Application of Improved Process Neural Network Based on the Fireworks Algorithm in the Temperature-Rise Predictions of a Large Generator Rotor

Abstract

:1. Introduction

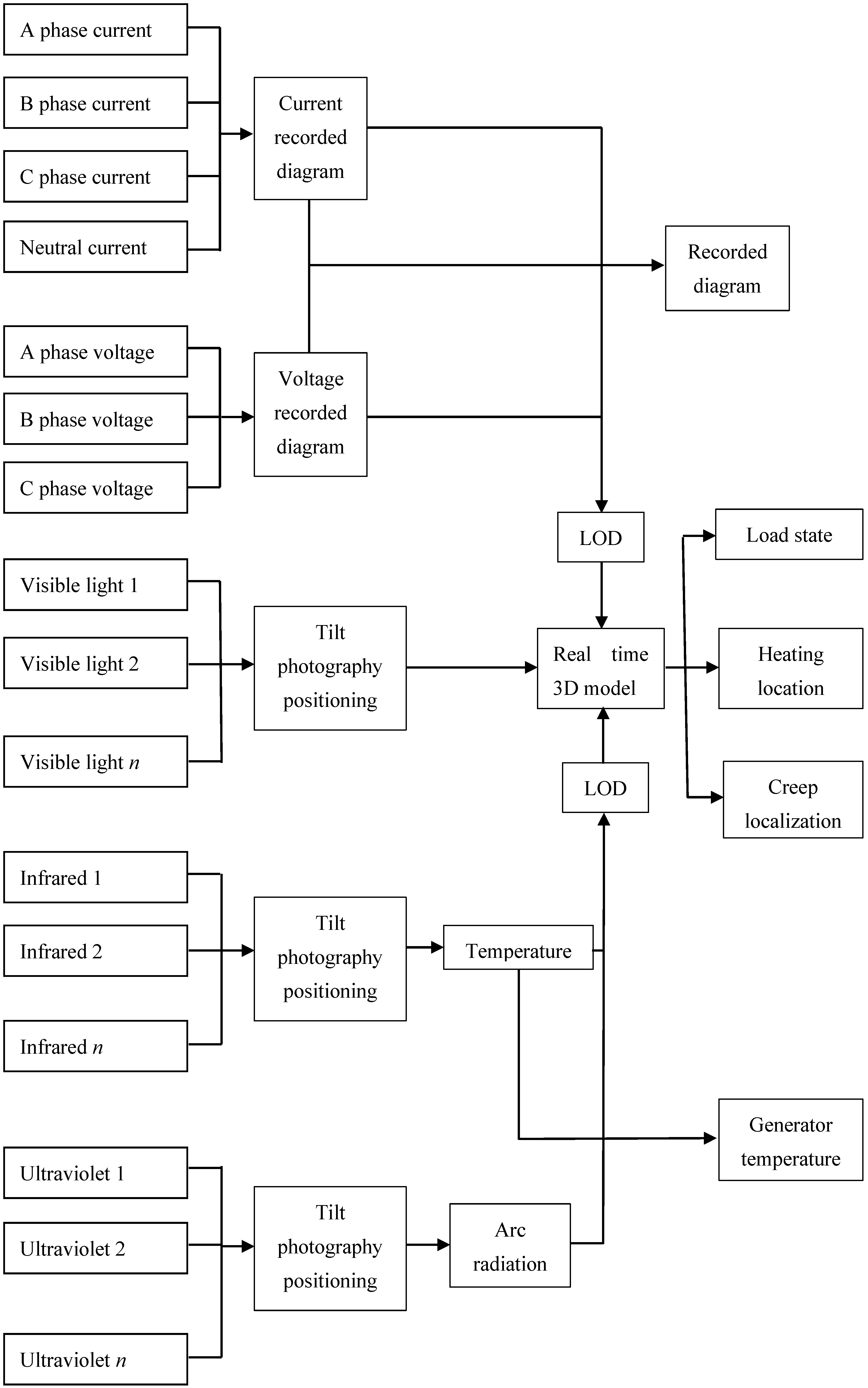

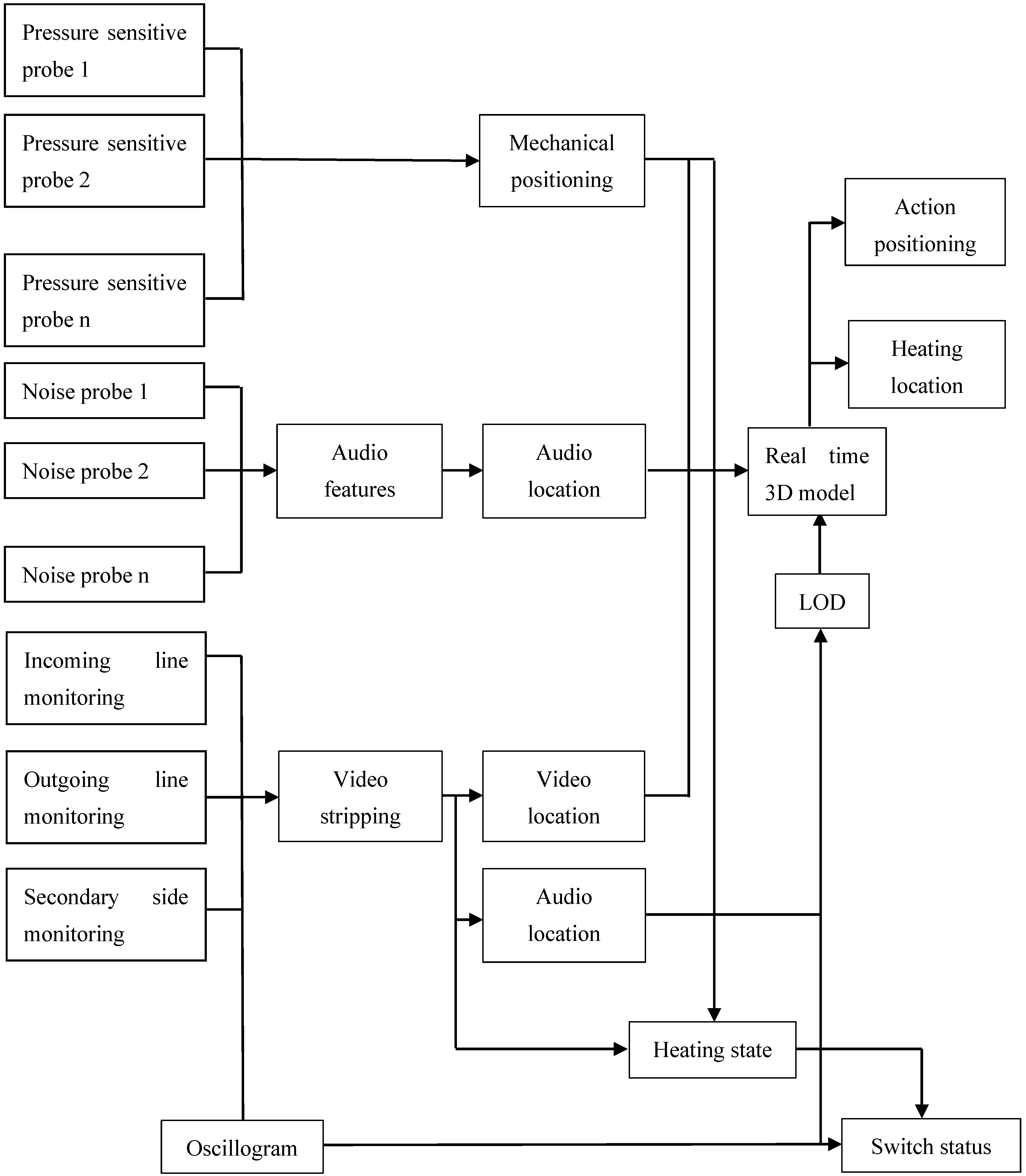

2. Requirements on Computing and Data Resources of Large Generator Operation States

2.1. Composition of Data Processing System

2.2. Difficulties in Intelligent Computing of Operation Data

3. Proposal and Verification of Improved LoTFWA

3.1. Classic Algorithm of LoTFWA

3.2. Improved LoTFWA Based on Location Feature Mapping Rules

3.3. Validation and Analysis of ILoTFWA

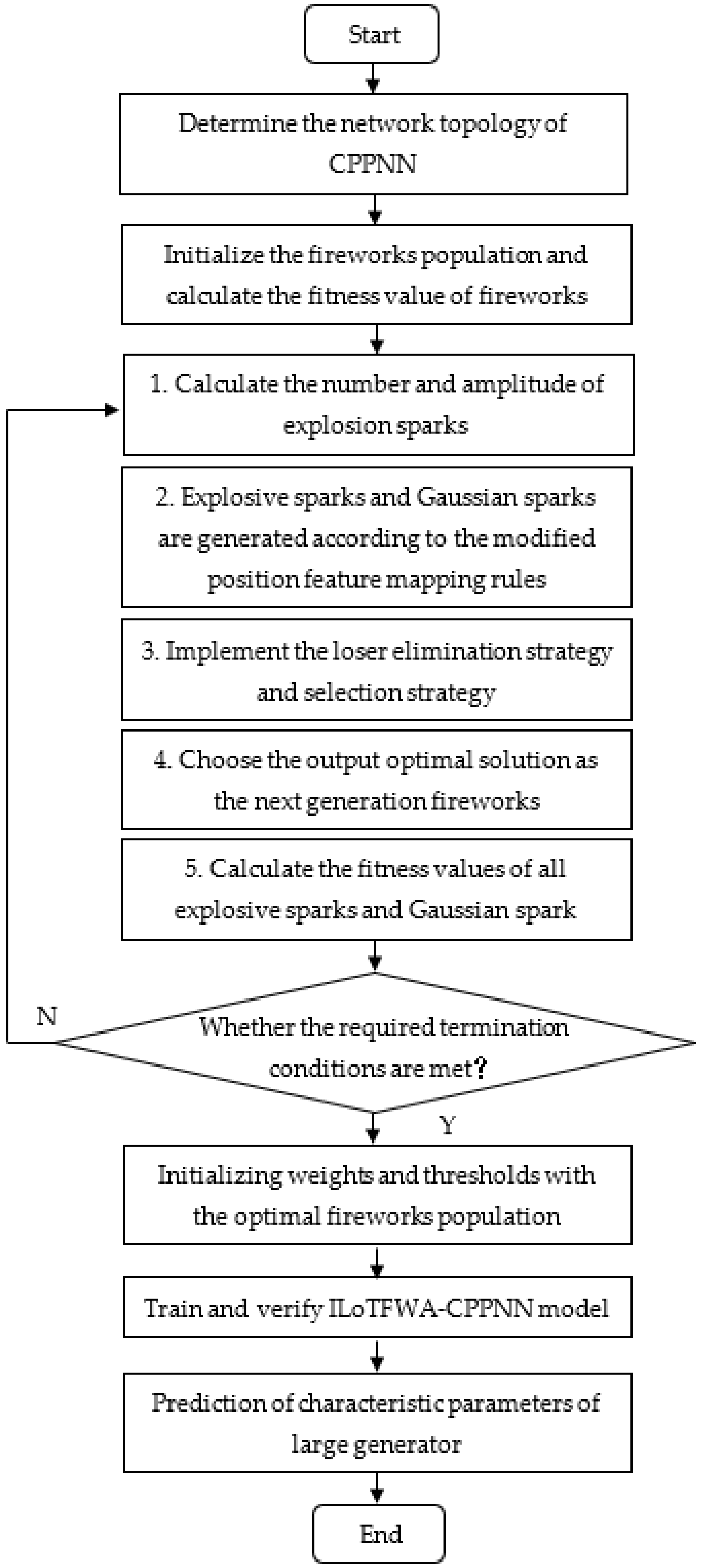

4. Process Neural Network Model Optimized by ILoTFWA

4.1. CPPNN Model

4.2. Structural Optimization Design of CPPNN Based on ILoTFWA

4.3. Validation of ILoTFWA-CPPNN Algorithm Model

5. Prediction and Analysis of Maximum Temperature Rise

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Z.T.; Li, H.; Yang, Y.; Zhang, H.B.; Fan, Z.N. Real-Time Monitoring System for Rotor Temperature of a Large Turbogenerator Based on SmartMesh IP Wireless Network Communication Technology. China Commun. 2022, 19, 150–163. [Google Scholar] [CrossRef]

- Tappura, K.; Juntunen, T.; Jaakkola, K.; Ruoho, M.; Tittonen, I.; Ritasalo, R.; Pudas, M. Large-area implementation and critical evaluation of the material and fabrication aspects of a thin-film thermoelectric generator based on aluminum-doped zinc oxide. Renew. Energy 2020, 147, 1292–1298. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.X.; Newbrook, D.W.; Dai, P.; Kees, C.H.; Huang, R.M. Artificial neural network enabled accurate geometrical design and optimisation of thermoelectric generator. Appl. Energy 2022, 305, 117800. [Google Scholar] [CrossRef]

- Xie, X.D.; Wen, S.P.; Zeng, Z.G.; Huang, T.W. Memristor-based circuit implementation of pulse-coupled neural network with dynamical threshold generators. Neurocomputing 2018, 284, 10–16. [Google Scholar] [CrossRef]

- Jin, X.; Chen, Y.M.; Wang, L.; Han, H.L.; Chen, P. Failure prediction, monitoring and diagnosis methods for slewing bearings of large-scale wind turbine: A review. Measurement 2021, 172, 108855. [Google Scholar] [CrossRef]

- Tekerek, A.; Kurt, E. Artificial neural network analysis on an axial flux permanent magnet generator having variable air gap and power regime. Sadhana Acad. Proc. Eng. Sci. 2021, 46, 240. [Google Scholar] [CrossRef]

- Sumathi, S.; Bansilal. Artificial Neural Network for coordinated control of STATCOM, generator excitation and tap changing transformer. J. Renew. Sustain. Energy 2015, 64, 536–541. [Google Scholar] [CrossRef]

- Shariati, O.; Aghamohammadi, M.R.; Potter, B. On-Line Determination of Salient-Pole Hydro Generator Parameters by Neural Network Estimator Using Operating Data (PEANN). IEEE Access 2021, 9, 134638–134648. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Verma, K.; Niazi, K.R.; Fozdar, M. Real-Time Monitoring of Post-Fault Scenario for Determining Generator Coherency and Transient Stability through ANN. IEEE Trans. Ind. Appl. 2018, 54, 685–692. [Google Scholar] [CrossRef]

- Sharifi, A.; Sharafian, A.; Ai, Q. Adaptive MLP neural network controller for consensus tracking of Multi-Agent systems with application to synchronous generators. Expert Syst. Appl. 2021, 184, 115460. [Google Scholar] [CrossRef]

- Wang, T.C.; Wang, J.Y.; Wu, Y.; Sheng, X. A fault diagnosis model based on weighted extension neural network for turbo-generator sets on small samples with noise. Chin. J. Aeronaut. 2020, 33, 2757–2769. [Google Scholar] [CrossRef]

- Duan, Y.Z.; He, X. A Non-convex Dispatch Problem with Generator Constraints Using Neural Network and Particle Swarm Optimization. Iran. J. Sci. Technol. Trans. Electr. Eng. 2020, 44, 185–196. [Google Scholar] [CrossRef]

- Yan, D.F.; Hu, B. Shared Representation Generator for Relation Extraction with Piecewise-LSTM Convolutional Neural Networks. IEEE Access 2019, 12, 31672–31680. [Google Scholar] [CrossRef]

- Yao, F.J.; Zhao, J.B.; Li, X.J.; Mao, L.; Qu, K.Q. RBF Neural Network Based Virtual Synchronous Generator Control with Improved Frequency Stability. IEEE Trans. Ind. Inform. 2021, 17, 4014–4024. [Google Scholar] [CrossRef]

- Wang, F.; Bao, W.; Wang, Y.; Wang, X.; Ren, K.; Wang, Z.; Li, J. Ejection state prediction for a pneumatic micro-droplet generator by BP neural networks. J. Adv. Mech. Des. Syst. Manuf. 2020, 14, JAMDSM0001. [Google Scholar] [CrossRef] [Green Version]

- Quan, Q.; Zhang, Z.Q. Supply Capability Evaluation of Intelligent Manufacturing Enterprises Based on Improved BP Neural Network. J. Math. 2022, 2022, 8572424. [Google Scholar] [CrossRef]

- Jin, X.H.; Xu, Z.W.; Qiao, W. Condition Monitoring of Wind Turbine Generators Using SCADA Data Analysis. IEEE Trans. Sustain. Energy 2021, 12, 202–210. [Google Scholar] [CrossRef]

- Kreischer, C. Modern methods to monitor end winding vibrations in turbo-generators. Compel Int. J. Comput. Math. Electr. Electron. Eng. 2019, 38, 1214–1223. [Google Scholar] [CrossRef]

- Sawant, S.S.; Wiedmann, M.; Gob, S.; Holzer, N.; Lang, E.W.; Gotz, T. Compression of Deep Convolutional Neural Network Using Additional Importance-Weight-Based Filter Pruning Approach. Appl. Sci. 2022, 12, 11184. [Google Scholar] [CrossRef]

- Ghazvini, M.; Varedi-Koulaei, S.M.; Ahmadi, M.H.; Kim, M. Optimization of MLP neural network for modeling flow boiling performance of Al2O3/water nanofluids in a horizontal tube. Eng. Anal. Bound. Elem. 2022, 7, 3214–3221. [Google Scholar] [CrossRef]

- Haddadi, A.; Zhao, M.X.; Kocar, I.; Karaagac, U.; Chan, K.W.; Farantatos, E. Impact of Inverter-Based Resources on Negative Sequence Quantities-Based Protection Elements. IEEE Trans. Power Deliv. 2021, 36, 289–298. [Google Scholar] [CrossRef]

- Li, L.; Chen, M.; Wang, F.; Xu, A.A. The Influence of Rotor Adjustment Parameters on the Dynamic Balance of a Scale-Model Rigid Variable Speed Rotor. Appl. Energy 2022, 12, 12125. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Kang, C.; Zhao, H.X.; Teng, S. Effects of in-line configuration of drag-type hydrokinetic rotors on inter-rotor flow pattern and rotor performance. Energy Convers. Manag. 2019, 196, 44–55. [Google Scholar] [CrossRef]

- Gulbahce, M.O.; Mcguiness, D.T.; Kocabas, D.A. Shielded axially slitted solid rotor design for high-speed solid rotor induction motors. IET Electr. Power Appl. 2018, 12, 1371–1377. [Google Scholar] [CrossRef]

- Schreier, L.; Bendl, J.; Chomat, M. Analysis of stator and rotor currents and torque of induction machine with rotor-bar faults. Electr. Eng. 2020, 103, 519–528. [Google Scholar] [CrossRef]

- Ghazvini, M.; Maddah, H.; Peymanfar, R.; Ahmadi, M.H.; Kumar, R. Experimental evaluation and artificial neural network modeling of thermal conductivity of water based nanofluid containing magnetic copper nanoparticles. Phys. A Stat. Mech. Its Appl. 2020, 551, 124127. [Google Scholar] [CrossRef]

- Liu, Z.P.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- He, X.G.; Xv, S.H. Process Neural Network, 1st ed.; Science Press: Beijing, China, 2007; pp. 18–24, 40–51, 147–150. [Google Scholar]

- Lin, C.H. Wind Turbine Driving a PM Synchronous Generator Using Novel Recurrent Chebyshev Neural Network Control with the Ideal Learning Rate. Energies 2016, 9, 441. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Mohammed, O.M.E.; Liu, Y.; Islam, M.R. Negative Sequence Voltage Compensating for Unbalanced Standalone Brushless Doubly-Fed Induction Generator. IEEE Trans. Power Electron. 2020, 359, 667–680. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.C.; Chen, L.; Huang, X.W.; Du, X.Z.; Yang, L.J. Performance of natural draft hybrid cooling system of large scale steam turbine generator unit. Appl. Therm. Eng. 2017, 122, 227–244. [Google Scholar] [CrossRef]

- Tan, Y.; Ding, J. Recent Advances in Fireworks Algorithm, 1st ed.; Science Press: Beijing, China, 2015; pp. 1–21. [Google Scholar]

- Ouyang, H.B.; Wei, W.Q.; Li, S.V.; Zhao, X.B.; Zou, D.X. A modified fireworks algorithm with dynamic search interval based on closed-loop control. Math. Comput. Simul. 2022, 200, 329–360. [Google Scholar]

- Han, S.F.; Zhu, K.; Zhou, M.C.; Liu, X.J.; Liu, H.Y.; Al-Turki, Y.; Abusorrah, A. A Novel Multiobjective Fireworks Algorithm and Its Applications to Imbalanced Distance Minimization Problems. IEEE CAA J. Autom. Sin. 2022, 9, 1476–1489. [Google Scholar] [CrossRef]

- Yu, J.Y.; Guo, J.S.; Zhang, X.F.; Zhou, C.H.; Xie, T.; Han, X. A Novel Tent-Levy Fireworks Algorithm for the UAV Task Allocation Problem under Uncertain Environment. IEEE Access 2022, 10, 102373–102385. [Google Scholar] [CrossRef]

- Li, J.; Tan, Y. Loser-Out Tournament-Based Fireworks Algorithm for Multimodal Function Optimization. IEEE Trans. Evol. Comput. 2018, 22, 679–691. [Google Scholar] [CrossRef]

- Guo, W.; Ge, B.; Gao, Y.; Li, M. Negative-sequence component analysis of an AP1000 nuclear turbo-generator in an internal short-circuit condition. Electr. Power Compon. Syst. 2015, 43, 633–643. [Google Scholar] [CrossRef]

- Cao, J.; Wang, D.; Wang, Q.M.; Yuan, X.L.; Wang, K.; Chen, C.L. Network Attack Detection Method of the Cyber-Physical Power System Based on Ensemble Learning. Appl. Sci. 2022, 12, 6498. [Google Scholar] [CrossRef]

- Camacho, A.; Castilla, M.; Miret, J.; Velasco, M.; Guzman, R. Positive-Sequence Voltage Control, Full Negative-Sequence Cancellation, and Current Limitation for Static Compensators. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 6613–6623. [Google Scholar] [CrossRef]

- Kou, G.F.; Jordan, J.; Cockerham, B.; Patterson, R.; VanSant, P. Negative-Sequence Current Injection of Transmission Solar Farms. IEEE Trans. Power Deliv. 2020, 35, 2740–2743. [Google Scholar] [CrossRef]

- Ni, J.K.; Shi, P. Global Predefined Time and Accuracy Adaptive Neural Network Control for Uncertain Strict-Feedback Systems with Output Constraint and Dead Zone. IEEE Trans. Syst. Man Cybern. Syst. 2021, 51, 7903–7918. [Google Scholar] [CrossRef]

- Li, J.; Zheng, S.; Tan, Y. Adaptive Fireworks Algorithm. Evol. Comput. 2014, 7, 3214–3221. [Google Scholar]

- Zheng, S.; Li, J.; Janecek, A. A cooperative framework for fireworks algorithm. IEEE ACM Trans. Comput. Biol. Bioinform. 2017, 14, 27–41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.; Zheng, S.; Tan, Y. The Effect of Information Utilization: Introducing a Novel Guiding Spark in the Fireworks Algorithm. IEEE Trans. Evol. Comput. 2017, 21, 153–166. [Google Scholar] [CrossRef]

- Guo, W.; Guo, J. Rotor transverse slots’ influence on negative sequence loss and heat distribution prediction of large generators based on Improved Radial Basis Function Process Neural Network. Math. Probl. Eng. 2022, 2022, 1865380. [Google Scholar] [CrossRef]

| Function Type | No. | Function Name |

|---|---|---|

| Unimodal function | 1 | Rotated Discus Function |

| 2 | Different Powers Function | |

| Multimodal function | 3 | Rotated Rosenbrocks Function |

| 4 | Rotated Schaffers F7 Function | |

| 5 | Rotated Ackleys Function | |

| 6 | Rotated Weierstrass Function | |

| 7 | Rotated Griewanks Function | |

| 8 | Rastrigins Function | |

| 9 | Rotated Rastrigins Function | |

| 10 | Non-Continuous Rotated Rastrigins Function | |

| 11 | Schwefel’s Function | |

| 12 | Rotated Schwefel’s Function | |

| 13 | Rotated Katsuura Function | |

| 14 | Lunacek Bi Rastrigin Function | |

| 15 | Rotated Lunacek Bi Rastrigin Function | |

| 16 | Expanded Griewanks plus Rosenbrocks Function | |

| Composite function | 17 | Composition Function 1 (Rotated) |

| 18 | Composition Function 2 (Unrotated) | |

| 19 | Composition Function 3 (Rotated) | |

| 20 | Composition Function 4 (Rotated) | |

| 21 | Composition Function 5 (Rotated) | |

| 22 | Composition Function 6 (Rotated) | |

| 23 | Composition Function 7 (Rotated) | |

| 24 | Composition Function 8 (Rotated) |

| Function No. | FWA | AFWA | CoFWA | GFWA | LoTFWA | ILoTFWA | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Std | Mean | Std | Mean | Std | Mean | Std | Mean | Std | Mean | Std | |

| 1 | 1.21 × 100 | 3.64 × 10−1 | 1.17 × 101 | 6.92 × 100 | 2.43 × 103 | 1.56 × 103 | 5.07 × 10−5 | 6.24 × 10−5 | 2.61 × 103 | 8.35 × 102 | 1.23 × 103 | 6.69 × 102 |

| 2 | 8.59 × 10−2 | 1.68 × 10−2 | 6.11 × 10−4 | 9.37 × 10−5 | 7.37 × 10−4 | 9.68 × 10−5 | 1.61 × 10−3 | 1.94 × 10−4 | 3.69 × 10−5 | 5.25 × 10−4 | 5.12 × 10−3 | 1.41 × 10−3 |

| 3 | 5.69 × 101 | 3.74 × 101 | 2.86 × 101 | 2.54 × 101 | 2.52 × 101 | 2.13 × 101 | 3.58 × 101 | 2.82 × 101 | 1.48 × 101 | 6.91 × 100 | 1.62 × 101 | 4.21 × 100 |

| 4 | 1.45 × 102 | 4.68 × 101 | 9.27 × 101 | 2.71 × 101 | 9.13 × 101 | 1.95 × 101 | 7.67 × 101 | 3.06 × 101 | 5.14 × 101 | 9.73 × 100 | 3.18 × 101 | 1.01 × 101 |

| 5 | 2.36 × 101 | 4.98 × 10−2 | 2.08 × 101 | 7.83 × 10−2 | 2.08 × 101 | 9.75 × 10−2 | 2.08 × 101 | 9.10 × 10−2 | 2.08 × 101 | 6.12 × 10−2 | 2.08 × 101 | 6.71 × 10−2 |

| 6 | 3.76 × 101 | 3.62 × 100 | 2.52 × 101 | 4.99 × 100 | 2.29 × 101 | 4.09 × 100 | 1.85 × 101 | 4.59 × 100 | 1.47 × 101 | 2.09 × 100 | 1.26 × 101 | 1.95 × 100 |

| 7 | 9.52 × 10-1 | 8.96 × 10−2 | 4.64 × 10-2 | 3.78 × 10-2 | 4.03 × 10−2 | 2.61 × 10−2 | 6.15 × 10−2 | 3.31 × 10−2 | 4.47 × 10−2 | 2.32 × 10−2 | 5.15 × 10−2 | 3.13 × 10−2 |

| 8 | 5.83 × 102 | 9.72 × 101 | 1.32 × 102 | 3.85 × 101 | 9.95 × 101 | 2.41 × 101 | 7.32 × 101 | 2.36 × 101 | 6.28 × 101 | 1.19 × 101 | 2.48 × 101 | 7.62 × 100 |

| 9 | 6.78 × 102 | 1.59 × 102 | 1.64 × 102 | 4.59 × 101 | 1.46 × 102 | 4.21 × 101 | 9.38 × 101 | 3.25 × 101 | 6.79 × 101 | 1.43 × 101 | 4.36 × 101 | 7.75 × 100 |

| 10 | 4.76 × 102 | 7.88 × 101 | 2.356 × 102 | 6.04 × 101 | 2.62 × 102 | 6.13 × 101 | 1.59 × 102 | 4.68 × 101 | 1.35 × 102 | 2.29 × 101 | 8.83 × 101 | 1.70 × 101 |

| 11 | 4.96 × 103 | 6.59 × 102 | 2.86 × 103 | 5.43 × 102 | 2.65 × 103 | 4.91 × 102 | 3.54 × 103 | 8.47 × 102 | 2.35 × 103 | 3.07 × 102 | 2.12 × 103 | 3.64 × 102 |

| 12 | 4.88 × 103 | 5.76 × 102 | 3.79 × 103 | 5.01 × 102 | 3.34 × 103 | 4.95 × 102 | 3.73 × 103 | 6.42 × 102 | 2.54 × 103 | 3.74 × 102 | 2.45 × 103 | 2.83 × 102 |

| 13 | 6.48 × 10-1 | 2.91 × 10-1 | 4.93 × 10−1 | 2.51 × 10−1 | 4.67 × 10-1 | 3.28 × 10-1 | 1.14 × 10−1 | 7.21 × 10−2 | 5.72 × 10−2 | 2.11 × 10−2 | 4.78 × 10−2 | 1.83 × 10−2 |

| 14 | 4.27 × 102 | 7.16 × 101 | 1.41 × 102 | 2.48 × 101 | 1.16 × 102 | 5.23 × 101 | 8.38 × 101 | 2.15 × 101 | 6.22 × 101 | 9.46 × 100 | 3.07 × 101 | 1.04 × 101 |

| 15 | 2.26 × 102 | 4.52 × 101 | 1.86 × 102 | 5.19 × 101 | 1.88 × 102 | 4.19 × 101 | 8.72 × 101 | 2.43 × 101 | 6.10 × 101 | 9.54 × 100 | 5.04 × 101 | 1.08 × 101 |

| 16 | 1.59 × 101 | 3.84 × 100 | 7.08 × 100 | 2.43 × 100 | 6.57 × 100 | 2.12 × 100 | 5.14 × 100 | 1.92 × 100 | 3.03 × 100 | 6.41 × 10−1 | 2.76 × 100 | 4.93 × 10−1 |

| 17 | 3.98 × 102 | 9.85 × 101 | 3.22 × 102 | 9.46 × 101 | 2.13 × 102 | 6.27 × 101 | 2.56 × 102 | 8.53 × 101 | 2.00 × 102 | 2.81 × 10−3 | 2.00 × 102 | 1.42 × 101 |

| 18 | 6.41 × 103 | 1.32 × 103 | 3.53 × 103 | 7.58 × 102 | 3.31 × 103 | 6.30 × 102 | 4.31 × 103 | 8.92 × 102 | 3.15 × 103 | 3.79 × 102 | 2.46 × 103 | 4.17 × 102 |

| 19 | 6.39 × 103 | 7.98 × 102 | 4.69 × 103 | 8.97 × 102 | 4.45 × 103 | 7.88 × 102 | 4.31 × 103 | 7.67 × 102 | 3.10 × 103 | 5.17 × 102 | 2.71 × 103 | 3.97 × 102 |

| 20 | 3.96 × 102 | 7.53 × 101 | 2.80 × 102 | 1.38 × 101 | 2.65 × 102 | 2.17 × 101 | 2.54 × 102 | 1.74 × 101 | 2.36 × 102 | 1.20 × 101 | 2.21 × 102 | 1.10 × 101 |

| 21 | 4.28 × 102 | 3.19 × 101 | 2.96 × 102 | 1.21 × 101 | 2.92 × 102 | 1.25 × 101 | 2.85 × 102 | 1.33 × 101 | 2.69 × 102 | 1.96 × 101 | 2.56 × 102 | 5.47 × 100 |

| 22 | 4.32 × 102 | 9.84 × 101 | 2.72 × 102 | 8.51 × 101 | 2.15 × 102 | 4.17 × 101 | 2.11 × 102 | 2.81 × 101 | 2.00 × 102 | 1.75 × 10−2 | 2.00 × 102 | 1.68 × 10−2 |

| 23 | 1.59 × 103 | 1.31 × 102 | 9.89 × 102 | 1.39 × 102 | 8.70 × 102 | 2.09 × 102 | 8.17 × 102 | 1.23 × 102 | 6.85 × 102 | 9.76 × 101 | 6.70 × 102 | 7.61 × 101 |

| 24 | 4.79 × 103 | 2.38 × 103 | 4.42 × 102 | 4.69 × 102 | 2.91 × 102 | 5.39 × 101 | 3.58 × 102 | 2.59 × 102 | 2.64 × 102 | 7.57 × 101 | 2.94 × 102 | 0.11 × 100 |

| No. | Measured Value | Calculation Results of the Maximum Temperature Rise of Generator Rotor (°C) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CPPNN | GA-CPPNN | PSO-CPPNN | FWA-CPPNN | ILoTFWA-CPPNN | |||||||

| Value | Relative Error | Value | Relative Error | Value | Relative Error | Value | Relative Error | Value | Relative Error | ||

| 1 | 30.4 | 31.9 | 4.9% | 31.1 | 2.3% | 31.6 | 3.9% | 31.3 | 3.0% | 30.9 | 1.6% |

| 2 | 28.6 | 29.3 | 2.4% | 29.5 | 3.1% | 29.4 | 2.8% | 29.4 | 2.8% | 29.1 | 1.7% |

| 3 | 32.2 | 33.6 | 4.3% | 31.1 | 3.4% | 32.9 | 2.2% | 33.1 | 2.8% | 32.9 | 2.2% |

| 4 | 28.3 | 29.4 | 3.9% | 29.5 | 4.2% | 29.3 | 3.5% | 29.5 | 4.2% | 29.0 | 2.5% |

| 5 | 29.7 | 31.2 | 5.1% | 30.4 | 2.4% | 30.6 | 3.0% | 30.3 | 2.0% | 30.4 | 2.4% |

| 6 | 22.0 | 23.6 | 7.3% | 22.9 | 4.1% | 22.7 | 3.2% | 23.2 | 5.5% | 22.5 | 2.3% |

| 7 | 38.1 | 40.9 | 7.3% | 40.5 | 6.3% | 40.8 | 7.1% | 40.7 | 6.8% | 40.2 | 5.5% |

| 8 | 24.5 | 25.8 | 5.3% | 25.1 | 2.5% | 25.2 | 2.9% | 25.3 | 3.3% | 25.3 | 3.2% |

| 9 | 35.4 | 37.1 | 4.8% | 36.1 | 2.0% | 36.8 | 4.0% | 36.2 | 2.3% | 36.2 | 2.3% |

| 10 | 30.7 | 31.8 | 3.6% | 28.7 | 6.5% | 31.4 | 2.3% | 31.8 | 3.6% | 31.3 | 2.0% |

| Average relative error | 4.89 | 3.68 | 3.49 | 3.63 | 2.57 | ||||||

| Average number of iterations | 4.7 | 3.9 | 3.8 | 3.9 | 3.2 | ||||||

| Position | Wedge Material | Negative-Sequence Component Proportion | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1% | 2% | 3% | 4% | 5% | 6% | 7% | 8% | 9% | 10% | ||

| Big tooth | Aluminum | 12.4 | 12.6 | 12.9 | 13.3 | 13.7 | 14.5 | 15.8 | 17.4 | 19.5 | 23.1 |

| Beryllium bronze | 15.2 | 15.4 | 15.7 | 16.0 | 16.6 | 17.7 | 19.1 | 20.8 | 23.0 | 27.1 | |

| Aluminum bronze | 19.0 | 19.1 | 19.4 | 19.8 | 20.5 | 21.8 | 23.3 | 24.9 | 26.8 | 30.4 | |

| Damping slot wedge | Aluminum | 13.3 | 13.5 | 13.8 | 14.1 | 14.6 | 15.6 | 17.2 | 18.7 | 20.9 | 24.3 |

| Beryllium bronze | 16.1 | 16.5 | 16.7 | 17.2 | 17.8 | 18.9 | 20.4 | 21.9 | 24.2 | 29.1 | |

| Aluminum bronze | 20.0 | 20.2 | 20.5 | 20.9 | 21.3 | 22.7 | 24.1 | 25.6 | 27.5 | 31.4 | |

| Slot wedge | Aluminum | 3.5 | 3.6 | 3.8 | 4.2 | 4.6 | 5.6 | 6.9 | 8.6 | 10.7 | 14.5 |

| Beryllium bronze | 6.7 | 6.8 | 7.1 | 7.4 | 7.9 | 9.2 | 10.6 | 12.1 | 14.3 | 18.0 | |

| Aluminum bronze | 10.3 | 10.4 | 10.6 | 10.9 | 11.5 | 13.1 | 14.7 | 16.3 | 18.4 | 22.6 | |

| Small tooth | Aluminum | 2.9 | 3.1 | 3.4 | 3.8 | 4.3 | 4.8 | 6.1 | 7.5 | 9.6 | 13.7 |

| Beryllium bronze | 5.8 | 6.0 | 6.3 | 6.7 | 7.4 | 8.1 | 9.4 | 10.8 | 12.7 | 16.8 | |

| Aluminum bronze | 9.1 | 9.3 | 9.6 | 9.8 | 10.9 | 12.2 | 13.6 | 15.2 | 17.1 | 21.5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, W.; Guo, J.; Miao, F. Application of Improved Process Neural Network Based on the Fireworks Algorithm in the Temperature-Rise Predictions of a Large Generator Rotor. Appl. Sci. 2023, 13, 2943. https://doi.org/10.3390/app13052943

Guo W, Guo J, Miao F. Application of Improved Process Neural Network Based on the Fireworks Algorithm in the Temperature-Rise Predictions of a Large Generator Rotor. Applied Sciences. 2023; 13(5):2943. https://doi.org/10.3390/app13052943

Chicago/Turabian StyleGuo, Wu, Jian Guo, and Fengjuan Miao. 2023. "Application of Improved Process Neural Network Based on the Fireworks Algorithm in the Temperature-Rise Predictions of a Large Generator Rotor" Applied Sciences 13, no. 5: 2943. https://doi.org/10.3390/app13052943

APA StyleGuo, W., Guo, J., & Miao, F. (2023). Application of Improved Process Neural Network Based on the Fireworks Algorithm in the Temperature-Rise Predictions of a Large Generator Rotor. Applied Sciences, 13(5), 2943. https://doi.org/10.3390/app13052943