A Method for Turning a Single Low-Cost Cube into a Reference Target for Point Cloud Registration

Abstract

1. Introduction

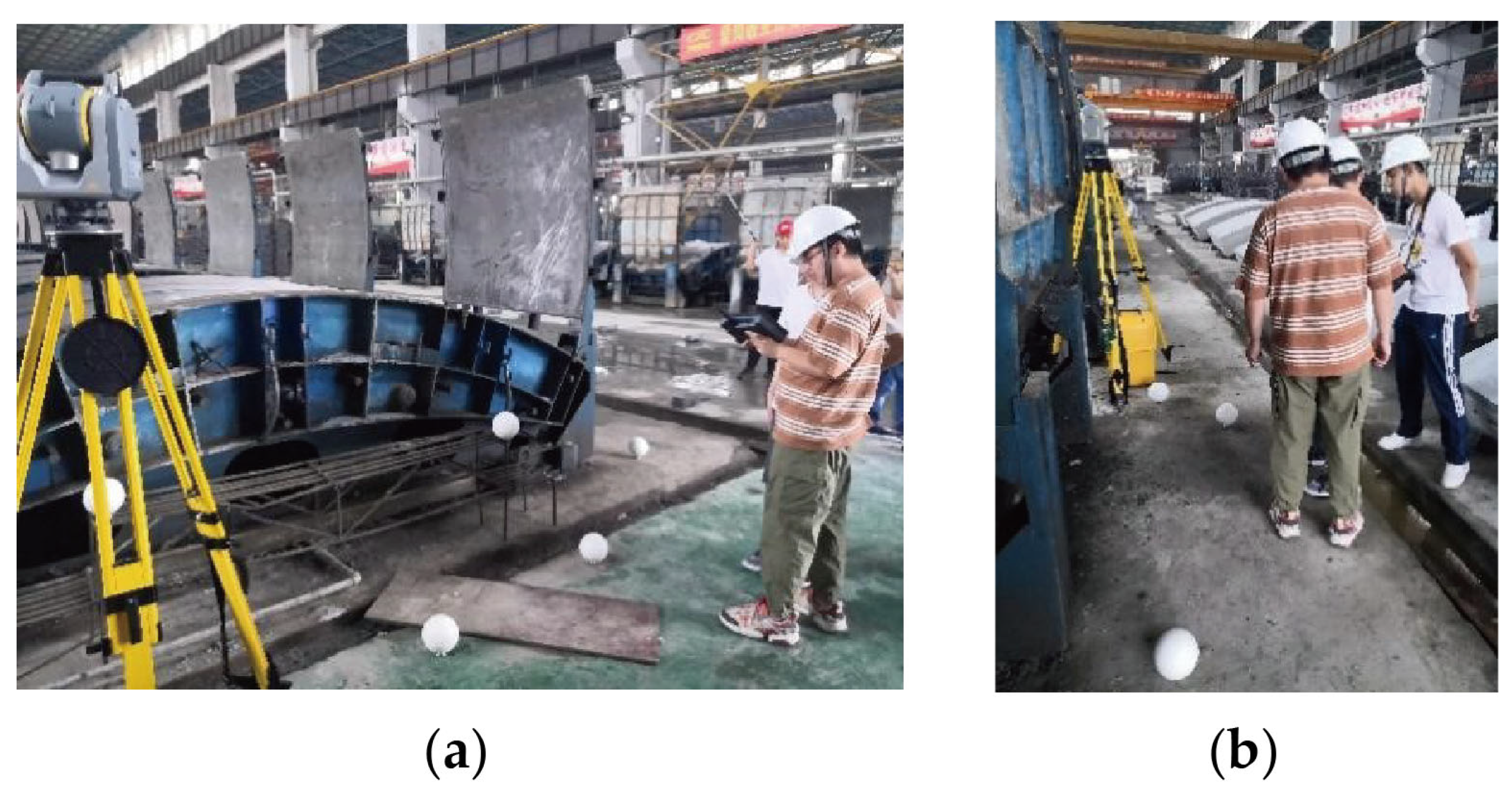

2. Materials and Methods

2.1. Overviews

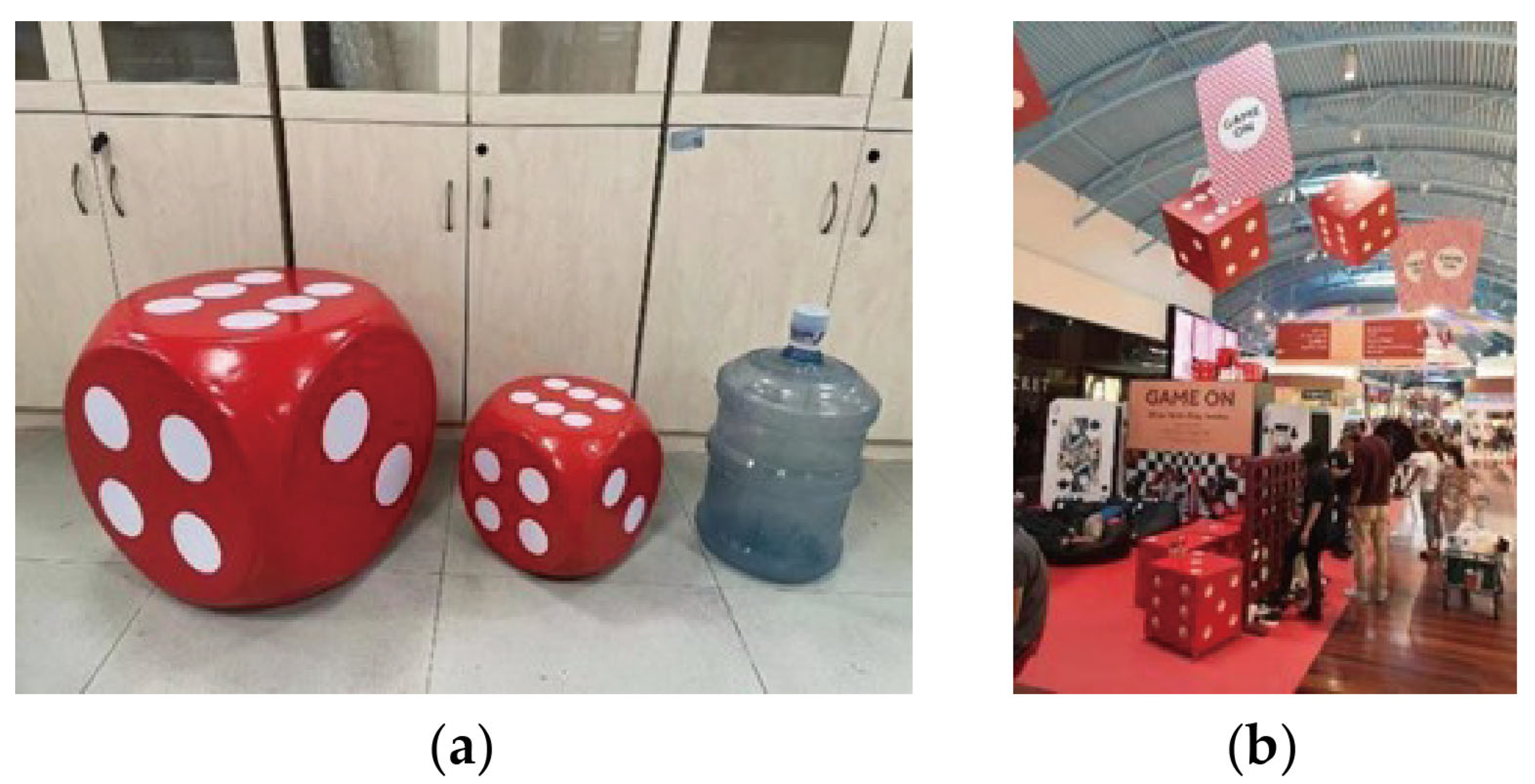

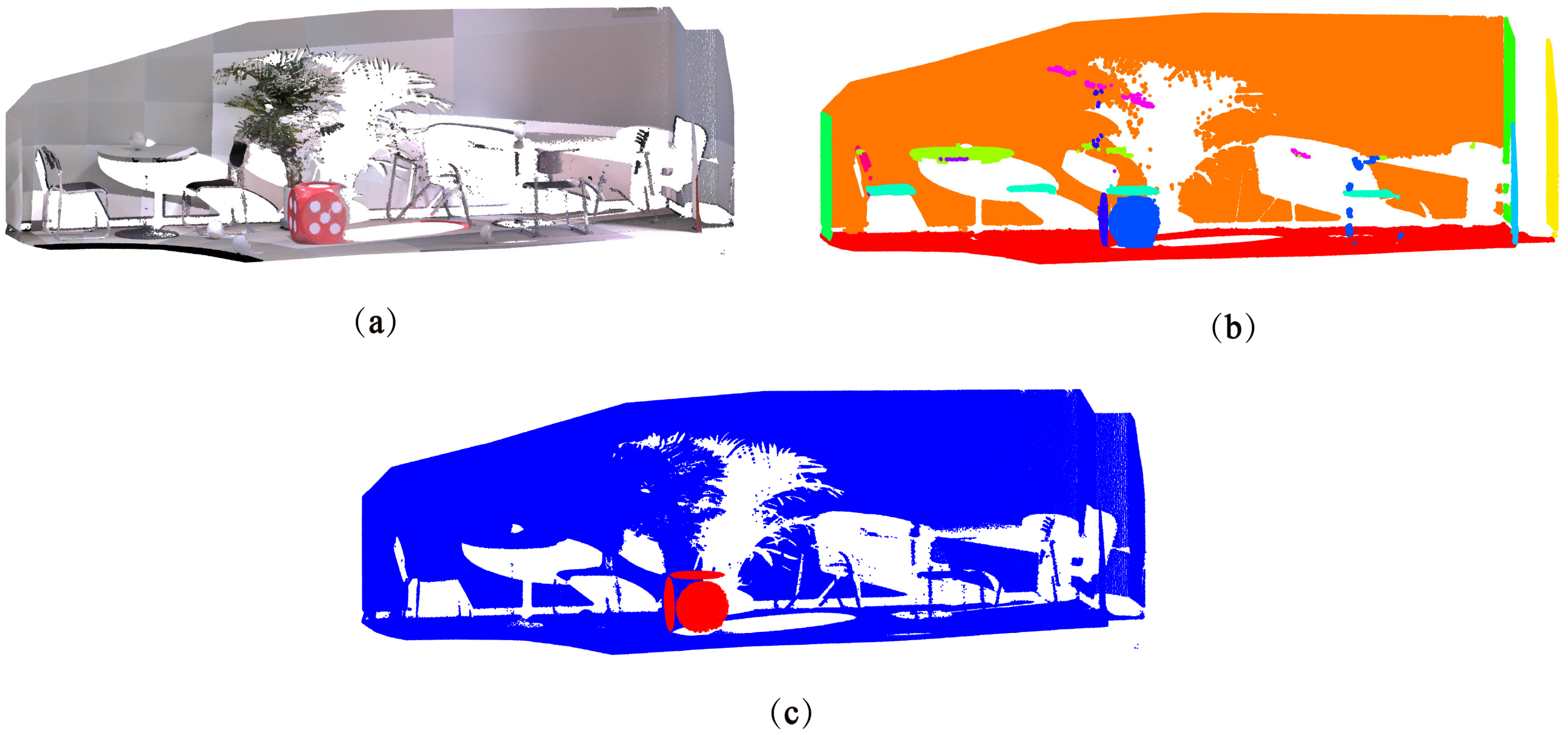

2.2. Automatic Target Extraction and Pips Recognition

2.3. Point Cloud Registration

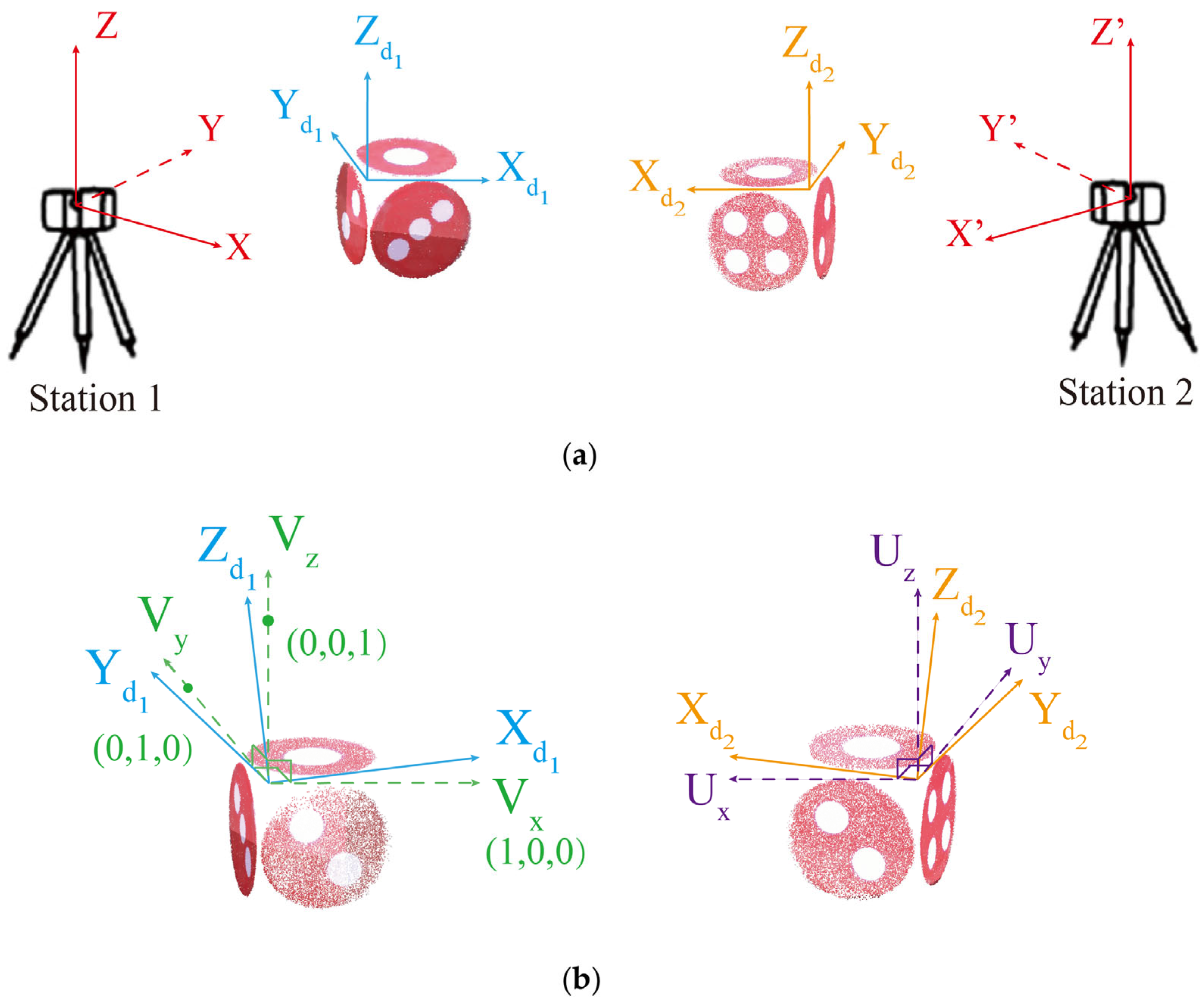

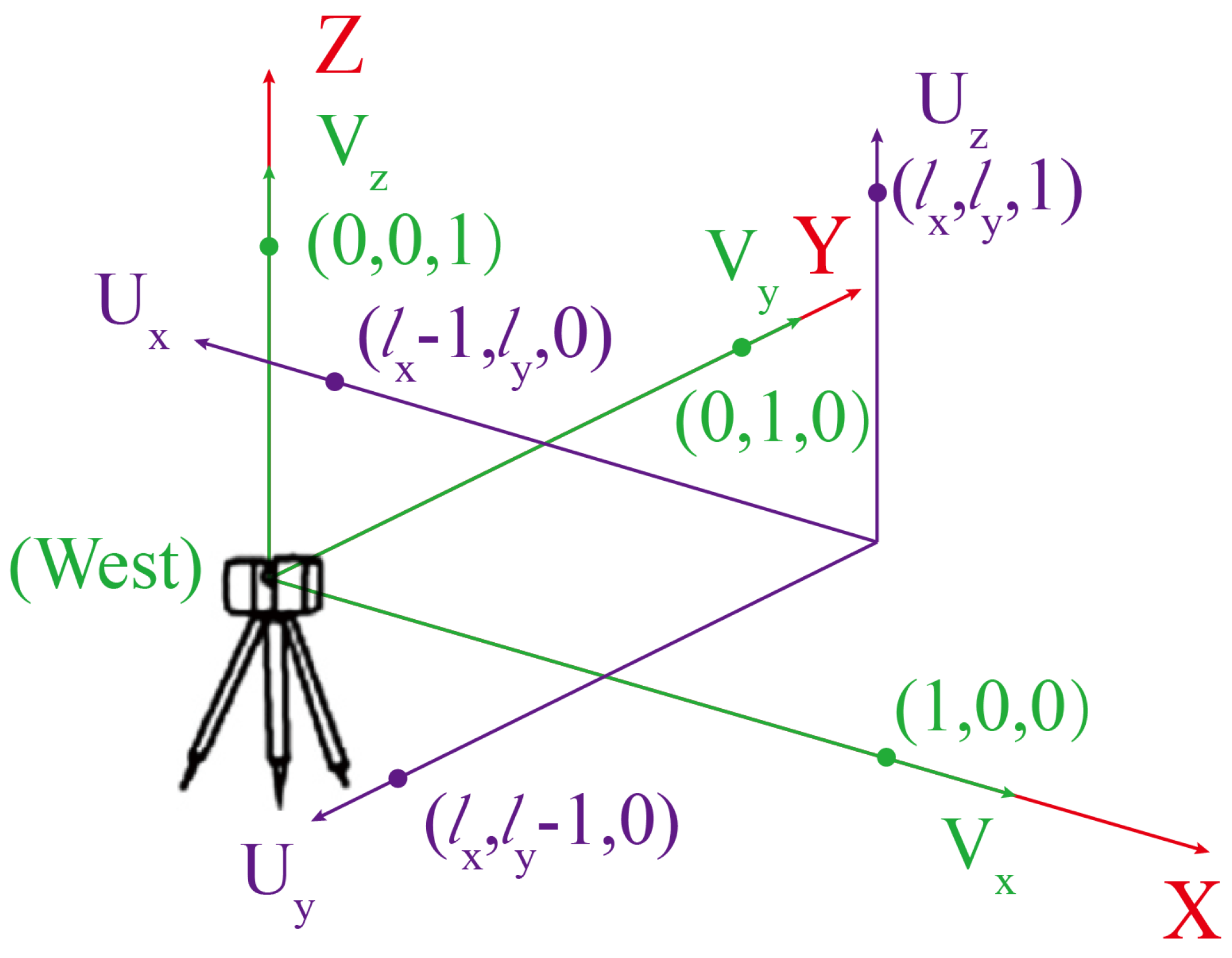

2.3.1. Coordinate System Construction

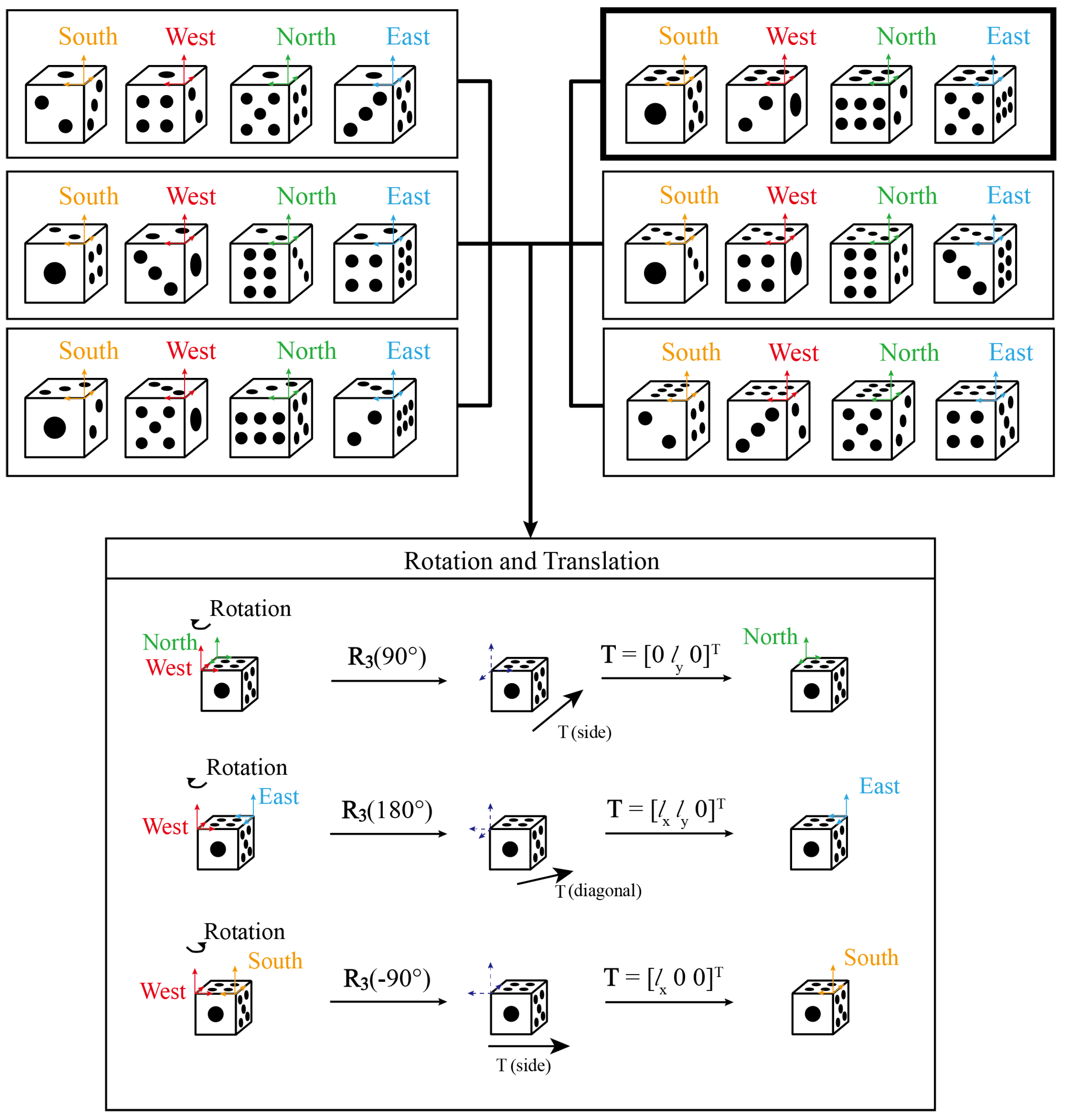

2.3.2. Conjugate Point Identification

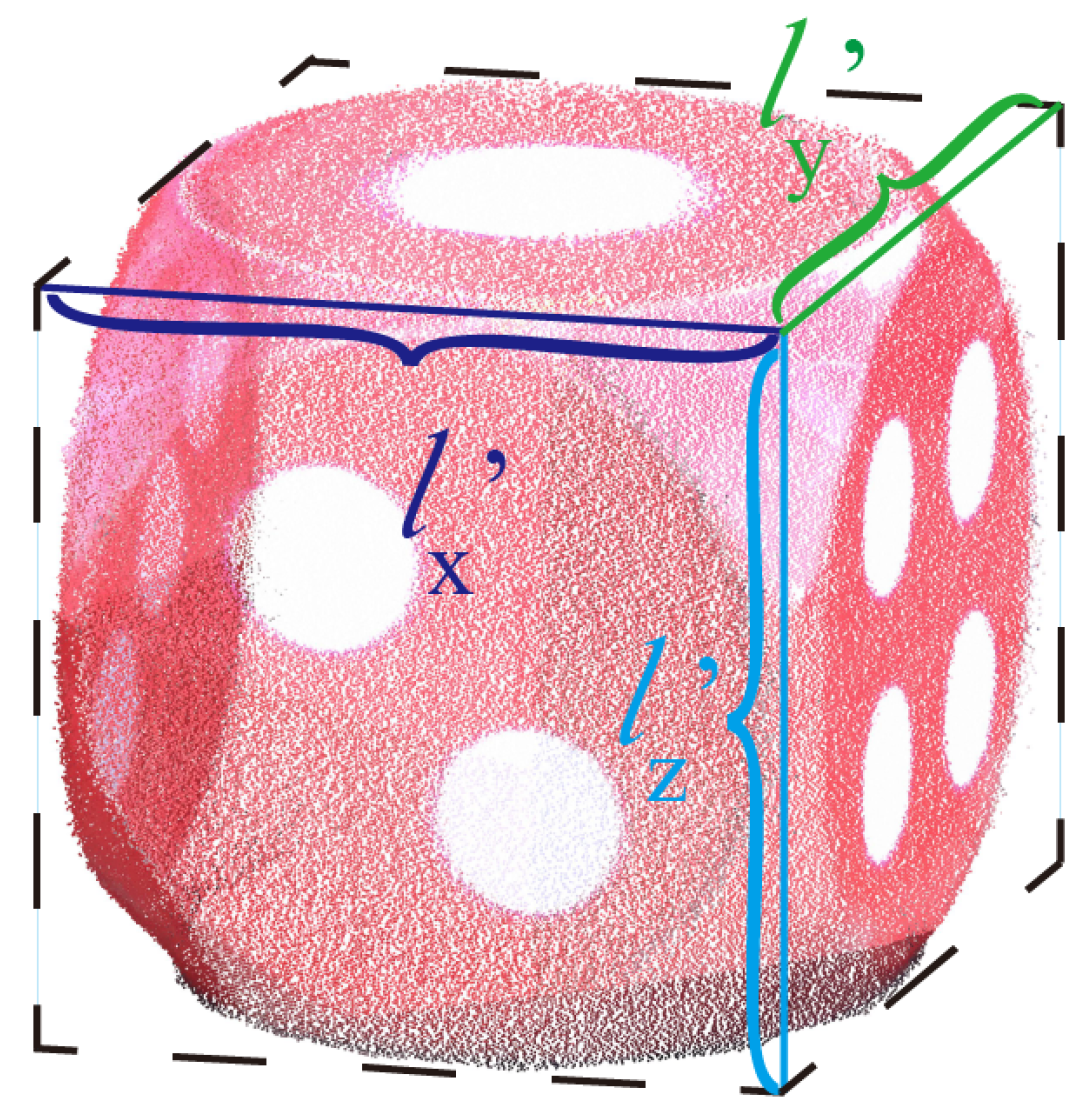

2.3.3. Die Dimension Calibration

- Some small planar features are first selected as calibration planes from each scan station;

- The root mean squared error (RMSE) of the calibration planes after the registration is computed based on the manufacturer-provided dimensions,

- A new set of dimensions, , as depicted in Figure 10, is computed in such a way that the RMSEs of the check planes, , are minimized:

- The estimated dimensions are then augmented into Equation (4) for refinement of the registration parameters.

3. Experiments

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, L.; Chen, S.; Liu, X.; Xu, H.; Wu, Y.; Li, M.; Chen, Y. Registration of laser scanning point clouds: A review. Sensors 2018, 18, 1641. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Mei, G.; Zhang, J.; Abbas, R.A. Comprehensive Survey on Point Cloud Registration. arXiv 2021, arXiv:2103.02690. [Google Scholar]

- Li, L.; Yang, M. Point Cloud Registration Based on Direct Deep Features With Applications in Intelligent Vehicles. IEEE Trans. Intell. Transp. 2021, 23, 13346–13357. [Google Scholar] [CrossRef]

- Xiong, B.; Li, D.; Zhou, Z.; Li, F. Fast Registration of Terrestrial LiDAR Point Clouds Based on Gaussian-Weighting Projected Image Matching. Remote Sens. 2022, 14, 1466. [Google Scholar] [CrossRef]

- Chuang, T.; Jaw, J. Multi-feature registration of point clouds. Remote Sens. 2017, 9, 281. [Google Scholar] [CrossRef]

- Ge, X. Automatic markerless registration of point clouds with semantic-keypoint-based 4-points congruent sets. ISPRS J. Photogramm. Remote Sens. 2017, 130, 344–357. [Google Scholar] [CrossRef]

- Liu, W.I. Novel method for sphere target detection and center estimation from mobile terrestrial laser scanner data. Measurement 2019, 137, 617–623. [Google Scholar] [CrossRef]

- Huang, J.; Wang, Z.; Bao, W.; Gao, J. A high-precision registration method based on auxiliary sphere targets. In Proceedings of the 2014 International Conference on Digital Image Computing: Techniques and Applications (DICTA), Wollongong, NSW, Australia, 25–27 November 2014; pp. 1–5. [Google Scholar]

- Urbančič, T.; Roškar, Z.; Kosmatin Fras, M.; Grigillo, D. New target for accurate terrestrial laser scanning and unmanned aerial vehicle point cloud registration. Sensors 2019, 19, 3179. [Google Scholar] [CrossRef]

- Yun, D.; Kim, S.; Heo, H.; Ko, K.H. Automated registration of multi-view point clouds using sphere targets. Adv. Eng. Inform. 2015, 29, 930–939. [Google Scholar] [CrossRef]

- Besl, P.J.; McKay, N.D. Method for registration of 3-D shapes. In Sensor Fusion IV: Control Paradigms and Data Structures; Spie: Bellingham, WA, USA, 1992; Volume 1611, pp. 586–606. [Google Scholar]

- Donoso, F.A.; Austin, K.J.; McAree, P.R. How do ICP variants perform when used for scan matching terrain point clouds? Robot. Auton. Syst. 2017, 87, 147–161. [Google Scholar] [CrossRef]

- Rusinkiewicz, S.; Levoy, M. Efficient variants of the ICP algorithm. In Proceedings of the Third International Conference on 3-D Digital Imaging and Modeling, Quebec, QC, Canada, 28 May–1 June 2001; pp. 145–152. [Google Scholar]

- Fangning, H.; Ayman, H. A closed-form solution for coarse registration of point clouds using linear features. J. Surv. Eng. 2016, 142, 4016006. [Google Scholar] [CrossRef]

- Sanchez, J.; Denis, F.; Checchin, P.; Dupont, F.; Trassoudaine, L. Global registration of 3D LiDAR point clouds based on scene features: Application to structured environments. Remote Sens. 2017, 9, 1014. [Google Scholar] [CrossRef]

- Xia, S.; Chen, D.; Wang, R.; Li, J.; Zhang, X. Geometric primitives in LiDAR point clouds: A review. IEEE J. Stars. 2020, 13, 685–707. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Tan, J.; Liu, H. Pairwise Coarse Registration of Indoor Point Clouds Using 2D Line Features. ISPRS Int. J. Geo-Inf. 2021, 10, 26. [Google Scholar] [CrossRef]

- Tao, W.; Hua, X.; Chen, Z.; Tian, P. Fast and automatic registration of terrestrial point clouds using 2D line features. Remote Sens. 2020, 12, 1283. [Google Scholar] [CrossRef]

- Wei, P.; Yan, L.; Xie, H.; Huang, M. Automatic coarse registration of point clouds using plane contour shape descriptor and topological graph voting. Automat. Constr. 2021, 134, 104055. [Google Scholar] [CrossRef]

- Kelbe, D.; Van Aardt, J.; Romanczyk, P.; Van Leeuwen, M.; Cawse-Nicholson, K. Marker-free registration of forest terrestrial laser scanner data pairs with embedded confidence metrics. IEEE Trans. Geosci. Remote 2016, 54, 4314–4330. [Google Scholar] [CrossRef]

- Chan, T.O.; Lichti, D.D.; Belton, D.; Nguyen, H.L. Automatic point cloud registration using a single octagonal lamp pole. Photogramm. Eng. Remote Sens. 2016, 82, 257–269. [Google Scholar] [CrossRef]

- Yang, B.; Zang, Y. Automated registration of dense terrestrial laser-scanning point clouds using curves. ISPRS J. Photogramm. 2014, 95, 109–121. [Google Scholar] [CrossRef]

- Pesci, A.; Teza, G. Terrestrial laser scanner and retro-reflective targets: An experiment for anomalous effects investigation. Int. J. Remote Sens. 2008, 29, 5749–5765. [Google Scholar] [CrossRef]

- Horn, B.K. Closed-form solution of absolute orientation using unit quaternions. Josa a 1987, 4, 629–642. [Google Scholar] [CrossRef]

- Rachakonda, P.; Muralikrishnan, B.; Cournoyer, L.; Cheok, G.; Lee, V.; Shilling, M.; Sawyer, D. Methods and considerations to determine sphere center from terrestrial laser scanner point cloud data. Meas. Sci. Technol. 2017, 28, 105001. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Yang, F.; Zhu, H.; Li, D.; Li, Y.; Tang, L. An improved RANSAC for 3D point cloud plane segmentation based on normal distribution transformation cells. Remote Sens. 2017, 9, 433. [Google Scholar] [CrossRef]

- Lichti, D.D.; Glennie, C.L.; Jahraus, A.; Hartzell, P.J. New Approach for Low-Cost TLS Target Measurement; ASCE: Reston, VA, USA, 2019. [Google Scholar]

- Canny, J. A computational approach to edge detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, 6, 679–698. [Google Scholar] [CrossRef]

- Ester, M.; Kriegel, H.; Sander, J.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the Second International Conference on Knowledge Discovery and Data Mining; AAAI Press: Washington, DC, USA, 1996; Volume 96, pp. 226–231. [Google Scholar]

- Szabo, F. The Linear Algebra Survival Guide: Illustrated with Mathematica; Academic Press: Cambridge, MA, USA, 2015. [Google Scholar]

- Forsythe, G.E. Computer Methods for Mathematical Computations; Series in Automatic Computation; Prentice-Hall: Hoboken, NJ, USA, 1977; Volume 259. [Google Scholar]

- Qi, X.; Lichti, D.D.; El Badry, M.; Chan, T.O.; El Halawany, S.I.; Lahamy, H.; Steward, J. Structural dynamic deflection measurement with range cameras. Photogramm. Record. 2014, 29, 89–107. [Google Scholar] [CrossRef]

| Datasets | Point Cloud | NO. of Points | Scanner-to-Die Distance (m) | Scan the Plane of the Dice |

|---|---|---|---|---|

| A | 1 (master) | 91,628 | 6.1 | Pips1\2\3 |

| 2 (slave) | 76,783 | 8.1 | Pips1\2\4 | |

| B | 1 (master) | 100,215 | 4.5 | Pips1\2\3 |

| 2 (slave) | 114,223 | 6.4 | Pips1\2\4 | |

| C | 1 (master) | 105,867 | 2.4 | Pips1\4\5 |

| 2 (slave) | 72,206 | 3.5 | Pips1\3\5 | |

| D | 1 (master) | 116,267 | 3.2 | Pips1\2\3 |

| 2 (slave) | 123,025 | 3.0 | Pips1\3\5 |

| Check Plane | Point Cloud | Orient | Approx. Dist. From Station 1/Dice 1 (m) | RMSE (mm) | |||

|---|---|---|---|---|---|---|---|

| Before Regist. (In Its Own Standalone Point Cloud) | After Die-Based Regist. (Without Dim. Calibration) | After Die-Based Regist. (With Dim. Calibration) | After Spherical Target (6) Regist. | ||||

| A-1 | 1 (master) | Vert. | 11.7/5.3 | 1.7 | 5·3 | 2.0 | 1.9 |

| 2 (slave) | 1.4 | ||||||

| A-2 | 1 (master) | 7.6/3.4 | 1.8 | 2.4 | 2.3 | 1.9 | |

| 2 (slave) | 1.5 | ||||||

| A-3 | 1 (master) | Horiz. | 9/2.5 | 1.2 | 5.8 | 2.4 | 1.6 |

| 2 (slave) | 1.3 | ||||||

| A-4 | 1 (master) | 7.7/1.8 | 1.6 | 2.6 | 1.9 | 2.0 | |

| 2 (slave) | 1.5 | ||||||

| Check Plane | Point Cloud | Orient | Approx. Dist. From Station 1/Dice 1 (m) | RMSE (mm) | |||

|---|---|---|---|---|---|---|---|

| Before Regist. (In Its Own Standalone Point Cloud) | After Die-Based Regist. (Without Dim. Calibration) | After Die-Based Regist. (With Dim. Calibration) | After Spherical Target (6) Regist. | ||||

| B-1 | 1 (master) | Vert. | 9.9/5.5 | 1.5 | 4.2 | 2.3 | 1.9 |

| 2 (slave) | 1.4 | ||||||

| B-2 | 1 (master) | 9.1/5.3 | 1.8 | 3.1 | 2.1 | 2.2 | |

| 2 (slave) | 1.8 | ||||||

| B-3 | 1 (master) | Horiz. | 6.4/1.5 | 1.2 | 3.4 | 1.8 | 1.3 |

| 2 (slave) | 1.2 | ||||||

| B-4 | 1 (master) | 10/3.4 | 1.2 | 4.3 | 1.8 | 1.4 | |

| 2 (slave) | 1.2 | ||||||

| Check Plane | Point Cloud | Orient | Approx. Dist. From Station 1/Dice 1 (m) | RMSE (mm) | |||

|---|---|---|---|---|---|---|---|

| Before Regist. (In Its Own Standalone Point Cloud) | After Die-Based Regist. (Without Dim. Calibration) | After Die-Based Regist. (With Dim. Calibration) | After Spherical Target (6) Regist. | ||||

| C-1 | 1 (master) | Vert. | 3.2/2.4 | 1.5 | 5.8 | 2.1 | 1.7 |

| 2 (slave) | 0.9 | ||||||

| C-2 | 1 (master) | 5.2/2.6 | 1.1 | 3.3 | 2.3 | 1.9 | |

| 2 (slave) | 1.5 | ||||||

| C-3 | 1 (master) | Horiz. | 2.5/0.5 | 1.3 | 4.5 | 1.7 | 1.9 |

| 2 (slave) | 1.2 | ||||||

| C-4 | 1 (master) | 5/1.8 | 1.2 | 3.4 | 1.6 | 1.7 | |

| 2 (slave) | 1.5 | ||||||

| Check Plane | Point Cloud | Orient | Approx. Dist. From Station 1/Dice 1 (m) | RMSE (mm) | |||

|---|---|---|---|---|---|---|---|

| Before Regist. (In Its Own Standalone Point Cloud) | After Die-Based Regist. (Without Dim. Calibration) | After Die-Based Regist. (With Dim. Calibration) | After Spherical Target (6) Regist. | ||||

| D-1 | 1 (master) | Vert. | 5.5/2.8 | 1.6 | 3.5 | 2.2 | 1.7 |

| 2 (slave) | 0.8 | ||||||

| D-2 | 1 (master) | 3.1/1.8 | 1.5 | 2.8 | 2.4 | 2.1 | |

| 2 (slave) | 1.2 | ||||||

| D-3 | 1 (master) | Horiz. | 2.9/1.2 | 1.2 | 5.5 | 1.6 | 1.7 |

| 2 (slave) | 1.3 | ||||||

| D-4 | 1 (master) | 6.3/3.2 | 0.9 | 5.5 | 1.6 | 1.8 | |

| 2 (slave) | 1.0 | ||||||

| Datasets | Point Cloud | Angle between Facets (XY/XZ/YZ) (°) | Original Die Side Length (m) | Average Side Length after Calibration (m) |

|---|---|---|---|---|

| A | 1 (master) | 90.1\89.6\90.1 | 0.500 | 0.480 |

| 2 (slave) | 90.4\90.3\89.5 | |||

| B | 1 (master) | 90.5\90.6\90.4 | 0.500 | 0.488 |

| 2 (slave) | 89.7\89.2\89.8 | |||

| C | 1 (master) | 89.1\89.6\88.3 | 0.500 | 0.489 |

| 2 (slave) | 90.2\89.8\89.3 | |||

| D | 1 (master) | 89.1\89.6\88.3 | 0.300 | 0.281 |

| 2 (slave) | 90.3\89.5\89.7 |

| Datasets | Registration Result (before Dim. Calibration) | Registration Result (after Dim. Calibration) |

|---|---|---|

| A |  |  |

| B |  |  |

| C |  |  |

| D |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, T.O.; Xia, L.; Lichti, D.D.; Wang, X.; Peng, X.; Cai, Y.; Li, M.H. A Method for Turning a Single Low-Cost Cube into a Reference Target for Point Cloud Registration. Appl. Sci. 2023, 13, 1306. https://doi.org/10.3390/app13031306

Chan TO, Xia L, Lichti DD, Wang X, Peng X, Cai Y, Li MH. A Method for Turning a Single Low-Cost Cube into a Reference Target for Point Cloud Registration. Applied Sciences. 2023; 13(3):1306. https://doi.org/10.3390/app13031306

Chicago/Turabian StyleChan, Ting On, Linyuan Xia, Derek D. Lichti, Xuanqi Wang, Xiong Peng, Yuezhen Cai, and Ming Ho Li. 2023. "A Method for Turning a Single Low-Cost Cube into a Reference Target for Point Cloud Registration" Applied Sciences 13, no. 3: 1306. https://doi.org/10.3390/app13031306

APA StyleChan, T. O., Xia, L., Lichti, D. D., Wang, X., Peng, X., Cai, Y., & Li, M. H. (2023). A Method for Turning a Single Low-Cost Cube into a Reference Target for Point Cloud Registration. Applied Sciences, 13(3), 1306. https://doi.org/10.3390/app13031306