Internet of Things Adoption in the Manufacturing Sector: A Conceptual Model from a Multi-Theoretical Perspective

Abstract

1. Introduction

- RQ1: What are the antecedents that affect IoT adoption in the MS?

- RQ2: How does perceived value affect IoT adoption in the MS?

2. Literature Review

2.1. The IoT Technology

2.2. IoT Benefits for the MS

2.3. IoT Challenges in the MS

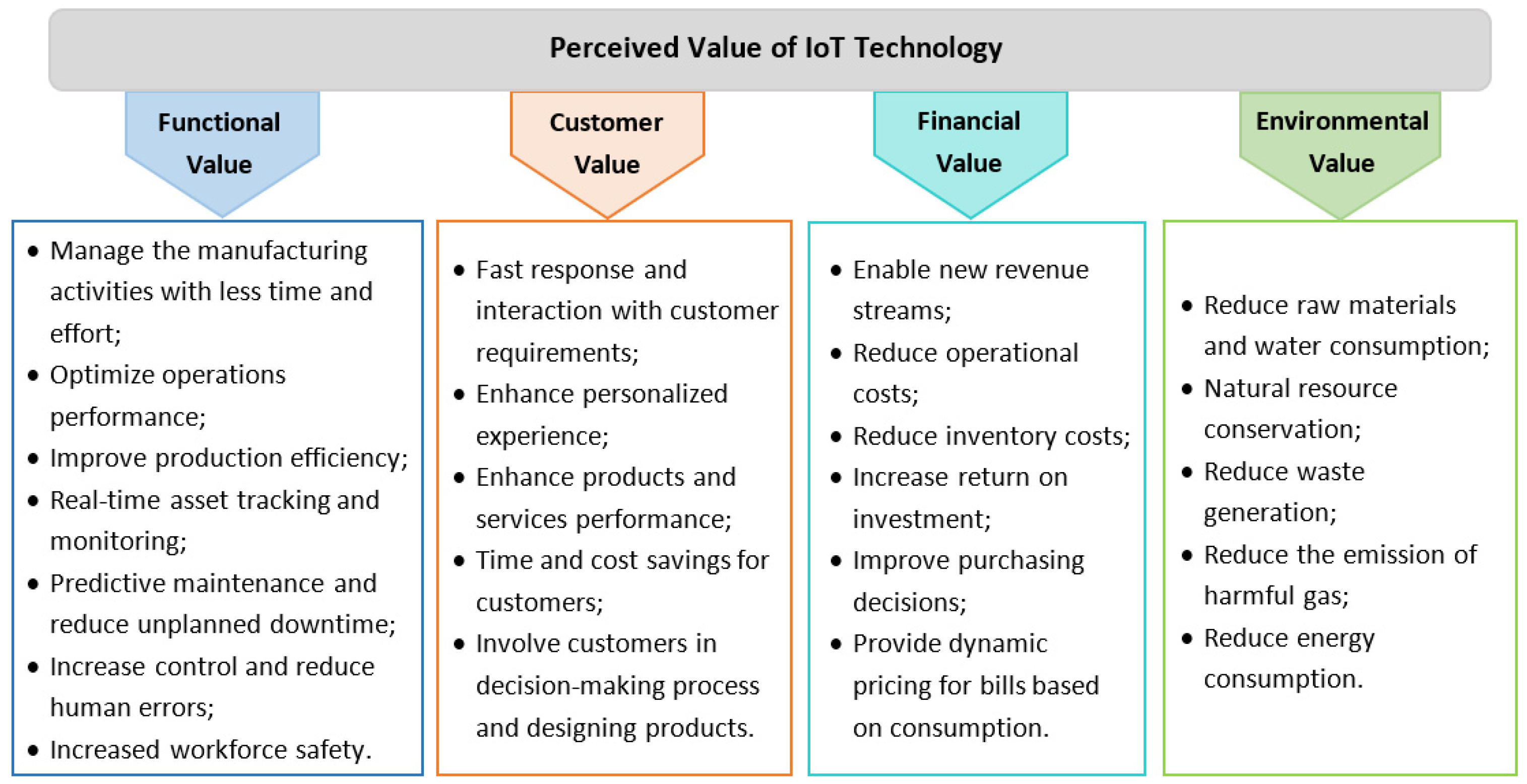

2.4. Perceived Value of IoT Technology

2.5. IoT Adoption in the MS

3. Research Method

4. Theoretical Rationale

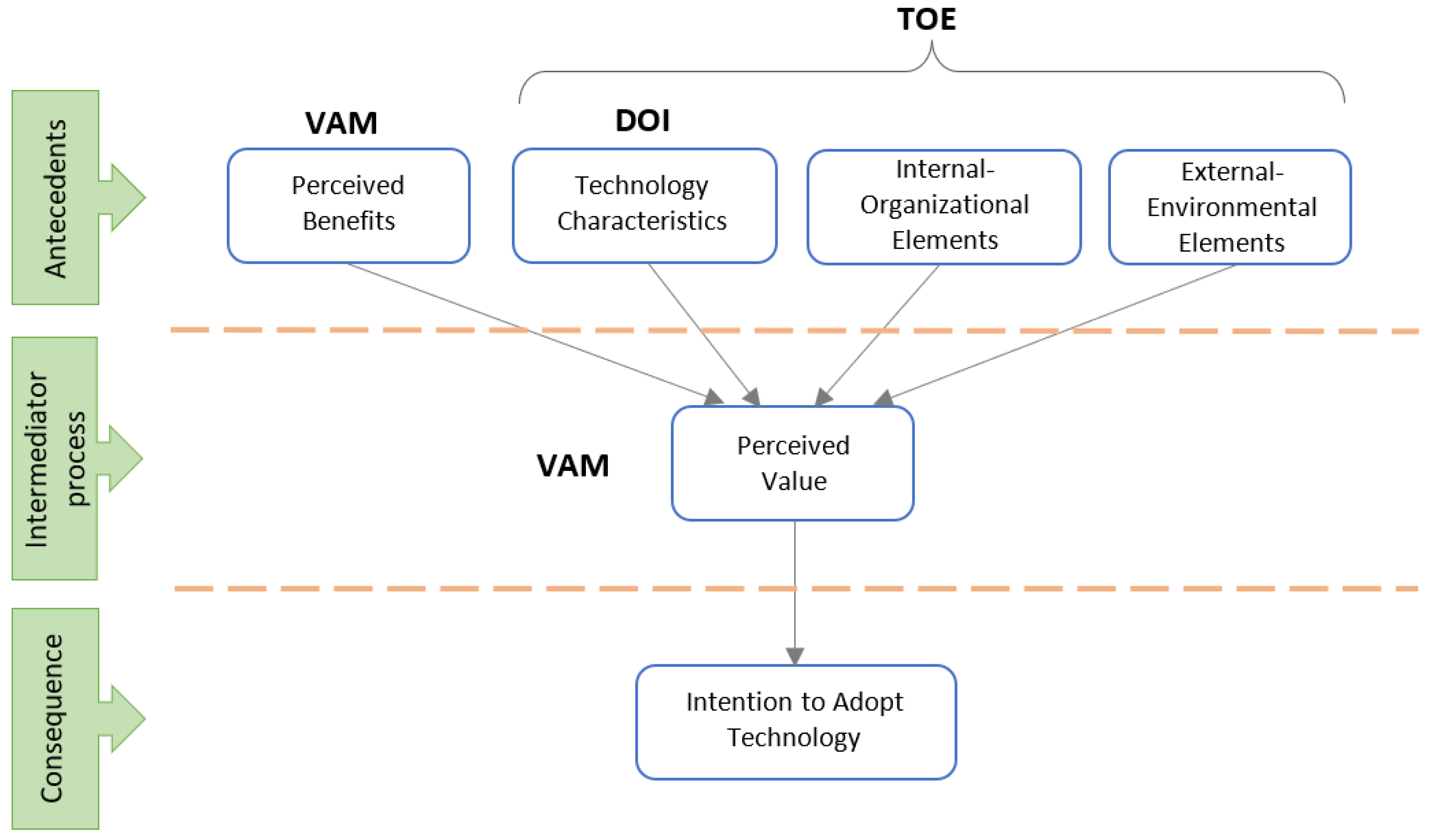

4.1. The VAM

4.2. The DOI Theory

4.3. The TOE Framework

4.4. The Multi-Theoretical Perspective

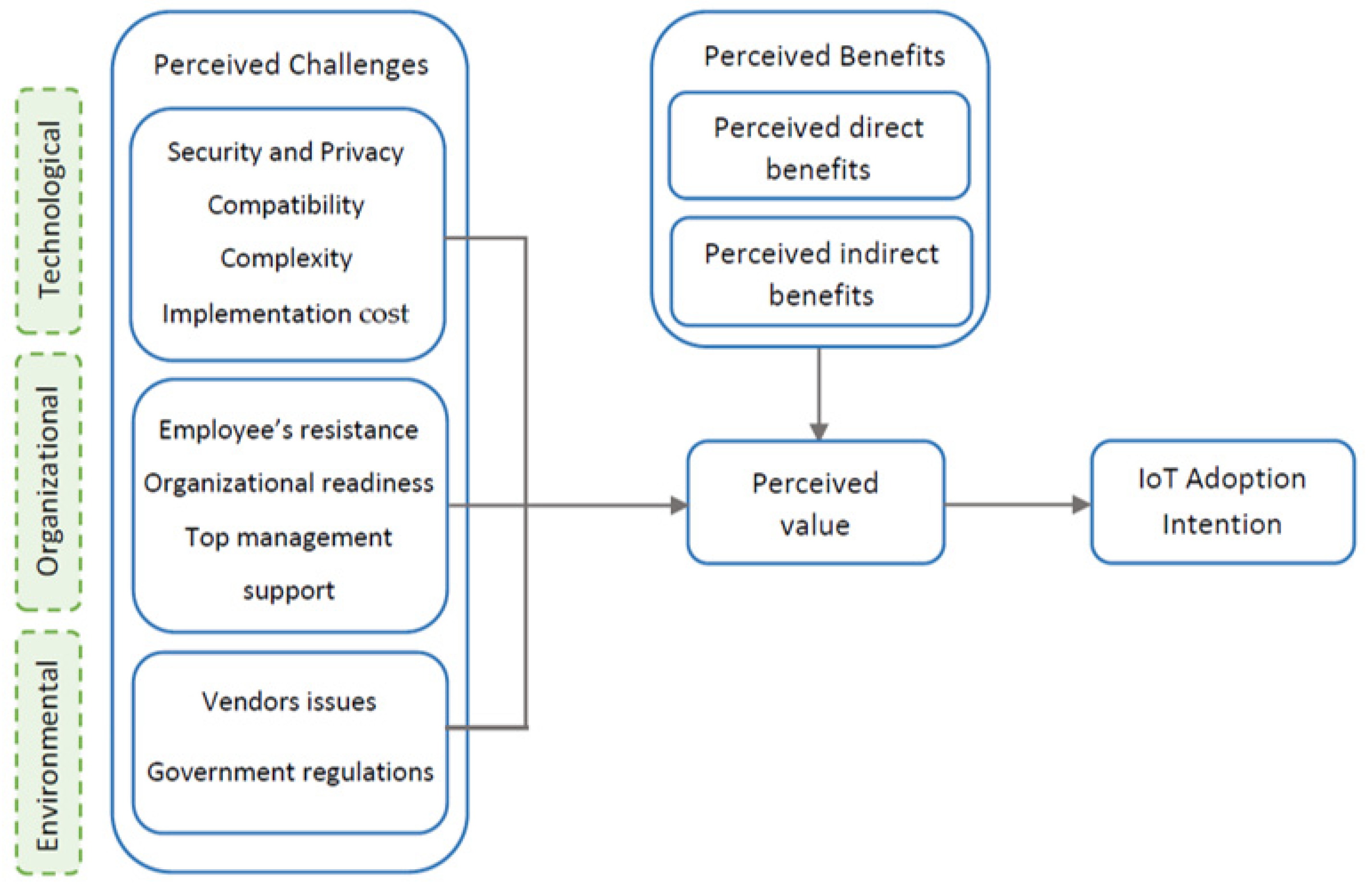

5. The Conceptual Model for IoT Adoption in the MS

5.1. Perceived Benefits

5.2. Perceived Challenges

5.2.1. Technological Challenges

Security and Privacy

Compatibility

Complexity

Implementation Cost

5.2.2. Organizational Challenges

Resistance from Employees

Organizational Readiness

Top Management Support

5.2.3. Environmental Challenges

Vendor Issues

Government Regulation

5.3. Perceived Value

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Quality Assessment Criteria |

|---|

| 1. Does the paper discuss IoT adoption factors/benefits/challenges? |

| 2. Is the objective of the paper clearly stated? |

| 3. Is the method of the paper clearly described? |

| 4. Are the study settings and sample justified? |

| 5. Is the data collection method(s) adequately described? |

| 6. Is the data analysis adequately described? |

| 7. Are the paper results and findings clearly stated? |

| 8. Are the paper limitations presented? |

| Ref | Q1 | Q2 | Q3 | Q4 | Q5 | Q6 | Q7 | Q8 | Total |

|---|---|---|---|---|---|---|---|---|---|

| [1] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [3] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 7 |

| [6] | 1 | 1 | 1 | 0.5 | 0.5 | 1 | 1 | 0 | 6 |

| [7] | 1 | 1 | 1 | 1 | 1 | 0.5 | 0.5 | 1 | 7 |

| [8] | 1 | 1 | 1 | 1 | 0.5 | 1 | 1 | 1 | 7.5 |

| [9] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [10] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [11] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [12] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [16] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 7 |

| [17] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 7 |

| [18] | 1 | 1 | 1 | 0.5 | 0.5 | 0.5 | 1 | 1 | 6.5 |

| [23] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [25] | 1 | 1 | 1 | 0.5 | 1 | 0.5 | 1 | 0 | 6 |

| [26] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [27] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [28] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [29] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [30] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [31] | 1 | 1 | 1 | 0.5 | 0.5 | 0.5 | 1 | 0 | 5.5 |

| [32] | 1 | 1 | 1 | 0.5 | 0.5 | 1 | 1 | 0 | 6 |

| [33] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [34] | 1 | 1 | 1 | 0.5 | 1 | 1 | 1 | 0 | 6.5 |

| [36] | 1 | 1 | 1 | 0.5 | 0.5 | 1 | 1 | 0.5 | 6.5 |

| [39] | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 5 |

| [42] | 1 | 1 | 1 | 1 | 0.5 | 1 | 1 | 0 | 6.5 |

| [43] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [44] | 1 | 1 | 1 | 0.5 | 0.5 | 1 | 1 | 1 | 7 |

| [45] | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 0 | 5 |

| [48] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [53] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 7 |

| [54] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [55] | 1 | 1 | 1 | 1 | 1 | 0.5 | 1 | 0 | 6.5 |

| [59] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [62] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [64] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [67] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [103] | 1 | 1 | 1 | 0.5 | 0.5 | 0.5 | 1 | 0 | 5.5 |

| [104] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

| [105] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 7 |

| [107] | 1 | 1 | 1 | 0.5 | 0.5 | 0 | 1 | 0 | 5 |

| [112] | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 8 |

References

- Krommuang, A.; Suwunnamek, O. Internet of Things (IoT) Application for Management in Automotive Parts Manufacturing. Int. J. Adv. Comput. Sci. Appl. 2022, 13, 639–650. [Google Scholar] [CrossRef]

- Yang, C.; Shen, W.; Wang, X. Applications of Internet of Things in manufacturing. In Proceedings of the 2016 IEEE 20th International Conference on Computer Supported Cooperative Work in Design (CSCWD), Nanchang, China, 4–6 May 2016; pp. 670–675. [Google Scholar]

- Kalsoom, T.; Ahmed, S.; Rafi-ul-shan, P.M.; Azmat, M.; Akhtar, P.; Pervez, Z.; Imran, M.A.; Ur-Rehman, M. Impact of IoT on Manufacturing Industry 4.0: A New Triangular Systematic Review. Sustainability 2021, 13, 12506. [Google Scholar] [CrossRef]

- Papakostas, N.; O’Connor, J.; Byrne, G. Internet of things technologies in manufacturing: Application areas, challenges and outlook. In Proceedings of the 2016 International Conference on Information Society (i-Society), Dublin, Ireland, 10–13 October 2016; pp. 126–131. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Satar, S.B.A.; Hussin, A.R.C.; Ali, Y.S. Drivers of Internet of Things Adoption in Oil and Gas Industry. Adv. Sci. Lett. 2018, 24, 7364–7370. [Google Scholar] [CrossRef]

- Savoury, R.D.; Burchell, J.M. Exploring the Influential Determinants of IoT Adoption in the U.S. Manufacturing Sector. Int. J. Appl. Manag. Technol. 2021, 20, 183–193. [Google Scholar] [CrossRef]

- Ehie, I.C.; Chilton, M.A. Understanding the influence of IT/OT Convergence on the adoption of Internet of Things (IoT) in manufacturing organizations: An empirical investigation. Comput. Ind. 2020, 115, 103166. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Joshi, S. Modeling the internet of things adoption barriers in food retail supply chains. J. Retail. Consum. Serv. 2019, 48, 154–168. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Manag. 2017, 21, 1–34. [Google Scholar] [CrossRef]

- Das, S. The Early Bird Catches the Worm—First Mover Advantage through IoT Adoption for Indian Public Sector Retail Oil Outlets. J. Glob. Inf. Technol. Manag. 2019, 22, 280–308. [Google Scholar] [CrossRef]

- Arnold, C.; Voigt, K.I. Determinants of Industrial Internet of Things Adoption in German Manufacturing Companies. Int. J. Innov. Technol. Manag. 2019, 16, 1950038. [Google Scholar] [CrossRef]

- Microsoft IoT SIGNALS. 2019. Available online: IoT-Signals-Microsoft-072019.pdf (accessed on 10 April 2021).

- Patel, B.M.; Shangkuan, J.; Thomas, C. What’s New with the Internet of Things? McKinsey Company. 2017. Available online: https://www.mckinsey.com/industries/semiconductors/our-insights/whats-new-with-the-internet-of-things (accessed on 1 August 2022).

- Buntz, B.; The State of IIoT Adoption in 2018. The State of Industrial IoT Adoption in 2018. 2018. Available online: itprotoday.com (accessed on 19 August 2022).

- Asadi, S.; Nilashi, M.; Iranmanesh, M.; Hyun, S.S.; Rezvani, A. Effect of internet of things on manufacturing performance: A hybrid multi-criteria decision-making and neuro-fuzzy approach. Technovation 2021, 118, 102426. [Google Scholar] [CrossRef]

- Sumrit, D. Evaluating readiness degree for Industrial Internet of Things adoption in manufacturing enterprises under interval-valued Pythagorean fuzzy approach. Prod. Manuf. Res. 2022, 10, 226–256. [Google Scholar] [CrossRef]

- Mustapha, H.; Kassim, R.; Rahmat, A. Internet of Things Adoption in Manufacturing: An Exploratory of Organizational Antecedents. In Advanced Transdisciplinary Engineering and Technology; Ismail, A., Mohd Daril, M.A., Öchsner, A., Eds.; Springer: Cham, Switzerland, 2022; pp. 339–351. ISBN 978-3-031-01488-8. [Google Scholar]

- Ihekoronye, V.U.; Nwakanma, C.I.; Anyanwu, G.O.; Kim, D.S.; Lee, J.M. Benefits, Challenges and Practical Concerns of IoT for Smart Manufacturing. In Proceedings of the 2021 International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Republic of Korea, 20–22 October 2021. [Google Scholar]

- Capgemini Research Institute. Unlocking the Business Value of IoT in Operations. Brochure Potrait. 2018. Available online: capgemini.com (accessed on 17 November 2022).

- Verma, S.; Bhattacharyya, S.S. Perceived strategic value-based adoption of Big Data Analytics in emerging economy: A qualitative approach for Indian firms. J. Enterp. Inf. Manag. 2017, 30, 354–382. [Google Scholar] [CrossRef]

- Vishwakarma, P.; Mukherjee, S.; Datta, B. Travelers’ intention to adopt virtual reality: A consumer value perspective. J. Destin. Mark. Manag. 2020, 17, 100456. [Google Scholar] [CrossRef]

- Ahmetoglu, S.; Che Cob, Z.; Ali, N. A Systematic Review of Internet of Things Adoption in Organizations: Taxonomy, Benefits, Challenges and Critical Factors. Appl. Sci. 2022, 12, 4117. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Lin, D.; Lee, C.K.M.; Lin, K. Research on effect factors evaluation of internet of things (IOT) adoption in Chinese agricultural supply chain. In Proceedings of the 2016 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bali, Indonesia, 4–7 December 2016; pp. 612–615. [Google Scholar] [CrossRef]

- Hsu, C.W.; Yeh, C.C. Understanding the factors affecting the adoption of the Internet of Things. Technol. Anal. Strateg. Manag. 2017, 29, 1089–1102. [Google Scholar] [CrossRef]

- Sivathanu, B. Adoption of industrial IoT (IIoT) in auto-component manufacturing SMEs in India. Inf. Resour. Manag. J. 2019, 32, 52–75. [Google Scholar] [CrossRef]

- Valmohammadi, C. Examining the perception of Iranian organizations on Internet of Things solutions and applications. Ind. Commer. Train. 2016, 48, 104–108. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Mangla, S.K.; Berwal, Y.P.S. Analyzing challenges to Internet of Things (IoT) adoption and diffusion: An Indian context. Procedia Comput. Sci. 2018, 125, 733–739. [Google Scholar] [CrossRef]

- Tu, M. An exploratory study of internet of things (IoT) adoption intention in logistics and supply chain management a mixed research approach. Int. J. Logist. Manag. 2018, 29, 131–151. [Google Scholar] [CrossRef]

- Ladasi, S.H.; Shihab, M.R.; Hidayanto, A.N.; Budi, N.F.A. Prioritizing Determinants of Internet of Things (IoT) Technology Adoption: Case Study of Agribusiness PT. XYZ. In Proceedings of the 2019 3rd International Conference on Informatics and Computational Sciences (ICICoS), Semarang, Indonesia, 29–30 October 2019; pp. 7–12. [Google Scholar] [CrossRef]

- Tarmizi, H.A.; Kamarulzaman, N.H.; Rahman, A.A.; Atan, R. Adoption of internet of things among Malaysian halal agro-food smes and its challenges. Food Res. 2020, 4, 256–265. [Google Scholar] [CrossRef]

- Rey, A.; Panetti, E.; Maglio, R.; Ferretti, M. Determinants in adopting the Internet of Things in the transport and logistics industry. J. Bus. Res. 2021, 131, 584–590. [Google Scholar] [CrossRef]

- Hawash, B.; Mokhtar, U.A.; Yusof, Z.M.; Mukred, M.; Gaid, A.S.A. Factors Affecting Internet of Things (IoT) Adoption in the Yemeni Oil and Gas Sector. In Proceedings of the 2021 International Conference of Technology, Science and Administration (ICTSA), Taiz, Yemen, 22–24 March 2021; pp. 1–7. [Google Scholar]

- Ashton, K. That ‘Internet of Things’ Thing. RFID J. 2009, 22, 97–114. [Google Scholar]

- Ramos, P.N.; Enteria, M.L.B.; Norona, M.I. Readiness Model Development in the Adoption of Internet of Things (IoT) among Philippine Manufacturing SMEs Using Force Field Analysis Approach and Structural Equation Modelling. In Proceedings of the Second Asia Pacific International Conference on Industrial Engineering and Operations Management, Surakarta, Indonesia, 14–16 September 2021. [Google Scholar]

- Badarinath, R.; Prabhu, V.V. Advances in Internet of Things (IoT) in Manufacturing. In Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing; Lödding, H., Riedel, R., Thoben, K.-D., von Cieminski, G., Kiritsis, D., Eds.; Springer: Cham, Switzerland, 2017; pp. 111–118. [Google Scholar]

- Alothman, H.A.; Khasawneh, M.T.; Nagarur, N.N. Internet of Things in Manufacturing: An Overview. In Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition. Volume 2: Advanced Manufacturing. Pittsburgh, PA, USA, 9–15 November 2018. [Google Scholar]

- Javaid, M.; Haleem, A.; Pratap Singh, R.; Rab, S.; Suman, R. Upgrading the manufacturing sector via applications of Industrial Internet of Things (IIoT). Sens. Int. 2021, 2, 100129. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E.; Milas, N. Industrial Big Data as a Result of IoT Adoption in Manufacturing. Procedia CIRP 2016, 55, 290–295. [Google Scholar] [CrossRef]

- Sidek, N.; Ali, N.; Rosman, R. Internet of things-based smart facilities management services successful implementation instrument development, validity, and reliability. In Proceedings of the 2019 6th International Conference on Research and Innovation in Information Systems (ICRIIS), Johor Bahru, Malaysia, 2–3 December 2019. [Google Scholar]

- Singh, G.; Gaur, L.; Ramakrishnan, R. Internet of things—Technology adoption model in India. Pertanika J. Sci. Technol. 2017, 25, 835–846. [Google Scholar]

- Haddud, A.; DeSouza, A.; Khare, A.; Lee, H. Examining potential benefits and challenges associated with the Internet of Things integration in supply chains. J. Manuf. Technol. Manag. 2017, 28, 1055–1085. [Google Scholar] [CrossRef]

- Seetharaman, A.; Patwa, N.; Saravanan, A.S.; Sharma, A. Customer expectation from Industrial Internet of Things (IIOT). J. Manuf. Technol. Manag. 2019, 30, 1161–1178. [Google Scholar] [CrossRef]

- Tripathi, S. System Dynamics perspective for Adoption of Internet of Things: A Conceptual Framework. In Proceedings of the 2019 10th International Conference on Computing, Communication and Networking Technologies (ICCCNT), Kanpur, India, 6–8 July 2019; pp. 1–10. [Google Scholar] [CrossRef]

- Ibrahim, F.S.; Esa, M.; Rahman, R.A. The adoption of IoT in the Malaysian construction industry: Towards construction 4.0. Int. J. Sustain. Constr. Eng. Technol. 2021, 12, 56–67. [Google Scholar] [CrossRef]

- Alkawsi, G.A.; Ali, N.; Baashar, Y. An Empirical Study of the Acceptance of IoT-Based Smart Meter in Malaysia: The Effect of Electricity-Saving Knowledge and Environmental Awareness. IEEE Access 2020, 8, 42794–42804. [Google Scholar] [CrossRef]

- Thibaud, M.; Chi, H.; Zhou, W.; Piramuthu, S. Internet of Things (IoT) in high-risk Environment, Health and Safety (EHS) industries: A comprehensive review. Decis. Support Syst. 2018, 108, 79–95. [Google Scholar] [CrossRef]

- Oke, A.E.; Arowoiya, V.A.; Akomolafe, O.T. Influence of the Internet of Things’ application on construction project performance. Int. J. Constr. Manag. 2020, 22, 2517–2527. [Google Scholar] [CrossRef]

- Caro, F.; Sadr, R. The Internet of Things (IoT) in retail: Bridging supply and demand. Bus. Horiz. 2019, 62, 47–54. [Google Scholar] [CrossRef]

- Pappas, N.; Caputo, A.; Pellegrini, M.M.; Marzi, G.; Michopoulou, E. The complexity of decision-making processes and IoT adoption in accommodation SMEs. J. Bus. Res. 2021, 131, 573–583. [Google Scholar] [CrossRef]

- MIMOS Berhad (Ed.) National Internet of Things (IoT) Strategic Roadmap: A Summary; MIMOS Berhad: Kuala Lumpur, Malaysia, 2015; ISBN 9789671139837. Available online: mimos.my (accessed on 14 October 2022).

- Brous, P.; Janssen, M.; Herder, P. The dual effects of the Internet of Things (IoT): A systematic review of the benefits and risks of IoT adoption by organizations. Int. J. Inf. Manag. 2020, 51, 101952. [Google Scholar] [CrossRef]

- Suciu, A.-D.; Tudor, A.I.M.; Chițu, I.B.; Dovleac, L.; Brătucu, G. IoT Technologies as Instruments for SMEs’ Innovation and Sustainable Growth. Sustainability 2021, 13, 6357. [Google Scholar] [CrossRef]

- Carcary, M.; Maccani, G.; Doherty, E.; Conway, G. Exploring the Determinants of IoT Adoption: Findings from a Systematic Literature Review; Springer International Publishing: New York, NY, USA, 2018; ISBN 9783319999500. [Google Scholar]

- Janssen, M.; Luthra, S.; Mangla, S.; Rana, N.P.; Dwivedi, Y.K. Challenges for adopting and implementing IoT in smart cities: An integrated MICMAC-ISM approach. Internet Res. 2019, 29, 1589–1616. [Google Scholar] [CrossRef]

- Tubaishat, A.; Paliath, S. Adoption Challenges of the Internet of Things: A Survey. In Proceedings of the 2018 3rd International Conference on Computer and Communication Systems (ICCCS), Nagoya, Japan, 27–30 April 2018; pp. 332–338. [Google Scholar]

- Jia, M.; Komeily, A.; Wang, Y.; Srinivasan, R.S. Adopting Internet of Things for the development of smart buildings: A review of enabling technologies and applications. Autom. Constr. 2019, 101, 111–126. [Google Scholar] [CrossRef]

- Birkel, H.S.; Hartmann, E. Impact of IoT challenges and risks for SCM. Supply Chain Manag. 2019, 24, 39–61. [Google Scholar] [CrossRef]

- Conway, J. The Industrial Internet of Things: An Evolution to a Smart Manufacturing Enterprise. Schneider Electric, Rueil-Malmaison, France, White Paper. 2016, p. 2. Available online: voltimum.pt (accessed on 14 October 2022).

- Pang, Z.; Chen, Q.; Han, W.; Zheng, L. Value-centric design of the internet-of-things solution for food supply chain: Value creation, sensor portfolio and information fusion. Inf. Syst. Front. 2015, 17, 289–319. [Google Scholar] [CrossRef]

- Kiel, D.; Arnold, C.; Voigt, K.I. The influence of the Industrial Internet of Things on business models of established manufacturing companies—A business level perspective. Technovation 2017, 68, 4–19. [Google Scholar] [CrossRef]

- Soldatos, J.; Gusmeroli, S.; Malo, P.; Di Orio, G. Internet of things applications in future manufacturing. In Digitising IndustryInternet of Things Connecting the Physical, Digital and Virtual Worlds; River Publishers: New York, NY, USA, 2016; pp. 153–183. [Google Scholar]

- Singh, R.; Bhanot, N. An integrated DEMATEL-MMDE-ISM based approach for analysing the barriers of IoT implementation in the manufacturing industry. Int. J. Prod. Res. 2020, 58, 2454–2476. [Google Scholar] [CrossRef]

- Gao, T.T.; Leichter, G.; Wei, Y.S. Countervailing effects of value and risk perceptions in manufacturers’ adoption of expensive, discontinuous innovations. Ind. Mark. Manag. 2012, 41, 659–668. [Google Scholar] [CrossRef]

- Kim, M.-K.; Joo, C.; Park, J.-H. Investigating the determinants of low adoption of tablet PCs in Korean firms: Effects of value perception and alternative attractiveness. Telemat. Inform. 2017, 34, 1557–1571. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Zailani, S.H.M.; Abdollahi, A. Knowledge Diffusion of the Internet of Things (IoT): A Main Path Analysis. Wirel. Pers. Commun. 2022, 126, 1177–1207. [Google Scholar] [CrossRef]

- Khajavi, S.H. Additive manufacturing in the clothing industry: Towards sustainable new business models. Appl. Sci. 2021, 11, 8994. [Google Scholar] [CrossRef]

- Gilson, L.L.; Goldberg, C.B. Editors’ Comment: So, What Is a Conceptual Paper? Gr. Organ. Manag. 2015, 40, 127–130. [Google Scholar] [CrossRef]

- Jaakkola, E. Designing conceptual articles: Four approaches. AMS Rev. 2020, 10, 18–26. [Google Scholar] [CrossRef]

- Cropanzano, R. Writing nonempirical articles for journal of management: General thoughts and suggestions. J. Manag. 2009, 35, 1304–1311. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Zeithaml, V.A. Consumer perceptions of price, quality, and value: A means-end model and synthesis of evidence. J. Mark. 1988, 52, 2–22. [Google Scholar] [CrossRef]

- Hsu, C.L.; Lin, J.C.C. Exploring factors affecting the adoption of internet of things services. J. Comput. Inf. Syst. 2018, 58, 49–57. [Google Scholar] [CrossRef]

- Lin, T.C.; Lee, C.K.; Lin, J.C.C. Determinants of Enterprise 2.0 adoption: A value-based adoption model approach. In Proceedings of the 2010 International Conference on Information Society, London, UK, 28–30 June 2010; pp. 12–18. [Google Scholar]

- Yu, J.; Lee, H.; Ha, I.; Zo, H. User acceptance of media tablets: An empirical examination of perceived value. Telemat. Inform. 2017, 34, 206–223. [Google Scholar] [CrossRef]

- Kim, M.K.; Oh, J.; Park, J.H.; Joo, C. Perceived value and adoption intention for electric vehicles in Korea: Moderating effects of environmental traits and government supports. Energy 2018, 159, 799–809. [Google Scholar] [CrossRef]

- Kim, H.-W.; Chan, H.C.; Gupta, S. Value-based Adoption of Mobile Internet: An empirical investigation. Decis. Support Syst. 2007, 43, 111–126. [Google Scholar] [CrossRef]

- Pal, D.; Arpnikanondt, C.; Funilkul, S.; Chutimaskul, W. The Adoption Analysis of Voice-Based Smart IoT Products. IEEE Internet Things J. 2020, 7, 10852–10867. [Google Scholar] [CrossRef]

- Sohn, K.; Kwon, O. Technology acceptance theories and factors influencing artificial Intelligence-based intelligent products. Telemat. Inform. 2020, 47, 101324. [Google Scholar] [CrossRef]

- Sneesl, R.; Jusoh, Y.Y.; Jabar, M.A.; Abdullah, S. Revising Technology Adoption Factors for IoT-Based Smart Campuses: A Systematic Review. Sustainability 2022, 14, 4840. [Google Scholar] [CrossRef]

- Qasem, Y.A.M.; Abdullah, R.; Yaha, Y.; Atana, R. Continuance use of cloud computing in higher education institutions: A conceptual model. Appl. Sci. 2020, 10, 6628. [Google Scholar] [CrossRef]

- Rogers, E.M. Diffusion of Innovations, 5th ed.; The Free Press: New York, NY, USA, 2003. [Google Scholar]

- Iacovou, C.L.; Benbasat, I.; Dexter, A.S. Electronic Data Interchange and Small Organizations: Adoption and Impact of Technology. MIS Q. 1995, 19, 465–485. [Google Scholar] [CrossRef]

- Kuan, K.K.Y.; Chau, P.Y.K. A perception-based model for EDI adoption in small businesses using a technology-organization-environment framework. Inf. Manag. 2001, 38, 507–521. [Google Scholar] [CrossRef]

- Çolak, H.; Kaǧnicioǧlu, C.H. Acceptance of Blockchain Technology in Supply Chains: A Model Proposal. Oper. Supply Chain Manag. 2022, 15, 17–26. [Google Scholar] [CrossRef]

- Depietro, R.; Wiarda, E.; Fleischer, M. The context for change: Organization, technology, and environment. Process. Technol. Innov. 1990, 199, 151–175. [Google Scholar]

- Ali, O.; Shrestha, A.; Osmanaj, V.; Muhammed, S. Cloud computing technology adoption: An evaluation of key factors in local governments. Inf. Technol. People 2020, 34, 666–703. [Google Scholar] [CrossRef]

- Mital, M.; Chang, V.; Choudhary, P.; Papa, A.; Pani, A.K. Adoption of Internet of Things in India: A test of competing models using a structured equation modeling approach. Technol. Forecast. Soc. Chang. 2018, 136, 339–346. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J. An integrated analysis of value-based adoption model and information systems success model for proptech service platform. Sustainability 2021, 13, 12974. [Google Scholar] [CrossRef]

- Lin, T.C.; Wu, S.; Hsu, J.S.C.; Chou, Y.C. The integration of value-based adoption and expectation-confirmation models: An example of IPTV continuance intention. Decis. Support Syst. 2012, 54, 63–75. [Google Scholar] [CrossRef]

- Chatterjee, S.; Rana, N.P.; Dwivedi, Y.K.; Baabdullah, A.M. Understanding AI adoption in manufacturing and production firms using an integrated TAM-TOE model. Technol. Forecast. Soc. Chang. 2021, 170, 120880. [Google Scholar] [CrossRef]

- Kumar Bhardwaj, A.; Garg, A.; Gajpal, Y. Determinants of Blockchain Technology Adoption in Supply Chains by Small and Medium Enterprises (SMEs) in India. Math. Probl. Eng. 2021, 2021, 5537395. [Google Scholar] [CrossRef]

- Alkhalil, A.; Sahandi, R.; John, D. An exploration of the determinants for decision to migrate existing resources to cloud computing using an integrated TOE-DOI model. J. Cloud Comput. 2017, 6, 1–20. [Google Scholar] [CrossRef]

- Bediako, I.A.; Zhao, X.; Antwi, H.A.; Mensah, C.N. Urban water supply systems improvement through water technology adoption. Technol. Soc. 2018, 55, 70–77. [Google Scholar] [CrossRef]

- Almaiah, M.A.; Alfaisal, R.; Salloum, S.A.; Hajjej, F.; Shishakly, R.; Lutfi, A.; Alrawad, M.; Al Mulhem, A.; Alkhdour, T.; Al-Maroof, R.S. Measuring Institutions’ Adoption of Artificial Intelligence Applications in Online Learning Environments: Integrating the Innovation Diffusion Theory with Technology Adoption Rate. Electron. 2022, 11, 3291. [Google Scholar] [CrossRef]

- Hiran, K.K.; Henten, A. An integrated TOE–DOI framework for cloud computing adoption in the higher education sector: Case study of Sub-Saharan Africa, Ethiopia. Int. J. Syst. Assur. Eng. Manag. 2020, 11, 441–449. [Google Scholar] [CrossRef]

- Varma, A. Fintech Adoption Choices of Small Businesses: A Technology Organization Environment (TOE) Framework study. Account. Financ. Res. 2019, 8, 86. [Google Scholar] [CrossRef]

- Yang, H.; Yu, J.; Zo, H.; Choi, M. User acceptance of wearable devices: An extended perspective of perceived value. Telemat. Inform. 2016, 33, 256–269. [Google Scholar] [CrossRef]

- Teo, T.S.H.; Lin, S.; Lai, K.H. Adopters and non-adopters of e-procurement in Singapore: An empirical study. Omega 2009, 37, 972–987. [Google Scholar] [CrossRef]

- Jiménez-Martínez, J.; Polo-Redondo, Y. The influence of EDI adoption over its perceived benefits. Technovation 2004, 24, 73–79. [Google Scholar] [CrossRef]

- Rad, B.; Ahmada, H. Internet of Things: Trends, Opportunities, and Challenges. Int. J. Comput. Sci. Netw. Secur. 2017, 17, 89–95. [Google Scholar] [CrossRef]

- Satar, S.B.A.; Hussin, A.R.C.; Yusof, A.F. Exploring internet of things adoption in Malaysian oil and gas industry. In Proceedings of the 2019 6th International Conference on Research and Innovation in Information Systems (ICRIIS), Johor Bahru, Malaysia, 2–3 December 2019. [Google Scholar] [CrossRef]

- Lu, Y.; Papagiannidis, S.; Alamanos, E. Internet of things: A systematic review of the business literature from the user and organisational perspectives. Technol. Forecast. Soc. Chang. 2018, 136, 285–297. [Google Scholar] [CrossRef]

- Wanasinghe, T.R.; Gosine, R.G.; James, L.A.; Mann, G.K.I.; Silva, O.D.; Warrian, P.J. The Internet of Things in the Oil and Gas Industry: A Systematic Review. IEEE Internet Things J. 2020, 7, 8654–8673. [Google Scholar] [CrossRef]

- Sharma, M.; Joshi, S.; Kannan, D.; Govindan, K.; Singh, R.; Purohit, H.C. Internet of Things (IoT) adoption barriers of smart cities’ waste management: An Indian context. J. Clean. Prod. 2020, 270, 122047. [Google Scholar] [CrossRef]

- Parra, D.T.; Guerrero, C.D. Decision-making IoT adoption in SMEs from a technological perspective. In Proceedings of the 2020 15th Iberian Conference on Information Systems and Technologies (CISTI), Seville, Spain, 24–27 June 2020. [Google Scholar] [CrossRef]

- Rizzuto, T.E.; Schwarz, A.; Schwarz, C. Toward a deeper understanding of IT adoption: A multilevel analysis. Inf. Manag. 2014, 51, 479–487. [Google Scholar] [CrossRef]

- Shahbaz, M.; Gao, C.; Zhai, L.L.; Shahzad, F.; Hu, Y. Investigating the adoption of big data analytics in healthcare: The moderating role of resistance to change. J. Big Data 2019, 6, 1–20. [Google Scholar] [CrossRef]

- Lutfi, A.; Alsyouf, A.; Almaiah, M.A.; Alrawad, M.; Abdo, A.A.K.; Al-Khasawneh, A.L.; Ibrahim, N.; Saad, M. Factors Influencing the Adoption of Big Data Analytics in the Digital Transformation Era: Case Study of Jordanian SMEs. Sustainability 2022, 14, 1802. [Google Scholar] [CrossRef]

- Opara-Martins, J.; Sahandi, R.; Tian, F. Critical review of vendor lock-in and its impact on adoption of cloud computing. In Proceedings of the International Conference on Information Society (i-Society 2014), London, UK, 10–12 November 2014; pp. 92–97. [Google Scholar]

- Lee, G. What roles should the government play in fostering the advancement of the internet of things? Telecomm. Policy 2019, 43, 434–444. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Yang, Y.; Shan, M.; He, B.; Gou, Z. Influences of barriers, drivers, and promotion strategies on green building technologies adoption in developing countries: The Ghanaian case. J. Clean. Prod. 2018, 200, 687–703. [Google Scholar] [CrossRef]

- Awa, H.O.; Ojiabo, O.U. A model of adoption determinants of ERP within T-O-E framework. Inf. Technol. People 2016, 29, 901–930. [Google Scholar] [CrossRef]

| Ref | Technology/Area | Theory | Constructs | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Perceived Value | Perceived Direct Benefits | Perceived Indirect Benefits | Security and Privacy | Compatibility | Complexity | Implementation Cost | Employees Resistance | Organizational Readiness | Top Management Support | Vendor Issues | Government Regulation | |||

| [7] | IoT adoption in manufacturing | DOI + TOE | X | X | X | X | ||||||||

| [21] | Big Data analytics adoption in manufacturing | TOE | X | X | X | X | X | |||||||

| [25] | IoT adoption in the agricultural supply chain | TOE | X | X | X | X | X | X | ||||||

| [27] | IoT adoption in auto-component manufacturing SMEs | TOE | X | X | X | X | X | X | ||||||

| [31] | IoT adoption in agribusiness | TOE + HOT-fit | X | X | X | X | X | X | ||||||

| [66] | Tablet PCs adoption in firms | VAM | X | X | X | X | ||||||||

| [75] | Enterprise 2.0 adoption in business | VAM | X | X | ||||||||||

| [84] | EDI adoption and impact on small organizations | TOE | X | X | X | |||||||||

| [85] | EDI adoption in small businesses | TOE | X | X | X | X | ||||||||

| [93] | Blockchain adoption in supply chains of SMEs | TAM + DOI + TOE | X | X | X | X | X | X | X | |||||

| [94] | Cloud computing adoption in industries | DOI + TOE | X | X | X | X | X | |||||||

| [95] | Water supply systems adoption in the urban area | DOI | X | X | ||||||||||

| [96] | AI applications adoption in learning institutions | DOI | X | X | ||||||||||

| [97] | Cloud computing adoption in the higher education sector | DOI + TOE | X | X | X | X | ||||||||

| [98] | Fintech adoption in small businesses | TOE | X | X | X | X | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmetoglu, S.; Che Cob, Z.; Ali, N. Internet of Things Adoption in the Manufacturing Sector: A Conceptual Model from a Multi-Theoretical Perspective. Appl. Sci. 2023, 13, 3856. https://doi.org/10.3390/app13063856

Ahmetoglu S, Che Cob Z, Ali N. Internet of Things Adoption in the Manufacturing Sector: A Conceptual Model from a Multi-Theoretical Perspective. Applied Sciences. 2023; 13(6):3856. https://doi.org/10.3390/app13063856

Chicago/Turabian StyleAhmetoglu, Sehnaz, Zaihisma Che Cob, and Nor’Ashikin Ali. 2023. "Internet of Things Adoption in the Manufacturing Sector: A Conceptual Model from a Multi-Theoretical Perspective" Applied Sciences 13, no. 6: 3856. https://doi.org/10.3390/app13063856

APA StyleAhmetoglu, S., Che Cob, Z., & Ali, N. (2023). Internet of Things Adoption in the Manufacturing Sector: A Conceptual Model from a Multi-Theoretical Perspective. Applied Sciences, 13(6), 3856. https://doi.org/10.3390/app13063856