Reconfigurable Terahertz Moiré Frequency Selective Surface Based on Additive Manufacturing Technology

Abstract

1. Introduction

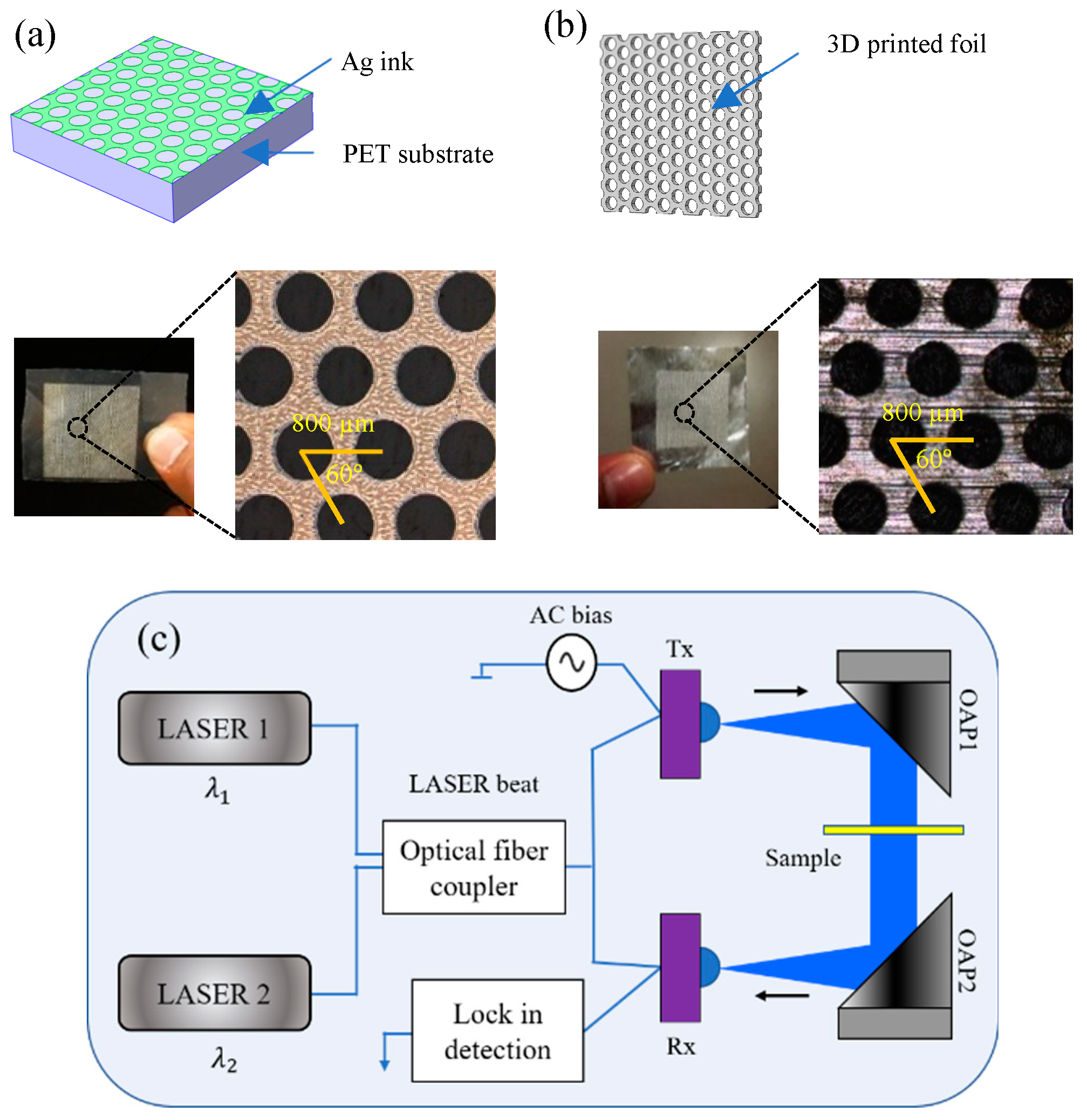

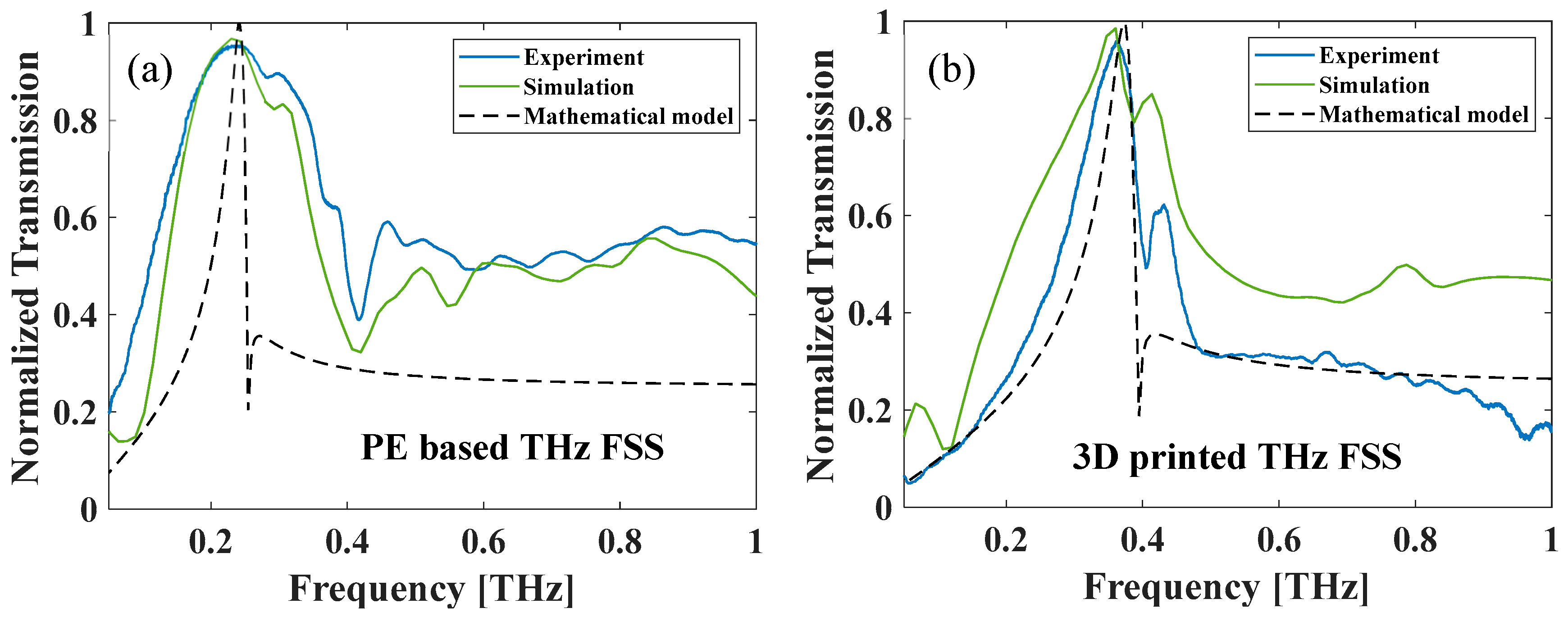

2. Modeling, Fabrication, and Experimental Characterization of THz FSSs

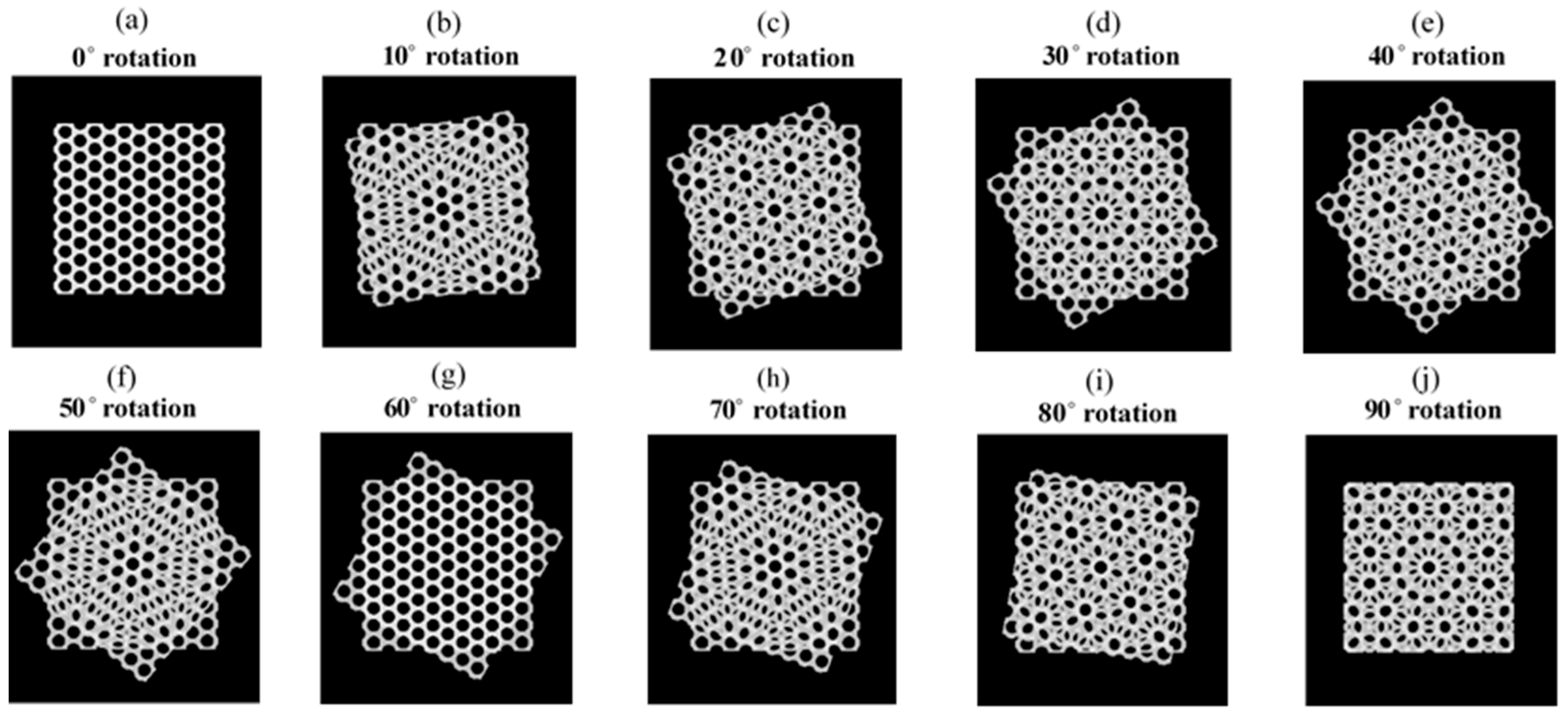

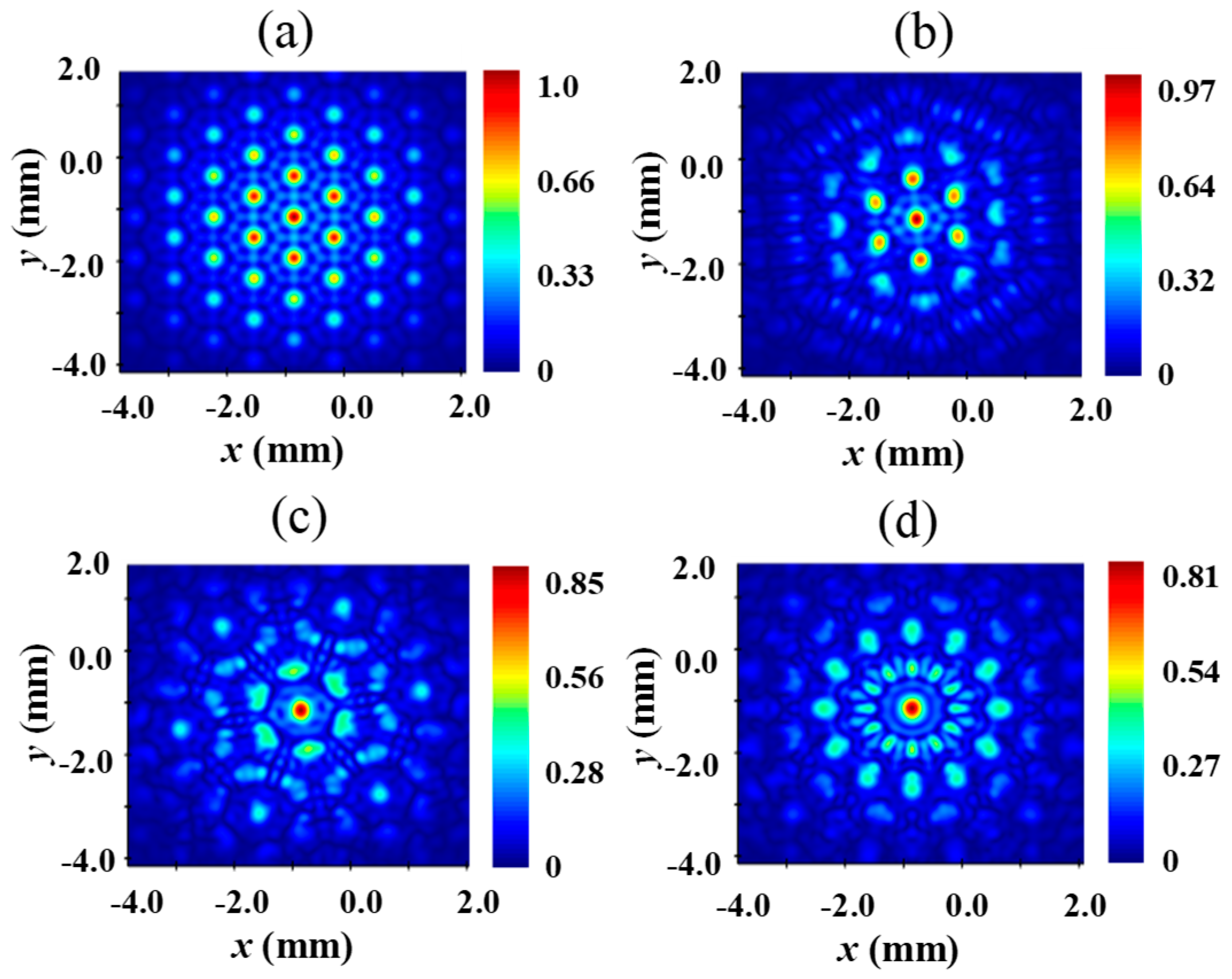

3. Analysis of Moiré THz Printed FSS

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tonouchi, M. Cutting-edge terahertz technology. Nat. Photon 2007, 1, 97–105. [Google Scholar] [CrossRef]

- Wu, J.-Y.; Xu, X.-F.; Wei, L.-F. Active metasurfaces for manipulatable terahertz technology. Chin. Phys. B 2020, 29, 094202. [Google Scholar] [CrossRef]

- Zhao, F.; Li, Z.; Li, S.; Dai, X.; Zhou, Y.; Liao, X.; Cao, J.C.; Liang, G.; Shang, Z.; Zhang, Z.; et al. Terahertz metalens of hyper-dispersion. Photon- Res. 2022, 10, 886. [Google Scholar] [CrossRef]

- Luo, L.; Chatzakis, I.; Wang, J.; Niesler, F.B.P.; Wegener, M.; Koschny, T.; Soukoulis, C.M. Broadband terahertz generation from metamaterials. Nat. Commun. 2014, 5, 3055. [Google Scholar] [CrossRef]

- Siday, T.; Vabishchevich, P.P.; Hale, L.L.; Harris, C.T.; Luk, T.S.; Reno, J.L.; Brener, I.; Mitrofanov, O. Terahertz Detection with Perfectly-Absorbing Photoconductive Metasurface. Nano Lett. 2019, 19, 2888–2896. [Google Scholar] [CrossRef]

- Anwar, R.S.; Mao, L.; Ning, H. Frequency Selective Surfaces: A Review. Appl. Sci. 2018, 8, 1689. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Nirantar, S.; Withayachumnankul, W.; Bhaskaran, M.; Sriram, S.; Al-Sarawi, S.F.; Abbott, D. Second-order terahertz bandpass frequency selective surface with miniaturized elements. IEEE Trans. Terahertz Sci. Technol. 2015, 5, 761–769. [Google Scholar] [CrossRef]

- Euler, M.; Fusco, V.; Cahill, R.; Dickie, R. 325 GHz single layer sub-millimeter wave FSS based split slot ring linear to circular polarization convertor. IEEE Trans. Antennas Propag. 2010, 58, 2457–2459. [Google Scholar] [CrossRef]

- Cheng, Y.Z.; Withayachumnankul, W.; Upadhyay, A.; Headland, D.; Nie, Y.; Gong, R.Z.; Bhaskaran, M.; Sriram, S.; Abbott, D. Ultrabroadband plasmonic absorber for Terahertz waves. Adv. Opt. Mater. 2014, 3, 376–380. [Google Scholar] [CrossRef]

- Xia, B.G.; Zhang, D.H.; Meng, J.; Huang, J.; Yao, C.F.; Zhang, J.S. Terahertz FSS for space borne passive remote sensing application. Electron. Lett. 2013, 49, 1398–1399. [Google Scholar] [CrossRef]

- Zhuldybina, M.; Ropagnol, X.; Bois, C.; Zednik, R.J.; Blanchard, F. Printing accuracy tracking with 2D optical microscopy and super-resolution metamaterial-assisted 1D terahertz spectroscopy. npj Flex. Electron. 2020, 4, 21. [Google Scholar] [CrossRef]

- Silalahi, H.M.; Chen, Y.-P.; Shih, Y.-H.; Chen, Y.-S.; Lin, X.-Y.; Liu, J.-H.; Huang, C.-Y. Floating terahertz metamaterials with extremely large refractive index sensitivities. Photonics Res. 2021, 9, 1970–1978. [Google Scholar] [CrossRef]

- Chen, H.-T.; Padilla, W.J.; Zide, J.M.O.; Gossard, A.C.; Taylor, A.J.; Averitt, R.D. Active terahertz metamaterial devices. Nature 2006, 444, 597–600. [Google Scholar] [CrossRef]

- Jia, W.; Sensale-Rodriguez, B. Terahertz metamaterial modulators based on wide-bandgap semiconductor lateral Schottky diodes. Opt. Mater. Express 2022, 12, 940–948. [Google Scholar] [CrossRef]

- Isić, G.; Vasić, B.; Zografopoulos, D.C.; Beccherelli, R.; Gajić, R. Electrically tunable critically coupled terahertz metamaterial absorber based on nematic liquid crystals. Phys. Rev. Appl. 2015, 3, 064007. [Google Scholar] [CrossRef]

- Liu, S.; Xu, F.; Zhan, J.; Qiang, J.; Xie, Q.; Yang, L.; Deng, S.; Zhang, Y. Terahertz liquid crystal programmable metasurface based on Resonance switching. Opt. Lett. 2022, 47, 1891–1894. [Google Scholar] [CrossRef]

- Yatooshi, T.; Ishikawa, A.; Tsuruta, K. Terahertz wavefront control by tunable metasurface made of graphene ribbons. Appl. Phys. Lett. 2015, 107, 053105. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, S.; Sun, L.; Shi, Q.W.; Huang, W.; Li, L.; Yang, Z. Photoinduced active terahertz metamaterials with nanostructured vanadium dioxide film deposited by sol-gel method. Opt. Express 2014, 22, 11070–11078. [Google Scholar] [CrossRef]

- Pryce, I.M.; Aydin, K.; Kelaita, Y.A.; Briggs, R.M.; Atwater, H.A. Characterization of the tunable response of highly strained compliant optical metamaterials. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2011, 369, 3447–3455. [Google Scholar] [CrossRef]

- Yang, R.; Lou, J.; Zhang, F.; Zhu, W.; Xu, J.; Cai, T.; Fu, Q.; Li, H.; Fan, Y. Active control of terahertz toroidal excitations in a hybrid metasurface with an electrically biased silicon layer. Adv. Photonics Res. 2021, 2, 2100103. [Google Scholar] [CrossRef]

- Wang, G.; Tian, H.; Wang, J.; Li, S.; Guo, W.; Zhou, Z. Electronically controlled flexible terahertz metasurface based on the loss modulation of Strontium Titanate. Opt. Lett. 2022, 47, 94–97. [Google Scholar] [CrossRef]

- Han, J.-H.; Kim, I.; Ryu, J.-W.; Kim, J.; Cho, J.-H.; Yim, G.-S.; Park, H.-S.; Min, B.; Choi, M. Rotationally reconfigurable metamaterials based on moiré phenomenon. Opt. Express 2015, 23, 17443–17449. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, S.; Liang, S.; Wu, Z.; Yang, Z.; Feng, Z.; Sun, H.; Zhou, Y.; Sun, L.; Chen, Z.; et al. Gbps Terahertz External Modulator Based on a Composite Metamaterial with a Double-Channel Heterostructure. Nano Lett. 2015, 15, 3501–3506. [Google Scholar] [CrossRef]

- Isic, G.; Sinatkas, G.; Zografopoulos, D.C.; Vasic, B.; Ferraro, A.; Beccherelli, R.; Kriezis, E.E.; Belic, M. Electrically tunable metal–semiconductor–metal terahertz metasurface modulators. IEEE J. Sel. Top. Quantum Electron. 2019, 25, 1–8. [Google Scholar] [CrossRef]

- Castro-Camus, E.; Koch, M.; Hernandez-Serrano, A.I. Additive manufacture of photonic components for the Terahertz Band. J. Appl. Phys. 2020, 127, 210901. [Google Scholar] [CrossRef]

- Irimia-Vladu, M.; Glowacki, E.D.; Sariciftci, N.S.; Bauer, S. Green materials for Electronics. Wiley-VCH 2017, 101, 75. [Google Scholar]

- Zhuldybina, M.; Ropagnol, X.; Trudeau, C.; Bolduc, M.; Zednik, R.; Blanchard, F. Contactless in situ electrical characterization method of printed electronic devices with terahertz spectroscopy. Sensors 2019, 19, 444. [Google Scholar] [CrossRef]

- Zhuldybina, M.; Ropagnol, X.; Blanchard, F. Towards in-situ quality control of conductive printable electronics: A review of possible pathways. Flex. Print. Electron. 2021, 6, 043007. [Google Scholar] [CrossRef]

- Furlan, W.D.; Ferrando, V.; Monsoriu, J.A.; Zagrajek, P.; Czerwińska, E.; Szustakowski, M. 3D printed diffractive terahertz lenses. Opt. Lett. 2016, 41, 1748–1751. [Google Scholar] [CrossRef]

- Hernandez-Serrano, A.I.; Weidenbach, M.; Busch, S.F.; Koch, M.; Castro-Camus, E. Fabrication of gradient-refractive-index lenses for terahertz applications by three-dimensional printing. J. Opt. Soc. Am. B 2016, 33, 928–931. [Google Scholar] [CrossRef]

- Ahmad, R.; Zhuldybina, M.; Ropagnol, X.; Blanchard, F. Terahertz metasurface based on additive manufacturing technology. In Proceedings of the 2022 Photonics North (PN), Niagara Falls, ON, Canada, 24–26 May 2022; p. 1. [Google Scholar] [CrossRef]

- Sushko, O.; Pigeon, M.; Donnan, R.S.; Kreouzis, T.; Parini, C.G.; Dubrovka, R. Comparative study of sub-THz FSS filters fabricated by inkjet printing, microprecision material printing, and photolithography. IEEE Trans. Terahertz Sci. Technol. 2017, 7, 184–190. [Google Scholar] [CrossRef]

- Yurduseven, O.; Ye, S.; Fromenteze, T.; Wiley, B.J.; Smith, D.R. 3D conductive polymer printed metasurface antenna for Fresnel focusing. Designs 2019, 3, 46. [Google Scholar] [CrossRef]

- Yudistira, H.T.; Tenggara, A.P.; Nguyen, V.D.; Kim, T.T.; Prasetyo, F.D.; Choi, C.G.; Choi, M.; Byun, D. Fabrication of terahertz metamaterial with high refractive index using high-resolution electrohydrodynamic jet printing. Appl. Phys. Lett. 2013, 103, 211106. [Google Scholar] [CrossRef]

- Li, J.; Shah, C.M.; Withayachumnankul, W.; Ung, B.S.-Y.; Mitchell, A.; Sriram, S.; Bhaskaran, M.; Chang, S.; Abbott, D. Mechanically tunable terahertz metamaterials. Appl. Phys. Lett. 2013, 102, 121101. [Google Scholar] [CrossRef]

- He, F.; Zhou, Y.; Ye, Z.; Cho, S.-H.; Jeong, J.; Meng, X.; Wang, Y. Moiré patterns in 2D materials: A Review. ACS Nano 2021, 15, 5944–5958. [Google Scholar] [CrossRef]

- Iwami, K.; Ogawa, C.; Nagase, T.; Ikezawa, S. Demonstration of focal length tuning by rotational varifocal moiré metalens in an IR-a wavelength. Opt. Express 2020, 28, 35602–35614. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ouyang, C.; Xu, Q.; Su, X.; Yang, Q.; Ma, J.; Li, Y.; Tian, Z.; Gu, J.; Liu, L.; et al. Moiré-driven electromagnetic responses and magic-angle in sandwiched hyperbolic metasurface. Photonics Res. 2022, 10, 2056–2065. [Google Scholar] [CrossRef]

- Kim, D.H.; Mohyuddin, W.; Woo, D.S.; Choi, H.C.; Kim, K.W. Design of a 75–140 GHz high-pass printed circuit board dichroic filter. Rev. Sci. Instrum. 2017, 88, 034704. [Google Scholar] [CrossRef]

- Park, J.W.; Kang, B.H.; Kim, H.J. A review of low-temperature solution-processed metal oxide thin-film transistors for Flexible Electronics. Adv. Funct. Mater. 2019, 30, 1904632. [Google Scholar] [CrossRef]

- Chen, C.-C. Transmission of microwave through perforated flat plates of finite thickness. IEEE Trans. Microw. Theory Tech. 1973, 21, 1–6. [Google Scholar] [CrossRef]

- Jin, Y.-S.; Kim, G.-J.; Jeon, S.-G. Terahertz dielectric properties of polymers. J. Korean Phys. Soc. 2006, 49, 513–517. [Google Scholar]

| Parameters | PE-Based THz FSS | 3D-Printed THz FSS |

|---|---|---|

| Lattice type | Triangular | Triangular |

| Fabrication method | R2R flexography | Powder bed fusion-selective laser melting system |

| Material | Ink: Ag Substrate: PET | Aluminum foil |

| Thickness | Ink: 352 nm Substrate: 125 µm | 100 µm |

| Conductivity | 4.40 106 S/m | 2.50 107 S/m |

| Peak resonance frequency (experimental) | 0.235 THz | 0.365 THz |

| Bandwidth (experimental) | 250 GHz | 180 GHz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, R.; Zhuldybina, M.; Ropagnol, X.; Trinh, N.D.; Bois, C.; Schneider, J.; Blanchard, F. Reconfigurable Terahertz Moiré Frequency Selective Surface Based on Additive Manufacturing Technology. Appl. Sci. 2023, 13, 3302. https://doi.org/10.3390/app13053302

Ahmad R, Zhuldybina M, Ropagnol X, Trinh ND, Bois C, Schneider J, Blanchard F. Reconfigurable Terahertz Moiré Frequency Selective Surface Based on Additive Manufacturing Technology. Applied Sciences. 2023; 13(5):3302. https://doi.org/10.3390/app13053302

Chicago/Turabian StyleAhmad, Redwan, Mariia Zhuldybina, Xavier Ropagnol, Ngoc Duc Trinh, Chloé Bois, Juan Schneider, and François Blanchard. 2023. "Reconfigurable Terahertz Moiré Frequency Selective Surface Based on Additive Manufacturing Technology" Applied Sciences 13, no. 5: 3302. https://doi.org/10.3390/app13053302

APA StyleAhmad, R., Zhuldybina, M., Ropagnol, X., Trinh, N. D., Bois, C., Schneider, J., & Blanchard, F. (2023). Reconfigurable Terahertz Moiré Frequency Selective Surface Based on Additive Manufacturing Technology. Applied Sciences, 13(5), 3302. https://doi.org/10.3390/app13053302