Abstract

Cement-based composites are generally non-conductors with high electrical resistivity, but they can be used as conductors by incorporating conductive materials. Recently, research has been actively conducted to develop high-conductive fiber-reinforced cement mortar (FRCM) due to increased interest in multifunctional cement mortar required by the market today. Thus, the present paper investigated the effect of the developed conductive FRCM containing carbon and steel fibers on the fresh and mechanical properties as well as electrical conductivity. The performance of conductivity FRCM was studied based on flow, unit weight, air content, three-point flexural, compression, and electrical resistance tests. In addition, their performance was also compared and reviewed with plain mortar (PM). Furthermore, the surface shape and element components of the developed conductive FRCM fracture surface were analyzed using a scanning electron microscopy (SEM) and an energy dispersive X-ray spectrometer (EDS). The results showed that the addition of steel fibers slightly decreased the relative flow value, whereas the incorporation of carbon fibers is very disadvantageous in terms of fluidity due to the fiber ball phenomenon. The unit weight of mixture containing carbon fibers was somewhat decreased, whereas the changes in the amount of air contents were relatively insignificant regardless of the fiber volume fractions. The flexural strength of conductive carbon fiber-reinforced cement mortar (CFRCM) and steel fiber-reinforced cement mortar (SFRCM) was significantly improved compared to that of PM. The compressive strength of CFRCM decreased significantly as the volume fraction of carbon fibers increased. Overall, even if the steel fibers were added up to 1.25%, the effect of improving the electrical conductivity of SFRCM was insignificant. In the case of the CFRCM used in this study, it was found that the percolation threshold existed between 0.3% and 0.4% fibers, and it was thus thought that the optimum dosage of carbon fiber should be secured by at least more than 0.4% in terms of electrical conductivity. Therefore, the most important factor for the electrical conductivity effect was found to be carbon fiber, whereas the effect of steel fiber was insignificant.

1. Introduction

Cement is a construction material mainly used in concrete structures due to its rich resources, good environmental adaptability, low cost and high compressive strength. Recently, many studies have been conducted on high-performance fiber-reinforced cement composites with high compressive strength, tensile strength, and deformability by using high-performance fibers or increasing the amount of fiber used. It is expected to be used for various purposes. In addition, studies on improving shear strength, increasing resistance to dynamic loads, and suppressing cracks are continuously increasing. In particular, fiber-reinforced cement composites produced with waste lathe scraps or steel fibers extracted from waste tires are highly utilized recycled fiber-reinforced cement composites to improve flexural performance [1,2]. Plenty of research has been conducted both domestically and internationally to evaluate the effect of other types of steel fibers on the performance of cement-based composites, and useful information is provided on the buckling performance evaluation of pultruded glass fiber reinforced polymer profiles infilled with waste steel fiber reinforced concrete under axial compression.

Cement-based materials are excellent in compressive strength but are very weak in tensile strength and have brittle properties. Various studies have been conducted on fiber-reinforced cement mortar (FRCM) as a method to improve these properties [3,4]. When the chopped fibers are incorporated into cement mortar, crack opening and propagation is suppressed through the bridging action of discontinuously arranged fibers in the matrix, and accordingly, flexural and tensile strength, toughness, impact resistance, deformation capacity, and ductility can be greatly improved [5,6].

In addition, the fresh and mechanical performance of FRCM is greatly affected by the type of fiber, fiber volume fractions, aspect ratio of fiber, strength of fiber, and interfacial adhesion force between the fiber and matrix. When carbon fiber or steel fiber is incorporated into plain mortar (PM), its strength and flexural toughness are improved, and it has a much greater effect on flexural or tension than compression. The reason for the increase in flexural and tensile strength in carbon fiber-reinforced cement mortar (CFRCM) and steel fiber-reinforced cement mortar (SFRCM) is due to the bridging effect of the fibers which suppresses the crack propagation and improves the flexural performance through a redistribution of stress [7,8].

Recently, to develop high-conductive multifunctional materials demanded by the market today, studies on electrical properties as well as on mechanical performance are being conducted on various aspects [9,10]. Cement mortar has been known for decades as a non-conductive material. However, electrically conductive cement mortar is an innovative type of cement composite, which incorporates a conductive material to form a continuous network of current flow. If electrical conductivity (hereinafter referred to as “conductivity”) is given to cement mortar that has the electrical properties of a non-conductor, which generally does not allow electricity to pass through, the application field of FRCM may be expanded to many fields and it is expected that new demand can be created. Chopped fibers mainly used as various reinforcing fibers in FRCM include carbon fibers [11,12,13], steel fibers [14,15,16,17,18], glass fibers [19,20,21], basalt fibers [22,23,24,25], and synthetic fibers [26,27,28,29,30,31]. In parallel with the development of textile technology in recent decades, their commercialization is being promoted.

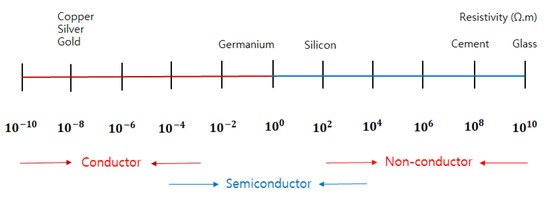

Figure 1 displays a comprehensive representation of electrical resistivity classified according to various materials. Generally, cement mortar which is an electrical non-conductor exhibits an electrical resistivity of about 106∼10 Ω.m. Metal materials that are electrical conductors or semi-conductors such as germanium and silicon have an electrical resistivity of 1.59 × 10−8∼2.5 × 102 Ω.m. In addition, it is known that carbon materials have an electrical resistivity of 3.5 × 10−5 Ω.m [32,33,34]. Therefore, when FRCM is fabricated by adding carbon fiber with excellent conductivity, it can be converted into cement mortar with electrical conductivity (easy to flow electricity) by greatly lowering the electrical resistance of non-conductive cement mortar to the level of 101 Ω.m.

Figure 1.

Electrical resistivity according to various materials.

On the other hand, research has been conducted continuously until now about carbon and steel fibers since they have conductivity which is very useful for improving the mechanical and electrical properties of FRCM [35]. In particular, carbon-based highly conductive materials include carbon fibers, carbon nanotubes, graphene, and graphite powder, while metal fibers include steel fibers and stainless fibers. When chopped carbon fibers with excellent properties such as high electrical conductivity, thermal conductivity, heat resistance, incombustibility, and corrosion resistance are used, the electrical resistance can be lowered to a certain level. That is why they are suitable for various applications such as self-sensing and self-monitoring [36,37,38,39,40], traffic monitoring [41,42], de-icing of frozen road pavements [43,44,45], corrosion protection of rebar [46], electrical grounding [47], and electromagnetic shielding [48,49], etc. In Korea, many studies on multifunctional FRCM with high conductivity have been conducted, while some foreign countries, such as Russia, North America, and Japan are improving their usability by actively developing advanced new materials for construction. However, studies on the mechanical performance improvement of FRCM incorporating various fibers into cement mortar have been continuously conducted, but until now, studies on the effect of incorporating carbon and steel fibers on electrical conductivity are somewhat insufficient. Adding conductive fibers such as carbon fiber and steel fiber to cement mortar can not only improve the mechanical properties but also effectively enhance the electrical conductivity performance of cement mortar.

The ultimate purpose of the present study is to develop a manufacturing technology for multifunctional FRCM with high conductivity by mixing carbon and steel fibers which are conductive materials. In this study, therefore, attempts were made to review the effect of varied fiber volume fractions of conductive CFRCM and SFRCM containing carbon and steel fibers on the fresh and mechanical properties as well as electrical conductivity in comparison with PM. Furthermore, the surface shape and composition of the developed conductive FRCM fracture surface were analyzed by a scanning electron microscope (SEM) and energy-dispersive X-ray spectrometer (EDS).

2. Experimental Program

In this study, an experiment was conducted to investigate the effect of carbon and steel fibers, which are conductive materials, on the fresh, mechanical properties and electrical conductivity of cement mortar. The performance of the conductive FRCM was planned to be compared and analyzed based on flow, unit weight, air content, three-point flexural, compression, and electrical resistance tests. Furthermore, it was planned to take measurements using SEM/EDS to analyze the surface shape and element components of the developed conductive FRCM fracture surface.

2.1. Experimental Plan

Table 1 exhibits the experimental factors and levels in this study. As for the mixture of cement mortar, the water–cement ratio (W/C) was 0.45, and the ratio of cement to sand was 1:2 by mass. At this time, the lengths of carbon and steel fibers were 6 mm and 30 mm, respectively. The target compressive strength was set at about 35 MPa at the age of 28 days. In order to investigate the effect on the fresh, mechanical properties and electrical conductivity of FRCM, it was divided into Group I and Group II. For the experiments, it was planned to measure the flow, unit weight, and air content of a mixture in the fresh state. In the hardened mortar state, it was planned to investigate the mechanical properties such as compressive strength and flexural strength at the age of 28 days. Besides, it was designed to measure the electrical resistance at each age (28, 56, and 91 days) to investigate the effect of conductive CFRCM and SFRCM on electrical conductivity. Furthermore, SEM/EDS image analysis was planned for the surface shape and elemental analysis of the developed conductive FRCM fracture surface.

Table 1.

Experimental factors and levels in this study.

2.2. Materials

The cement used in this study was Type I ordinary Portland cement (OPC) with a density of 3.15 and a fineness of 3710 cm2/g manufactured by domestic company Hanil Hyundai Cement Co., Ltd. (Gangwon-do, Republic of Korea). Standard sand from Hyangho-ri, Jumunjin-eup, Gangneung-si, Gangwon-do was used to prepare a uniform cement mortar. In addition, the standard sand is a natural round particle containing 98% or more of silicon dioxide (SiO2) as specified by KSL ISO 679, with an average particle diameter of 0.5 mm or less. The specific gravity and water absorption of the fine aggregate in the dry saturated state were 2.65 and 0.1%, respectively. The physical and chemical properties of the cement and fine aggregate are shown in Table 2 and Table 3. The admixture used in this study is a polycarboxylic acid-based high-performance superplasticizer (SP) product manufactured by Sica Korea Co., Ltd. (Chungnam-do, Republic of Korea). Table 4 shows the specification properties of the SP.

Table 2.

Physical and chemical properties of ASTM Type I Portland cement.

Table 3.

Physical properties of fine aggregate.

Table 4.

Properties of superplasticizer.

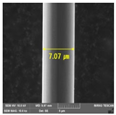

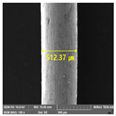

Polyacrylonitrile (PAN) and pitch are commonly used as precursors to carbon fibers. The PAN-based carbon fiber is more widely available due to its broader use in structural cement composites although pitch-based carbon fibers are cheaper. PAN-based carbon fiber shows higher tensile strength but lower modulus of elasticity compared to pitch-based carbon fiber. The chopped carbon fibers used in this study are a product of Japanese company T, and have a length of 6 mm and a diameter of 7 µm, and their tensile strength and modulus of elasticity are 4900 MPa and 230 GPa, respectively. Polyacrylonitrile (PAN)-based carbon fiber with a carbon content of 92% or more and an electrical resistivity of 1.6 × 10−3 Ω.cm was used. The steel fiber used in this study has a length of 30 mm, a diameter of 0.5 mm, and a tensile strength of 1100 MPa. The steel fiber is a product of domestic company K, and is a hook type with hook-ends and, at the same time, a bundle type with several strands attached to each other to facilitate material input. Table 5 shows the properties of the carbon and steel fibers which are used as conductive materials in this study. As can be seen in Table 5, the photograph of the morphology of the carbon fiber was taken at 10,000 times magnification through SEM. The diameter of the carbon fiber is about 7.07 μm and the surface shows a fairly smooth state, demonstrating that it has a poor surface texture that makes interfacial adhesion force with the cement mortar very difficult. On the other hand, the photograph of the morphology of the steel fiber was taken at 150 times magnification through SEM. The diameter of the steel fiber is about 512.37 μm, and the surface is somewhat rough, forming a surface texture that is advantageous for interfacial adhesion force in the cement mortar. In the case of the carbon fibers, the interfacial adhesion force between the fibers and matrix is relatively weak due to the non-hydrophilicity of the fiber surface, so the adhesion performance with the cement mortar is very low.

Table 5.

Properties of conductive fibers used in this study.

2.3. Mix Proportions, Mixing Method, and Manufacturing Specimens

In this study, a design mixture was selected to investigate the effect on fresh, mechanical properties, and electrical conductivity of cement mortar incorporating carbon and steel fibers, which are conductive materials. The mix proportions of the PM and FRCM are listed in Table 6, in which conductive FRCM is divided into Group I and Group II. In Group I, to examine the fresh and mechanical properties of conductive CFRCM and SFRCM, the variation in fiber volume fractions was set to four types: 0.5%, 0.75%, 1.0%, and 1.25% fibers by volume. In group II, to investigate the effect on electrical conductivity, the variation in fiber volume fractions was set at 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, 0.6%, and 0.75% by volume in the case of the carbon fiber mix, while at 0.25%, 0.5%, 0.75%, 1.0%, and 1.25% in the case of the steel fiber mix; a total of 12 levels were set for both fiber mixes. For mixing, a Hobart-type electric mixer with a nominal capacity of about 4.73 L was utilized in compliance with the test regulations of KS L 5109, and the mixing ratio was set as cement:standard sand:mixing water = 1:2:0.45. In order to maintain the dispersibility and workability of carbon fibers, the amount of the admixtures added was 0.5% of the mass of cement and, in the case of PM and SFRCM containing steel fiber, no additional admixture was used.

Table 6.

Mix proportions of PM and FRCM.

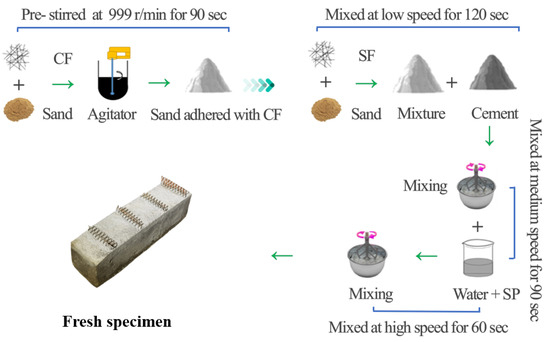

Figure 2 shows the fabrication process of conductive cement mortar specimens. As exhibited in Figure 2, this study suggests a new pre-dispersion method for uniform dispersion of carbon fibers in CFRCM. In the fabrication process of SFRCM, however, the pre-dispersion method was omitted. Firstly, carbon fibers and standard sand were put in a dispersion container and stirred at a speed of 999 rpm/min for 90 s to mix them fully so that the carbon fibers are attached completely to the surface of the fine aggregate. Secondly, the cement was put into the mixer and mixed at low speed for 30 s, and then mixed again without mixing water for 90 s to perfectly disperse the fibers. Thirdly, the mixing water and admixture were slowly added into the mixing vessel and mixed at a medium speed for 90 s. Again, the mixer was rotated at a high speed for 60 s to obtain a final mortar mixture. The total mixing time was about 6 min. Finally, the cement mortar mixture was poured into the mold, the surface layer was levelled to make the mortar uniform, and the side of the mold was hit about 25 times with a rubber hammer until the surface became flat without irregularities. Then, after the specimen production was finished, all specimens were covered with a plastic sheet to prevent sudden moisture evaporation and cured at room temperature for 24 h. All specimens were demolded 24 h after casting. Thereafter, they were cured under the standard condition at a temperature of 20 ± 2 °C for 28 days.

Figure 2.

Fabrication process of conductive cement mortar specimen.

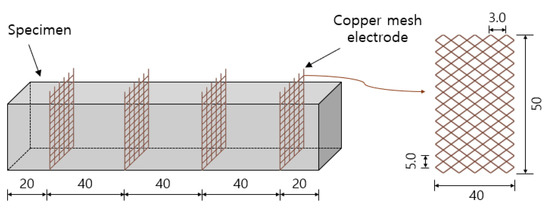

On the other hand, Figure 3 features a schematic diagram of configuration and installation of a copper mesh electrode on a cement mortar specimen to measure the electrical resistance value (Ω). For cement mortar, as shown in Figure 3, four copper meshes were embedded into the specimens as electrodes equally at intervals of 40 mm in a parallel on a prism of 40 × 40 × 160 mm3 in size. At this time, a copper mesh electrode was used to minimize discontinuity between different materials at the point where copper and cement mortar have contact with each other. Moreover, in order to minimize the air voids inside the specimen, a vibrating compaction was performed to maintain uniform contact between the copper mesh and cement mortar by softly vibrating the specimen for about 3 min on a laboratory vibrating table. Then, to minimize the effect of conductivity due to the curing environment at the time of measuring electrical resistance, the mold was demolded after 24 h and all specimens were stored in an environmental chamber (i.e., 23 ± 0.5 °C with a relative humidity of 40 ± 1%) during the curing period (28, 56, and 91 days). To ensure the acquisition of reliable data, at least three specimens were prepared from all mixtures.

Figure 3.

Schematic view of electrical resistance measurement specimen and configuration of copper mesh electrodes (dimensions in mm).

2.4. Experimental Methods

2.4.1. Flow Test

The flow test in the fresh mixture state was measured using a flow table and a flow cone according to the test regulations of KS L 5111 [50]. Immediately after the mixture was discharged, it was poured into a conical mold with a lower diameter of 100 mm, upper diameter of 70 mm, and a height of 50 mm in two layers and compacted 20 times. When the dispersion stopped after falling, the diameters in three diagonal directions passing through the center were measured and its average value was set as the flow value.

2.4.2. Unit Weight Test

For the unit weight test in the state of fresh mixtures according to the test regulations of KS F 2409 [51], the mixtures were put up to about 1/3 of the container and evenly compacted with a compactor. The outside of the container was further beaten with a rubber hammer about 10 to 15 times until the compaction bubbles disappeared and no large air bubbles were visible on the surface of the cement mortar. In order to measure the weight of the completed container, the mass of the sample in the container was calculated as in Equation (1) using the mass of the container that was measured before the test.

here, M is the unit weight of the mixture (kg/m3), W is the mass of the mixture in the container (kg), and V is the volume of the container (m3).

2.4.3. Air Content Test

According to the test regulations of KS L 3136 [52], the air content test in the fresh state of mixtures was carried out by measuring the air content as seen in Equation (2) using a container of cylindrical shape that could hold 400 mL of water at 20 °C with an inner diameter of 76 mm and a depth of 88 mm.

here, w is the mass of 400 mL of the mixture (g), and P is the percentage of the mixed water based on the cement used.

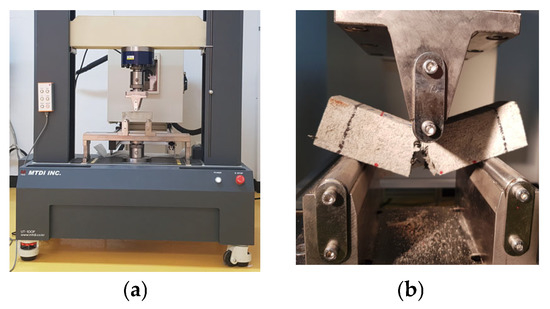

2.4.4. Three-Point Flexural Test

In order to investigate the mechanical properties of cement mortar in the hardened state, the three-point flexural test was conducted with a mold manufactured according to the test regulations of KS L ISO 679 [53], and the strength was measured at the age of 28 days. After curing, the prisms with a size of 40 × 40 × 160 mm were installed on a steel roller with a circular cross-section using a universal testing machine (MTDI Co., Ltd., Daejeon, Republic of Korea, UT-100F) with a capacity of 100 kN. Then, the flexural strength was measured by the three-point loading method under the condition of 50 N/s as a load control. Figure 4a shows the setup for the flexural test, and Figure 4b shows the appearance of the damaged specimen. The flexural strength in the three-point loading method was obtained from Equation (3).

here, fr is the flexural strength (MPa), P is the maximum load obtained from the experiment (N), L is the span of the specimen (120 mm), b is the width of the specimen (40 mm), and h is the height of the specimen (40 mm).

Figure 4.

Flexural test; (a) test setup, and (b) damaged specimen.

2.4.5. Compressive Test

After the first measurement of the flexural strength using the same universal testing machine, the fractured specimen was mounted on a press mold to measure the compressive strength. At this time, the loading of the compressive test was accelerated at a constant speed under the condition of 2400 N/s.

2.4.6. Electrical Resistance Test

In general, two-probe and four-probe methods are used as a means to measure for the electrical conductivity test of cement mortar. Although the circuit of the two-probe method is simpler, the four-probe method is preferred because it relieves the contact resistance between the specimen and electrode [54,55]. For cement mortar, the four-probe method has a pair of electrodes on the outside and a pair of electrodes on the inside, that is, two pairs of electrodes as a whole. While arranging constant current to flow through the outer pair of electrodes, the difference in voltage generated by the supply of current from the inner pair of electrodes is measured. Electricity introduction can be divided into the direct current (DC) and alternating current (AC) methods, and the use of the direct current (DC) method is the simplest of both methods for conducting electrical conductivity tests. In the present study, the four-probe method was adopted to perform the electrical conductivity test of cement mortar. Figure 5 displays the electrical resistance measurement procedure and test equipment of a cement mortar specimen. The electrical resistance of all specimens was measured at each age (28, 56, and 91 days). To measure electrical resistance, a digital multimeter (precision current source, Keithley 6220) supplies DC (I) to the two outer electrodes, and Keithley 2182A (nanovoltmeter) uses the two inner electrodes to measure voltage (V). The authorized current is available in the range of ±100 fA to ±100 mA, and the measurement range of electrical resistance value is available in the range of 10 nΩ to 200 MΩ. Thus, it may be said that electrical resistivity is a value that evaluates the properties of a material through which current flows. Meanwhile, electrical conductivity is expressed as σ, which is the reciprocal of electrical resistivity, and the unit is S/cm. The electrical conductivity σ (in S/cm) of cement mortar was obtained from the reciprocal of the electrical resistivity by applying the Equation (4).

here, ρ is the electrical resistivity (in Ω.cm), L is the distance between the two inner electrodes (4 cm), A is the area of the electrodes (16 cm2), and R is the measured electrical resistance based on Ohm’s law (i.e., R = V/I).

Figure 5.

The electrical resistance measurement procedure and experimental equipment of cement mortar specimen; (a) schematic diagram, and (b) experimental equipment.

2.4.7. Observation by SEM/EDS

In this study, it was planned to observe the surface shape of the conductive FRCM fracture surfaces by SEM imaging, and its components were analyzed by EDS used at the same time. The equipment used for analysis was TESCAN’s MIRA3-LMH high-resolution FE-SEM (model name), and Bruker’s EDS detector was additionally used for component analysis of hydration products. Following the strength test, the fibers obtained by pulverizing the cured specimen were dried and coated with platinum in a vacuum, and then the images and components were analyzed by means of SEM/EDS.

3. Results and Discussion

3.1. Properties of Fresh Mortar

3.1.1. Flow

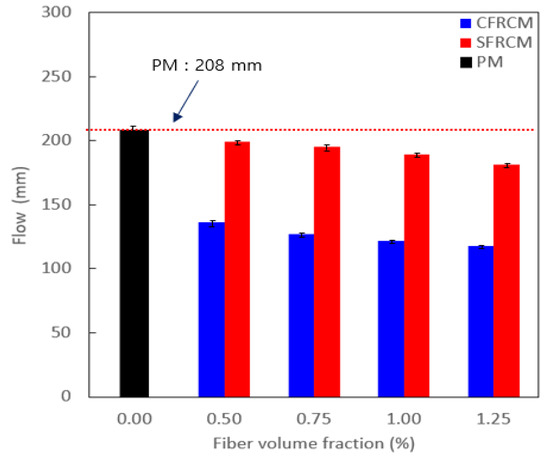

Figure 6 shows the flow of the mixture containing carbon and steel fibers according to the variation in the fiber volume fractions compared to the PM. As shown in Figure 6, the flow values of the PM and mixture containing steel fiber were 208 mm and 181 to 199 mm, respectively, satisfying the target value of 180 mm. On the other hand, however, the flow performance tends to decrease significantly as the fiber volume fraction increases in the case of a mixture containing carbon fibers. When the carbon fiber was mixed, a small lump was observed in the mixture, and it can be seen that the workability was significantly reduced. The reason why the carbon wall has a hollow structure is because the viscosity and specific surface area increases due to the absorption of some mixed water, and the resulting aggregation of fibers is thought to have a tendency to decrease the flow significantly compared to PM. These findings have also been reported in previous studies [9,56]. Figure 7 is a photographic representation of the fluidity of PM and a mixture containing carbon and steel fibers. In the case of the carbon fibers, aggregation and localization of fibers would occur during dry mixing, and smooth dispersibility tended to be difficult even during wet mixing. As the volume fraction of the carbon fibers increased, entanglement between each fiber easily occurred, which greatly affected workability as well. In the case of the carbon fiber mixture containing 1.25% fiber, particularly, separation and agglomeration of fibers occurred severely, and it was hard to form a mixture due to cracking caused from localization.

Figure 6.

Flow test results of mixtures with fiber volume fractions.

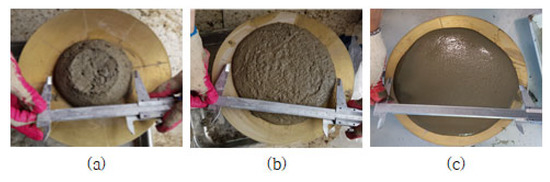

Figure 7.

Flow test measurement appearance; (a) carbon fiber 1.25%, (b) steel fiber 1.25%, and (c) plain mortar.

3.1.2. Unit Weight

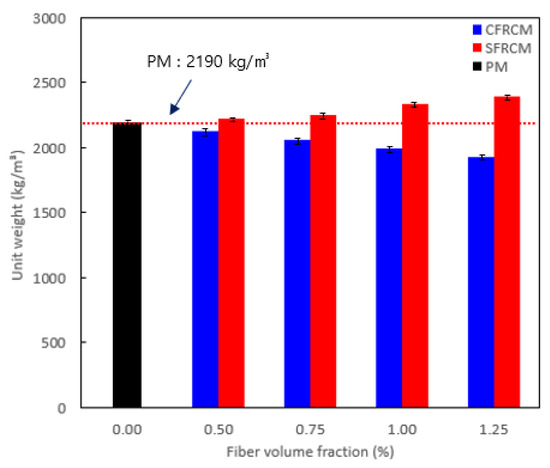

Figure 8 represents the unit weight of the mixture containing carbon and steel fibers according to the variation in the fiber volume fractions compared to PM. As seen in Figure 8, the unit weight of the mixture containing steel fibers increased with increasing volume fractions as expected. Conversely, as the volume fraction of carbon fibers increased, there was a tendency to gradually decrease considerably. In the case of a mixture containing carbon fibers, the unit weight could be reduced by about 3% or more as the fiber volume fractions increased, and it could be reduced by about 12% or more compared to PM. This decrease is believed to be attributed to the difference between the density of cement and carbon fibers, and it is judged that the unit weight decreased because a lot of carbon fibers, which have a relatively smaller density than cement, were mixed. In addition, it may be due to an increase in the entrapped air content in the mixture as the volume fractions of carbon fibers increased. Such findings as in this study have also been reported in previous studies [9,56].

Figure 8.

Unit weight test results of mixtures with fiber volume fractions.

3.1.3. Air Content

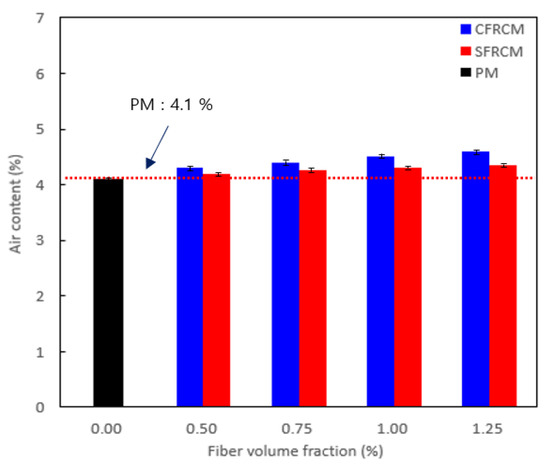

Figure 9 shows the air content in the mixture containing carbon and steel fibers according to the variation in the fiber volume fractions compared to PM. As found in Figure 9, the air content in PM was about 4.1%, and the variation in the relative air content following the fiber volume fractions was not very significant. Regardless of the volume fractions of carbon and steel fibers, the variation in the relative air content was insignificant compared to PM, but as the fiber volume fractions increased, all of them tended to increase slightly accordingly. These results indicate that the effect of the carbon and steel fiber mixture on the air content is not very large, and the quality of the air content does not vary significantly as the fiber volume fraction increases. Results like in this study have also been reported in previous studies which found that, when fibers are mixed, the air content tends to increase due to the increase of micropores on the surface to which fiber and cement mortar are attached [56].

Figure 9.

Air content test results of mixtures with fiber volume fractions.

3.2. Properties of Hardened Mortar

3.2.1. Flexural Strength

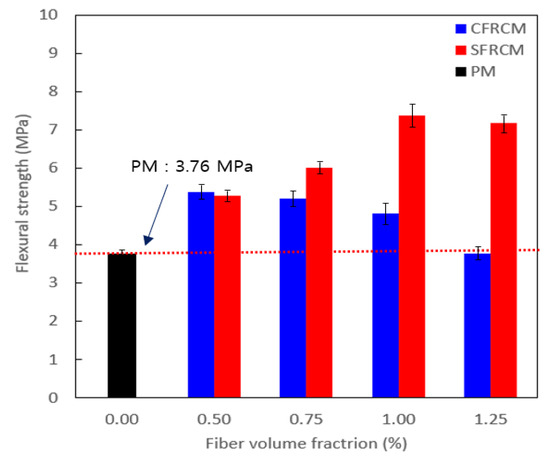

Figure 10 shows the measurement results of flexural strength at the age of 28 days of conductive CFRCM and SFRCM according to the variation in fiber volume fractions compared to PM. As indicated in Figure 10, the average flexural strength of PM was measured to be 3.76 MPa, and as the volume fraction of carbon fibers increased, the flexural strength showed a tendency to decrease somewhat. In the case of CFRCM containing 1.25% fiber, particularly, the flexural strength decreased rapidly. On the other hand, SFRCM showed significantly higher flexural strength as the fiber volume fractions increased. In the case of CFRCM containing 0.5% fiber obtained from this test result, the flexural strength increased approximately by 1.62 MPa compared to PM, and CFRCM containing 0.75% fiber turned out to increase by about 1.45 MPa. Furthermore, in the case of CFRCM containing 1.0% fiber, the flexural strength increased by about 1.06 MPa compared to PM, and CFRCM containing 1.25% fiber was almost similar to 0.01 MPa. Accordingly, in the case of CFRCM containing 0.5%, 0.75%, 1.0%, and 1.25% fibers, the flexural strength was improved by about 43.1%, 38.6%, 28.2%, and 0.3%, respectively, compared to PM. The flexural strength was somewhat improved until the volume fraction of carbon fibers reached 1.0%, but the incremental effect was not so great when the volume fraction of carbon fiber was 1.25%. It is apparent that this has low flexural strength because it is not good in terms of dispersibility and workability due to the incorporation of a large amount of carbon fibers. These findings have also been reported in previous studies [9,56]. In the case of SFRCM containing 0.5% fiber, however, the flexural strength increased by about 1.51 MPa compared to PM, and SFRCM containing 0.75% fiber increased almost by 2.26 MPa, Moreover, in the case of SFRCM containing 1.0% fiber, the flexural strength increased almost by 3.61 MPa compared to PM, whereas SFRCM containing 1.25% fiber increased by about 3.41 MPa. Therefore, in the case of SFRCM containing 0.5%, 0.75%, 1.0%, and 1.25% fibers, the flexural strength was improved by about 40.1, 60.1, 96.0, and 90.7%, respectively, compared to PM. This is thought to be because the steel fiber played a bridging role to prevent crack propagation and to improve flexural strength through stress redistribution.

Figure 10.

The effect of fiber volume fractions on the flexural strength of developed conductive CFRCM, SFRCM versus PM specimens.

3.2.2. Compressive Strength

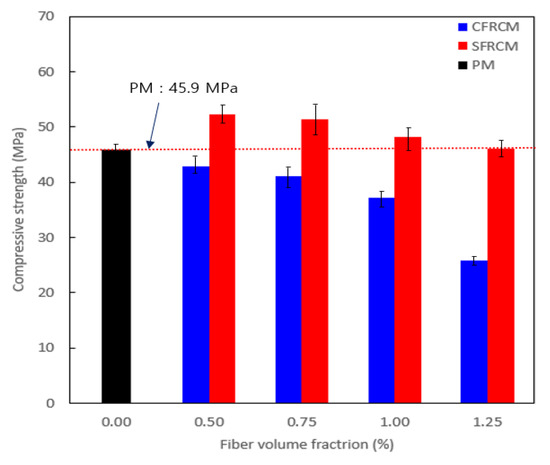

Figure 11 demonstrates the results of measuring the compressive strength of conductive CFRCM and SFRCM at the age of 28 days according to the variation in fiber volume fractions in comparison to PM. As evidenced in Figure 11, the average compressive strength of PM was measured to be 45.9 MPa, and as the fiber volume fractions increased, all of the compressive strengths tended to decrease gradually. In all FRCM except for CFRCM, the target compressive strength turned out to be 35 MPa or more, and in the case of SFRCM, it was almost similar to or slightly higher than that of PM, indicating equivalent or higher compressive strength. In the case of CFRCM containing 0.5% fiber as obtained from this test result, the compressive strength was decreased by 3.0 MPa compared to PM, while CFRCM containing 0.75% fiber was decreased by 4.8 MPa compared to PM. Besides, in the case of CFRCM containing 1.0% fiber, the compressive strength was decreased by about 8.7 MPa compared to PM, and CFRCM containing 1.25% fiber was decreased by about 20.1 MPa. In terms of the ratio, therefore, it could be said that the compressive strength of CFRCM containing 0.5%, 0.75%, and 1.0% fibers was reduced by about 6.5%, 10.4%, and 18.9%, respectively, compared to PM, and CFRCM containing 1.25% fiber was less by about 43.8% significantly. In the case of CFRCM containing 1.25% fiber, particularly, it is hard to uniformly disperse the fibers in the cement mortar, and agglomeration occurs when the fibers become entangled, and the compressive strength becomes significantly low instead due to insufficient dispersion and increased air voids. It is judged that the compressive strength of carbon fibers were lowered because the interfacial adhesion force between the fibers and matrix in the cement mortar after hardening was weak due to the non-hydrophilic material on the fiber surface. The research results were also reported in previous studies [9,56]. However, in the case of SFRCM containing 0.5% fiber, the compressive strength increased by approximately 6.4 MPa compared to PM and, in SFRCM containing 0.75% fiber, the compressive strength increased by about 5.5 MPa compared to PM. Moreover, in the case of SFRCM containing 1.0% fiber, the compressive strength increased by about 2.2 MPa compared to PM and, in SFRCM containing 1.25% fiber, it was almost similar to 0.1 MPa. Consequently, in the case of SFRCM containing 0.5%, 0.75%, 1.0%, and 1.25% fibers, the compressive strength was improved by about 13.9%, 12.0%, 4.8%, and 0.2%, respectively, compared to PM. This increase in compressive strength is considered to be because the formation and propagation of micro cracks in the cement mortar can be suppressed due to the bridging role of steel fibers.

Figure 11.

The effect of fiber volume fractions on the compressive strength of developed conductive CFRCM, SFRCM versus PM specimens.

3.3. Electrical Conductivity of the Development CFRCM and SFRCM

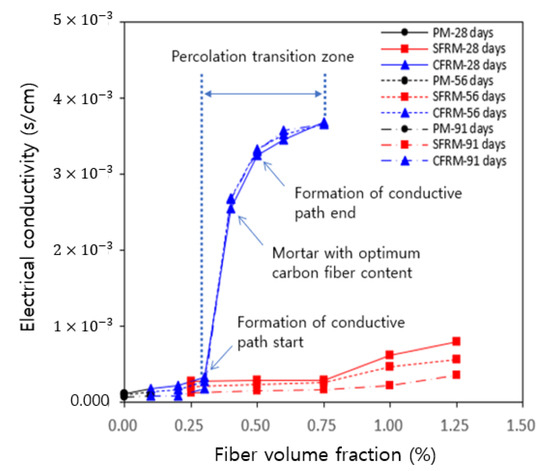

Electrical conductivity of cement mortar occurs in electronic conduction as well as in ionic conduction. Electronic conduction signifies the flow of electric current due to the movement of free electrons in fibers, and ionic conduction refers to electrical conductivity due to the movement of ions in the water of pores [57]. In a cement mortar, when the volume fraction of fibers starts from “0”, increases gradually, and the proportion exceeds a certain percentage, the distance between the fibers is narrowed and electrons hop through the non-conductive (cement mortar) area between the fibers, while conductivity is created in the cement mortar. As the volume fraction of fibers keeps increasing, a region appears in which the flow of electrons rapidly increases. Such a phenomenon is called a percolation phenomenon, and the time at which percolation starts or the state of fibers at this time is called a percolation threshold [58]. That is, the percolation threshold refers to the dosages in the state in which a continuous conductive pathway is secured through the contact between adjacent conductive internal particles (fibers). The most important of the state quantities at the percolation threshold are the volume fraction of fibers. Table 7 shows the average electrical conductivity (σ) measurement results of the developed conductive FRCM and PM according to the fiber volume fractions at each age (28, 56, and 91 days) and are also compared in Figure 12. As shown in Table 7 and Figure 12, the electrical conductivity slightly increased as the volume fraction of steel fibers increased compared to PM, but overall, the electrical conductivity did not improve significantly even if steel fibers were added up to 1.25%. It is thus made clear that the electrical conductivity could not be significantly improved in SFRCM containing steel fibers because the steel fibers used in this study could not form conductive pathways. In contrast, Figure 12 displays that the percolation transition region for CFRCM exhibits a so-called S-curve. It can be seen here that CFRCM reveals the onset of conductive pathways formation between 0.3% and 0.4% fibers, thereby increasing the conductivity. In particular, when the volume fraction of carbon fibers exceeds 0.4%, the percolation phenomenon takes place, rapidly increasing the electrical conductivity, and the carbon fibers start to come into contact and form a conductive pathway, thus greatly increasing the conductivity. However, the volume fraction of carbon fibers showed a gradual increase by 0.5~0.6%, and the ratio decreased somewhat since a conductive path was already formed. The reason for the decrease in the electrical conductivity of CFRCM in the region following the percolation phenomenon is thought to result from the occurrence of voids due to the mixing of a large dosage of fibers and from fiber ball phenomenon in which fibers aggregate with each other and, consequently, the amount of voids increases. The detected percolation threshold for CFRCM used in this study was 0.4% in terms of securing electrical conductivity, showing the optimal dosage of carbon fiber. Therefore, the upper limit of the percolation threshold may determine the optimal dosage of carbon fiber for the electrical conductivity of CFRCM. These findings have also been reported in previous studies [59,60].

Table 7.

The results of average electrical conductivity measurements for the studied specimens.

Figure 12.

Variation of electrical conductivity by fiber volume fractions in CFRCM, SFRCM, and PM specimens at 28 days, 56 days, and 91 days, respectively.

As shown in Table 7, for example, the average electrical conductivity of PM (plain mortar mix) at the age of 28, 56, and 91 days was about 1.05 × 10−4 S/cm, 8.66 × 10−5 S/cm, and 6.18 × 10−5 S/cm, respectively, and that of SFRCM containing 1.25% fiber (Steel125 mix) was about 7.94 × 10−4 S/cm, 5.51 × 10−4 S/cm, and 3.57 × 10−4 S/cm, respectively. In contrast, the average electrical conductivity of CFRCM (Carbon75 mix) containing 0.75% fiber was about 3.68 × 10−3 S/cm, 3.65 × 10−3 S/cm, and 3.64 × 10−3 S/cm, respectively, which is almost identical. In addition, the average electrical conductivity of CFRCM (Carbon10 mix) containing 0.1% fiber at the age of 28, 56, and 91 days was about 1.71 × 10−4 S/cm, 1.37 × 10−4 S/cm, and 7.44 × 10−5 S/cm, respectively. The average electrical conductivity of CFRCM (Carbon40 mix) containing 0.4% fiber, which is the optimum dosage of carbon fiber, is about 2.54 × 10−3 S/cm, 2.67 × 10−3 S/cm, and 2.66 × 10−3 S/cm, respectively, showed a reverse trend. That is to say, when the carbon fiber volume fraction was 0.4%, the electrical conductivity showed a high increase of about 2.36 × 10−3 S/cm, 2.53 × 10−3 S/cm, and 2.58 × 10−3 S/cm, respectively. This is increase of 14.8, 19.5, and 35.7 times more than that of CFRCM (Carbon10 mix) containing 0.1% fiber, and an increase of 24.2, 30.8 and 43.1 times more than that of PM. It was here confirmed that the larger number of mixed individuals a carbon fiber has and the higher the fiber volume fractions get, the better the connectivity between the fibers will be, and thus the electrical conductivity of CFRCM can be highly improved. It also became obvious that, by incorporating more fibers, a conductive pathway is formed, which further improves the electrical conductivity of CFRCM. From this study, it was ascertained that, as the volume fraction of carbon fibers increases, the connectivity between the fiber particles is perfected, and the electrical conductivity of CFRCM is significantly improved due to the excellent connectivity between the carbon fibers and the increased number of mixed fibers. However, the increase in the dosage of carbon fibers beyond the critical point did not cause a noticeable change in the conductivity because the conductive pathway was already formed. Therefore, it is judged that carbon fibers could effectively contribute to improving the electrical conductivity since they have a very small diameter and high aspect ratio (ℓ/d > 857) compared to steel fibers, and they are distributed at the interface between the fibers and matrix in CFRCM containing carbon fibers.

3.4. Microstructure Analysis

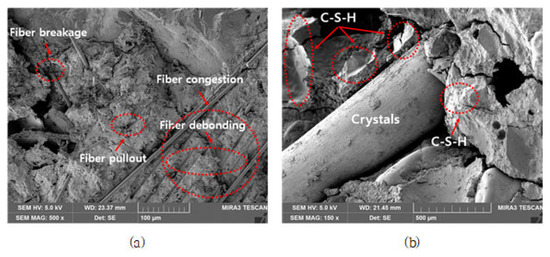

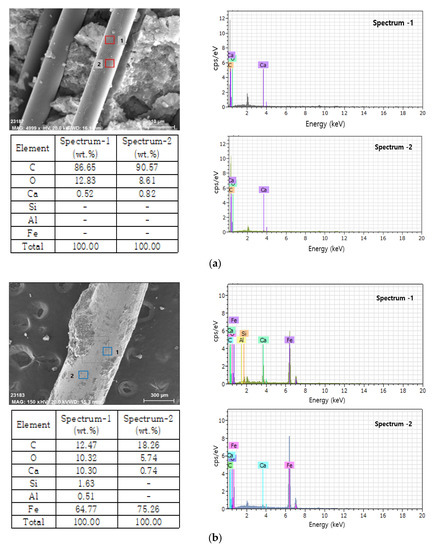

In general, in the case of cement composites, the average thickness of the interface transition zone (ITZ) between the cement mortar and aggregate is known to be about 10 to 50 μm, and the thickness of this ITZ is reported to affect the strength and durability of the cement composites [61,62]. Figure 13 shows the photos taken for the surface shape of the developed conductive CFRCM and SFRCM fracture surfaces through SEM image observation. As shown in Figure 13a, a carbon fiber has a round and circular shape, and the fiber surface is very clean and fairly smooth in shape. This seems to be because the interfacial adhesion force between the fibers and the matrix is low as carbon fibers are difficult to crystalize cement particles and hydration products and have low affinity. As featured in Figure 13b, however, large and small cement particles and hydration products are formed and attached on and around the surface area of the steel fibers. This indicates that the interfacial adhesion force between the fibers and matrix was significantly improved due to the formation and increase of cement particles and hydration products. As a consequence, we can judge that the steel fiber reacts with calcium hydroxide (Ca(OH2)), a primary hydration product, and soluble components such as calcium (Ca), silicon (Si), and aluminum (Al) in the cement mortar to form calcium silicate hydrate (C-S-H) gels, etc., inducing the formation of cement hydration products.

Figure 13.

SEM images of conductive CFRCM and SFRCM; (a) carbon fiber (500×), and (b) steel fiber (150×).

Figure 14 shows the results of elemental analysis by EDS spectra of carbon and steel fibers taken from the fracture surfaces of the development conductive CFRCM and SFRCM specimens developed after the flexural test. For elemental analysis of hydration products, the amount of element components (C, O, Ca, Fe, etc.) on the fiber surface was measured through EDS attached to SEM. As a measuring method to accurately determine the amount of component elements, the amount of elements was measured by obtaining the average value of the area of the two points at an arbitrary location at the same distance from each fiber. As seen in Figure 14, from the elemental analysis by EDS spectra of a developed conductive CFRCM specimen containing carbon fibers detected 86.65% of carbon (C), 12.83% of oxygen (O) and a small amount of calcium (Ca) 0.52%, respectively, in the red position (1). In addition, it was analyzed that the components indicated in the red position (2) contain 90.57% of carbon (C), 8.61% of oxygen (O), and a small amount of calcium (Ca) 0.82%. Besides, in the developed conductive SFRCM specimen containing steel fibers, iron (Fe) 64.76%, carbon (C) 12.47%, oxygen (O) 10.32%, calcium (Ca) 10.3%, and a small amount of silicon (Si) 1.63% and aluminum (AI) 0.51% were detected from the components indicated in the blue position (1). At the same time, it was analyzed that the components indicated in the blue position (2) contain 75.25% of iron (Fe), 18.26% of carbon (C), 5.74% of oxygen (O), and 0.74% of calcium (Ca) in a small amount. Accordingly, the carbon fibers in the developed conductive CFRCM specimen showed that a large amount of carbon (C) and a small amount of calcium (Ca) were present, while the hydration products were confirmed in the steel fiber in the developed conductive SFRCM specimen, and a small amount of silicon (Si) and aluminum (Al) as well as calcium (Ca) were detected, indicating that the hydration reaction is actively proceeding. Such results of the elemental analysis by the EDS spectrum are almost in agreement with the results of SEM images shown in Figure 13.

Figure 14.

EDS analysis results of the carbon and steel fibers captured at the fracture surface in CFRCM and SFRCM; (a) carbon fibers, and (b) steel fibers.

4. Conclusions

In this study, the effect on the fresh and mechanical properties as well as electrical conductivity of developed conductive FRCM containing carbon and steel fibers were compared and reviewed with PM. The results obtained from this study may be summarized as follows:

- Although the target flow value of the mixture containing PM and steel fibers was satisfied, it appeared that the flow value was significantly reduced in the case of the carbon fibers compared to PM due to some absorption of mixed water during mixing.

- The unit weight could be reduced by about 3% or more as the volume fraction of carbon fibers increased, and decreased by about 12% or more compared to PM. On the other hand, it was found that the change in the air contents were relatively insignificant regardless of the fiber volume fractions.

- Both conductive CFRCM and SFRCM showed an overall increase in flexural strength compared to PM, and CFRCM had an effect of improving the flexural strength of about 0.3 to 43.1%, whereas SFRCM had a greater effect on improving the flexural strength of about 40.1 to 96.0%.

- The compressive strength of developed conductive SFRCM was generally higher than that of PM, whereas in the case of developed conductive CFRCM, the decreasing tendency was larger as the volume fraction of carbon fibers increased.

- The developed conductive CFRCM and SFRCM were clearly different in terms of electrical conductivity enhancement. In the case of CFRCM, the electrical conductivity increased significantly as the fiber dosages increased. However, incorporation of carbon fibers beyond the percolation threshold (i.e., 0.4%) does not develop conductivity because the conductive path is already formed.

- The results of SEM/EDS analysis showed that in the case of SFRCM containing steel fibers, the interfacial adhesion force was superior to that of CFRCM containing carbon fibers because crystals of hydration product of cement were formed on the fiber surface and C-S-H gels were distributed within the cement mortar.

Author Contributions

Conceptualization, H.-M.J. and J.-G.P.; methodology, H.-M.J. and J.-G.P.; validation, G.-H.H. and D.-J.S.; formal analysis, H.-M.J. and J.-G.P.; investigation, J.-G.P., D.-J.S. and D.-Y.L.; writing—original draft preparation, H.-M.J. and J.-G.P.; writing—review and editing, G.-H.H. and D.-J.S.; visualization, J.-G.P., D.-J.S. and D.-Y.L.; supervision, G.-H.H.; project administration, G.-H.H.; funding acquisition, G.-H.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Basic Science Research Program through the National Research Foundation of Korea (NRF) of the Ministry of Education, Republic of Korea (Grant no. NRF-2018R1A6A1A03025542).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (Grant no. NRF-2018R1A6A1A03025542).

Conflicts of Interest

The authors declare that there is no conflict of interest.

References

- Ma, Z.; Shen, J.; Wang, C.; Wu, H. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132, 1–18. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVC-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar]

- ACI 544.2R-89; Measurement of Properties of Fiber Reinforced Concrete (Reapproved 2009). ACI Committee 544: Farmington Hills, MI, USA, 2009.

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Kim, D.J.; Naaman, A.E.; El-Tawil, S. Comparative flexural behavior of four fiber reinforced cementitious composites. Cem. Concr. Compos. 2008, 30, 917–928. [Google Scholar] [CrossRef]

- Banthia, N.; Sappakittipakorn, M. Toughness enhancement in steel fiber reinforced concrete through fiber hybridization. Cem. Concr. Res. 2007, 37, 1366–1372. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Gao, Z.; Wang, F. A review on fracture properties of steel fiber reinforced concrete. J. Build. Eng. 2023, 67, 1–23. [Google Scholar] [CrossRef]

- Tran, T.K.; Kim, D.J. High strain rate effects on direct tensile behavior of high performance fiber reinforced cementitious composites. Cem. Concr. Compos. 2014, 45, 186–200. [Google Scholar] [CrossRef]

- Dehghani, A.; Aslani, F. The effect of shape memory alloy, steel, and carbon fibres on fresh, mechanical, and electrical properties of self-compacting cementitious composites. Cem. Concr. Compos. 2020, 112, 103659. [Google Scholar] [CrossRef]

- You, I.H.; Lee, S.J.; Zi, G.S.; Lim, D.H. Influence of carbon fiber incorporation on electrical conductivity of cement composites. Appl. Sci. 2020, 10, 8993. [Google Scholar] [CrossRef]

- Hembach, M.; Möller, H.; Neumann, T.; Volkmer, D. Carbon fibre reinforced cement-based composites as smart floor heating materials. Compos. Part B Eng. 2016, 90, 465–470. [Google Scholar] [CrossRef]

- Yakhlaf, M.; Safiuddin, M.; Soudki, K.A. Properties of freshly mixed carbon fibre reinforced self-consolidating concrete. Constr. Build. Mater. 2013, 46, 224–231. [Google Scholar] [CrossRef]

- Urano, T.; Murakami, K.; Mitsui, Y.; Sakai, H. Study on the size effect of tensile characteristics of carbon fibre-reinforced cement composites. Compos. Part A Appl. Sci. Manuf. 1996, 27, 183–187. [Google Scholar] [CrossRef]

- Khaloo, A.; Raisi, E.M.; Hosseini, P.; Tahsiri, H. Mechanical performance of self-compacting concrete reinforced with steel fibers. Constr. Build. Mater. 2014, 51, 179–186. [Google Scholar] [CrossRef]

- Li, B.; Xu, L.; Chi, Y.; Huang, B.; Li, C. Experimental investigation on the stress-strain behavior of steel fiber reinforced concrete subjected to uniaxial cyclic compression. Constr. Build. Mater. 2017, 140, 109–118. [Google Scholar] [CrossRef]

- Frazão, C.; Barros, J.; Camões, A.; Alves, A.C.; Rocha, L. Corrosion effects on pullout behavior of hooked steel fibers in self-compacting concrete. Cem. Concr. Res. 2016, 79, 112–122. [Google Scholar] [CrossRef]

- Holschemacher, K.; Mueller, T.; Ribakov, Y. Effect of steel fibres on mechanical properties of high-strength concrete. Mater. Des. 2009, 31, 2604–2615. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Barluenga, G.; Hernández-Olivares, F. Cracking control of concretes modified with short AR-glass fibers at early age. Experimental results on standard concrete and SCC. Cem. Concr. Res. 2007, 37, 1624–1638. [Google Scholar] [CrossRef]

- Mebarkia, S.; Vipulanandan, C. Compressive behavior of glass-fiber reinforced polymer concrete. Am. Soc. Civ. Eng. 1992, 4, 91–105. [Google Scholar] [CrossRef]

- Tassew, S.T.; Lubell, A.S. Mechanical properties of glass fiber reinforced ceramic concrete. Constr. Build. Mater. 2014, 51, 215–224. [Google Scholar] [CrossRef]

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-based fiber reinforced materials and structural applications in civil engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- Shafiq, N.; Ayub, T.; Khan, S.U. Investigating the performance of PVA and basalt fibre reinforced beams subjected to flexural action. Compos. Struct. 2016, 153, 30–41. [Google Scholar] [CrossRef]

- Ralegaonkar, R.; Gavali, H.; Aswath, P.; Abolmaali, S. Application of chopped basalt fibers in reinforced mortar: A review. Constr. Build. Mater. 2018, 164, 589–602. [Google Scholar] [CrossRef]

- Rybin, V.A.; Utkin, A.V.; Baklanova, N.I. Alkali resistance, microstructural and mechanical performance of zirconia-coated basalt fibers. Cem. Concr. Res. 2013, 53, 1–8. [Google Scholar] [CrossRef]

- Alhozaimy, A.M.; Soroushian, P.; Mirza, F. Mechanical properties of polypropylene fiber reinforced concrete and the effects of pozzolanic materials. Cem. Concr. Compos. 1996, 18, 85–92. [Google Scholar] [CrossRef]

- Thong, C.C.; Teo, D.C.L.; Ng, C.K. Application of polyvinyl alcohol (PVA) in cement-based composite materials: A review of its engineering properties and microstructure behavior. Constr. Build. Mater. 2016, 107, 172–180. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, C.H.; Li, Q.F.; Zhang, T.H. Effect of polypropylene fiber on fracture properties of cement treated crushed rock, Compos. Part B Eng. 2013, 55, 48–54. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.; Wang, J.; Shi, Y.; Zheng, Y.; Ling, Y. Effect of nano-particle on durability of polyvinyl alcohol fiber reinforced cementitious composite. Sci. Adv. Mater. 2020, 12, 249–262. [Google Scholar] [CrossRef]

- Wang, Y.; Li, V.C.; Backer, S. Tensile properties of synthetic fiber reinforced mortar. Cem. Concr. Compos. 1990, 12, 29–40. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; El-Ghareeb, M.A.; Abdel-Rahman, M.A.; El Sayed, A.N. Multifunctional electrically conductive concrete using different fillers. J. Build. Eng. 2018, 15, 61–69. [Google Scholar] [CrossRef]

- Whittington, H.W.; McCarter, J.; Forde, M.C. The conduction of electricity through concrete. Mag. Concr. Res. 1981, 33, 48–60. [Google Scholar] [CrossRef]

- Kang, S.H. Electrically conductive concrete. J. Korea Concr. Inst. 1998, 10, 34–40. [Google Scholar]

- Belli, A.; Mobili, A.; Bellezze, T.; Tittarelli, F. Commercial and recycled carbon/steel fibers for fiber-reinforced cement mortars with high electrical conductivity. Cem. Concr. Compos. 2020, 109, 103569. [Google Scholar] [CrossRef]

- Yildirim, G.; Sarwary, M.H.; Al-Dahawi, A.; Öztürk, O.; Anil, Ö.; Şahmaran, M. Piezoresistive behavior of CF- and CNT based reinforced concrete beams subjected to static flexural loading: Shear failure investigation. Constr. Build. Mater. 2018, 168, 266–279. [Google Scholar] [CrossRef]

- Yildirim, G.; Öztürk, O.; Al-Dahawi, A.; Ulu, A.A.; Şahmaran, M. Self-sensing capability of Engineered Cementitious Composites: Effects of aging and loading conditions. Constr. Build. Mater. 2020, 231, 117132. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.G.; Ou, J.P. A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials. Cem. Concr. Res. 2004, 34, 435–438. [Google Scholar] [CrossRef]

- Chiarello, M.; Zinno, R. Electrical conductivity of self-monitoring CFRC. Cem. Concr. Compos. 2005, 27, 463–469. [Google Scholar] [CrossRef]

- Sarwary, M.H.; Yildirim, G.; Al-Dahawi, A.; Anil, Ö.; Khiavi, K.A.; Toklu, K.; Şahmaran, M. Self-sensing of flexural damage in large-scale steel-reinforced mortar beams. ACI Mater. J. 2019, 116, 209–221. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Kwon, E. A self-sensing carbon nanotube/cement composite for traffic monitoring. Nanotechnology 2009, 20, 445501. [Google Scholar] [CrossRef]

- Shi, Z.Q.; Chung, D.D.L. Carbon fiber-reinforced concrete for traffic monitoring and weighing in motion. Cem. Concr. Res. 1999, 29, 435–439. [Google Scholar] [CrossRef]

- Sassani, A.; Arabzadeh, A.; Ceylan, H.; Kim, S.H.; Sajed Sadati, S.M.; Gopalakrishnan, K.; Taylor, P.C.; Abdualla, H. Carbon fiber-based electrically conductive concrete for salt-free deicing of pavements. J. Clean. Prod. 2018, 203, 799–809. [Google Scholar] [CrossRef]

- Wu, J.; Lui, J.; Yang, F. Three-phase composite conductive concrete for pavement deicing. Constr. Build. Mater. 2015, 75, 129–135. [Google Scholar] [CrossRef]

- Sassani, A.; Ceylan, H.; Kim, S.H.; Arabzadeh, A.; Taylor, P.C.; Gopalakrishnan, K. Development of carbon fiber-modified electrically conductive concrete for implementation in Des Moines International Airport. Case Stud. Constr. Mater. 2018, 8, 277–291. [Google Scholar] [CrossRef]

- James, A.; Bazarchi, E.; Chiniforush, A.A.; Aghdam, P.P.; Hosseini, M.R.; Akbarnezhad, A.; Martek, I.; Ghodoosi, F. Rebar corrosion detection, protection, and rehabilitation of reinforced concrete structures in coastal environments: A review. Constr. Build. Mater. 2019, 224, 1026–1039. [Google Scholar] [CrossRef]

- Purba, M.; Purba, A. The effect of conductive cement as an grounding media of electrode on earth resistance. ResearchGate 2019, 7, 1337–1344. [Google Scholar]

- Chiou, J.-M.; Zheng, Q.; Chung, D.D.L. Electromagnetic interference shielding by carbon fibre reinforced cement. Composites 1989, 20, 379–381. [Google Scholar] [CrossRef]

- Jung, M.J.; Lee, Y.S.; Hong, S.G.; Moon, J.H. Carbon nanotubes (CNTs) in ultra-high performance concrete (UHPC): Dispersion, mechanical properties, and electromagnetic interference (EMI) shielding effectiveness (SE). Cem. Concr. Res. 2020, 131, 106017. [Google Scholar] [CrossRef]

- KS L 5111; Flow Table for use in Tests of Hydraulic Cement. Korean Agency for Technology and Standards (KATS): Eumseong County, Republic of Korea, 2017.

- KS F 2409; Standard Test Method for Unit Weight and Air Content (Gravimetric) of Fresh Concrete. Korean Agency for Technology and Standards (KATS): Eumseong County, Republic of Korea, 2016.

- KS L 3136; Testing Method for Air Content of Hydraulic Cement Mortar. Korean Agency for Technology and Standards (KATS): Eumseong County, Republic of Korea, 2015.

- KS L ISO 679; Methods of Testing Cements-Determination of Strength. Korean Agency for Technology and Standards (KATS): Eumseong County, Republic of Korea, 2016.

- Han, B.; Guan, X.; Ou, J. Electrode design, measuring method and data acquisition system of carbon fiber cement paste piezoresistive sensors. Sens. Actuators A Phys. 2007, 135, 360–369. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Double percolation in the electrical conduction in carbon fiber reinforced cement-based materials. Carbon 2007, 45, 263–267. [Google Scholar] [CrossRef]

- Heo, G.H.; Park, J.G.; Song, K.C.; Park, J.H.; Jun, H.M. Mechanical properties of SiO2-coated carbon fiber-reinforced mortar composites with different fiber length and fiber volume fractions. Adv. Civ. Eng. 2020, 2020, 8881273. [Google Scholar] [CrossRef]

- Chen, B.; Wu, K.; Yao, W. Conductivity of carbon fiber reinforced cement-based composites. Cem. Concr. Compos. 2004, 26, 291–297. [Google Scholar] [CrossRef]

- Xie, P.; Gu, P.; Beaudoin, J.J. Electrical percolation phenomena in cement composites containing conductive fibres. J. Mater. Sci. 1996, 31, 4093–4097. [Google Scholar] [CrossRef]

- Chang, D.D.L. Cement reinforced with short carbon fibers: A multifunctional material. Compos. Part B Eng. 2000, 31, 511–526. [Google Scholar] [CrossRef]

- Lee, N.K.; Park, G.J.Y.; Jung, J.J.; Kim, S.W. A study on the electrical conductivity and electromagnetic shielding of high performance fiber reinforced cementitious composites. J. Korea Inst. Struct. Maint. Inspec. 2019, 23, 37–43. [Google Scholar]

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

- Metha, P.K. Concrete-Structure, Properties, and Materials; Prentice-Hall: Englewood Cliffs, NJ, USA, 1986; pp. 64–69. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).