Prevent Workers from Injuries in the Brewing Company via Using Digital Human Modelling Technology

Abstract

1. Introduction

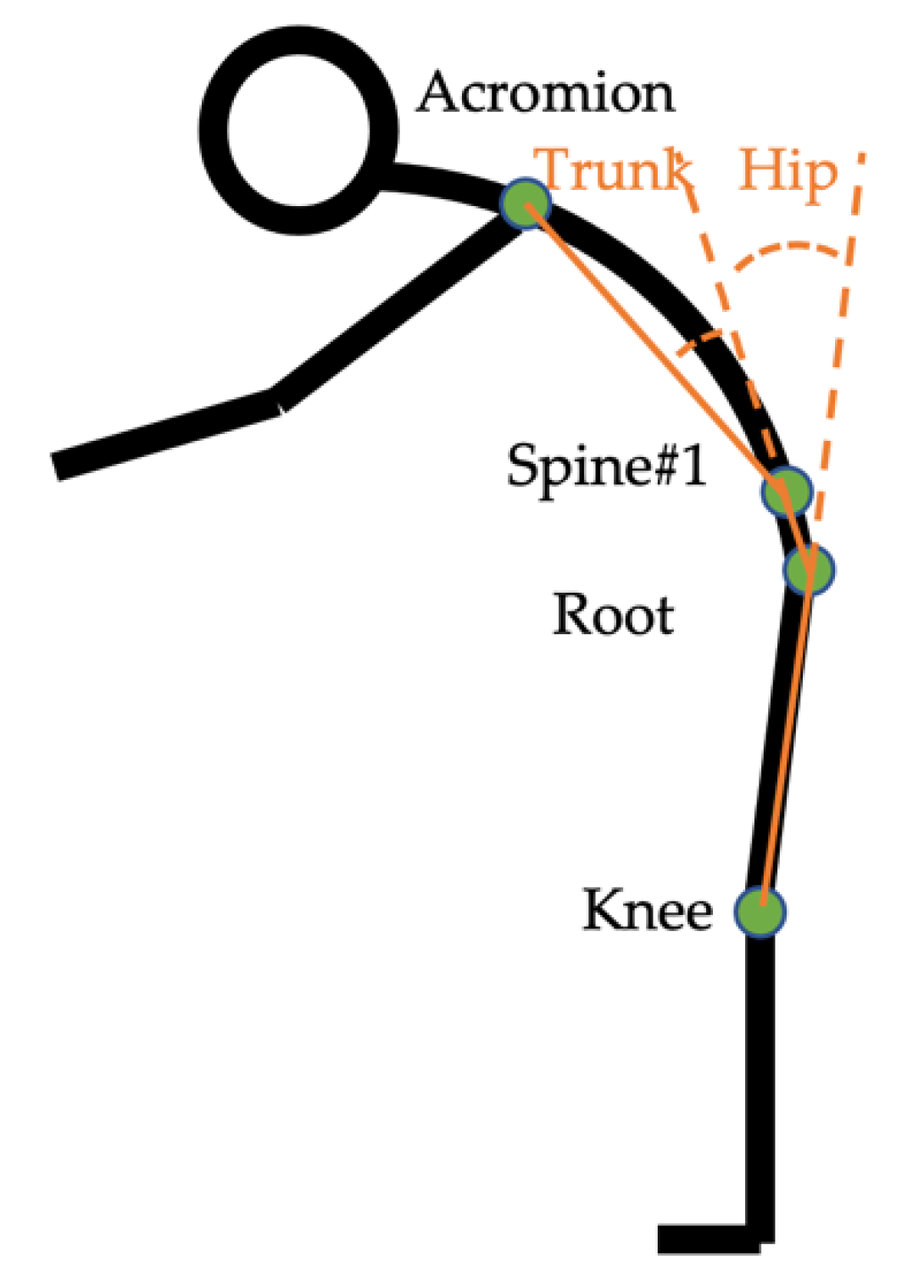

2. Methods

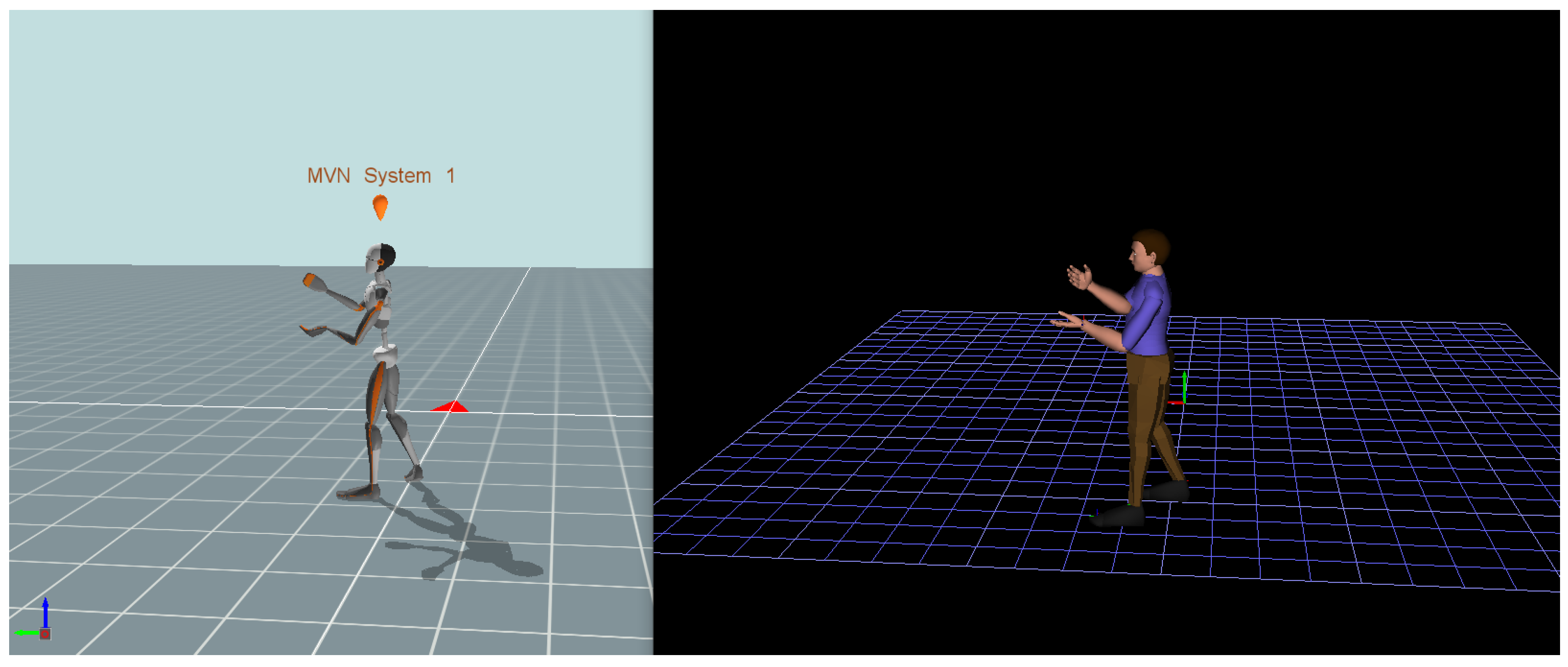

2.1. System Setup

2.2. Task Performance and the Specific Poses in Each of the Tasks

2.3. Data Analysis

3. Results

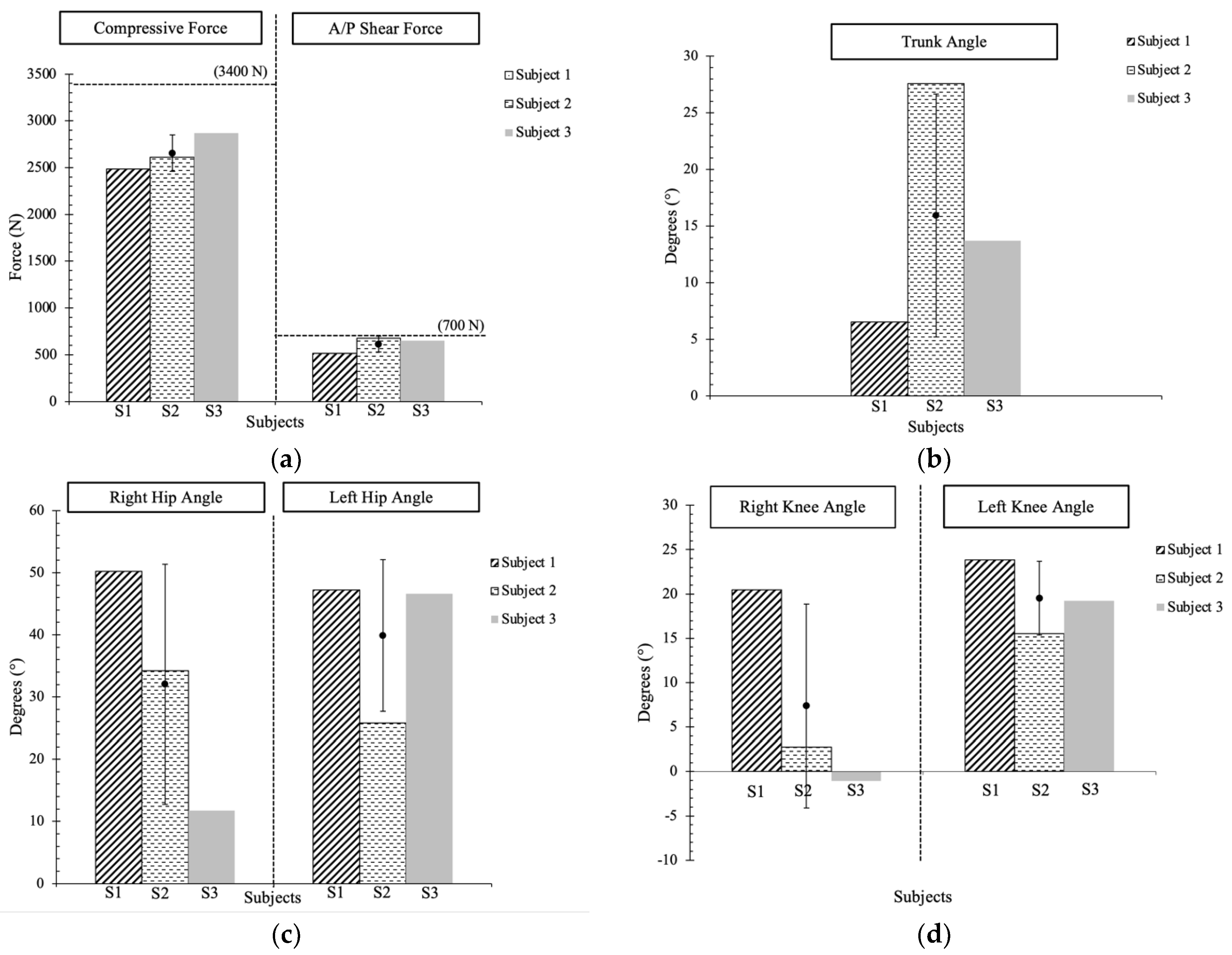

3.1. Pose#1 in Task#1

- Trunk: range from 6.5° to 27.6° (15.9 ± 10.7°) in Figure 5b;

- Right hip: range from 11.7° to 50.2° (32.1 ± 19.3°) in Figure 5c;

- Left hip: range from 25.8° to 47.2° (39.9 ± 12.2°) in Figure 5c;

- Right knee: range from −1.1° to 20.4° (7.4 ± 11.5°) in Figure 5d;

- Left knee: range from 15.5° to 23.8° (19.5 ± 4.2°) in Figure 5d.

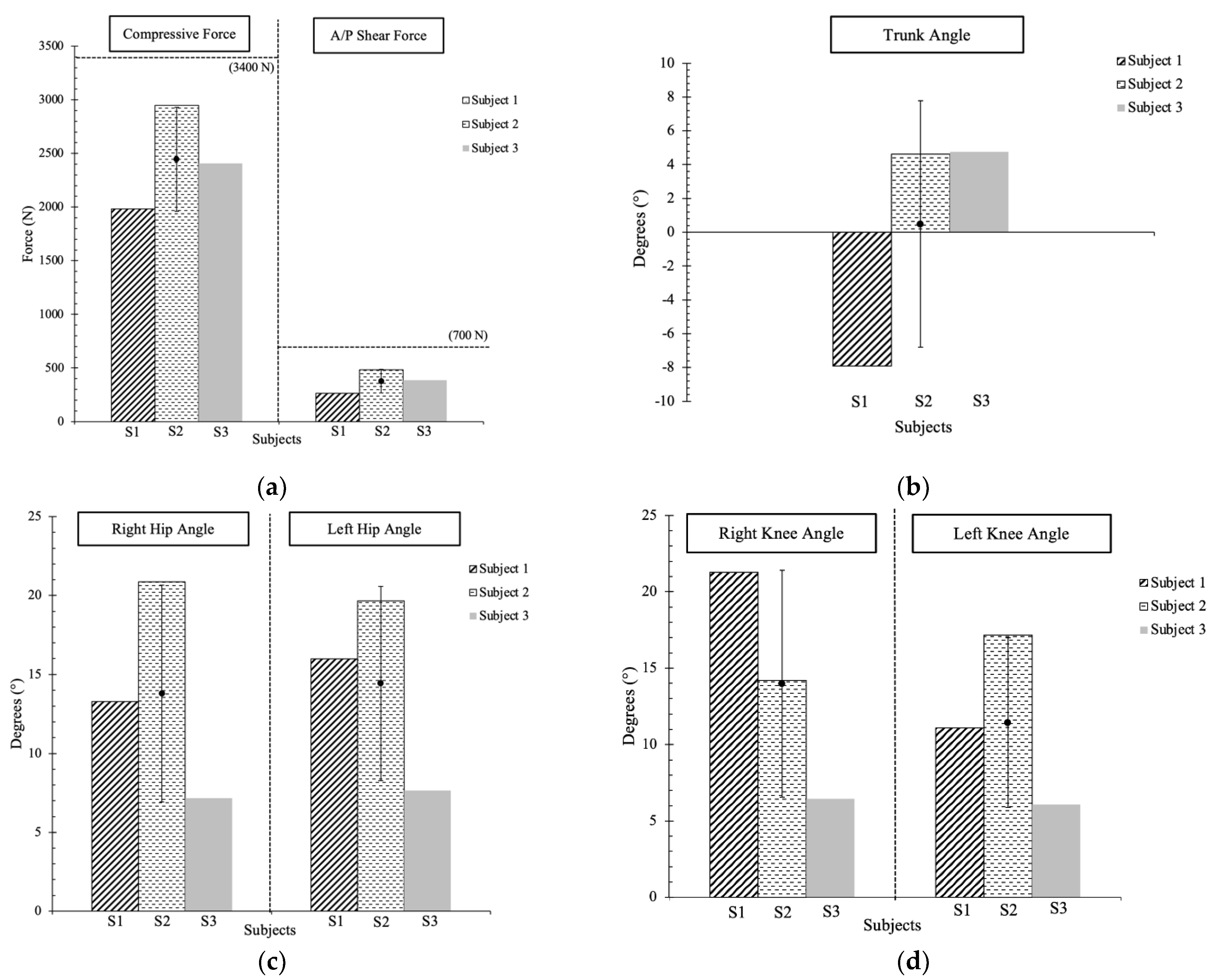

3.2. Pose#2 in Task#1

- Trunk: range from −7.9° to 4.8° (0.5 ± 7.3°) in Figure 6b;

- Right hip: range from 7.2° to 20.9° (13.8 ± 6.9°) in Figure 6c;

- Left hip: range from 7.7° to 19.7° (14.4 ± 6.2°) in Figure 6c;

- Right knee: range from 6.5° to 21.3° (14.0 ± 7.4°) in Figure 6d;

- Left knee: range from 6.1° to 17.2° (11.4 ± 5.5°) in Figure 6d.

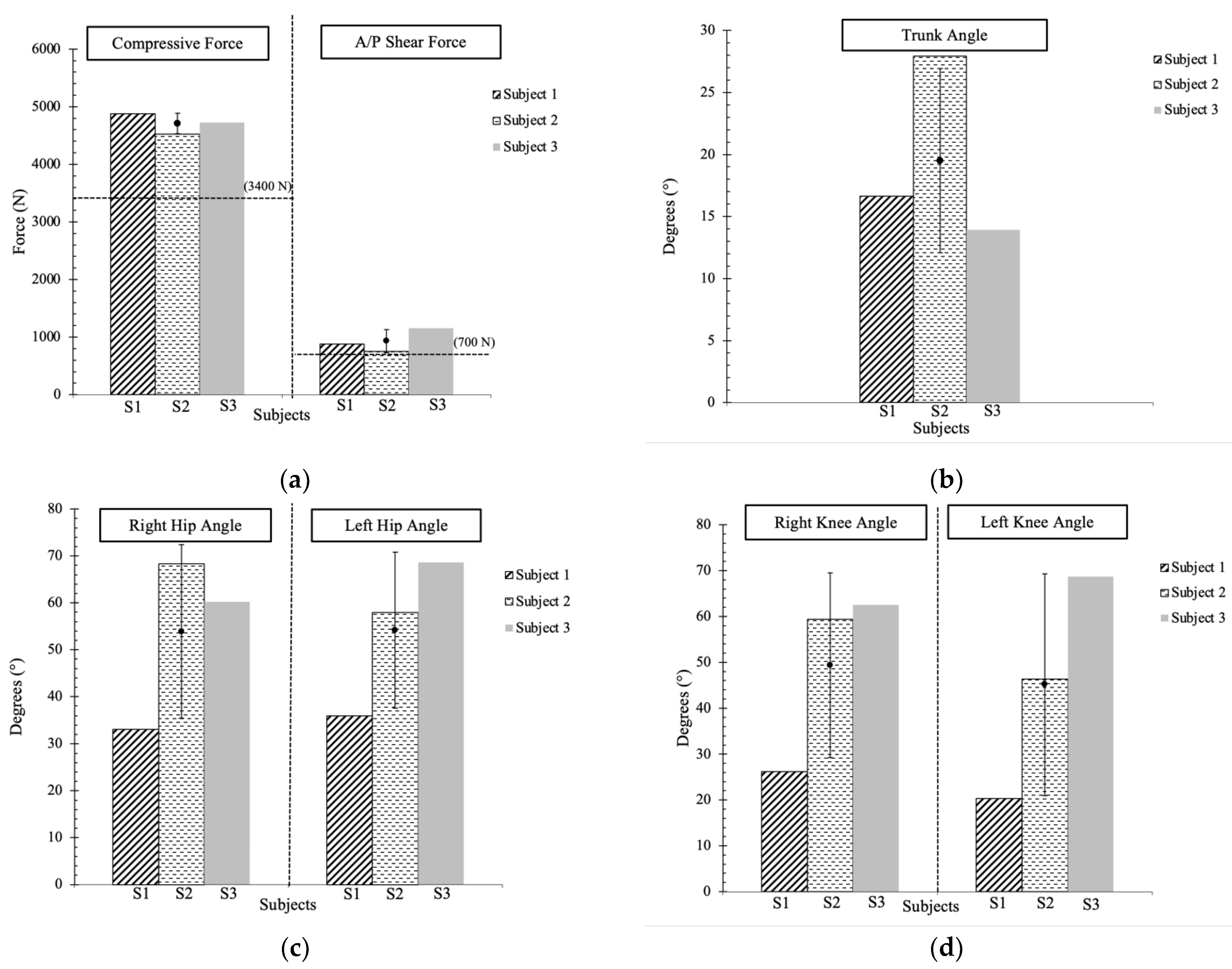

3.3. Pose#1 in Task#2

- Trunk: range from 13.9° to 27.9° (19.5 ± 7.4°) in Figure 7b;

- Right hip: range from 33.1° to 68.4° (53.9 ± 18.5°) in Figure 7c;

- Left hip: range from 36.0° to 68.6° (54.2 ± 16.7°) in Figure 7c;

- Right knee: range from 26.2° to 62.6° (49.4 ± 20.2°) in Figure 7d;

- Left knee: range from 20.4° to 68.7° (45.2 ± 24.2°) in Figure 7d.

3.4. Pose#2 in Task#2

- Trunk: range from 1.0° to 9.0° (3.9 ± 4.4°) in Figure 8b;

- Right hip: range from 8.2° to 32.7° (18.0 ± 12.9°) in Figure 8c;

- Left hip: range from 13.5° to 28.8° (19.8 ± 8.0°) in Figure 8c;

- Right knee: range from 15.4° to 31.6° (25.0 ± 8.5°) in Figure 8d;

- Left knee: range from 17.3° to 34.9° (28.0 ± 9.4°) in Figure 8d.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Statistics, B.O.L. The Economics Daily: Back Injuries Prominent in Work-Related Musculoskeletal Disorder Cases in 2016. U.S. Department of Labor. Available online: https://www.bls.gov/opub/ted/2018/back-injuries-prominent-in-work-related-musculoskeletal-disorder-cases-in-2016.htm (accessed on 8 October 2022).

- Post, J.L. Five Workplace Safety Tips on Tap: How Craft Breweries Can Keep Workers Injury-Free. Craft Brewing Business. Retrieved September 6, 2022. Available online: https://www.craftbrewingbusiness.com/featured/five-workplace-safety-tips-on-tap-how-craft-breweries-can-keep-workers-injury-free/ (accessed on 26 September 2022).

- B.A. Pennsylvania’s Craft Beer Sales & Production Statistics, 2021. Available online: https://www.brewersassociation.org/statistics-and-data/state-craft-beer-stats/?state=PA (accessed on 22 January 2023).

- Association, B. State Craft Beer Sales & Production Statistics. Available online: https://www.brewersassociation.org/statistics/by-state/ (accessed on 15 September 2022).

- Lavery, N. Occupational Health and Breweries: A Collaborative Approach. Master Brew. Assoc. Am. 2021, 58, 34–36. [Google Scholar]

- Brents, C.; Rosecrance, J. Work-Related injuries among craft brewery workers in Colorado, 2015–2018. In Proceedings of the Human Factors Society Conference, Seattle, WA, USA, 28 October–1 November 2019; p. 129. [Google Scholar]

- Xsens. Measuring Low Back Biomechanics during Beer Keg Handling. Available online: https://www.xsens.com/cases/measuring-low-back-biomechanics-beer-keg-handling (accessed on 8 October 2022).

- De Beer, A.; Cordier, W. Spinal revival: The management of lower back pain. S. Afr. Gen. Pract. 2022, 3, 19–21. [Google Scholar] [CrossRef]

- Finnie, S. Brewers Association. The Ergonomics of Brewing: Avoiding Injury and Staying the Course in the Brewery. Available online: https://www.brewersassociation.org/seminars/the-ergonomics-of-brewing-avoiding-injury-and-staying-the-course-in-the-brewery/ (accessed on 15 September 2022).

- Finnie, S.; Lavery, N. Brewers Association. Brewery Ergonomics: How to Stay Safe and Healthy in Your Brewery. Available online: https://www.brewersassociation.org/seminars/brewery-ergonomics-how-to-stay-safe-and-healthy-in-your-brewery/ (accessed on 23 January 2023).

- Embry, E.; Stinchfield, M. Brewers Association. Praise and Paradox: What We Learned from the Brewers Association Safety and Injury Survey. Available online: https://www.brewersassociation.org/seminars/praise-and-paradox-what-we-learned-from-the-brewers-association-safety-and-injury-survey/ (accessed on 15 September 2022).

- Hussain, M.M.; Qutubuddin, S.; Kumar, K.P.R.; Reddy, C.K. Digital human modeling in ergonomic risk assessment of working postures using RULA. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019; pp. 5–7. [Google Scholar]

- Cao, W. Ergonomic Assessment of Sonography Workplace and Posture Parameters Using Digital Human Modeling; State University of New York at Binghamton: Binghamton, NY, USA, 2011. [Google Scholar]

- Maurya, C.M.; Karmakar, S.; Das, A.K. Digital human modeling (DHM) for improving work environment for specially-abled and elderly. SN Appl. Sci. 2019, 1, 1–9. [Google Scholar] [CrossRef]

- Siemens. Human Factor and Ergonomics. Available online: https://www.plm.automation.siemens.com/global/en/products/manufacturing-planning/human-factors-ergonomics.html (accessed on 2 February 2023).

- Santoshuman. Products for Human-Centric Design. Available online: https://www.santoshumaninc.com/products/ (accessed on 2 February 2023).

- DASSAULT Systems. DELMIA Products. Available online: https://www.3ds.com/products-services/delmia/ (accessed on 2 February 2023).

- Sammie. The SAMMIE DHM SYSTEM. Available online: https://www.lboro.ac.uk/microsites/lds/sammie/dhm.html (accessed on 2 February 2023).

- AnyBody. AnyBody Technology. Available online: https://www.anybodytech.com (accessed on 21 February 2023).

- OpenSim. Simbios. Available online: https://opensim.stanford.edu (accessed on 21 February 2023).

- Estrada, J.E.; Vea, L.A. Modelling and Simulation of Spine in Sitting Posture in a Computer-Related Workplace. IJCSMC 2018, 7, 121–135. [Google Scholar]

- Iriondo Pascual, A.; Högberg, D.; Syberfeldt, A.; Brolin, E.; Perez Luque, E.; Hanson, L.; Lämkull, D. Multi-objective optimization of ergonomics and productivity by using an optimization framework. In Proceedings of the Congress of the International Ergonomics Association, online, 13–18 June 2021; pp. 374–378. [Google Scholar]

- Fletcher, S.R.; Johnson, T.L.; Thrower, J. A study to trial the use of inertial non-optical motion capture for ergonomic analysis of manufacturing work. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 90–98. [Google Scholar] [CrossRef]

- Ji, X.; Piovesan, D.; Conley, K. The Effect of Pulling Effort on Lumbar Spine via Applying Digital Human Modeling Technology. In Proceedings of the Institute of Industrial and Systems Engineers (IISE) Annual Conference, Seattle, WA, USA, 21–24 May 2022; pp. 21–24. [Google Scholar]

- Ji, X.; Piovesan, D.; Arenas, M.; Liu, H. Analysis of Healthcare Push and Pull Task via JACK: Predicted Joint Accuracy during Full-Body Simulation. Appl. Sci. 2022, 12, 6450. [Google Scholar] [CrossRef]

- Quintero-Duran, M.; Paul, G. Ergonomic assessment of a physical task using two different digital human modelling systems: A case study. Int. J. Hum. Factors Model. Simul. 2018, 6, 298–313. [Google Scholar] [CrossRef]

- Paul, G.; Quintero-Duran, M. Ergonomic Assessment of Hospital Bed Moving Using DHM Siemens JACK. In Proceedings of the 19th Triennial Congress of the International Ergonomics Association, Melbourne, VIC, Australia, 9–14 August 2015. [Google Scholar]

- Cao, W.; Jiang, M.; Han, Y.; Khasawneh, M.T. Ergonomic assessment of patient barrow lifting technique using digital human modeling. In Proceedings of the Digital Human Modeling and Applications in Health, Safety, Ergonomics, and Risk Management. Human Body Modeling and Ergonomics: 4th International Conference, DHM 2013, Held as Part of HCI International 2013, Las Vegas, NV, USA, 21–26 July 2013; Proceedings, Part II 4, 2013. pp. 20–29. [Google Scholar]

- Wagner, D.W.; Reed, M.P.; Rasmussen, J. Assessing the importance of motion dynamics for ergonomic analysis of manual materials handling tasks using the AnyBody Modeling System. SAE Trans. 2007, 116, 2092–2101. [Google Scholar]

- Fritzsche, L.; Galibarov, P.E.; Gärtner, C.; Bornmann, J.; Damsgaard, M.; Wall, R.; Schirrmeister, B.; Gonzalez-Vargas, J.; Pucci, D.; Maurice, P. Assessing the efficiency of exoskeletons in physical strain reduction by biomechanical simulation with AnyBody Modeling System. Wearable Technol. 2021, 2, e6. [Google Scholar] [CrossRef]

- Alexander, N.; Schwameder, H.; Baker, R.; Trinler, U. Effect of different walking speeds on joint and muscle force estimation using AnyBody and OpenSim. Gait Posture 2021, 90, 197–203. [Google Scholar] [CrossRef] [PubMed]

- Chaffin, D.B. Improving digital human modelling for proactive ergonomics in design. Ergonomics 2005, 48, 478–491. [Google Scholar] [CrossRef]

- Ji, X.; Littman, A.; Hettiarachchige, R.O.; Piovesan, D. The Effect of Key Anthropometric and Biomechanics Variables Affecting the Lower Back Forces of Healthcare Workers. Sensors 2023, 23, 658. [Google Scholar] [CrossRef]

- Cutler, B.; Merritt, T.; Eger, T.; Godwin, A. Using Peak Vicon data to drive Classic JACK animation for the comparison of low back loads experienced during para-rowing. Int. J. Hum. Factors Model. Simul. 2015, 5, 99–112. [Google Scholar] [CrossRef]

- Qi, Z.; Chen, Y. Investigation of Ergonomics in Photocuring 3D Printing Post-Processing Using Jack. In Proceedings of the 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA), Bangkok, Thailand, 16–21 April 2020; pp. 326–329. [Google Scholar]

- Lad, U. Comparing the Kinematic and Kinetic Outputs from Digital Human Modeling Tools to a Lab-Based Rigid-Link Model for the Investigation of Musculoskeletal Disorder Hazards During Patient Handling; University of Waterloo: Waterloo, ON, Canada, 2018. [Google Scholar]

- Ji, X.; Tiari, S. Posture evaluation for the full-body dynamic simulation in JACK Siemens PLM. Int. J. Hum. Factors Ergon. 2022, 9, 261–281. [Google Scholar] [CrossRef]

- Rhén, I.-M.; Forsman, M.; Örtengren, R.; Högberg, D.; Keyvani, A.; Lämkull, D.; Hanson, L. Ergonomic risk assessment in DHM tools employing motion data-exposure calculation and comparison to epidemiological reference data. Int. J. Hum. Factors Model. Simul. 2018, 6, 31–64. [Google Scholar] [CrossRef]

- Wegner, D.; Chiang, J.; Kemmer, B.; Lämkull, D.; Roll, R. Digital Human Modeling Requirements and Standardization; SAE Technical Paper 0148-7191; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Haggag, H.; Hossny, M.; Nahavandi, S.; Creighton, D. Real time ergonomic assessment for assembly operations using kinect. In Proceedings of the 2013 UKSim 15th International Conference on Computer Modelling and Simulation, Cambridge, UK, 10–12 April 2013; pp. 495–500. [Google Scholar]

- Caputo, F.; Greco, A.; D ‘Amato, E.; Notaro, I.; Spada, S. Imu-based motion capture wearable system for ergonomic assessment in industrial environment. In Proceedings of the Advances in Human Factors in Wearable Technologies and Game Design: Proceedings of the AHFE 2018 International Conferences on Human Factors and Wearable Technologies, and Human Factors in Game Design and Virtual Environments, Orlando, FL, USA, 21–25 July 2018; pp. 215–225. [Google Scholar]

- Bortolini, M.; Faccio, M.; Gamberi, M.; Pilati, F. Motion Analysis System (MAS) for production and ergonomics assessment in the manufacturing processes. Comput. Ind. Eng. 2020, 139, 105485. [Google Scholar] [CrossRef]

- Constantinescu, C.; Todorovic, O.; Ippolito, D. Comprehensive modelling and simulation towards the identification of critical parameters for evaluation of exoskeleton-centred workplaces. Procedia CIRP 2019, 79, 176–179. [Google Scholar] [CrossRef]

- Movella. MVN Awinda. Available online: https://www.movella.com/products/motion-capture/xsens-mvn-awinda (accessed on 2 February 2023).

- Roetenberg, D.; Luinge, H.; Slycke, P. Xsens MVN: Full 6DOF human motion tracking using miniature inertial sensors. Xsens Motion Technol. BV Tech. Rep. 2009, 1, 1–7. [Google Scholar]

- Waters, T.R.; Putz-Anderson, V.; Garg, A.; Fine, L.J. Revised NIOSH equation for the design and evaluation of manual lifting tasks. Ergonomics 1993, 36, 749–776. [Google Scholar] [CrossRef]

- Gallagher, S.; Marras, W.S. Tolerance of the lumbar spine to shear: A review and recommended exposure limits. Clin. Biomech. 2012, 27, 973–978. [Google Scholar] [CrossRef]

- Cavaguchi, A.M.; Oliveira, M.R.; Macedo, C.G.; Souza, P.E.d.; Aguiar, A.F.; Dallaire, M.; Ngomo, S.; Silva, R.A.d. Impact of lifting of two types of barrels on postural control, trunk muscle recruitment, and kinematic measures in manual workers. Int. J. Environ. Res. Public Health 2019, 16, 2183. [Google Scholar] [CrossRef] [PubMed]

- Rohlmann, A.; Bauer, L.; Zander, T.; Bergmann, G.; Wilke, H.-J. Determination of trunk muscle forces for flexion and extension by using a validated finite element model of the lumbar spine and measured in vivo data. J. Biomech. 2006, 39, 981–989. [Google Scholar] [CrossRef] [PubMed]

- Schoenfeld, B.J. Squatting kinematics and kinetics and their application to exercise performance. J. Strength Cond. Res. 2010, 24, 3497–3506. [Google Scholar] [CrossRef] [PubMed]

- UNC. Environment, Health and Safety. Lifting and Material Handling. Available online: https://ehs.unc.edu/topics/ergonomics/lifting-and-material-handling/ (accessed on 3 November 2021).

| Subjects | Body Height (m) | Body Weight (kg) |

|---|---|---|

| S1 | 1.68 | 89.0 |

| S2 | 1.78 | 63.5 |

| S3 | 1.75 | 84.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Hettiarachchige, R.O.; Littman, A.L.E.; Lavery, N.L.; Piovesan, D. Prevent Workers from Injuries in the Brewing Company via Using Digital Human Modelling Technology. Appl. Sci. 2023, 13, 3593. https://doi.org/10.3390/app13063593

Ji X, Hettiarachchige RO, Littman ALE, Lavery NL, Piovesan D. Prevent Workers from Injuries in the Brewing Company via Using Digital Human Modelling Technology. Applied Sciences. 2023; 13(6):3593. https://doi.org/10.3390/app13063593

Chicago/Turabian StyleJi, Xiaoxu, Ranuki O. Hettiarachchige, Alexa L. E. Littman, Nicole L. Lavery, and Davide Piovesan. 2023. "Prevent Workers from Injuries in the Brewing Company via Using Digital Human Modelling Technology" Applied Sciences 13, no. 6: 3593. https://doi.org/10.3390/app13063593

APA StyleJi, X., Hettiarachchige, R. O., Littman, A. L. E., Lavery, N. L., & Piovesan, D. (2023). Prevent Workers from Injuries in the Brewing Company via Using Digital Human Modelling Technology. Applied Sciences, 13(6), 3593. https://doi.org/10.3390/app13063593