Benefit Analysis of Grid-Connected Floating Photovoltaic System on the Hydropower Reservoir

Abstract

1. Introduction

- ○

- Floating PV plants have a selling price of 1783 VND/kWp, which is equal to 7.69 UScent/kWp.

- ○

- Solar farm PV plants have a selling price of 1644/kWp VND, which is equal to 7.09 UScent/kWp.

- ○

- Rooftop PV plants have a selling price of 1943 VND/kWp, which is equal to 8.38 UScent/kWp.

2. Environmental, Technical, Financial Specifications of the Plant

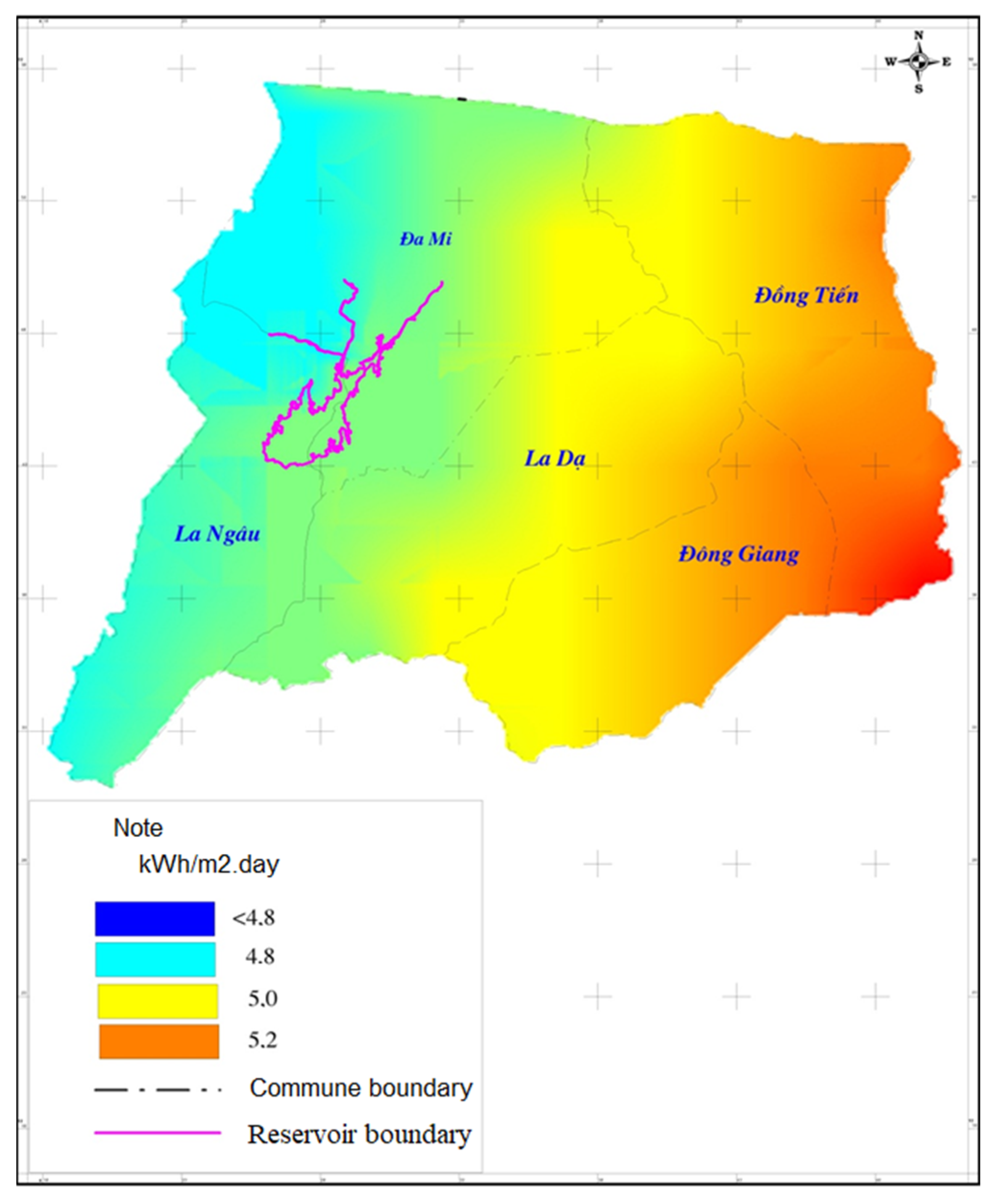

2.1. Solar Radiation Data at the Plant Area

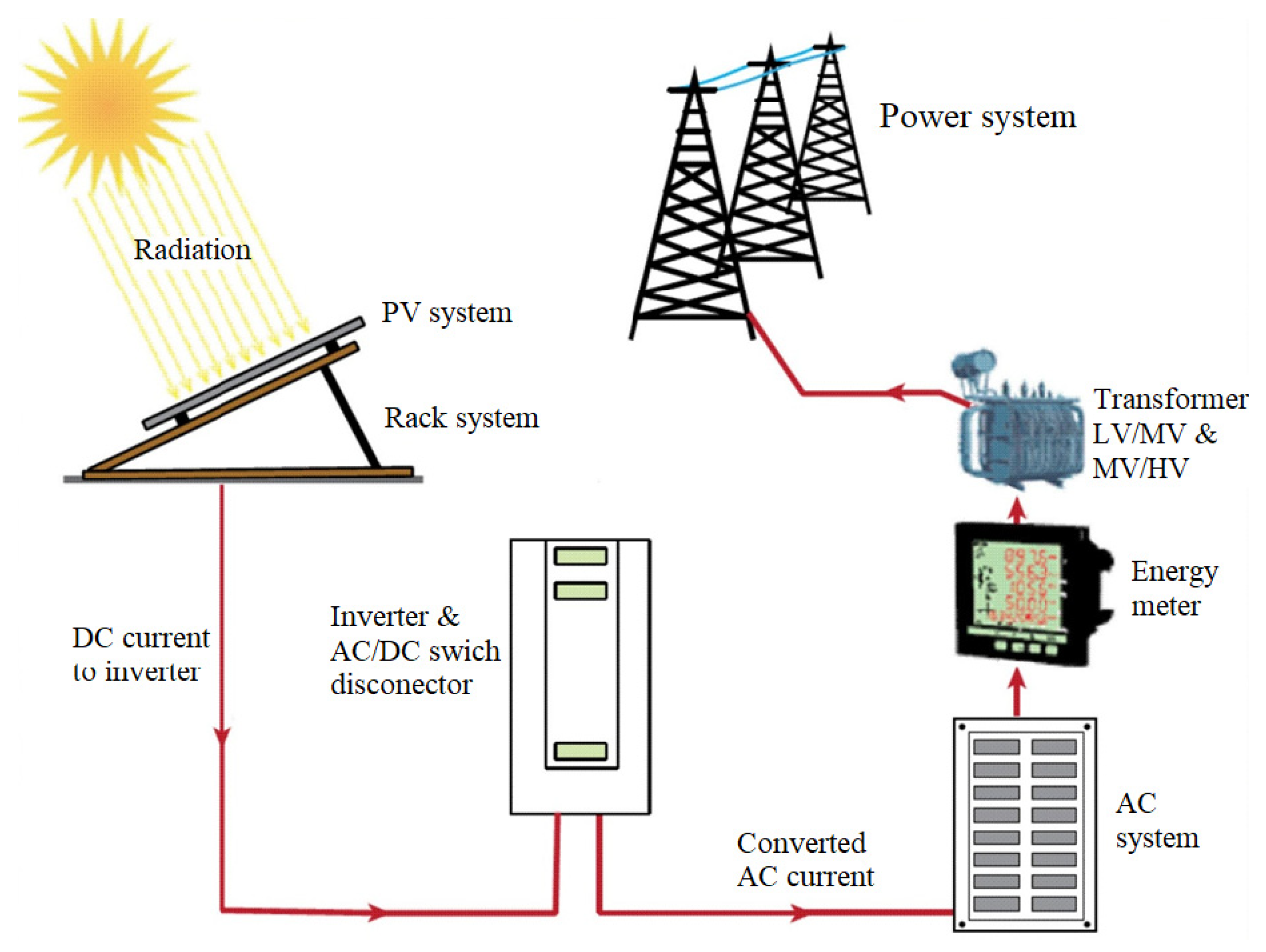

2.2. Specifications

- ○

- PV module: each photovoltaic panel consists of many photovoltaic cells (PV cells) connected together; the photovoltaic panels will be connected in series (string) and parallel (array) to achieve the required DC output power.

- ○

- Inverter: a power electronic device that converts DC current into AC current suitable for connection to the power grid.

- ○

- Mounting system: with the solution of installing panels on the water, the rack system is replaced by a floating float system.

- ○

- Step up transformers: depending on the capacity scale and regional utility grid conditions, the voltage level can be changed appropriately (for example 22 kV, 35 kV, 110 kV, 220 kV…). With high voltage levels, the electricity will need to go through 2 levels of transformers.

- ○

- Infrastructure for grid connection: specifically, here is the substation, including protection, metering, and control equipment.

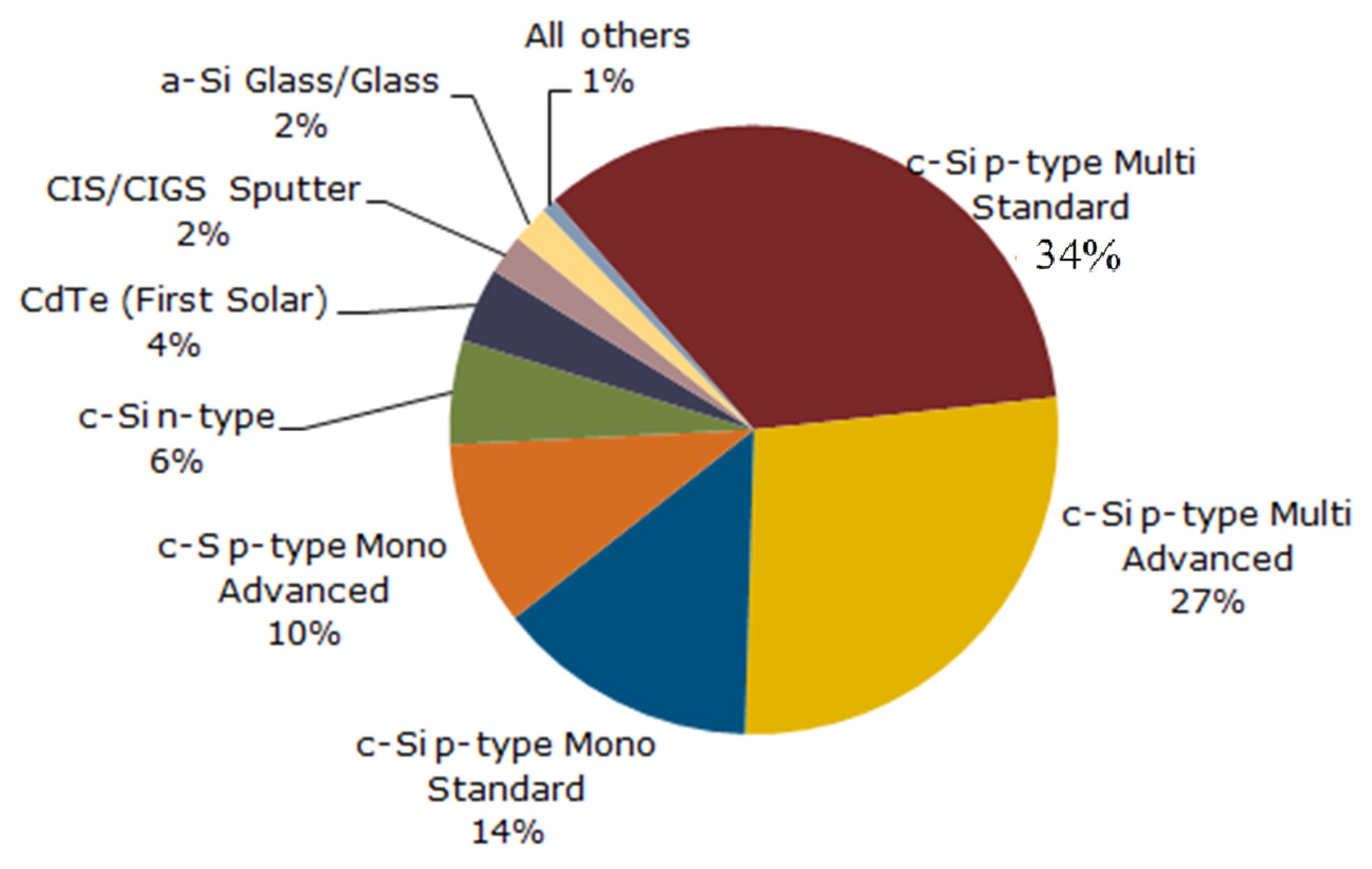

2.2.1. PV Module

2.2.2. Inverter

2.3. Environmental Impact Assessment

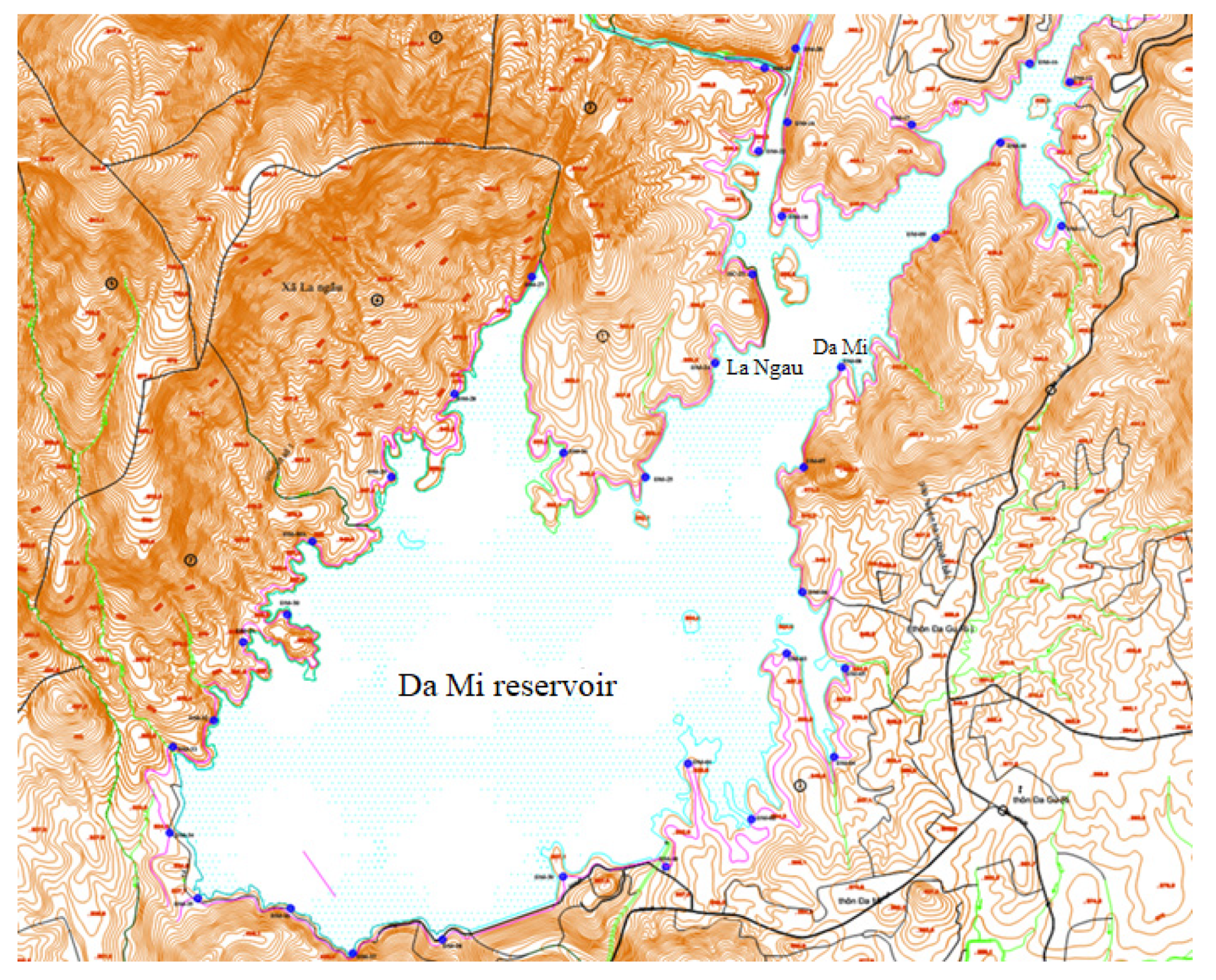

2.3.1. Current Status of Da Mi Hydropower Reservoir

2.3.2. Impact of System Components on the Natural Environment

PV Panel

Substation

Power Line

2.3.3. Effects on People’s Livelihood, National Security, History and Culture

2.4. Incentives and Financial Support

2.4.1. Tax

- ○

- First 4 years of profit: 0% tax rate

- ○

- Next 9 years: 5% tax rate

- ○

- Next 2 years: 10% tax rate

- ○

- The remaining years: 20% tax rate

2.4.2. Electricity Price

2.4.3. Loan Interest Rate

2.4.4. Pay

2.5. Other Financial Parameters

2.6. Cost of PV System

- ○

- Operation and maintenance (O&M) cost is temporarily calculated as: 1.2% (value of construction and equipment of the work) O&M cost increases every year by 2.5%.

- ○

- The cost of dismantling and handling the equipment of the PV plant after the end of the plant includes the following costs: the cost of dismantling the panels and equipment, the cost of transportation to the concentrated location, and the cost of treatment. The cost of handling PV panels is calculated by the cost of destroying the lead battery. All dismantling, transportation, and disposal costs are included in the final year operating costs of the plant.

2.6.1. Depreciation

- ○

- Depreciation of fixed assets by the linear method: Depreciation period of equipment is 10 years, depreciation of the remaining value is 15 years. Value for depreciation calculation is the total investment value of the plant.

2.6.2. Discount Factor

- ○

- Applying Decision No. 2014/QD-BCN on 13 June 2007 on promulgating provisional regulations on economic and financial analysis of investment by the Ministry of Industry and Trade in this plant are as follows:

- ○

- Analysis of financial performance: calculated according to the average financial discount rate for investment sources (WACC) is 7.03%.

- ○

- Economic discount rate 10%.

2.6.3. Total Investment

- ○

- Total investment includes all expenses, such as: costs of compensation, support and resettlement; construction cost; equipment cost; plant management cost; construction investment consulting cost; other expenses and provision expenses are presented in Table 5, below.

3. Economy-Financial Analysis

3.1. Main Calculation

3.1.1. Net Profit Value—NPV

- ○

- where, R is the annual revenue, com is the cost of operating and maintaining the system, IT is the total investment cost of the plant and

- ○

- where, a is the discount rate and n is the life of the plant in years.

- ○

- where, 𝐶𝑖𝑛𝑣 is the replacement cost of the inverters and 𝑛1, 𝑛2 and 𝑛3 is the year in which the replacement will take place.

3.1.2. Internal Rate of Return—ROI (IRR)

3.1.3. Benefit–Cost Ratio—B/C

- ○

- where, Bi is the revenue in year i, Ci is the cost at year i.

3.1.4. Payback Period—PP (Years)

- ○

- where, Ct is discounted (net) cash inflow for the duration of investment ($), C0 is total initial investment costs ($), DPP is discounted payback period (years).

3.1.5. Net Present Cost—NPC

- ○

- ○

- where n refers to the number of years.

- ○

- where, Cann.t is the annualized total cost (including the component-related expenses such as capital, replacement, and maintenance ($)) and Eserved is the annual served energy (kWh).

3.2. National Economy Analysis of the Plant

3.2.1. Meeting the Demand for Electricity Load Growth

3.2.2. Impact on the Environment

3.2.3. Other Effects

3.2.4. Evaluation of Economic Benefits with Other Alternative Energy Sources

3.3. Plant Financial Analysis

- ○

- The financial internal rate of return FIRR must be greater than the cost of capital determined by the borrowing rate or the required cost of the corresponding source of capital.

- ○

- NPV > 0 when calculated according to the discount factor of each required capital source.

- ○

- Benefit-to-cost ratio B/C > 1

- ○

- The sooner the payback period, the better

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saavedra, M.M.R.; Fontes, C.H.d.O.; Freires, F.G.M. Sustainable and Renewable Energy Supply Chain: A System Dynamics Overview. Renew. Sustain. Energy Rev. 2018, 82, 247–259. [Google Scholar] [CrossRef]

- Dominkovi, D.F.; Bacekovi, I.; Sveinbjörnsson, D.; Pedersen, A.S.; Krajaci, G. On the way towards smart energy supply in cities: The impact of interconnecting geographically distributed district heating grids on the energy system. Energy 2017, 137, 941–960. [Google Scholar] [CrossRef]

- Erdiwansyah; Mamat, R.; Sani, M.; Sudhakar, K. Renewable energy in Southeast Asia: Policies and recommendations. Sci. Total Environ. 2019, 670, 1095–1102. [Google Scholar] [CrossRef] [PubMed]

- Daliento, S.; Chouder, A.; Guerriero, P.; Pavan, A.M.; Mellit, A.; Moeini, R.; Tricoli, P. Monitoring, Diagnosis, and Power Forecasting for Photovoltaic Fields: A Review. Int. J. Photoenergy 2017, 2017, 1356851. [Google Scholar] [CrossRef]

- Lin, A.; Lu, M.; Sun, P.; Lin, A.; Lu, M.; Sun, P. The Influence of Local Environmental, Economic and Social Variables on the Spatial Distribution of Photovoltaic Applications across China’s Urban Areas. Energies 2018, 11, 1986. [Google Scholar] [CrossRef]

- Alsafasfeh, M.; Abdel-Qader, I.; Bazuin, B.; Alsafasfeh, Q.; Su, W. Unsupervised Fault Detection and Analysis for Large Photovoltaic Systems Using Drones and Machine, Vision. Energies 2018, 11, 2252. [Google Scholar] [CrossRef]

- Zsiborács, H.; Baranyai, N.H.; Csányi, S.; Vincze, A.; Pintér, G. Economic Analysis of Grid-Connected PV System Regulations: A Hungarian Case Study. Electronics 2019, 8, 149. [Google Scholar] [CrossRef]

- Islam, M.M.M.; Kowsar, A.; Haque, A.K.M.M.; Hossain, M.K.; Ali, H.; Rubel, M.H.K.; Rahman, F. Techno-economic Analysis of Hybrid Renewable Energy System for Healthcare Centre in Northwest Bangladesh. Process Integr. Optim. Sustain. 2022, 1–14. [Google Scholar] [CrossRef]

- Ahmed, P.; Rahman, M.F.; Haque, A.K.M.M.; Mohammed, M.K.A.; Toki, G.F.I.; Ali, M.H.; Kuddus, A.; Rubel, M.H.K.; Hossain, M.K. Feasibility and Techno-Economic Evaluation of Hybrid Photovoltaic System: A Rural Healthcare Center in Bangladesh. Sustainability 2023, 15, 1362. [Google Scholar] [CrossRef]

- Chowdhury, T.; Chowdhury, H.; Hasan, S.; Rahman, S.; Bhuiya, M.M.K.; Chowdhury, P. Design of a stand-alone energy hybrid system for a makeshift health care center: A case study. J. Build. Eng. 2021, 40, 102346. [Google Scholar] [CrossRef]

- Glaisa, K.A.; Elayeb, M.E.; Shetwan, M.A. Potential of Hybrid System Powering School in Libya. Energy Procedia 2014, 57, 1411–1420. [Google Scholar] [CrossRef]

- Aisa, A.; Sharata, A.; Alkhrbash, A.A.; Almoner, M. Modeling and Simulation of a Hybrid Power System for Hospital in Sabratha, Libya via HOMER Software. In Proceedings of the 2022 IEEE 2nd International Maghreb Meeting of the Conference on Sciences and Techniques of Automatic Control and Computer Engineering (MI-STA), Sabratha, Libya, 23–25 May 2022; pp. 161–166. [Google Scholar]

- Aziz, A.S.; Tajuddin, M.F.N.; Adzman, M.R.; Mohammed, M.F.; Ramli, M.A.M. Feasibility analysis of grid-connected and islanded operation of a solar PV microgrid system: A case study of Iraq. Energy 2020, 191, 116591. [Google Scholar] [CrossRef]

- Al-Karaghouli, A.; Kazmerski, L.L. Optimization and life-cycle cost of health clinic PV system for a rural area in southern Iraq using HOMER software. Sol. Energy 2010, 84, 710–714. [Google Scholar] [CrossRef]

- Rad, M.A.V.; Vaghar, M.P.; Kouravand, A.; Bellos, E.; Kasaeian, A. Techno-economic evaluation of stand-alone energy supply to a health clinic considering pandemic diseases (COVID-19) challenge. Sustain. Energy Technol. Assess. 2022, 51, 101909. [Google Scholar]

- Isa, N.M.; Das, H.S.; Tan, C.W.; Yatim, A.H.M.; Lau, K.Y. A techno-economic assessment of a combined heat and power photovoltaic/fuel cell/battery energy system in Malaysia hospital. Energy 2016, 112, 75–90. [Google Scholar] [CrossRef]

- Riayatsyah, T.M.I.; Geumpana, T.A.; Fattah, I.M.R.; Rizal, S.; Mahlia, T.M.I. Techno-Economic Analysis and Optimisation of Campus Grid-Connected Hybrid Renewable Energy System Using HOMER Grid. Sustainability 2022, 14, 7735. [Google Scholar] [CrossRef]

- Sharma, S.K.; Palwalia, D.K.; Shrivastava, V. Performance Analysis of Grid-Connected 10.6 kW (Commercial) Solar PV Power Generation System. Appl. Sol. Energy 2019, 55, 269–281. [Google Scholar] [CrossRef]

- Shahzad, M.K.; Zahid, A.; Rashid, T.U.; Rehan, M.A.; Ali, M.; Ahmad, M. Techno-economic feasibility analysis of a solar-biomass off grid system for the electrification of remote rural areas in Pakistan using HOMER software. Renew. Energy 2017, 106, 264–273. [Google Scholar] [CrossRef]

- Alsagri, A.S.; Alrobaian, A.A.; Nejlaoui, M. Techno-economic evaluation of an off-grid health clinic considering the current and future energy challenges: A rural case study. Renew. Energy 2021, 169, 34–52. [Google Scholar] [CrossRef]

- Guerra, K.; Haro, P.; Gutiérrez, R.E.; Gómez-Barea, A. Facing the high share of variable renewable energy in the power system: Flexibility and stability requirements. Appl. Energy 2022, 310, 118561. [Google Scholar] [CrossRef]

- Karim, M.E.; Karim, R.; Islam, M.T.; Muhammad-Sukki, F.; Bani, N.A.; Muhtazaruddin, M.N. Renewable Energy for Sustainable Growth and Development: An Evaluation of Law and Policy of Bangladesh. Sustainability 2019, 11, 5774. [Google Scholar] [CrossRef]

- Kowsar, A.; Haque, N.; Islam, S.; Debnath, S.C.; Rahaman, M.; Alam, F. Techno-economic evaluation of a 29-kW micro-grid hybrid photovoltaic system for a healthcare center in Bangladesh. AIP Conf. Proc. 2022, 2681, 020071. [Google Scholar] [CrossRef]

- Montero, I.; Miranda, M.T.; Barrena, F.; Sepúlveda, F.J.; Arranz, J.I. Analysis of photovoltaic self-consumption systems for hospitals in southwestern Europe. Energy Build. 2022, 269, 112254. [Google Scholar] [CrossRef]

- Singh, A.; Baredar, P.; Gupta, B. Computational Simulation & Optimization of a Solar, Fuel Cell and Biomass Hybrid Energy System Using HOMER Pro Software. Procedia Eng. 2015, 127, 743–750. [Google Scholar] [CrossRef]

- Thevenard, D.; Pelland, S. Estimating the uncertainty in long-term photovoltaic yield predictions. Sol. Energy 2013, 91, 432–445. [Google Scholar] [CrossRef]

- Rojas-Zerpa, J.C.; Yusta, J.M. Application of Multicriteria Decision Methods for Electric Supply Plantning in Rural and Remote Areas. Renew. Sustain. Energy Rev. 2015, 52, 557–571. [Google Scholar] [CrossRef]

- Praveenkumar, S.; Agyekum, E.B.; Kumar, A.; Ampah, J.D.; Afrane, S.; Amjad, F.; Velkin, V.I. Techno-Economics and the Identification of Environmental Barriers to the Development of Concentrated Solar Thermal Power Plants in India. Appl. Sci. 2022, 12, 10400. [Google Scholar] [CrossRef]

- Ghaithan, A.M.; Mohammed, A. An Optimization Model for Sizing a Hybrid Photovoltaic-Wind-Grid-Connected System in Saudi Arabia. Process Integr. Optim. Sustain. 2022, 6, 1027–1042. [Google Scholar] [CrossRef]

- Adaramola, M.S.; Quansah, D.A.; Agelin-Chaab, M.; Paul, S.S. Multipurpose renewable energy resources based hybrid energy system for remote community in northern Ghana. Sustain. Energy Technol. Assess. 2017, 22, 161–170. [Google Scholar] [CrossRef]

- Lau, K.Y.; Tan, C.W.; Yatim, A.H.M. Effects of ambient temperatures, tilt angles, and orientations on hybrid photovoltaic/diesel systems under equatorial climates. Renew. Sustain. Energy Rev. 2018, 81, 2625–2636. [Google Scholar] [CrossRef]

- Nourdine, B.; Saad, A. Hybrid System for Powering Moroccan Healthcare Centers in Remote Rural Areas. J. Electr. Eng. Technol. 2021, 16, 809–820. [Google Scholar] [CrossRef]

- Olatomiwa, L.; Mekhilef, S. Techno-economic feasibility of hybrid renewable energy system for rural health centre (RHC): The wayward for quality health delivery. In Proceedings of the 2015 IEEE Conference on Energy Conversion (CENCON), Johor Bahru, Malaysia, 19–20 October 2015; pp. 504–509. [Google Scholar] [CrossRef]

- Rahman, M.M.; Saha, S.; Majumder, M.Z.H.; Suki, T.T.; Akter, F.; Haque, M.A.S.; Hossain, M.K. Energy Conservation of Smart Grid System Using Voltage Reduction Technique and Its Challenges. Evergreen 2022, 9, 924–938. [Google Scholar] [CrossRef]

- Zsiborács, H.; Baranyai, N.H.; Vincze, A.; Pintér, G. An Economic Analysis of the Shading Effects of Transmission Lines on Photovoltaic Power Plant Investment Decisions: A Case Study. Sensors 2021, 21, 4973. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Liu, Y.; Zhang, X.; Yang, X.T. Simulation Design and Benefit Analysis of Grid-Connected Photovoltaic System. Appl. Mech. Mater. 2014, 694, 169–172. [Google Scholar] [CrossRef]

- Zsiborács, H.; Pályi, B.; Baranyai, H.N.; Veszelka, M.; Farkas, I.; Pintér, G. Energy performance of the cooled amorphous silicon photovoltaic (PV) technology. Idojaras 2016, 120, 415–430. [Google Scholar]

- International Energy Agency. Technology Roadmap Solar Photovoltaic Energy; International Energy, Agency: Paris, France, 2014; pp. 1–60. [Google Scholar]

- Green, M.A.; Emery, K.; Hishikawa, Y.; Warta, W.; Dunlop, E.D. Solar cell efficiency tables (version 48). Prog. Photovolt. Res. 2016, 24, 905–913. [Google Scholar] [CrossRef]

- Benick, J.; Richter, A.; Muller, R.; Hauser, H.; Feldmann, F.; Krenckel, P.; Riepe, S.; Schindler, F.; Schubert, M.C.; Hermle, M. High-Efficiency n-Type HP mc Silicon Solar Cells. IEEE J. Photovolt. 2017, 7, 1171–1175. [Google Scholar] [CrossRef]

- Green, M.A.; Hishikawa, Y.; Dunlop, E.D.; Levi, D.H.; Hohl-Ebinger, J.; Ho-Baillie, A.W.Y. Solar cell efficiency tables (version 51). Prog. Photovolt. Res. 2018, 26, 3–12. [Google Scholar] [CrossRef]

- Panasonic Corporation. Solar Cell Achieves World’s Highest Energy Conversion Efficiency of 25.6% at Research Level. Available online: http://news.panasonic.com/global/press/data/2014/04/en140410-4/en140410-4.html (accessed on 15 February 2018).

- SecondSol Inc. New and Used PV Module Prices. Available online: https://www.secondsol.com/en/categories/Photovoltaic-Modules_40939 (accessed on 20 February 2018).

- Gionta, E. Design, Feasibility study and environmental analysis of a grid connected PV system in Cambodia. Thesis to obtain the Master of Science Degree in Energy Engineering and Management. Master’s Thesis, TÉCNICO LISBOA, Lisbon, Portugal, November 2018. [Google Scholar]

- HOMERPro. HOMER Help Files; HOMER Pro, version 3.14.5; HOMER Grid: Boulder, CO, USA, 2021. [Google Scholar]

- Brealey, R.; Myers, S.; Allen, F. Principles of Corporate Finance, 13th ed.; McGraw-Hill/Irwin: New York, NY, USA, 2019. [Google Scholar]

- Mandal, S.; Das, B.K.; Hoque, N. Optimum sizing of a stand-alone hybrid energy system for rural electrification in Bangladesh. J. Clean. Prod. 2018, 200, 12–27. [Google Scholar] [CrossRef]

- Peerapong, P.; Limmeechokchai, B. Optimal electricity development by increasing solar resources in diesel-based micro grid of island society in Thailand. Energy Rep. 2017, 3, 1–13. [Google Scholar] [CrossRef]

- Singh, S.; Singh, M.; Kaushik, S.C. Feasibility study of an islanded microgrid in rural area consisting of PV, wind, biomass and battery energy storage system. Energy Convers. Manag. 2016, 128, 178–190. [Google Scholar] [CrossRef]

- Heydari, A.; Askarzadeh, A. Optimization of a biomass-based photovoltaic power plant for an off-grid application subject to loss of power supply probability concept. Appl. Energy 2016, 165, 601–611. [Google Scholar] [CrossRef]

| Location | Researchers & Methodology | Design Specification | Remarks in Benefit Evaluation |

|---|---|---|---|

| Northwestern region of Bangladesh | Md. Mahai Menul Islam et al. [8] used HOMER Powering Health Tool and HOMER Pro to analyze the technical and financial data. | The microgrid hybrid PV system: 80 Solar panel: 120 cell 400 Wp mono-crystalline panel, 20.8% efficiency. 1 Grid tied inverter: 25 kW 3 Phase inverter with 98.6% efficiency. 1 Generator: 28 kW generator. | The return on investment, internal rate of return, discounted payback, and payback time are estimated as 9.8%, 12.7%, 6.95 years, and 7.53 years, respectively. The electricity production cost is US$ 0.065. |

| Thakurgaon, Bangladesh | Polash Ahmed et al. [9] used HOMER Pro to perform the techno—economic evaluation. | The microgrid hybrid PV system: 24 kW PV panel: 400 Wp, MONO PERC HALF CELL MODULE, 19.88% efficiency. 11 kW Converter. 17 kW Diesel Generator. | The electricity production cost was $0.06/kWh; CO2 emissions 399 kg/year; Investment expenses will be recovered in 7.7 years. |

| Saint Martin Island, Bangladesh | Tamal Chowdhury et al. [10] used Homer pro software to design and model the system. | A stand-alone energy hybrid system: PV module: 327 W. Diesel Generator: 57 kW, 50 Hz. Wind turbine: 1 kW, 12–48 VDC. Battery: 6 V, 820 Ah (4.92 kWh). Inverter: 1 kW. | Levelized cost of energy (LCOE) is 35% lower than the solar home system. The PB, ROI, and IRR of the optimized system are 7 years, 10, and 13%, respectively. 27% less CO2 than a diesel-based fuel system. |

| Misurata, Libya | Khalil Abdulfattah Glaisa et al. [11] used HOMER to evaluate the different configuration options. | Power system Components Considered: Generator 1 kW. PV panels 1 kW. Wind turbine 20 kW. Trojan L-16 battery. Converter 1 kW. | Case 1: NPC of 293,961 US$, COE of US$ 0.191/kWh, and RF of 53%. Case 2: NPC of 384,181 US$, COE of US$ 0.25/kWh, and RF of 79%. Case 3: NPC of 753,505 US$ and COE of US$ 0.489/kWh, and RF of 71%. |

| Sabratha, Libya | Ahmed Aisa et al. [12] used HOMER software for optimizations and simulations. | A 10 kW wind turbine. A 350 W solar panel. The batteries and generator systems were selected. | The optimization performance at PV array 1507.73 MWh/yr, wind turbine 596.81 MWh/yr, and generator 588.31 MWh/yr, while the cost of energy is $0.182/kWh. |

| Baghdad, Iraq | Ali Saleh Aziz et al. [13] used HOMER software to carry out the overall analysis using five different control strategies. | A PV microgrid system to supply electricity for a household. PV module: Canadian solar-mono, 18% efficiency. Converter: the PH18-5048 Plus on/off-grid hybrid inverter, 5 kW. Battery: Trojan SAGM 12,205, 12-V batteries, 2.63 kWh. Grid: The PV arrays supply the daytime only. Controller: management system. | The NPC of $29,713. The lowest CO2 emissions with 64.9% and 4533 kg/year, respectively. The NPC by 11.6%, while increasing the CO2 emissions by 32.7%. |

| southern Iraq | Ali Al-Karaghouli and L.L. Kazmerski [14] Used the HOMER software. | The most economic system for a remote health clinic in southern Iraq having a daily load of 31.6 kWh is composed of 6 kW PV modules, 80 batteries (225 Ah and 6 V), and a 3 kW inverter. | COE US$ 0.238/kWh. Prevent 14,927 kg/yr of CO2, 36.8 kg/yr of CO, 329 kg/yr of NOx, 4.08 kg/yr of HC, 30 kg/yr of SO2, and 278 kg/yr of suspended particles. |

| Chutani village, Iran | Mohammad Amin Vaziri Rad et al. [15] considered COVID-19 scenarios. | The optimized includes a 5.2 kW PV, a 2.7 kW converter, a 2 kW DG, and a 5 kWh battery. | COE of $0.133/kWh. |

| Cheras, Selangor, Malaysia | Normazlina Mat Isa et al. [16] used HOMER software to perform the techno-economic analysis. | The proposed cogeneration system consists of grid connected photovoltaic, fuel cell, and battery generating both electricity and heat at the same time. | The NPC is $ 98,318 and LCOE is $0.0841/kWh. COE can be saved up to 30%. It only produces 25,708 kg/yr of CO2, 111 kg/yr of SO2 and 54.5 kg/yr of NO. |

| Aceh, Indonesia | T.M.I. Riayatsyah et al. [17] used HOMER to analyse and optimise the renewable energy. | The system architecture consists of power sources from the utility, PV, wind turbine, lithium battery, and converter are connected to a local utility grid. | 682 kW solar PV, 100 kW wind turbine and 431 kW converter, which contributed 62% and 20%, respectively. The CoE decreased to $0.0446/kWh from $0.06/kWh. |

| Rajasthan, India | Santosh Kumar Sharma et al. [18] used MATLAB for the analysis of MPP tracker. | A rooftop grid-connected solar PV power plant: 83 PV modules of TRINA. 34.35 kW Inverter. | The value of PP and LCCE, have been calculated as 6 years, 0.007 respectively. |

| Punjab, Pakistan | M. Kashif Shahzad et al. [19] used HOMER to design and perform techno-economic analysis. | The hybrid system: Solar modules of 10 kW. Biogas fueled generator of 8 kW. 32 Li-ion, 6.0 volt batteries of 167 Ah. Converter of 12 kW. | The NPC of PKR4.48M. Provides 432 electricity to the consumers at the low cost of 5.51 PKR/kWh. Payback period of 9.5 years. |

| All regions located in Saudi Arabia | Ali Sulaiman Alsagri et al. [20] used HOMER software to assess the techno-economic and environmental aspects of the possible solutions. | A hybrid energy system including PV panels, diesel generator, and battery bank is considered: The development of off-grid renewable systems is not economically attractive. PV module: Sharp ND-250QCS, 15.3% Efficiency. Diesel Generator: GREAVES Power, 25% Minimum Load Ratio. Battery Unit: 1 kWh Li-Ion, 3000 kWh. Fuel Cell Unit: Proton-exchange membrane, 40% Efficiency. Converter: 95% Inverter Efficiency. | The COE of the optimal system is 0.105 $/kWh, which can reach 0.120 $/kWh in the areas with poor solar radiation. A 2 kW electrolyzer, despite the unfavorable increase in the energy costs, can reduce the excess electricity from 32.5% to 6%. The cost of energy can increase by up to 23.8%; moreover, by imposing fuel restrictions, the excess electricity can reach more than 60%. |

| Technology | p-Si | m-Si | HIT | a-Si | CdTe | CIGS/CIS |

|---|---|---|---|---|---|---|

| Efficiency | 13–17% | 16–21% | 18–20% | 6–9% | 8–16% | 8–14% |

| Temperature coefficient | −0.45%/°C | −0.45%/°C | 0.29%/°C | −0.21%/°C | −0.25%/°C | −0.35%/°C |

| PV Type | Capacity (Wp) | Efficiency (%) | Number of Panels | PV Energy (MWh/Year) | Total Area of Panels (ha) |

|---|---|---|---|---|---|

| 72 cell-poly | 305 | 15.72 | 155,740 | 69,609 | 30.22 |

| 310 | 15.98 | 153,220 | 69,552 | 29.73 | |

| 315 | 16.23 | 150,800 | 69,381 | 29.26 | |

| 320 | 16.49 | 148,440 | 69,340 | 28.80 | |

| 325 | 16.75 | 146,160 | 69,500 | 28.36 | |

| 330 | 17.01 | 143,940 | 69,519 | 27.93 | |

| 335 | 17.26 | 141,800 | 69,569 | 27.51 |

| Parameters | Eaton | SMA | Schneider | ABB | |||

|---|---|---|---|---|---|---|---|

| 1670 | 2000 | 2200 | 1000 | 2500 | 680 | 1000 | |

| AC capacity (kW) at pf = 1 (50 °C) | 1666 | 2000 | 2200 | 900 | 2250 | 680 | 1000 |

| AC capacity (kVA) (50 °C) | 1831 | 2000 | 2200 | 900 | 2250 | 680 | 1000 |

| DC voltage (V) | 550–1000 | 550–1000 | 605–1000 | 625–850 | 850–1425 | 550–885 | 600–850 |

| DC max current (A) | 3100 | 3700 | 3700 | 1635 | 3000 | 1280 | 1710 |

| AC voltage (V) | 356 | 384 | 423 | 365–465 | 440–660 | 380 | 400 |

| AC max current (A) | 2707 | 3000 | 3000 | 1568 | 2624 | 1040 | 1445 |

| No | Category of Work | Pre-Tax Value | VAT Tax | Value after Tax |

|---|---|---|---|---|

| 1 | Compensation, support and resettlement expenses | 5711 | 0 | 5711 |

| 2 | Construction cost | 501,098 | 50,110 | 551,208 |

| 3 | Equipment cost | 594,622 | 59,462 | 654,084 |

| 4 | Project management cost | 10,747 | 0 | 10,747 |

| 5 | Construction investment consulting cost | 32,356 | 3236 | 35,592 |

| 6 | Other cost | 70,966 | 3542 | 74,508 |

| 7 | Redundancy cost | 97,417 | 9610 | 107,027 |

| Total investment | 1,312,917 | 125,960 | 1,438,877 |

| Economic Indicators Achieved | Result | Unit |

|---|---|---|

| - Electricity price | 14.5 | UScent/kWh |

| - IRR | 17.2 | % |

| - NPV | 664.3 | billions VND |

| - B/C | 1.55 | |

| - Payback time | 9.3 | year |

| Financial Targets Achieved | Result | Unit |

|---|---|---|

| Financial discount factor (iF) | 6.95 | % |

| Electricity price | 9.35 | UScent/kWh |

| IRR | 11.14 | % |

| NPV | 220.3 | billions VND |

| B/C | 1.211 | |

| Payback time | 14.4 | year |

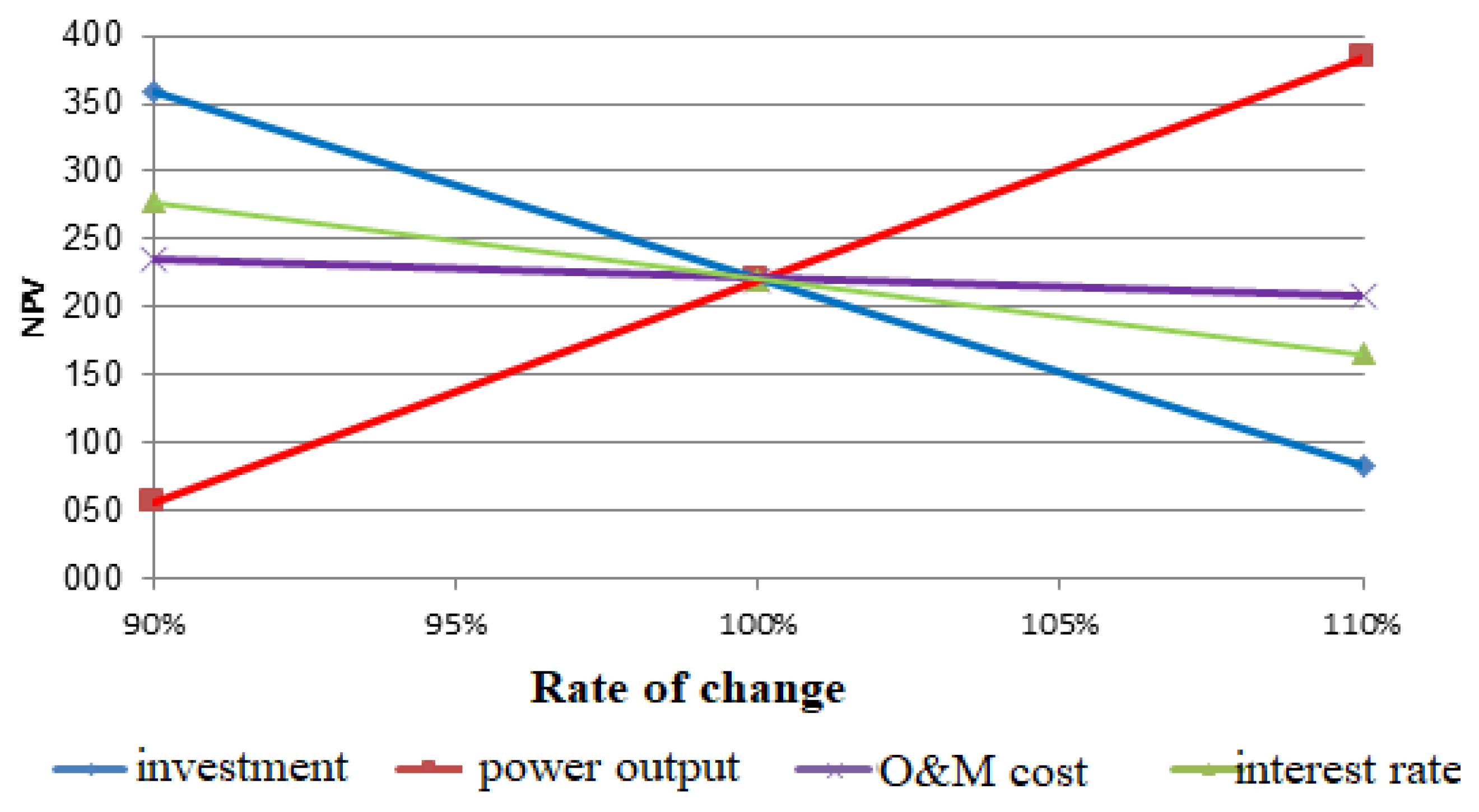

| No. | Targets | 1. Investment Capital Increased by 10% | 2. Power Generation Reduced by 10% | 3. O&M Costs Increased by 10% | 4. Investment Capital Increased by 10%, Electricity Generation Decreased by 10% |

|---|---|---|---|---|---|

| 1 | IRR % | 8.43% | 8.08% | 10.9% | 5.70% |

| 2 | NPVf (billions VND) | 82.9 | 56.8 | 205.50 | 79.2 |

| 3 | B/Cf | 1.073 | 1.055 | 1.20 | 0.931 |

| 4 | Discounted payback period (years) | 17.5 | 18.0 | 14.7 | >20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, N.-H.; Le, B.-C.; Bui, T.-T. Benefit Analysis of Grid-Connected Floating Photovoltaic System on the Hydropower Reservoir. Appl. Sci. 2023, 13, 2948. https://doi.org/10.3390/app13052948

Nguyen N-H, Le B-C, Bui T-T. Benefit Analysis of Grid-Connected Floating Photovoltaic System on the Hydropower Reservoir. Applied Sciences. 2023; 13(5):2948. https://doi.org/10.3390/app13052948

Chicago/Turabian StyleNguyen, Nghia-Hieu, Bao-Chi Le, and Thanh-Trung Bui. 2023. "Benefit Analysis of Grid-Connected Floating Photovoltaic System on the Hydropower Reservoir" Applied Sciences 13, no. 5: 2948. https://doi.org/10.3390/app13052948

APA StyleNguyen, N.-H., Le, B.-C., & Bui, T.-T. (2023). Benefit Analysis of Grid-Connected Floating Photovoltaic System on the Hydropower Reservoir. Applied Sciences, 13(5), 2948. https://doi.org/10.3390/app13052948