Abstract

Solar energy is free from noise and environmental pollution. It could be used to replace non-renewable sources such as fossil fuels, which are in limited supply and have negative environmental impacts. The first generation of solar cells was made from crystalline silicon. They were relatively efficient, however very expensive because they require a lot of energy to purify the silicon. Nowadays, the production of solar cells has been improved since the first generation (thin-film solar cells, dye-sensitized solar cells, perovskite solar cells, and organic solar cells). In this work, the development of solar cells was discussed. The advantages, limitations, challenges, and future trends of these solar cells were also reported. Lastly, this article emphasized the various practices to promote solar energy and highlighted the power conversion efficiency of the fabricated devices.

1. Introduction

The process of the conversion of energy from the most abundant source, the sun, into electricity is termed as the photovoltaic effect [1]. Semiconductor materials are the basic requirement for the process of the conversion of photons into electrons [2]. These materials can be divided into organic and inorganic [3] substances.

Photovoltaic solar-cell technologies can be divided into three distinct generations [4]. The first generation was crystalline silicon. This technology currently dominates the global solar-cell market due to it has good performance and stability. The second generation is based on thin films of amorphous silicon and inorganic semiconductor elements such as copper indium gallium selenide (CIGS), cadmium telluride (CdTe), and copper indium selenide (CuInSe2). Moreover, the third generation is based on organic semiconductors. Organic solar cells can either be based on dye-sensitized solar cells [5], multiple junctions based on group IV and group III–V elements, and hybrid solar cells that contain inorganic quantum dots or nanomaterials with organic materials [6]. The potential of organic solar cells for practical applications [7] is demonstrated by recent enhancements in the power-conversion efficiency (PCE).

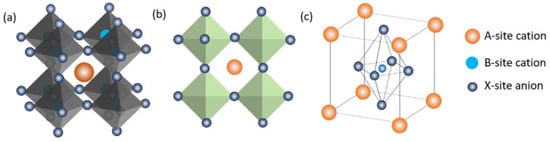

Organic–inorganic hybrid perovskites (OIHPs) are a group of materials which show magnificent potential for high performance and low production costs in photovoltaic technology [8]. Any material which has an identical crystal structure with calcium titanium oxide (CaTiO3) is recognized as a “perovskite” structure, as named by the Russian Mineralogist Lev Alek-sevich von Perrovski (1839). These perovskites have a stoichiometry of ABX3 three-dimensional structure, where the “A” and “B”-sites are occupied by larger and smaller cations, respectively, and the anion resides at the “X”-site. The 3D crystal structure of ABX3 consists of corner-shared BX6 octahedrals and “A” cations occupy the cavity between them [9,10]. Materials with perovskite structures are quite abundant in nature and can be found in an enormous number of compounds that show a wide range of physical properties, applications, and importance.

Perovskite solar cells can have a conventional (regular) or an inverted PSC structure, depending on the architecture. TiO2 and n-type semiconductors are used in the normal configuration, whereas p-type poly (3,4-ethylene dioxythiophene)-poly(styrene sulfonate) (PEDOT: PSS) are used in the inverted configuration. Typical mesoscopic perovskite solar cell structures consist of a glass surface with a transparent conducting oxide (TCO), such as in FTO (F:SnO2), in which an anode is deposited on the glass substrate, a dense (compact) layer of TiO2 is a hole-blocking layer, and a mesoporous layer of TiO2 serves as an electron-transporting layer (ETL). Moreover, a layer of the perovskite material is used for light absorption, followed by a hole-transporting layer, followed by metal contacts to complete the device’s structure. This type of solar cell has an organic material with a perovskite structure in its absorbing layer, most typically a lead–metal hybrid (Methylammonium lead iodide perovskite, MAPbI3). Methylammonium lead iodide is an ambipolar semiconductor that may transmit both electrons and holes to the collecting electrodes. Because of this, perovskite solar cells can operate without a hole or electron conductor. The Spiro-OMeTAD polymer composition is the HTL material most frequently utilized in perovskite solar cells.

Perovskite solar cells’ superior absorption capabilities and low exciton binding energy are two of their most notable features. Light absorption is the initial physical process in solar systems. When a photon activates an active material with an energy higher than its bandgap, an exciton (electron-hole pairs) is produced. Excitons must reach the contacts after being photogenerated in the perovskite to be retrieved. The charge-transport capabilities of the perovskite play a role in this process. Compared with conventional solar cells, perovskite serves as an absorber in thin-film solar cells to offer effective transport of excitons. The remarkable PCE of these perovskite solar cells is produced by the material’s outstanding charge-transport properties. They possess long charge-carrier diffusion lengths surpassing 5 m and the associated lifetimes of 1 s in both single-crystal and polycrystalline films. These diffusion lengths guarantee that the produced charge can be recovered even from thicker films that absorb the input light completely. However, the interfacial contacts with the charge extraction layer also have a role in the device’s ultimate quality. After absorption and charge transmission, the photovoltaic process requires the extraction of the photogenerated charge. As a result, the optimal extraction interface should provide the least possible voltage, current, and FF loss. An optimal selective contact should not absorb light to prevent the reduction of light intensity in the perovskite. Similarly, there should not be any energetic losses during the absorber injection (no interfacial recombination). These contact materials need to be selective to enable one kind of carrier to be injected, but they also need to lower series resistance.

One of two major processes can result in charge separation in perovskite. One involves injecting photogenerated electrons into an n-type semiconductor such as TiO2, while the other involves injecting holes into a p-type material that transports holes, such as spiro-OMeTAD. To stop holes from reaching the TCO substrate (anode) and short-circuiting the cell, a hole-blocking layer is utilized between the TCO-conducting substrate and the mesoscopic scaffold and/or perovskite layer. On the other hand, using a mesoporous TiO2 layer greatly lessens the hysteresis behavior of PSC even if a hybrid organic–inorganic perovskite absorber can transfer photogenerated electrons to the conductive substrate itself.

Dye-sensitized solar cells (DSSC) were first discovered by professor Michael Gratzel in 1991. The DSSC consists of a working electrode [11], a counter electrode, and an electrolyte. Dyes (natural organic materials and synthetic materials) are attached to the TiO2 films, serve as the working electrodes. The DSSC consisting of ruthenium (II) polypyridyl complex (N3 dye) [12] showed a power-conversion efficiency of about 10%. A platinum conductive glass served as the counter electrode [11]. The working principle of DSSC converts sunlight into electricity through the creation of exciton. The semiconductor material is placed on a conductive transparent plate to form a thin layer. A dye monolayer layer is placed on the surface of the semiconductor. Photoexcitation experienced by the dye produces electrons excited from the valence band to the conduction band of the dye, which then enter the conduction band of the metal oxide. This electron injection is performed through the connection between titanium and the carboxyl group in the dye. This process produces a positively charged dye and a negatively charged TiO2 particle. The electrons then exit through the external circuit to the opposite electrode. This flow of electrons is used as electrical energy. The electron vacancies in the valence band of the dye are replaced by electrons from the electrolyte. The electrolyte used in DSSC is usually an organic solvent containing a redox system such as an iodide–triiodide pair. The regeneration of the sensitizer by iodide occurs by donating electrons in the valence band of the oxidized dye. The iodide is regenerated by reducing the triiodide at the opposite electrode by utilizing electrons from the external circuit. This process takes place continuously as a cycle so that a continuous current is produced.

Metal chalcogenide films are considered as important materials for solar-cell applications [13]. Several types of films (metal sulfide, metal selenide, and metal telluride) have been prepared using a vacuum method or non-vacuum deposition technique [14]. These films could be cheaper to produce, show good quality materials, and have the most potential for the future.

In this work, the advantages and limitations of each type of solar cell (thin-film solar cells, dye-sensitized solar cells, and organic solar cells) were highlighted. Photovoltaic parameters were investigated based on the selected literature review.

2. Organic Solar Cells

2.1. Advantages of Organic Solar Cells over Inorganic Solar Cells

The advantages of organic solar cells (OSC) over inorganic solar cells are threefold [15,16]. Firstly, in terms of the materials, limited silicon wafer technology leads to heavy, rigid, fragile, and bulky materials that are only available in a couple of colors. Conversely, the materials for OSC are light-weight, thin, flexible, and color-tunable, and can be customized to any design. Secondly, the fabrication process of inorganic solar cells is expensive, complicated, energy-intensive, must be conducted at high temperatures, and has limitations in the possible sizes of fabrications. On the other hand, OSC technology is cheap, simple, non-energy consuming, can be fabricated at ambient temperature, has no limitations in the size of fabrication, and has high speed production besides various possibilities of printing and coating fabrication techniques (such as inkjet, screen, and spray). Finally, the applications of inorganic solar cell are limited only to rooftops and open fields compared with the unlimited possibilities of OSC applications such as windows, screens, smart glasses, automotives, and the charging of mobile devices and laptops [17,18,19].

2.2. Challenges for Organic Solar Cell Technology

Silicon is the most widely used material for the commercial photovoltaic market due to its high-power conversion efficiency [20,21,22]. Inorganic solar cells are associated with certain challenges such their its high-cost and complicated and energy-intensive fabrication protocols. Organic solar cells are gaining attention due to their simple fabrication protocols. OSC technology has not yet gained much attention commercially because of its low power-conversion efficiency (PCE) and limited lifetime [23,24]. The heterojunction generated by contact of donor and acceptor material is the basis of OSC. There are a number of challenges in OSC technology such as limited absorption efficiency of donor materials, hindered exciton diffusion, charge dissociation, and transport of charges. Different approaches to overcome these challenges could be improved in exciton diffusion length, crystal structure, and the collection of photogenerated carriers. These improvements can be realized by the application of polymer-based nanocomposites, plasmonics, and tandem architectures. Moreover, hybrid nanocomposites (composed of both organic and inorganic materials) can be a synergistic combination to take advantage of the unique properties of both components [25,26,27]. The operation of hybrid solar cells has more similarities with OSC. Hybrid solar cells are composed of n-type inorganic material along with p-type semiconductor polymer and are capable of achieving high PCE.

2.3. Materials for Organic Solar Cells

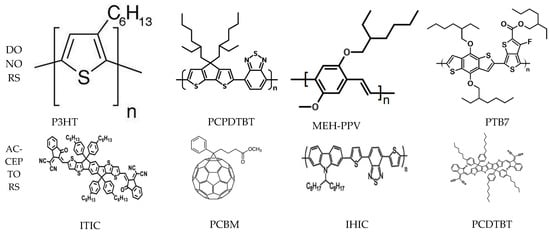

Organic materials for OSC can be derivative of small molecules or semiconducting polymers [28]. Organic semiconductors have conjugated organic moieties such as dendrimers, pigments, dyes, polymers, and small molecules, which can be a good choice for OSC. Any OSC requires two types of materials: an electron pair donor and an electron pair acceptor. Conjugated polymers are employed as donor materials. Initially, poly(1,4-phenylenevinylene) (PPV) and its derivatives gained considerable attention due to their appropriate optoelectronic properties [29,30]. Later, polythiophene and its derivative, especially poly(3-hexylthiophene), P3HT, began to be used widely (as a donor material) owing to its stability, high carrier mobility, and solubility [31,32,33]. The structures of some important donor materials for OSC technology are listed in Figure 1. Although fullerene and its derivatives dominated OSC technology in the initial phase [34,35,36,37,38], small molecules such as 3,9-bis(2-methylene-(3-(1,1-dicyanomethylene)-indanone)-5,5,11,11-tetrakis(4hexylphenyl)-dithieno [2,3-d:2′,3′-d′]-s-indaceno [1,2-b:5,6-b′]dithiophene (ITIC), IHIC, and PCDTBT (termed as non-fullerene acceptors, NFA) have attracted considerable attention recently due to their superior properties [39,40,41,42]. Moreover, donor–acceptor conjugated polymers such as poly [2,6-(4,4-bis-(2-ethylhexyl)-4H-cyclopenta [2,1-b;3,4-b′]dithiophene)-alt-4,7(2,1,3-benzothiadiazole)], PCPDTBT [43], and poly [2,7-(9,9-dioctylcarbazole)-alt-4,7-bis(thiophen-2-yl)benzo-2,1,3-thiadiazole], PCzDTBT [44] have been employed. The structures of some important fullerene and non-fullerene acceptor materials are depicted in Figure 1.

Figure 1.

The structures of some important donor and acceptor materials of OSC.

The engineering of the input donor and acceptor materials can help in improving the optoelectronic properties of these materials, which, in turn, improve the performance of OSC. One of the major limitations of the donor materials for OSC is their limited capacity of absorbing the whole wavelength range of the solar spectrum. The absorption efficiency can be improved by increasing the HOMO level, decreasing the LUMO level, or by compressing the band gap between HOMO–LUMO levels [45,46]. Polymers have higher molar mass and possess longer conjugation lengths, and hence the energy band gap is lower [47,48,49]. Voltametric p-type doping can also help in improving the optoelectronic properties through broadening of the absorption spectrum [50,51,52,53]. Regioregularity of polymers facilitates the mobility of excitons and thus improve the performance of OSC [54,55,56]. Physiochemical properties of OSC materials can be easily tuned by changing their chemistry, which is a unique advantage compared with conventional inorganic solar cells. For instance, the introduction of flexible side-chains such as alkyl or alkoxy leads to an improvement of solubility while the introduction of electron-donating or -withdrawing substituents can help in the alignment of electronic energy levels. The improvement of the optoelectronic properties of polymers by chemical modifications is shown for several polymers such as poly(p-phenylene vinylene) [57] and P3HT [58,59,60]. Electron-withdrawing groups such as Fluorine on the polymer chain improve the charge transference by tuning of the LUMO level [61], while electron-donating substituents on the polymer chain enhance charge-carrier mobility by minimizing the structural defects due to an increase in the HOMO energy level [62,63,64].

Moreover, large donor–acceptor interfaces as provided by nanostructures render effective exciton dissociation and efficient charge transport [65,66,67,68,69,70,71,72]. Conjugated polymer-based metallic nanoparticles can be prepared by several methods [73,74,75]. Different metals can have peculiar and dissimilar effects on the optoelectronic properties of the nanocomposites and their performance in the context of solar cells [76,77,78,79,80]. The incorporation of silver (Ag) and gold (Au) nano particles in polymer bulk heterojunction solar cells enhances their performance owing to the improved absorption of sunlight. In the context of OSC, conjugated polymer nanowires are mostly used due to their ability to create percolation pathways for both electrons and holes, leading to higher device efficiency [81,82,83,84]. The applications of polymer nanowires have several advantages such as (a) better control over morphology, (b) appropriate matching of the exciton diffusion lengths to the widths and lengths of polymer nanowires, (c) large interfacial area between donor and acceptor, (d) existence of electrically bi-continuous morphology, (e) achievement of high absorption coefficient and high carrier mobilities, (f) possibility of manufacturing devices with high surface areas, and (g) the avoidance of blend phase-separation difficulties [85,86]. Thermal annealing of the P3HT/PCBM mixture at 120 °C for 60 min renders P3HT nanowires with improved crystallinity of P3HT and enhances the demixing between P3HT and PCBM [87].

2.4. Fabrication of Organic Solar Cells

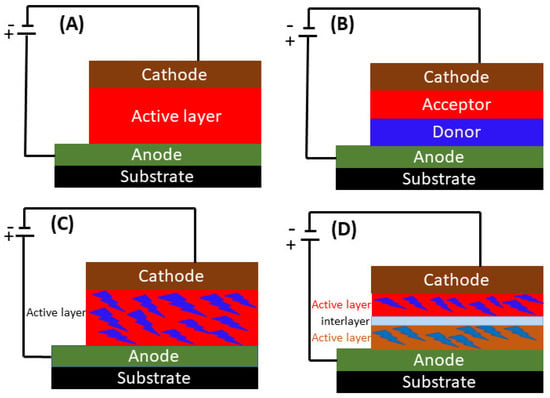

Organic photovoltaics fabricated as one active layer are termed as single-layer OPVs, while multiple active layers based OPV are termed as multiple layers or hetero-junctions [88]. Single-layer OPVs suffer from low PCE. The introduction of multiple layers or heterojunctions in OPVs results in an improvement in the OSC. The process of a heterojunction OPV consists of four distinct steps, namely, (i) the generation of an electron-hole pair (exciton) by absorption of the photon, (ii) diffusion of the exciton to the interface, (iii) the generation of free carriers by the dissociation of excitons, and (iv) carrier transport and collection at the electrode. The first generation of OSC was comprised of a single layer possessing very low PCE due to inefficient dissociation exciton (Figure 2A).

Figure 2.

The fabrication of OSC: (A) single active layer, (B) bilayer heterojunction, (C) bulk heterojunction, (D) tandem heterojunction.

Later developments in OSC technology led to heterojunction cells that could be subdivided into bilayer heterojunctions, bulk heterojunctions, and tandem heterojunctions. In bilayer or planer heterojunctions, layers of donor and acceptor materials are sandwiched between two electrodes (Figure 2B). Planer heterojunctions also suffer from low PCE due to their short diffusion length and the low mobility of the generated excitons. In order to improve the PCE, it is required to match the diffusion length to the dimensions of the bilayer heterojunction, ultimately resulting in ultrathin films with low optical absorption.

On the other hand, dispersed or bulk heterojunctions are composed of blends of donor and acceptor materials (Figure 2C). Bulk heterojunctions facilitate the diffusion of excitons to the interface and achieve high PCE compared with planar heterojunctions. The most widely used combination of donor and acceptor materials for bulk heterojunctions is P3HT: PCBM [89,90]. The PCE has improved by up to 18% for bulk heterojunctions [91,92,93]. The absorption of light in single-layer, bilayer, and bulk heterojunction is limited to a small window of the visible light spectrum: either the short- or long-wavelength region. Tandem heterojunction provides an opportunity to exploit a wide wavelength region based on two sub-cells with complementary absorption spectra [94,95]. The sub-cells are separated by an interlayer that is responsible for the alignment of the quasi-Fermi level of both cells (Figure 2D). Owing to the elaborated advantages, tandem solar cells are gaining more attention recently. Tandem inorganic solar cells are restricted by the high cost for the required crystal growth and lattice matching. However, tandem OSC is gaining increasing interest and application owing to the simple and economical manufacturing. For bulk heterojunctions, the input materials should possess matched absorption spectra, appropriate energy level alignment, nanoscale phase separation, and high charge mobility [96].

2.5. Operation of Organic Solar Cells

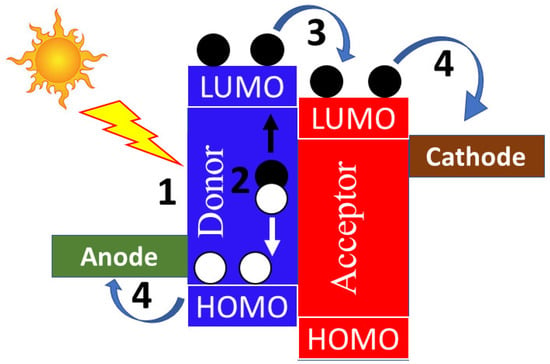

The operation of OSC is completely different from that of conventional silicon-based inorganic solar cells in terms of the material properties and architecture [97]. Free charge carriers are not immediately created by absorption of light in OSC, unlike traditional inorganic solar cells. An electrically neutral electron-hole pair is formed (as an exciton). It is a tightly bound electron-hole pair with a life span in the order of nano-seconds. The design and geometry of OPV devices are largely impacted by the excitonic character of the organic semiconductor material. The understanding of the basic operation of OPV is imperative for coping with the limitations and challenges of the materials and fabrication. The dissociation of the exciton is necessary for the generation of the photovoltaic effect. Exciton binding energy is in the range of 0.3–1.0 eV. Obviously, more energy than the binding energy is required to dissociate excitons and free the carrier. This is a relatively high energy requirement compared to its inorganic counterpart. The light is absorbed by the acceptor, resulting in creation of excitons. If the thermal energy generated is less than the exciton binding energy, electron and hole will undergo recombination. However, if the thermal energy is more than the exciton binding energy, free charges will be created that result in the separation of the electron and hole. Consequently, photogenerated carriers accumulate on the electrodes, electrons at the cathode, and holes at the anode. The working principle of OSC is demonstrated in Figure 3. The absorption of sunlight results in the generation of an electron-hole pair (exciton). High energy absorption leads to valence electrons of the donor jumping from their highest occupied molecylar orbital (HOMO) to the least unoccupied molecular orbital (LUMO) level, leaving behind holes at the HOMO level (separation of excitons into electrons and holes). Electrons then jump from the LUMO of the donor to the LUMO of the acceptor, which is at a lower energy level. Finally, the electrons from the LUMO of the acceptor are transported and collected at the cathode while holes at the HOMO of the donor are transported to anode, which completes the circuit. In this context, the alignment of the energy levels of the donor and acceptor materials, the absorption profiles, mobility of charges, and miscibility of the materials are critical factors [98].

Figure 3.

Energy level diagram demonstrating the operation of OSC.

2.6. Performance Properties of Organic Solar Cells

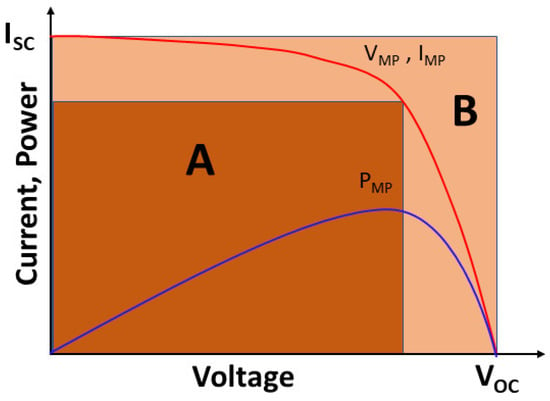

The important electrical characteristics of OSC that are correlated to its performance are the open-circuit voltage, short-circuit current, maximum power point, fill factor, power conversion efficiency, and quantum efficiency. The expected values and interdependence of these parameters are demonstrated on a classical current–voltage (IV) curve (Figure 4).

Figure 4.

Current voltage (IV) curve of organic solar cells.

The maximum possible voltage that can be generated by a photovoltaic (PV) cell is termed as open-circuit voltage (VOC). It refers to difference between the HOMO of the donor and the LUMO of the acceptor material.

Current flowing in the absence of any external resistance (0 voltage) through an illuminated solar cell is termed as short-circuit current (ISC). It refers to the maximum possible current produced by the device. The point of the current voltage characteristic curve (IV) curve that renders the maximum rectangle area is termed as the maximum power point (PMP). At a maximum current and voltage, the ratio of the actual maximum power the output to its theoretical output is termed as the fill factor (FF). The FF is higher for larger inner areas (A), as shown in Figure 4.

The power conversion efficiency (PCE) is undoubtedly the most important parameter of performance of any OSC. It is a ratio of the output of OSC to the input of energy from sunlight. The abovementioned parameters from the IV curve are used to calculate the PCE, where Pin is the irradiance value.

Quantum efficiency (QE) is the efficiency of the device as a function of the incident radiation wavelength.

2.7. Efficiency Highlights

Generally, organic compounds are considered to be non-conductors. The discovery of conducting polymers was a breakthrough in this context. Recently, conjugated polymers have gained significant attention is OSC technology since they can act as electron donors in the active layer of OSC. Tandem solar cells prepared by a bulk heterojunction possessing complementary absorbing materials have achieved better performance compared with single cells. Easy processing, low entropy of mixing, and efficient exciton dissociation are the major advantages associated with polymer solar cells compared with small-molecule solar cells. In this section, we briefly discuss the important highlights of the maximum efficiency achieved by OSC.

P3HT is a classical donor conjugated polymer which show comparatively low PCE. A significant improvement in the PCE and other performance parameters for a P3HT-based OSC was recently reported as the introduction of additives [99]. P3HT was used as the donor with 2,2′-((2Z,2′Z)-((12,13-bis(2-butyloctyl)-3,9-diundecyl-12,13-dihydro-[1,2,5]-thiadiazolo [3,4-e]thieno [2″,3″:4′,5′]thieno [2′,3′:4,5]pyrrolo [3,2-g]thieno [2′,3′:4,5]thieno [3,2-b]indole-2,10-diyl)bis(methane-lylidene))bis(5,6-dichloro-1H-indene-1,3(2H)-dione) (ZY-4Cl) as the acceptor while using SA4 as a sloid additive. The additive caused enhanced molecular packing and phase separation, which ultimately resulted in an augmented charge transport and the reduced recombination of carriers. The VOC, ISC, FF, and PCE of the manufactured dev ice were found to be 0.90 V, 17.0 mA/cm2, 0.67, and 10.24%, respectively.

The OSC composed of bithienyl-benzodithiophene-alt-fluorobenzotriazole copolymers/ITIC indicated remarkably high ISC, VOC, FF, and PCE of 17.43 mA/cm, 0.89 V, 0.64, and 9.53%, respectively [100]. The same group demonstrated an improvement in the OSC performance by changing the acceptor material [101]. Herein, the authors introduced meta-alkyl-phenyl substitution on ITIC. While using bithienyl-benzodithiophene-alt-fluorobenzotriazole copolymers as the donor and substituted ITIC (m-ITIC) as the acceptor, a significant improvement in the performance parameters was achieved. A higher PCE of 11.7% along with a VOC of 0.912 V, FF of 0.70, and ISC of 18.31 mA/cm2 was shown by the reported OSC device.

In this context, a new conjugated polymer donor and small molecule acceptor were synthesized, namely, Poly[(2,6-(4,8-bis(5-(2-ethylhexylthio)-4-fluorothiophen-2-yl)-benzo [1,2-b:4,5-b′]dithiophene))-alt-(5,5-(1′,3′-di-2-thienyl-5′,7′-bis(2-ethylhexyl)benzo [1′,2′-c:4′,5′-c′]dithiophene-4,8-dione)] (PBDB-T-SF) and 3,9-bis(2-methylene-((3-(1,1-dicyanomethylene)-6,7-difluoro)-indanone))-5,5,11,11-tetrakis(4-hexylphenyl)-dithieno [2,3-d:2′,3′-d′]-s-indaceno [1,2-b:5,6-b′]dithiophene (ITIC-4F) by Hou and co-workers [102]. The OSC based on PBDBT-SF:IT-4F possessed significantly higher ISC (20.50 mA/cm2), VOC (0.88 V), FF (0.719), and PCE (13%). Moreover, a single-junction OSC made of poly[(2,6-(4,8-bis(5-(2-ethylhexyl)thiophen-2-yl)benzo [1,2-b:4,5b′]dithiophene)-co-(1,3-di(5-thiophene-2-yl)-5,7-bis(2-ethylhexyl)benzo [1,2-c:4,5-c′]dithiophene-4,8-dione)] (PBDB-T) as the donor and 3,9-bis(2-methylene-((3-(1,1-dicyanomethylene)-6/7-methyl)-indanone))-5,5,11,11-tetrakis(4-hexylphenyl)-dithieno [2,3-d:2′,3′-d′]-s-indaceno [1,2-b:5,6-b′]dithiophene (ITIC-M) as the acceptor achieved a PCE of 12.05% [103]. The values of VOC, ISC, and FF of the fabricated OSC were found to be 0.94 V, 17.44 mA/cm2, and 0.735, respectively.

Possibilities of improvements in the multijunction efficiency based on the design principles were demonstrated by combining tandem with a solution-processed non-fullerene-acceptor-based infrared-absorbing subcell on a visible-absorbing fullerene-based subcell [104]. A high PCE of 15% along with a Voc of 1.59 V, Isc of 13.3 mA/cm2, and fill factor of 0.71 were achieved. The effect of regioregularity of the backbone and the fused-ring core modulation of the polymer acceptor on the performance of OSC was demonstrated by Fu and co-workers [105]. The OSC was fabricated using PBDB-T as the donor with a new class of polymeric acceptor benzotriazole (BTz)-core fused-ring segment. A maximum PCE of 15.8% was achieved for the regioregular acceptor (PZT-γ)-based OSC in addition to an enhanced Isc, VOC, and FF of 24.7 mA/cm2, 0.896 V, and 0.71, respectively. The application of a novel polymer acceptor, PYT-1S1Se, an asymmetrical selenophene-fused backbone, while using Poly[(2,6-(4,8-bis(5-(2-ethylhexyl-3-fluoro)thiophen-2-yl)-benzo [1,2-b:4,5-b′]dithiophene))-alt-(5,5-(1′,3′-di-2-thienyl-5′,7′-bis(2-ethylhexyl)benzo [1′,2′-c:4′,5′-c′]dithiophene-4,8-dione)] (PBDB-TF) as the donor polymer was able to achieve a high PCE, VOC, ISC, and FF of 16.3%, 0.926 V, 24.1 mA/cm2, and 0.73, respectively [106]. The development of novel polymeric acceptors by polymerizing an efficient small-molecule acceptor, 2,2′-((2Z,2′Z)-((12,13-bis(2-ethylhexyl)-3,9-(2-butyloctyl)-12,13-dihydro-[1,2,5]thiadiazolo [3,4-e]thieno [2″,3″:4′,5′]thieno [2′,3′:4,5]pyrrolo [3,2-g]thieno [2′,3′:4,5]thieno [3,2-b]indole-2,10-diyl)bis(methanylylidene))bis(5,6-difluoro-3-oxo-2,3-dihydro-1H-indene-2,1-diylidene))dimalononitrile (L8-BO) and its subsequent OSC device manufacturing with PBDB-TF as the donor, was demonstrated by Sun and co-workers [107]. The fabricated all polymer-OSC devices achieved a Voc of 0.949 V, Jsc of 23.73 mA/cm2, FF of 0.74, and PCE of 16.76%.

An effective strategy for improvement in the performance of OSC is additive engineering. However, only limited concentrations of traditional additives can be incorporated, such as 1,8-diiodooctane (DIO) or 1-chloronaphthalene (CN) along with an induced lower stability. Moreover, additional thermal treatment is required, which is an obvious hurdle for industrial applications. In this context, 1,3-diiodobenzene (1,3-DIB) has proved to be a versatile and effective solid additive [108]. A NFA thiadiazolo [3,4-e]thieno [2″,30′:4′,50]thieno [20,30:4,5]pyrrolo [3,2-g]thieno [20,30:4,5]thieno [3,2-b]indole-2,10-diyl)bis(methanylylidene))bis(5,6-difluoro-3-oxo-2,3-dihydro-1H-indene-2,1-diylidene))dimalononitrile (Y6) has gained considerable interest recently. The incorporation of 1,3-DIB in PDBD-TF:Y6 resulted in an improvement in Voc, Jsc, FF, and PCE from 0.87 V, 25.08 mA/cm2, 0.71, and 15.36% to 0.85 V, 26.0 mA/cm2, 0.76, and 16.90%, respectively. All-polymer OSCs have gained significant attention recently. A ternary-all-polymer OSC composed of PDBD-TF as the donor along with a combination of poly[(2,2′-((2Z,2′Z)-((12,13-bis(2-octyldodecyl)-3,9-diundecyl-12,13-ihydro [1,2,5]thiadiazolo [3,4e]thieno [2″,3″:4′,5′]thieno [2′,3′:4,5]pyrrolo [3,2-g]thieno [2′,3′:4,5]thieno [3,2-b]-indole-2,1′-diyl)bis(methanylylidene))bis(3-oxo-2,3-dihydro-1H-indene-2,1-diylidene))dimalononitrile-alt-2,5-thiophene)] (PYT) and a novel fluorinated polymer named PY2F-T as the acceptor had Voc, Isc, FF, and PCE of 0.90 V, 25.2 mA/cm2, 0.76, and 17.2%, respectively. A new donor–acceptor polymer where donor D18 was connected to a fused ring acceptor DTBT was proposed for the improvement of the OSC performance [109]. The single-junction OSC based on D18:Y6 demonstrated a PCE of 18.22% owing to its high hole mobility and wide band gap of D18.

The improvement in the performance by the incorporation of additives has gained considerable interest. Two volatile solid additives (SADs) are designed according to their conformation; SAD1 is a twisted-type while SAD2 is a planar-type [110]. The effect of the conformation of the additive is evaluated by using it with PDBD-TF as the donor and either 2,2′- [[12,13-Bis(2-butyloctyl)-12,13-dihydro-3,9-dinonylbisthieno [2″,3″:4′,5′]thieno [2′,3′:4,5]pyrrolo [3,2-e:2′,3′-g][1–3]benzothiadiazole-2,10-diyl]bis[methylidyne(5,6-chloro-3-oxo-1H-indene-2,1(3H)-diylidene) ]]bis[propanedinitrile] (BTP-eC9) or L8-BO as the acceptor material. In all cases, the performance properties improved compared with OSC without additive. However, planar-type SAD (SAD1) had the best performance, owing to its better insertion in the constituents of OSC. The best-performing device (PDBD-TF:L8-BO-SAD2) achieved Voc, Isc, FF, and PCE of 0.889 V, 26.73 mA/cm2, 0.79, and 18.85%, respectively.

Selectivity in the fabrication process can have a significant effect on the performance of OSC. A binary OSC device composed of Poly[(2,6-(4,8-bis(5-(2-ethylhexyl-3-chloro)thiophen-2-yl)-benzo [1,2-b:4,5-b′]dithiophene))-alt-5,5′-(5,8-bis(4-(2-butyloctyl)thiophen-2-yl)dithieno [3′,2′:3,4;2″,3″:5,6]benzo [1,2-c][1,2,5]thiadiazole)] (D18) as the donor and L8-BO as the acceptor material is used for the evaluation of fabrication process [111]. Sequential deposition resulted in higher performance properties compared with blend heterojunction. OSCs prepared by blend casting had Voc, Isc, FF, and PCE of 0.911 V, 26.31 mA/cm2, 0.76, and 18.14%, respectively, compared with 0.918 V, 26.86 mA/cm2, 0.77, and 19.05% for the OSC prepared by sequential deposition. A combination of an asymmetric selenium-substituted pseudosymmetric electron acceptor, BS3TSe-4F, and Y6 acceptors with D18 as the donor had a record high efficiency of OSC [112]. The fabricated device possessed Voc, Isc, FF, and PCE of 0.845 V, 29.41 mA/cm2, 0.77, and 19.03%, respectively.

Suppressing the charge recombination along with improving charge extraction are critically important for the performance of any OSC. Peng and coworkers reported an improvement in the abovementioned properties by the combination of side-chain engineering of new nonfullerene acceptors (NFAs) in a ternary blend along with a volatilizable solid additive [113]. Thes hindrance of BTP-Th in molecular packing and phase separation is reduced by fluorination of side chains making BTP-FTh. The donor used in this case was Poly [[6,7-difluoro[(2-hexyldecyl)oxy]-5,8-quinoxalinediyl]-2,5-thiophenediyl ]] (PTQ10). An OSC composed of PTQ10 as the donor and binary blend of acceptor materials BTP-FTh:IDIC (0.8:0.2) along with dithieno [3,2-b:2′,3′-d]thiophene (DTT) as additive rendered Voc, Isc, FF, and PCE of 0.870 V, 27.17 mA/cm2, 0.81, and 19.05%, respectively.

Most recently, a record high PCE was reported by Hou and coworkers for a tandem organic solar cell through the introduction of an interconnecting layer composed of electron-beam-evaporated TiOx and PEDOT:PSS [114]. The two sub-cells were PBDB-TF:GS-ISO/TiO1.76 and TiO1.76/PEDOT:PSS, where an efficient electron extraction and low Schottky barriers were obtained due to control of O2 flux during evaporation. For the first time, a PCE of more than 20% was obtained by any OSC. The archived Voc, Isc, FF, and PCE of the best device were 2.01 V, 13.14 mA/cm2, 0.77, and 20.27%, respectively. The study opens a new era of 20% PCE in OSC technology.

2.8. Commercialization Perspective

Efficiency and stability enhancement of OSC are the major challenges in the commercialization of OSC. For improvements in efficiency, several approaches are employed, such as broadening in the absorption of the solar light spectrum, exciton diffusion/dissociation, transport of charges, and collection of charges. On this front, organic materials with broad absorption ranges have been used, and tandem structures of materials have complementary absorption spectra. Improvement in the diffusion/dissociation efficiency can be improved by bulk heterojunction. The formation of nanoscale morphologies can improve the charge transport and charge collection. Moreover, inverted configurations cause interface stability and the degradation of the device and hence improve the overall stability of OSC.

In the last decade, significant progress has been made in the field of OSC. Material design and chemistry of the input materials along with fabrication techniques are the major fronts to address in the context of commercialization. In the last couple of years, a major breakthrough in OSC technology was the achievement of more than 20% PCE. Thickness-intensive photovoltaic properties, high performance, air-insensitivity, green solvents, and no requirement of extra treatment are the required features in the context of commercialization. All of these features must be addressed well from a commercialization perspective. All-polymer OSCs are stable, use green solvents, and achieve a fairly high efficiency that makes them promising candidates for commercialization. Moreover, the introduction of a high-performance interface layer between the complementary sub-cells of tandem OSCs is a promising approach to achieve high efficiency. Generally, photovoltaic materials have complex chemistry and hence are expensive. The exploration of low-cost photovoltaic materials is one of the major interests in context of commercialization. The applications of OSC in portable devices and building-integrated materials will be a great evolution, and we anticipate OSC may constitute a major share in the future of commercial products for renewable solar energy generation [115].

2.9. Recommendations and Suggestions for Improvement and Future Works

Improved OSC efficiency and higher OSC stability are essential for commercial applications. Utilizing tandem solar cells, molecularly tailored donor and acceptor materials, and low-band-gap donor materials can increase the efficiency. Future research should be focused on device stability in areas such as (i) the development of new polymer donor materials with balanced rigidity/flexibility and crystallinity/amorphism properties to simultaneously improve photo/air, thermal, and mechanical stabilities; (ii) the use of non-fullerene acceptors in place of PCBM for better photo/air, thermal, and mechanical stabilities; (iii) developing a comprehensive understanding of OSC device degradation mechanisms with oxygen, water, and irradiation; (iv) the creation of a universal standard for OSC stability tests; (v) the enhancement of OSCs in PCE based on polymers with cleavable side chains and photo/air-stable units; and (vi) the creation of a sophisticated, encapsulating technology for OSCs. The PCE of OSCs have already exceeded 21%; however, stability issues are still a concern in context of commercialization.

2.10. Computational for Organic Solar Cells

The process of synthesizing new materials for OSCs is time-consuming and expensive. Consequently, a computer model for predicting the PCE of a new device without physical experiments is required. The Scharber equation can predict the PCE of any OSC using a few key parameters that can be determined computationally through density functional theory (DFT) and machine learning (ML). The Harvard Clean Energy Project Database (CEPDB) contains computationally predicted PCE values for 2.3 million potential organic photovoltaic systems through machine-learning models.

In this context, the PCE, the short-circuit current density Jsc, the open-circuit voltage Voc, the HOMO energy, the LUMO energy, and the HOMO−LUMO gap are reported as computed by the DFT methods described by Hachmann and co-workers using the Scharber equation.

where FF is the fill factor and Pin is the input power.

The open-circuit voltage given by the expression below is derived by Scharber and co-workers.

where “e” is the electron charge, “EdonorHOMO” is the energy of the highest occupied molecular orbital (HOMO) of the donor material in the cell, “EacceptorLUMO” is the energy of the lowest unoccupied molecular orbital (LUMO) of the acceptor material in the cell, and 0.3 is an empirical correction.

The short-circuit current density is given by

where the external quantum efficiency EQE set to 0.65 in the Scharber model, Eg is the band gap of the donor material, and ϕph is the incident solar photo flux density as a function of energy E.

3. Perovskite Solar Cells

3.1. The Meaning of Perovskite

Originally, the term “perovskite” referred to the calcium titanate crystal structure, which was identified in 1839 by German mineralogist Gustav Rose and given the name by Russian mineralogist Lev Perovski. Compounds with perovskite structures typically contain the formula ABX3, where ‘A’ and ‘B’ stand for cations and ‘X’ is an anion joining the two cations. These metal halide perovskites, consisting of lead (Pb2+), methyl-ammonium CH3NH3+, an organic cation, and a halide anion such as iodide (I) or bromide (Br), have drawn much attention as prospective perovskite solar-cell materials in recent years. Figure 5 displays three-dimensional (3D) and two-dimensional (2D) schematic designs as well as the usual unit cell arrangement of a perovskite compound. Usually, structures can be built from a wide variety of unique component combinations. By changing the composition of these substances, researchers may produce perovskite crystals with a variety of properties, including physical, optical, magnetic, and electrical.

Figure 5.

(a) 3D and (b) 2D schematic diagrams and (c) the schematic diagram of a perovskite unit cell [116].

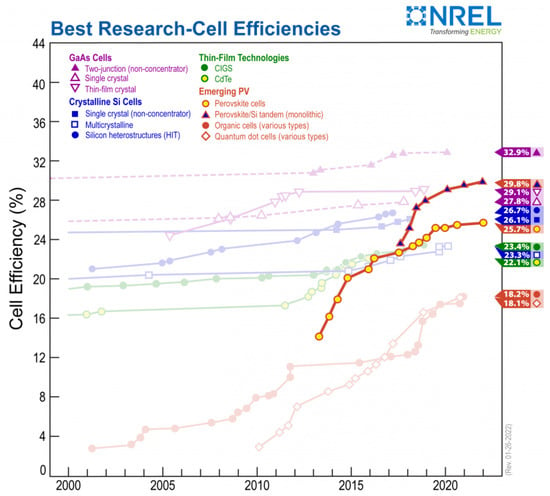

In 1958, Chr. Kn. Moller first discovered halide perovskites for cesium lead halides [117]. Following this, it was also observed that small organic molecules with effective radii less than 260 pm (such as MA (CH3NH3), FA (CH(NH)2)) could also accommodate the inside of the lead halide octahedrons from the analysis of Goldschimdt’s tolerance factor/octahedral factor; additionally, Dieter Weber, in 1978, successfully synthesized MAPbX3 (X = halogens (I, Br, Cl or Mixtures of them) and superhalogen (BF4, PF6)) for the first time [118]. Thereafter, researchers started working on layered 2D perovskite systems (commonly, (R-NH3)2MX4), where the extended inorganic lead halide octahedral cage is separated by large organo-ammonium cations [119]. The resurgent hybrid perovskite was initiated by the introduction of three-dimensional hybrid perovskites (CH3NH3PbI3 and CH3NH3PbBr3) as absorbers [120] in mesoporous solar cells by Miyasaka and co-workers in 2009. Since then, researchers across the globe have used them as absorber materials in photovoltaic cells and achieved PCE as high as 25.7% in sa ingle junction [121] and 29.8% in monolithic perovskite/Si tandem solar cells (Figure 6). Superior optoelectronic properties such as low bandgap with direct nature, high optical absorption both in visible and IR regions, ultrahigh diffusion length, high defect tolerance, large and balanced electron-hole mobilities, high photoluminescence quantum yield, and low surface recombination velocity make them attractive candidates for solar-cell application [122,123].

Figure 6.

The efficiency records for perovskite solar cells and monolithic perovskite/Si tandem solar cells compared with other photovoltaic technologies [121].

Nowadays, the various structures of perovskite solar cells such as mesoporous, planar, and inverted structures have been developed. In the mesoporous solar cells, the device structure was composed of glass/fluorine-doped tin oxide (FTO)/dense electron transport layer (ETL)/mesoporous oxide layer/perovskite layer (~500 nm)/hole transport layer (HTL)/metal electrode [124,125,126]. The mesoporous TiO2 is used as an ETL material allowing perovskites to penetrate into the pores to form an interconnected absorbing layer. Additionally, titanium dioxide (TiO2) also prevents the electron-hole recombination in the FTO by blocking the holes. Experimental results revealed that other oxide materials such as zinc oxide (ZnO), aluminum oxide (Al2O3), and zirconium dioxide (ZrO2) were also used as mesoporous oxide layers. In this structure, Spiro-OMeTAD (2,2′,7,7′-Tetrakis [N, N-di(4-methoxyphenyl) amino]-9,9′-spirobifluorene) is the most used HTL and noble metals such as Au, Ag, and Pt are used as the counter electrodes. In the case of planar structure, the mesoporous ETL is removed and only two sharp interfaces are observed between perovskites and two transport layers (ETL and HTL). As a result, the rapid and effective separation of electrons and holes are observed through the ETL and HTL, respectively [127]. Due to the minimum number of interfaces, planar heterojunction structures help to understand the operating mechanisms of light absorption and electron-hole separation precisely and optimize the structure for the development of highly efficient laminated perovskite photovoltaic cells. Besides the two abovementioned structures, perovskite solar cells without HTL have become an interesting research project due to their advantages of easy and simple device fabrication and high stability [128]. These perovskite materials served the purpose of both light absorbers and hole transport channels. Using device simulation, Minemoto and Murata showed that the built-in electric field was not affected if the work function of metal electrodes was close to the valence band maximum of the light-absorbing materials for the case of HTL-free perovskite solar cells [129].

Usually, the perovskite layer is spin-coated on the substrate via either a single-step or two-step process. In the single-step process, perovskite precursor (a mixture of CH3NH3I and PbI2 dissolved in DMF:DMSO) is spin-coated onto the FTO substrate in one step and kept at 1000 C to achieve a uniform perovskite film. In recent times, an anti-solvent method is effective, in which the perovskite precursor solution is prepared in the polar solvent and quenched during the process of spin coating by a non-polar solvent. It is often observed that precise control over the volume of quenching solvent and timing is very much essential to achieve uniform morphology and optimal device performance. In the two-step process, lead iodide (PbI2) was the first to be spin-coated and then transferred into a vessel where 1 molar CH3NH3I was dissolved in isopropanol. Other than these two frequently used methods, OIHPs can also be deposited via a ‘vacuum-assisted solution process’ (VASP) in which perovskite films are coated and annealed in a chamber filled with the organic component vapor [130].

3.2. Advantages and the Challenges of Perovskite Solar Cells

Perovskite photovoltaics have a high light-absorption coefficient (104 cm−1), which results in an impressive photocurrent generation [131], long carrier diffusion length, and solution processability [132,133,134]. Perovskite solar cells are cheaper to produce, owing to their inexpensive and naturally abundant materials (lead, iodine, carbon, and hydrogen) [135]. These solar cells show better defect tolerance than other solar semiconductors on the market [136], which increases their reusability and lowers production costs. Despite their benefits, the commercialization of perovskite solar cells is hampered by another factor. Water by itself (moisture) and other polar solvents provide a serious problem for perovskite solar cells. These solvents can alter the solvated phases of a perovskite and occasionally hydrate a perovskite to produce a monohydrate phase. Polar solvents can considerably be prevented from harming perovskite solar cells by modifying deposition techniques, according to reports. However, environmental moisture is unavoidable [137].

It is observed that various external factors such as oxygen, light, and heat have expedited the degradation, which can be slowed by choosing a proper composition of the perovskite material (such as FA0.85MA0.1Cs0.05PbI2.7Br0.3, which show better stability and power conversion efficiency) [138,139,140,141]. In addition, it was noted that the deposition of more hydrophobic and UV-stable ETL/HTL has improved the stability of the device (replacing TiO2 with SnO2). The combination of Ruddlesden–Popper (RP) 2D-layered perovskites with conventional 3D perovskites has improved the stability of the device as 2D perovskite passivate/encapsulate the device [142].

On the other hand, the use of an excessive amount of lead in the perovskite component is also another big challenge in its commercialization. As an alternative, tin-based perovskites are studied, but the PCE of such devices [143] is poor (PCE ~13%). Current-voltage hysteresis between the forward and reverse bias is another major issue. Although the reason for hysteresis is still under debate, it is commonly ascribed to the combination of ion migration with high levels of charge-carrier recombination. To achieve a truly low cost-per-watt and dominate the photovoltaic market, solar cells based on OIHPs should satisfy the much-heralded trio of high-power-conversion efficiency (PCE), yearlong lifetimes, and ultra-low manufacturing costs. Certainly, OIHP-based solar-cell devices are quite farther ahead than other thin-film technologies, as they have shown enormous potential for achieving this.

3.3. Future Prospective

According to us, future research is likely to focus on the following steps: (i) reduction of halide defect sites through additives and passivation, (ii) the inclusion of 2D perovskites and better-optimized interface materials to increase the efficiency and stability, (iii) the use of inorganic charge-extraction layers rather than organic ones to improve both efficiency and stability, and (iv) proper understanding of charge-carrier transport mechanism.

3.4. The Difficulties and Strategies for Improving Solar Cell Stability

The hydrophilic and volatile nature of organic molecules make hybrid perovskite vulnerable to degradation through humidity and heat, which limits the long-term stability of perovskite solar cells for industrial applications. Several fundamental strategies have been adopted to slow down the degradation of the absorber materials and increase device stability: (i) develop a more resilient perovskite absorber via cation substitution/doping; (ii) controlling perovskite crystallization by novel approaches such as solvent engineering and the use of additives or non-halide, (iii) using carbon-based functional materials such as carbon nanotubes (CNT), graphene, or fullerene (C60) between the perovskite absorber and the hole-transport materials, and (iv) developing a protective layer (encapsulation technique) around the absorber material. To date, most perovskite solar cells with high stability are inverted (p-i-n) type (maintaining >90% of the initial power conversion efficiency over 1000 h).

3.5. Current Progress of Tandem Solar Cells

A steep absorption edge, exceptionally low sub-gap absorption, tunable bandgap (by changing halide composition), and desirable Voc of 1.15 V corroborate the hybrid perovskite as a suitable candidate for top wide-bandgap cells in the tandem configuration. Furthermore, the low-temperature fabrication of perovskite helps to monolithically integrate it as a top cell without damaging the bottom cell. A high power-conversion efficiency (PCE) of 32.5% and 29.8% has been achieved in monolithic 2T and 4T perovskite/silicon tandem solar cells, where perovskite was used as the top sub-cell and silicon as the bottom cells, respectively. Other than the above, various perovskite-based tandem cells such as perovskite/CZTSSe (PCE~14.2%), perovskite/CIGS (PCE~26.8%), perovskite-DSSC (PCE~17.5%), and perovskite-perovskite (PCE~25.9%) have been widely developed in recent years and will be ready for commercialization within a couple of years.

3.6. Commercialization of Solar Cells

Irrespective of the high power-conversion efficiencies of Si, CIGS, and CZTSSe-based solar cells, high manufacturing costs and limitations in large-scale production are considered as major drawbacks for further versatile applications. Thus, various types of lost-cost solar cells such as small-organic molecule/polymer-based solar cells, dye-sensitized solar cells are being investigated aiming to replace Si-based solar cells. Recently, hybrid perovskite solar cells are considered as a potential replacement for Si-based solar cells due to their low production cost, high power conversion efficiency, lightweight, and possibility of flexible device fabrication. Yes, it is true that stability of perovskite solar cells is the major drawback, which pales in comparison to the 25-year stability of silicon. The longest reported lifetime for the prototype single-junction perovskite solar cell was 6000 h under continuous one-sun illumination before degrading by beyond 80% of its initial performance. As an alternative of single-junction cells, perovskite–Si tandem cells show better stability. Thus, several companies such as Oxford PV, Hanwha Q Cells, Greatcell Energy, Saule technologies, Quantum Solution, and Energy Materials are in the advanced stages of commercializing perovskite solar cells.

3.7. Lead-Free Perovskite Solar Cells

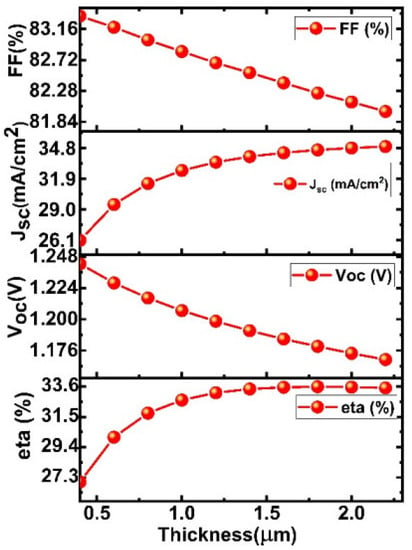

The study of the properties of lead-free perovskite solar cells has been performed by many researchers. Methylammonium tin iodide (CH3NH3SnI3) could be used to replace lead due to its narrower band gap, eco-friendliness, wider visible absorption spectrum, and excellent mobility. Ahmad and co-workers [144] described a solar cell made from glass/ITO (as an electron-transport layer)/n-type WS2/CH3NH3SnI3/p-type P3HT (as a hole-transporting layer)/Au. Tungsten disulfide (WS2) indicated a small, indirect band gap (1.3 eV), a big direct band gap value (2 eV), a high carrier mobility, and excellent conductivity. The homo-polymer poly (3-hexylthiophene), called P3HT, showed a wide band gap, high hole mobility, robust hydrophobicity, high thermal stability, and relatively low cost. The experimental findings showed power conversion efficiency (due to number of carriers increased) and the short circuit current density increased (due to more photons falling on it); however, the fill factor and open-circuit voltage reduced (due to an increase in dark saturation current) with the increase in the film thickness (Figure 7). It is noted that more photons were absorbed when the film thickness was increased. These photons could penetrate deeper into the absorber layer, resulting in the production of more electron-hole pairs in devices. The photovoltaic parameters (fill factor = 81.59%, open-circuit voltage = 1.0997 V, power-conversion efficiency = 33.46%, short-circuit current density = 37.17 mA/cm2) were studied under optimized conditions. Nihal and co-workers proposed zinc magnesium oxide (ZnMgO) and MASnBr3 as an electron-transport layer and hole-transport layer, respectively [145]. The photovoltaic behaviors (fill factor = 82.01%, open circuit voltage = 0.95V, power conversion efficiency = 26.33%, short circuit current density = 33.85 mA/cm2) were investigated in specific solar cells (Zn0.75Mg0.25O/CH3NH3SnI3/MASnBr3). Komal and co-workers used ZnTe (as the hole-transport layer) to replace spiro-OMeTAD, which is a very expensive) material [146]. The power conversion efficiency reached 22.96% (simulation model) and 8.41% (fabrication model) based on the experimental results.

Figure 7.

The effect of the perovskite layer thickness on solar cell parameters [144].

4. Dye-Sensitized Solar Cells

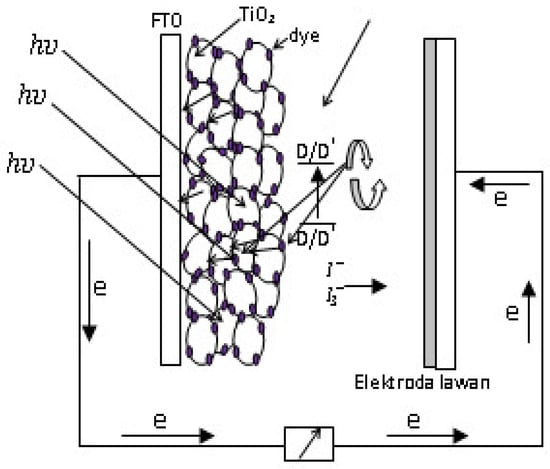

Dye-sensitized solar cells (DSSC) are solar cells made of semiconductors that are coated with a dye to increase the efficiency of sunlight [147]. This type of solar cell was first introduced by Michael Gratzel. DSSCs are composed of a working electrode consisting of fluorine tin oxide (FTO) glass, titanium dioxide (TiO2), dye, an electrolyte consisting of an I¯/I3¯ redox pair, and a counter electrode consisting of platinum. DSSCs work in the visible region. DSSC components have undergone various developments over the years to increase their efficiency.

4.1. Advantages and Limitations of Dye-Sensitized Solar Cells

Some of the advantages offered by dye-sensitized solar cells, including their relatively low cost of fabrication, operability under scattered light conditions, and the variable shape of the cell, which can be made opaque or opaque or optically transparent, thereby providing more value from an artistic point of view [148]. Organic solar cells have dyes derived from organic and synthetic organic materials. Examples of dyes from organic materials are mangosteen, juwet fruit, water henna, nail henna, blueberries, binahong leaves, carrots, kenikir, and mangosteen peel. Synthetic organic dyes such as ruthenium complex (N719) could produce a higher efficiency of 10.4–11.1% [149,150]. However, the cost of producing ruthenium complex dyes is still relatively high, thus encouraging the development of new dye sensitizers (complexes of osmium, rhenium, iron, and iridium) [151].

The advantages of using synthetic, organic dyes include their higher conversion efficiency (an efficiency increase of up to 30% in synthetic dyes, with organic dyes being 5%), increased chemical and thermal stability, the color being difficult to degrade compared with organic dyes, and having a higher electron movement than organic dyes. There have been many studies using natural organic dyes and ruthenium dyes with a wide variety of solvents, including research conducted [152] using nano-particle TiO2 paste, ruthenium dye (N719), and counter electrodes (platinum) to produce the greatest efficiency of 0.121%. Hardani and co-workers [153] made DSSC using TiO2 doping carbon nanotubes with various concentrations and ruthenium (N719) as a dye, and the resulting efficiency was 1.3%. Another research group [154] used TiO2 nanoparticles as the active electrode and ruthenium complex (N719) as a dye and the greatest efficiency reached 2.17%.

The solid electrolyte based on PEG polymer gel (polyethylene glycol) containing redox coupling is used (to replace liquid electrolyte) to reduce electrolyte degradation. During the experiment, the doctor blade/slip-casting and spin-coating techniques were used for TiO2 coating. In comparison with other processes, this doctor blade/slip-casting method is incredibly straightforward and uncomplicated. The spin-coating technique is used to deposit homogeneous thin films on a flat substrate. While, the doctor blade/slip-casting technique is a technique for coating the TiO2 suspension on semiconductor glass utilizing a stir rod/spatula by rolling it on the glass surface to flatten the dripping TiO2 suspension. The substrate’s center, which either rotates slowly or not at all, receives a modest amount of coating material. The coating substance is subsequently dispersed throughout the substrate using centrifugal force as the substrate is rotated quickly. The device used for spin coating is called a “coater” or “spinner”. Spin coating is a straightforward TiO2-deposition technology that produces films with regulated thickness and great uniformity by rotating the TiO2 paste at a specific speed.

4.2. Definition and Fundamental of Dye-Sensitized Solar Cells

DSSC generally uses indium tin oxide (ITO) or fluorine-doped tin oxide (FTO) as a substrate. The oxide substrate layer functions as a current collector and the substrate material itself as a sealing layer between the cells in the DSSC and the outside air [155].

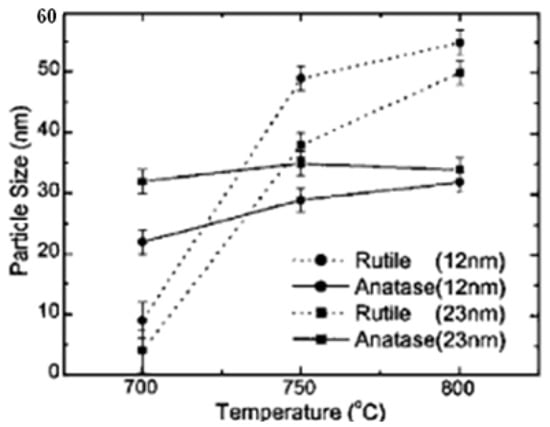

Titanium dioxide (TiO2) is the material of choice used as a working electrode or photoelectrode in DSSC. The three modifications of TiO2 include anatase, rutile, and brookite, but only anatase and rutile are stable [156]. Brookite is difficult to produce and therefore is not considered in DSSC applications [157]. The particle sizes of anatase and rutile increase[158] with increasing temperature. Figure 8, showing different growth rates, shows that rutile has a much higher growth rate than anatase. The growth rate of anatase is flat at 800 °C.

Figure 8.

Changes in the particle size of anatase and rutile as a function of annealing temperature [158].

The absorbance spectrum defines the possibility of a useful semiconductor for photocatalysts having a band gap (Eg) proportional to the photon energy of the visible or ultraviolet spectrum (Eg < 3.5 eV). Most authors have determined that the energy gap of rutile is 3.0 eV and that of anatase is 3.2 eV. A larger active surface area and a more effective photocatalyst [159] can be observed in the anatase phase.

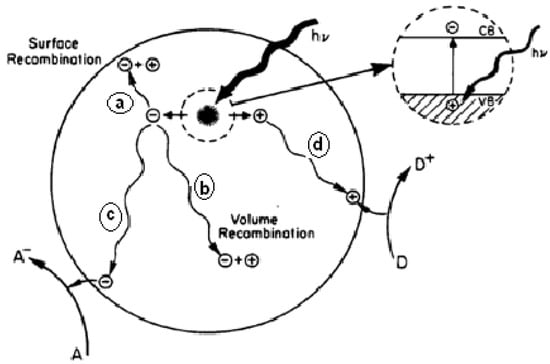

The photocatalytic process is based on the dual ability of a semiconductor material (TiO2) to absorb photons and carry out transformation reactions at the material junction simultaneously. Figure 9 shows several photoexcitation pathways [160] followed by electron and hole de-excitation. The enlarged portion of Figure 9 shows electrons excited from the valence band (Ev) to the conduction band (Ec) due to photons with energy (hv) equal to or greater than the band gap of the semiconductor.

Figure 9.

The schematic of photoexcitation followed by de-excitation on the semiconductor’s surface [160].

From Figure 9, it is assumed that the semiconductor remains intact, and the charge transfer is uniform to the adsorbed organic or inorganic molecules. The excited electron-hole pair can go through several paths as follows: the semiconductor can donate electrons on the surface to reduce the adsorbed acceptor (), for example, oxygen (lane c). Holes can migrate to the surface and electrons from donors (D/D+) can join holes (c lanes). Competition for electron transfer to adsorbed molecules by the separate recombination of electrons and holes occurs in the volume of the semiconductor particles (band b) or on the semiconductor’s surface (lane a).

Electron paramagnetic resonance spectroscopy (EPR) showed that the detected electrons were either captured as Ti3+ or as electrons in the conduction band, while the holes were trapped in the O− free-oxygen center resulting from the O2− lattice in the valence band. The reaction is written as follows [161]:

4.3. The Development of Natural Dye from Plant Extracts in DSSCs

Many researchers have developed DSSCs by utilizing various types of natural dyes from plant extracts. Some that have been developed include dye extracts or plant pigments such as chlorophyll extract [162], anthocyanins [163], and beta carotene [164]. One of the results of the DSSC that has been developed [164] by using carotenoids succeeded in making DSSCs with an efficiency of 3% and which were stable after 1 h of sunlight exposure. Beta-carotene is found in every part of the plant, namely from flowers, fruits, stems, and roots, and provides pigments to fruits and flowers with distinctive red, orange, and yellow colors [165]. Plant pigmentation occurs because the structure of the pigment interacts with sunlight to change wavelengths that are either transmitted or reflected by plant tissues [166,167,168].

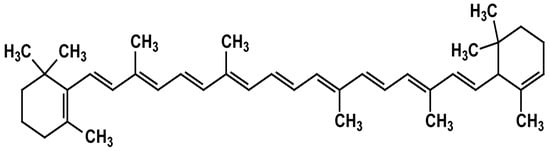

Carotenoids are involved in photosystems and contribute to energy absorption in the visible light spectrum by transferring the absorbed energy to chlorophyll. Carotenoids also protect from excess light through energy dissipation, the detoxification of free radicals, and limiting damage to cell membranes. In addition, highly conjugated carotenoids can function as short-wire molecules that mediate the electron transfer in donor–acceptor complexes and membranes. Figure 10 shows beta-carotene having a series of delocalizations, but on a larger scale with 11 carbon–carbon double bonds conjugated together [169]. Beta-carotene absorbs the visible light spectrum between 380 and 520 nm. Therefore, it takes less energy to push electrons on beta-carotene than TiO2, which works in the ultraviolet range (<400 nm). The number of conjugated double bonds (CDB), maximum absorption (λmax), and carotenoid colors are presented in Table 1.

Figure 10.

The structure of beta-carotene [169].

Table 1.

Trivial name and semi-systematic names of carotenoids.

The trivial and semi-systematic names of carotenoids are shown in Table 1. The number of conjugated double bonds (CDB) was compared with the maximum absorbance spectra (λmax) and the color of the carotenoid solutions. The maximum absorbance spectra expressed in acetonitrile/ethyl acetate solution were measured using high-performance liquid chromatography (HPLC) with a PDA detector [170] unless otherwise stated. Beta-carotene is one of the most abundant classes of carotenoids found in food and is used as a food coloring. Plants that produce beta-carotene include corn [171], pumpkin, carrots, tomatoes, and melinjo fruit. Schematically the working principle of DSSC is shown in Figure 11. In the simplest arrangement, the DSSC consists of a transparent conductive glass coated with nanocrystalline TiO2 (nc-TiO2), a dye molecule bound to the nc–TiO2 surface, and an electrolyte such as I¯/I3¯, with illuminated cells capable of generating voltages and currents [172].

Figure 11.

The working principle of dye-sensitized solar cells [172].

4.4. Commercialization of DSSC

Dye-sensitized solar cells have attracted increasing attention (cost effectiveness and ease of production) in the last few years. Research is ongoing to improve the efficiency and stability of solar cells. Technically speaking, natural dyes are inefficient and show very weak binding properties with titanium dioxide. Therefore, synthetic dye was used to create the most stable and effective dyes. Based on the analysis, the world DSSC market size was valued at approximately USD 90.5 million, in 2019, and is expected to reach an annual growth rate of 12.4% (from 2020 to 2027). This solar cell could be used in building-integrated photovoltaic, portable charging, automobile, electronic gadgets, and mobile devices. Several factors such as the installation of off-grid solar cells in African countries, the European Union cutting down its carbon emissions, the movement towards renewable energy sources, and enhanced technological development in the solar energy system increase the demand for DSSC.

4.5. Tandem Dye-Sensitized Solar Cells

Researchers have reported that tandem cells could be used to enhance the performance of solar cells. During the experiment, two TiO2 films were put face-to-face (as electrodes), while the platinum mesh sheet was served as counter electrode. The experimental results confirmed that efficiency was increased (from 1.8% to 3.9%) due to the current density being added. Another research group revealed that tandem-structured cells show lower circuit currents and higher open-circuit voltage when compared to conventional DSSC. Technically speaking, tandem design could be divided into three types, namely n-type DSSC + n-type DSSC (higher efficiency could be reached), n-type DSSC + other solar conversion devices (could be employed in industrial applications), and n-type DSSC + p-type DSSC (lower efficiency).

4.6. The Future of DSSC

In the future, DSSC will emerge as an attractive solar energy technology due to its provision of an economical option to p–n junction solar cells. Several research works have been carried out to enhance the efficiency of solar cells. Researchers have reported that light absorption must achieve the highest visible and near-infrared spectrum to gain better efficiency values.

5. Thin-Film Solar Cells

Currently, there are different types of thin-film materials that have been and are employed in solar-cell applications. Technically speaking, these materials have several advantages such as low production cost, being environmentally friendly, and the formation of films can be conducted in various substrates [173].

5.1. CdTe Film Solar Cells

Cadmium telluride (CdTe) films show high degradation durability, near-optimum band-gap value (1.45 eV), a low production cost, and high direct absorption coefficient (104 cm−1), and can be used to replace silicon-based solar cells. Generally, CdTe-based solar cells consist of glass, transparent conducting oxide (serving as the front contact), a CdS window layer, a CdTe absorber layer, and back contact. However, this type of solar cell has many problems such as glass breakage (during the production process) and poor thermal conductivity (causing very poor performance). The preparation of CdTe films onto flexible metal foils and polymer substrate can solve these problems. The power conversion efficiency was shown to be 11% for devices prepared on polyimide foils [174], indicating the superstrate and substrate configurations. Several deposition methods have been reported to produce cadmium-tellurium thin films (Table 2). The photovoltaic properties of the obtained films were studied.

Table 2.

The growth of CdTe films using various deposition methods and the photovoltaic properties.

5.2. Cu(In,Ga)Se2 Film Solar Cells

The Cu(In,Ga)Se2 (CIGS) films are already available in the global solar panel market due to their excellent radiation tolerance, high absorption coefficient (105 cm−1), suitable band gap value (1.04 eV to 1.65 eV), and long-term stability. However, these films are very expensive because of the indium and gallium (poor abundance). Several deposition techniques have been reported for the preparation of CIGS films and the photovoltaic parameters were studied as well (Table 3). Thin films could be deposited onto rigid glass substrates, and successfully reached power conversion efficiencies of up to 20.3%. However, the current focus of the production of films onto flexible substrates (metal foils and polyimide films) is because of their significantly lower cost. Polyimide films are highly desirable due to electrical insulation and enabling direct monolithic interconnection.

Table 3.

The growth of CIGS films using various deposition methods and the photovoltaic properties.

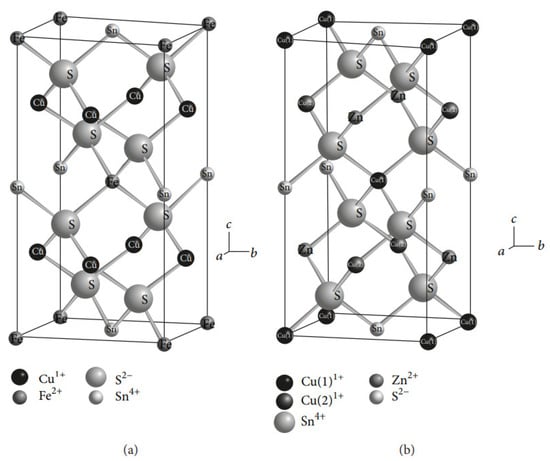

5.3. Cu2ZnSnS4 Film Solar Cells

Copper–zinc–tin sulfide (Cu2ZnSnS4) films are becoming increasingly prominent for several reasons. These materials could replace indium and gallium in CIGS films, as their constituents are Earth-abundant and do not contain cadmium (toxic material). The experimental results showed that CZTS-based solar cells have an excellent absorption coefficients (more than 104 cm−1), tunable band gap values (1.45 eV to 1.6 eV), and greater stability in the kesterite phase (Figure 12) when compared with stannite and wurtzite. Researchers have reported that vacuum and non-vacuum deposition techniques have been used to produce CZTS films (Table 4). Further, they concluded that high-quality films could be synthesized using the vacuum-deposition method; however, this entails increased production costs.

Figure 12.

Crystal structures of (a) stannite and (b) kesterite [207].

Table 4.

The growth of CZTS films using various deposition methods and the photovoltaic properties.

5.4. CuInX (X = S, Se, and Te) Film Solar Cells

Several deposition methods have been used to produce CuInSe2, CuInTe2, and CuInS2 films (Table 5). It is noted that the non-vacuum deposition method offers an attractive cost-saving opportunity, higher deposition speed, and less waste of chemicals when compared with the vacuum-deposition technique. The obtained films could be employed for solar-cell applications because of long-term stability under solar radiation, excellent absorption coefficients (105 cm−1) in the visible light portion, and suitable band gap values (1.5 eV).

Table 5.

The growth of CuInX (X = S, Se, and Te) films using various deposition methods and the photovoltaic properties.

5.5. Other Metal Chalcogenide Film Solar Cells

Based on the literature review, several types of metal sulfide, metal telluride, and metal selenide films have been prepared using different deposition methods. The photovoltaic behavior of these films was studied (Table 6) as reported by many researchers.

Table 6.

The growth of different types of thin films using various deposition methods and the photovoltaic properties.

5.6. Quantum Confinement Effect in Thin-Film Materials

Several researchers have reported quantum confinement effects in the obtained nanostructured materials. The chemical precipitation method has been used to produce cadmium sulfide and Gd-doped CdS films [260]. Based on the Raman spectra analysis, 1LO,2LO and 3LO peaks have been moved to lower wavenumbers in Gd-doped CdS films (296, 591, and 896 cm−1) when compared with CdS films (301, 598, and 902 cm−1) because a smaller ionic radius could be observed in Gd (0.94 A) than in cadmium (0.96 A). In addition, they pointed out that the absorption edge had been shifted to a longer wavelength (due to the quantum confinement effect), when compared with CdS based on the optical absorption spectra. Zinc selenide films have been synthesized on glass substrates using the e-beam evaporation method [261]. Experimental results confirmed that the blue shift of the band gap occurred (about 0.16 eV in the thinner films). The band gap increased from 2.62 eV, 2.67 eV to 2.78 eV when the film thickness was reduced from 47 nm, 12.3 nm to 7.9 nm according to optical absorption spectroscopy analysis. The presence of a strong quantum-confinement effect has been reported based on theoretical calculation using the potential morphing method. Azizian and co-workers [262] described the synthesis of SnS films via the ultrasonic irradiation method. The experimental findings showed that the absorption edge had been moved towards the lower wavelength side (blue shift). The particle size and the direct band gap were found to be 4 nm and 1.74 eV (blue shifted when compared with the bulk band gap), respectively. The chemical deposition (spin-coating method) of SnSe (tin selenide) films exhibited size-dependent electronic band gap values [263]. The particle size (10.13 nm to 14.32 nm) and film thickness (1 μm to 4 μm) increased when the band gap was reduced (1.92 eV to 1.51 eV). It was noted that the obtained band gap was higher when compared with bulk value (1.1 eV) because of the quantum confinement effects.

5.7. The Wavelength of Light and Its Effects on the Solar Cells

Solar panels are designed to adsorb sunlight in a particular wavelength range (called a band gap). Usually, these panels are able to absorb light in the visible area (different colors have different amounts of energy). Thin-film solar cells can absorb a wider range of wavelengths (400–1100 nm) when compared with crystalline silicon solar cells (850 nm). Solar panels can produce electricity from sunlight. Photons hit the solar panel and electrons flow through the material and produce an electric current.

Researchers have reported that the highest efficiency strongly depends on the band gap. If the band gap value is too high, most photons do not cause the photovoltaic effect. In contrast, most photons have more energy to excite electrons if the band gap is too low. Currently, the band gap values for CdTe and silicon were found to be 1.5 eV and 1.1 eV, respectively.

Ogherohwo and co-workers [264] highlighted that the wavelengths of light affect the performance of solar cells. The specification of the solar module was reported (maximum system voltage = 8V, short circuit current-238Ma, open circuit voltage = 6.5V, dimensions = 180 mm × 120 mm, weight = 3 kg, temperature co-efficient = 25 °C). Based on Table 7, red color produced the highest power-conversion efficiency when compared with the other colors.

Table 7.

Output power and efficiency of the solar cells [264].

5.8. Future Prospects and Commercialization of Thin-Film Technologies

Based on the analysis, the world thin-film solar cell market size [265] was valued at $11.3 billion (in 2020) and is expected to rise to $25.3 billion (by 2030). Several factors such as the declination of solar price, high electricity demand, and increased solar-cell capacity have contributed to the growth of the market Cadmium telluride films dominate the solar cell market, followed by amorphous silicon and copper indium gallium selenide films. Thin films have been deposited on metal, glass, and plastic. The obtained materials (film thickness) were 20 times lighter when compared with crystalline silicon wafers. In the future, thin-film solar panels could be implemented in the residential industry due to lower installation costs.

Polycrystalline thin-film solar cells could be the most promising candidates for solving the energy production problem due to their low cost in large-scale industrial production and their improved power conversion efficiency. The time-stability should be maintained (within 25 years) in hot, hard conditions. Thickness reduction is needed to optimize the internal resistance (solar cell device) and minimize electrical power loss. In the CuInSe2-based solar cells, efficiency could be improved by reducing the recombination current. Non-hazardous CZTS films could be used to replace CIGS films (indium and gallium are rare). The precise tuning of the band gap (CZTS films) could be carried out by adding some impurities (Ag, Na, Sb). In CdTe-based solar cells, the performance of solar cells could be improved by adding a buffer layer (reducing the shunt-resistance problem).

6. Conclusions

A solar cell is a device that can convert solar radiation into electrical energy. Solar cells are very important develop, considering that the sun supplies a clean and unlimited source of energy. Developing solar cells is one of the most important efforts to save the world from the energy crisis and pollution. This has led many researchers to develop organic solar cells, perovskite solar cells, thin-film-based solar cells, and DSSC solar cells. Several disadvantages of solar cells have been reported by researchers. For example, the commercialization of perovskite solar cells is hampered by lead toxicity and their long-term stability. Currently, the light-induced deterioration of perovskite solar cells under operational conditions (moisture, oxygen, heat, and common stress) is a major problem for outdoor perovskite solar-cell applications. Their efficiency is impacted by the continual breakdown of the MAPbI3 due to exposure to light. Based on the photovoltaic properties of the obtained films, the power conversion efficiency is strongly dependent on the experimental conditions and deposition method.

Author Contributions

Thin-film solar cells, H.S.; DSSC solar cells, H., perovskite solar cells, P.N., B.S.M. and T.D.M.; organic solar cell, M.I.M. All authors have read and agreed to the published version of the manuscript.

Funding

The partial APC was funded by INTI International University (HSM).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank INTI International University for partial financial support in this work (HSM).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mohd, R.; Santosh, B.; Suvarna, S.; Pooja, V.; Anil, T. A review paper on electricity generation from solar energy. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5, 1884–1889. [Google Scholar]