Influence of Annealing on Gas-Sensing Properties of TiOx Coatings Prepared by Gas Impulse Magnetron Sputtering with Various O2 Content

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

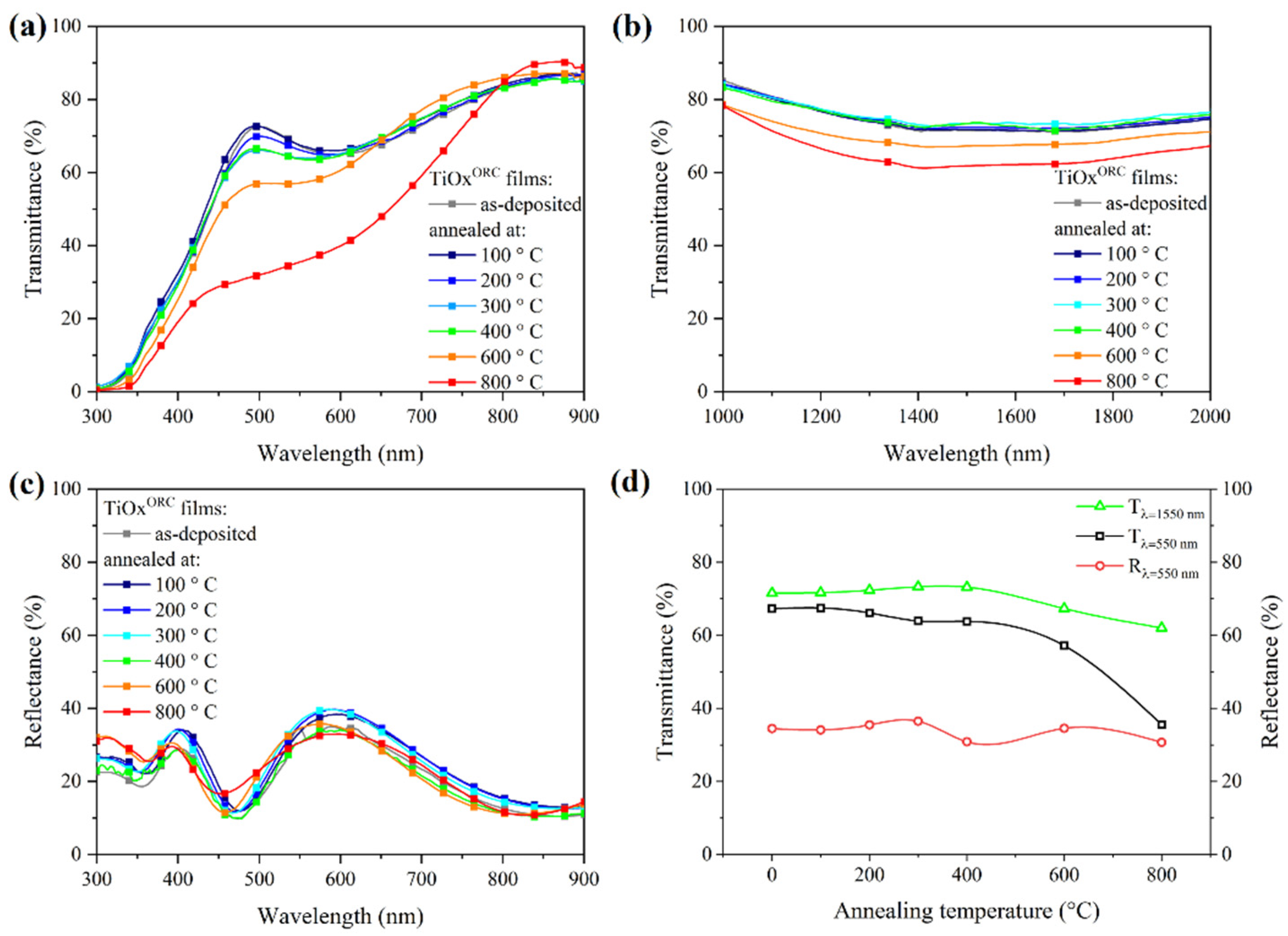

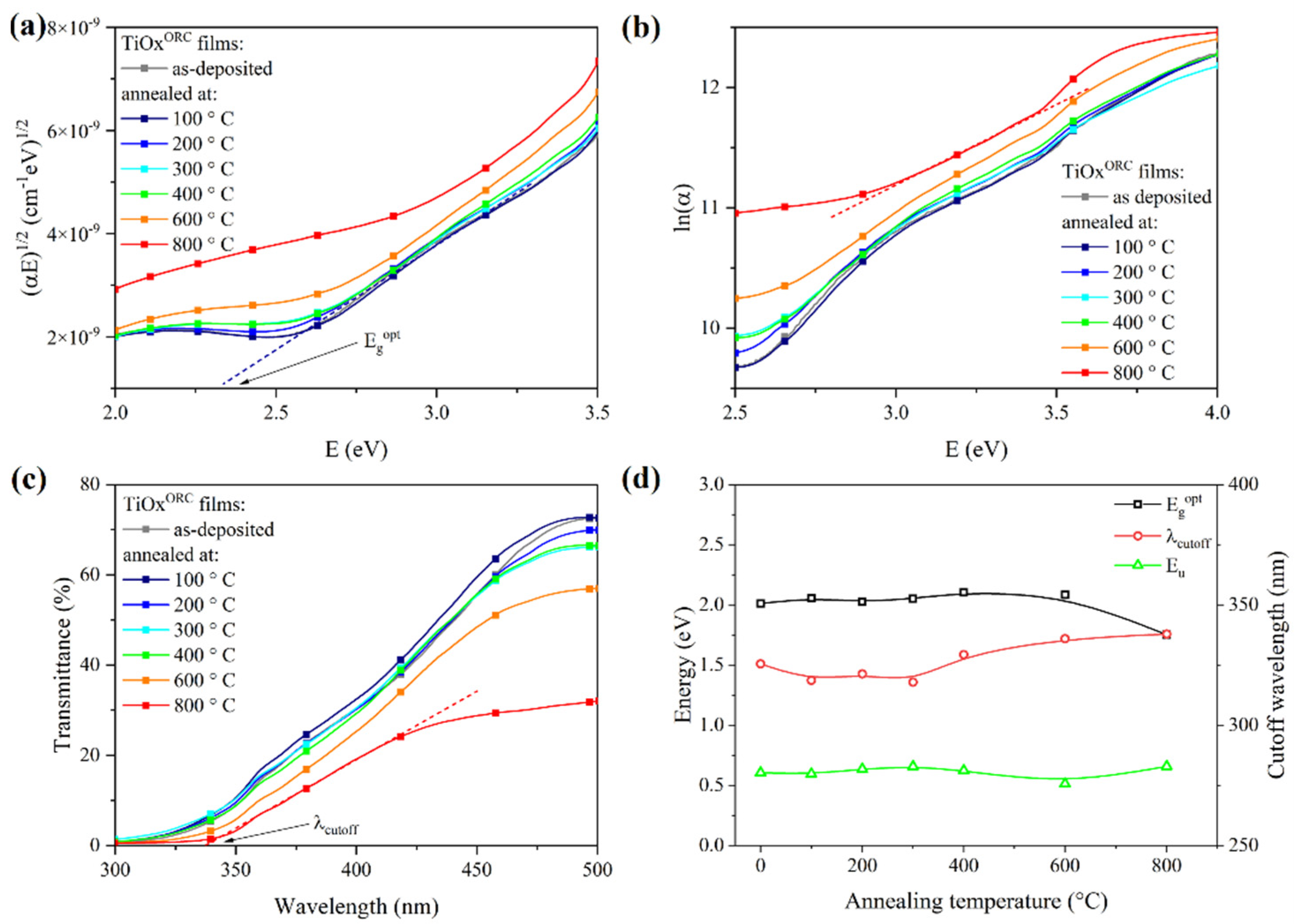

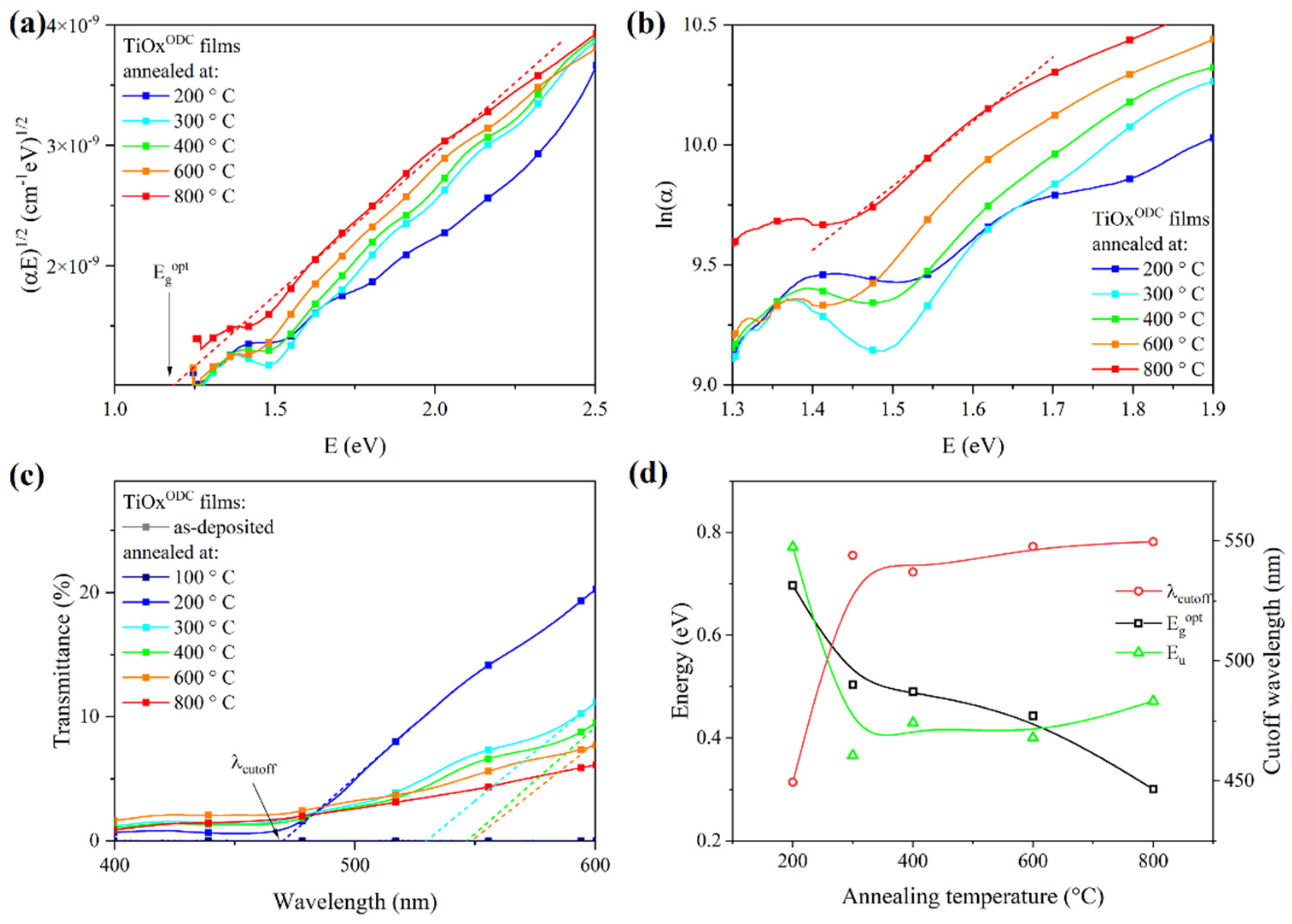

3.1. Optical Properties

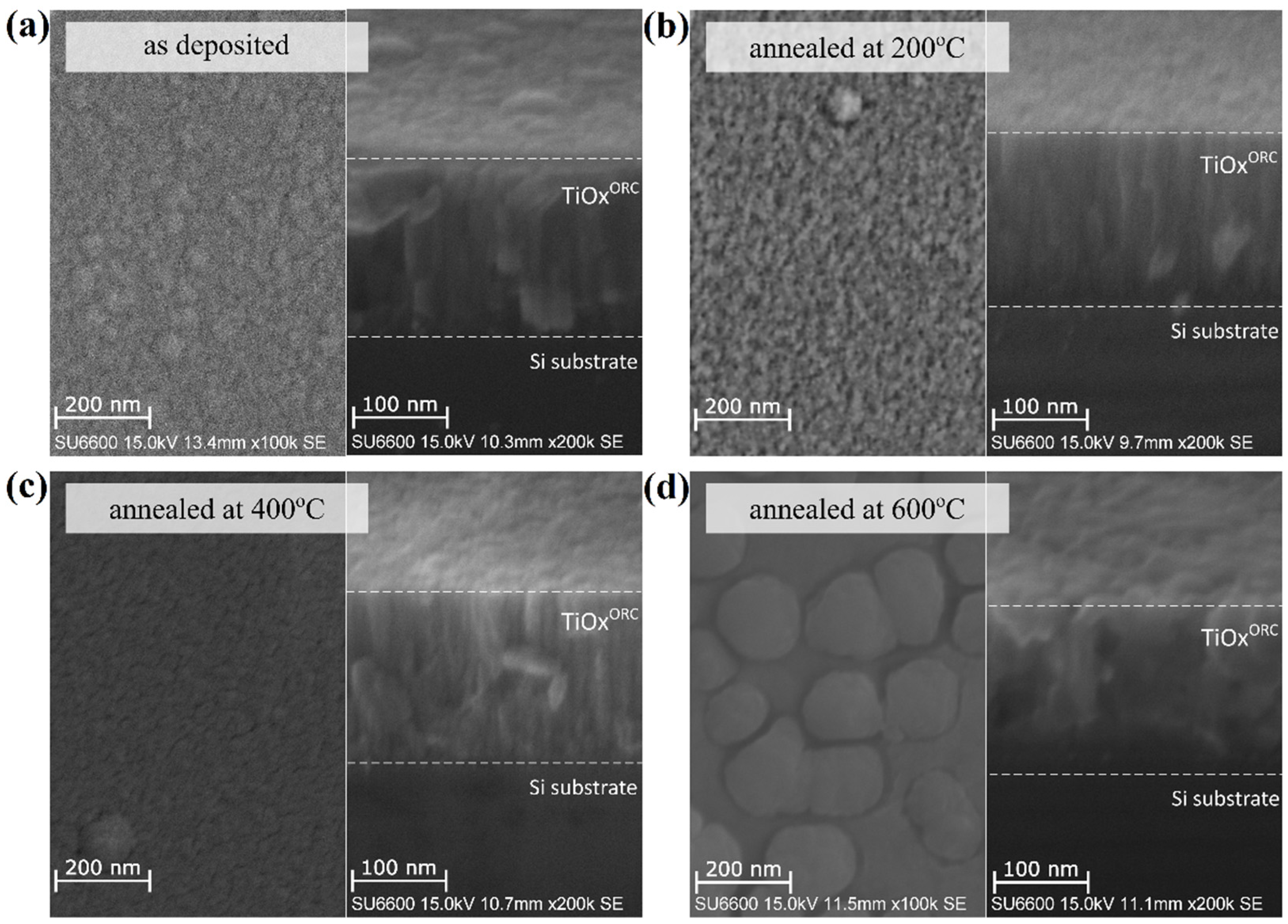

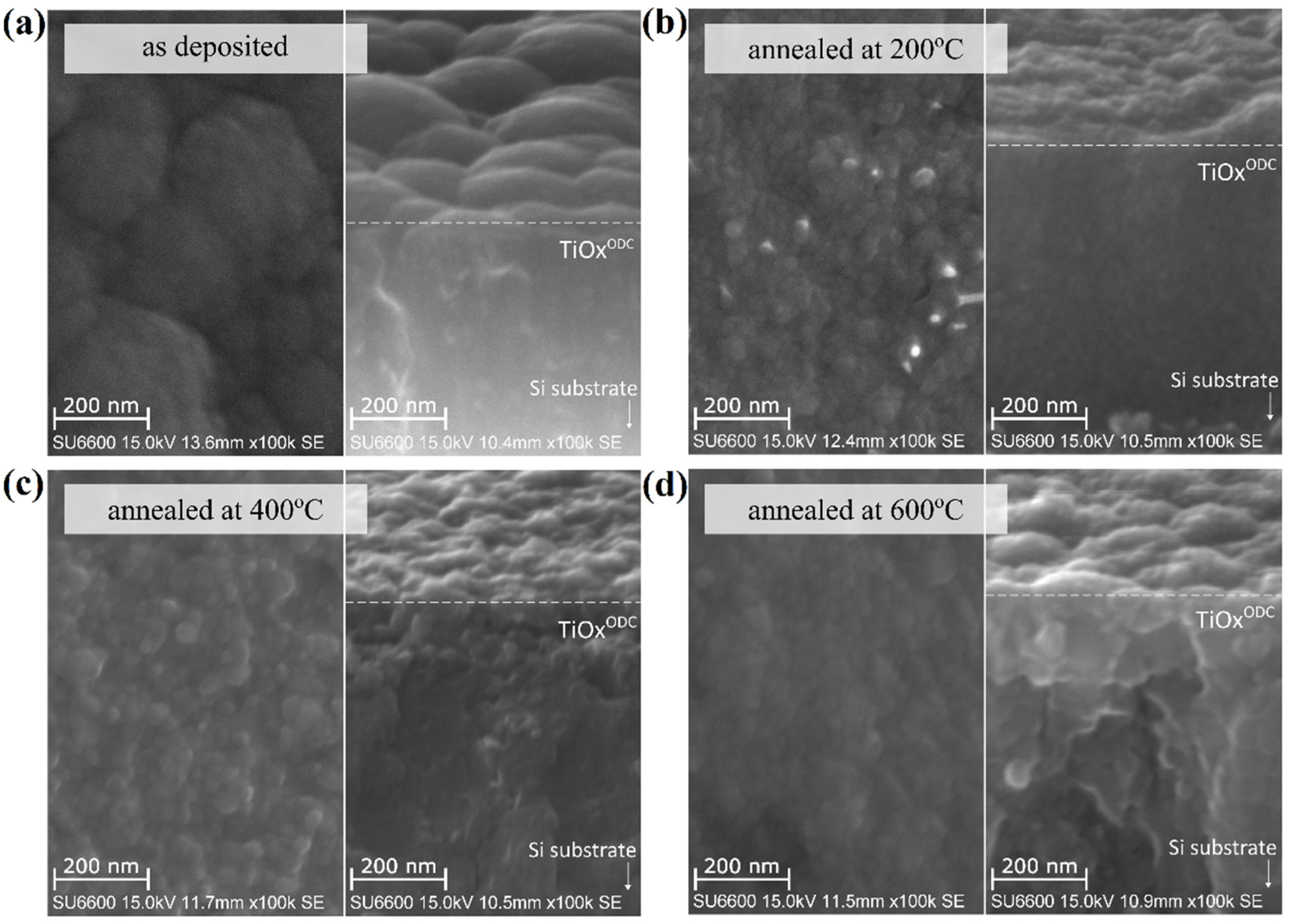

3.2. Structural and Surface Properties

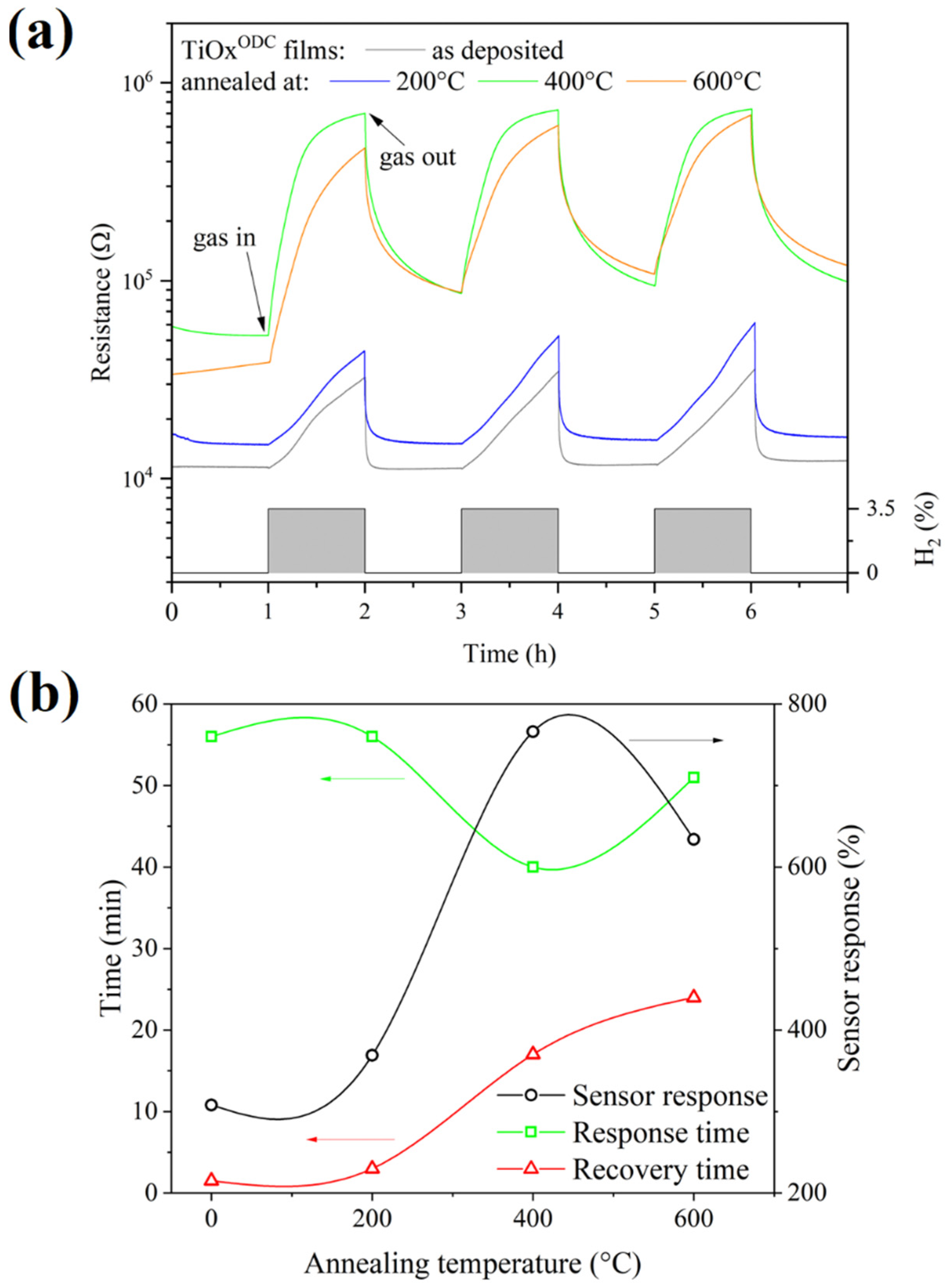

3.3. Gas-Sensing Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Henning, R.A.; Leichtweiss, T.; Dorow-Gerspach, D.; Schmidt, R.; Wolff, N.; Schürmann, U.; Decker, Y.; Kienle, L.; Wuttig, M.; Janek, J. Phase formation and stability in TiOx and ZrOx thin films: Extremely sub-stoichiometric functional oxides for electrical and TCO applications. Z. Kristallogr. Cryst. Mater. 2017, 232, 161–183. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Ramanavicius, A. Insights in the Application of Stoichiometric and Non-Stoichiometric Titanium Oxides for the Design of Sensors for the Determination of Gases and VOCs (TiO2−x and TinO2n−1 vs. TiO2). Sensors 2020, 20, 6833. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Sohn, H.Y.; Mohassab, Y.; Lan, Y. Structures, preparation and applications of titanium suboxides. RSC Adv. 2016, 6, 79706–79722. [Google Scholar] [CrossRef]

- Hasan, M.M.; Haseeb, A.S.M.A.; Saidur, R.; Masjuki, H.H. Effects of Annealing Treatment on Optical Properties of Anatase TiO2 Thin Films. World J. Nucl. Sci. Technol. 2009, 40, 221–225. [Google Scholar]

- Zapata-Torres, M.; Hernández-Rodríguez, E.; Mis-Fernandez, R.; Meléndez-Lira, M.; Amaya, O.C.; Bahena, D.; Rejon, V.; Peña, J. Visible and infrared photocatalytic activity of TiO thin films prepared by reactive sputtering. Mater. Sci. Semicond. Process. 2015, 40, 720–726. [Google Scholar] [CrossRef]

- Reddy, Y.A.K.; Kang, I.-K.; Shin, Y.B.; Lee, H.C.; Reddy, P.S. Oxygen partial pressure and thermal annealing dependent properties of RF magnetron sputtered TiO2−x films. Mater. Sci. Semicond. Process. 2015, 32, 107–116. [Google Scholar] [CrossRef]

- Mazur, M. Analysis of the properties of functional titanium dioxide thin films deposited by pulsed DC magnetron sputtering with various O2:Ar ratios. Opt. Mater. 2017, 69, 96–104. [Google Scholar] [CrossRef]

- Rafieian, D.; Ogieglo, W.; Savenije, T.; Lammertink, R.G.H. Controlled formation of anatase and rutile TiO2 thin films by reactive magnetron sputtering. AIP Adv. 2015, 5, 097168. [Google Scholar] [CrossRef]

- Hassanien, A.; Akl, A.A. Optical characterizations and refractive index dispersion parameters of annealed TiO2 thin films synthesized by RF-sputtering technique at different flow rates of the reactive oxygen gas. Phys. B Condens. Matter 2020, 576, 411718. [Google Scholar] [CrossRef]

- Mohamed, S.; Kappertz, O.; Pedersen, T.P.L.; Drese, R.J.; Wuttig, M. Properties of TiOx coatings prepared by dc magnetron sputtering. Phys. Status Solidi (A) 2003, 198, 224–237. [Google Scholar] [CrossRef]

- Ju, Y.; Li, L.; Wu, Z.; Jiang, Y. Effect of Oxygen Partial Pressure on the Optical Property of Amorphous Titanium Oxide Thin Films. Energy Procedia 2011, 12, 450–455. [Google Scholar] [CrossRef]

- Dorow-Gerspach, D.; Wuttig, M. Metal-like conductivity in undoped TiO2−x: Understanding an unconventional transparent conducting oxide. Thin Solid Films 2019, 669, 1–7. [Google Scholar] [CrossRef]

- Villarroel, R.; Espinoza-González, R.; Lisoni, J.; González-Moraga, G. Influence of the oxygen consumption on the crystalline structure of titanium oxides thin films prepared by DC reactive magnetron sputtering. Vacuum 2018, 154, 52–57. [Google Scholar] [CrossRef]

- Chen, G.; Lee, C.; Niu, H.; Huang, W.; Jann, R.; Schütte, T. Sputter deposition of titanium monoxide and dioxide thin films with controlled properties using optical emission spectroscopy. Thin Solid Films 2008, 516, 8473–8478. [Google Scholar] [CrossRef]

- Mao, Q.; Liu, M.; Li, Y.; Wei, Y.; Yang, Y.; Huang, Z. Black TiOx Films with Photothermal-Assisted Photocatalytic Activity Prepared by Reactive Sputtering. Materials 2021, 14, 2508. [Google Scholar] [CrossRef]

- Barros, H.W.S.; Duarte, D.A.; Sagás, J.C. Optical and electrical properties of Ti suboxides grown by reactive grid-assisted magnetron sputtering. Thin Solid Films 2020, 696, 137762. [Google Scholar] [CrossRef]

- Hasan, M.; Haseeb, A.; Saidur, R.; Masjuki, H.; Hamdi, M. Influence of substrate and annealing temperatures on optical properties of RF-sputtered TiO2 thin films. Opt. Mater. 2010, 32, 690–695. [Google Scholar] [CrossRef]

- Karunagaran, B.; Kim, K.; Mangalaraj, D.; Yi, J.; Velumani, S. Structural, optical and Raman scattering studies on DC magnetron sputtered titanium dioxide thin films. Sol. Energy Mater. Sol. Cells 2005, 88, 199–208. [Google Scholar] [CrossRef]

- Miller, M.J.; Wang, J. Coupled effects of deposition and annealing temperatures on optical, electrical and mechanical properties of titanium oxide thin films. Vacuum 2015, 120, 155–161. [Google Scholar] [CrossRef]

- Mittireddi, R.T.; Patel, N.M.; Gautam, A.R.S.; Soppina, V.; Panda, E. Non-stoichiometric amorphous TiOx as a highly reactive, transparent anti-viral surface coating. J. Alloys Compd. 2021, 881, 160610. [Google Scholar] [CrossRef]

- Leichtweiss, T.; Henning, R.A.; Koettgen, J.; Schmidt, R.M.; Holländer, B.; Martin, M.; Wuttig, M.; Janek, J. Amorphous and highly nonstoichiometric titania (TiOx) thin films close to metal-like conductivity. J. Mater. Chem. A 2014, 2, 6631–6640. [Google Scholar] [CrossRef]

- Radecka, M.; Zakrzewska, K.; Czternastek, H.; Stapiński, T.; Debrus, S. The influence of thermal annealing on the structural, electrical and optical properties of TiO2−x thin films. Appl. Surf. Sci. 1993, 65–66, 227–234. [Google Scholar] [CrossRef]

- Huang, J.-H.; Wong, M.-S. Structures and properties of titania thin films annealed under different atmosphere. Thin Solid Films 2011, 520, 1379–1384. [Google Scholar] [CrossRef]

- Yao, J.; Shao, J.; He, H.; Fan, Z. Optical and electrical properties of TiOx thin films deposited by electron beam evaporation. Vacuum 2007, 81, 1023–1028. [Google Scholar] [CrossRef]

- Chodun, R.; Dypa, M.; Wicher, B.; Langier, K.N.; Okrasa, S.; Minikayev, R.; Zdunek, K. The sputtering of titanium magnetron target with increased temperature in reactive atmosphere by gas injection magnetron sputtering technique. Appl. Surf. Sci. 2022, 574, 151597. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Mazur, M.; Pokora, P.; Wrona, A.; Bilewska, K.; Kijaszek, W.; Kotwica, T.; Posadowski, W.; Domaradzki, J. Properties of Metallic and Oxide Thin Films Based on Ti and Co Prepared by Magnetron Sputtering from Sintered Targets with Different Co-Content. Materials 2021, 14, 3797. [Google Scholar] [CrossRef]

- Mazur, M.; Lubańska, A.; Domaradzki, J.; Wojcieszak, D. Complex Research on Amorphous Vanadium Oxide Thin Films Deposited by Gas Impulse Magnetron Sputtering. Appl. Sci. 2022, 12, 8966. [Google Scholar] [CrossRef]

- Khan, A.F.; Mehmood, M.; Durrani, S.; Ali, M.; Rahim, N. Structural and optoelectronic properties of nanostructured TiO2 thin films with annealing. Mater. Sci. Semicond. Process. 2015, 29, 161–169. [Google Scholar] [CrossRef]

- Hou, Y.-Q.; Zhuang, D.-M.; Zhang, G.; Zhao, M.; Wu, M.-S. Influence of annealing temperature on the properties of titanium oxide thin film. Appl. Surf. Sci. 2003, 218, 98–106. [Google Scholar] [CrossRef]

- Yildirim, G.; Akdogan, M.; Varilci, A.; Terzioglu, C. Role of annealing environment and partial pressure on structure and optical performance of TiO2 thin films fabricated by rf sputter method. Cryst. Res. Technol. 2010, 45, 1161–1165. [Google Scholar] [CrossRef]

- Amor, S.; Guedri, L.; Baud, G.; Jacquet, M.; Ghedira, M. Influence of the temperature on the properties of sputtered titanium oxide films. Mater. Chem. Phys. 2003, 77, 903–911. [Google Scholar] [CrossRef]

- Wiatrowski, A.; Wojcieszak, D.; Mazur, M.; Kaczmarek, D.; Domaradzki, J.; Kalisz, M.; Kijaszek, W.; Pokora, P.; Mańkowska, E.; Lubanska, A.; et al. Photocatalytic Coatings Based on TiOx for Application on Flexible Glass for Photovoltaic Panels. J. Mater. Eng. Perform. 2022, 31, 6998–7008. [Google Scholar] [CrossRef]

- Mazur, M.; Wojcieszak, D.; Wiatrowski, A.; Kaczmarek, D.; Lubańska, A.; Domaradzki, J.; Mazur, P.; Kalisz, M. Analysis of amorphous tungsten oxide thin films deposited by magnetron sputtering for application in transparent electronics. Appl. Surf. Sci. 2021, 570, 151151. [Google Scholar] [CrossRef]

- Zakrzewska, K.; Radecka, M. TiO2-Based Nanomaterials for Gas Sensing—Influence of Anatase and Rutile Contributions. Nanoscale Res. Lett. 2017, 12, 89. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Lu, H.; Zhang, J.; Gao, J.; Zhu, G.; Yang, Z.; Yin, F.; Wang, C. Crystal facet-dependent p-type and n-type sensing responses of TiO2 nanocrystals. Sens. Actuators B Chem. 2018, 263, 557–567. [Google Scholar] [CrossRef]

- Hazra, A.; Das, S.; Kanungo, J.; Sarkar, C.; Basu, S. Studies on a resistive gas sensor based on sol–gel grown nanocrystalline p-TiO2 thin film for fast hydrogen detection. Sens. Actuators B Chem. 2013, 183, 87–95. [Google Scholar] [CrossRef]

| TiOxORC Coating | Tλ = 550 nm | Rλ = 550 nm | λcut-off | Egopt | Eu | |

|---|---|---|---|---|---|---|

| as deposited | 67.3 | 34.5 | 325.5 | 2.01 | 0.61 | |

| annealed at: | 100 °C | 67.5 | 34.1 | 318.7 | 2.06 | 0.59 |

| 200 °C | 66.2 | 35.5 | 321.4 | 2.03 | 0.64 | |

| 300 °C | 63.9 | 36.5 | 317.9 | 2.05 | 0.66 | |

| 400 °C | 63.8 | 30.9 | 329.4 | 2.10 | 0.62 | |

| 600 °C | 57.2 | 34.5 | 335.9 | 2.08 | 0.51 | |

| 800 °C | 35.5 | 30.7 | 337.8 | 1.75 | 0.66 | |

| TiOxODC Coating | Tλ = 550 nm | Rλ = 550 nm | λcut-off | Egopt | Eu | |

|---|---|---|---|---|---|---|

| as deposited | 0.0 | 14.3 | – | – | – | |

| annealed at: | 100 °C | 0.0 | 16.2 | – | – | – |

| 200 °C | 13.4 | 20.5 | 449.5 | 0.70 | 0.77 | |

| 300 °C | 7.0 | 28.1 | 544.0 | 0.50 | 0.37 | |

| 400 °C | 6.3 | 21.6 | 537.0 | 0.49 | 0.43 | |

| 600 °C | 5.3 | 20.3 | 547.7 | 0.44 | 0.40 | |

| 800 °C | 4.2 | 19.6 | 549.7 | 0.30 | 0.47 | |

| Thin Film | Annealing Temperature | Phase | 2θ | (hkl) | d (nm) | dPDF (nm) | D (nm) | |

|---|---|---|---|---|---|---|---|---|

| TiOxORC | as deposited | amorphous | - | - | - | - | - | - |

| 200 °C | amorphous | - | - | - | - | - | - | |

| 400 °C | amorphous | - | - | - | - | - | - | |

| 600 °C | amorphous | - | - | - | - | - | - | |

| TiOxODC | as deposited | amorphous | - | - | - | - | - | - |

| 200 °C | Ti | 35.53° | (100) | 0.2524 | 0.2555 | 11.4 | 65-3362 | |

| Ti | 38.67° | (002) | 0.2327 | 0.2342 | 10.1 | 65-3362 | ||

| 400 °C | TiO2-anatase | 25.16° | (101) | 0.3536 | 0.3520 | 10.8 | 21-1272 | |

| Ti | 35.44° | (100) | 0.2531 | 0.2555 | 13.5 | 65-3362 | ||

| Ti | 38.56° | (002) | 0.2333 | 0.2342 | 11.2 | 65-3362 | ||

| 600 °C | TiO2-anatase | 25.23° | (101) | 0.3526 | 0.3520 | 21.1 | 21-1272 | |

| TiO2-anatase | 32.48° | (020) | 0.2755 | 0.2749 | 20.0 | 21-1236 | ||

| Ti | 35.50° | (100) | 0.2527 | 0.2555 | 19.7 | 65-3362 | ||

| Ti | 38.68° | (002) | 0.2326 | 0.2342 | 14.5 | 65-3362 | ||

| TiO2-anatase | 48.41° | (200) | 0.1879 | 0.1892 | 12.8 | 21-1272 | ||

| TiO2-anatase | 48.91° | (312) | 0.1861 | 0.1852 | 15.8 | 65-2448 | ||

| TiO2-anatase | 53.82° | (105) | 0.1702 | 0.1700 | 16.1 | 21-1272 | ||

| TiO2-anatase | 55.12° | (211) | 0.1665 | 0.1665 | 19.6 | 21-1272 | ||

| TiO2-anatase | 62.35° | (204) | 0.1488 | 0.1408 | 13.5 | 21-1272 | ||

| Ti | 66.13° | (002) | 0.1412 | 0.1409 | 12.3 | 51-0631 | ||

| TiO2-anatase | 70.27° | (220) | 0.1338 | 0.1338 | 19.6 | 21-1272 | ||

| TiO2-anatase | 75.29° | (215) | 0.1261 | 0.1265 | 13.6 | 21-1272 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wojcieszak, D.; Kapuścik, P.; Kijaszek, W. Influence of Annealing on Gas-Sensing Properties of TiOx Coatings Prepared by Gas Impulse Magnetron Sputtering with Various O2 Content. Appl. Sci. 2023, 13, 1724. https://doi.org/10.3390/app13031724

Wojcieszak D, Kapuścik P, Kijaszek W. Influence of Annealing on Gas-Sensing Properties of TiOx Coatings Prepared by Gas Impulse Magnetron Sputtering with Various O2 Content. Applied Sciences. 2023; 13(3):1724. https://doi.org/10.3390/app13031724

Chicago/Turabian StyleWojcieszak, Damian, Paulina Kapuścik, and Wojciech Kijaszek. 2023. "Influence of Annealing on Gas-Sensing Properties of TiOx Coatings Prepared by Gas Impulse Magnetron Sputtering with Various O2 Content" Applied Sciences 13, no. 3: 1724. https://doi.org/10.3390/app13031724

APA StyleWojcieszak, D., Kapuścik, P., & Kijaszek, W. (2023). Influence of Annealing on Gas-Sensing Properties of TiOx Coatings Prepared by Gas Impulse Magnetron Sputtering with Various O2 Content. Applied Sciences, 13(3), 1724. https://doi.org/10.3390/app13031724