Corrosion Effects on the Mechanical Properties of Spun Pile Materials

Abstract

1. Introduction

2. Methods

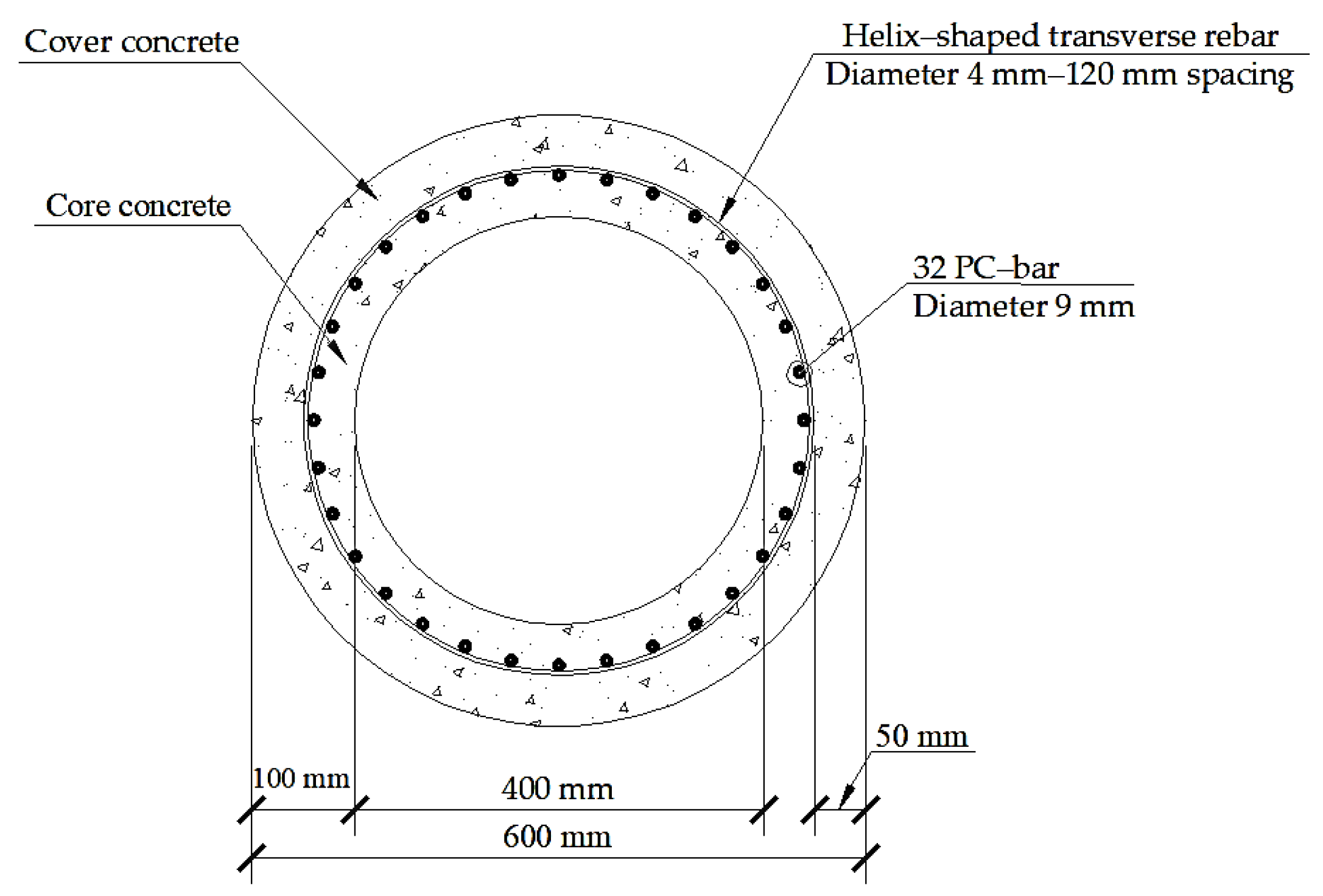

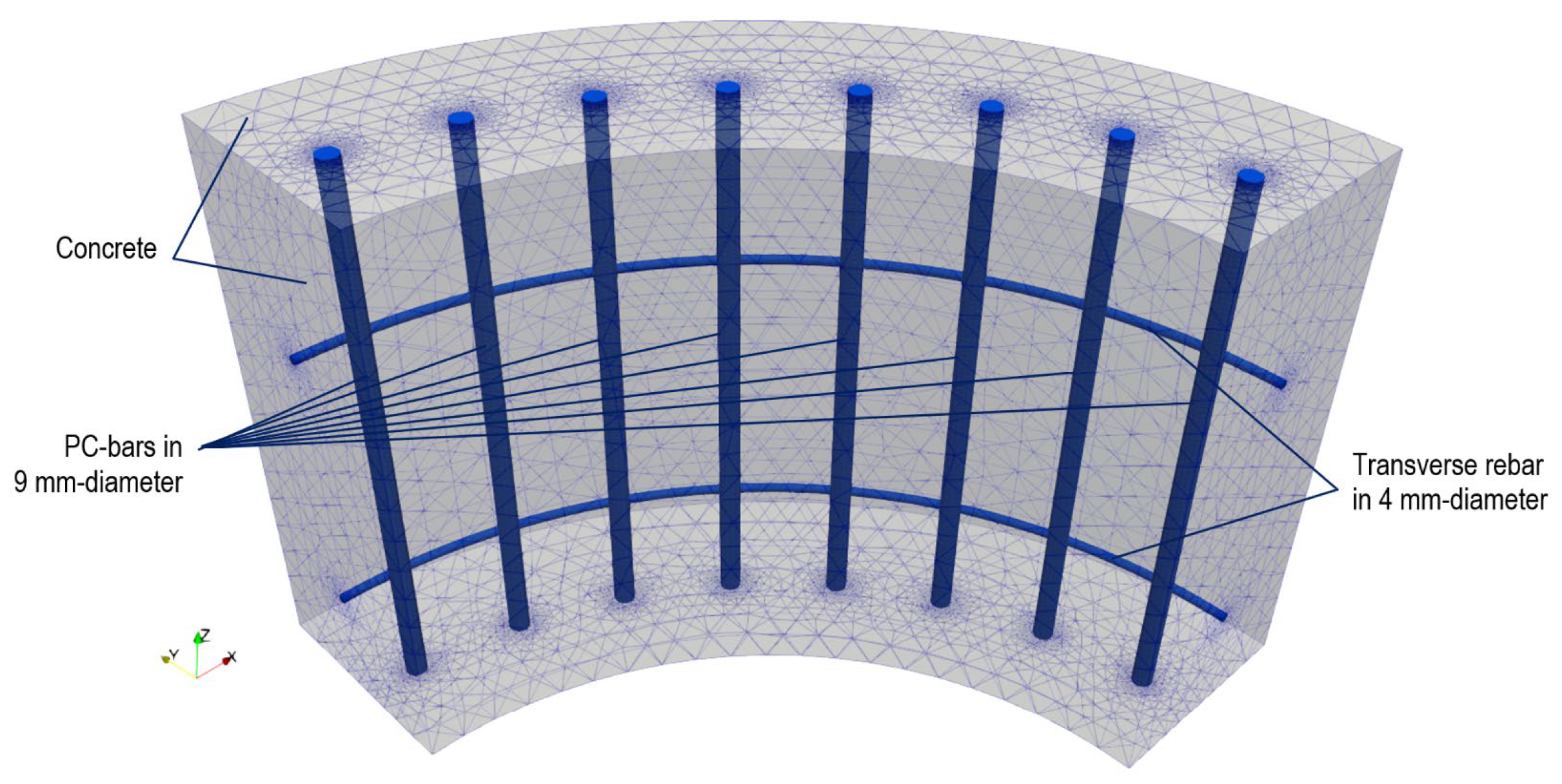

2.1. Model Geometry and Material Properties

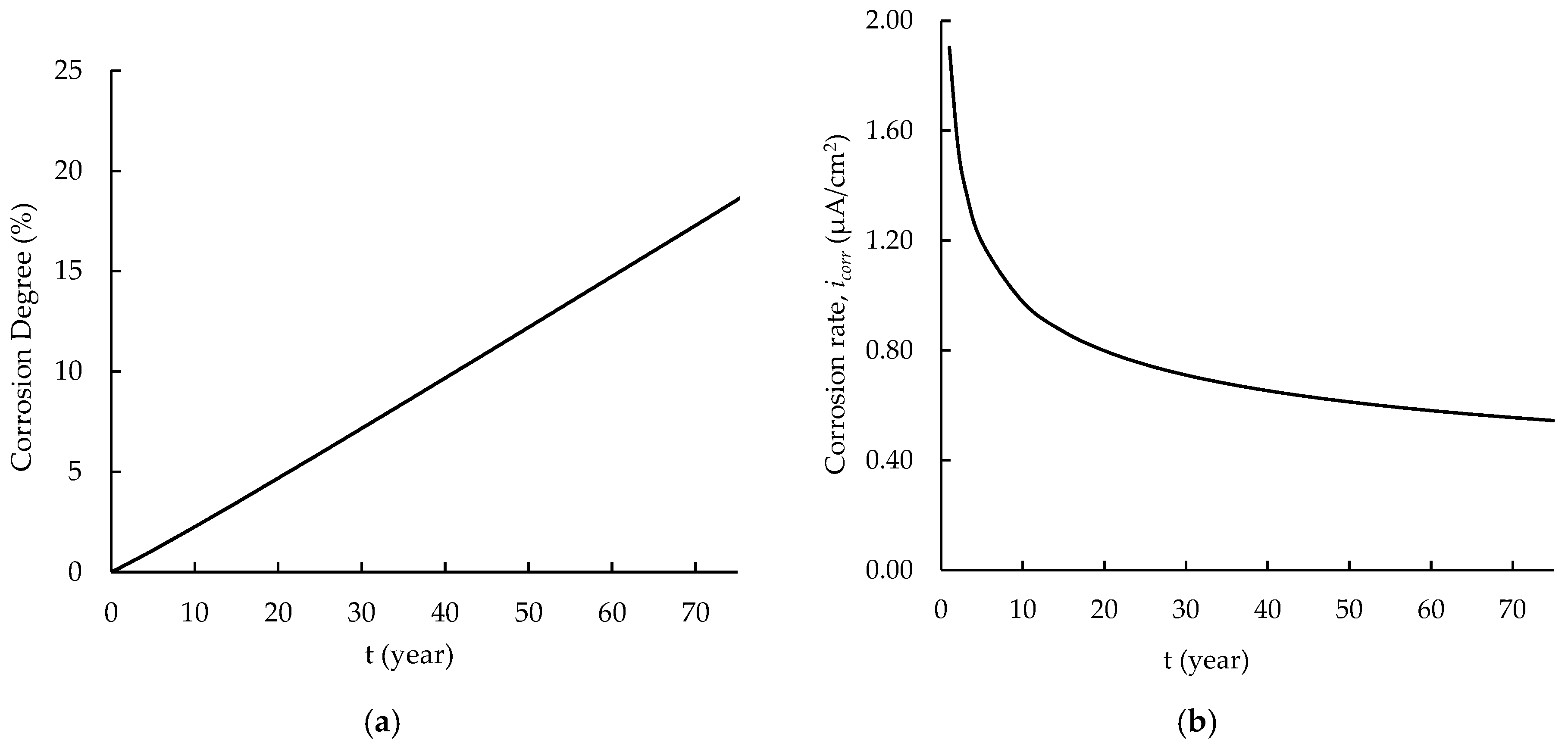

2.2. Corrosion Model

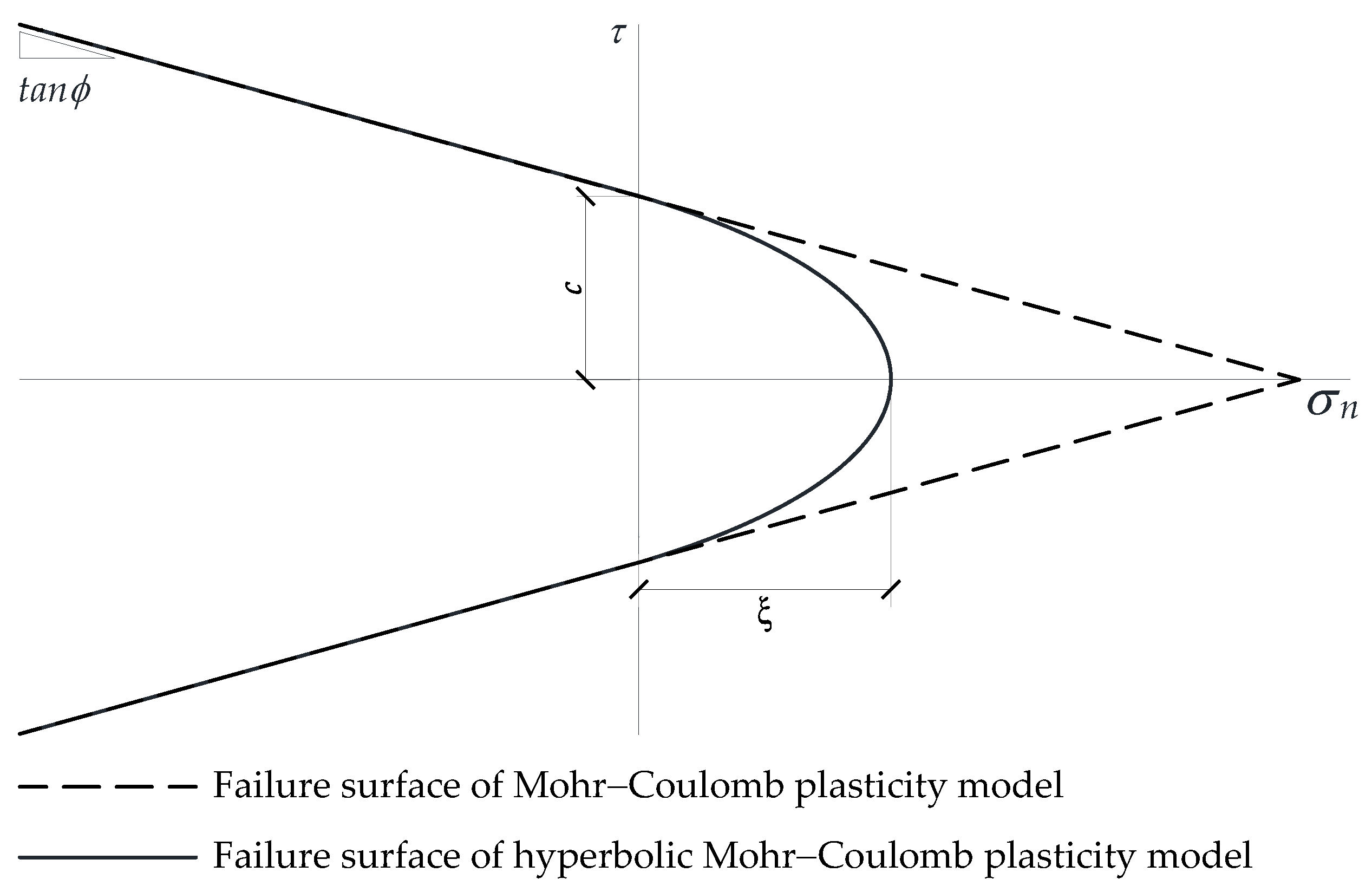

2.3. Material Model

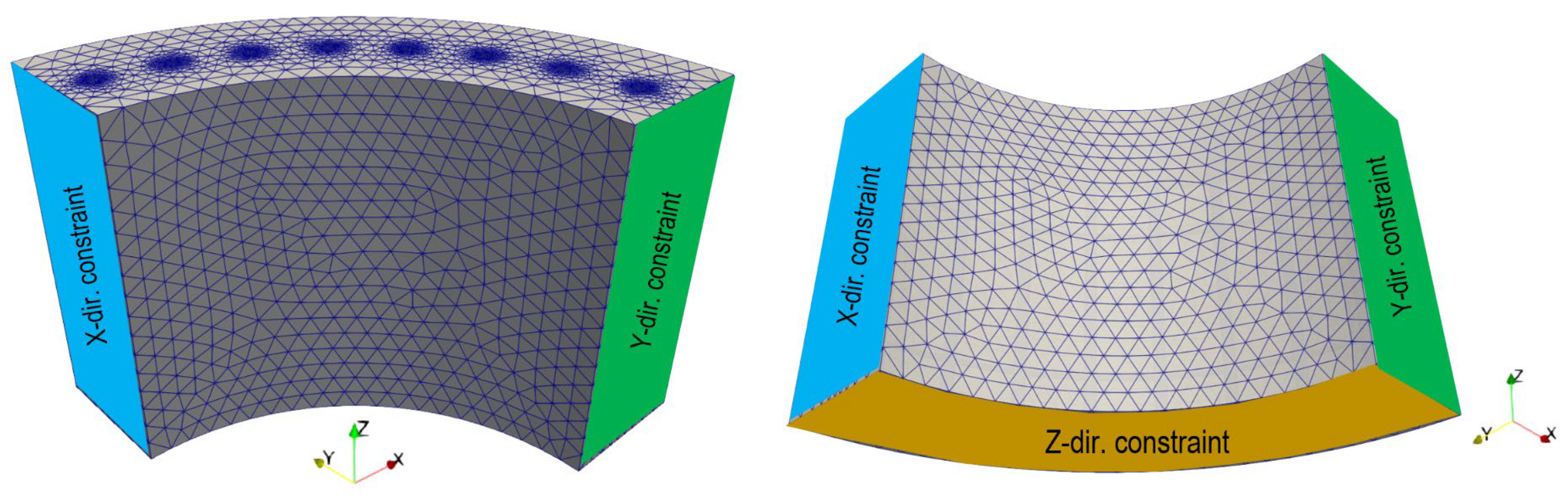

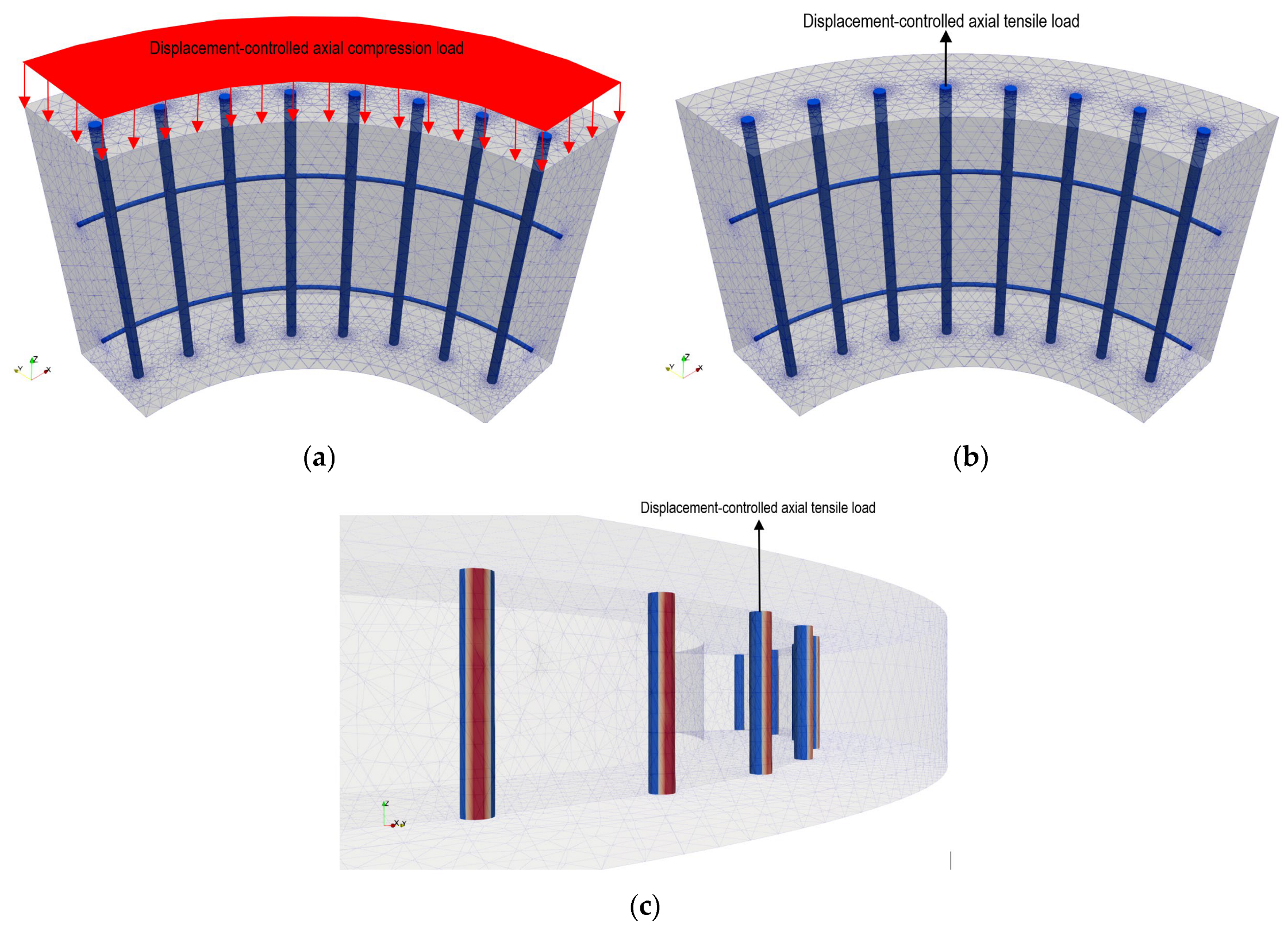

2.4. Finite Element Model

3. Results and Discussion

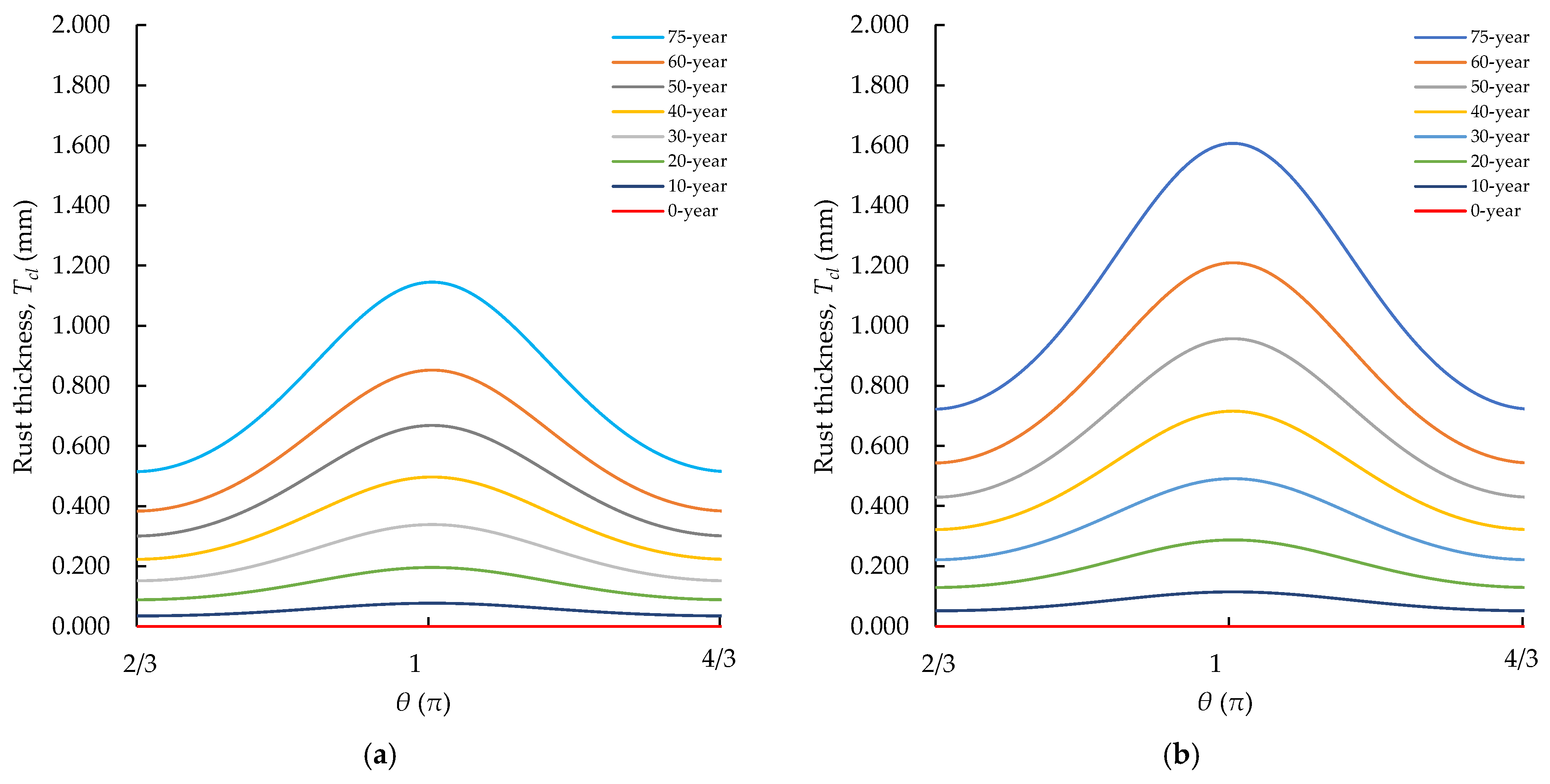

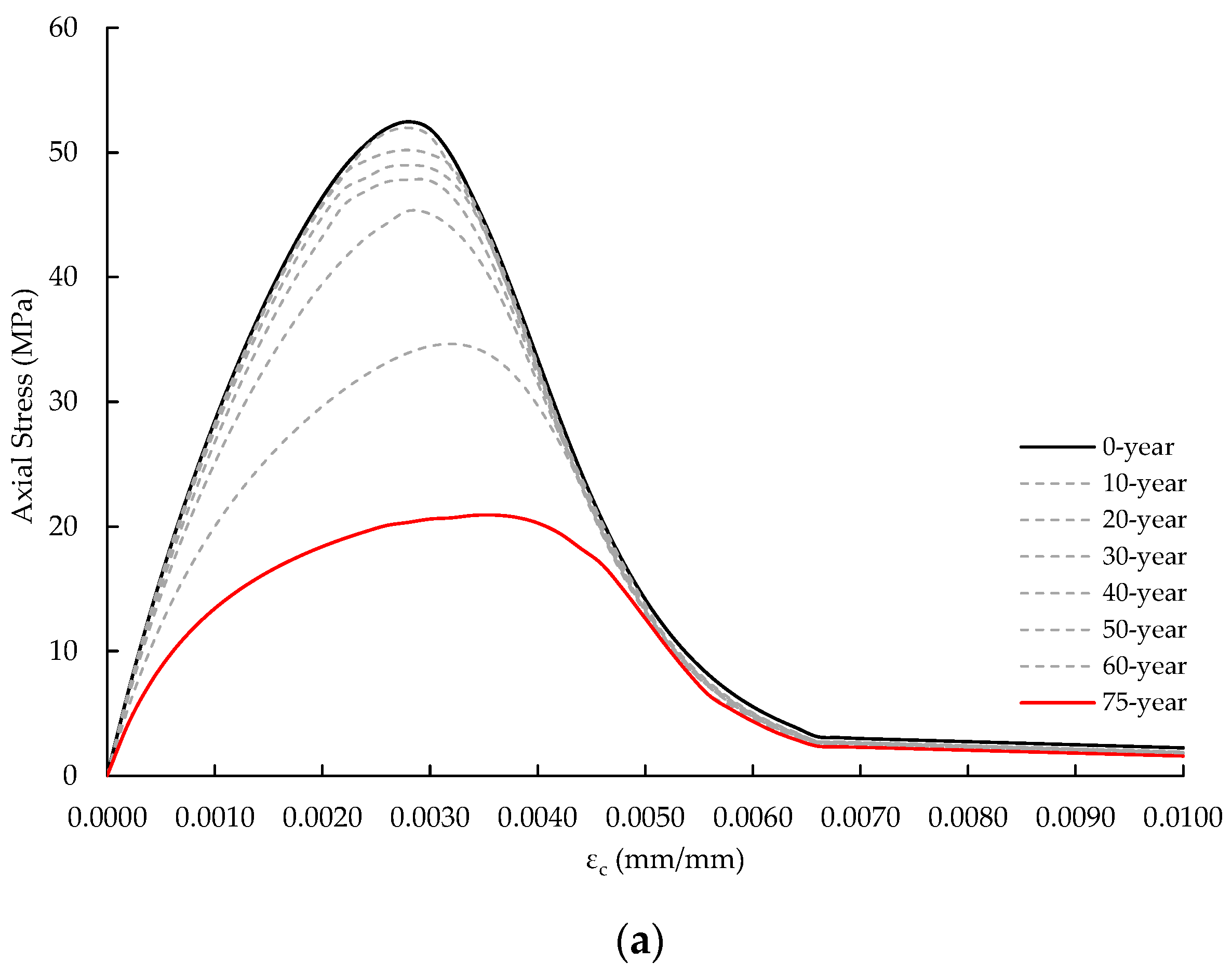

3.1. Nonuniform Rust Distribution

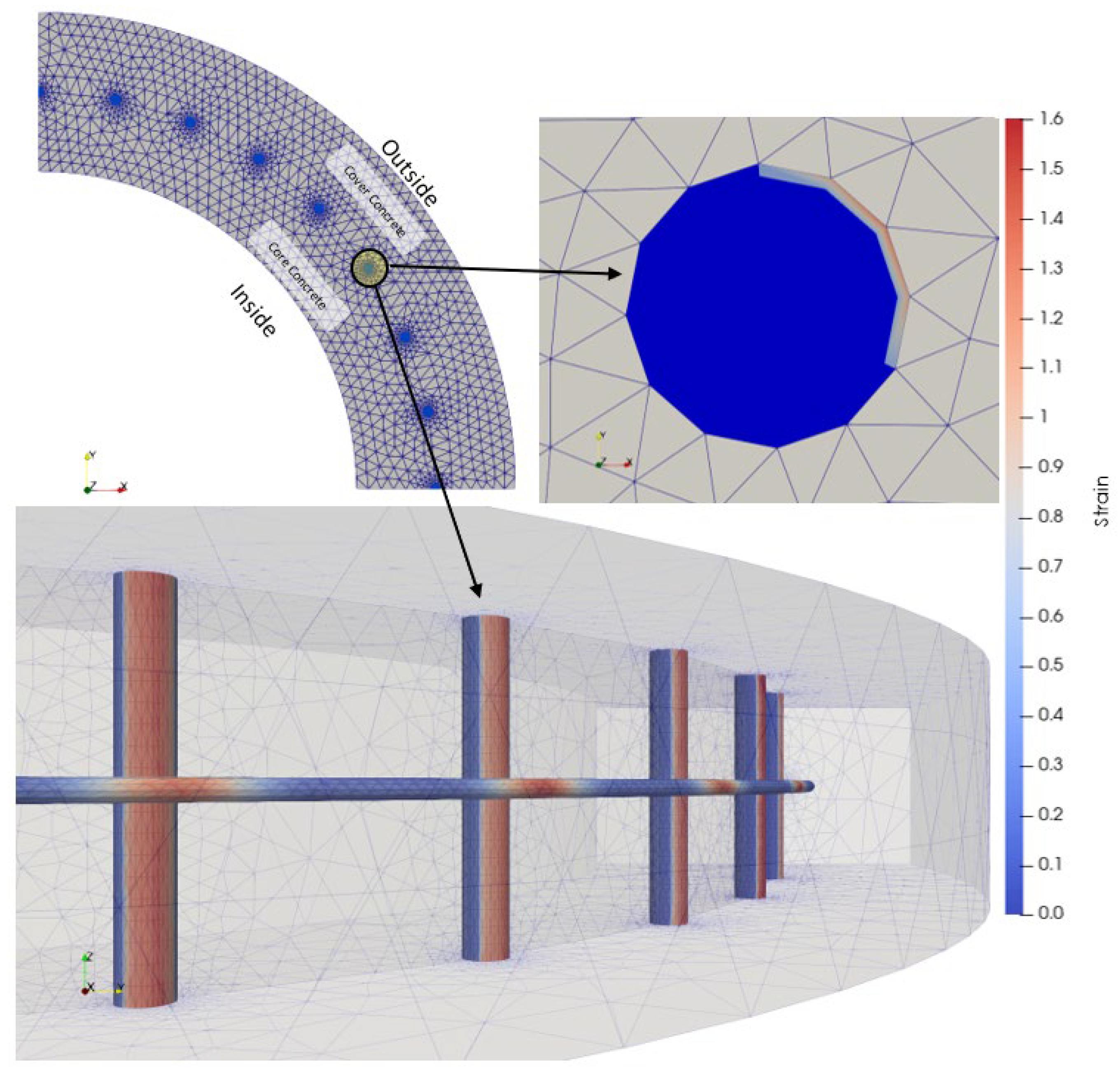

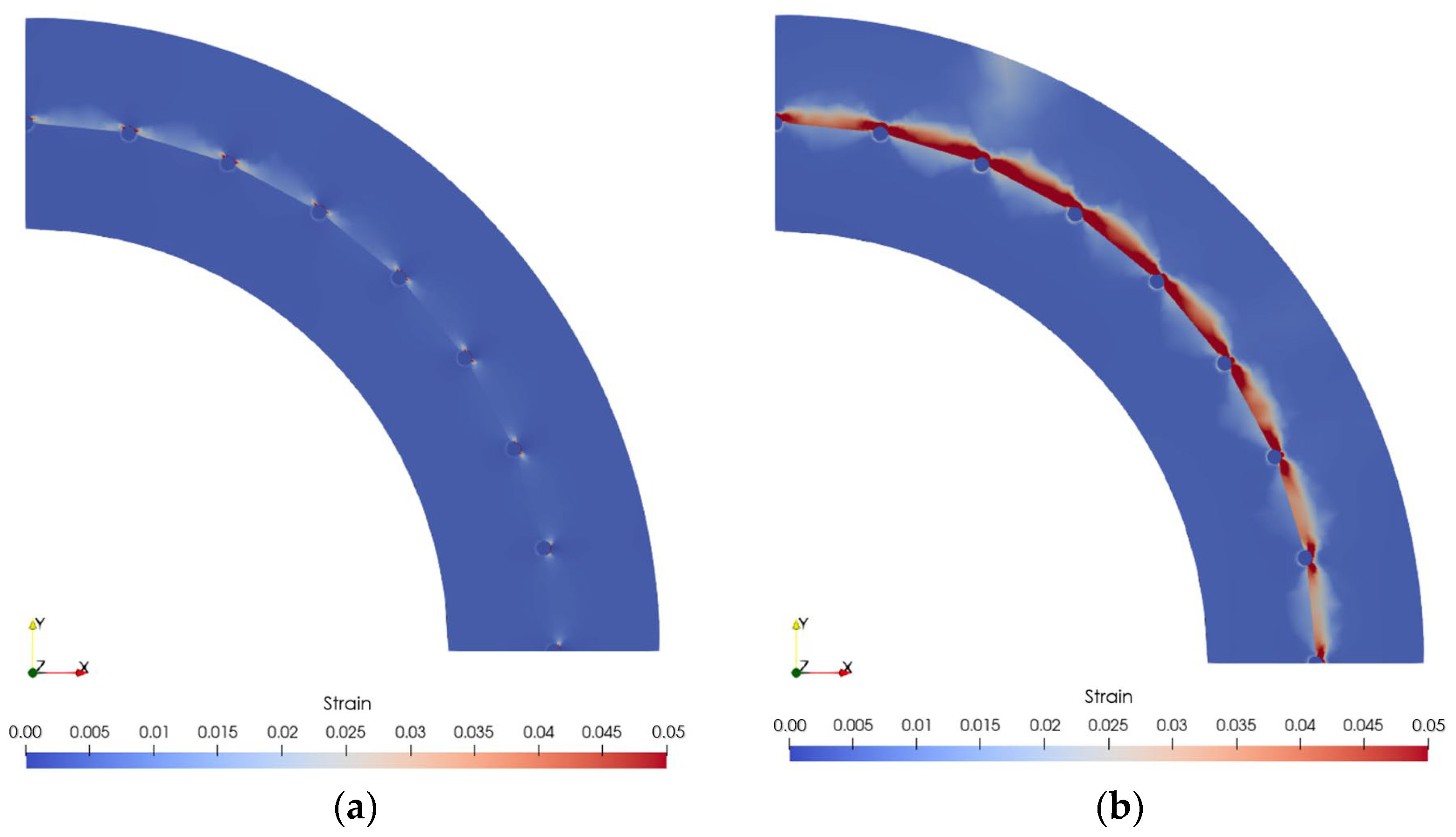

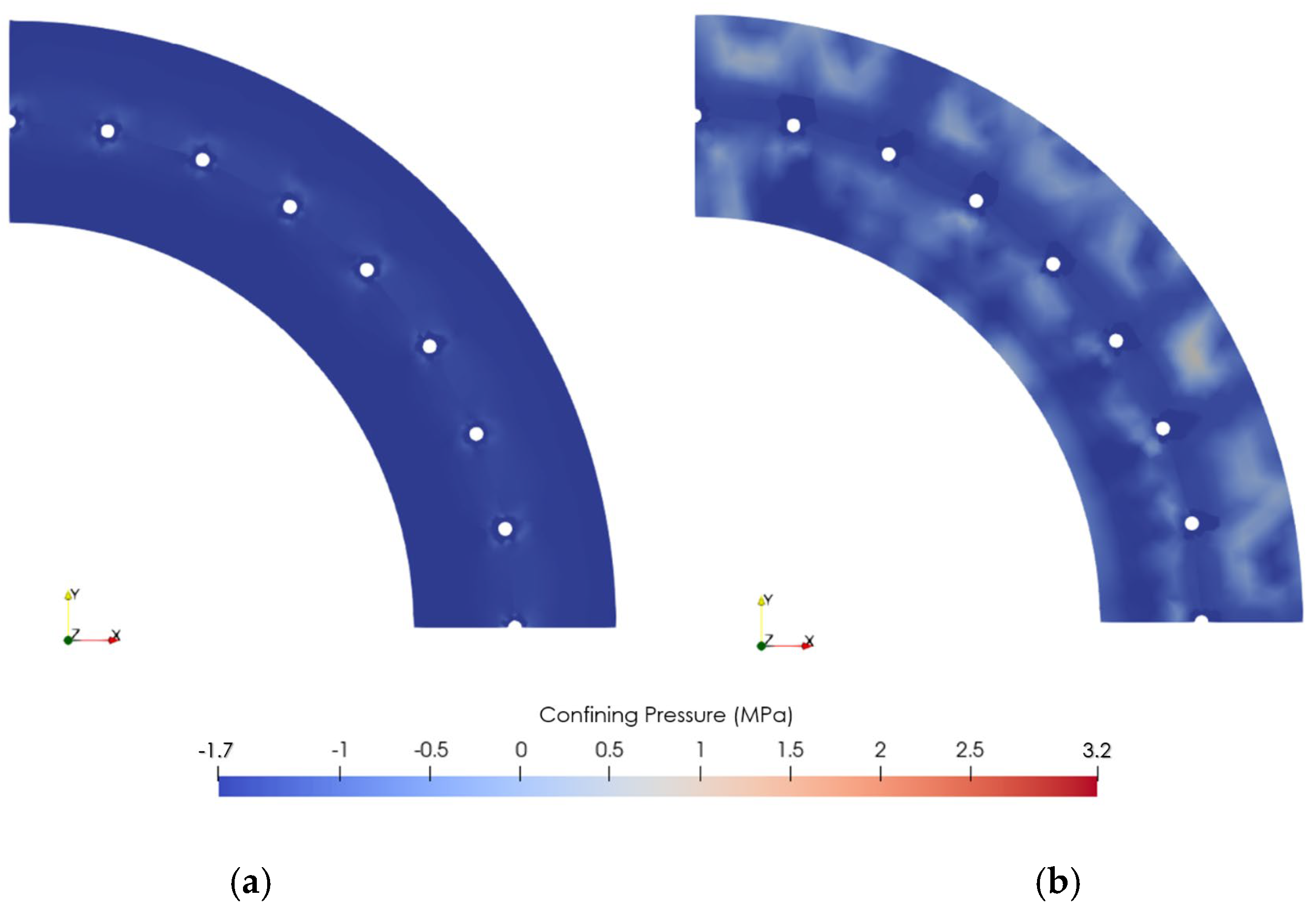

3.2. Corrosion Effect on the Concrete Strain Distribution

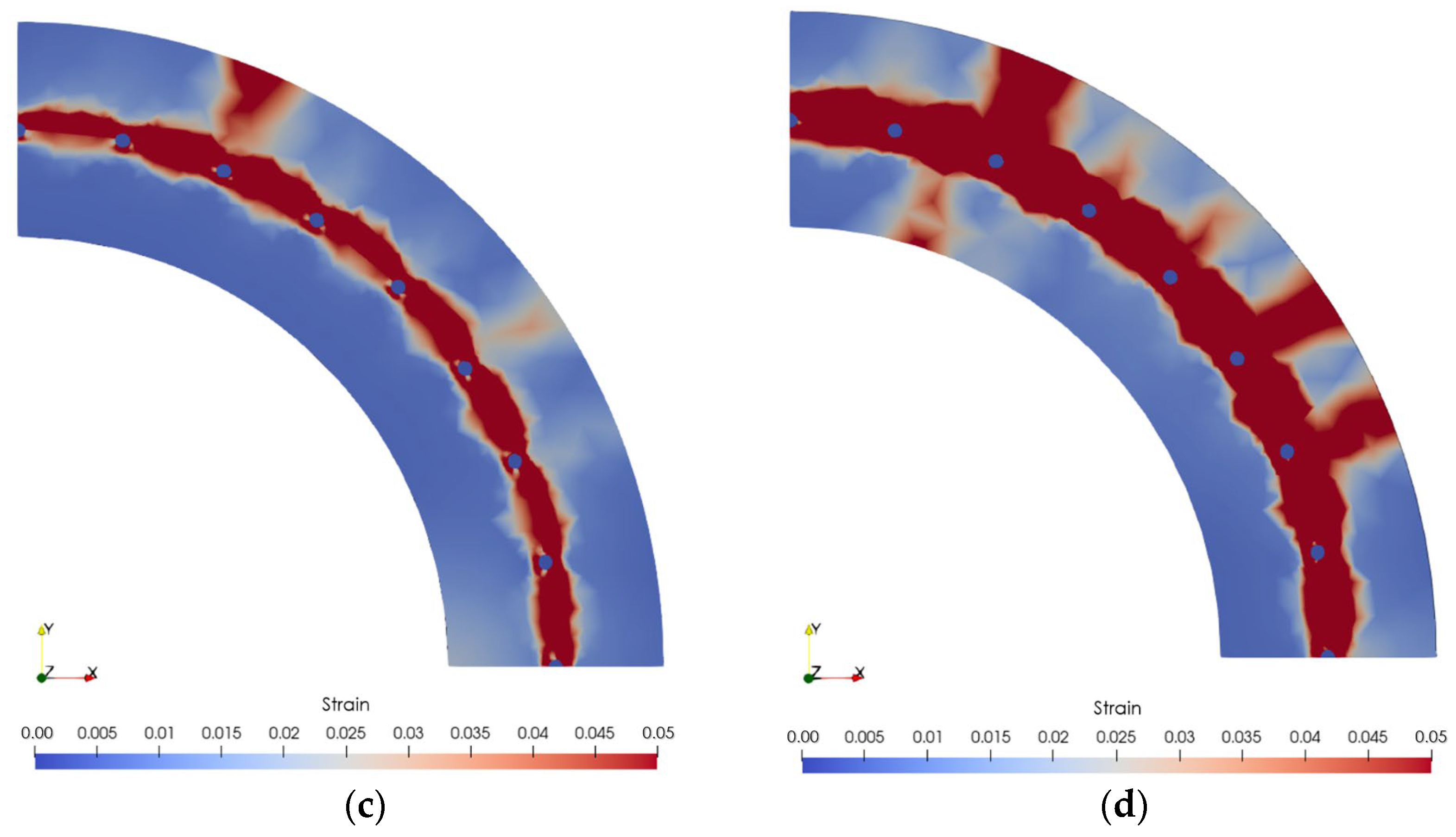

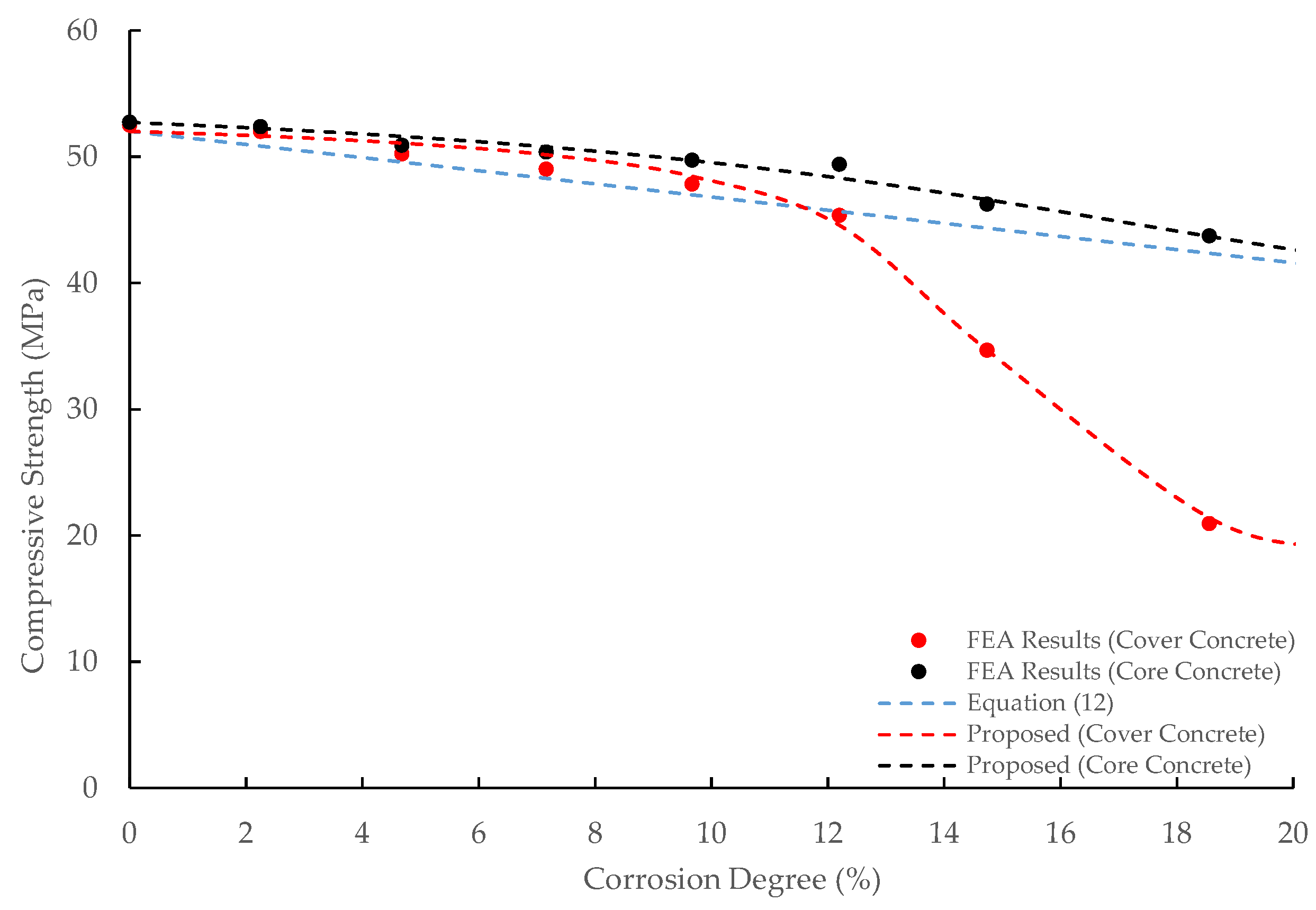

3.3. Corrosion Effect on Concrete Compressive Strength

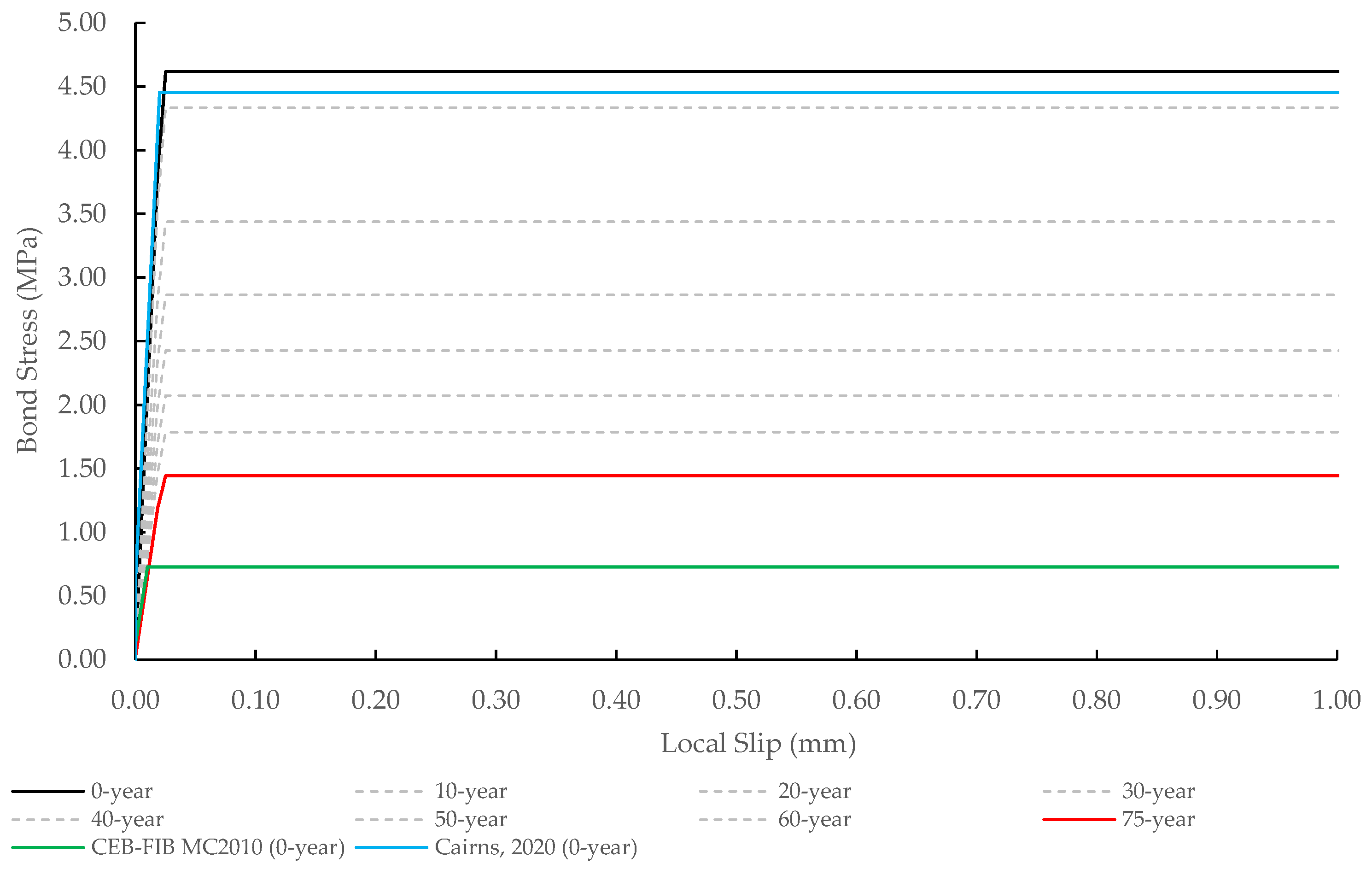

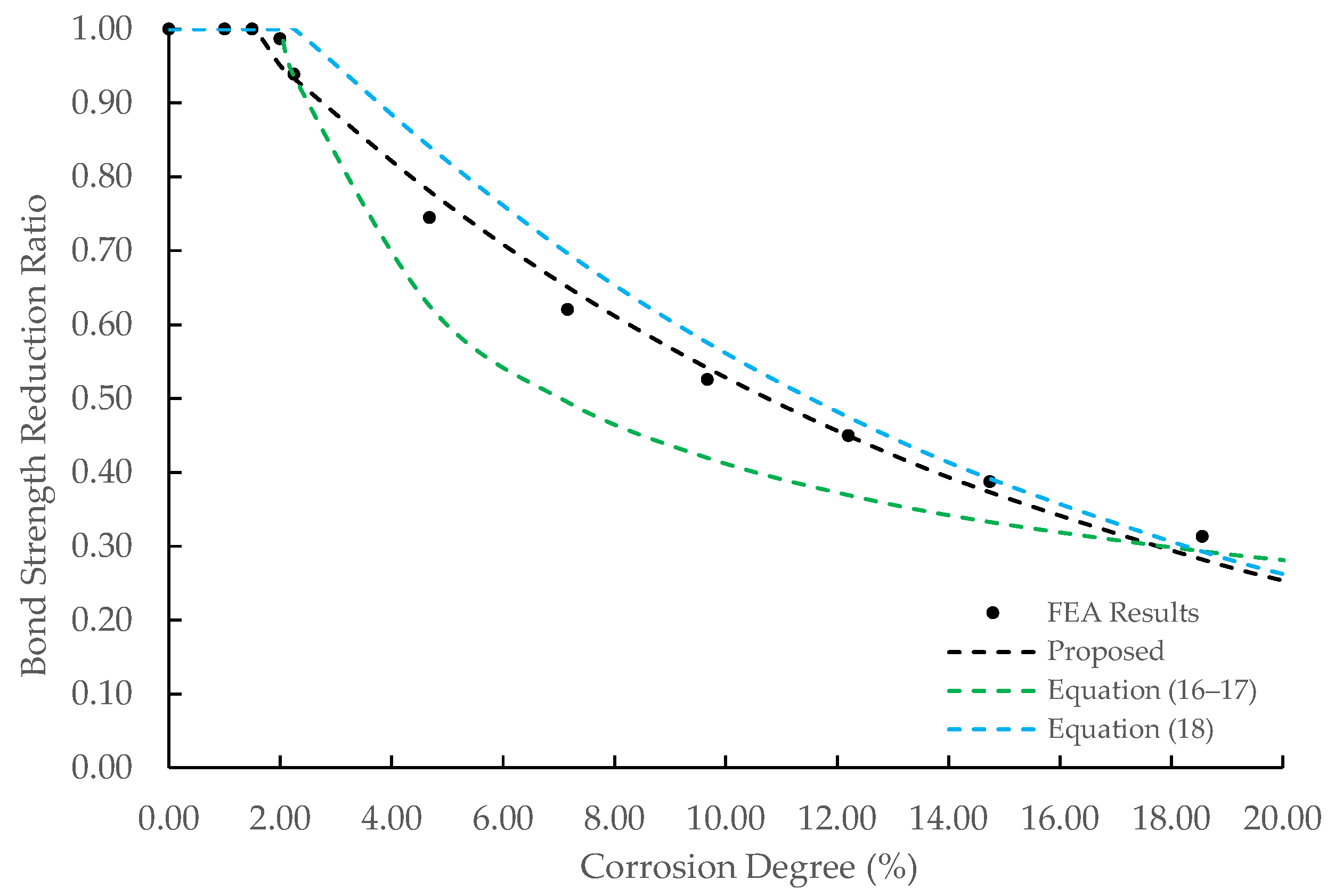

3.4. Corrosion Effect on Bond Strength

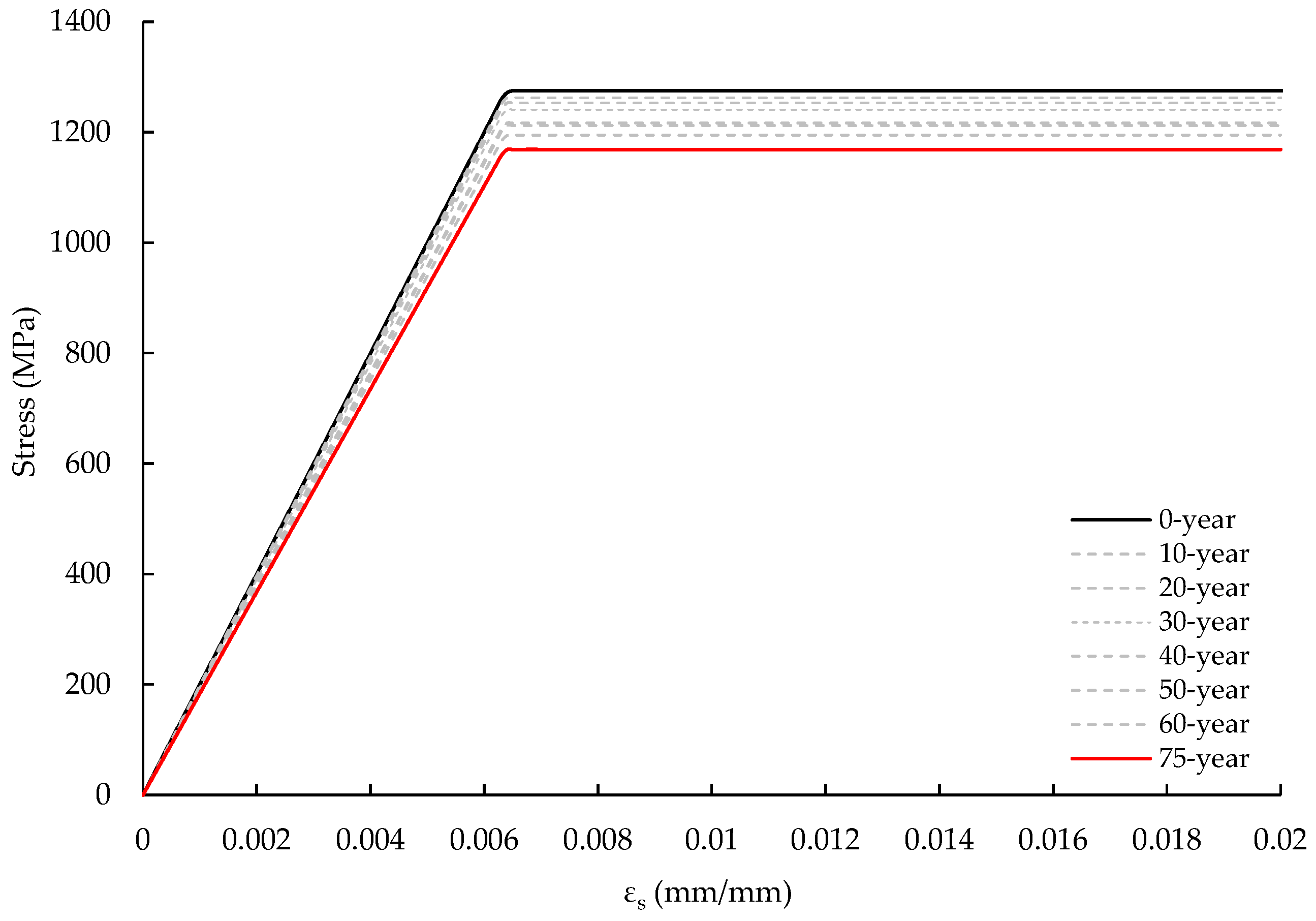

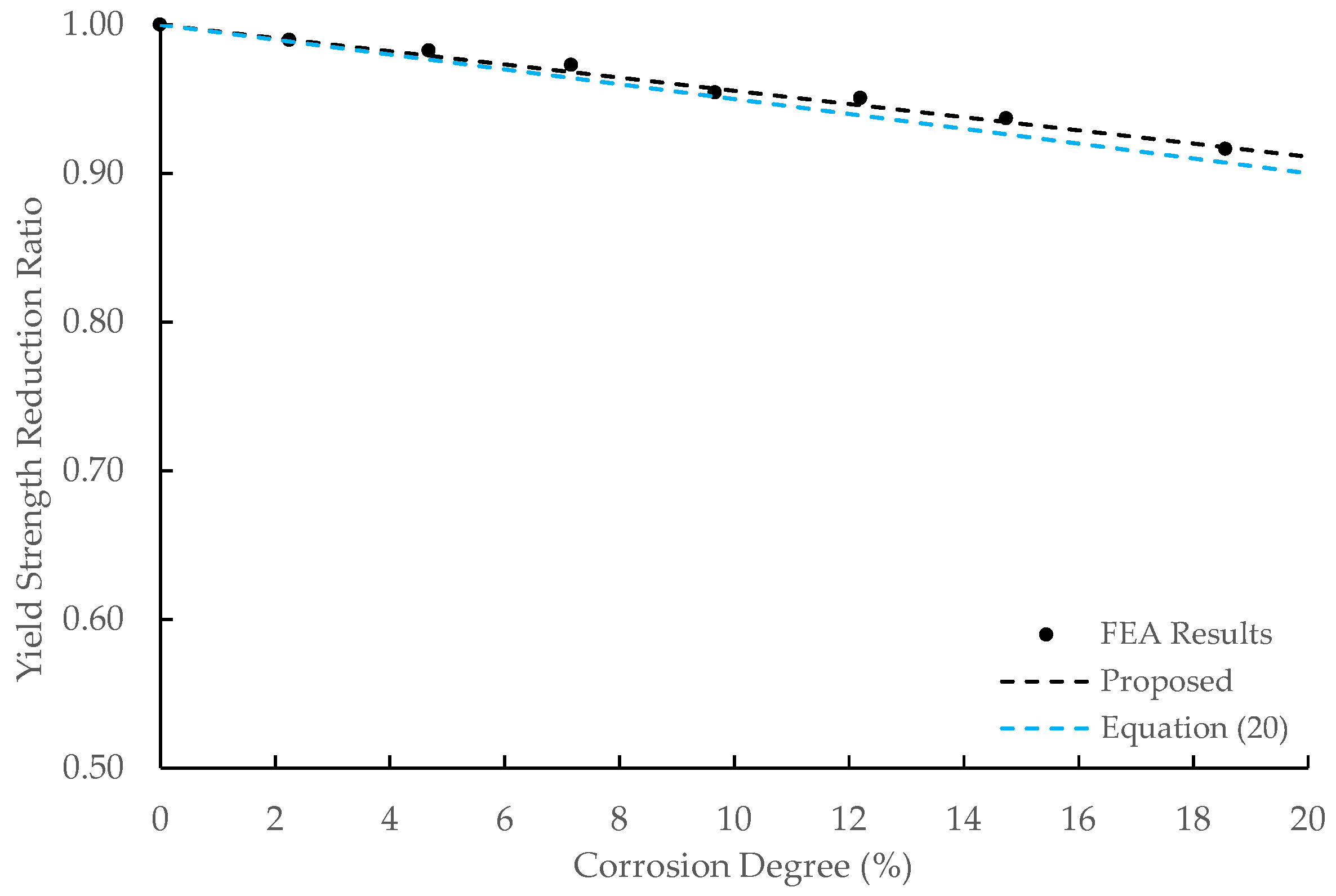

3.5. Corrosion Effect on Yield Strength of PC-Bar

4. Conclusions

- The diameter of the rebar affects the magnitude of the rust thickness. At the same corrosion degree, the rust thickness that occurred on the transverse rebar was more significant than the rust on the PC-bar.

- The nonuniform rust distribution exerts an internal pressure on the outer side of the spun pile and influences the crack distribution in a spun pile section. As a result, interconnection cracks were predicted to form along the PC-bars at a corrosion degree larger than 10%. Cover concrete spalling was anticipated after the corrosion degree reached 14.74%.

- The nonuniform rust distribution caused a significant compressive strength reduction in the cover concrete compared to the core concrete, primarily at corrosion degrees larger than 12%. The proposed equations successfully predicted the decline of the concrete compressive strength for the cover and core concrete. In contrast, the previous study’s equation slightly underestimated the core concrete compressive strength reduction. In addition, it significantly overestimated the cover concrete compressive strength reduction in the extensive corrosion degree range.

- The bond strength was reduced inverse-exponentially against the corrosion degree due to cracks in the concrete around the corroded rebar. The proposed equation could predict the bond strength decrease precisely, while the equations proposed by previous studies overestimated or underestimated the FEA results.

- The yield strength of the PC-bar was reduced linearly against the corrosion degree. The equation to predict the yield strength reduction ratio was proposed and was found in line with that suggested by a previous study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- JIS A 5335-1987; Pretensioned Spun Concrete Piles. Japanese Industrial Standards Committee: Tokyo, Japan, 1987.

- Apostolopoulos, C.A.; Papadakis, V.G. Consequences of Steel Corrosion on the Ductility Properties of Reinforcement Bar. Constr. Build. Mater. 2008, 22, 2316–2324. [Google Scholar] [CrossRef]

- Tuutti, K. Corrosion of Steel in Concrete; Swedish Cement and Concrete Research Institute: Stockholm, Sweden, 1982. [Google Scholar]

- Ge, X.; Dietz, M.S.; Alexander, N.A.; Kashani, M.M. Nonlinear Dynamic Behaviour of Severely Corroded Reinforced Concrete Columns: Shaking Table Study. Bull. Earthq. Eng. 2020, 18, 1417–1443. [Google Scholar] [CrossRef]

- Kivell, A. Effects of Bond Deterioration Due to Corrosion on Seismic Performance of Reinforced Concrete Structures; University of Canterbury: Christchurch, New Zealand, 2012. [Google Scholar]

- Zhao, Y.; Karimi, A.R.; Wong, H.S.; Hu, B.; Buenfeld, N.R.; Jin, W. Comparison of Uniform and Non-Uniform Corrosion Induced Damage in Reinforced Concrete Based on a Gaussian Description of the Corrosion Layer. Corros. Sci. 2011, 53, 2803–2814. [Google Scholar] [CrossRef]

- Stewart, M.G. Spatial Variability of Pitting Corrosion and Its Influence on Structural Fragility and Reliability of RC Beams in Flexure. Struct. Saf. 2004, 26, 453–470. [Google Scholar] [CrossRef]

- Ou, Y.C.; Susanto, Y.T.T.; Roh, H. Tensile Behavior of Naturally and Artificially Corroded Steel Bars. Constr. Build. Mater. 2016, 103, 93–104. [Google Scholar] [CrossRef]

- Du, Y.G.; Clark, L.A.; Chan, A.H.C. Residual Capacity of Corroded Reinforcing Bars. Mag. Concr. Res. 2005, 57, 135–147. [Google Scholar] [CrossRef]

- Kashani, M.M.; Crewe, A.J.; Alexander, N.A. Nonlinear Cyclic Response of Corrosion-Damaged Reinforcing Bars with the Effect of Buckling. Constr. Build. Mater. 2013, 41, 388–400. [Google Scholar] [CrossRef]

- Zhu, W.; François, R.; Poon, C.S.; Dai, J.G. Influences of Corrosion Degree and Corrosion Morphology on the Ductility of Steel Reinforcement. Constr. Build. Mater. 2017, 148, 297–306. [Google Scholar] [CrossRef]

- Fernandez, I.; Bairán, J.M.; Marí, A.R. Mechanical Model to Evaluate Steel Reinforcement Corrosion Effects on σ-ε and Fatigue Curves. Experimental Calibration and Validation. Eng. Struct. 2016, 118, 320–333. [Google Scholar] [CrossRef]

- Almusallam, A.A. Effect of Degree of Corrosion on the Properties of Reinforcing Steel Bars. Constr. Build. Mater. 2001, 15, 361–368. [Google Scholar] [CrossRef]

- Shayanfar, M.A.; Barkhordari, M.A.; Ghanooni-Bagha, M. Effect of Longitudinal Rebar Corrosion on the Compressive Strength Reduction of Concrete in Reinforced Concrete Structure. Adv. Struct. Eng. 2016, 19, 897–907. [Google Scholar] [CrossRef]

- Chung, L.; Jay Kim, J.H.; Yi, S.T. Bond Strength Prediction for Reinforced Concrete Members with Highly Corroded Reinforcing Bars. Cem. Concr. Compos. 2008, 30, 603–611. [Google Scholar] [CrossRef]

- Bhargava, K.; Ghosh, A.K.; Mori, Y.; Ramanujam, S. Corrosion-Induced Bond Strength Degradation in Reinforced Concrete-Analytical and Empirical Models. Nucl. Eng. Des. 2007, 237, 1140–1157. [Google Scholar] [CrossRef]

- Mirzaeefard, H.; Hariri-Ardebili, M.A.; Mirtaheri, M. Time-Dependent Seismic Fragility Analysis of Corroded Pile-Supported Wharves with Updating Limit States. Soil Dyn. Earthq. Eng. 2021, 142, 106551. [Google Scholar] [CrossRef]

- Schmuhl, D.T.; Loos, S.; Hur, J.; Shafieezadeh, A. Time-Dependent Probabilistic Capacity Degradation Assessment of Prestressed Concrete Piles in Marine Environment. Struct. Infrastruct. Eng. 2018, 14, 1372–1385. [Google Scholar] [CrossRef]

- Qu, C.X.; Yi, T.H.; Li, H.N.; Chen, B. Closely Spaced Modes Identification through Modified Frequency Domain Decomposition. Meas. J. Int. Meas. Confed. 2018, 128, 388–392. [Google Scholar] [CrossRef]

- Qu, C.X.; Yi, T.H.; Li, H.N. Mode Identification by Eigensystem Realization Algorithm through Virtual Frequency Response Function. Struct. Control Heal. Monit. 2019, 26, e2429. [Google Scholar] [CrossRef]

- Xi, X.; Yang, S.; Li, C.Q. A Non-Uniform Corrosion Model and Meso-Scale Fracture Modelling of Concrete. Cem. Concr. Res. 2018, 108, 87–102. [Google Scholar] [CrossRef]

- Jeon, C.H.; Lee, J.B.; Lon, S.; Shim, C.S. Equivalent Material Model of Corroded Prestressing Steel Strand. J. Mater. Res. Technol. 2019, 8, 2450–2460. [Google Scholar] [CrossRef]

- Vu, K.A.T.; Stewart, M.G. Structural Reliability of Concrete Bridges Including Improved Chloride-Induced Corrosion Models. Struct. Saf. 2000, 22, 313–333. [Google Scholar] [CrossRef]

- PT. Wijaya Karya Beton. Wika Beton Brochure—The Precast Concrete Manufacturer; PT. Wijaya Karya Beton: Bekasi, Indonesia, 2017. [Google Scholar]

- Piscesa, B.; Attard, M.M.; Samani, A.K.; Tangaramvong, S. Plasticity Constitutive Model for Stress-Strain Relationship of Confined Concrete. ACI Mater. J. 2017, 114, 361–371. [Google Scholar] [CrossRef]

- Chen, W.F.; Han, D.J. Plasticity for Structural Engineers; Springer: New York, NY, USA, 1988. [Google Scholar]

- Ranjbaran, A. Embedding of Reinforcements in Reinforced Concrete Elements Implemented in DENA. Comput. Struct. 1991, 40, 925–930. [Google Scholar] [CrossRef]

- Ranjbaran, A. Mathematical Formulation of Embedded Reinforcements in 3D Brick Elements. Commun. Numer. Methods Eng. 1996, 12, 897–903. [Google Scholar] [CrossRef]

- Xu, G.; Liu, L.; Bao, H.; Wang, Q.; Zhao, J. Mechanical Properties of Steel Corrosion Products in Reinforced Concrete. Mater. Struct. Constr. 2017, 50, 115. [Google Scholar] [CrossRef]

- Piscesa, B.; Attard, M.M.; Samani, A.K. 3D Finite Element Modeling of Circular Reinforced Concrete Columns Confined with FRP Using a Plasticity Based Formulation. Compos. Struct. 2018, 194, 478–493. [Google Scholar] [CrossRef]

- Piscesa, B.; Attard, M.M.; Prasetya, D.; Samani, A.K. Modeling Cover Spalling Behavior in High Strength Reinforced Concrete Columns Using a Plasticity-Fracture Model. Eng. Struct. 2019, 196, 109336. [Google Scholar] [CrossRef]

- Dwi Puspitasari, N.; Piscesa, B.; Mario, M.A.; Prasetya, D.; Faimun, F.; Aji, P.; Suprobo, P. Parameter Identification for Modeling Steel Fiber Reinforced Concrete under Compression to Prevent Concrete Cover Spalling under Severe Earthquake Loading Condition. E3S Web Conf. 2020, 156, 05028. [Google Scholar] [CrossRef]

- Piscesa, B.; Attard, M.M.; Samani, A.K. Three-Dimensional Finite Element Analysis of Circular Reinforced Concrete Column Confined with FRP Using Plasticity Model. Procedia Eng. 2017, 171, 847–856. [Google Scholar] [CrossRef]

- Hughes, T.J.R. The Finite Element Method—Linear Static and Dynamic Finite Element Analysis; Prentice-Hall Inc.: Englewood Cliffs, NJ, USA, 1987. [Google Scholar]

- Dang, H.K.; Yacoub, T.; Curran, J.; Visser, M.; Wai, D. Evaluate the Performance of an Accelerated Initial Stiffness Method in Three Dimensional Finite Element Analysis. Comput. Geotech. 2014, 62, 293–303. [Google Scholar] [CrossRef]

- Cerfontaine, B.; Dieudonné, A.C.; Radu, J.P.; Collin, F.; Charlier, R. 3D Zero-Thickness Coupled Interface Finite Element: Formulation and Application. Comput. Geotech. 2015, 69, 124–140. [Google Scholar] [CrossRef]

- Carol, I.; Prat, P.C.; Lopez, C.M. Normal/Shear Cracking Model: Application to Discrete Crack Analysis. J. Eng. Mech. 1997, 123, 765–773. [Google Scholar] [CrossRef]

- Fédération internationale du béton (fib). CEB-FIP Model Code 2010; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2010; ISBN 978-2-88394-095-6. [Google Scholar]

- Cairns, J. Local Bond–Slip Model for Plain Surface Reinforcement. Struct. Concr. 2021, 22, 666–675. [Google Scholar] [CrossRef]

| Concrete Material Properties | ||

|---|---|---|

| Cover concrete compressive strength (MPa) | 52 | |

| εc | Strain at cover concrete peak strength | 0.00275 |

| Core concrete compressive strength (MPa) | 52 | |

| εcc | Strain at core concrete peak strength | 0.00323 |

| PC-Bar and Transverse Rebar Material Properties | ||

| PC-bar yield strength (MPa) | 1275 | |

| PC-bar ultimate strength (MPa) | 1420 | |

| Es | PC-bar elastic modulus (MPa) | 196,500 |

| σini | PC-bar initial stress (MPa) | 781 |

| Transverse rebar yield strength (MPa) | 360 | |

| Transverse rebar ultimate strength (MPa) | 540 | |

| Ess | Transverse rebar elastic modulus (MPa) | 196,500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Refani, A.N.; Nagao, T. Corrosion Effects on the Mechanical Properties of Spun Pile Materials. Appl. Sci. 2023, 13, 1507. https://doi.org/10.3390/app13031507

Refani AN, Nagao T. Corrosion Effects on the Mechanical Properties of Spun Pile Materials. Applied Sciences. 2023; 13(3):1507. https://doi.org/10.3390/app13031507

Chicago/Turabian StyleRefani, Afif Navir, and Takashi Nagao. 2023. "Corrosion Effects on the Mechanical Properties of Spun Pile Materials" Applied Sciences 13, no. 3: 1507. https://doi.org/10.3390/app13031507

APA StyleRefani, A. N., & Nagao, T. (2023). Corrosion Effects on the Mechanical Properties of Spun Pile Materials. Applied Sciences, 13(3), 1507. https://doi.org/10.3390/app13031507