Ceramic Matrix Composites for Aero Engine Applications—A Review

Abstract

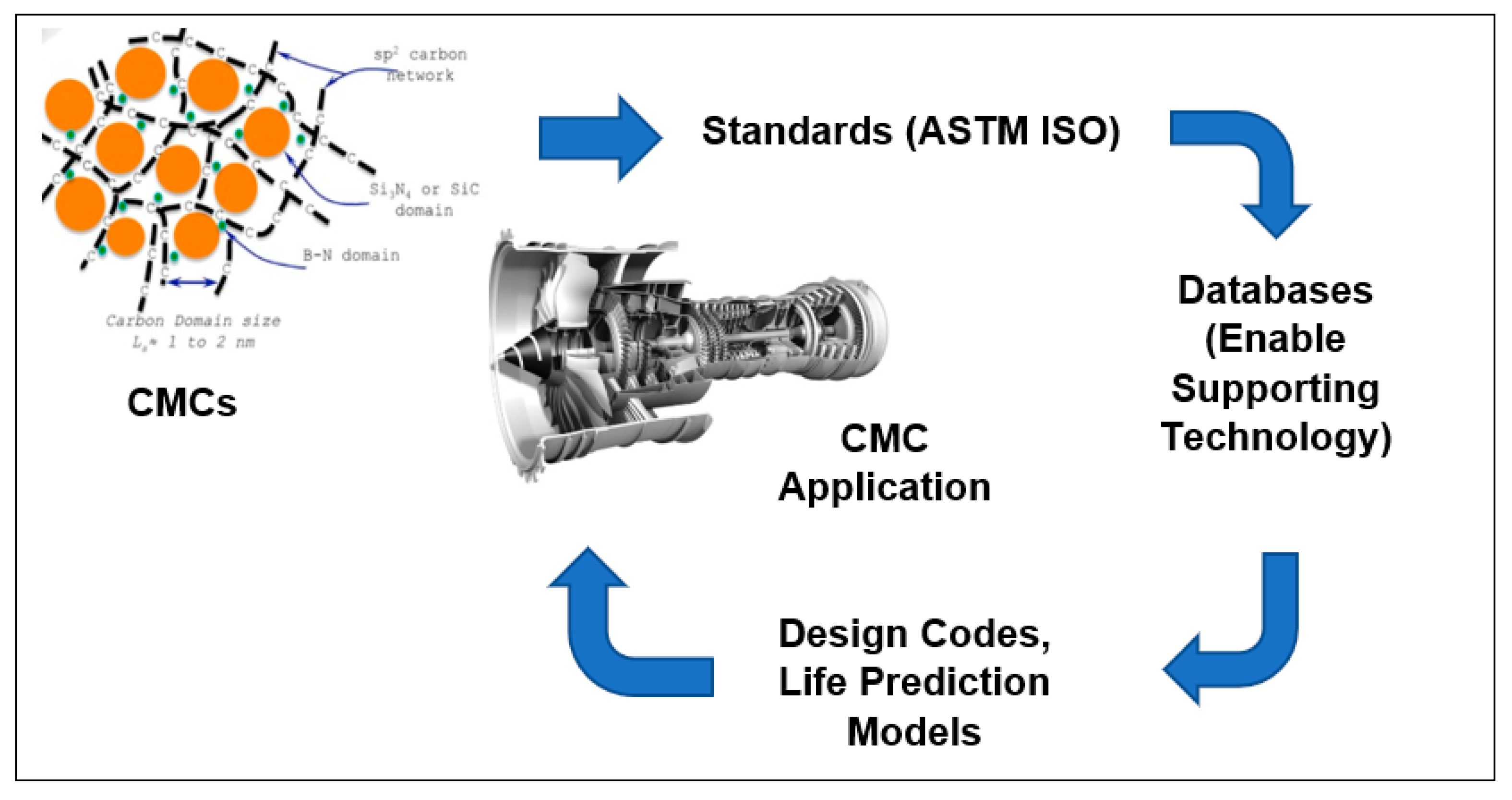

1. Introduction

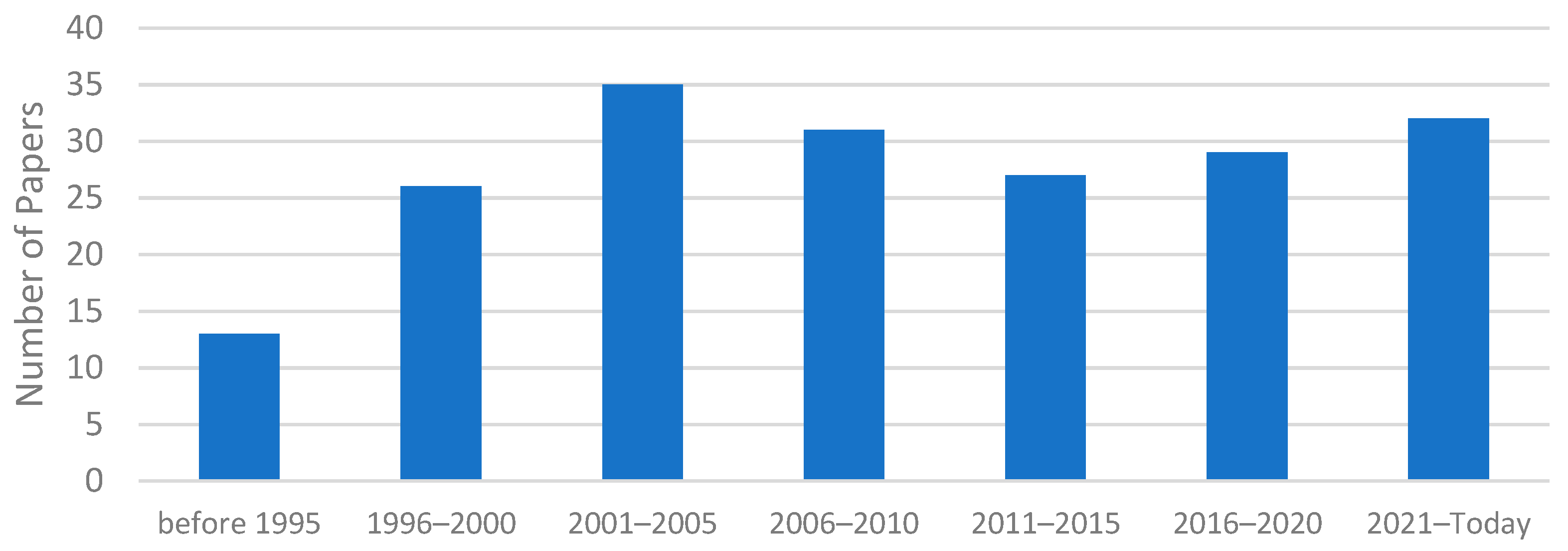

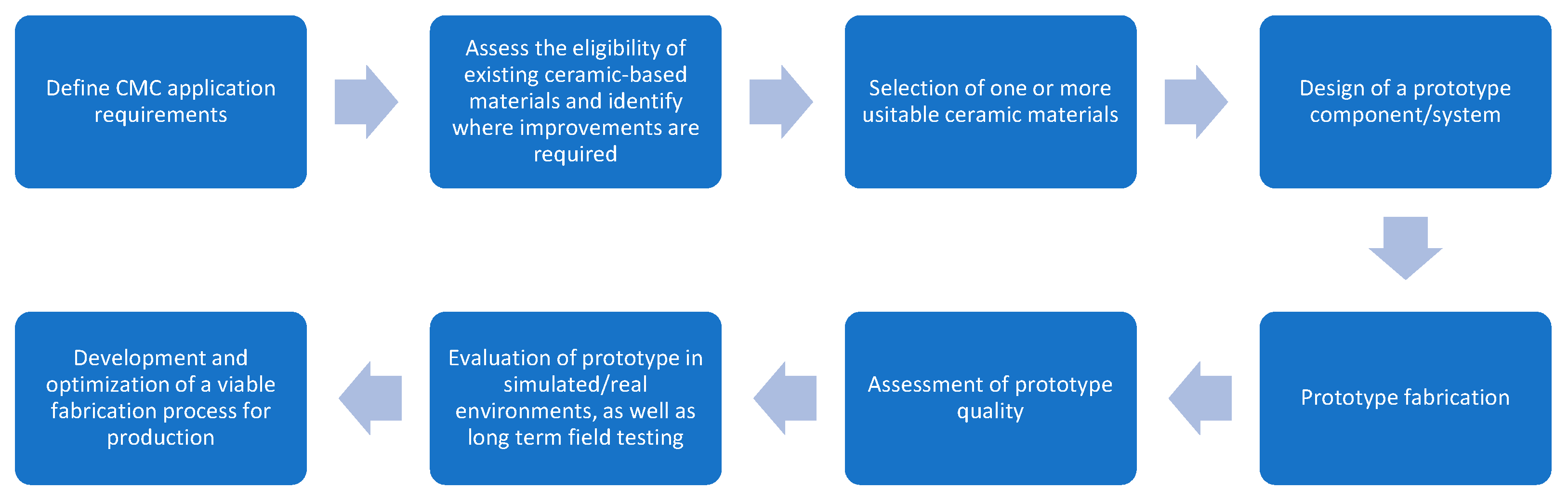

2. Methodology

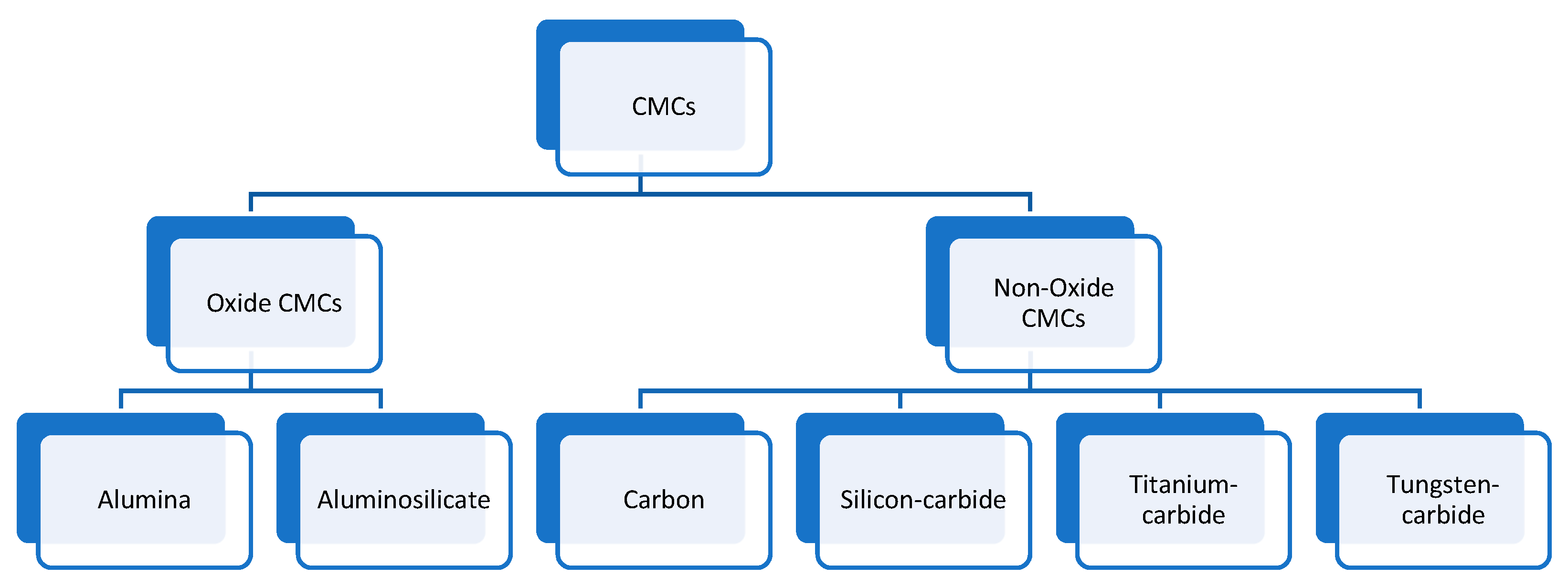

3. Materials Classification

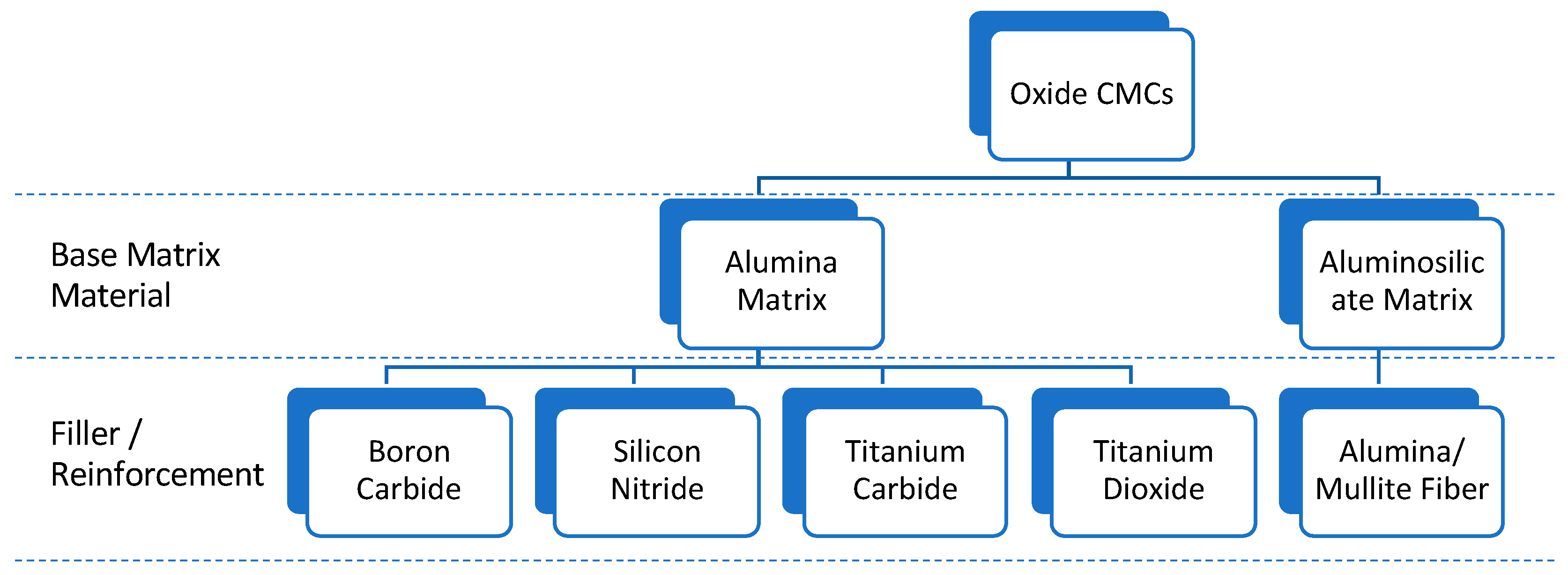

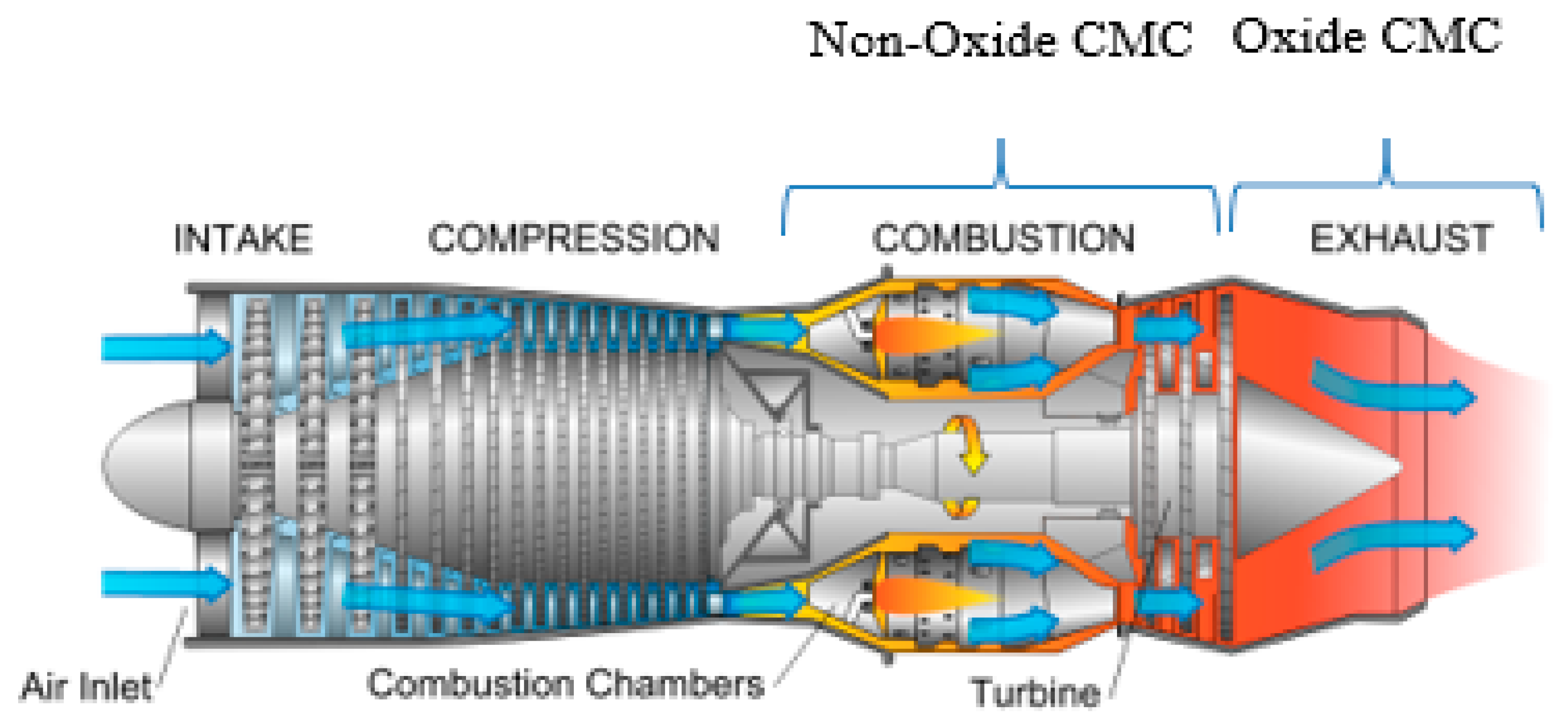

4. Oxide CMCs

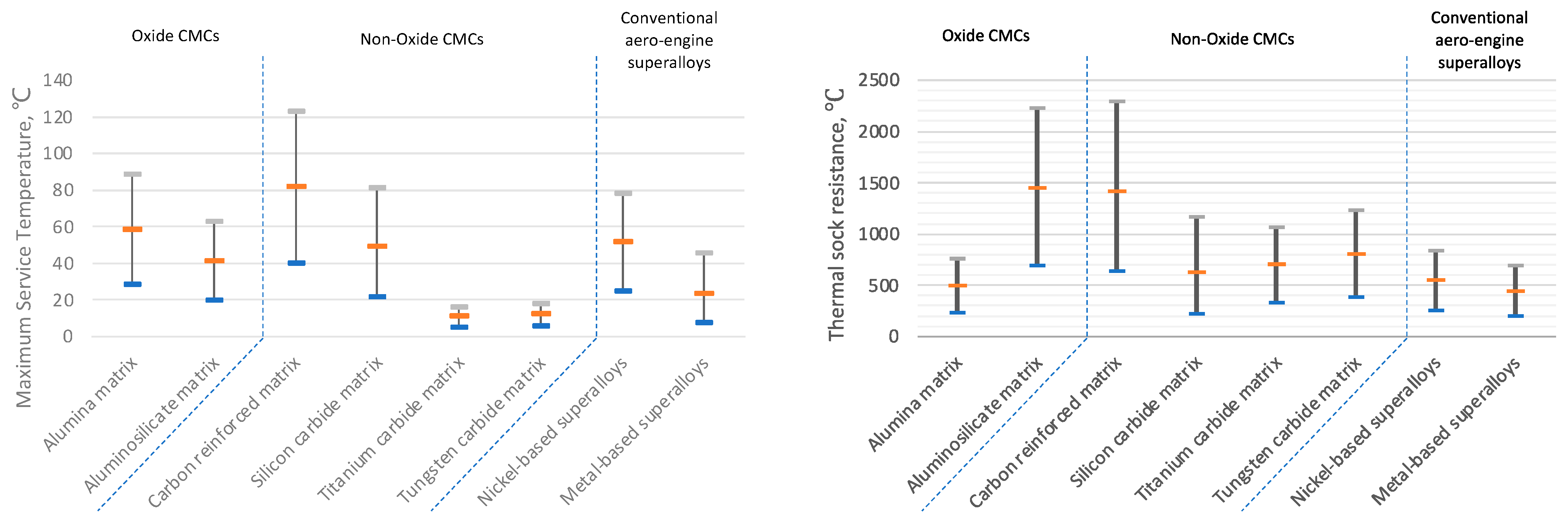

4.1. Alumina Matrix CMCs

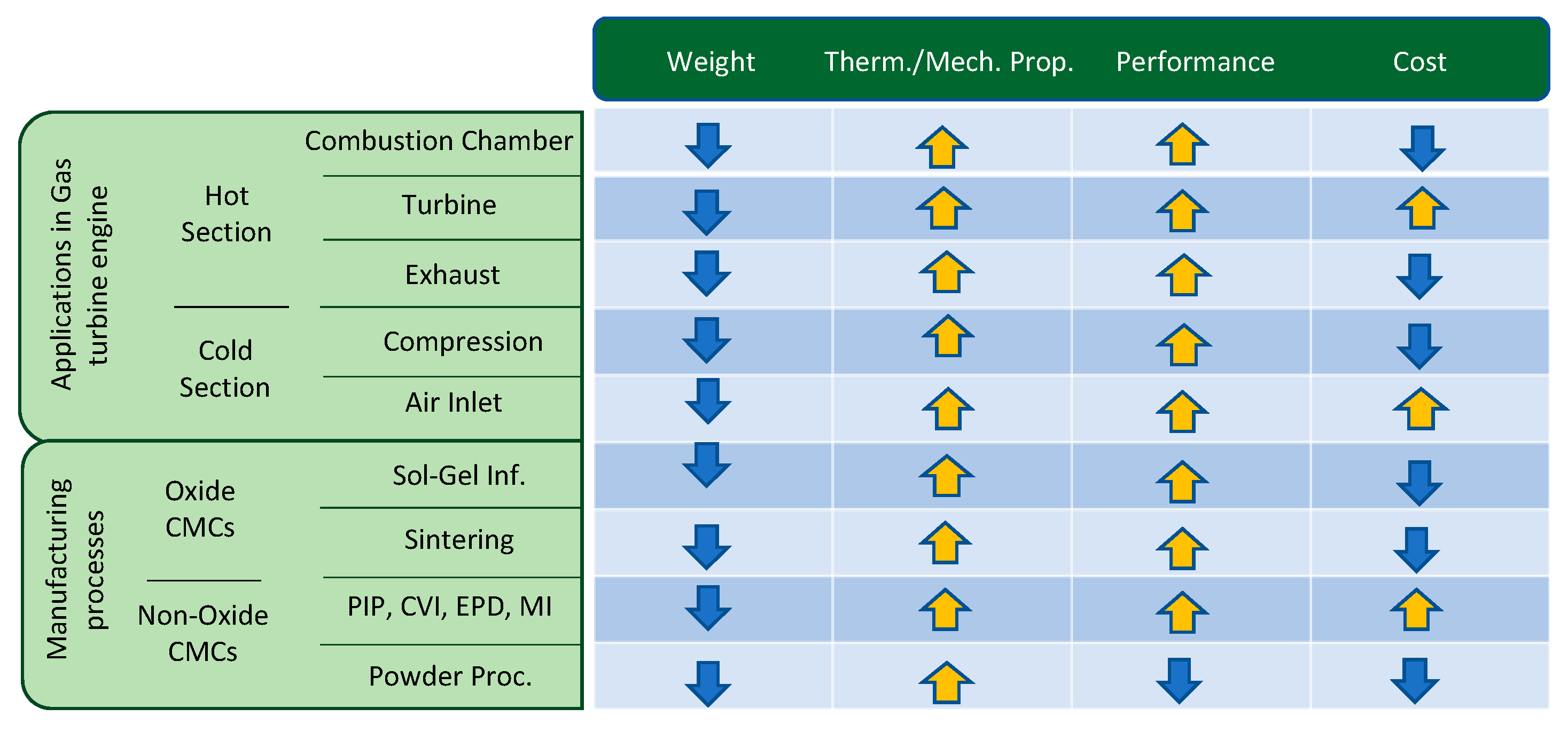

- Alumina and Boron Carbide

- Alumina and Silicon Nitride

- Alumina and Titanium Carbide

- Alumina and Titanium Dioxide

4.2. Aluminosilicate Matrix CMCs

- Aluminosilicate matrix and alumina/mullite fiber CMCs

5. Non-Oxide CMCs

5.1. Carbon Matrix CMCs

- Carbon/Carbon matrix CMCs

- Carbon/Resin matrix CMCs

- Carbon/Metal matrix CMCs

5.2. Silicon Carbide Matrix CMCs

5.3. Titanium Carbide CMCs

5.4. Tungsten Carbide CMCs

- Tungsten Carbide-Carbon CMCs.

- Nickel and Nickel/Chrome bonded Tungsten carbide CMCs

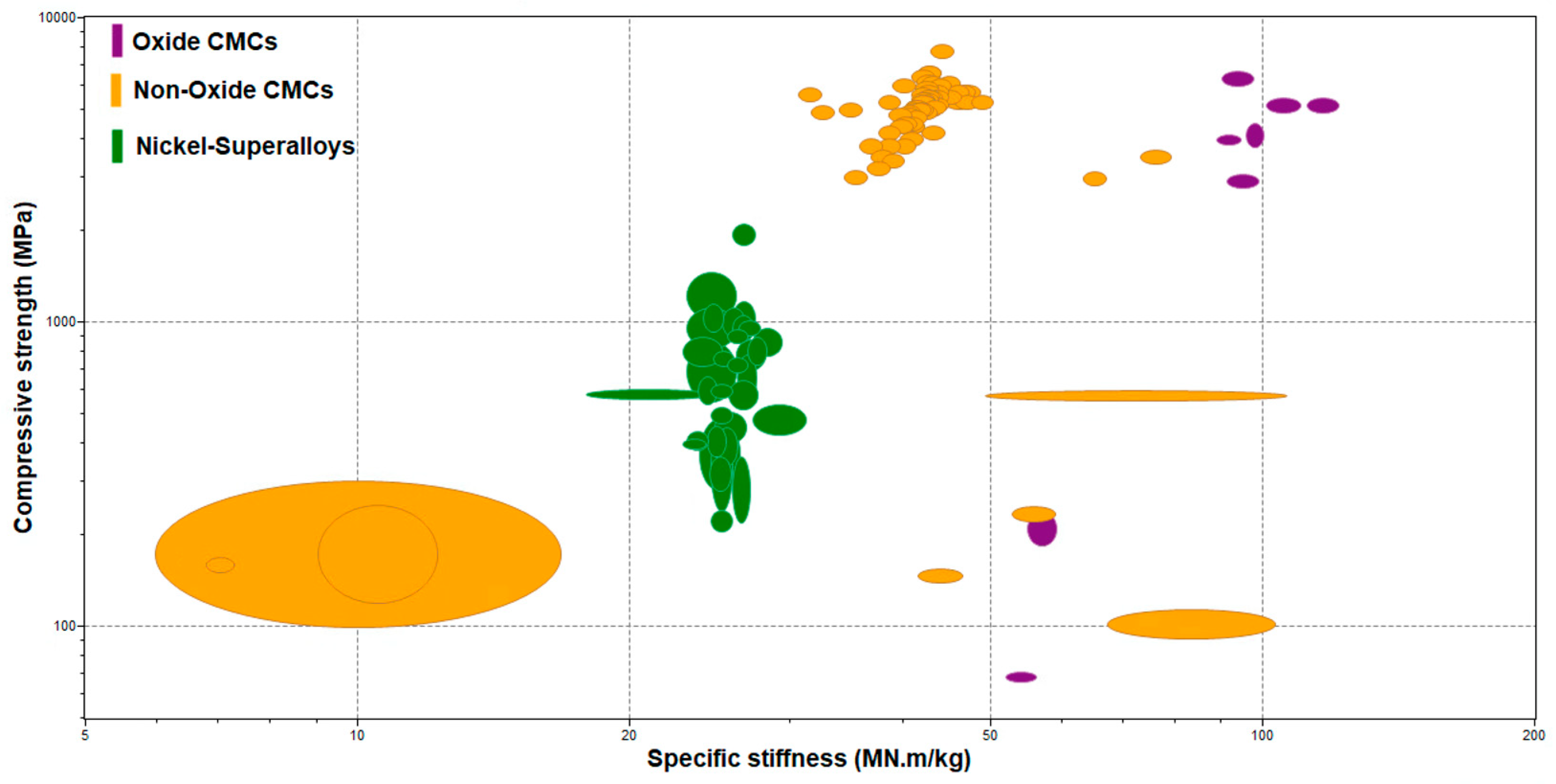

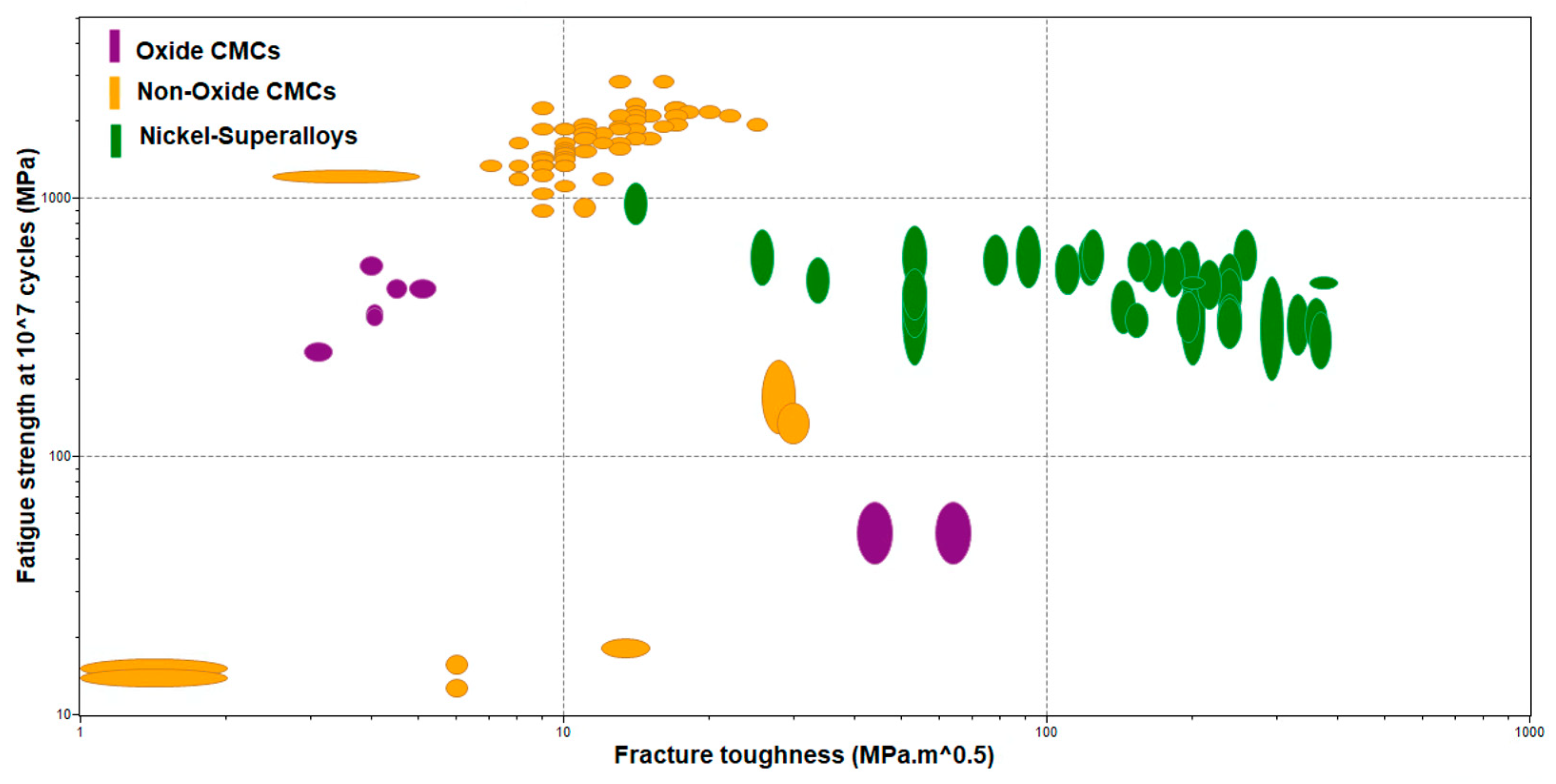

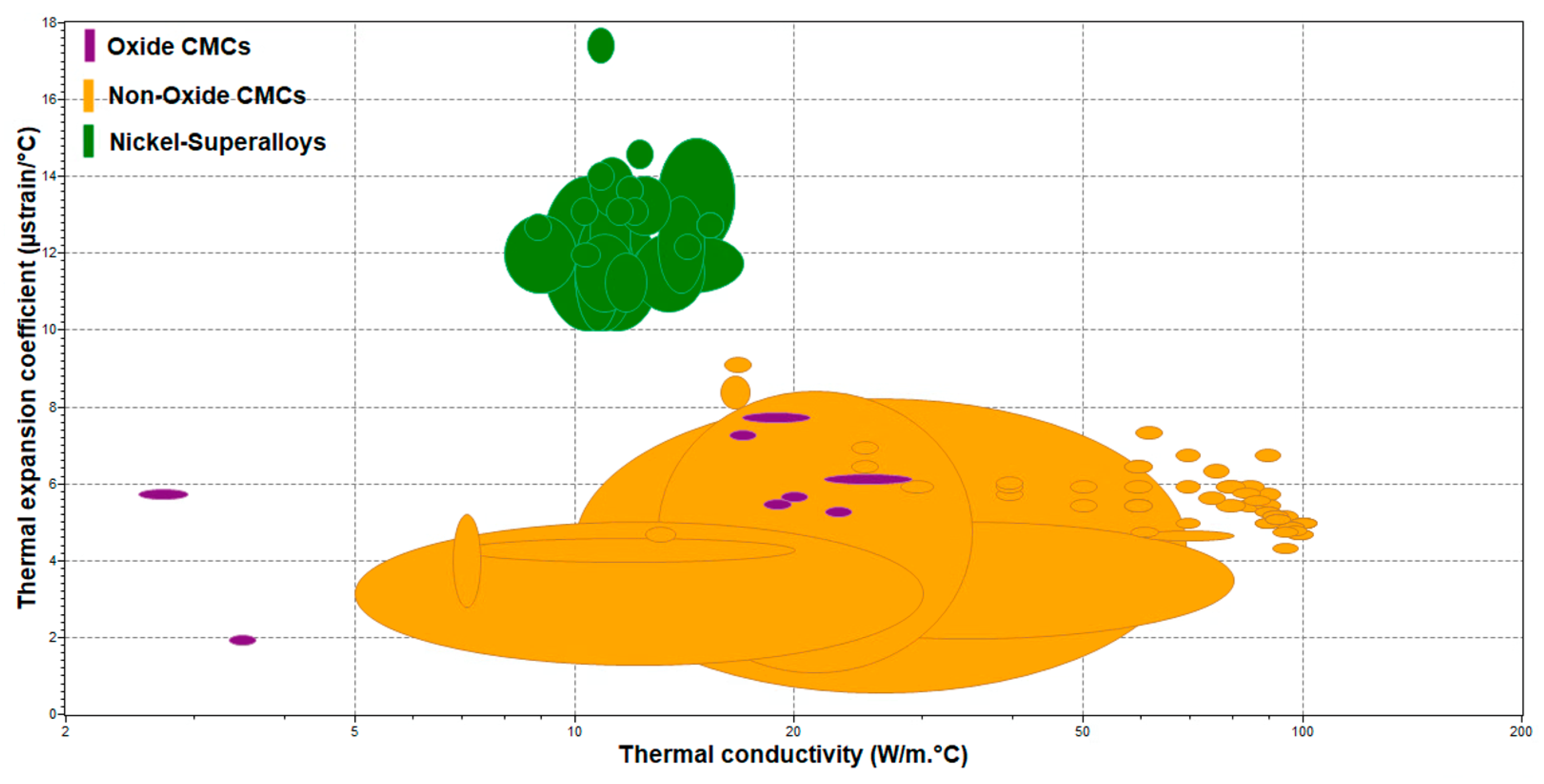

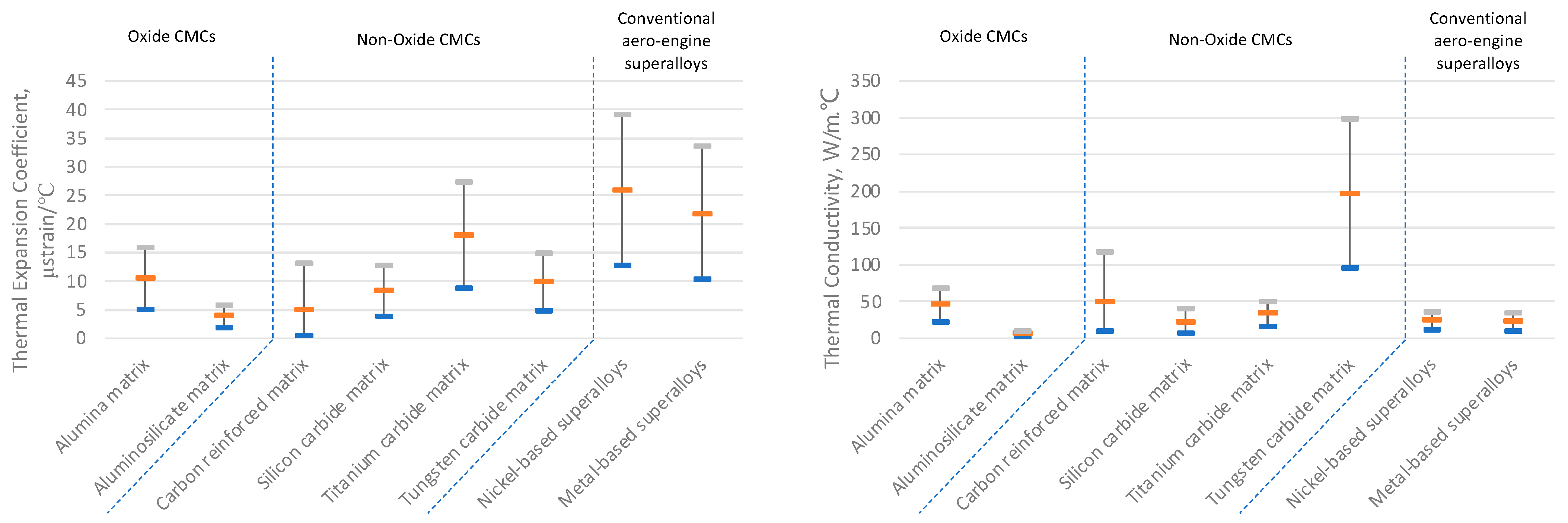

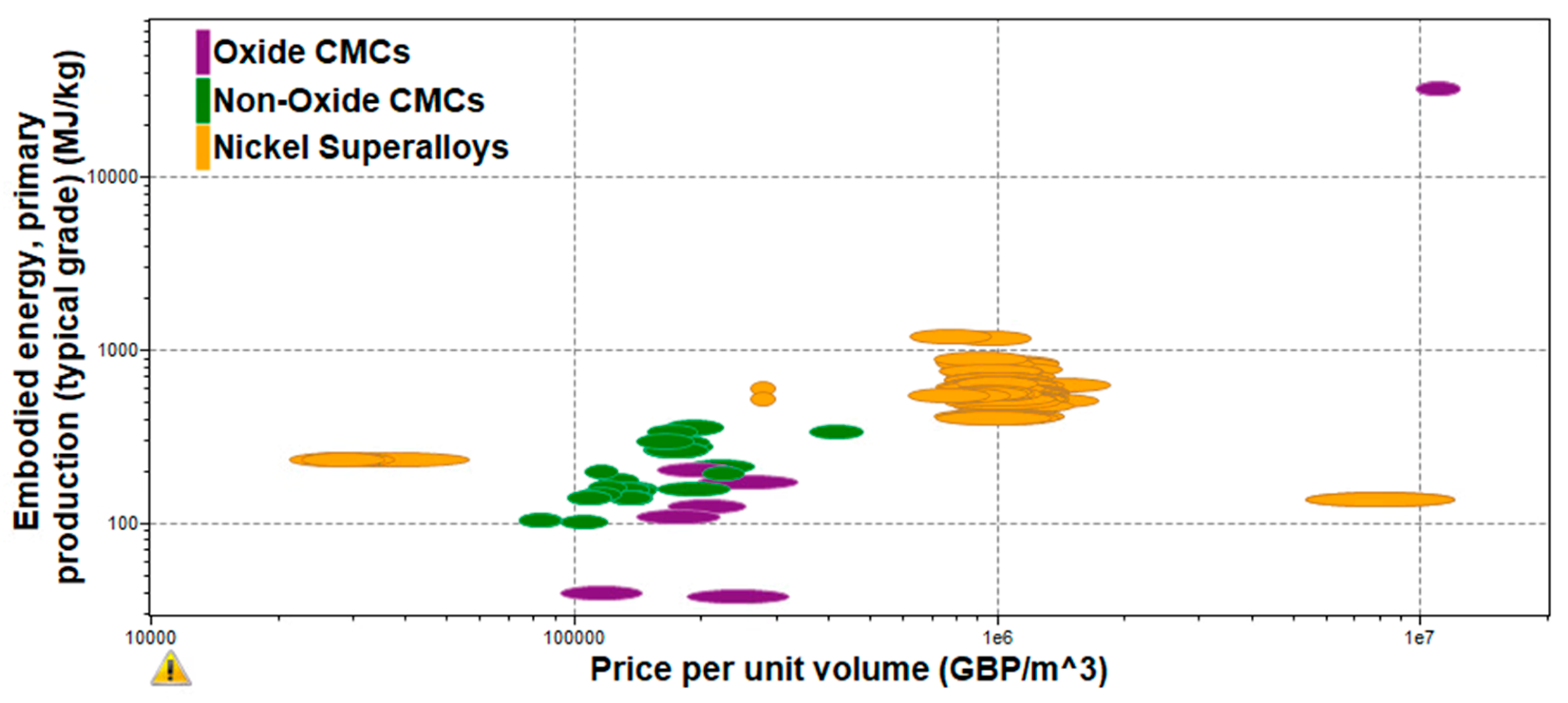

6. Mechanical and Thermal Properties of CMCs

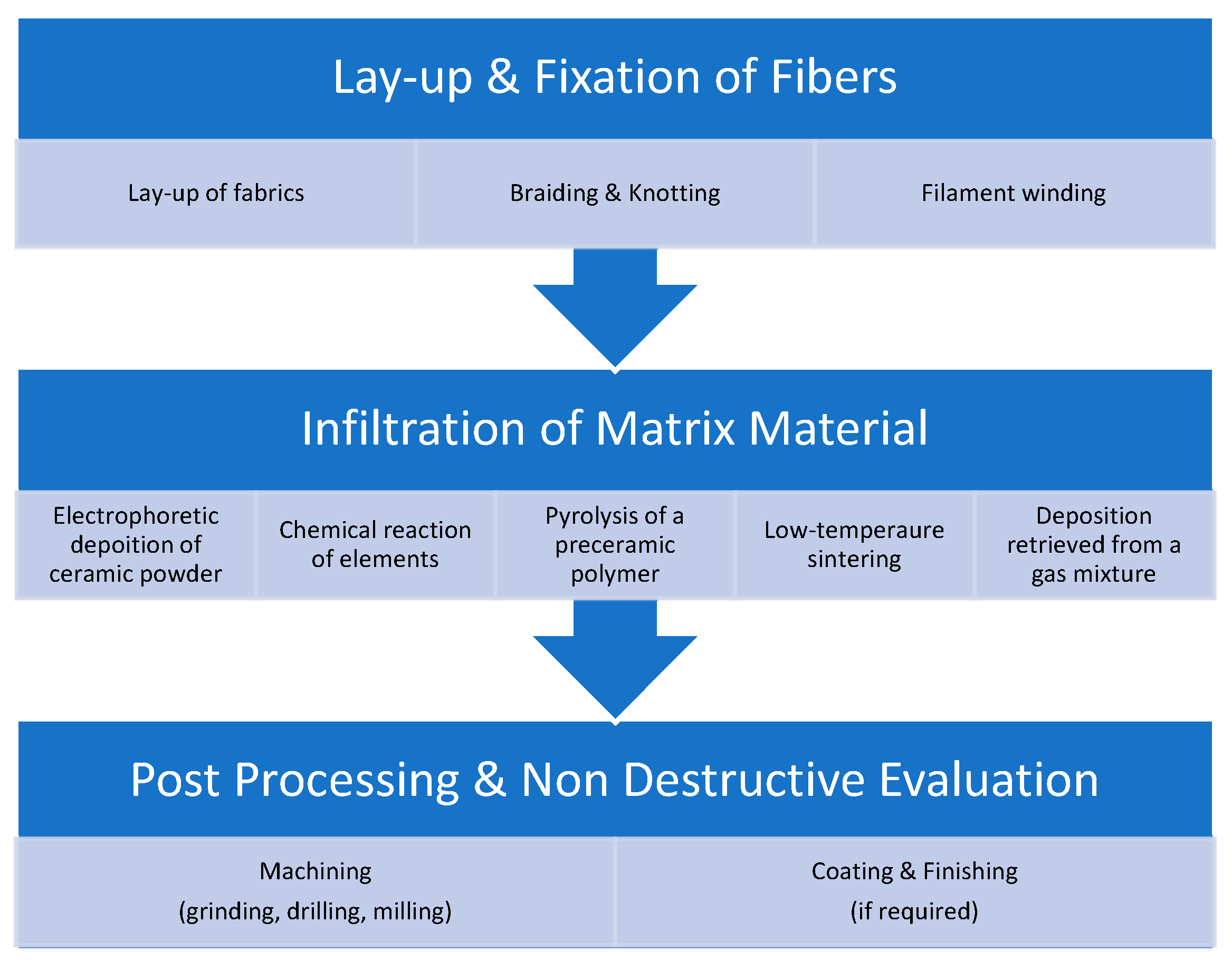

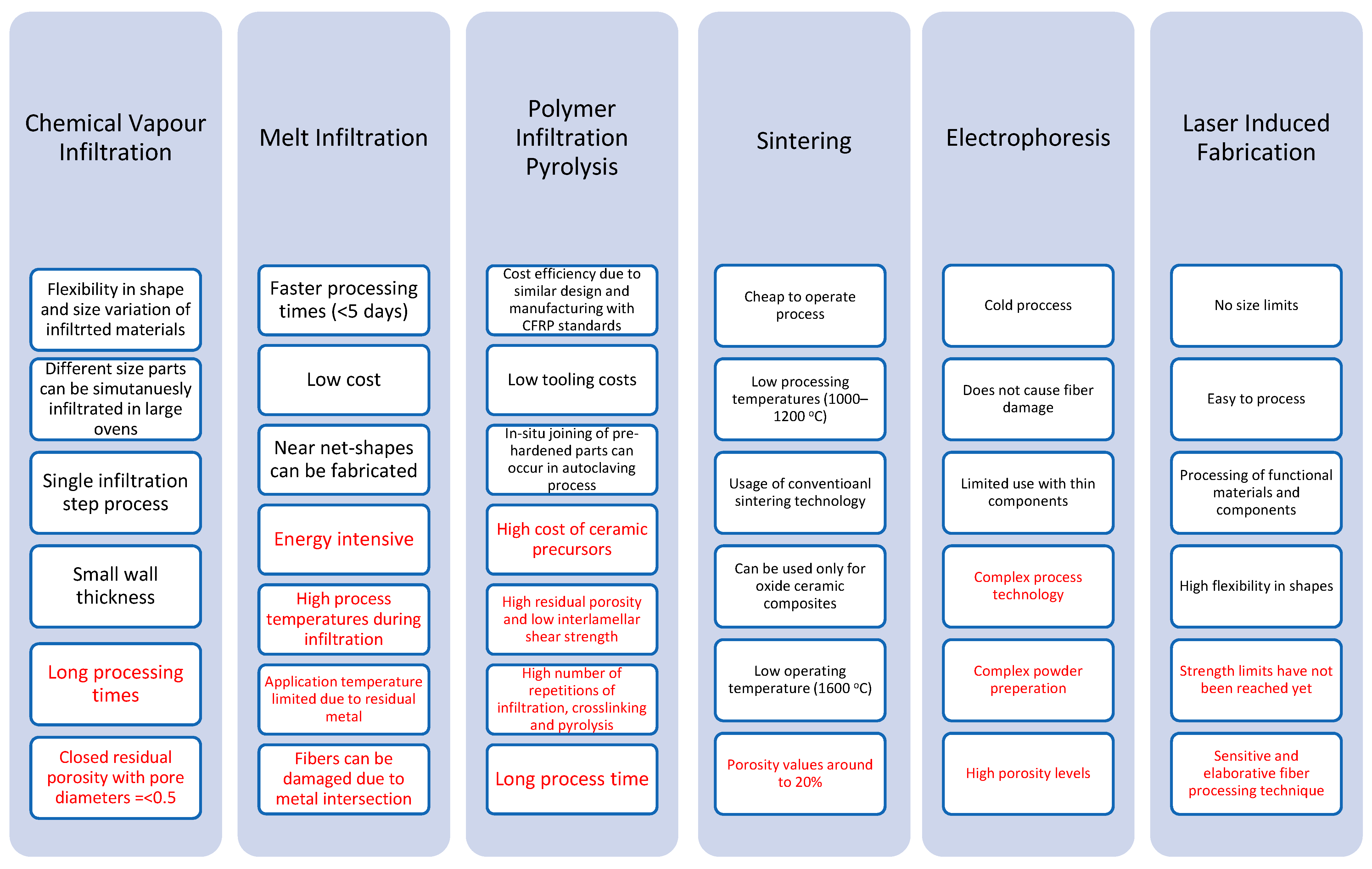

7. Manufacturing Processes for CMCs

7.1. Electrophoretic Deposition of a Ceramic Powder

7.2. Matrix Deposition/Infiltration from a Gas Phase

7.3. Melt Infiltration

7.4. Matrix Forming via Pyrolysis of C- & Si-Containing Polymers

7.5. Matrix Forming via Sol-Gel

7.6. Matrix Forming via Sintering

7.7. Matrix Forming via Chemical Reaction

7.8. Selecting the Most Appropriate Manufacturing System

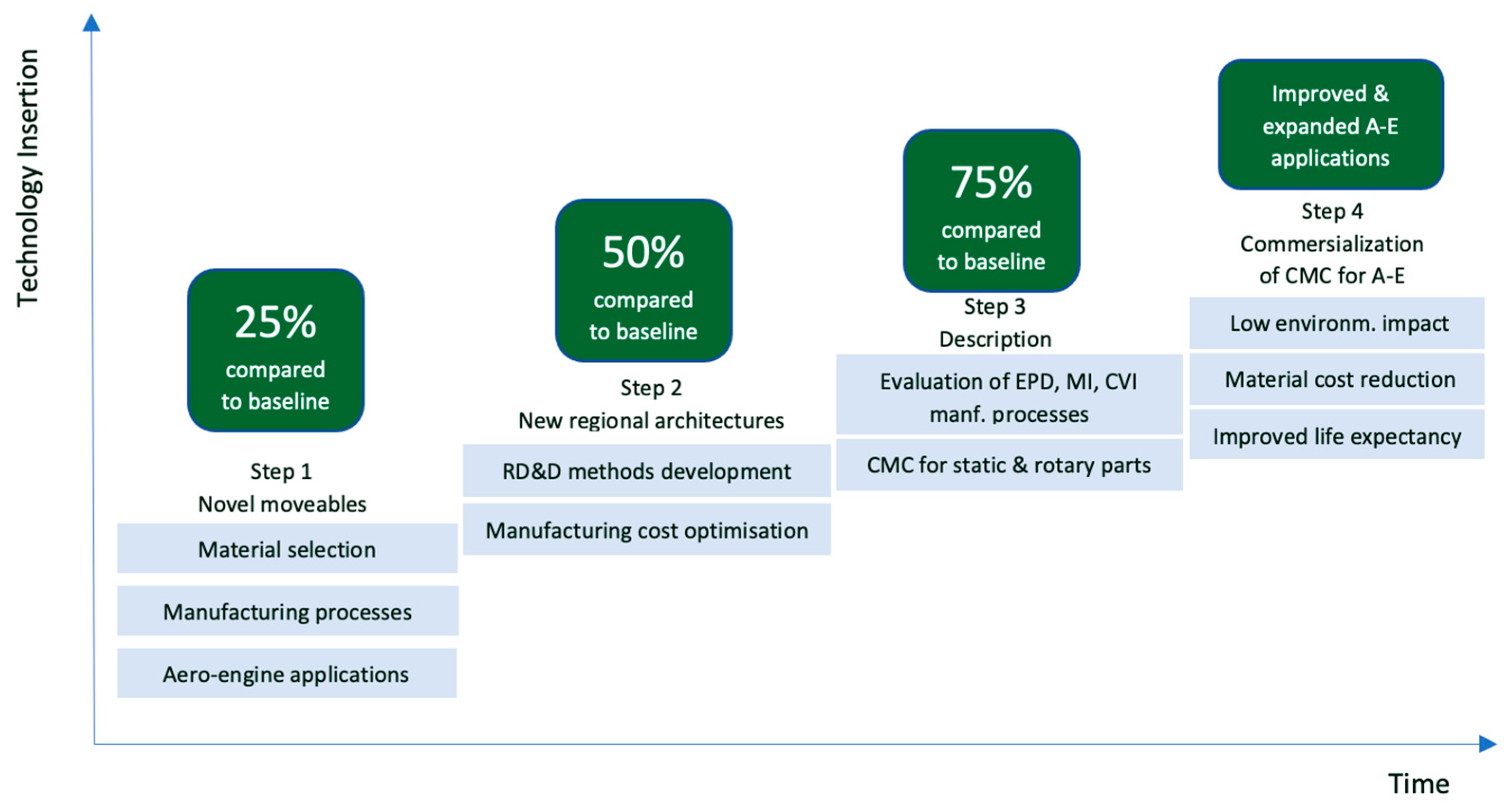

8. The Future of CMCs

8.1. CMC Adoption Roadmap

8.2. Technology Considerations

9. Outcome

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guglielmi, P.; Nunes, G.; Hablitzel, M.; Hotza, D.; Janssen, R. Production of Oxide Ceramic Matrix Composites by a Prepreg Technique. Mater. Sci. Forum 2012, 727–728, 556–561. [Google Scholar] [CrossRef]

- Rudinger, A.; Noth, A.; Pritzkow, W. Oxide Ceramic Matrix Composites-Manufacturing, Machining, Properties, and Industrial Applications. Technol. Insights Ceram. Appl. 2015, 23, 347–362. [Google Scholar]

- Grigorev, S.N.; Fedorov, S.V.; Hamdy, K. Materials, properties, manufacturing methods and cutting performance of innovative ceramic cutting tools—A review. Manuf. Revolut. 2019, 6, 1–27. [Google Scholar] [CrossRef]

- Zoli, L.; Vinci, A.; Galizia, P.; Melandri, C.; Sciti, D. On the thermal shock resistance and mechanical properties of novel unidirectional UHTCMCs for extreme environments. Sci. Rep. 2018, 8, 9148. [Google Scholar] [CrossRef] [PubMed]

- Pritzkow, W.E.; Almeida, R.S.; Mateus, L.B.; Tushtev, K.; Rezwan, K. All-oxide ceramic matrix composites (OCMC) based on low-cost 3M Nextel™ 610 fabrics. J. Eur. Ceram. Soc. 2020, 41, 3177–3187. [Google Scholar] [CrossRef]

- Krenkel, W. Ceramic Matrix Composites: Fiber Reinforced Ceramics and Their Applications; John Wiley & Sons: Hoboken, NJ, USA, 2008; Volume 102, pp. 420–431. [Google Scholar]

- Vijaya, R.B.; Elanchezhian, C.; Jaivignesh, M.; Rajesh, S.; Parswajinan, C.; Siddique, A. Evaluation of mechanical properties of aluminum alloy–alumina–boron carbide metal matrix composites. Mater. Des. 2014, 58, 332–338. [Google Scholar] [CrossRef]

- Diaz, O.G.; Luna, G.G.; Liao, Z.; Axinte, D. The new challenges of machining Ceramic Matrix Composites (CMCs): Review of surface integrity. Int. J. Mach. Tools Manuf. 2019, 139, 3–30. [Google Scholar]

- Mungiguerra, S.; Martino, G.D.; Savino, R. Ultra-High-Temperature Ceramic Matrix Composites in hybrid rocket propulsion environment. AIAA Propuls. Energy Forum 2018, 15, 129–135. [Google Scholar]

- Hickman, R.; Mc Kechnie, T.; Agarwal, A. Net shape fabrication of high-temperature materials for rocket engine components. In Proceedings of the 37th Joint Propulsion Conference and Exhibit, Salt Lake City, UT, USA, 8–11 July 2001; Volume 31, p. 3435. [Google Scholar]

- Pandey, V.K. Fracture Behavior of Aluminum/Alumina and Aluminum/Boron Carbide Functionally Graded Materials. Ph.D. Thesis, Indian Institute of Technology Delhi (IITD), New Delhi, India, 2019; pp. 247–254. [Google Scholar]

- Glass, D. Ceramic matrix composite (CMC) thermal protection systems (TPS) and hot structures for hypersonic vehicles. In Proceedings of the 15th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, Dayton, OH, USA, 28 April–1 May 2008. [Google Scholar]

- Brennan, J.J. Interfacial characterization of a slurry-cast melt-infiltrated SiC/SiC ceramic-matrix composite. Acta Mater. 2000, 48, 4619–4628. [Google Scholar] [CrossRef]

- Hillig, W.B. Melt Infiltration Approach to Ceramic Matrix Composites. J. Am. Ceram. Soc. 2005, 71, 96–99. [Google Scholar] [CrossRef]

- Chae, K.; Chun, D.; Kim, D.; Bai, Y.; Eun, K.J. Microstructural Evolution During the Infiltration Treatment of Titanium Carbide-Iron Composite. Am. Ceram. Soc. 1990, 73, 1979–1987. [Google Scholar] [CrossRef]

- Krstic, Z.; Krstic, V.D. Silicon nitride: The engineering material of the future. J. Mater. Sci. 2011, 47, 535–552. [Google Scholar] [CrossRef]

- Han, W.; Li, Y.; Chen, G.; Yang, Q. Effect of sintering additive composition on microstructure and mechanical properties of silicon nitride. Mater. Sci. Eng. A 2017, 700, 19–24. [Google Scholar] [CrossRef]

- Volkmann, E.; Tushtev, K.; Koch, D.; Wilhelmi, C.; Goring, J.; Rezwan, K. Assessment of three oxide/oxide ceramic matrix composites: Mechanical performance and effects of heat treatments. Compos. Part A Appl. Sci. Manuf. 2015, 68, 19–28. [Google Scholar] [CrossRef]

- Wilson, D.M.; Visser, L.R. High-performance oxide fibers for metal and ceramic composites. Compos.-Part A Appl. Sci. Manuf. 2013, 32, 1143–1153. [Google Scholar] [CrossRef]

- Jefferson, G.; Keller, K.A.; Hay, R.S.; Kerans, R.J. Oxide/oxide composites with fiber coatings. Ceram. Matrix Compos. 2008, 8, 187–204. [Google Scholar]

- Keller, K.; Jefferson, K.G.; Kerans, R. Oxide-oxide composites. In Handbook of Ceramic Composites; Bansal, N., Ed.; Kluwer Academic Publishers: Boston, MA, USA, 2005; Volume 32, pp. 377–421. [Google Scholar]

- Kaya, C.; Kaya, F.; Butler, E.G.; Boccaccini, A.R.; Chawla, K.K. Development and characterization of high-density oxide fiber-reinforced oxide ceramic matrix composites with improved mechanical properties. J. Eur. Ceram. Soc. 2009, 9, 1631–1639. [Google Scholar] [CrossRef]

- Chawla, K.K. Ceramic Matrix Composite Materials Interface. In Ceramic Matrix Composites, 2nd ed.; Chawla, K.K., Ed.; Springer Science & Business Media: Boston, MA, USA, 2003; Volume 12, pp. 139–167. [Google Scholar]

- Park, S.J.; Seo, M.K. Element and Processing. Interface Sci. Technol. 2011, 18, 431–499. [Google Scholar]

- Pelaez, M.; Nolan, N.T.; Pillai, S.C.; Seery, M.K.; Falaras, P.; Kontos, A.G.; Dunlop, P.S.; Hamilton, J.W.; Byrne, J.A.; O’shea, K.; et al. A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl. Catal. B Environ. 2012, 125, 331–349. [Google Scholar] [CrossRef]

- Wanga, L.; Liua, W.; Golub, J.; Zhanga, Q.; Zhou, F.; Wanga, Y.; Ruiqing, C. Study on the wear resistance of graphene modified nanostructured Al2O3/TiO2 coatings. Appl. Surf. Sci. 2019, 492, 272–279. [Google Scholar] [CrossRef]

- Poges, S.; Monteleone, C.; Petroski, K.; Richards, G.; Suib, S.L. Preparation, and characterization of an oxide-oxide continuous fiber-reinforced ceramic matrix composite with a zinc oxide interphase. Ceram. Int. 2017, 43, 17121–17127. [Google Scholar] [CrossRef]

- Aviation, G.E. GE Successfully Tests World’s First Rotating Ceramic Matrix Composite Material for Next-Gen Combat Engine. 2015. Available online: https://www.geaerospace.com/press-release/military-engines/ge-successfully-tests-worlds-first-rotating-ceramic-matrix-composite (accessed on 31 December 2022).

- Parlier, M.; Ritti, M.; Jankowiak, A. Potential and Perspectives for Oxide/Oxide Composites. Aerosp. Lab 2011, 3, 1–12. [Google Scholar]

- Tye, A.; Lewis, M.H. Evaluation of novel interphases for oxide/oxide ceramic matrix composites. Br. Ceram. Trans. 1999, 98, 286–290. [Google Scholar] [CrossRef]

- Baldus, H.; Jansen, M. Novel high-performance ceramics—amorphous inorganic networks from molecular precursors. Angew. Chem. Int. Ed. 1997, 36, 328–343. [Google Scholar] [CrossRef]

- Cavdar, U.; Altintas, A.; Karaca, B. In-situ compaction and sintering of Al2O3-B4C composites by using a High-Frequency Induction System. Met. Mater. 2018, 56, 177–181. [Google Scholar] [CrossRef]

- Lin, X.; Ownby, P. Pressureless sintering of B4C whisker reinforced Al2O3 matrix composites. J. Mater. Sci. 2000, 35, 411–418. [Google Scholar] [CrossRef]

- Datye, A.; Koneti, S.; Gomes, G.; Wu, K.-H.; Lin, H.-T. Synthesis and characterization of aluminum oxide-boron carbide coatings by air plasma spraying. Ceram. Int. 2010, 36, 1517–1522. [Google Scholar] [CrossRef]

- Hamid, A.; Hadian, M.; Alizadeh, A. Processing and Mechanical Properties of Boron Carbide–Titanium Diboride Ceramic Matrix Composites. Appl. Compos. Mater. 2006, 13, 191–198. [Google Scholar]

- Badica, P.; Grasso, S.; Borodianska, H.; Xie, S.S.; Li, P.; Tatarko, P.; Reece, M.J.; Sakka, Y.; Vasylkiv, O. Tough anf dense boron carbide obtained by high-pressure (300 MPa) and low temperature (1600 °C) spark plasma sintering. J. Ceram. Soc. Jpn 2014, 122, 271–275. [Google Scholar] [CrossRef]

- Vozarov, M.; Neubauer, E.; Baca, L.; Kitzmantel, M.; Feranc, J.; Trembosov, V. Preparation of fully dense boron carbide ceramics by Fused Filament Fabrication (FFF). J. Eur. Ceram. Soc. 2023, 43, 1751–1761. [Google Scholar] [CrossRef]

- Toptan, F.; Kilicarslan, A.; Karaaslan, A.; Cigdem, M.; Kerti, I. Processing and microstructural characterization of AA 1070 and AA 6063 matrix B4Cp reinforced composites. Mater. Des. 2010, 31, 87–91. [Google Scholar] [CrossRef]

- Kim, H.W.; Koh, Y.H.; Kim, H.E. Densification, and mechanical properties of B4C with Al2O3 as a sintering additive. J. Am. Ceram. Soc. 2000, 83, 2363–2365. [Google Scholar]

- Sharma, P.; Sharma, S.; Khanduja, D. Production, and some properties of Si3N4 reinforced aluminum alloy composites. J. Asian Ceram. Soc. 2015, 3, 352–359. [Google Scholar] [CrossRef]

- Ramesh, C.; Keshavamurthy, R.; Channabasappa, B.H. Microstructure and mechanical properties of Ni-P coated Si3N4 reinforced Al6061 composites. Mater. Sci. Eng. A 2009, 502, 99–106. [Google Scholar] [CrossRef]

- Layden, G.K. Process Development for Pressure-Less Sintering of SiAlON Ceramic Components; Final Report, Contract N00019-75-0232; Naval Air System Command: Patuxent River, MD, USA, 1976. [Google Scholar]

- Gauckler, L.J.; Lukas, H.L.; Petzow, A.G. Contribution to the Phase Diagram Si3N4-AlN-Al2O3-SiO2. J. Am. Ceram. Soc. 1975, 58, 346–347. [Google Scholar] [CrossRef]

- Yeh, H.C.; Sanders, W.A.; Fiyalko, J.L. Silicon nitride-aluminum oxide solid solution (SiAION) formation and densification by pressure sinterin. Report no. E-8317; NASA Technical Memorandum, National Aeronautics and Space Administration: Washington, DC, USA, 1975. [Google Scholar]

- Lange, F.F. Fabrication and Properties of Silicon Cbihpounds-Task I. Fabrication Microstructure and Selected Properties of SiAlON Compositions; Westinghouse Research Labs.: Large, PA, USA, 1974. [Google Scholar]

- Crandall, W.B.; Hed, A.Z.; Shipley, L.E. Preparation and Evaluation of SiAlON; Final Report ARL-TR-74-0099; Aerospace Research Laboratory, Air Force Systems Command: Springfiel, VA, USA, 1974. [Google Scholar]

- Hisaichi, O.; Shoju, M.; Masakazu, O.; Kaoru, M.; Tadashi, S. Potential application of ceramic matrix composites to aero-engine components. Compos. Part A 1999, 30, 489–496. [Google Scholar]

- Lee, S.M. (Ed.) Handbook of Composite Reinforcements; VCH: Cambridge, UK, 1993. [Google Scholar]

- Hariharasakthisudhan, P.; Swaminathan, J. Characterizing the Compression Behavior of Al2O3/Si3N4 Nano-Sized Particulate Reinforced Ceramic Matrix Composites. Indian J. Sci. Technol. 2016, 9, 42. [Google Scholar] [CrossRef]

- Lee, C.S. Novel Joining of Dissimilar Ceramics in the Si3N4-Al2O3 System Using Polytypoid Functional Gradients. Acta Mater. 2001, 49, 3775–3780. [Google Scholar] [CrossRef]

- Jimoh, A. Calculate-Reinforcement of Titanium Matrix Composites with Borides, Materials Sciences and Applications. 2010. Available online: https://core.ac.uk/download/pdf/39668225.pdf (accessed on 21 February 2023).

- Boatemaa, L.; Brouwer, J.C.; Zwaag, S.; Sloof, W. The effect of the TiC particle size on the preferred oxidation temperature for self-healing of oxide ceramic matrix materials. Ceram. J. Mater. Sci. 2018, 53, 5973–5986. [Google Scholar] [CrossRef]

- Cai, K.; Axen, N.; Manyatsa, R. Preparation, Microstructures and Properties of Al2O3-TiC Composites. Ceram. Int. 2002, 28, 217–222. [Google Scholar] [CrossRef]

- Rocha-Rangel, E.; Hernández-Silva, D.; Terrés-Rojas, E.; Martínez-Franco, E. Alumina-based composites are strengthened with titanium and titanium carbide dispersions. J. Silic. Based Compos. Mater. 2010, 62, 75–78. [Google Scholar] [CrossRef]

- Sarkar, P.; Datta, S.; Nicholson, P.S. A functionally graded ceramic/ceramic and metal/ceramic composites by electrophoretic deposition. Compos. Part B-Eng. 2003, 28, 49–56. [Google Scholar] [CrossRef]

- Yoshioka, S.; Boatemaa, L.; van der Zwaag, S.; Nakao, W.; Sloof, W.G. On the use of TiC as high-temperature healing particles in alumina-based composites. J. Eur. Ceram. Soc. 2016, 36, 24–35. [Google Scholar] [CrossRef]

- Refugio-García, E.; Hernández-Silva, D.; Terrés-Rojas, E.; Rodríguez-García, J.A.; Rocha-Rangel, E. Microstructure of Alumina-Matrix Composites Reinforced with Nanometric Titanium and Titanium Carbide Dispersions. Mater. Res. 2012, 15, 898–902. [Google Scholar] [CrossRef][Green Version]

- Leyens, C.; Hausmann, J.; Kumpfert, J. Continuous Fiber Reinforced Titanium Matrix Composites: Fabrication, Properties, and Applications. Adv. Eng. Mater. 2003, 5, 399–410. [Google Scholar] [CrossRef]

- Das, R.; Ambardekar, V.; Pratim, B.P. Titanium Dioxide and Its Applications in Mechanical, Electrical, Optical, and Biomedical Fields. In Titanium Dioxide-Advances and Applications; InTech Open: Rijeka, Croatia, 2022. [Google Scholar] [CrossRef]

- Kim, I.J.; Gauckler, L. Excellent Thermal Shock Resistant Materials with low Thermal Expansion Coefficients. J. Ceram. Process. Res. 2008, 9, 240–245. [Google Scholar]

- Ulvi Gezici, L.; Gul, B.; Çavdar, U. The mechanical and tribological characteristics of Aluminum-Titanium dioxide composites. Rev. Metal. 2018, 54, 121–142. [Google Scholar] [CrossRef]

- Forero-Duran, M.; Dulce-Moreno, H.J.; Ferrer-Pacheco, M.; Vargas-Galvis, F. Wear and corrosion behaviour of Al2O3-TiO2 coatings produced by flame thermal projection. J. Phys. 2017, 935, 2–5. [Google Scholar] [CrossRef]

- Djendel, M.; Allaoui, O.; Boubaaya, R. Characterization of Alumina-Titania Coatings Produced by Atmospheric Plasma Spraying on 304 SS Steel. Acta Phys. Pol. A 2017, 132, 538–540. [Google Scholar] [CrossRef]

- Thomas, H.A.J.; Stevens, R. Aluminium Titanate—A Literature Review—Part 1: Microcracking Phenomena. Br. Ceram. Trans. J. 1989, 88, 144–151. [Google Scholar]

- Chengxin, Z.; Feng, C.; Yang, X.; Zhihang, P. Thermal shock resistance of Al2O3/SiO2 composites by sol-gel. Ceram. Int. 2019, 45, 11270–11274. [Google Scholar] [CrossRef]

- Anggono, J. Mullite Ceramics: Its properties, structure, and synthesis. J. Tek. Mersin 2005, 7, 1–10. [Google Scholar]

- Takada, H.; Nakahira, A.; Ueda, S.; Niihara, K.; Ohnishi, H. Improvement of mechanical properties of natural mullite/SiC nanocomposites. J. Jpn. Soc. 1991, 38, 348–351. [Google Scholar]

- Cui, K.; Zhang, Y.; Fu, T.; Wang, J.; Zhang, X. Toughening Mechanism of Mullite Matrix Composites: A Review. Coatings 2020, 10, 672. [Google Scholar] [CrossRef]

- Chauhan, S.; Kumar, A.; Singh, I.; Kumar, P. Effect of Fly Ash Content on Friction and Dry Sliding Wear Behavior of Glass Fiber Reinforced Polymer Composites-A Taguchi Approach. J. Miner. Mater. Charact. Eng. 2010, 9, 365–387. [Google Scholar] [CrossRef]

- Manu, S.; Rajan, T.P.D.; Pai, B.C. Structure and properties of squeeze infiltrated zirconia grade-aluminosilicate short fiber reinforced aluminum composites. J. Alloy. Compd. 2016, 688, 135. [Google Scholar]

- Garshin, A.P.; Kulik, V.I.; Matveev, S.; Nilov, A.S. Contemporary technology for preparing fiber-reinforced composite materials with a ceramic refractory matrix (review). Refract. Ind. Ceram. 2017, 58, 148–161. [Google Scholar] [CrossRef]

- Li, B.; Chen, H.; Chen, J.; Yan, M.; Hou, X.; Li, Y. Improvement of thermal shock performance by residual stress field toughening in periclase-hercynite refractories. Ceram. Int. 2018, 44, 24–31. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, H.; Liu, H.; Wang, J. Microstructure and room temperature mechanical properties of mullite fibers after heat-treatment at elevated temperatures. Mater. Sci. Eng. A 2013, 578, 287–293. [Google Scholar] [CrossRef]

- Schneider, J.; Schreuer, B.H. Structure and properties of mullite-a review. J. Eur. Ceram. Soc. 2008, 28, 329–344. [Google Scholar] [CrossRef]

- Carelli, E.A.V.; Fujita, H.; Yang, J.Y.; Zok, F.W. Effects of thermal aging on the mechanical properties of a porous-matrix ceramic composite. J. Am. Ceram. Soc. 2002, 85, 595–602. [Google Scholar] [CrossRef]

- Chawla, K. Interface engineering in mullite fiber/mullite matrix composites. J. Eur. Ceram. Soc. 2008, 28, 447–453. [Google Scholar] [CrossRef]

- Zhang, D.; Meyer, P.; Waas, A.M. An experimentally validated computational model for progressive damage analysis of notched oxide/oxide woven ceramic matrix composites. Compos. Struct. 2017, 161, 264–274. [Google Scholar] [CrossRef]

- Di Girolamo, G.; Blasi, K.; Schioppa, M. Microstructural and thermal properties of plasma sprayed mullite coatings. Ceram. Int. 2010, 36, 1389–1395. [Google Scholar] [CrossRef]

- Lee, K.N.; Zhu, D.; Lima, R.S. Perspectives on Environmental Barrier Coatings (EBCs) Manufactured via Air Plasma Spray (APS) on Ceramic Matrix Composites (CMCs): A Tutorial Paper. J. Therm. Spray Tech. 2021, 30, 40–58. [Google Scholar] [CrossRef]

- Stolzenburg, F.; Johnson, M.; Lee, K.; Jacobson, N.; Faber, K. The interaction of calcium–magnesium–aluminosilicate with ytterbium silicate environmental barrier materials. Surf. Coat. Technol. 2015, 284, 44–50. [Google Scholar] [CrossRef]

- Yang, R.; Qi, Z.; Gao, Y.; Yang, J.; Zhou, Y.; Liu, H.; Jiao, J. Processing and Properties of Oxide Fiber Reinforced Alumina Composites. IOP Conf. Ser. Mater. Sci. Eng. Eng. 2019, 678, 012033. [Google Scholar] [CrossRef]

- Holmquist, M.G.; Radsick, T.C.; Sudre, O.H.; Lange, F.F. Fabrication, and testing of all-oxide CFCC tubes. Compos. Part. A-Appl. Sci. Manuf. 2003, 34, 163–170. [Google Scholar] [CrossRef]

- Jacobson, N.S.; Opila, E.J. Oxidation and Corrosion of Non-Oxide Ceramics. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Naslain, R.; Rossignol, J.Y.; Hagenmuller, P.; Christin, F.; Heŕaud, L.; Choury, J.J. Synthesis and properties of new composite materials for high-temperature applications based on carbon fibers and C-SiC or C-TiC hybrid matrices. Rev. Chim. Miner. 1981, 18, 544–564. [Google Scholar]

- Naslain, R. Design, preparation, and properties of non-oxide CMCs for application in engines and nuclear reactors: An overview. Compos. Sci. Technol. 2004, 64, 155–170. [Google Scholar] [CrossRef]

- Dhanasekar, S.; Ganesan, A.T.; Rani, T.L.; Vinjamuri, V.K.; Rao, M.N.; Shankar, E.; Dharamvir, E.; Kumar, P.S.; Golie, W.M. A Comprehensive Study of Ceramic Matrix Composites for Space Applications. Adv. Mater. Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Wu, D.; Wang, Y.; Shang, L.; Pu, Y.; Gao, Z. Thermo-mechanical properties of C/SiC composite structure under extremely high temperature environment up to 1500C. Compos. Part B 2016, 90, 424–431. [Google Scholar] [CrossRef]

- MacKEnzie, K.J.D. Innovative applications of inorganic polymers (geopolymers). In Handbook of Alkali-Activated Cements, Mortars, and Concretes; Woodhead Publishing: Cambridge, UK, 2015; pp. 777–805. [Google Scholar]

- Machacek, J. Non-Oxide Ceramics. In Ceramic Technology; University of Chemistry: Prague, Czech Republic, 2007. [Google Scholar]

- Monacha, S. Porous Carbons. Sadhana 2003, 28, 335–348. [Google Scholar] [CrossRef]

- Zhang, R.; Li, Y. Structures and high-temperature frictional behaviors of coal pitch-derived carbonaceous mesophases (CMs)ball milled for different durations. Tribol. Lett. 2008, 32, 209–213. [Google Scholar] [CrossRef]

- Park, S.J.; Seo, M.K. Types of Composites. Interface Sci. Technol. 2011, 18, 501–629. [Google Scholar]

- Fitzer, E.; Manocha, L.M. Carbon reinforcements and carbon-carbon composites. Carbon Compos. 1998, 29, 71–95. [Google Scholar]

- Krenkel, W. Carbon Fibre Reinforced Silicon Carbide Composites (C/SiC, C/C-SiC). In Handbook of Ceramic Composites; Springer: Boston, MA, USA, 2005; pp. 117–148. [Google Scholar]

- Thielicke, B.; Soltész, U.; Krenkel, W.; Morawietz, K. Creep of a C/C-SiC composite under interlaminar shear loading at high temperatures. In Proceedings of the ICCM12, Paris, France, 5–9 July 1999. [Google Scholar]

- Freudenberg, W.; Wich, F.; Langhof, N.; Schaffoner, S. Additive manufacturing of carbon fiber reinforced ceramic matrix composites based on fused filament fabrication. J. Eur. Ceram. Soc. 2022, 42, 1822–1828. [Google Scholar] [CrossRef]

- Bhatt, P.; Goe, A. Carbon Fibres: Production, Properties and Potential Use. Mat. Sci. Res. India 2017, 14, 52–57. [Google Scholar] [CrossRef]

- Ahmad, S.; Ali, S.; Salman, M.; Baluch, A.H. A comparative study on the effect of carbon-based and ceramic additives on the properties of fiber-reinforced polymer matrix composites for high-temperature applications. Ceram. Int. 2021, 47, 33956–33971. [Google Scholar] [CrossRef]

- Deng, Y.; Li, W.; Zhang, X.; Li, Y.; Kou, H.; Shao, J.; Zhang, X.; Qu, Z. Modeling on temperature-dependant first matrix cracking stress for fiber reinforced ceramics considering fiber debonding and residual thermal stress. Ceram. Int. 2018, 44, 21666–21674. [Google Scholar] [CrossRef]

- Michio, I. New Carbons-Control of Structure and Functions. J. Eur. Ceram. Soc. 2000, 7, 468–521. [Google Scholar]

- Krishna, K.V.; Seshagirirao, V. Carbon fibre reinforced (CFRC)-A special material. Intern. In Proceedings of the ASME 2012 Pressure Vessels and Piping Conference, Toronto, ON, Canada, 15–19 July 2012. [Google Scholar]

- Lewandowska, S.M.; Komender, J.; Gorecki, A.; Kowalski, M. Fixation of carbon fiber-reinforced carbon composite implanted into bone. J. Mater. Sci. Mater. Med. 1997, 8, 485–488. [Google Scholar] [CrossRef] [PubMed]

- Buschow, K.H.J.; Cahn, R.W.; Flemings, M.C.; Ilschner, B.; Kramer, E.J.; Mahajan, S. Encyclopedia of Materials: Science and Technology. MRS Bull. 2004, 29, 512. [Google Scholar]

- Edie, D.D. The effect of processing on the structure and properties of carbon fibers. Carbon Ceram. Bull. 1988, 36, 345–362. [Google Scholar] [CrossRef]

- Mouritz, P.A. Metal matrix, fiber-metal and ceramic matrix composites for aerospace applications. In Introduction to Aerospace Materials; Woodhead Publishing: Cambridge, UK, 2012; Volume 16, pp. 394–410. [Google Scholar]

- Sreejith, M.; Rajeev, R. Fiber reinforced composites for aerospace and sports applications. Fiber Reinf. Compos. 2021, 45, 112–124. [Google Scholar]

- Tatsuo, O. Carbon/Carbon Composites, and their properties. Carbon Alloy. 2003, 33, 523–544. [Google Scholar]

- Naik, P.; Javarajub, T. Carbon-Carbon composites by preformed yarn method. Int. J. Mech. Mater. Eng. 2011, 6, 133–139. [Google Scholar]

- Probst, K.J.; Besmann, T.M.; Stinton, D.P.; Lowden, R.A.; Anderson, T.J.; Starr, T.L. Recent advances in forced-flow, thermal-gradient CVI for refractory composites. Surf. Coat. Technol. 1999, 120, 250–258. [Google Scholar] [CrossRef]

- Peng, H. Brazing of oxide, carbide, nitride and composite ceramics. Adv. Brazing 2013, 7, 194–220. [Google Scholar]

- Fitzer, E. Present state and future applications in carbon fibers, filaments, and composites. Carbon Fibers 1989, 7, 15–27. [Google Scholar]

- Kochendorfer, R. Ceramic matrix composites in ceramic engineering and science. Am. Ceram. Soc. 2001, 22, 11–22. [Google Scholar]

- Scarponi, C. Carbon-Carbon composites in aerospace engineering. Adv. Compos. Mater. Aerosp. Eng. 2016, 51, 385–412. [Google Scholar]

- Park, S.; Seo, M. Interface Science and Composites. Interface Sci. Technol. 2011, 43, 84–102. [Google Scholar]

- Hurwitz, F. Ceramic Matrix, and Resin Matrix Composites: A Comparison. In Proceedings of the 32nd National SAMPE Symposium and Exhibition, Anaheim, CA, USA, 6–9 April 1987. [Google Scholar]

- Alveston, J.; Cooper, G.; Kelly, A. Single, and Multiple Fracture, in the Properties of Fiber Composites. In Conference 86 Proceedings; National Physical Laboratory: Teddington, UK, 1971. [Google Scholar]

- Gardiner, G. Bridging the Gap between CFRP and CMC. Composite World. 2020. Available online: https://www.compositesworld.com/articles/bridging-the-gap-between-cfrp-and-cmcs (accessed on 23 December 2022).

- Zhiyuan, Y.; Rongchang, L.; Zhenghua, P.; Yonglian, T. Carbon Fiber Reinforced Epoxy Resin Matrix Composites Materials Science. Adv. Compos. Mater. 2017, 16, 323–345. [Google Scholar]

- Wu, G.; Kou, K.; Chao, M.; Zhuo, L.; Zhang, J.; Li, N. Preparation and characterization of bismaleimide-triazine/epoxy Interpenetrating polymer networks. J. Thermochem. Acta 2012, 537, 44–50. [Google Scholar] [CrossRef]

- Gang, L.; Peng, L.; Zhang, C.; Yunhua, Y.; Haiyang, L.; Zhang, S.; Xiaolong, Y.; Zhongmin, X.; Seungkon, R. Inhomogeneous carbon fiber/epoxy composite toughening using electrospun polysulfone membranes by in situ phases. J. Compos. Sci. Technol. 2008, 68, 984–987. [Google Scholar]

- Kai-Bing, H.; Jin, L.; Qun, F.; Zhen, C. The enhancement of carbon fiber modified with an electrolyzed coating to the mechanical properties of epoxy resin composites. J. Compos. Part A 2008, 39, 1133–1140. [Google Scholar]

- Ma, Q.S.; Chen, Z.H.; Zheng, W.W.; Hu, H.F. Processing, and characterization of three-dimensional carbon fiber-reinforced Si/O/C composites via precursor pyrolysis. Mater. Sci. Eng. A 2003, 352, 212–216. [Google Scholar] [CrossRef]

- Rahmani, H.; Najafi, S.H.M.; Saffarzadeh-Matin, S.; Ashori, A. Mechanical Properties of Carbon Fiber/Epoxy Composites: Effects of number of plies, fiber contents, and angle-ply layers. Polym. Eng. Sci. 2014, 54, 2676–2682. [Google Scholar] [CrossRef]

- Baldacim, S.A.; Cairo, C.A.A.; Silva, C.R.M. Mechanical properties of ceramic composites. J. Mater. Process. Technol. 2001, 119, 273–276. [Google Scholar] [CrossRef]

- Ly, Q.; Taylor, R.; Day, R. Carbon fiber-reinforced CMCs by PCS infiltration. J. Mater. Sci. 2001, 36, 4027–4035. [Google Scholar] [CrossRef]

- Yu, N.; Lim, W.; Suh, J.; Lee, D. A graphite-coated carbon fiber epoxy composite bipolar plate for polymer electrolyte membrane cell-cell. J. Power Sources 2011, 196, 9868–9875. [Google Scholar] [CrossRef]

- Ginger, G. Out-of-Autoclave Prepregs: Hype or Revolution? Composite World. 2011. Available online: https://www.compositesworld.com/articles/out-of-autoclave-prepregs-hype-or-revolution (accessed on 23 December 2022).

- Patil, S. Carbon Composites Implementations in Automotive. Carbon Composites for Automotive. 2021. Available online: https://www.compositesworld.com/articles/carbon-fiber-in-automotive-at-a-dead-end (accessed on 23 December 2022).

- NASA. Silicon Carbide (SiC) Fiber Reinforced SiC Matrix Composites. Materials and Coatings, Lightweight High-Performance SiC/SiC Ceramic Composite Materials and SiC Fibers for Use in Extreme Environments. 2020; pp. 12–28. Available online: https://technology.nasa.gov/patent/LEW-TOPS-25 (accessed on 21 February 2023).

- Mileiko, S. Carbon-Fibre/Metal-Matrix Composites: A Review. J. Compos. Sci. 2022, 6, 297. [Google Scholar] [CrossRef]

- Ganguli, R.; Hills, A. Metal Impregnated Composites and Methods of Making. Int. CI. 2006, 60, 869–884. [Google Scholar]

- Marcio, F.M.; Carvalho, C.; Cairo, C. SiCf/SiC Composite: Attainment Methods, Properties, and Characterization. In Advances in Ceramics-Synthesis and Characterization Processing and Specific Applications; InTech Open: Rijeka, Croatia, 2002; volume 23, pp. 331–375. [Google Scholar] [CrossRef]

- Takeda, M.; Sakamoto, J.; Saeki, A.; Imai, Y.; Ichikawa, H. High-Performance silicon carbide fiber hi-nicalon for ceramic matrix composites. In Proceedings of the 19th Annual Conference on Composites, Advanced Ceramics, Materials, and Structures—A: Ceramic Engineering and Science Proceedings, Cocoa Beach, FL, USA, 8–12 January 1995; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1995; volume 8, pp. 836–859. [Google Scholar]

- Kablov, E.N.; Grashchenkov, D.V.; Isaeva, N.V.; Solntsev, S.S. Perspective high-temperature ceramic composite materials. Russ. J. Gen. Chem. 2011, 81, 986–991. [Google Scholar] [CrossRef]

- Naslain, R.R. SiC-Matrix Composites: Nonbrittle Ceramics for Thermo-Structural Application. Int. J. Appl. Ceram. Technol. 2005, 2, 75–84. [Google Scholar] [CrossRef]

- Yang, W.; Araki, H.; Kohyama, A.; Thaveethavorn, S.; Suzuki, H.; Noda, T. Fabrication in-situ SiC nanowires/SiC matrix composite by chemical vapor infiltration process. Mater. Lett. 2004, 58, 423–490. [Google Scholar] [CrossRef]

- Spitsberg, I.; Steibel, J. Thermal and Environmental Barrier Coatings for SiC/SiC CMCs in Aircraft Engine Applications. Int. J. Appl. Ceram. Technol. 2005, 1, 291–301. [Google Scholar] [CrossRef]

- Di Carlo, J.A.; Yun, H.M.; Morscher, G.N.; Bhatt, R.T. SiC/SiC Composites for 1200 °C and Above. Compos. J. Am. Ceram. Soc. 2004, 11, 90–139. [Google Scholar]

- Morscher, G.N.; Mann Yun, H.; DiCarlo, J.A.; Thomas-Ogbuji, L. Effect of a BN Interphase that Debonds Between the Interphase and the Matrix in SiC/SiC. Composites. J. Am. Ceram. Soc. 2004, 87, 104–112. [Google Scholar] [CrossRef]

- Ogbuji, T. A Pervasive Mode of Oxidation Degradation in a SiC/SiC Composite. J. Am. Ceram. Soc. 1998, 81, 2777–2784. [Google Scholar] [CrossRef]

- Karakoc, O.; Koyanagi, T.; Nozawa, T.; Katoh, Y. Fiber/matrix debonding evaluation of SiCf/SiC composites using micropillar compression technique. Compos. Part B Eng. 2021, 224, 109–189. [Google Scholar] [CrossRef]

- Li, L. Fatigue Life Prediction of Fiber-Reinforced Ceramic-Matrix Composites with Different Fiber Preforms at Room and Elevated Temperatures. Materials 2016, 9, 207. [Google Scholar] [CrossRef]

- Qinglong, A.N.; Chen, J.; Ming, W.; Chen, M. Machining of SiC ceramic matrix composites: A review. Chin. J. Aeronaut. 2021, 34, 540–567. [Google Scholar]

- Yamada, R.; Taguchi, T.; Igawa, N. Mechanical and thermal properties of 2D and 3D SiC/SiC composites. J. Nucl. Mater. 2000, 283–287, 574–578. [Google Scholar] [CrossRef]

- Zhu, S.; Mizuno, M.; Kagawa, Y.; Cao, J.; Nagano, Y.; Kaya, H. Creep, and fatigue behavior in Hi-Nicalon™-fiber-reinforced silicon carbide composites at high temperatures. J. Am. Ceram. Soc. 1999, 82, 117–128. [Google Scholar] [CrossRef]

- Zhu, S.; Mizuno, M.; Kagawa, Y.; Mutoh, Y. Monotonic tension, fatigue, and creep behavior of SiC-fiber-reinforced SiC–matrix composites: A review. Compos. Sci. Technol. 1999, 59, 833–851. [Google Scholar] [CrossRef]

- Parashivamurthy, K.I.; Kumar, R.K.; Seetharamu, S.; Chandrasekharaiah, M.N. Review on TiC Reinforced Steel Composites. J. Mater. Sci. 2001, 36, 4519–4530. [Google Scholar] [CrossRef]

- Li, Y.; Bai, P.; Wang, Y.; Hu, J.; Guo, Z. Effect of TiC content on Ni/TiC composites by direct laser fabrication. Mater. Des. 2009, 30, 1409–1412. [Google Scholar] [CrossRef]

- Pirso, J.; Viljus, M.; Letunovits, S. Sliding wear of TiC–NiMo cermets. Tribol. Int. 2004, 37, 817–824. [Google Scholar] [CrossRef]

- Niki, E.; Kohara, S.; Tajiri, M.; Tatsuzawa, K. Sintering of Nickel Bonded Titanium Carbides. Mater. Trans. Jim. 1964, 5, 1–7. [Google Scholar] [CrossRef][Green Version]

- Hussainova, I. Effect of microstructure on the erosive wear of titanium carbide-based cermets. Wear 2003, 255, 121–128. [Google Scholar] [CrossRef]

- LaSalvia, J.C.; Kim, D.K.; Meyers, M.A. Effect of Mo on microstructure and mechanical properties of TiC-Ni-based cermets produced by combustion synthesis-impact forging technique. Mater. Sci. Eng. 1996, 206, 71–80. [Google Scholar] [CrossRef]

- Farías, I.; Olmos, L.; Jiménez, O.; Flores, M.; Braem, A.; Vleugels, J. Wear modes in open porosity titanium matrix composites with TiC addition processed be spark plasma sintering. Trans. Nonferrous Met. Soc. China 2019, 29, 1653–1664. [Google Scholar] [CrossRef]

- Hussainova, I.; Pirso, J. Microstructural Aspects of Erosive Wear of Particle Reinforced Composites. In Advances in Powder Metallurgy & Particulate Materials; Metal Powder Industries Federation: Princeton, NJ, USA, 2003; Volume 5, pp. 171–181. [Google Scholar]

- Kubarsepp, J.; Reshetnyak, H. Abrasive wear performance of carbide-based composites. Wear 1994, 177, 185–193. [Google Scholar]

- Zikin, A.; Badisch, E.; Hussainova, I.; Tomastik, C.; Danninger, H. Characterisation of TiC-NiMo reinforced Ni-based hardfacing. Surf. Coat. Technol. 2013, 236, 36–44. [Google Scholar] [CrossRef]

- Cardarelli, F. Materials Handbook: A Concise Desktop Reference; Springer Science & Business Media: New York, NY, USA, 2008; Volume 5, p. 640. [Google Scholar]

- Kwon, Y.S.; Kim, H.T.; Choi, D.W.; Kim, J.S. Mechanical properties of binder less WC produced by SPS process. In Novel Materials Processing by Advanced Electromagnetic Energy Sources; Elsevier: Amsterdam, The Netherlands, 2005; Volume 1, pp. 275–279. [Google Scholar]

- Naboychenko, S.N.; Murasova, I.B.; Neikov, O.D. Production of Refractory Metal Powders. In Handbook of Non-Ferrous Metal Powders; Elsevier: Amsterdam, The Netherlands, 2009; pp. 436–484. [Google Scholar] [CrossRef]

- Jia, C.; Sun, L.; Tang, H.; Qu, X. Hot pressing of nanometer WCeCo powder. Int. J. Refract. Met. Hard Mater. 2007, 25, 53–56. [Google Scholar] [CrossRef]

- Cramer, D.S.; Covino, B.S. Corrosion of Cemented Carbides. In ASM Handbook: Corrosion Materials; ASM International: Materials Park, OH, USA, 2005; Volume 13B. [Google Scholar]

- Sun, J.; Zhao, J.; Huang, Z.; Yan, K.; Shen, X.; Xing, J.; Gao, Y.; Jian, Y.; Yang, H.; Li, B. A Review on Binderless Tungsten Carbide: Development and Application. Nano-Micro Lett. 2020, 12, 13. [Google Scholar] [CrossRef]

- Armstrong, R.W. The Hardness and Strength Properties of WC-Co Composites. Materials 2011, 4, 1287–1308. [Google Scholar] [CrossRef]

- Kubarsepp, J.; Juhani, K.; Tarraste, M. Abrasion and Erosion Resistance of Cermets: A Review. Materials 2022, 15, 69. [Google Scholar] [CrossRef]

- Poetschke, J.; Richter, V.; Michaelis, A. Fundamentals of sintering nanoscaled binderless hardmetals. Int. J. Refract. Met. Hard Mater. 2015, 49, 124–132. [Google Scholar] [CrossRef]

- Imasato, S.; Sakaguchi, S.; Okada, T.; Hayashi, Y. Effect of WC Grain Size on Corrosion Resistance of WC-Co Cemented Carbide. J. Jpn. Soc. Powder Powder Metall. 2001, 48, 609–615. [Google Scholar] [CrossRef][Green Version]

- Ungár, T.; Borbély, A.; Goren-Muginstein, G.R.; Berger, S.; Rosen, A.R. Particle size, size distribution and dislocations in nanocrystalline tungsten-carbide. Nanostruct. Mater. 1911, 11, 103–113. [Google Scholar] [CrossRef]

- Richter, V. Hard sintered materials made of nano-sized powders. Annu. Rep. Fraunhofer IKTS 1995, 28, 44–45. [Google Scholar]

- Gubernat, A.; Pawel, R.; Grabowski, G.; Zientara, D. Hot pressing of tungsten carbide with and without sintering additives. Int. J. Refract. Met. Hard Mater. 2014, 43, 193–199. [Google Scholar] [CrossRef]

- Yang, D.Y.; Kang, S.J.L. Suppression of abnormal grain growth in WC-Co via pre-sintering treatment. Int. J. Refract. Met. Hard Mater. 2009, 27, 90–94. [Google Scholar] [CrossRef]

- Li, H.; Yan, L.; Meng, L.; Li, Y.; Ai, F.; Zhang, H.; Jiang, Z. Effect of Ni on the Microstructure and Diffusion Behavior at the Interface of WC/High-Speed Steel Composites. Metals 2021, 11, 341. [Google Scholar] [CrossRef]

- Tarragó, J.M.; Ferrari, C.; Reig, B.; Coureaux, D.; Schneider, L.; Llanes, L. Mechanics and mechanisms of fatigue in a WC-Ni hardmetal and comparative study with respect to WC-Co hardmetals. Int. J. Fatigue 2015, 70, 252–257. [Google Scholar] [CrossRef]

- Bonny, K.; De Baets, P.; Vleugels, J.; Huang, S.; Lauwers, B. Tribological characteristics of WC–Ni and WC–Co cemented carbide in dry reciprocating sliding contact. Tribol. Trans. 2009, 52, 481–491. [Google Scholar] [CrossRef]

- Zhang, F.G.; Zhu, X.P.; Lei, M.K. Microstructural evolution and its correlation with hardening of WC–Ni cemented carbides irradiated by high-intensity pulsed ion beam. Surf. Coat Technol. 2012, 206, 4146–4155. [Google Scholar] [CrossRef]

- Tracey, V.A. Nickel in hardmetals. Int. J. Refract. Met. Hard Mater. 1992, 11, 137–149. [Google Scholar] [CrossRef]

- Norgren, S.; Garcia, J.; Blomqvist, A.; Yin, L. Global trends in the hardmetals industry. In Proceedings of the 18th Plansee Seminar, Reutte: Plansee Group, Reutte, Austria, 3–7 June 2013; pp. 1–29. [Google Scholar]

- Correa, E.O.; Santos, J.N.; Klein, A.N. Microstructure and mechanical properties of WC Ni–Si based cemented carbides developed by powder metallurgy. Int. J. Refract. Met. Hard Mater. 2010, 28, 572–575. [Google Scholar] [CrossRef]

- Shi, K.; Zhou, K.; Li, Z.; Zan, X.; Xu, S.; Min, Z. Effect of adding method of Cr on microstructure and properties of WC–9Ni–2Cr cemented carbides. Int. J. Refract. Met. Hard Mater. 2013, 38, 1–6. [Google Scholar] [CrossRef]

- Rombouts, M.; Persoons, R. Development and characterization of nickel based tungsten carbide cladded coatings. Phys. Procedia 2010, 5, 333–339. [Google Scholar] [CrossRef]

- Amado, J.M.; Tobar, M.J.; Yanez, A.; Amigo, V.; Candel, J.J. Crack Free Tungsten Carbide Reinforced Ni(Cr) Layers obtained by Laser Cladding. Phys. Procedia 2011, 12, 338–344. [Google Scholar] [CrossRef]

- Malcolm, T.; Murray, S.; Furrer, D. Introducing New Materials into Aero-Engines-Risks and Rewards, a User’s Perspective. In Proceedings of the 7th International Symposium on Superalloy 718 and Derivatives, Pittsburgh, PA, USA, 10–13 October 2010; John Wiley & Sons: New York, NY, USA, 2010. [Google Scholar] [CrossRef]

- Boyer, R.R.; Cotton, J.D.; Mohaghegh, M.; Schafrik, R.E. Materials considerations for aerospace applications. Mater. Res. Soc. 2015, 40, 1055–1175. [Google Scholar] [CrossRef]

- Stout, B.J.; Pelletier, G.D. Method for Manufacturing Ceramic Matrix Composite Structures. World Intellectual Property Organization Publications no. WO 2006/076069 A1. 2006. Available online: https://patentimages.storage.googleapis.com/0c/3e/3b/0f0c6ff40f84e4/WO2006076069A1.pdf (accessed on 23 December 2022).

- Naslain, R.; Langlais, F.; Fedou, R. The CVI-Processing of Ceramic Matrix Composites. J. Phys. Coll. 1989, 50, 191–207. [Google Scholar] [CrossRef]

- Wang, X.; Schmidt, F.; Hanaor, D.; Kamm, P.H.; Li, S.; Gurlo, A. Additive manufacturing of ceramics from preceramic polymers: A versatile stereolithographic approach assisted by violence click chemistry. Add. Man. 2019, 27, 80–90. [Google Scholar] [CrossRef]

- Ziegler, G.; Richter, I.D.; Suttor, D. Fiber-reinforced composites with polymer-derived matrix: Processing, matrix formation, and properties. Comp. Part A App. Sci. Man. 1999, 30, 411–417. [Google Scholar] [CrossRef]

- Simon, R. Progress in Processing and Performance of Porous-Matrix Oxide/Oxide Composites. Int. J. App. Cer. Tech. 2005, 2, 141–149. [Google Scholar] [CrossRef]

- Bao, Y.; Nicholson, P.S. Constant Current Electrophoretic Infiltration Deposition of Fiber-Reinforced Ceramic Composites. J. Am. Ceram. Soc. 2007, 90, 1063–1070. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Kaya, C.; Chawla, K.K. Use of electrophoretic deposition in the processing of fiber-reinforced ceramic and glass matrix composites: A review. Compos. A 2001, 32, 997–1006. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Kaya, C. The use of electrophoretic deposition for the fabrication of ceramic and glass matrix composites. Ceram. Trans. 2004, 153, 57–66. [Google Scholar]

- Ordnung, M.; Lehmann, J.; Ziegler, G. Electrophoretic deposition of silicon powder for the production of fiber-reinforced ceramic matrix composites. In Electrophoretic Deposition, Fundamentals and Applications; The Electrochemical Society: Honolulu, HI, USA, 2002; pp. 255–263. Available online: https://books.google.co.uk/books?hl=en&lr=&id=wkWj4njEJl8C&oi=fnd&pg=PA255&dq=+electrophoretic+deposition+of+silicon+powder&ots=sRYb6d3QK-&sig=Z91jmL-xZaU9AXREAq3TO8z5-ks#v=onepage&q=electrophoretic%20deposition%20of%20silicon%20powder&f=false (accessed on 21 February 2023).

- Kooner, S.; Westby, W.S.; Watson, C.M.A.; Farries, P.M. Processing of Nextel 720/mullite composition. composite using electrophoretic deposition. J. Eur. Ceram. Soc. 2000, 20, 631–638. [Google Scholar] [CrossRef]

- Manocha, L.M.; Panchal, C.; Manocha, S. Silica/silica composites through electrophoretic infiltration. Effect of processing conditions on densification of composites. Sci. Eng. Comp. Mater. 2000, 9, 219–230. [Google Scholar] [CrossRef]

- Kaya, C.; Kaya, F.; Boccaccini, A.R. Electrophoretic de-position infiltration of 2-D metal fiber-reinforced cordierite matrix composites of tubular shape. J. Mater. Sci. 2002, 37, 4145–4153. [Google Scholar] [CrossRef]

- Kaya, C.; Kaya, F.; Atiq, S.; Boccaccini, A.R. Electrophoretic deposition of ceramic coatings on ceramic composite substrates. Br. Ceram. Trans. 2003, 102, 99–102. [Google Scholar] [CrossRef]

- Novak, S.; König, K.; Iveković, A. Electrophoretic Deposition in Production of Ceramic Matrix Composites. In Electrophoretic Deposition of Nanomaterials. Nanostructure Science and Technology; Dickerson, J., Boccaccini, A., Eds.; Springer: New York, NY, USA, 2012. [Google Scholar]

- Corni, I.; Ryan, M.P.; Boccaccini, A.R. Electrophoretic deposition: From traditional ceramics to nanotechnology. J. Eur. Ceram. Soc. 2008, 28, 1353–1367. [Google Scholar] [CrossRef]

- Vignoles, G.L. Modeling of chemical vapor infiltration processes. Adv. Compos. Manuf. Process Des. 2015, 17, 415–458. [Google Scholar]

- Lamon, J. Chemical Vapor Infiltrated SiC/SiC Composites (CVI/SiC/SiC). In Handbook of Ceramic Composites; Springer: New York, NY, USA, 2005; pp. 55–76. [Google Scholar]

- Timofeev, P.A.; Timofeev, I.A.; Bogachev, E.A.; Timofeev, A.N. Modern approaches to the manufacture of ceramic matrix composite materials for long-term operation at temperatures above 1000 °C. Review of world experience and capabilities of JSC “Kompozit”. IOP Conf. Ser. Mater. Sci. Eng. 2019, 683, 012038. [Google Scholar] [CrossRef]

- Lazzeri, A. CVI Processing of Ceramic Composites. In Ceramic and Composites Processing Methods; Wiley: New York, NY, USA, 2012; pp. 313–349. [Google Scholar]

- Naslain, R.R.; Langlais, F. CVD—Processing of ceramic—Ceramic composite materials. In Materials Science Research: Tailoring Multiphase and Composite Ceramics; Springer: Heidelberg, Germany, 1986; Volume 20, pp. 145–164. [Google Scholar]

- Weiss, R. Carbon/carbons and their industrial applications. In Ceramic Matrix Composites, Fiber Reinforced Ceramics and Their Applications; Krenkel, W., Ed.; Wiley-VCH Verlag GmbH & Co.: Weinheim, Germany, 2006; pp. 69–112. [Google Scholar]

- Besmann, T.M.; McLaughlin, J.C.; Lin, H.T. Fabrication of ceramic composites—Forced CVI. J. Nucl. Mater. 1995, 219, 31–35. [Google Scholar] [CrossRef]

- Lackey, W.; Starr, T. Fabrication of fiber-reinforced ceramic composites by chemical vapor infiltration: Processing, structure, and properties. In Proceedings of the 8th Annual Conference on Composites and Advanced Ceramic Materials: Ceramic Engineering and Science Proceedings, Cocoa Beach, FL, USA, 15–18 January 1984; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1990; pp. 397–445. [Google Scholar]

- Yin, Y.; Binner, J.; Cross, T. Cross Microwave-assisted chemical vapor infiltration for ceramic matrix composites. Ceram. Trans. 1997, 80, 349–356. [Google Scholar]

- Binner, J.; Vaidhyanathan, B. When should microwaves be used to process technical ceramics? In Materials Science Forum; Trans Tech Publications, Ltd.: Stafa-Zurich, Switzerland, 2009; Volume 606, pp. 51–59. [Google Scholar]

- Cioni, B.; Lazzeri, A. Modeling and development of a microwave-assisted pilot plant for the production of SiC-based matrix composites. Int. J. Chem. React. Eng. 2008, 6, 1–23. [Google Scholar]

- Timms, L.A.; Westby, W.; Prentice, C.; Jaglin, D.; Shatwell, R.A.; Binner, J.G.P. Reducing chemical vapor infiltration time for ceramic matrix composites. J. Microsc. 2001, 201, 316–323. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.P.; Qian, J.M.; Qiao, G.J.; Jin, Z.H. Improvement of film boiling chemical vapor infiltration process for fabrication of large size C/C composite. Mater. Lett. 2006, 60, 1269–1272. [Google Scholar] [CrossRef]

- Kutemeyer, M.; Schomer, L. Fabrication of ultra high temperature ceramic matrix composites using a reactive melt infiltration process. J. Eur. Ceram. Soc. 2016, 36, 3647–3655. [Google Scholar] [CrossRef]

- Naslain, R.R. Ceramic Matrix Composites: Matrices and Processing. In Encyclopedia of Materials: Science and Technology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 1060–1066. [Google Scholar]

- Zoli, L.; Sciti, D. Efficacy of a ZrB2-SiC matrix in protecting C fibers from oxidation in novel UHTCMC materials. Mater. Des. 2016, 113, 207–213. [Google Scholar] [CrossRef]

- Yin, X.; He, S.; Zhang, L.; Fan, S.; Cheng, L.; Tian, G.; Li, T. Fabrication and characterization of a carbon fibre reinforced carbon-silicon carbide-titanium silicon carbide hybrid matrix composite. Mater. Sci. Eng. A 2010, 527, 835–841. [Google Scholar] [CrossRef]

- Kopeliovich, D. Advances in the manufacture of ceramic matrix composites using infiltration techniques. Adv. Ceram. Matrix Compos. 2014, 5, 79–108. [Google Scholar]

- Mingazzini, C.; Brentari, A.; Burgio, F.; Burresi, E.; Scafè, M.; Pilloni, L.; Caretti, D.; Nanni, D. Optimization of a pyrolysis procedure for obtaining SiC-SiCf CMC by PIP for term structural applications. In Advances in Science and Technology; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2013; Volume 77, pp. 153–158. [Google Scholar]

- Kopeliovich, K. Fabrication of Ceramic Matrix Composites by Polymer Infiltration and Pyrolysis (PIP). 2012. Available online: https://www.substech.com/dokuwiki/doku.php?id=fabrication_of_ceramic_matrix_composites_by_polymer_infiltration_and_pyrolysis_pip (accessed on 23 December 2022).

- Francis, A. Progress in polymer-derived functional silicon-based ceramic composites for biomedical and engineering applications. Mater. Res. Express 2018, 5, 062003. [Google Scholar] [CrossRef]

- Singh, D.; Singh, J.P. The effect of Processing in Strength of Nicalon Fibers in Nicalon Fiber-SiC Matrix Composites. In Proceedings of the 16th Annual Conference on Composites and Advanced Ceramic Materials: Ceramic Engineering and Science Proceedings, Cocoa Beach, FL, USA, 7–10 January 1992; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1992. [Google Scholar]

- Dey, A.; Chatterjee, M.; Naskar, M.K.; Basu, K. Near-net-shape fiber-reinforced ceramic matrix composites by the sol infiltration technique. Mater. Lett. 2003, 57, 2919–2926. [Google Scholar] [CrossRef]

- Naskar, M.K.; Chatterjee, M.; Dey, A.; Basu, K. Effects of processing parameters on the fabrication of near-net-shape fiber-reinforced oxide ceramic matrix composites via sol-gel route. Ceram. Int. 2004, 30, 257–265. [Google Scholar] [CrossRef]

- Young, S.K. Sol-Gel Science for Ceramic Materials. Mater. Matters 2006, 13, 8. [Google Scholar]

- Nazeri, A.; Bescher, E.; Mackenzie, J.D. Ceramic Composites by the Sol-Gel Method: A Review. In Ceramic Engineering and Science Proceedings; John Wiley & Sons: Hoboken, NJ, USA, 2008; Volume 14, pp. 1–19. [Google Scholar]

- Saruhan, B. Fabrication of Oxide-Matrix Composites. In Oxide-Based Fiber-Reinforced Ceramic-Matrix Composites; Springer: New York, NY, USA, 2003. [Google Scholar]

- Molinari, A. Fundamentals of Sintering: Solid State Sintering. In Encyclopedia of Materials: Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 2022; Volume 3, pp. 471–480. [Google Scholar]

- Liu, P.S.; Chen, G.F. Making Porous Metals: Processing and Applications; Elsevier: Amsterdam, The Netherlands, 2014; pp. 21–112. [Google Scholar]

- Wei, Z.Y.; Meng, G.H.; Chen, L.; Li, G.R.; Liu, M.J.; Zhang, W.X.; Zhao, L.N.; Zhang, Q.; Zhang, X.D.; Wan, C.L.; et al. Progress in ceramic materials and structure design toward advanced thermal barrier coatings. J. Adv. Ceram. 2022, 11, 985–1068. [Google Scholar] [CrossRef]

- Laszkiewicz, L.J. Spark Plasma Sintering/Field Assisted Sintering Technique as a Universal Method for the Synthesis, Densification and Bonding Processes for Metal, Ceramic and Composite Material. J. Appl. Mater. Eng. 2021, 60, 53–69. [Google Scholar] [CrossRef]

- Kochendörfer, R.; Lützenburger, N. Applications of CMCs Made via the Liquid Silicon Infiltration (LSI) Technique High-Temperature. In High Temperature Ceramic Matrix Composites; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2001; pp. 277–287. [Google Scholar]

- Margiotta, J.C.; Zhang, D.; Nagle, D.C. A Microstructural evolution during silicon carbide (SiC) formation by liquid silicon infiltration using optical microscopy. Int. J. Refract. Met. Hard Mater. 2010, 28, 191–197. [Google Scholar] [CrossRef]

- Schulte-Fischedick, J.; Seiz, S.; Lützenburger, N.; Wanner, A.; Voggenreiter, H. The crack development on the micro- and mesoscopic scale during the pyrolysis of carbon fibre reinforced plastics to carbon/carbon composites. Compos. Part A-Appl. Sci. Manuf. 2007, 39, 2171–2181. [Google Scholar] [CrossRef]

- Axinte, A.; Ungureanu, D.; Țăranu, N.; Bejan, L.; Isopescu, D.N.; Lupășteanu, R.; Hudișteanu, I.; Roșca, V.E. Influence of Woven-Fabric Type on the Efficiency of Fabric-Reinforced Polymer Composites. Materials 2022, 15, 3165. [Google Scholar] [CrossRef]

- Zivic, F.; Palic, N.; Jovanović, Ž.; Grujovic, N. Processing Routes for Ceramic Matrix Composites (CMCs). In Encyclopedia of Materials: Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 20–36. [Google Scholar] [CrossRef]

- Eichner, M.; Richerson, W.D. Advanced Ceramics Technology Roadmap—Charting Our Course. 1999. Available online: https://advancedceramics.org/clientuploads/pdf/ceramics_roadmap.pdf (accessed on 20 December 2022).

- Willyard, C.H.; McClees, C.W. Motorola’s technology roadmap process. Res.-Technol. Manag. 1987, 30, 13–19. [Google Scholar] [CrossRef]

- Bartusch, R.; Nebelung, M.; Roosen, A.; Scharrer, K.; Werr, U. Thesis paper to prepare a strategic roadmap for ceramic process engineering, part 2: Silicate ceramics. Ceram. Forum Int. 2007, 84, 11–17. [Google Scholar]

- Stephen, F. Global Roadmap for Ceramic and Glass Technology; Wiley Interscience, 1st International Congress on Ceramics; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Rodel, J.; Kounga, A.B.; Weissenberger-Eibl, M.; Koch, D.J. Development of a roadmap for advanced ceramics: 2010–2025. J. Eur. Ceram. Soc. 2009, 29, 1549–1560. [Google Scholar] [CrossRef]

- Costa, D.; Boden, O.; Punie, M.Y.; Zappacosta, M. Science, and Technology Road Mapping: From Industry to Public Policy; IPTS-Report; 2003; Issue 73, 27–32. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC26457 (accessed on 20 December 2022).

- Rana, S.; Fangueiro, R. Advanced Composite Materials for Aerospace Engineering Processing, Properties, and Applications; Composite Science and Engineering No.70; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Yushanov, P.S.; Crompton, J.S.; Koppenhoefer, K.C. Simulation of Manufacturing Process of Ceramic Matrix Composites. In Proceedings of the COMSOL Conference, Hannover, Germany, 4–6 November 2008. [Google Scholar]

- Shestakov, A. Silicon carbide fibers and whiskers for ceramic matrix composites (review). Ind. Lab. Diagn. Mater. 2021, 87, 51–63. [Google Scholar] [CrossRef]

- Mehra, A. Ceramic Matrix Composites Market Worth $25.0 Billion by 2031. MarketsandMarkets™ INC. 2021. Available online: https://www.marketsandmarkets.com/Market-Reports/ceramic-matrix-composites-market-60146548.html?gclid=Cj0KCQiAutyfBhCMARIsAMgcRJQaL22VzdDI8tvVPX1lALJBkqtenKmeWz0RU08T7zSiubNIESIGABsaAigUEALw_wcB (accessed on 24 December 2022).

- Gavada, O.; Axinte, D.A.; Butler, P.; Novovic, D. On understanding the microstructure of SiC/SiC Ceramic Matrix Composites (CMCs) after a material removal process. Mater. Sci. Eng. 2019, 743, 1–11. [Google Scholar]

- Halbig, M.; Singh, M. Additive Manufacturing of SiC-Based Ceramics and Ceramic Matrix Composites. In Proceedings of the 11th International Conference on Ceramic Materials and Components for Energy and Environmental Applications, Vancouver, BC, Canada, 14–19 June 2015. [Google Scholar]

- Steibel, J. Ceramic Matrix Composites Taking Flight at GE Aviation; American Ceramic Society Bulletin: Westerville, OH, USA, 2019; Volume 98, No. 3; Available online: https://ceramics.org/wp-content/uploads/2019/03/April-2019_Feature.pdf (accessed on 23 December 2022).

- Bansal, N.P.; Lamon, J. Ceramic Matrix Composites Materials, Modelling, and Technology; Wiley: New York, NY, USA, 2015; pp. 347–384. [Google Scholar]

- Schwartz, M.M. Joining of Composite Matrix Materials; ASM International: Materials Park, OH, USA, 1994. [Google Scholar]

- Singh, M. Critical Needs for Robust and Reliable Database for Design and Manufacturing of Ceramic Matrix Composites. National Aeronautics and Space Administration: Pasadena, CA, USA, 1999. [Google Scholar]

- Roth, R.; Clark, J.P.; Frank, R. The Potential for CMCs to Replace Superalloys in Engine Exhaust Ducts. JOM 1994, 46, 32–35. [Google Scholar] [CrossRef]

- Dillon, S.J.; Harmer, M.P. Mechanism of solid-state single-crystal conversion in alumina. J. Am. Ceram. Soc. 2007, 90, 993–995. [Google Scholar] [CrossRef]

- Phaal, R.; Farrukh, C.; Probert, D. Collaborative technology road mapping: Network development and research prioritization. Int. J. Technol. Intell. Plan. 2004, 1, 39–55. [Google Scholar]

- Kostoff, R.; Schaller, R. Science and technology roadmaps. IEEE Trans. Eng. Manag. 2001, 48, 132–143. [Google Scholar] [CrossRef]

- Riedel, R.; Mera, G.; Hauser RKlonczynski, A. Silicon-based polymer-derived ceramics: Synthesis, properties, and applications—A review. J. Ceram. Soc. Jpn. 2006, 114, 425–444. [Google Scholar] [CrossRef]

- Green, D.J.; Guillon, O.; Rödel, J. Constrained sintering: A delicate balance of scales. J. Eur. Ceram. Soc. 2008, 28, 1451–1466. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karadimas, G.; Salonitis, K. Ceramic Matrix Composites for Aero Engine Applications—A Review. Appl. Sci. 2023, 13, 3017. https://doi.org/10.3390/app13053017

Karadimas G, Salonitis K. Ceramic Matrix Composites for Aero Engine Applications—A Review. Applied Sciences. 2023; 13(5):3017. https://doi.org/10.3390/app13053017

Chicago/Turabian StyleKaradimas, George, and Konstantinos Salonitis. 2023. "Ceramic Matrix Composites for Aero Engine Applications—A Review" Applied Sciences 13, no. 5: 3017. https://doi.org/10.3390/app13053017

APA StyleKaradimas, G., & Salonitis, K. (2023). Ceramic Matrix Composites for Aero Engine Applications—A Review. Applied Sciences, 13(5), 3017. https://doi.org/10.3390/app13053017