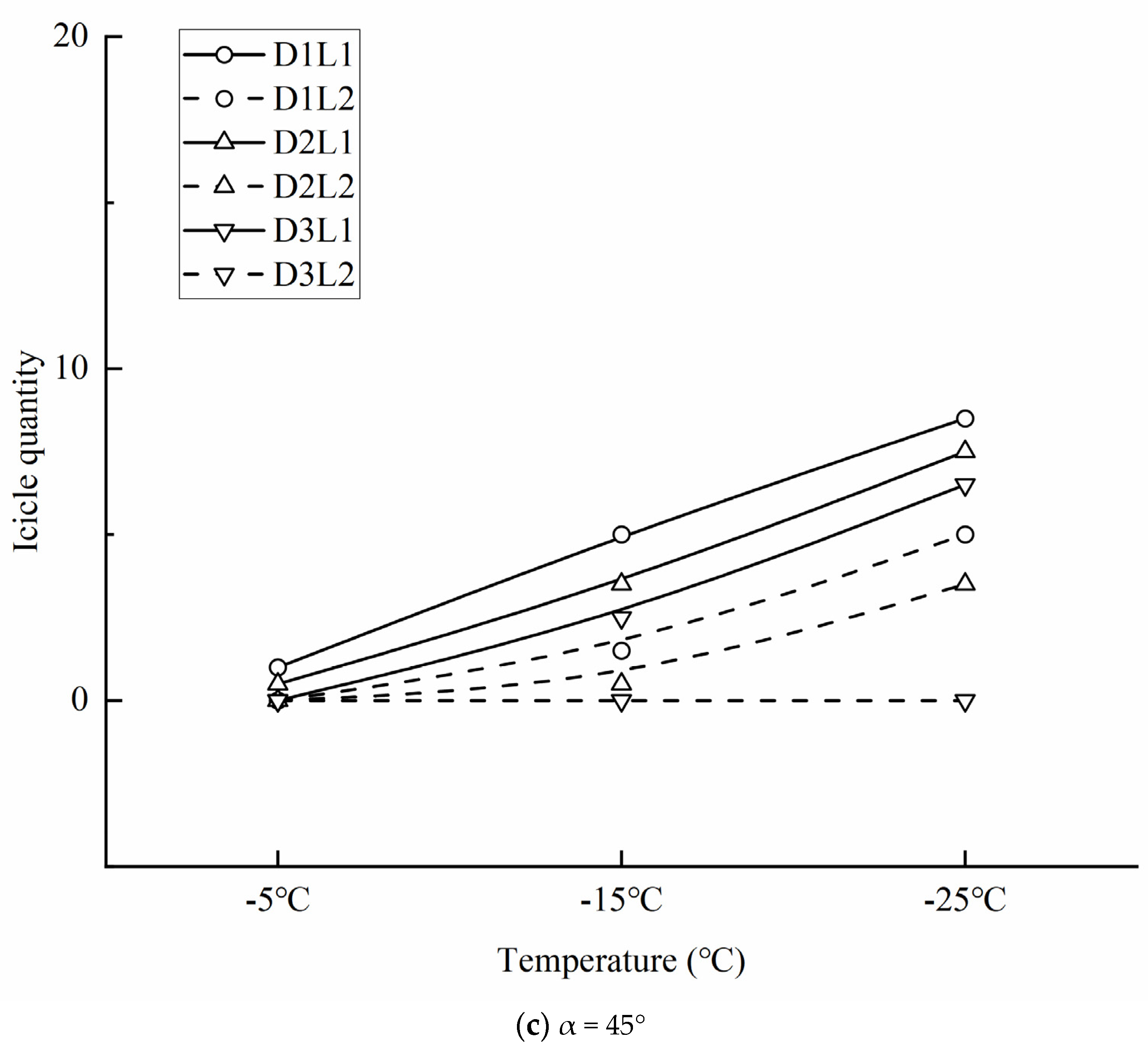

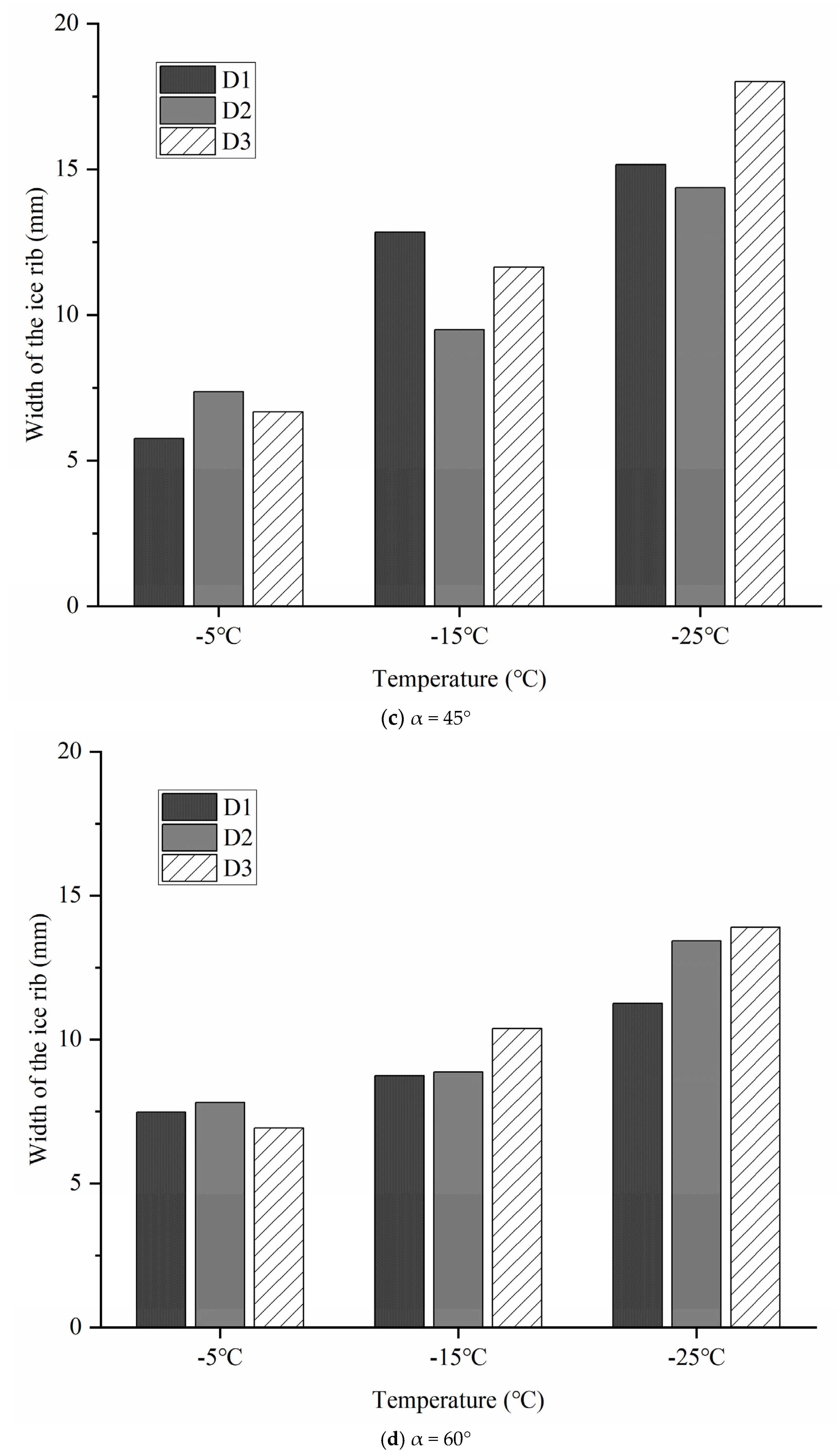

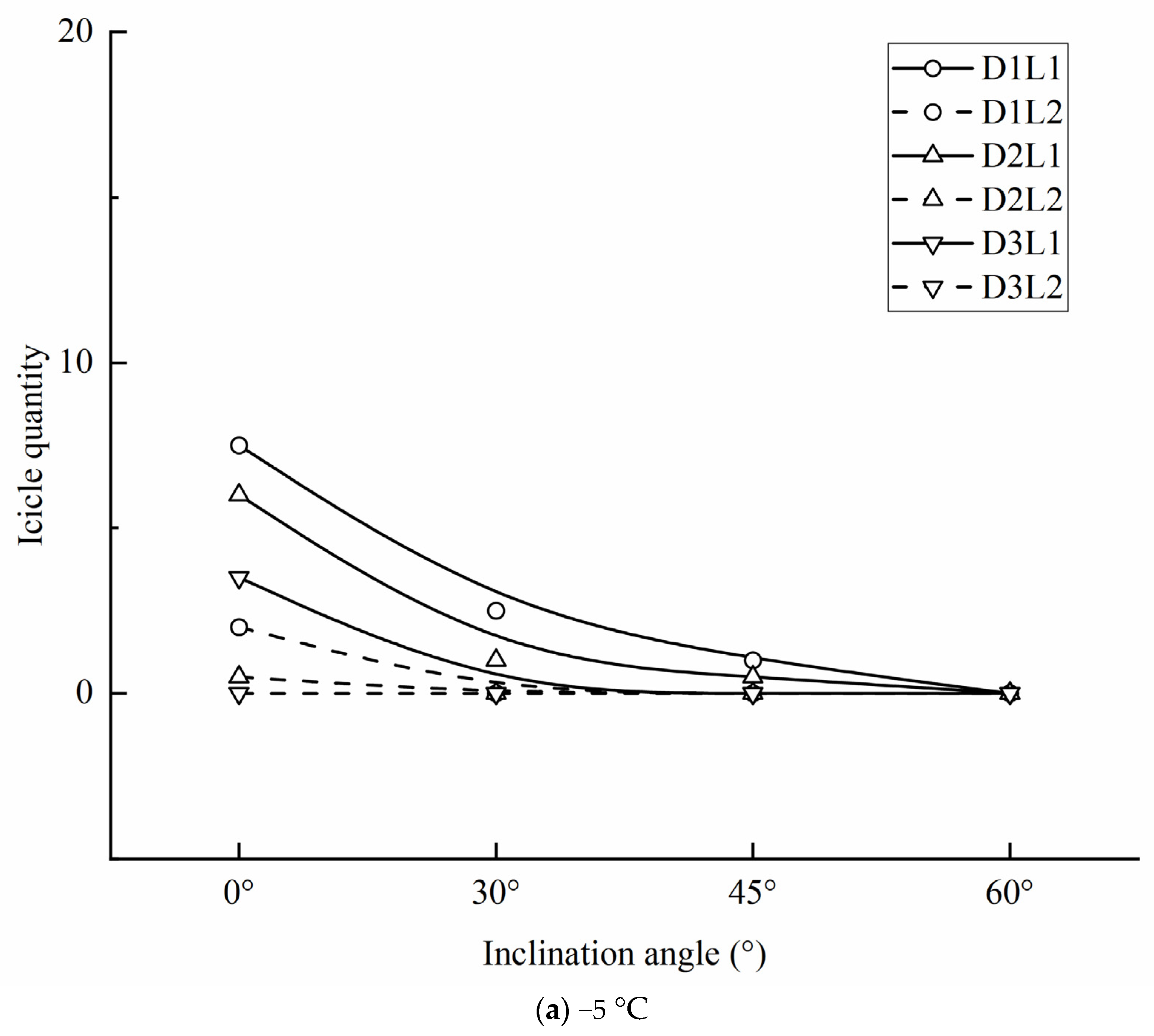

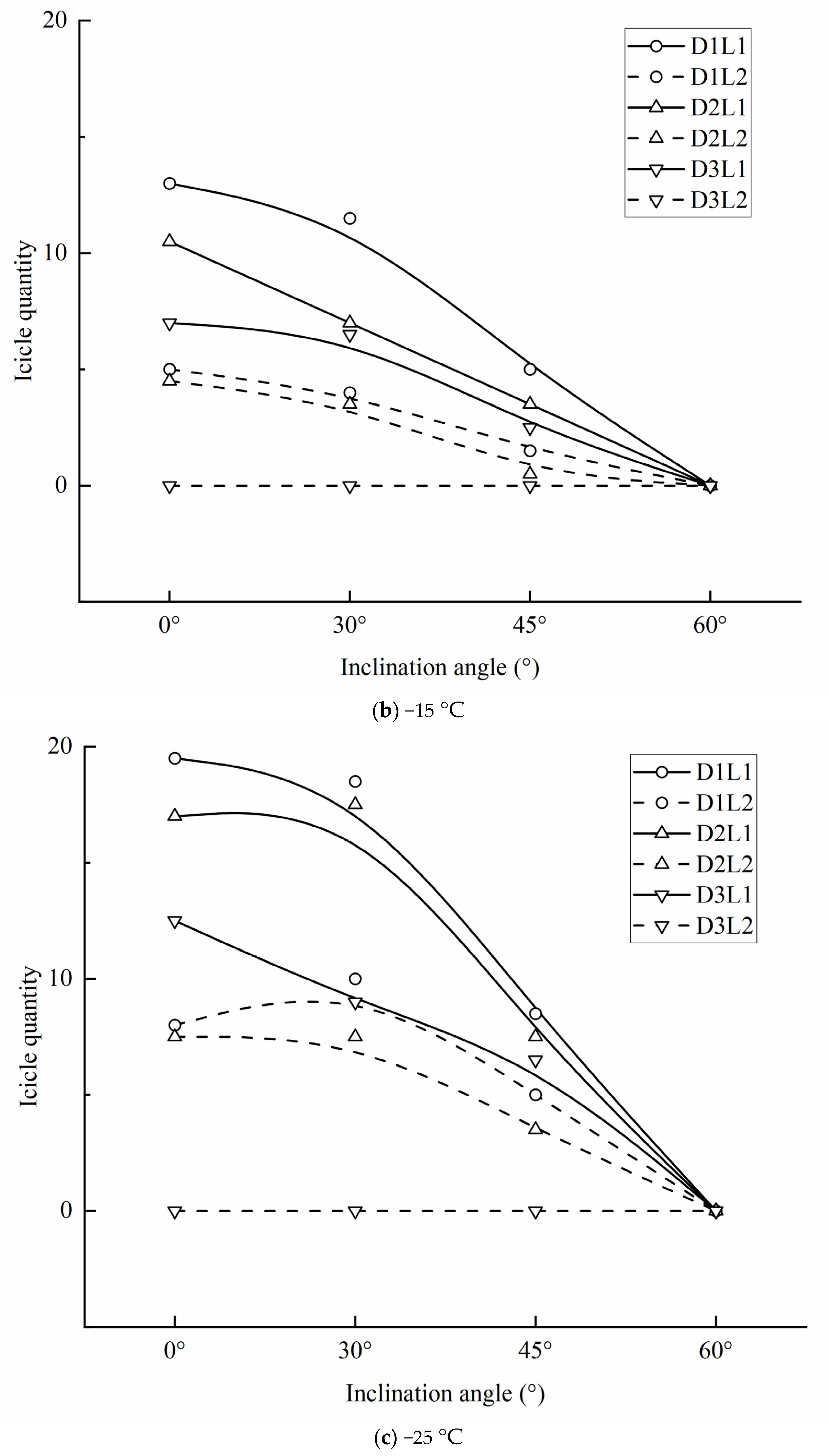

3.3. Effect of Change of Inclination Angle and Diameter of Cable on Bottom Icing Condition

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jung, H.J.; Yang, T.H.; Jang, B.S. Field application of a robotic system on cable stays of incheon bridge for snow removal. Paper presented at: ISARC 2011. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction, Seoul, Republic of Korea, 29 June–2 July 2011. [Google Scholar]

- Oohira, T.; Tanaka, Y.; Ishimoto, K.; Sato, S. Predicting snow falling from cables of a cable-stayed bridge. Paper presented at: IWAIS 2007. In Proceedings of the 12th International Workshop on Atmospheric Icing of Structures, Yokohama, Japan, 9–12 October 2007. [Google Scholar]

- Makkonen, L. Models for the growth of rime, glaze, icicles and wet snow on structures. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Eng. Sci. 2000, 358, 2913–2939. [Google Scholar] [CrossRef]

- Farzaneh, M. (Ed.) Atmospheric Icing of Power Networks; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar] [CrossRef]

- Nims, D.K.; Hunt, V.J.; Helmicki, A.J.; Ng, T.M.T. Ice Prevention or Removal on the Veteran’s Glass City Skyway Cables; No. FHWA/OH-2014/11; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2014. [Google Scholar]

- De Gregorio, F.; Ragni, A.; Airoldi, M.; Romano, G.P. PIV Investigation on Airfoil with Ice Accretions and Resulting Performance Degradation. In ICIASF 2001 Record, 19th International Congress on Instrumentation in Aerospace Simulation Facilities (Cat. No. 01CH37215); IEEE: New York, NY, USA, 2001; pp. 94–105. [Google Scholar] [CrossRef]

- Waldman, R.; Liu, Y.; Zhang, K.; Hu, H. High-Speed Imaging to Quantify the Transient Ice Accretion Process on a NACA 0012 Airfoil. In 53rd AIAA Aerospace Sciences Meeting; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2015; p. 0033. [Google Scholar] [CrossRef]

- Zhang, K.; Wei, T.; Hu, H. An experimental investigation on the surface water transport process over an airfoil by using a digital image projection technique. Exp. Fluids 2015, 56, 173. [Google Scholar] [CrossRef]

- Makkonen, L.; Lozowski, E.P. Numerical Modelling of Icing on Power Network Equipment. In Atmospheric Icing of Power Networks; Springer: Dordrecht, The Netherlands, 2008; pp. 83–117. [Google Scholar] [CrossRef]

- Naterer, G.F. Coupled liquid film and solidified layer growth with impinging supercooled droplets and Joule heating. Int. J. Heat Fluid Flow 2003, 24, 223–235. [Google Scholar] [CrossRef]

- Lébatto, E.B.; Farzaneh, M.; Lozowski, E.P. Conductor icing: Comparison of a glaze icing model with experiments under severe laboratory conditions with moderate wind speed. Cold Reg. Sci. Technol. 2015, 113, 20–30. [Google Scholar] [CrossRef]

- Peng, Y.; Veerakumar, R.; Liu, Y.; He, X.; Hu, H. An experimental study on dynamic ice accretion and its effects on the aerodynamic characteristics of stay cables with and without helical fillets. J. Wind. Eng. Ind. Aerodyn. 2020, 205, 104326. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Peng, Y.; Hu, H. An experimental study on the dynamic ice accretion processes on bridge cables with different surface modifications. J. Wind. Eng. Ind. Aerodyn. 2019, 190, 218–229. [Google Scholar] [CrossRef]

- Szilder, K.; D’Auteuil, A.; McTavish, S. Predicting ice accretion from freezing rain on bridge stay cables. Cold Reg. Sci. Technol. 2021, 187, 103285. [Google Scholar] [CrossRef]

- Demartino, C.; Koss, H.H.; Georgakis, C.T.; Ricciardelli, F. Effects of ice accretion on the aerodynamics of bridge cables. J. Wind. Eng. Ind. Aerodyn. 2015, 138, 98–119. [Google Scholar] [CrossRef]

- Demartino, C.; Ricciardelli, F. Aerodynamic stability of ice-accreted bridge cables. J. Fluids Struct. 2015, 52, 81–100. [Google Scholar] [CrossRef]

- Górski, P.; Pospíšil, S.; Kuznetsov, S.; Tatara, M.; Marušić, A. Strouhal number of bridge cables with ice accretion at low flow turbulence. Wind. Struct. 2016, 22, 253–272. [Google Scholar] [CrossRef]

- Kleissl, K.; Georgakis, C.T. Comparison of the aerodynamics of bridge cables with helical fillets and a pattern-indented surface. J. Wind. Eng. Ind. Aerodyn. 2012, 104, 166–175. [Google Scholar] [CrossRef]

- Koss, H.; Lund, M.S.M. Experimental investigation of aerodynamic instability of iced bridge cable sections. In Proceedings of the 6th European and African Wind Engineering Conference Robinson College, Cambridge, UK, 7–11 July 2013. [Google Scholar]

- Hofmeister, W.H.; Bayuzick, R.J.; Robinson, M.B. Dual purpose pyrometer for temperature and solidification velocity measurement. Rev. Sci. Instrum. 1990, 61, 2220–2223. [Google Scholar] [CrossRef]

- Brassard, J.D.; Blackburn, C.; Toth, M.; Momen, G. Ice accretion, shedding, and melting on cable-stayed bridges: A laboratory performance assessment. Cold Reg. Sci. Technol. 2022, 204, 103672. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Hu, H. An experimental investigation of dynamic ice accretion process on a wind turbine airfoil model considering various icing conditions. Int. J. Heat Mass Transf. 2019, 133, 930–939. [Google Scholar] [CrossRef]

- Zhang, K.; Hu, H. An experimental study on the transient behavior of wind-driven water runback over a flat surface. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 1123. [Google Scholar] [CrossRef]

- Waldman, R.M.; Li, H.; Hu, H. An experimental investigation on the effects of surface wettability on water runback and ice accretion over an airfoil surface. In Proceedings of the 8th AIAA Atmospheric and Space Environments Conference, Washington, DC, USA, 13–17 June 2016; p. 3139. [Google Scholar] [CrossRef]

- Makkonen, L. A model of icicle growth. J. Glaciol. 1988, 34, 64–70. [Google Scholar] [CrossRef]

- Górski, P.; Tatara, M.; Pospíšil, S.; Trush, A. A new approach to registering ice covers simulated on a sectional model of a bridge stay cable in laboratory conditions. Measurement 2021, 179, 109500. [Google Scholar] [CrossRef]

- Mohammadian, B.; Sarayloo, M.; Abdelaal, A.; Raiyan, A.; Nims, D.K.; Sojoudi, H. Experimental and theoretical studies of wet snow accumulation on inclined cylindrical surfaces. Model. Simul. Eng. 2020, 2020, 9594685. [Google Scholar] [CrossRef]

- Abdelaal, A.; Nims, D.; Jones, K.; Sojoudi, H. Prediction of ice accumulation on bridge cables during freezing rain: A theoretical modeling and experimental study. Cold Reg. Sci. Technol. 2019, 164, 102782. [Google Scholar] [CrossRef]

- Makkonen, L. Modeling power line icing in freezing precipitation. Atmos. Res. 1998, 46, 131–142. [Google Scholar] [CrossRef]

- Makkonen, L. Modeling of ice accretion on wires. J. Appl. Meteorol. Climatol. 1984, 23, 929–939. [Google Scholar] [CrossRef]

- Szilder, K. Simulation of ice accretion on a cylinder due to freezing rain. J. Glaciol. 1994, 40, 586–594. [Google Scholar] [CrossRef]

- Lébatto, E.B.; Farzaneh, M.; Lozowski, E.P. Three-dimensional morphogenetic model of ice accretion on a non-rotating cylinder. In Proceedings of the 11. International Workshop on Atmospheric Icing of Structures (IWAIS 2005), Montreal, PQ, Canada, 12–16 June 2005. [Google Scholar]

- Szilder, K. Snow accretion prediction on an inclined cable. Cold Reg. Sci. Technol. 2019, 157, 224–234. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Geng, Z.; Xiao, H.; Pei, Y.; Yang, K. An Experimental Study on Ice Accretion under Bridge Cable in Different Conditions. Appl. Sci. 2023, 13, 3963. https://doi.org/10.3390/app13063963

Li W, Geng Z, Xiao H, Pei Y, Yang K. An Experimental Study on Ice Accretion under Bridge Cable in Different Conditions. Applied Sciences. 2023; 13(6):3963. https://doi.org/10.3390/app13063963

Chicago/Turabian StyleLi, Wentao, Zhiyuan Geng, Henglin Xiao, Yaoyao Pei, and Kang Yang. 2023. "An Experimental Study on Ice Accretion under Bridge Cable in Different Conditions" Applied Sciences 13, no. 6: 3963. https://doi.org/10.3390/app13063963

APA StyleLi, W., Geng, Z., Xiao, H., Pei, Y., & Yang, K. (2023). An Experimental Study on Ice Accretion under Bridge Cable in Different Conditions. Applied Sciences, 13(6), 3963. https://doi.org/10.3390/app13063963