Abstract

Thermal shock is the physical process of rapid cooling of a hot object. The physical and mechanical properties of rocks that have undergone thermal shock will change. This variation can be applied to the development of geothermal in limestone reservoirs and serve as an effective means of enhancing heat exchange capacity. The essence of this is rock thermal shock rupture. The reason for the change in rock properties due to thermal shock is distinguished from other factors and is a process of instantaneous impact thermal stress caused by non-constant heat transfer, resulting in rock damage from microscopic damage to macroscopic damage. In order to study the variation of physical and mechanical properties of limestone with heating and cooling temperatures under the effect of thermal shock, a self-developed thermal shock test device was used to test the physical and mechanical properties of limestone heated to 100 °C~600 °C after thermal shock. The results strongly suggest that the heating temperature under the effect of thermal shock is the main factor affecting the evolution of basic physical properties of limestone; with the increase in heating temperature, the color of the specimen changes from off-white to white, the mass decreases and the volume nonlinearly increases, with a maximum reduction of 1.39% in mass and a maximum expansion of 2.79% in volume at 600 °C. Indeed, 500 °C is the temperature of abrupt mass loss. The heating temperature and the cooling medium temperature act together to deteriorate the mechanical properties of limestone. With increasing heating temperature (decreasing cooling temperature), the uniaxial compressive strength of limestone decreased by 39.5% (19.3%), modulus of elasticity by 59.5% (22.9%), tensile strength by 42.9% (7.6%), and cohesion by 43.2% (22.5%). The peak strain increases by 74.2% and the angle of internal friction increases by 27% (25.9%). The above data are average values. The empirical equations of the compressive strength, modulus of elasticity, tensile strength of limestone under the action of thermal shock versus heating temperature were obtained. The differences in the physical and mechanical properties of limestone after two heat treatments (thermal shock and high-temperature heating) were compared and analyzed, and the results showed that the physical and mechanical properties of limestone deteriorated more severely after thermal shock compared to high-temperature heating. The research results can provide technical support for the drilling of geothermal development and wellbore stability assessment in limestone reservoirs, and enrich the theory of high-temperature rock mechanics.

1. Introduction

Thermal shock phenomena are commonly found in the field of science and technology. For example, geothermal development, thermal rock breaking, high-temperature overwater tunnel construction, nuclear waste disposal, etc. Therefore, rock thermal shock has received a lot of attention. Rock thermal shock is a phenomenon in which a large amount of heat exchange occurs in a short time when a rock is sharply heated or cooled, and the temperature dramatically changes, creating a huge temperature gradient inside the rock [1,2]. Rocks are a typical porous media material, and the mineral crystals that make up the rock have different lattice energies and thermal expansion coefficients. As the degree of thermal shock increases, the thermal shock velocity increases, the intermolecular binding force decreases, and the thermal stress of the shock exceeds the destructive strength of the rock [3,4,5,6]. The rock will generate a large number of fractures and cracks from the micro and fine levels, promoting the connectivity of the fracture network. This leads to changes in physical and mechanical properties such as bulk density, compressive strength, and tensile strength [7,8]. These variations are complex, and are different for different rock types [9]. Therefore, the study of the evolution of physical and mechanical properties of rocks under the effect of thermal shock is of great significance for the in-depth understanding and development of high-temperature rock mechanics.

Many researchers have performed extensive studies on high-temperature rock mechanics, including porosity and longitudinal wave velocity [10,11,12], static properties [13,14,15,16,17], kinetic properties [18], and the intrinsic connection between physical and mechanical properties and microstructural changes of different types of rocks [19]. The temperature conditions under which the above conclusions were obtained are real-time high temperature or after high temperature. In recent years, due to the urgent engineering needs, the damage characteristics of rocks after thermal shock action have received wide attention. Some scholars have analyzed the physical and mechanical characteristics and evolution laws of granite under thermal impact by combining mechanical tests with theoretical studies. It is believed that the cooling rate during thermal shock can have a large effect on the mechanical properties of the rock [20,21,22]. In order to explore the damage mechanism of granite by high temperature and thermal shock, respectively, relevant experimental analysis was conducted, and it was pointed out that the mechanical strength deterioration of granite after thermal shock treatment was higher [23,24,25]. Similar patterns have been found for other types of rocks [26,27]. It can be seen that most of the studies around the evolution law of physical and mechanical properties of rocks under the action of temperature are focused on real-time high temperature or after the action of high temperature, and the study under the action of thermal shock needs to be deepened.

Limestone is a carbonate rock with calcite as its main component, which is an important industrial raw material. It is also one of the most widely distributed minerals in the Earth’s crust [18]. The southeastern region of China is located at the southeastern edge of the Eurasian continent. The geological and tectonic movements are intense, forming hydrothermal geothermal resources with abundant reserves [28]. Most of the thermal reservoirs in this area are sedimentary rock formations dominated by limestone. In the development of geothermal resources in the region, thermal shock action can increase the permeability of limestone reservoirs, promote the construction of artificial thermal storage, and improve the efficiency of heat extraction. It can also protect the stability of the drilling envelope by controlling the reduction of limestone thermal shock rupture. Therefore, it is of great engineering value and practical significance to study the physical and mechanical properties of limestone under the action of thermal shock. Most of the former researches have focused on the effects of different cooling methods on the rocks as the study of thermal shock effects. In this paper, the joint effect of both heating and cooling factors on the physical and mechanical properties of limestone during thermal shock will be experimentally studied. The results will enrich the theory of high-temperature rock mechanics and provide technical support for geothermal mining.

2. Specimen and Laboratory Test

2.1. Specimen

The test material is limestone from the Permian formation in Guangdong Province, China (this stratum is rich in geothermal resources). The specimen is made from a homogeneous, dense, naturally water-bearing rock sample with no internal defects. By XRD analysis, the average mineral fraction of the limestone samples was 92.1% calcite, 1.8% quartz, 1.7% dolomite, and 4.4% illite group clay minerals.

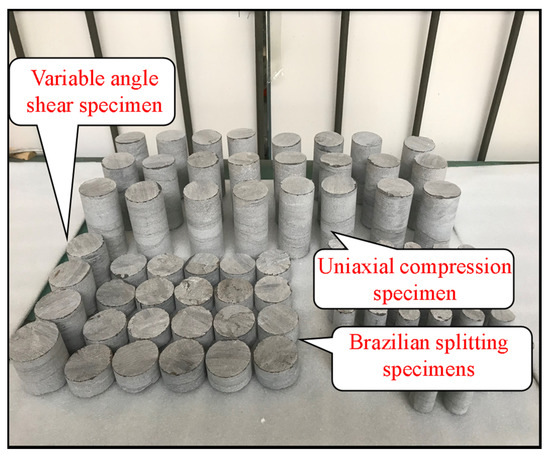

The specimens were processed into uniaxial compression specimens, Brazilian split specimens, and variable angle shear specimens according to the specimen size standard recommended by the International Society of Rock Mechanics. The specimens were cylindrical with a diameter of 50 mm and a height-to-diameter ratio of 2:1, 1:2, and 1:1, respectively. The specimens were screened, and finally the specimens with parallel top and bottom end surfaces and good flatness and high integrity were obtained, measuring the volume and mass of each specimen. The processing accuracy was guaranteed to meet the test requirements, and some specimens are shown in Figure 1.

Figure 1.

Schematic diagram of part of the specimen.

2.2. Experimental Equipment

As shown in Figure 2, the test equipment used in this paper are: a rock coring drilling machine (A), a high precision electronic scale (B), a programmable temperature-controlled muffle furnace (C), a rock thermal shock rupture test bench (D), a microcomputer-controlled electric-hydraulic servo press (E).

Figure 2.

Actual picture of the test equipment a rock coring drilling machine (A), a high precision electronic scale (B), a programmable temperature-controlled muffle furnace (C), a rock thermal shock rupture test bench (D), a microcomputer-controlled electric-hydraulic servo press (E).

The rock thermal impact rupture test bench was developed by the Key Laboratory of Ministry of Education of Taiyuan University of Technology for in situ modification. The length, width, and height of this test stand were 600, 600, and 550 mm, respectively. It could control the temperature of the circulating medium between 10 °C~350 °C, with a temperature control accuracy of 0.5 °C, and internal circulation through microcomputer-controlled high-temperature-resistant oil pump. The equipment could realize the rapid cooling of high temperature rocks in constant temperature medium. At the same time, the larger working volume and circulating pump could ensure no heat gathering near the high temperature rock during the cooling process. The accuracy of the test was further ensured.

2.3. Experimental Method

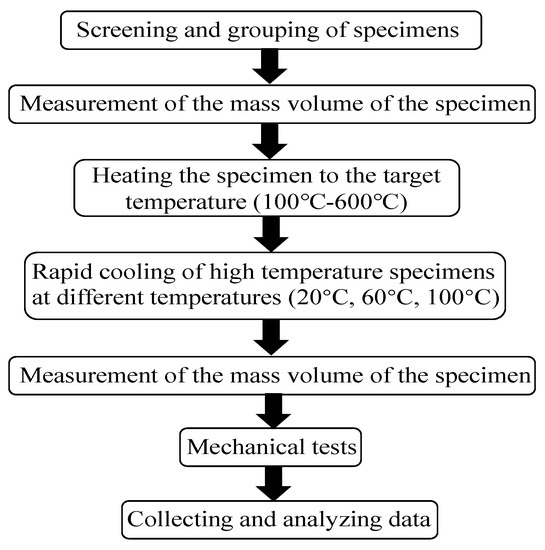

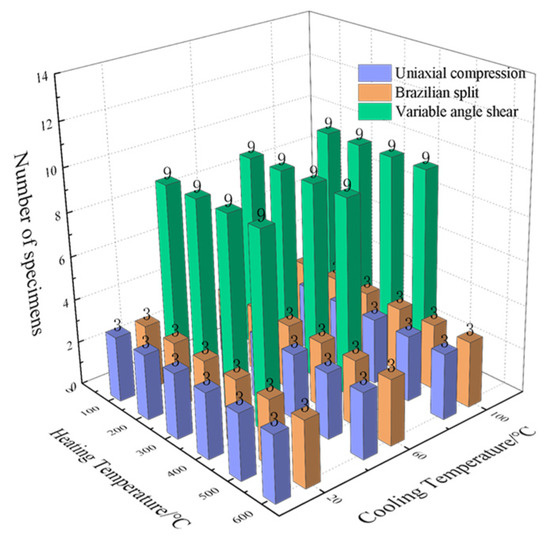

The experimental study program is shown in Figure 3. The limestone specimens were heated to 100 °C–600 °C at a heating rate of 3 °C/h, respectively, and held in a muffle furnace for 4 h. Then, the stable high temperature specimens were quickly cooled in water at different temperatures (20 °C, 60 °C, 100 °C). The mass and volume of each specimen were measured after cooling. A group of normal temperature limestone specimens without thermal shock treatment was set as the control group. A total of 19 temperature working conditions were set for the experiment. Finally, the uniaxial compression test, Brazilian split test, and variable angle shear test were performed by microcomputer-controlled electro-hydraulic servo press, and the test data were analyzed by taking the average value. The test piece grouping information is shown in Figure 4.

Figure 3.

Specimen grouping information.

Figure 4.

Specimen grouping information chart.

2.4. Thermal Shock Experiment

Thermal shock was applied into the high temperature limestone specimens by placing them in water of 20 °C, 60 °C, and 100 °C, respectively, at a pressure of 0.1 MPa (1 atmosphere of pressure). The experimental procedures are presented below: First, the specimen was put into the muffle furnace and heated to the target temperature (e.g., 100 °C) at a heating rate of 3 °C/h and kept at a constant temperature for 4 h. This step ensures stable heating of the specimen to avoid thermal shock due to excessive heating rate. Next, the high-temperature specimen was put into the thermal shock rupture test bench for quickly cooling. During the cooling, the cooling water in the test bench was kept circulating and the water temperature was kept constant (20 °C, 60 °C, 100 °C). The volume of cooling water was more than 1000 times that of the specimens to avoid local concentration of heat around the specimens. The surface temperature of the specimen was continuously measured until it reached the temperature of the cooling water, i.e., (20 °C, 60 °C, 100 °C) ± 0.5 °C, respectively. The specimen were removed and let to freely dry in the air for 7 days. The above procedure was performed for heating temperatures of 200 °C, 300 °C, 400 °C, 500 °C, and 600 °C, respectively.

2.5. Mechanical Performance Test

The limestone specimens treated with thermal shock were clamped on a 600 kN microcomputer-controlled electro-hydraulic servo press and loaded by displacement control method. By varying the test mold and loading rate, uniaxial compression tests (loading rate of 0.001 mm/s), Brazilian splitting tests (loading rate of 0.001 mm/s), and variable angle shear tests (loading rate of 0.002 mm/s) were performed at three shear angles of 45°, 50°, and 55°, respectively. The calculation of various mechanical parameters of limestone specimens was carried out by applying relevant equations.

3. Results

3.1. Fundamental Physical Properties

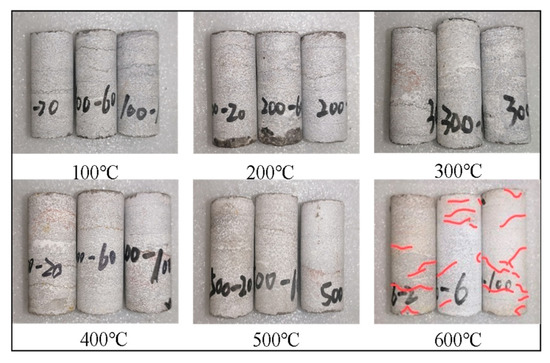

As shown in Figure 5, the apparent color of Huizhou limestone under the effect of thermal shock is mainly affected by the peak temperature of heating. The surface of the specimen heated at 300 °C or less is grayish white, with local greenish gray and rusty red mineral inclusions. When heated to 400 °C~500 °C, the surface of the specimen changes to earthy yellow and the range of rusty red increases. In contrast to the conclusions reached by other studies [12] (significant changes in limestone surface color after high temperature action at 700 °C), the apparent color of the specimens significantly changed at 600 °C under thermal shock; i.e., an overall shift to white. It shows that the thermal shock effect is stronger than the high temperature effect on limestone when the heating temperature is the same.

Figure 5.

Specimen apparent color change diagram (the fissures were marked in red).

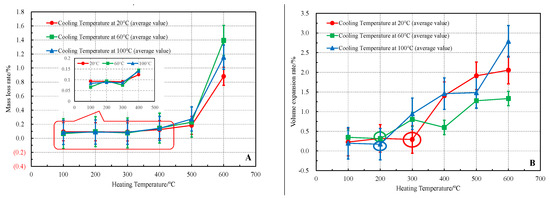

The tests showed that the mass of limestone specimens decreased and the volume increased under the effect of thermal shock. The decrease in mass of limestone under thermal shock is due to evaporation of internal water, the decomposition of some minerals, and a small amount of flaking of rock chips. The expansion of mineral grains and the generation of a large number of fractures under thermal shock combined to cause the increase in limestone volume. Mass loss results of limestone specimens are presented in Figure 6A. The mass loss rate of limestone increases with the increase in heating temperature after thermal shock. Taking cooling in water at 20 °C as an example: the mass loss rate of the specimen below 300 °C remains unchanged at about 0.092%. A slow increase in mass loss rate to 0.183% from 300 °C to 500 °C, with an increase of 101% compared to 300 °C. When the temperature increases to 600 °C, the mass loss rate of limestone rapidly increases to 0.882%, which is 4.82 times that of 500 °C and, even more, 9.48 times that of 100 °C. The main reason for the change in the mass of the specimen within 500 °C is the evaporation and release of the water inside the rock. The mass loss of limestone from 20 °C to 300 °C is mainly dominated by the evaporation of free water. Because the water content of the specimen is small, the mass remains essentially unchanged at this stage. Within the temperature range of 300 °C~500 °C, the combined water inside the limestone gradually evaporates and the mass of the specimen slowly decreases. Above 500 °C, the internal mineral components of limestone gradually decompose. Moreover, the thermal shock rupture produced by the specimen at this temperature is significant at either cooling temperature, and a small number of mineral particles flake off from the specimen. Therefore, the mass of limestone rapidly decreases at this stage, and the mass loss rate increases significantly.

Figure 6.

Mass loss rate (A) and volume expansion rate (B) of limestone specimens after thermal shock.

Due to the anisotropy of limestone and the different thermal expansion coefficients of different mineral particles, the volume of the specimen nonlinearly increases, so the data distribution of the volume expansion rate of high-temperature limestone after the thermal shock is more discrete. As shown in Figure 6B, the variation of limestone volume with heating temperature is similar after thermal shock in water at different temperatures. The volume of limestone increases with increasing heating temperature (general trend), but there are differences in the inflection point temperature of volume abrupt change (the part marked by circles in the figure). The volume abrupt change temperature is 300 °C for limestone cooled in 20 °C water, and 200 °C for limestone cooled in 60 °C and 100 °C water. This indicates that limestone undergoes rapid volume expansion after a threshold of heating temperature under the effect of thermal shock (this change is nonlinear), and that cooling temperature affects this threshold temperature. It is further shown that the effect of thermal shock on limestone is jointly controlled by both heating and cooling phases. Take thermal shock cooling in water at 100 °C as an example: for peak temperatures in the range of 100 °C ~200 °C, the volume expansion rate of the specimen slightly decreases, and the change range is 0.172~0.196%. The volume expansion rate rapidly increases when the heating temperature exceeded 200 °C. The volume expansion of the specimen at 600 °C was 2.788%, which was 16.2 times higher than that at 200 °C, indicating that the heating temperature had a significant effect on the volume change of limestone.

3.2. Mechanical Properties

3.2.1. Uniaxial Compressive Strength

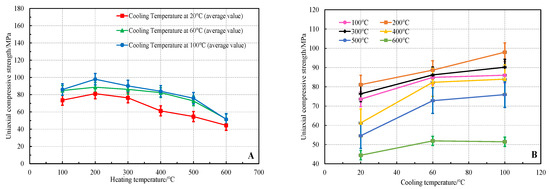

Uniaxial compressive strength is the peak stress that the sample can withstand during loading in the uniaxial compression test. The uniaxial compressive strength of the original rock (limestone specimen without thermal shock treatment) was 91.45 MPa (σ = 4.456), and the results of the uniaxial compressive strength of heated limestone specimens affected by thermal shock are shown in Figure 5.

It can be seen that the uniaxial compressive strength of the rock sample increases and then decreases with the increase in heating temperature T at a given cooling temperature from Figure 7A, and the inflection point temperature is 200 °C. When the cooling temperature is 20 °C, the average uniaxial compressive strength of limestone increases from 73.63 MPa (σ = 3.83) at 100 °C to 81.13 MPa (σ = 1.89) at 200 °C, an increase of 9.8%, and then decreases to 44.47 MPa (σ = 7.37) at 600 °C, a decrease of 45.2%. It is worth noting that the strength values are very strongly scattered for the temperatures 100, 200, and 300 °C. This is because the mechanical strength of limestone is more influenced by the primary tectonics in the lower temperature section. Limestone of different formations can have large differences in the thermal-mechanical response. Therefore, the experimental results reflect more scattered numerical points.

Figure 7.

Results of uniaxial compressive strength of limestone with heating temperature (A) and cooling temperature (B).

This is because thermal shock causes thermal expansion and deformation of the limestone sample below 200 °C, which is believed to close the primary voids, thus leading to an increase in the uniaxial compressive strength of the specimen. With the increase in heating temperature, the internal voids of the specimen re-open and generate new pores and fissures, forming a complex network of fissures leading to the decrease in the uniaxial compressive strength of the specimen. By analyzing the test results, it was found that the uniaxial compressive strength of limestone correlated well with the heating temperature at a given cooling temperature. Therefore, the two parameters were fitted in the range of 200 °C to 600 °C and were found to have an exponential relationship:

where σc is the uniaxial compressive strength at different cooling temperatures (MPa); T is the heating temperature, and its range is from 200 °C to 600 °C; R^2 is the correlation coefficient.

σc20 °C = 114.8e^(−0.002T), (R^2 = 0.975)

σc60 °C = 123.2e^(−0.001T), (R^2 = 0.800)

σc100 °C = 139.9e^(−0.001T), (R^2 = 0.845)

From Figure 7B, it can be seen that the uniaxial compressive strength of high-temperature limestone samples increases with the increase in cooling temperature. As an example, the limestone sample was cooled at different temperatures at 600 °C: the average uniaxial compressive strength decreased from 51.46 MPa (σ = 5.97) at 100 °C to 44.47 MPa (σ = 7.37) at 20 °C, an increase of 13.6%.

This is because the greater the temperature difference per unit distance and per unit time, the higher the temperature gradient, the greater the thermal stress, and the more serious the damage caused to the rock sample.

3.2.2. Peak Strain

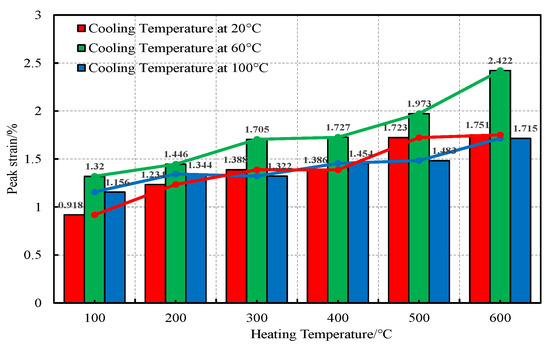

Brittle damage of rocks is characterized by small peak strains, an instantaneous release of elastic energy, and accompanying loud sounds. Ductile damage is the opposite, not only is the peak strain larger, but the elastic energy is also slowly released without instantaneous damage. In the uniaxial compression test, the strain corresponding to the uniaxial compressive strength of the specimen is the peak strain, and the value of the peak strain can be obtained by in the stress-strain curve. The peak strain can, to a certain extent, reflect the brittle-ductile characteristics of the specimen. Figure 6 shows the variation of limestone peak strain with temperature after thermal shock. In addition, the peak strain of the original rock is 1.194%.

As shown in Figure 8, the peak strain of the limestone sample after thermal shock increases with the increase in heating temperature. It shows that the peak strain of the limestone sample increases from 0.918% at 100 °C to 1.751% at 600 °C after thermal shock at 20 °C, an increase of 90.7%. Peak strain increases from 1.32% at 100 °C to 2.422% at 600 °C after thermal shock at 60 °C, an increase of 83.5%. Peak strain increases from 1.156% at 100 °C to 1.715% at 600 °C after thermal shock at 100 °C, an increase of 48.4%. All of the above data show that the peak strain increases with increasing heating temperature when limestone is cooled by thermal shock at a constant temperature. The thermal shock promotes the transformation of limestone from brittle to ductile characteristics. It is noteworthy that the absolute value of the peak strain is always highest when the high temperature limestone is cooled at 60 °C. This indicates that peak strain and thermal shock temperature difference ΔT do not have an obvious linear relationship. Although the peak temperature of heating and the cooling temperature jointly affect the evolution of peak strain, there is a very complex mechanism of action between the two for the effect of peak strain. We can then investigate this direction in depth.

Figure 8.

Trends of peak strain of limestone with temperature after thermal shock.

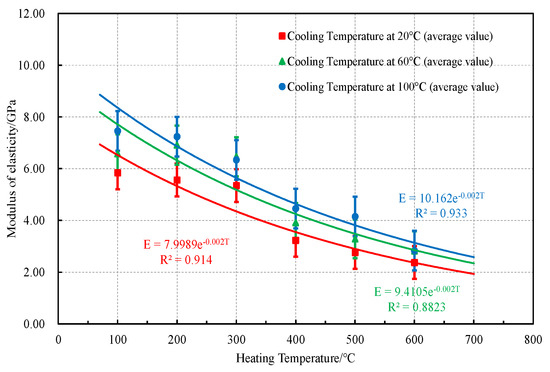

3.2.3. Modulus of Elasticity

The modulus of elasticity is an important mechanical parameter to characterize the stiffness of the rock, and the results of the variation of the elastic modulus of limestone with temperature after thermal shock are shown in Table 1. In addition, the average modulus of elasticity of the original rock is 7.71 GPa (Emin = 6.87 GPa, Emax = 8.64 GPa, σ = 0.73), which is greater than the average modulus of elasticity of the limestone sample after thermal shock. By analyzing the test results, we can see that the modulus of elasticity decreases with the increase in heating temperature after thermal shock of high temperature limestone. This indicates that the thermal shock destroys the structural integrity of the specimen, resulting in a reduction in limestone stiffness and a decrease in elastic modulus.

Table 1.

Modulus of elasticity of limestone after thermal shock.

The elastic modulus of limestone after thermal shock and the heating temperature (100 °C~600 °C) were fitted as shown in Figure 9. There is a good exponential function relationship between the two parameters. The following empirical expressions were obtained.

where E is the elastic modulus at different cooling temperatures (GPa); T is the heating temperature, its range is from 100 °C to 600 °C; R^2 is the correlation coefficient.

E20 °C = 7.999e^(−0.002T), (R^2 = 0.914)

E60 °C = 9.411e^(−0.002T), (R^2 = 0.882)

E100 °C = 10.162e^(−0.002T), (R^2 = 0.933)

Figure 9.

Trends of elastic modulus of limestone with temperature after thermal shock.

3.2.4. Tensile Strength

Tensile strength is one of the very important mechanical parameters of rocks. It is the average stress on the broken section perpendicular to the direction of tensile stress action in the moment of failure. Because the tensile strength of rocks is much smaller than the compressive strength, it is easy to produce tensile damage. Therefore, the study of the tensile properties of rocks is of great significance to reveal the stability of rocks.

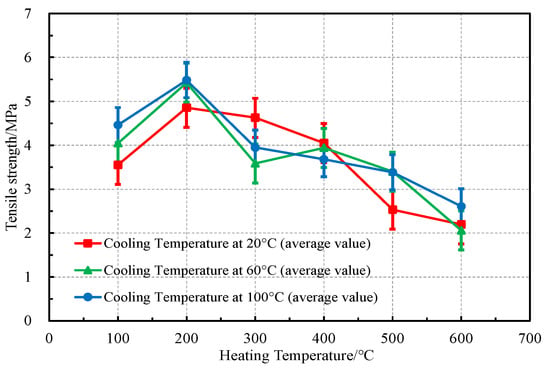

As shown in Figure 10, the tensile strength of limestone specimens after thermal shock at different cooling temperatures showed a tendency to increase and then decrease with increasing heating temperature. It is worth mentioning that this is consistent with the evolution of uniaxial compressive strength with heating temperature. The reasons for this result are described in Section 3.2.1. The tensile strength of limestone specimens decreased from 3.39 MPa of the original rock to 2.19 MPa (35.4%), 2.06 MPa (39.2%), and 2.61 MPa (23%) after thermal shock in water at 20 °C, 60 °C, and 100 °C, respectively. The percentages in parentheses are the reduction rates. It can be seen that the cooling temperature also has some effect on the tensile strength. A good exponential relationship between the tensile strength and heating temperature of limestone in the range of 200 °C to 600 °C was fitted, as shown below:

where σt is the tensile strength at different cooling temperatures (MPa); T is the heating temperature, its range is from 200 °C to 600 °C; R^2 is the correlation coefficient.

σt20 °C = 8.337e^(−0.002T), (R^2 = 0.908)

σt60 °C = 7.791e^(−0.002T), (R^2 = 0.811)

σt100 °C = 7.148e^(−0.002T), (R^2 = 0.930)

Figure 10.

Trends of tensile strength of limestone with temperature after thermal shock.

The above data indicate that thermal shock has a large effect on the tensile properties of limestone, and the tensile properties of limestone are significantly deteriorated after thermal shock. Therefore, researchers in the engineering field should focus on the weakening characteristics of the tensile strength of rocks after thermal shock.

3.2.5. Shear Strength Curve

The damage of rocks under natural conditions is mostly compression-shear damage, so it is important to study the shear properties of rocks. Shear strength is one of the important parameters of rock mechanical properties, defined as the maximum tangential stress on the shear surface of a rock specimen when it is sheared. In this paper, the shear strength of limestone is obtained by variable angle shear test. The tangential stress τ and the direct stress σ of the specimen are calculated by Equations (10) and (11).

where A is the projected area of the shear damage surface (mm2); α is the shear angle (°), f is the rolling friction coefficient between the testing machine indenter and the shear rollers, f = 1/n d, n is the number of rollers, d is the diameter of the rollers (cm). In this test, n = 10; d = 8 cm.

τ = P/A (sinα − f cosα)

σ = P/A (cosα + f sinα)

After obtaining τ, σ for three angles (45°, 50°, 55°) through the test, the shear strength curve was obtained by least squares fitting in the direct stress—tangential stress coordinate system, and the test values were averaged for analysis in this paper. The summarized results are shown in Table 2.

Table 2.

Summary table of variable angle shear test results of limestone under thermal shock.

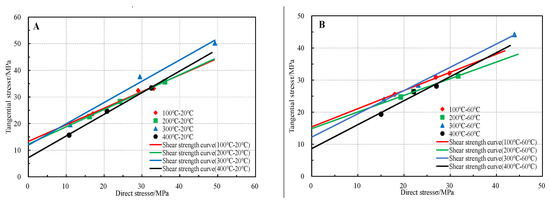

From Table 2, it can be seen that the characteristics of shear strength curves of limestone after thermal shock at different temperature working conditions are similar, so a set of typical curves were plotted for analysis. As shown in Figure 11A, the shear strength curve of limestone specimens after thermal shock in water of a given temperature increases in inclination and decreases in intercept with the increase in heating temperature, which shows a rotation in the σ-τ coordinate system in the counterclockwise direction. From Figure 11B, it can be seen that the shear strength curves of limestone specimens at the same temperature after thermal shock in water at different temperatures decrease in inclination and increase in intercept with the increase in cooling temperature, and rotate in the clockwise direction in the σ-τ coordinate system. The change characteristics are opposite to the shear strength curves at different heating temperatures. The shear strength curve obtained from the test can determine whether the limestone remains stable after thermal shock in a high temperature environment: if the stress value at the measured position in the rock lies in the region below the curve, the rock is stable; otherwise, the rock is destabilized. Therefore, the shear strength curve of rocks under thermal shock is important for the analysis of high temperature rock stability.

Figure 11.

Limestone shear strength curves for different heating temperatures (A) and different cooling temperatures (B) after thermal shock.

3.2.6. Cohesion and Internal Friction Angle

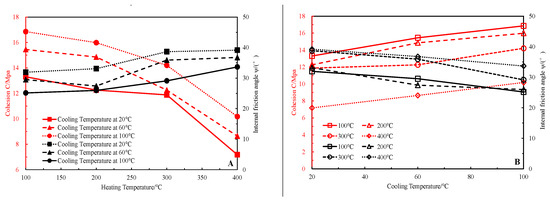

Cohesion and internal friction angle, as two important parameters of rocks, are not only indicators of shear strength of rocks, but also important parameters for engineering design. Figure 12 shows the results of cohesion and internal friction angle with temperature for the limestone specimens after thermal shock.

Figure 12.

Limestone shear parameters for different heating temperatures (A) and different cooling temperatures (B) after thermal shock.

After thermal shock of limestone specimens in water at the same temperature, the cohesion monotonically decreases and the angle of internal friction monotonically increases with the increase in heating temperature. In addition, the rate of change of cohesion with the heating temperature of limestone specimens was higher than the angle of internal friction. After thermal shock of limestone specimens of the same temperature in water at different temperatures, the cohesion monotonically increases and the internal friction angle monotonically decreases when the cooling temperature increases. The cohesion and internal friction angle show opposite trends. This is because the different thermal expansion coefficients after the limestone experiences thermal shock lead to irregular deformation between minerals, which enhances the mutual friction and mutual occlusion between rock particles, resulting in the increase in internal friction angle with the increase in heating temperature. In this process, the limestone continuously produces thermal shock rupture and the molecular force between mineral particles decreases, leading to a continuous decrease in cohesion with the increase in heating temperature. The results are similar to the experimental results made by Meng et al. [29], who studied the variation law of cohesion and internal friction angle of limestone after high temperature from 20 °C to 800 °C, which also provided ideas for the subsequent research content of this paper. The shear parameters should be studied and discussed in a broader temperature range.

All of the above data indicate that thermal shock has a significant effect on the shear parameters of limestone, and that the combined effect of heating and cooling temperatures produces deterioration in the shear properties of limestone.

4. Discussion

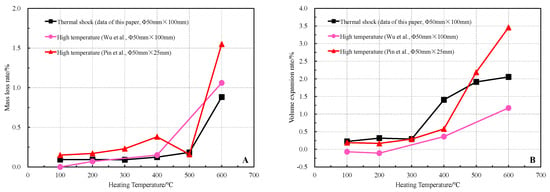

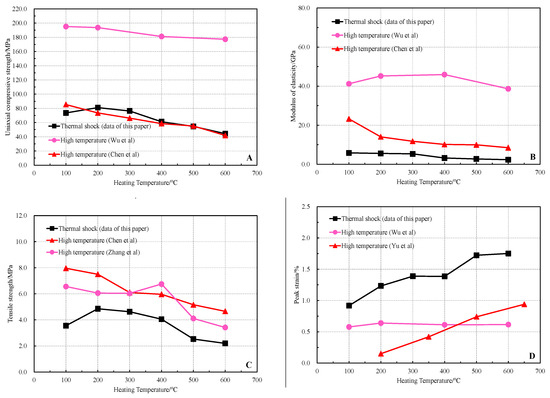

The physical and mechanical properties of brittle materials such as rocks, ceramics, and glass change under the effect of temperature. H. Tian et al. [30] concluded that the heating temperature, heating rate, holding time, and cooling rate affect the mechanical properties of the rock. Chen et al. [11] reported that the history of temperature action also affects the mechanical properties of rock samples and the reliability of the test. Based on the above points, this section will compare the experimental results of physical and mechanical parameters of limestone obtained by different scholars [10,11,18,31,32] after different heat treatment methods (the thermal shock data in Figure 11 and Figure 13 are selected from the experimental results of limestone cooling in water at 20 °C in this paper). The heat treatment methods used by other authors all utilized a muffle furnace to completely heat the specimens and then slowly cool them to room temperature. The heat treatment method in this paper is thermal shock. Several of the limestones compared are of different origins, but have roughly the same mineral content and average density. One of the limestone specimens used by Wu [10] et al. had a higher quartz content (95%) than several others. It is further shown that different heat treatment methods have different effects on the mechanical properties of limestone.

Figure 13.

Results of the evolution of mass loss rate (A) and volume expansion rate (B) of limestone under different heat treatments (the black part is the data obtained after cooling the high temperature limestone in water at 20 °C) [10,18].

Three sets of test results with different heat treatment methods were selected for analysis. The characteristics of the variation of limestone mass loss rate and volume expansion rate with heating temperature (100 °C to 600 °C) were compared. As shown in Figure 13, the mass loss rate and volume expansion rate of limestone show an overall increasing trend with the increase in heating temperature regardless of the heat treatment method. Compared with the results after high temperature, the limestone after thermal shock has a smaller mass loss rate and a larger volume expansion rate. Density is the ratio of mass to volume. The above comparison results show that limestone at the same heating temperature has a lower bulk density after thermal shock than after high temperature. The authors believe that due to the fact that thermal stress generated by the thermal shock is greater than the high temperature, the limestone undergoes thermal rupture to generate a large number of voids, resulting in a significant decrease in density. Under thermal shock, limestone generates a large number of voids at the microscopic level. As the degree of thermal shock action intensifies, microscopic cracks accumulate and eventually lead to macroscopic damage. This is the root cause of the deterioration of the mechanical properties of limestone.

The results of the variation of mechanical parameters of limestone with heating temperature (100 °C~600 °C) under different heat treatment conditions are plotted in Figure 14. The uniaxial compressive strength, modulus of elasticity, and tensile strength of limestone decrease and the peak strain increases with the increase in heating temperature in both heat treatments [10,11,31,32].

Figure 14.

Results of the evolution of mechanical parameters of limestone under different heat treatments.The uniaxial compressive strength (A), modulus of elasticity (B), tensile strength (C) and the peak strain (D) (the black part is the data obtained after cooling the high temperature limestone in water at 20 °C) [10,11,31,32].

From Figure 14, it can be seen that the uniaxial compressive strength of limestone after thermal shock is significantly lower in the present study than that of limestone after high temperature treatment alone (Wu et al. [10]), but it is similar to the test results obtained by Chen et al. [11]. Comparing the data in this paper with those obtained by Chen et al. [11]. it was found that the uniaxial compressive strength of limestone after thermal shock at 20 °C decreased by 36.66 MPa (σcmin = 28 MPa, σcmax = 49.4 MPa, σ = 9.2) in the range of 200 °C to 600 °C, while the uniaxial compressive strength of limestone after heating alone (Chen et al. [11]) decreased by 31.62 MPa. This indicates that the decay rate of compressive strength of limestone after thermal shock is faster.

The elastic modulus of limestone after thermal shock is smaller than that after high temperature. In addition, the values of elastic modulus obtained by Wu et al. are larger than the data obtained from the other two tests. This is because the mineral content of the constituent limestone has a greater effect on the elastic modulus; the higher the calcite content, the higher the strength of the limestone. The mineral contents of limestone used in the three groups of tests conducted for comparison were different; the calcite content of Jiaozuo limestone used by Wu et al. was 95%, and the calcite content of Osaka limestone used by Chen et al. and Huizhou limestone used in this paper were both 92%, so the elastic modulus value of Jiaozuo limestone after high temperature was the largest.

In the range of heating temperature, the tensile strength of limestone after thermal shock is less overall than that of limestone after high temperature, and only 0.45–0.8 times of the tensile strength of limestone after high temperature. In addition, the peak strains of limestone increases with the increase in heating temperature in both heat treatments, and the peak strains of limestone after thermal shock (0.92~1.75%) are significantly larger than those after high temperature (0.58~0.64%; 0.15~0.94%). This indicates that thermal shock increases the deformability of limestone and more actively promotes the transformation of limestone from brittle to ductile characteristics.

The above graphical data show that thermal shock induces a higher level of limestone deterioration than high temperature thermal treatment alone. The authors’ view is that the heat exchange with the environment is more efficient during thermal shock of limestone cooled by water and the temperature gradient within the rock is greater than that of a single high-temperature action. The higher thermal shock stress can rupture the rock more easily and lead to the degradation of mechanical properties. In addition, rocks are non-homogeneous, the mineral fraction and content of similar rocks, primary and secondary void density, distribution patterns, and rock scales also affect the physical and mechanical properties under temperature action. The above factors will be studied in the future.

5. Conclusions

Research has shown that thermal shock reduces the physical and mechanical properties of rocks and can even lead to rock fracture, and this finding has been applied to engineering construction. However, previous studies on thermal shock on rocks have usually only been conducted in a qualitative manner. The study conducted an experimental study on the physical and mechanical properties of limestone after thermal shock from 100 °C to 600 °C, and the following conclusions were obtained.

(1) After thermal shock, the apparent color, mass, and volume of limestone changed and were mainly affected by the peak heating temperature. The apparent color of the specimen gradually changed from off-white to white with the increase in heating temperature. The mass of the specimen decreased with the increase in heating temperature, with a maximum decrease of 1.39%, and 500 °C was the sudden change temperature of mass loss. The volume of the specimen nonlinearly increased with the increase in heating temperature, and the maximum increase was 2.79%.

(2) Thermal shock has a significant effect on the mechanical properties of limestone, and the peak temperature of heating in combination with abrupt cooling act together to deteriorate the mechanical properties of limestone. Thermal shock has a significant effect on the mechanical properties of limestone, and the heating and cooling temperatures work together to deteriorate the mechanical properties of limestone. As the heating temperature increased (cooling temperature decreased), the uniaxial compressive strength, elastic modulus, tensile strength, and cohesion of limestone decreased by 39.5%, 59.5%, 42.9%, and 43.2% (19.3%, 22.9%, 7.6% and 22.5%), respectively. Peak strain and angle of internal friction increased by 74.2% and 27%, respectively. The ductility characteristics of limestone were enhanced.

(3) The mechanical parameters of limestone after thermal shock had a good exponential function correlation with the heating temperature. The empirical equations of uniaxial compressive strength, elastic modulus, and tensile strength of limestone at different cooling temperatures versus heating temperature were obtained by fitting the experimental results.

(4) The differences in physical and mechanical properties of limestone after thermal shock and high temperature were compared and analyzed. It was found that the thermal shock in the course of quenching the heated specimens had a stronger deterioration effect on the physical and mechanical properties of limestone than the heating itself.

The above conclusions reveal the macro-mechanical properties of limestone under the action of thermal shock. The effect of thermal shock on the physical and mechanical properties of limestone was quantitatively characterized. The complex combined effect of heating and cooling temperatures is proposed on the basis of previous studies of the effect of single factors (high or low temperature) on rock properties. This enriches the theory of high-temperature rock mechanics and provides technical support for the drilling and wellbore stability assessment of geothermal development in limestone reservoirs. Next, we will study the fine-scale fracture characteristics of rocks under thermal shock using a variety of non-destructive testing and visualization techniques. We will also combine them with the evolution of macroscopic mechanical parameters of rocks to study the interrelationship between them and further reveal the mechanism of rock rupture by thermal impact.

Author Contributions

Y.D. performed the experimental work and wrote the manuscript. B.X. developed the idea of the research, supervised the research, and revised the manuscript. S.H. assisted with the experimental work and revised the manuscript. L.C. supervised the research and revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was sponsored by the General Pro-gram of National Natural Science Foundation of China (Grant no. 51874207).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hu, X.D.; Song, X.Z.; Li, G.S.; Shen, Z.H.; Lyu, Z.H.; Shi, Y.; Zheng, R. An analytical model to evaluate the heating conditions for drilling in hard rock using an innovative hydrothermal spallation method. Appl. Therm. Eng. 2018, 142, 709–716. [Google Scholar] [CrossRef]

- Sun, T.; Ma, Z. Microwave heating and fracturing of granite: Insights from infrared thermal imaging. J. Therm. Stress. 2022, 45, 762–771. [Google Scholar] [CrossRef]

- Cong, Y.Z.; Zhai, C.; Yu, X.; Xu, J.Z.; Sun, Y.; Tang, W.; Zheng, Y.F.; Wu, J.G. Study on typical temperature effect mechanism of multi-component coal during low-temperature thermal expansion. Case Stud. Therm. Eng. 2023, 143, 102744. [Google Scholar] [CrossRef]

- Tang, S.B.; Zhang, H.; Tang, C.A.; Liu, H.Y. Numerical model for the cracking behavior of heterogeneous brittle solids subjected to thermal shock. Int. J. Solids Struct. 2016, 80, 520–531. [Google Scholar] [CrossRef]

- Foraboschi, P. Analytical modeling to predict thermal shock failure and maximum temperature gradients of a glass panel. Mater. Des. 2017, 134, 301–319. [Google Scholar] [CrossRef]

- Wang, Q.S.; Chen, H.D.; Wang, Y.; Sun, J.H. Thermal shock effect on the glass thermal stress response and crack propagation. Procedie Eng. 2013, 62, 717–724. [Google Scholar] [CrossRef]

- Ge, S.K.; Wu, C.L.; He, C.L.; Wang, Y.H.; Chen, D.L.; Shi, B.B. Thermal damage of high-temperature sandstone subjected to cooling shock and its effect on capturing acoustic emission signals during fracture. Eng. Fail. Anal. 2023, 145, 107003. [Google Scholar] [CrossRef]

- Takarli, M.; Prince, W.; Siddique, R. Damage in granite under heating / cooling cycles and water freeze—Thaw condition. Int. J. Rock Mech. Min. Sci. 2008, 45, 1164–1175. [Google Scholar] [CrossRef]

- Wang, F.; Konietzky, H. Thermo-Mechanical Properties of Granite at Elevated Temperatures and Numerical simulation of thermal cracking. Rock Mech. Rock Eng. 2019, 52, 3737–3755. [Google Scholar] [CrossRef]

- Wu, G.; Teng, N.G.; Wang, Y. Research on physical and mechanical properties of limestone after high temperature. Chin. J. Geotech. Eng. 2011, 33, 259–264. [Google Scholar]

- Chen, Y.L.; Zhang, Y. Experimental study on physical and mechanical properties of limestone heat-treated at different temperatures. Chin. J. Rock Mech. Eng. 2017, 36, 3732–3739. [Google Scholar]

- Weng, L.; Wu, Z.; Liu, Q. Influence of heating/cooling cycles on the micro/ macrocracking characteristics of Rucheng granite under unconfined compression. Bull. Eng. Geol. Env. 2020, 79, 1289–1309. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Feng, Z.J.; Zhao, Y.; Wan, Z.J. Experimental investigation on thermal cracking, permeability under HTHP and application for geothermal mining of HDR. Energy 2017, 132, 305–314. [Google Scholar] [CrossRef]

- Feng, Z.J.; Zhao, Y.S.; Zhang, Y.; Wan, Z.J. Real-time permeability evolution of thermally cracked granite at triaxial stresses. Appl. Therm. Eng. 2018, 133, 194–200. [Google Scholar] [CrossRef]

- Gautam, P.K.; Verma, A.K.; Jha, M.K.; Sharma, P.; Singh, T.N. Effect of high temperature on physical and mechanical properties of granite. J. Appl. Geophys. 2018, 159, 460–474. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Shao, S.; Chen, B.K.; Lashin, A.; Al Arifi, n.; Rathnaweera, T.D. Mechanical behaviour of Australian Strathbogie granite under in-situ stress and temperature conditions: An application to geothermal energy extraction. Geothermics 2017, 65, 44–59. [Google Scholar] [CrossRef]

- Xi, B.P.; Wu, Y.C.; Wang, S.; Xiong, G.M.; Zhao, Y.S. Experimental study on high temperature thermal damage mechanical properties of granite in Gonghe Basin, Qinghai. Chin. J. Rock Mech. Eng. 2020, 39, 69–83. [Google Scholar]

- Ping, Q.; Su, H.P.; Ma, D.D.; Zhang, H.; Zhang, C.L. Experimental study on physical and dynamic properties of limestone under different high temperature effects. Chin. J. Rock Soil Mech. 2021, 42, 932–942+953. [Google Scholar]

- Zhao, Y.Y.; Wei, K.; Zhou, J.Q.; Li, X.; Chen, Y.F. Laboratory study and micromechanical analysis of mechanical behaviors of three thermally damaged rocks. Chin. J. Rock Mech. Eng. 2017, 36, 142–151. [Google Scholar]

- Shao, S.S.; Wasantha, P.L.P.; Ranjith, P.G.; Chen, B.K. Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int. J. Rock Mech. Min. Sci. 2014, 70, 381–387. [Google Scholar] [CrossRef]

- Wang, F.; Konietzky, H.; Frühwirt, T.; Li, Y.W.; Dai, Y.J. Impact of cooling on fracturing process of granite after high-speed heating. Int. J. Rock Mech. Min. Sci. 2020, 125, 104155. [Google Scholar] [CrossRef]

- Xi, B.P.; Wu, Y.C.; Zhao, Y.S. Experimental study on the correlation between macroscopic mechanical parameters and thermal shock velocity of granite under thermal shock. J. Rock Mech. Eng. 2019, 38, 2194–2207. [Google Scholar]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K.; Abdulagatov, I.M. Temperature-dependent mechanical behavior of Australian Strathbogie granite with different cooling treatments. Eng. Geol. 2017, 229, 31–44. [Google Scholar] [CrossRef]

- Isaka, B.L.A.; Gamage, R.P.; Rathnaweera, T.D.; Perera, M.S.A.; Chandrasekharam, D.; Kumari, W.G.P. An Influence of Thermally-Induced Micro-Cracking under Cooling Treatments: Mechanical Characteristics of Australian Granite. Energies 2018, 11, 1338. [Google Scholar] [CrossRef]

- Srinivasan, V.; Hasainar, H.; Singh, T.N. Singh. Experimental study on failure and fracturing attributes of granite after thermal treatments with different cooling conditions. Eng. Geol. 2022, 310, 106867. [Google Scholar] [CrossRef]

- Brotóns, V.; Tomás, R.; Ivorra, S.A.J.C.; Alarcón, J.C. Temperature influence on the physical and mechanical properties of a porous rock: San Julian’s calcarenite. Eng. Geol. 2013, 167, 117–127. [Google Scholar] [CrossRef]

- Rathnaweera, T.D.; Ranjith, P.G.; Gu, X.; Perera, M.S.A.; Kumari, W.G.P.; Wanniarachchi, W.A.M.; Haque, A.; Li, J.C. Experimental investigation of thermomechanical behaviour of clay-rich sandstone at extreme temperatures followed by cooling treatments. Int. J. Rock Mech. Min. Sci. 2018, 107, 208–223. [Google Scholar] [CrossRef]

- Wang, X. Formation Conditions and Hydro-Geochemical Characteristics of Geothermal Water Systems in Typical Deep and Large Fault Zones along the Coast of Guangdong. Ph.D. Thesis, China University of Geosciences, Beijing, China, 2018. [Google Scholar]

- Meng, Q.B.; Qian, W.; Liu, J.F.; Zhang, M.W.; Lu, M.M.; Wu, Y. Analysis of triaxial compression deformation and strength characteristics of limestone after high temperature. Arab. J. Geosci. 2020, 13, 153. [Google Scholar] [CrossRef]

- Tian, H.; Kempka, T.; Yu, S.; Ziegler, M. Mechanical properties of sandstones exposed to high temperature. Rock Mech. Rock Eng. 2016, 49, 321–327. [Google Scholar] [CrossRef]

- Yu, X.J.; Li, X.Z.; Wu, Y.; Liu, M.Z.; Deng, L.C. Experimental study on changes of physical and mechanical properties of limestone after high temperature. Chin. J. People’s Yangtze River 2020, 51, 196–202. [Google Scholar]

- Zhang, W.Q. Research on the Microscopic Mechanism and Macroscopic Physical and Mechanical Properties Evolution Characteristics of Thermal Damage of Rock. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2017. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).