Topology Optimization of an Aerospace Bracket: Numerical and Experimental Investigation

Abstract

:1. Introduction

2. Materials and Methods

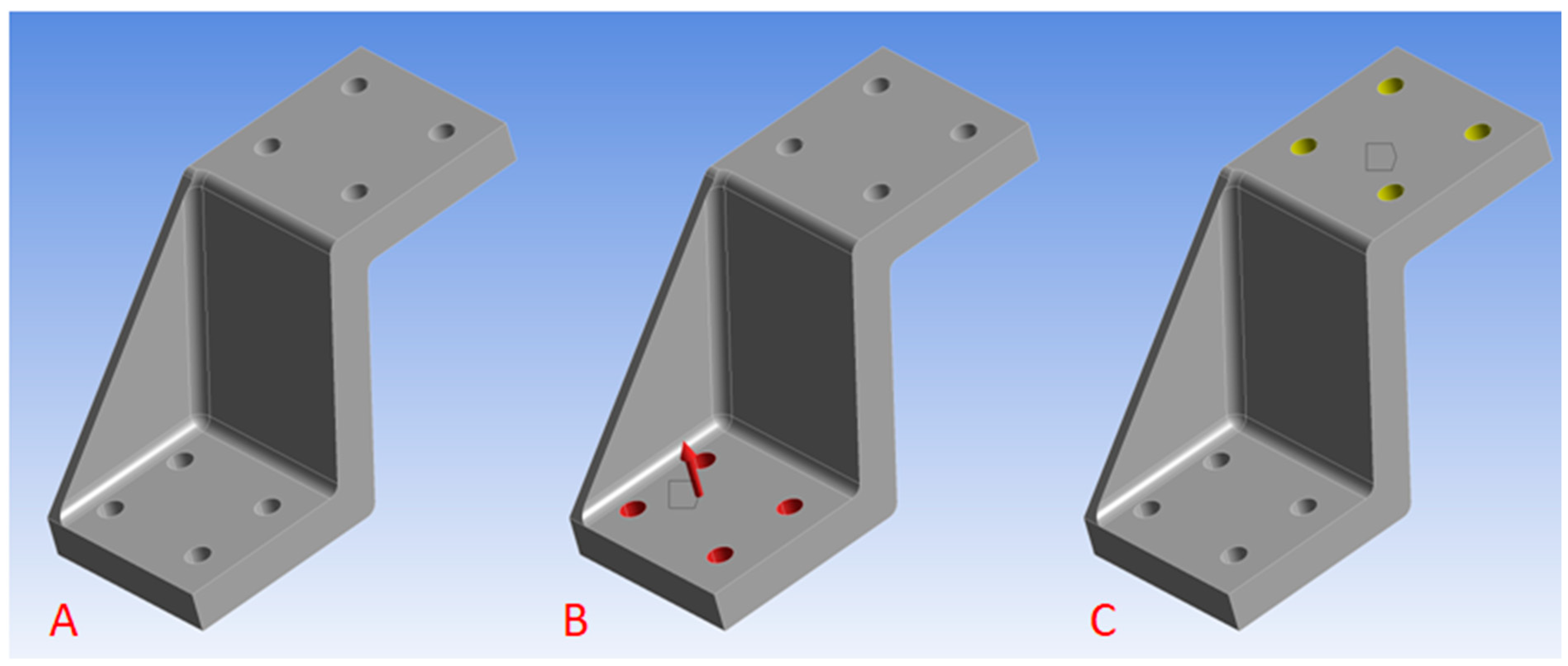

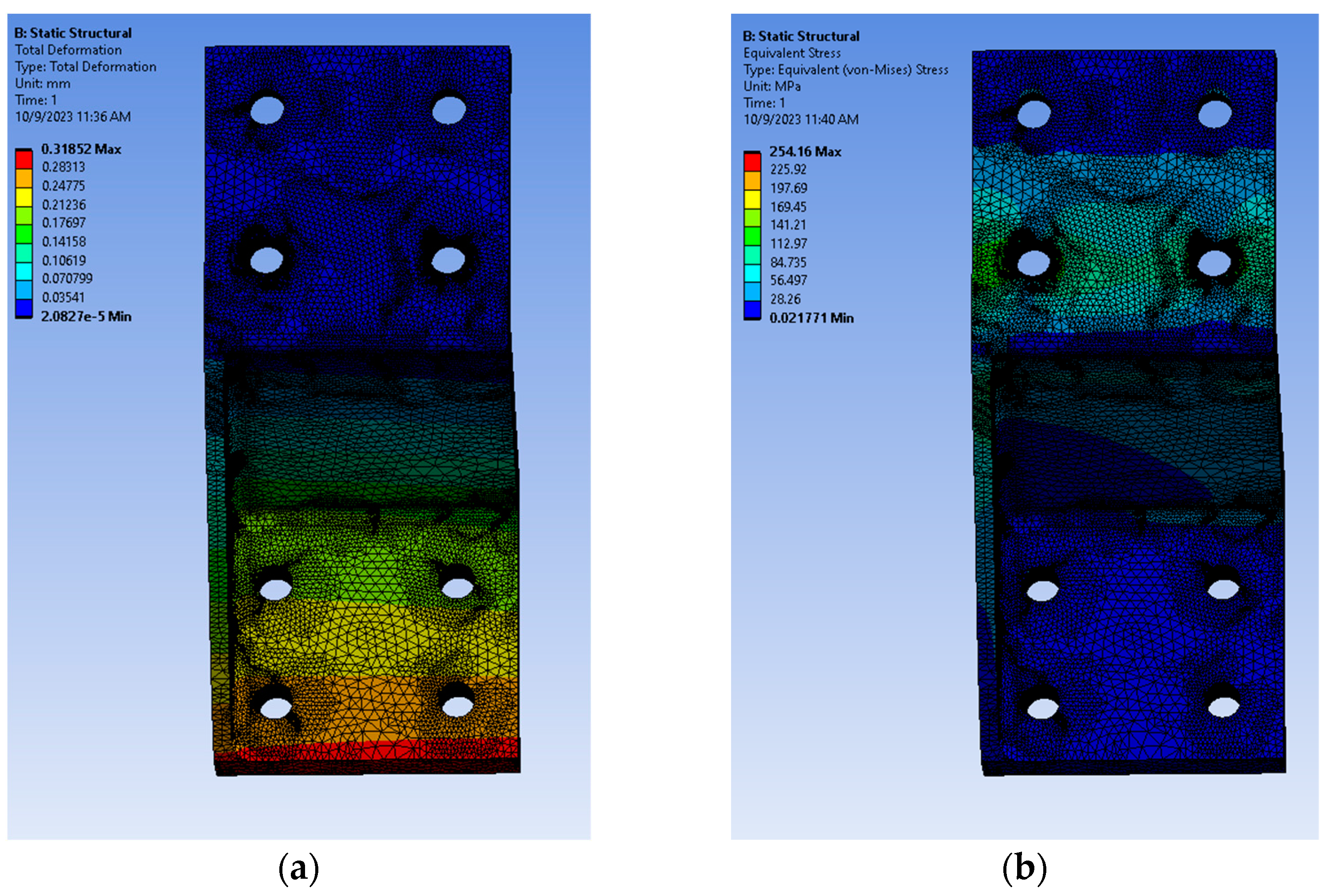

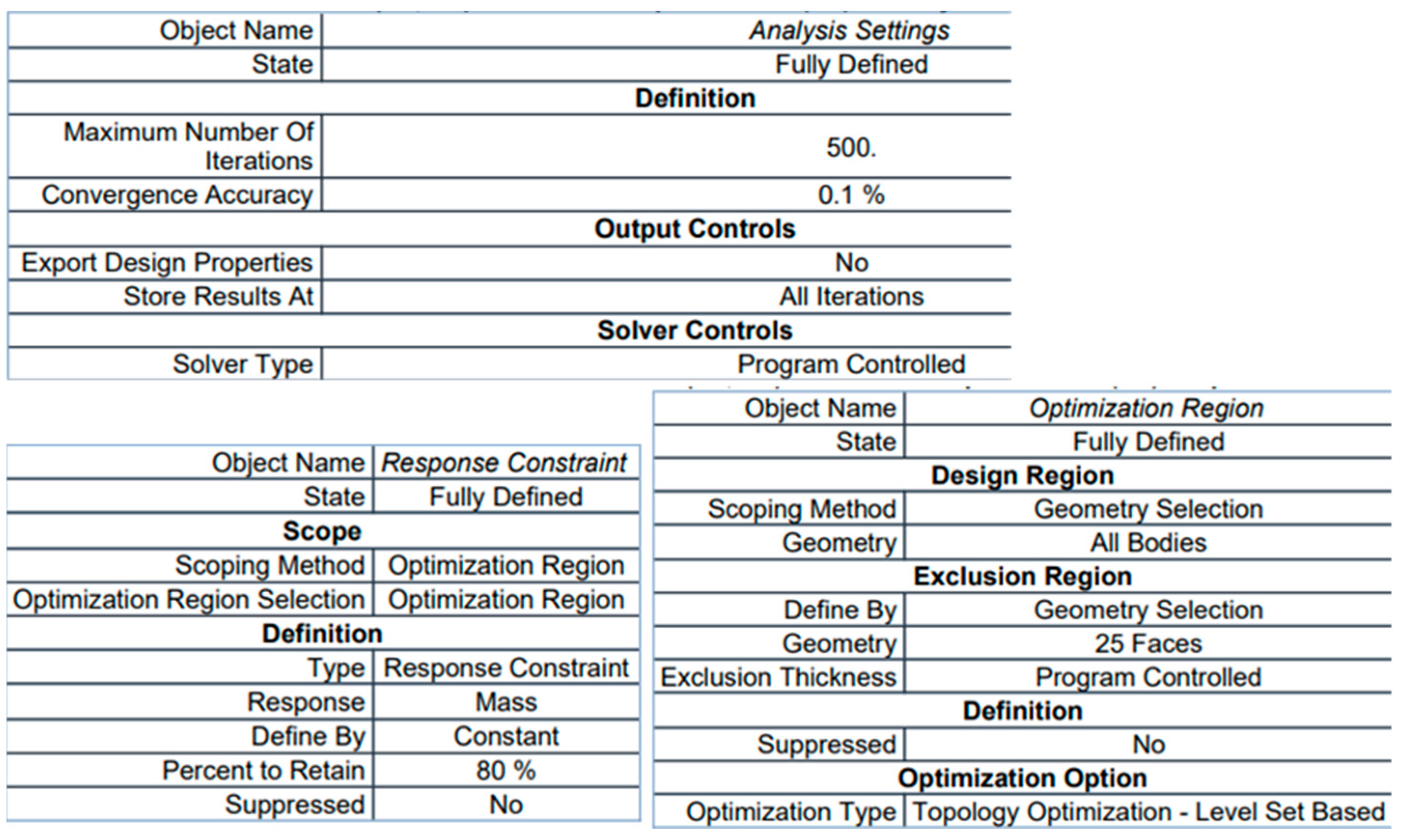

2.1. ANSYS Static Structural Setup for Topology Optimization Analysis

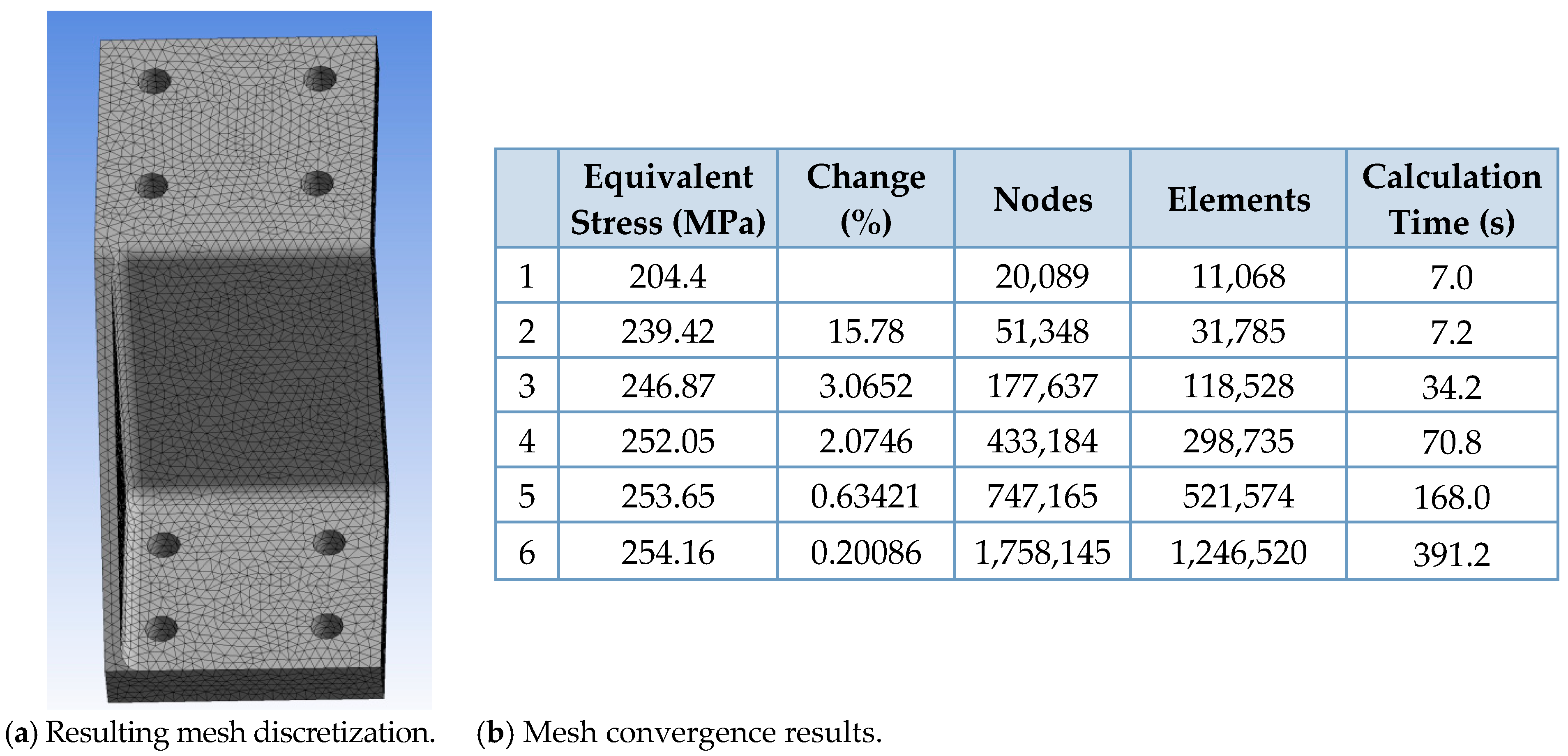

2.2. Mesh Refinement

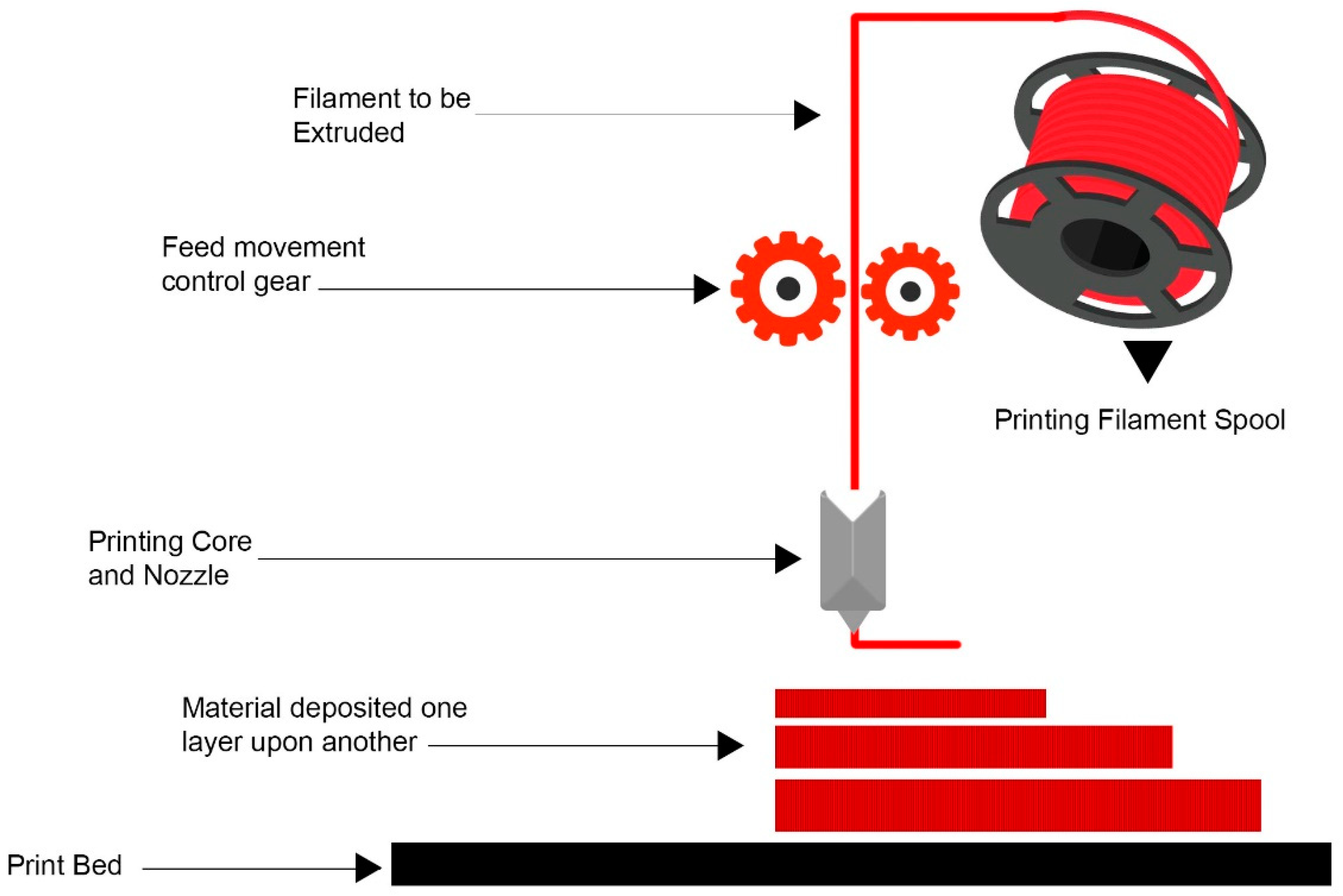

2.3. Fused Deposition Modeling

2.4. Additive Manufacturing of Parts

- The infill density and its pattern affect the mechanical properties of the FDM 3D-printed part [43].

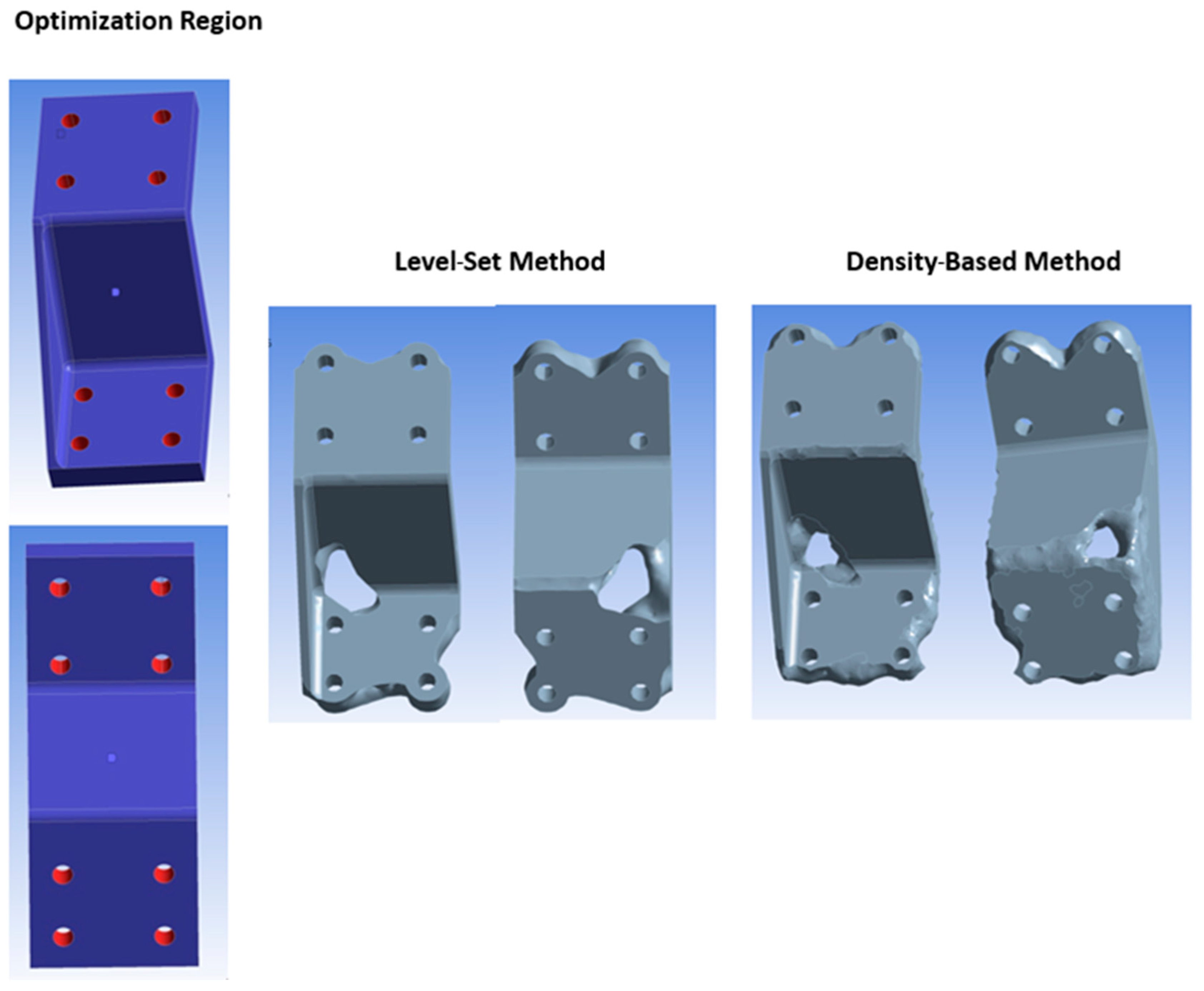

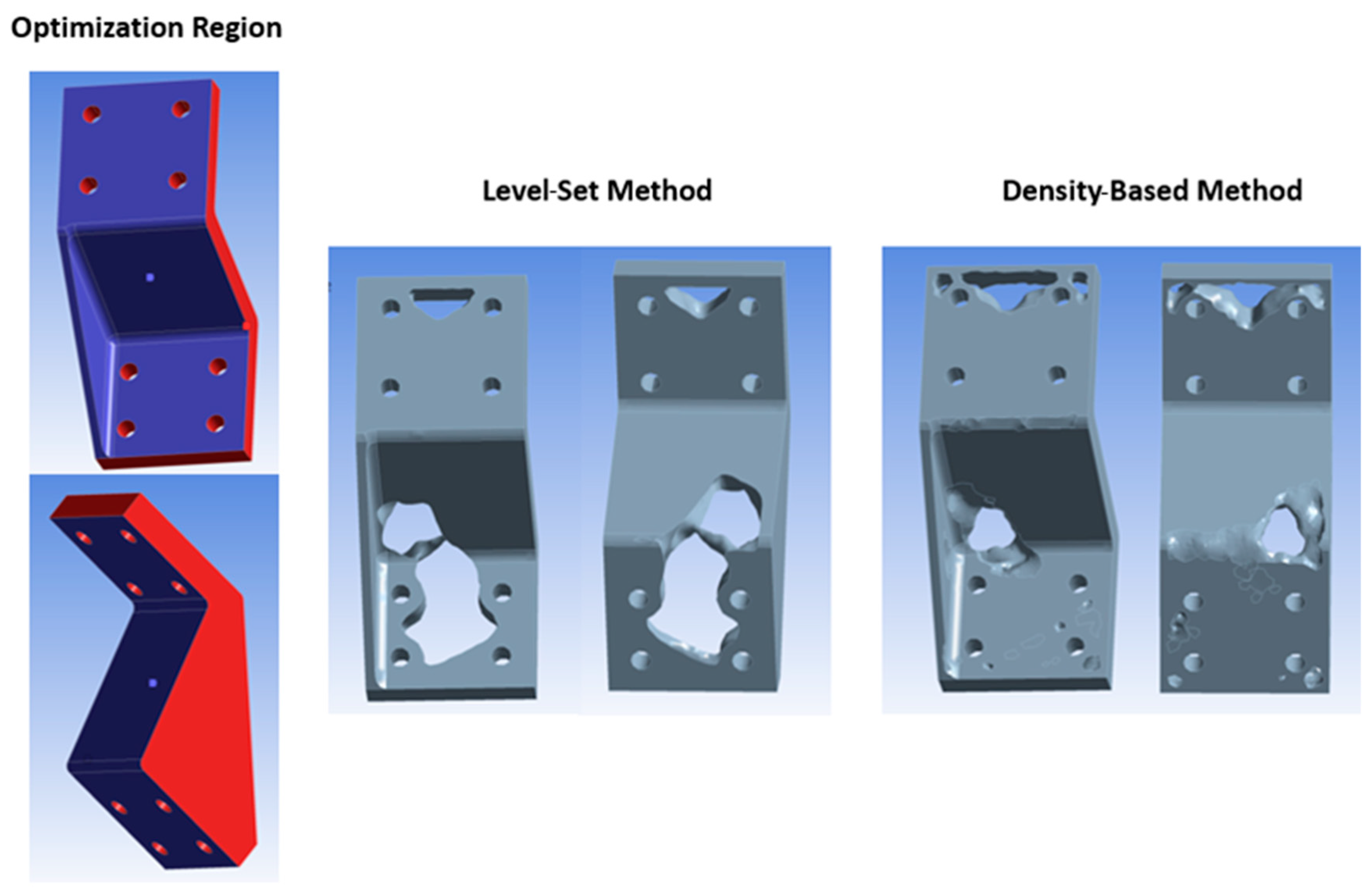

3. Results and Discussion

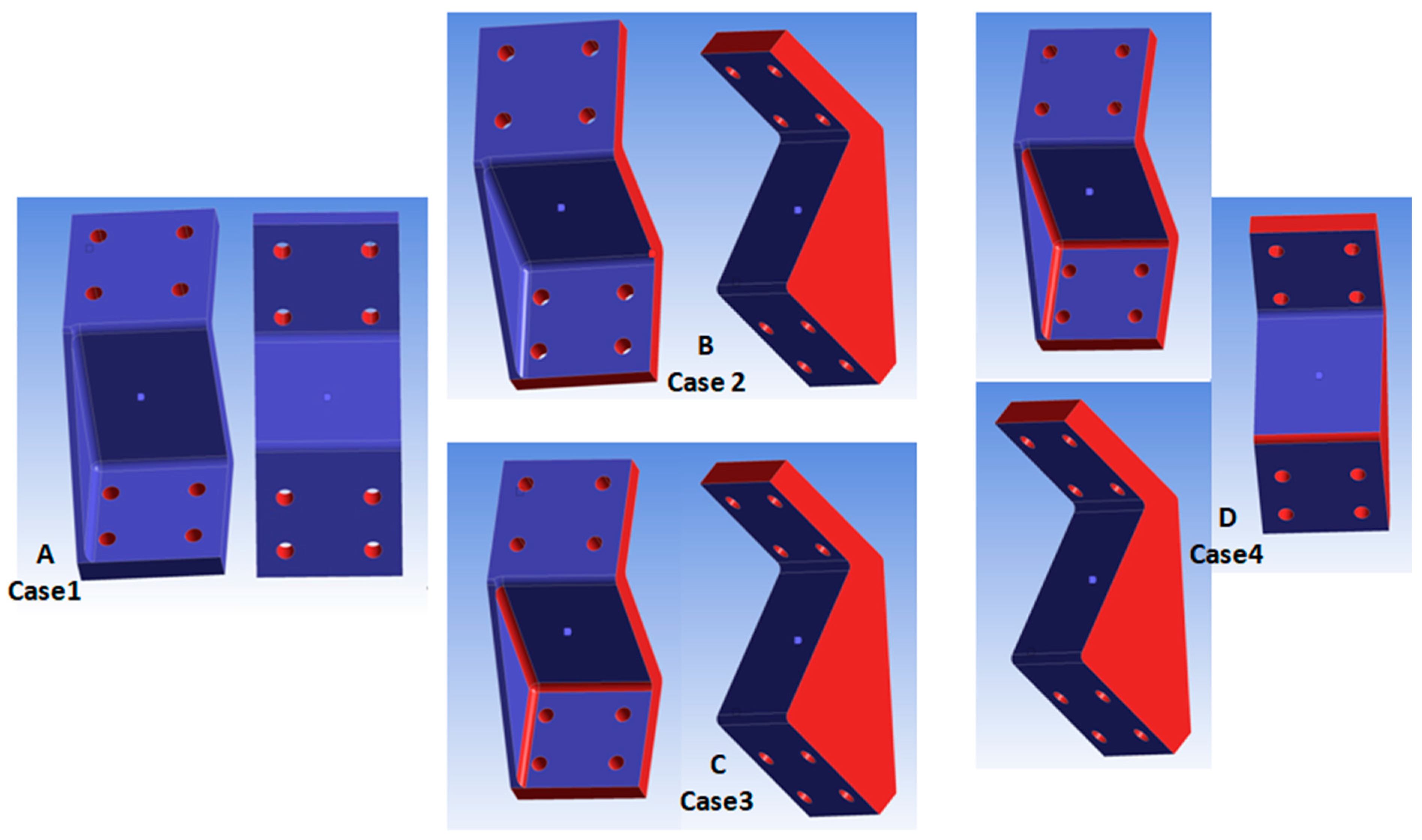

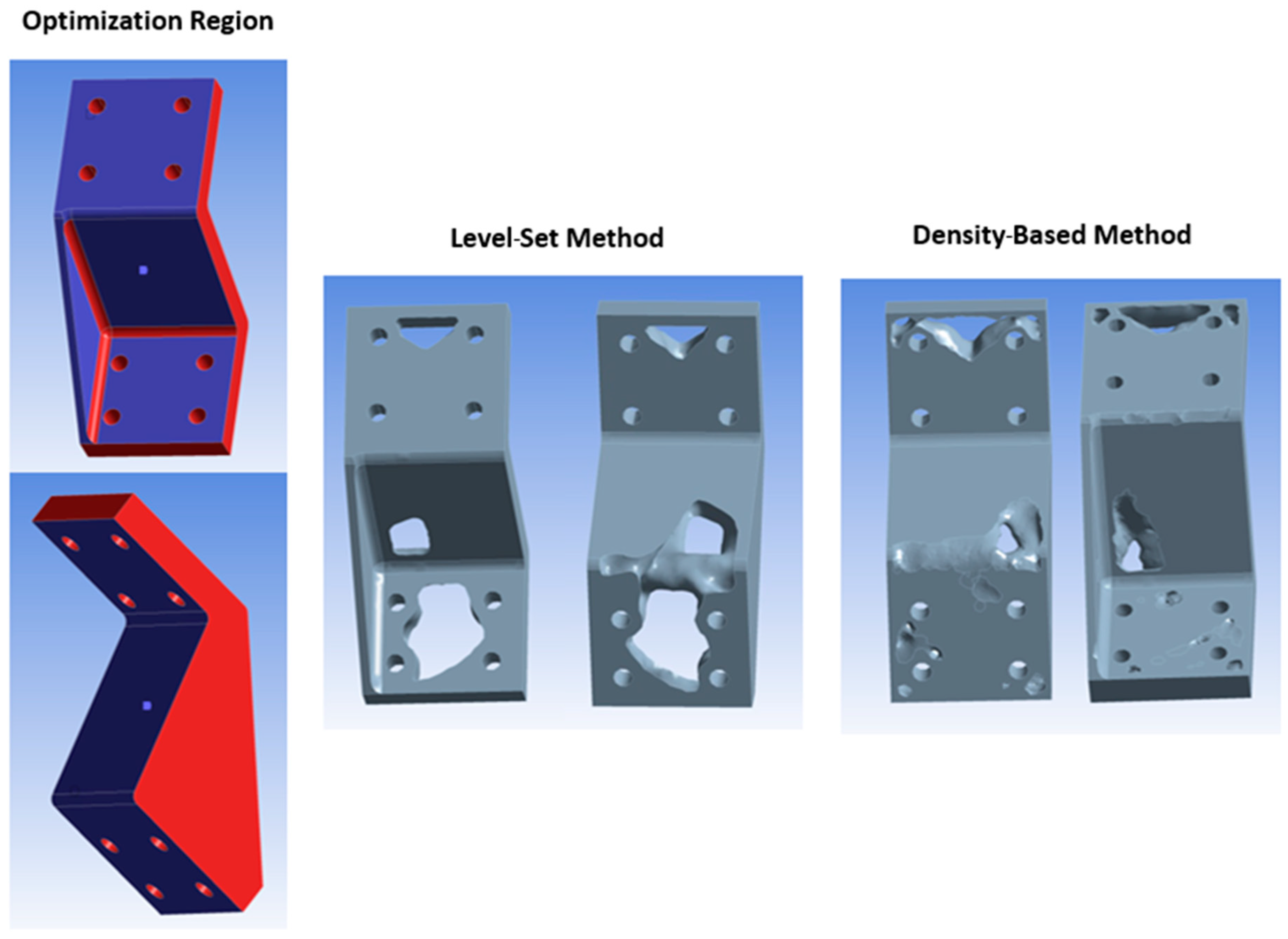

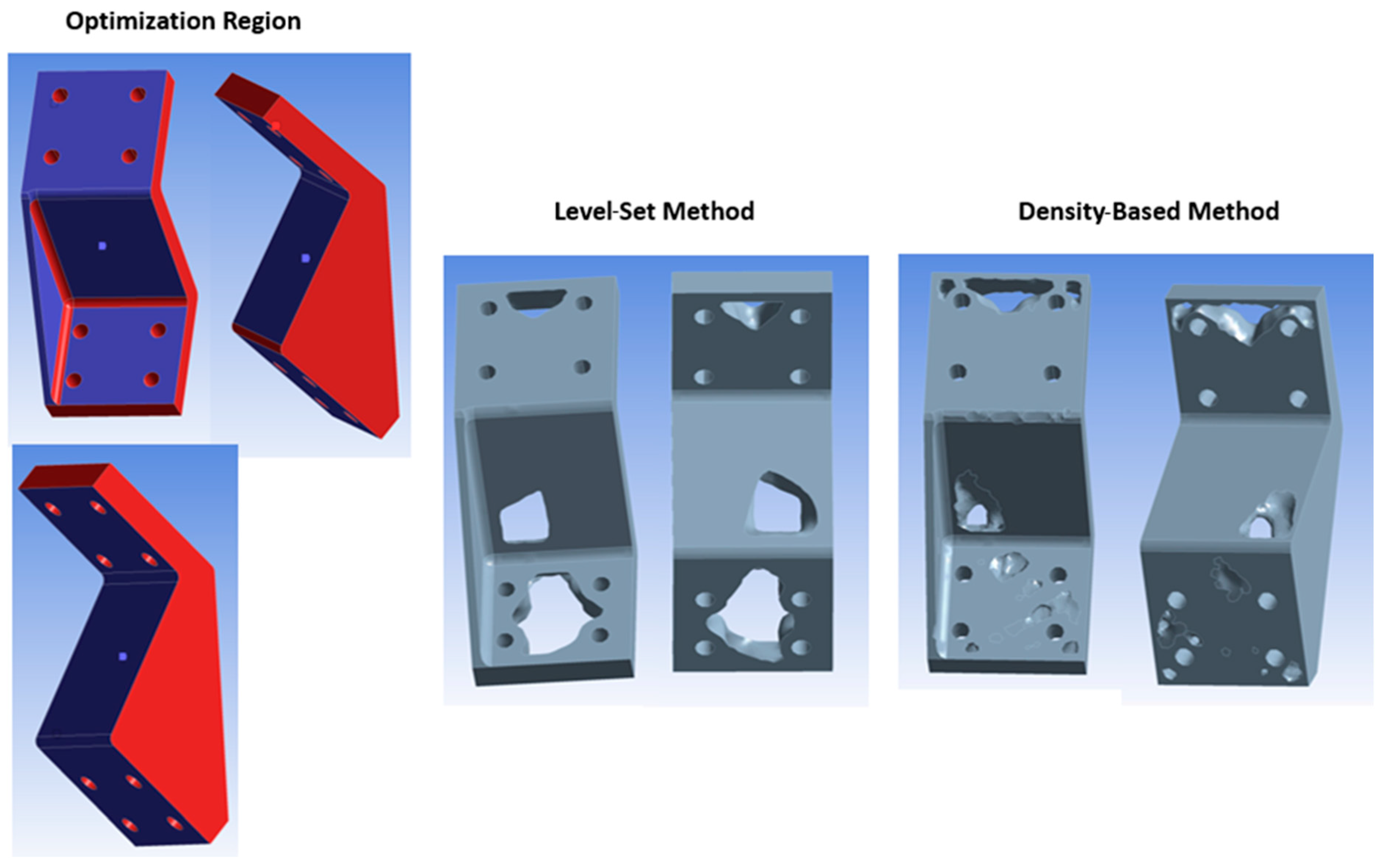

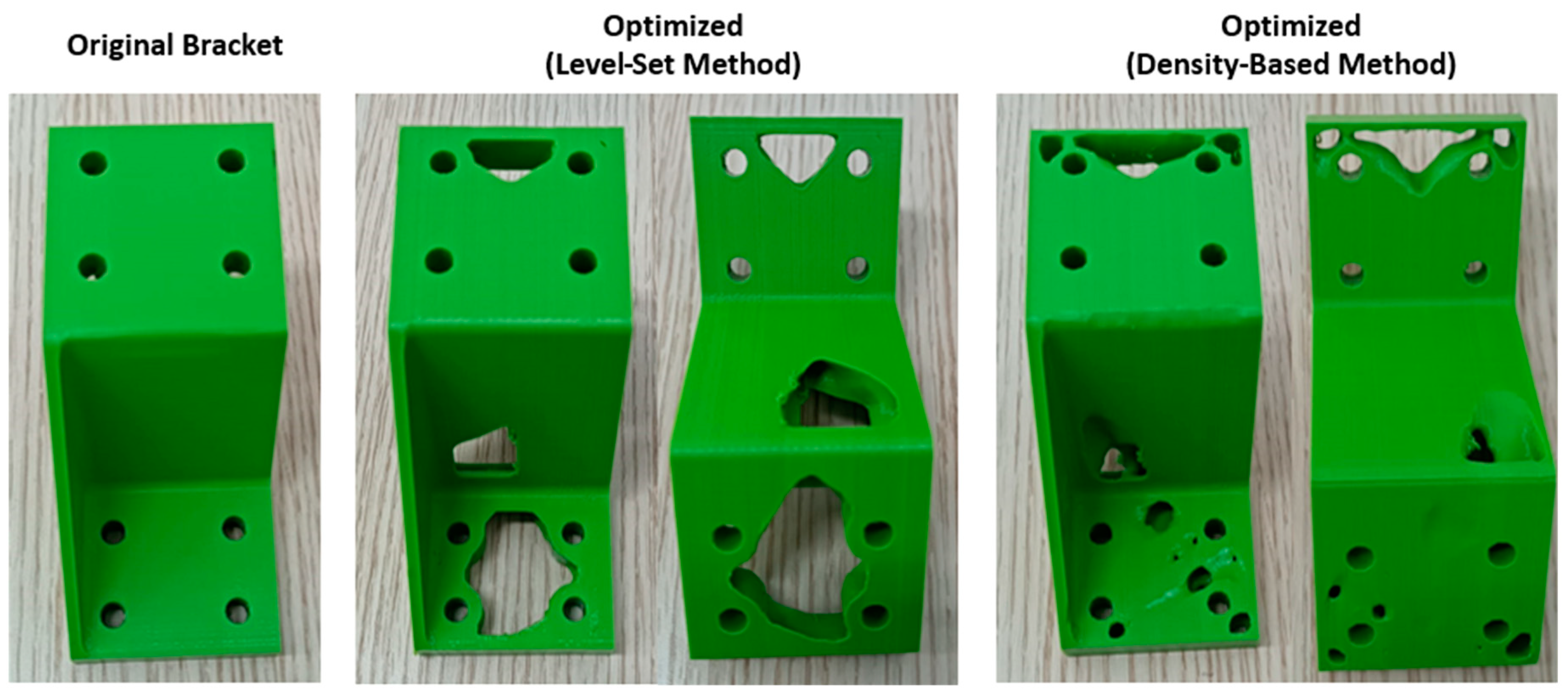

3.1. Optimization Results

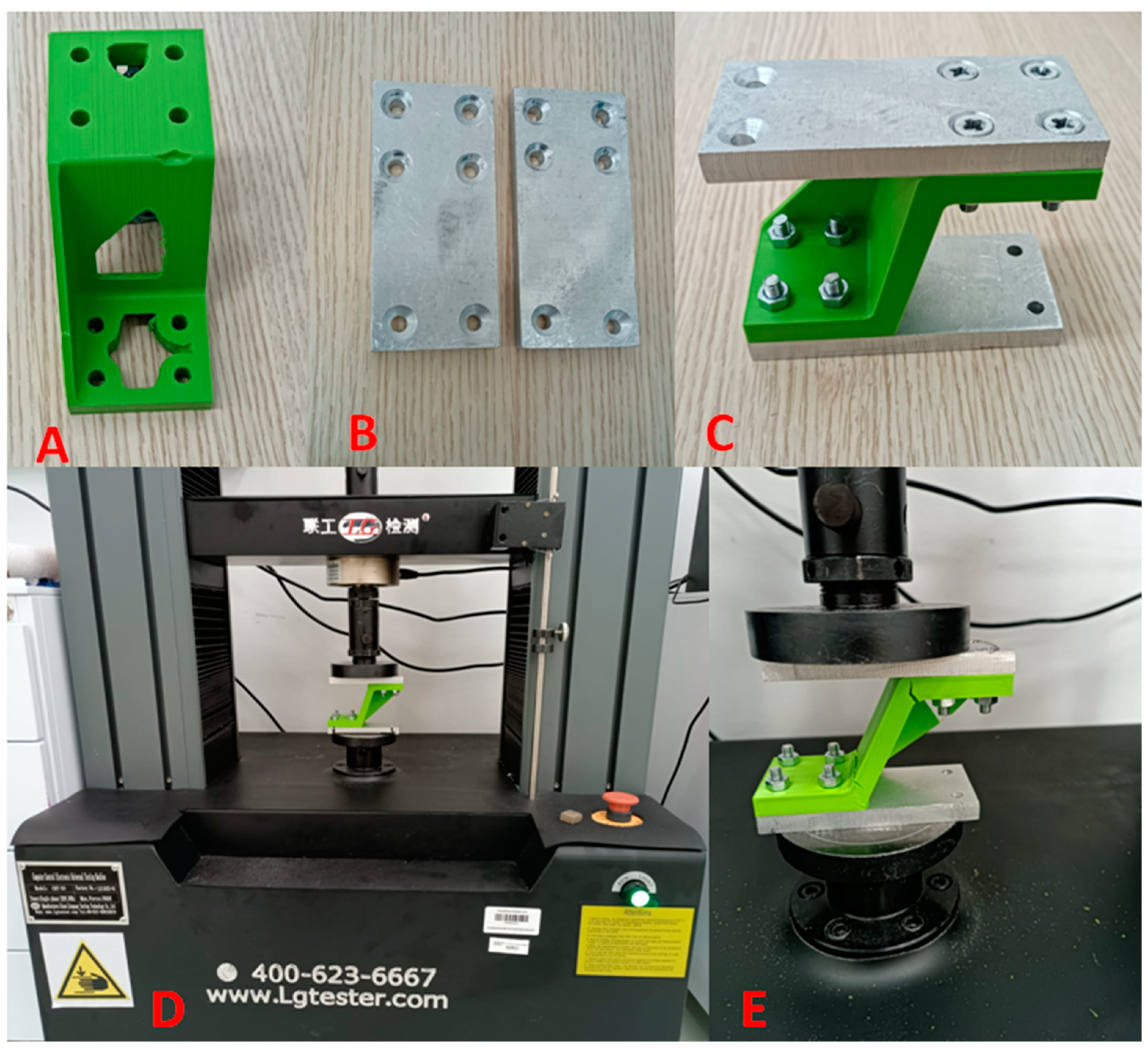

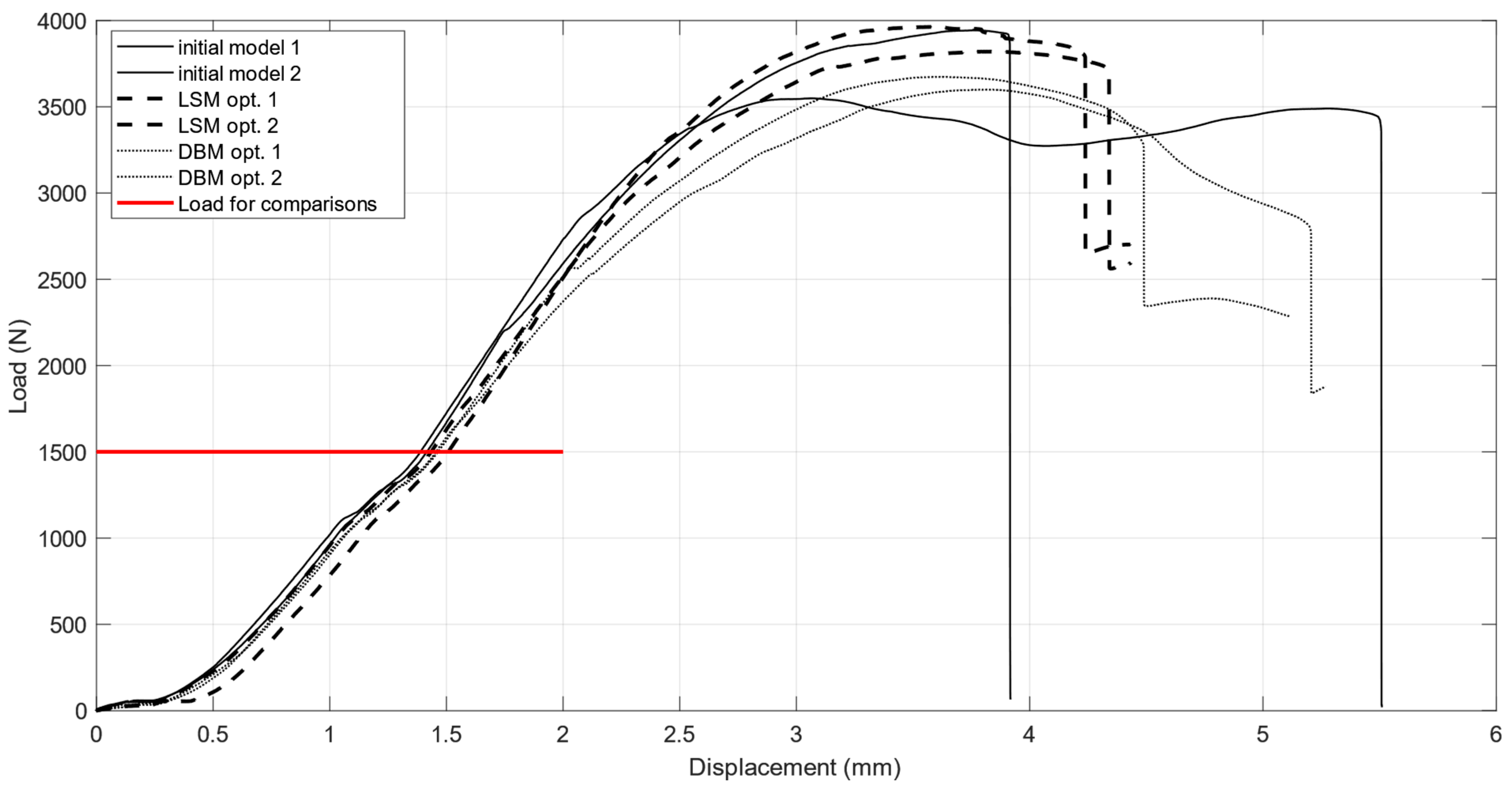

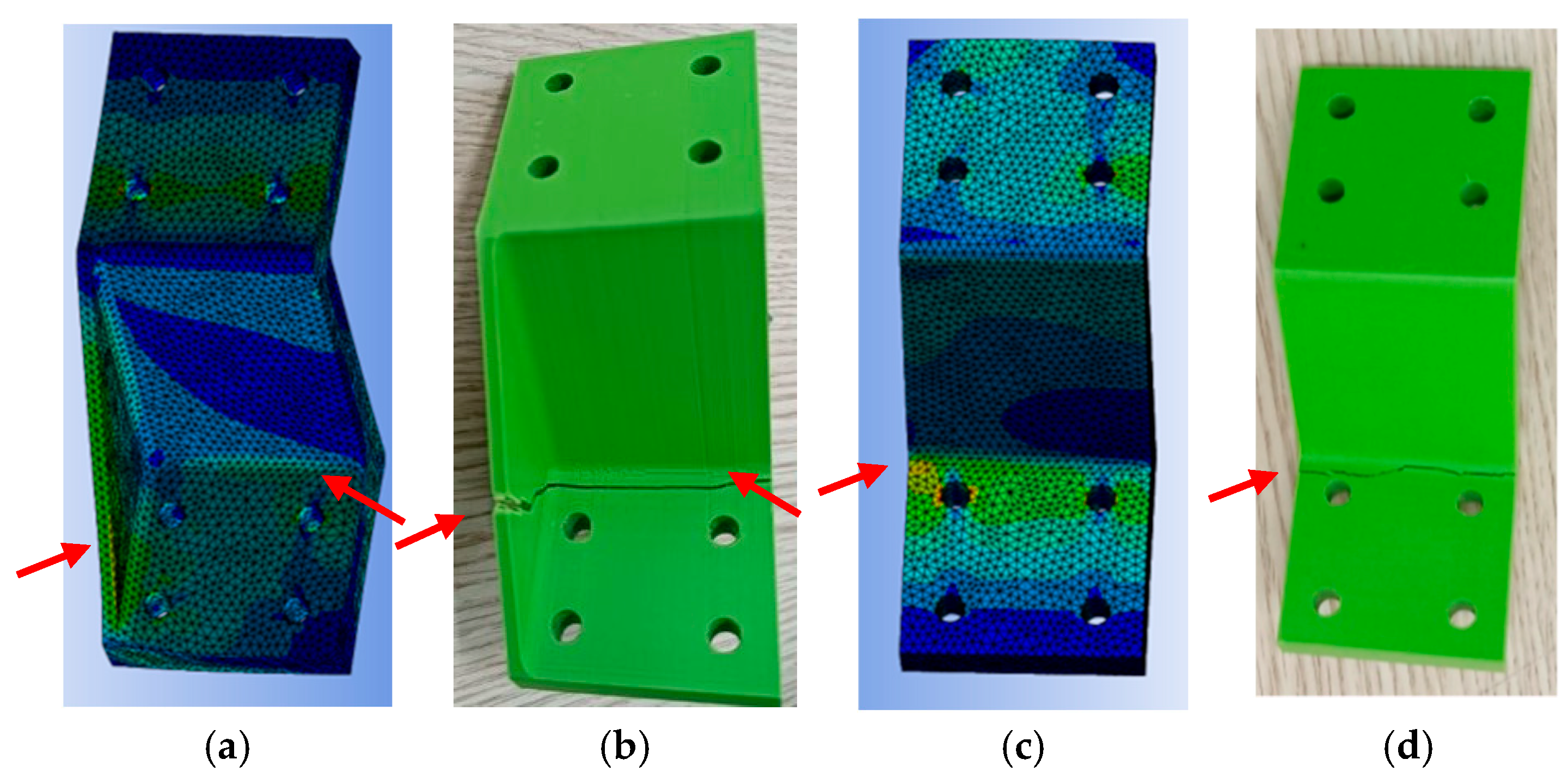

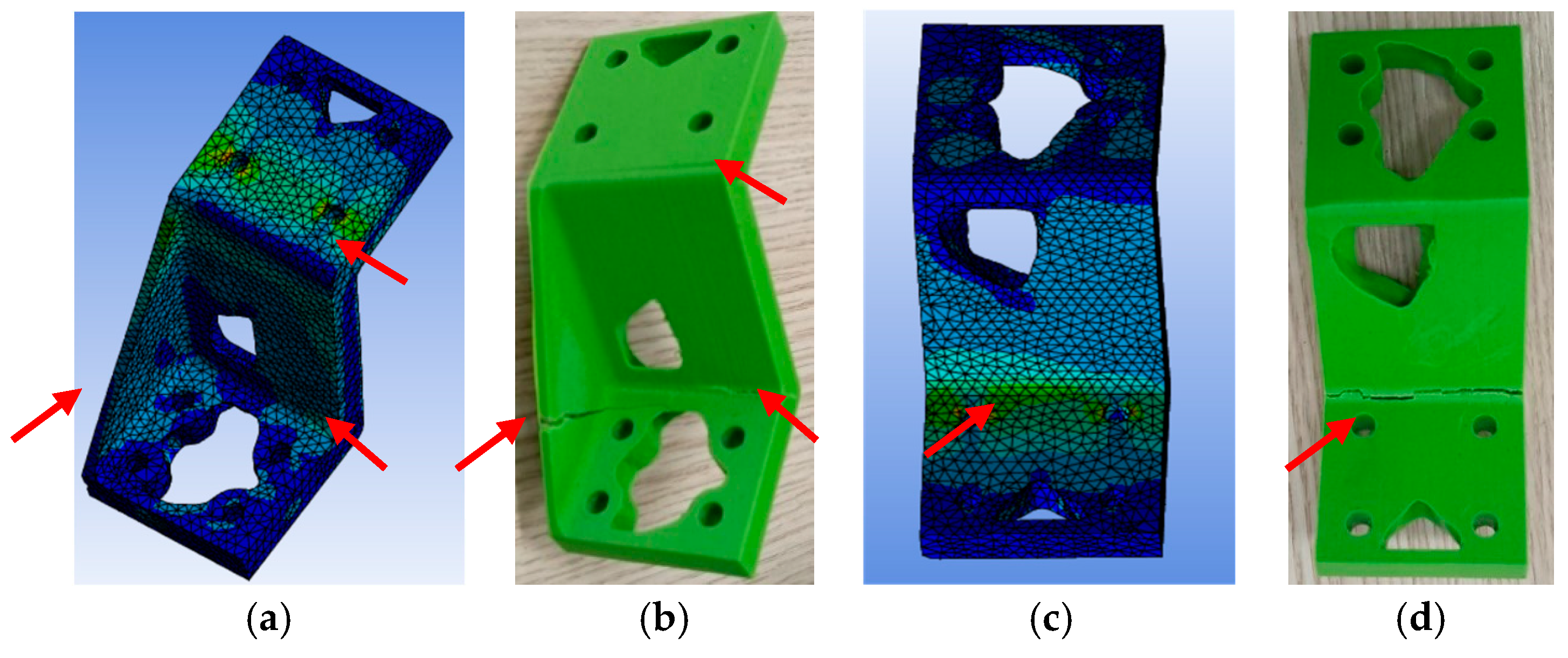

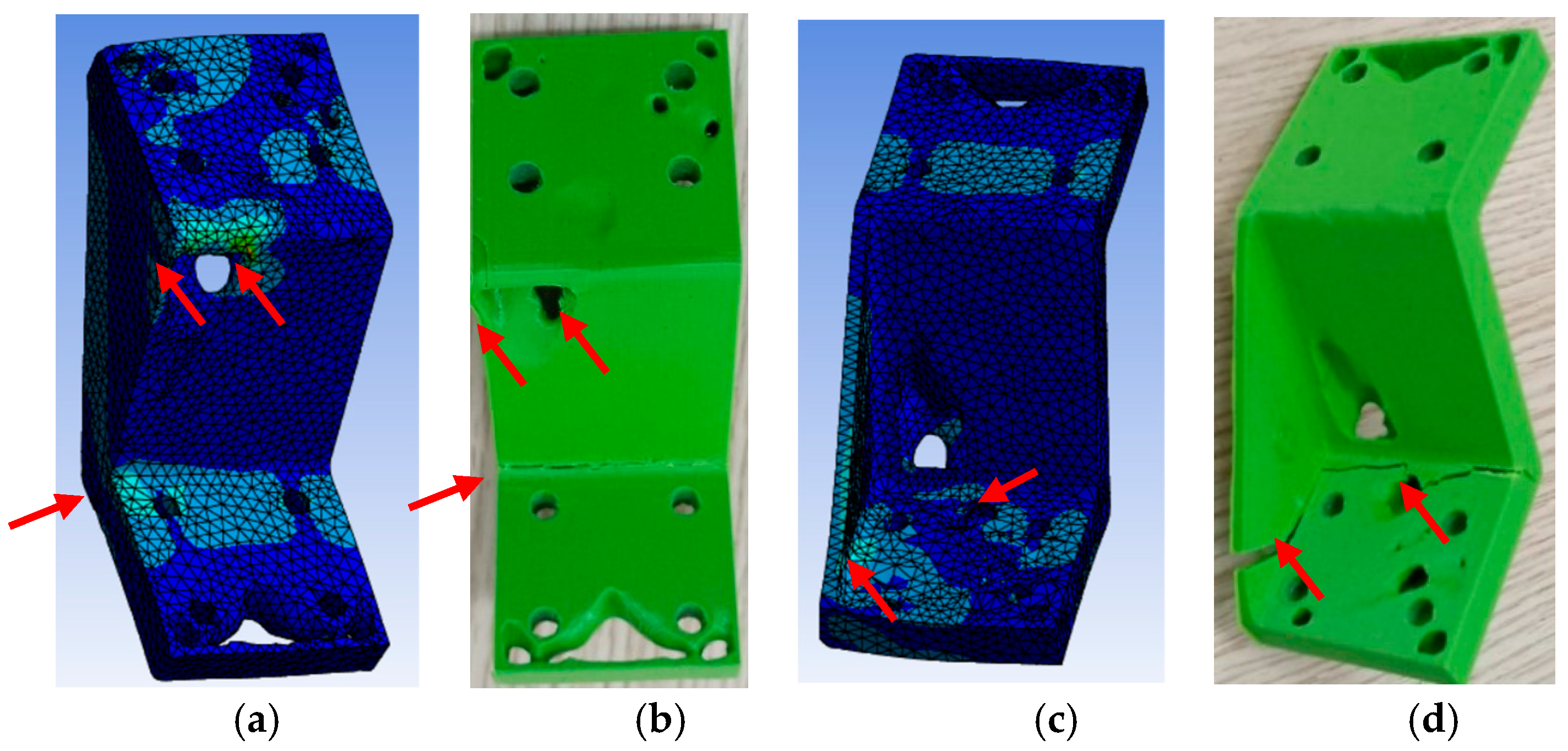

3.2. Experimental Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Society of Manufacturing Engineers and SME. Additive Manufacturing Glossary. Available online: https://www.sme.org/technologies/additive-manufacturing-glossary/ (accessed on 22 November 2022).

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- ASTM F2792-12a; Standard Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012.

- Ali, M.H.; Batai, S.; Sarbassov, D. 3D printing: A critical review of current development and future prospects. Rapid Prototyp. J. 2019, 25, 1108–1126. [Google Scholar] [CrossRef]

- Diegel, O.; Kristav, P.; Motte, D.; Kianian, B. Additive manufacturing and its effect on sustainable design. In Environmental Footprints and Eco-Design of Products and Processes; SGS Hong Kong Limited: Hong Kong, China, 2016. [Google Scholar] [CrossRef]

- Bhuvanesh, M.K.; Sathiya, P. Methods and materials for additive manufacturing: A critical review on advancements and challenges. Thin-Walled Struct. 2021, 159, 107228. [Google Scholar] [CrossRef]

- Thomas, D. Costs, benefits, and adoption of additive manufacturing: A supply chain perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef] [PubMed]

- Pérez, M.; Carou, D.; Rubio, E.M.; Teti, R. Current advances in additive manufacturing. Procedia CIRP 2020, 88, 439–444. [Google Scholar] [CrossRef]

- Sabiston, G.; Kim, I.Y. 3D topology optimization for cost and time minimization in additive manufacturing. Struct. Multidiscip. Optim. 2020, 61, 731–748. [Google Scholar] [CrossRef]

- Kazybek, K.; Konstantinos, K.; Didier, T. Topology Optimization for Additive Manufacturing. In Proceedings of the EUSPEN, Advancing Precision in Additive Manufacturing, Virtual, 21–23 September 2021; EUSPEN: St. Gallen, Switzerland, 2021. Available online: https://www.euspen.eu/events/sig-meeting-additive-manufacturing-2021/?subid=sig-meeting-additive-manufacturing-2021 (accessed on 8 September 2023).

- Formlabs, Topology Optimization 101: How to Use Algorithmic Models to Create Lightweight Design. Available online: https://formlabs.com/blog/topology-optimization/ (accessed on 8 September 2023).

- Prathyusha, A.L.R.; Raghu Babu, G. A review on additive manufacturing and topology optimization process for weight reduction studies in various industrial applications. Mater. Today Proc. 2022, 62, 109–117. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Querin, O.M.; Victoria, M.; Alonso, C.; Ansola, R.; Martí, P. Topology Design Methods for Structural Optimization; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Dems, K. First- and second-order shape sensitivity analysis of structures. Struct. Optim. 1991, 3, 79–88. [Google Scholar] [CrossRef]

- Sigmund, O.; Maute, K. Topology optimization approaches: A comparative review. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 1988, 71, 197–224. [Google Scholar] [CrossRef]

- Bendsøe, M.P. Optimal shape design as a material distribution problem. Struct. Optim. 1989, 1, 193–202. [Google Scholar] [CrossRef]

- Van Dijk, N.P.; Langelaar, M.; van Keulen, F. Critical Study of Design Parametrization in Topology Optimization: The influence of design parametrization on local minima. In Proceedings of the 2nd International Conference on Engineering Optimization, Lisbon, Portugal, 6–9 September 2010. [Google Scholar]

- Van Dijk, N.P.; Maute, K.; Langelaar, M.; Van Keulen, F. Level-set methods for structural topology optimization: A review. Struct. Multidiscip. Optim. 2013, 48, 437–472. [Google Scholar] [CrossRef]

- Wang, M.Y.; Wang, X.; Guo, D. A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 2003, 192, 227–246. [Google Scholar] [CrossRef]

- Allaire, G.; Jouve, F.; Toader, A.M. Structural optimization using sensitivity analysis and a level-set method. J. Comput. Phys. 2004, 194, 363–393. [Google Scholar] [CrossRef]

- Osher, S.; Sethian, J.A. Fronts propagating with curvature-dependent speed: Algorithms based on Hamilton-Jacobi formulations. J. Comput. Phys. 1988, 79, 12–49. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Sigmund, O. Optimization of Structural and Mechanical Systems; World Scientific: Singapore, 2007. [Google Scholar]

- Huang, X.; Xie, Y.M. A further review of ESO type methods for topology optimization. Struct. Multidiscip. Optim. 2010, 41, 671–683. [Google Scholar] [CrossRef]

- Dunning, P.D.; Kim, H.A. Introducing the sequential linear programming level-set method for topology optimization. Struct. Multidiscip. Optim. 2015, 51, 631–643. [Google Scholar] [CrossRef]

- Haveroth, G.A.; Thore, C.J.; Correa, M.R.; Ausas, R.F.; Jakobsson, S.; Cuminato, J.A.; Klarbring, A. Topology optimization including a model of the layer-by-layer additive manufacturing process. Comput. Methods Appl. Mech. Eng. 2022, 398, 115203. [Google Scholar] [CrossRef]

- Lee, H.H. Finite Element Simulations with ANSYS Workbench 18; SDC Publications: Mission, KA, USA, 2018. [Google Scholar]

- Thompson, M.K.; Thompson, J.M. ANSYS Mechanical APDL for Finite Element Analysis; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Bacciaglia, A.; Ceruti, A.; Liverani, A. A systematic review of voxelization method in additive manufacturing. Mech. Ind. 2019, 20, 630. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Bhardwaj, A.; Verma, S. Additive Manufacturing: A 3-Dimensional Approach in Periodontics. J. Adv. Med. Med. Res. 2020, 32, 105–117. [Google Scholar] [CrossRef]

- Rouf, S.; Malik, A.; Singh, N.; Raina, A.; Naveed, N.; Siddiqui, M.I.H.; Haq, M.I.U. Additive manufacturing technologies: Industrial and medical applications. Sustain. Oper. Comput. 2022, 3, 258–274. [Google Scholar] [CrossRef]

- Ultimaker. UltiMaker Cura 5.3.0. Available online: https://github.com/Ultimaker/Cura/releases/tag/5.3.0-beta.1 (accessed on 8 September 2023).

- Ultimaker. Ultimaker Material, PLA. Available online: https://ultimaker.com/materials/pla (accessed on 8 September 2023).

- Rayegani, F.; Onwubolu, G.C. Fused deposition modelling (fdm) process parameter prediction and optimization using group method for data handling (gmdh) and differential evolution (de). Int. J. Adv. Manuf. Technol. 2014, 73, 509–519. [Google Scholar] [CrossRef]

- Galetto, M.; Verna, E.; Genta, G. Effect of process parameters on parts quality and process efficiency of fused deposition modeling. Comput. Ind. Eng. 2021, 156, 107238. [Google Scholar] [CrossRef]

- UKEssays. Principles of Additive Manufacturing. Available online: https://www.ukessays.com/essays/engineering/principles-of-additive-manufacturing-engineering-essay.php?vref=1 (accessed on 8 September 2023).

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Improving dimensional accuracy of Fused Deposition Modelling processed part using grey Taguchi method. Mater. Des. 2009, 30, 4243–4252. [Google Scholar] [CrossRef]

- Nuţă, A.B.; Ulmeanu, M.E.; Doicin, C.V. Design for 3D Printing: Case study for a cold plastic deformation mould. MATEC Web Conf. 2021, 343, 04008. [Google Scholar] [CrossRef]

- 3D Hubs. The Impact of Layer Height on a 3D Print. Available online: https://www.3dhubs.com/knowledge-base/impact-layer-height-3d-print/ (accessed on 8 September 2023).

- Luzanin, O.; Guduric, V.; Ristic, I.; Muhic, S. Investigating impact of five build parameters on the maximum flexural force in FDM specimens—A definitive screening design approach. Rapid Prototyp. J. 2017, 23, 1088–1098. [Google Scholar] [CrossRef]

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A review on the various processing parameters in FDM. Mater. Today Proc. 2020, 37, 509–514. [Google Scholar] [CrossRef]

- Alafaghani, A.; Qattawi, A. Investigating the effect of fused deposition modeling processing parameters using Taguchi design of experiment method. J. Manuf. Process. 2018, 36, 164–174. [Google Scholar] [CrossRef]

| Nr. | Original | Optimized (LSM) | Optimized (DBM) |

|---|---|---|---|

| 1 | 1.25 | 1.47 | 1.9 |

| 2 | 1.39 | 1.44 | 1.47 |

| 3 | 1.46 | 1.51 | 1.46 |

| 4 | 1.71 | 1.44 | 1.56 |

| 5 | 1.42 | 1.49 | 1.43 |

| Mean | 1.45 | 1.47 | 1.56 |

| Std. Dev. | 0.150 | 0.028 | 0.174 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okorie, O.; Perveen, A.; Talamona, D.; Kostas, K. Topology Optimization of an Aerospace Bracket: Numerical and Experimental Investigation. Appl. Sci. 2023, 13, 13218. https://doi.org/10.3390/app132413218

Okorie O, Perveen A, Talamona D, Kostas K. Topology Optimization of an Aerospace Bracket: Numerical and Experimental Investigation. Applied Sciences. 2023; 13(24):13218. https://doi.org/10.3390/app132413218

Chicago/Turabian StyleOkorie, Onyekachi, Asma Perveen, Didier Talamona, and Konstantinos Kostas. 2023. "Topology Optimization of an Aerospace Bracket: Numerical and Experimental Investigation" Applied Sciences 13, no. 24: 13218. https://doi.org/10.3390/app132413218

APA StyleOkorie, O., Perveen, A., Talamona, D., & Kostas, K. (2023). Topology Optimization of an Aerospace Bracket: Numerical and Experimental Investigation. Applied Sciences, 13(24), 13218. https://doi.org/10.3390/app132413218