Impact of Storage Conditions of Yogurt Dry Ingredients on the Physicochemical Properties of the Final Product

Abstract

:1. Introduction

2. Materials and Methods

2.1. Milk Powders

2.2. Microbial Cultures

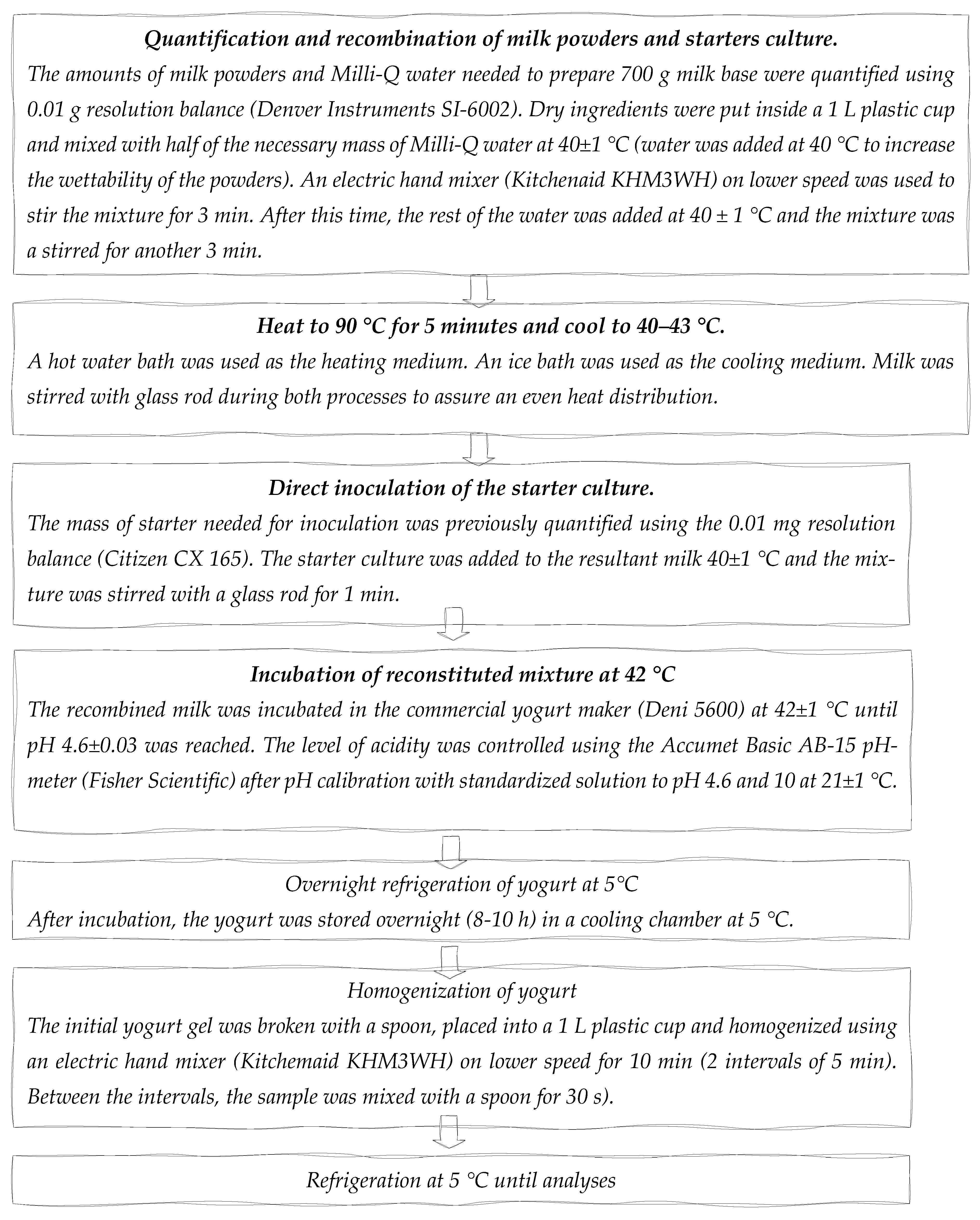

2.3. Yogurt Manufacturing

2.4. Experimental Design

2.5. Lactic Bacteria Count

2.6. Incubation Time Measurements

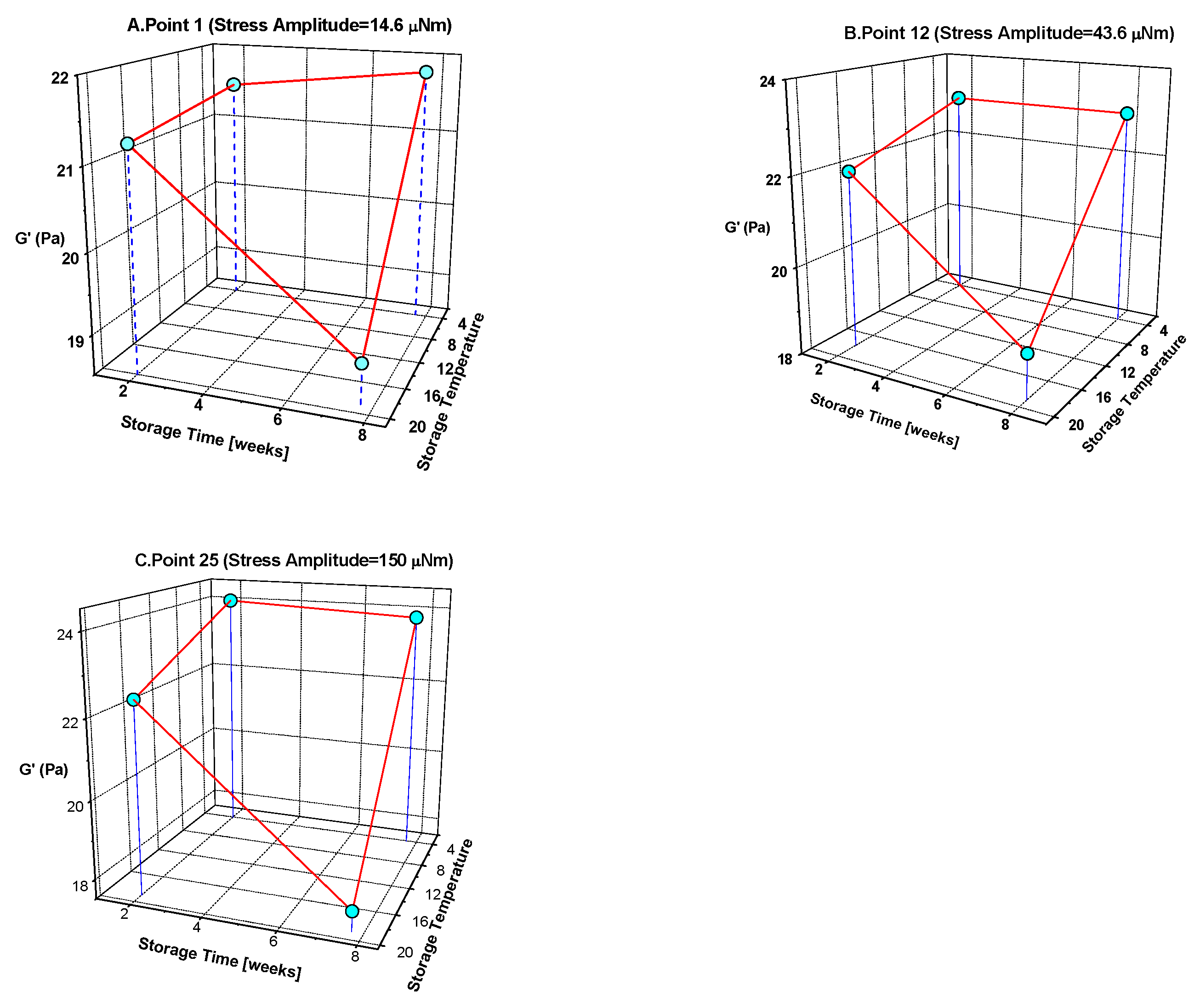

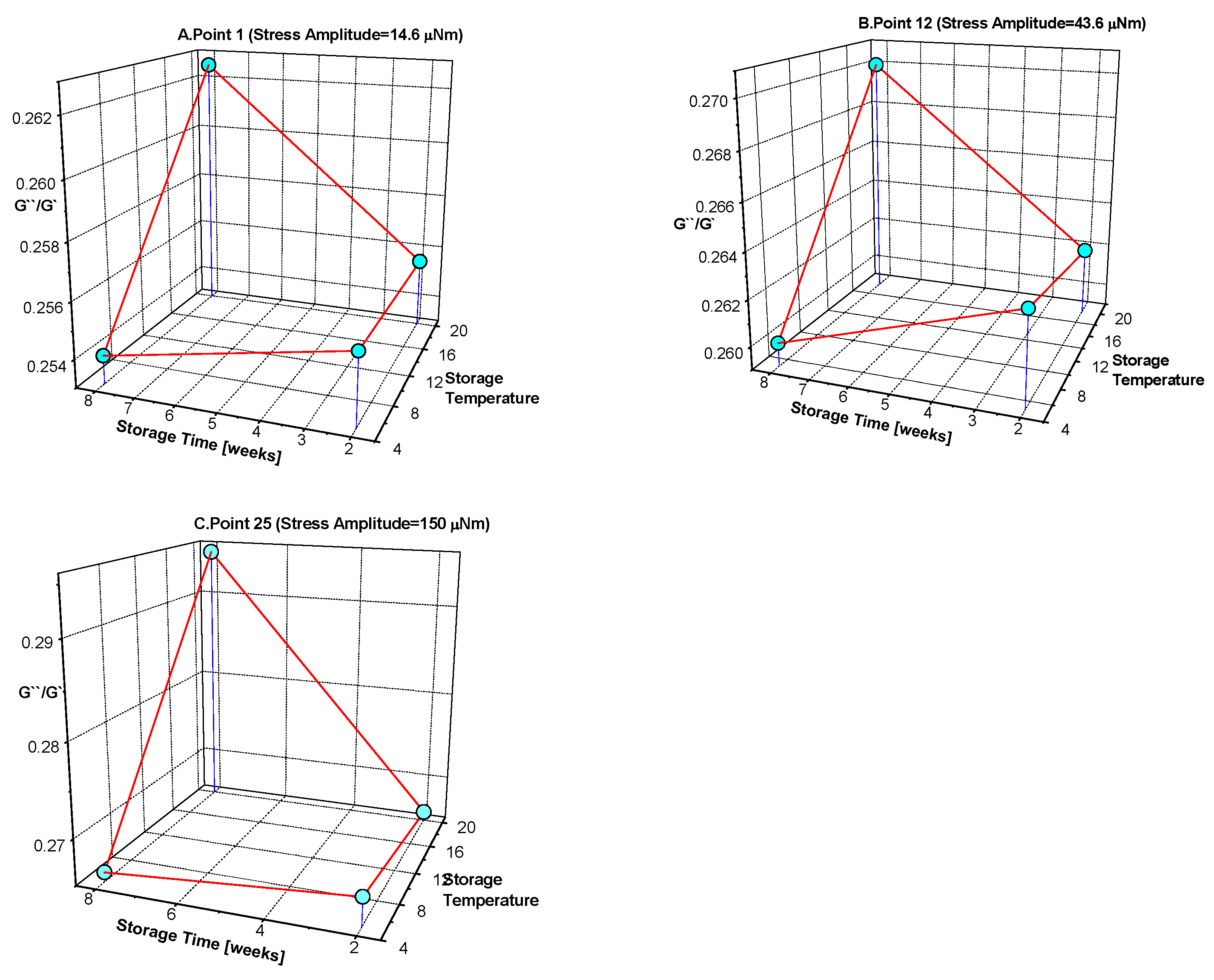

2.7. Dynamic Rheological Measurements

2.8. Ultrasonic Viscosity Measurements

2.9. Penetration Test of the Yogurt

2.10. Water Activity

2.11. Dried Yogurt Surface Topography

2.12. Statistical Analysis

3. Results and Discussion

3.1. Bacteria Count

3.2. Rheological Properties

3.3. Incubation Time

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kneifel, W. Recombined and filled milks. In Encyclopedia of Food Science, Food Technology and Nutrition; Academic Press: London, UK, 1993; pp. 4921–4926. [Google Scholar]

- Tong, P.S. Recombined and reconstituted products. In Encyclopedia of Dairy Sciences; Elsevier Science: Burlington, MA, USA, 2002; pp. 2401–2404. [Google Scholar]

- Bylund, G. Dairy Processing Handbook: Tetra Pak Processing Systems AB; Tetra Pak Processing Systems AB: Lund, Sweden, 1995; pp. 13–36. [Google Scholar]

- Kjærgaard Jensen, G. Milk powders: Specifications in relation to the products to be manufactured. In Recombination of Milk and Milk Products, Proceedings of the Seminar Organized by The International Dairy Federation and The University of Alexandria, Alexandria, Egypt, 12–16 November 1988; International Dairy Federation: Brusseles, Belgium, 1990; pp. 104–125. [Google Scholar]

- Augustin, M.A.; Margetts, C.L. Milk powders in the marketplace. In Encyclopedia of Food Sciences and Nutrition (2nd Edition); Academic Press: London, UK, 2003; pp. 4694–4702. [Google Scholar]

- Avisar, Y.K. Milk fat globule size, powder hydration time, para—casein content and textural properties of recombined white-brined cheese produced by direct recombination system. J. Food Process. Preserv. 2010, 34, 223–240. [Google Scholar] [CrossRef]

- Caric, M. Milk powders: Types and manufacture. In Encyclopedia of Dairy Sciences; Elsevier Science: Burlington, MA, USA, 2002; pp. 1869–1874. [Google Scholar]

- Jimenez-Flores, R.; Kosikowski, F.V. Properties of ultrafiltered skim milk retentate powders. J. Dairy Sci. 1986, 69, 329–339. [Google Scholar] [CrossRef]

- El-Samragy, Y.A.; Hansen, C.L.; McMahon, D.J. Production of ultrafiltered skim milk retentate powder. 1. Composition and physical properties. J. Dairy Sci. 1993, 76, 388–392. [Google Scholar] [CrossRef] [PubMed]

- El-Samragy, Y.A.; Hansen, C.L.; McMahon, D.J. Production of ultrafiltered skim milk retentate powder. 2. Functional properties. J. Dairy Sci. 1993, 76, 2886–2890. [Google Scholar] [CrossRef]

- Mistry, V.V.; Pulgar, J.B. Physical and Storage Properties of High Milk Protein Powder. Int. Dairy J. 1996, 6, 195–203. [Google Scholar] [CrossRef]

- Patocka, G.; Cervenkova, R.; Narine, S.; Jelen, P. Rheological behaviour of dairy products as affected by soluble whey protein isolate. Int. Dairy J. 2006, 16, 399–405. [Google Scholar] [CrossRef]

- Isleten, M.; Karagul-Yuceer, Y. Effects of functional dairy based proteins on nonfat yogurt quality. J. Food Qual. 2008, 31, 265–280. [Google Scholar] [CrossRef]

- Oliveira, M.N.; Sodini, I.; Remeuf, F.; Corrieu, G. Effect of milk supplementation and culture composition on acidification, textural properties and microbiological stability of fermented milks containing probiotic bacteria. Int. Dairy J. 2001, 11, 935–942. [Google Scholar] [CrossRef]

- Marafon, A.P.; Sumi, A.; Alcantara, M.R.; Tamime, A.Y.; Nogueira, O.M. Optimization of the rheological properties of probiotic yoghurts supplemented with milk proteins. LWT Food Sci. Technol. 2011, 44, 511–519. [Google Scholar] [CrossRef]

- Marafon, A.P.; Sumi, A.; Granato, D.; Alcantara, M.R.; Tamime, A.Y.; de Oliveira, M.N. Effects of partially replacing skimmed milk powder with dairy ingredients on rheology, sensory profiling, and microstructure of probiotic stirred-type yogurt during cold storage. J. Dairy Sci. 2011, 94, 5330–5340. [Google Scholar] [CrossRef]

- Mistry, V.V.; Hassan, H.N. Manufacture of nonfat yogurt from a high milk protein powder. J. Dairy Sci. 1992, 75, 947–957. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Martinez, C.; Becerra, M.; Chafer, M.; Albors, A.; Carot, J.M.; Chiralt, A. Influence of substituting milk powder for whey powder on yoghurt quality. Trends Food Sci. Technol. 2002, 13, 334–340. [Google Scholar] [CrossRef]

- Guzman-Gonzalez, M.; Morais, F.; Ramos, M.; Amigo, L. Influence of skimmed milk concentrate replacement by dry dairy-products in a low fat set-type yoghurt model system. I: Use of whey protein concentrates, milk protein concentrates and skimmed milk powder. J. Sci. Food Agric. 1999, 79, 1117–1122. [Google Scholar] [CrossRef]

- Guzman-Gonzalez, M.; Morais, F.; Amigo, L. Influence of skimmed milk concentrate replacement by dry dairy products in a low-fat set-type yoghurt model system. Use of caseinates, co-precipitate and blended dairy powders. J. Sci. Food Agric. 2000, 80, 433–438. [Google Scholar] [CrossRef]

- Tamime, A.Y.; Robinson, R.K. Microstructure of concentrated and dried milk products. In Structure of Dairy Products; Blackwell Pub.: Oxford, UK, 2007; pp. 104–133. [Google Scholar]

- Durso, L.; Hutkins, R. Starter cultures. In Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Academic Press: London, UK, 2003; pp. 5583–5593. [Google Scholar]

- Wigley, R.C. Starter cultures: Uses in the food industry. In Encyclopedia of Food Microbiology; Academic Press: London, UK, 1999; pp. 2084–2095. [Google Scholar]

- Surono, I.; Hosono, A. Starter cultures. In Encyclopedia of Dairy Sciences; Elsevier Science: Burlington, MA, USA, 2002; pp. 1023–1028. [Google Scholar]

- Powell, I.B.; Broome, M.C.; Limsowtin, G.K.Y. Starter cultures: General aspects. In Encyclopedia of Dairy Sciences; Elsevier Science: Burlington, MA, USA, 2002; pp. 261–268. [Google Scholar]

- Peighambardoust, S.H.; Golshan, T.A.; Hesari, J. Application of spray drying for preservation of lactic acid starter cultures: A review. Trends Food Sci. Technol. 2011, 22, 215–224. [Google Scholar] [CrossRef]

- Silva, J.; Freixo, R.; Gibbs, P.; Teixeira, P. Spray-drying for the production of dried cultures. Int. J. Dairy Technol. 2011, 64, 321–335. [Google Scholar] [CrossRef]

- Andersen, A.; Fog-Petersen, M.; Larsen, H.; Skibsted, L. Storage stability of freeze-dried starter cultures (Streptococcus thermophilus) as related to physical state of freezing matrix. LWT 1999, 32, 540–547. [Google Scholar] [CrossRef]

- Lee, W.J.; Lucey, J.A. Structure and physical properties of yogurt gels: Effect of inoculation rate and incubation temperature. J. Dairy Sci. 2004, 87, 3153–3164. [Google Scholar] [CrossRef]

- Jumah, R.Y.; Abu-Jdayil, B.; Shaker, R.R. Effect of type and level of starter culture on the rheological properties of set yogurt during gelation process. Int. J. Food Prop. 2001, 4, 531–544. [Google Scholar] [CrossRef]

- Sodini, I.; Remeuf, F.; Haddad, S.; Corrieu, G. The relative effect of milk base, starter, and process on yogurt texture: A review. Crit. Rev. Food Sci. Nutr. 2004, 44, 113–137. [Google Scholar] [CrossRef]

- Wu, S.; Li, D.; Yang, B.L.; Mao, Z.H.; Li, S.J.; Bhandari, B.; Chen, X.D. Effects of incubation temperature, starter culture level and total solids content on the rheological properties of yogurt. Int. J. Food Eng. 2009, 5, 1–17. [Google Scholar] [CrossRef]

- Salvador, A.; Fiszman, S.M. Textural and sensory characteristics of whole and skimmed flavored set-type yogurt during long storage. J. Dairy Sci. 2004, 87, 4033–4041. [Google Scholar] [CrossRef]

- Raikos, V.; Juskaite, L.; Vas, F.; Hayes, H.E. Physicochemical properties, texture, and probiotic survivability of oat-based yogurt using aquafaba as a gelling agent. Food Sci. Nutr. 2020, 8, 6426–6432. [Google Scholar] [CrossRef]

- Pachenari, A.; Conway, P.L.; Playne, M.J. Bifidus-blood agar a differentiatin medium for isolation and enumeration of Bifidobacteria from faecal sample. Biosci. Microflora 2011, 20, 1342–1441. [Google Scholar] [CrossRef]

- Mani-López, E.; Palou, E.; López-Malo, A. Probiotic viability and storage stability of yogurts and fermented milks prepared with several mixtures of lactic acid bacteria. J. Dairy Sci. 2014, 97, 2578–2590. [Google Scholar] [CrossRef]

- Damin, M.R.; Minowa, E.; Alcântara, M.R.; Oliveira, M.N. Effect of cold storage on culture viability and some rheological properties of fermented milk prepared with yogurt and probiotic bacteria. J. Texture Stud. 2008, 39, 40–55. [Google Scholar] [CrossRef]

- Lee, W.-J.; Lucey, J.A. Impact of Gelation Conditions and Structural Breakdown on the Physical and Sensory Properties of Stirred Yogurts. J. Dairy Sci. 2006, 89, 2374–2385. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Altintas, Z. Transglutaminase-Induced Free-Fat Yogurt Gels Supplemented with Tarragon Essential Oil-Loaded Nanoemulsions: Development, Optimization, Characterization, Bioactivity, and Storability. Gels 2022, 8, 551. [Google Scholar] [CrossRef]

- Horne, D. Casein micelle structure and stability. In Milk Proteins from Expression to Food; Academic Press: Burlington, MA, USA, 2008; pp. 133–162. [Google Scholar]

- Brodziak, A.; Król, J.; Barłowska, J.; Teter, A.; Florek, M. Changes in the Physicochemical Parameters of Yoghurts with Added Whey Protein in Relation to the Starter Bacteria Strains and Storage Time. Animals 2020, 10, 1350. [Google Scholar] [CrossRef]

- Agoda-Tandjawa, G.; Dieudé-Fauvel, E.; Girault, R.; Baudez, J.C. Using water activity measurements to evaluate rheological consistency and structure strength of sludge. J. Chem. Eng. 2013, 228, 799–805. [Google Scholar] [CrossRef]

- Kumar, K.; Gandhi, D.N. Innovative techniques in the starter culture preservation: A review. Int. J. Food Sci. Technol. 2009, 46, 190–195. [Google Scholar]

- Saxelin, M.; Grenov, B.; Svensson, U.; Fonden, R.; Reniero, R.; Mattila-Sandholm, T. The technology of probiotics. Trends Food Sci. Technol. 1999, 10, 387–392. [Google Scholar] [CrossRef]

- Saarela, M.; Virkajärvi, I.; Alakomi, H.L.; Mattila-Sandholm, T.; Vaari, A.; Suomalainen, T.; Mättö, J. Influence of fermentation time, cryoprotectant and neutralization of cell concentrate on freeze-drying survival, storage stability, and acid and bile exposure of Bifidobacterium animalis ssp. lactis cells produced without milk-based ingredients. J. Appl. Microbiol. 2005, 99, 1330–1339. [Google Scholar] [CrossRef] [PubMed]

- Achour, M.; Mtimet, N.; Cornelius, C.; Zgouli, S.; Mahjoub, A.; Thonart, P.; Hamdi, M. Application of the accelerated shelf life testing method (ASLT) to study the survival rates of freeze-dried Lactococcus starter cultures. J. Chem. Technol. Biotechnol. 2001, 76, 624–628. [Google Scholar] [CrossRef]

- Bruno, F.A.; Shah, N.P. Food microbiology and safety—Viability of two freeze-dried strains of Bifidobacterium and of commercial preparations at various temperatures during prolonged storage. J. Food Sci. 2003, 68, 2336–2339. [Google Scholar] [CrossRef]

- Santivarangkna, C.; Kulozik, U.; Foerst, P. Review article: Inactivation mechanisms of lactic acid starter cultures preserved by drying processes. J. Appl. Microbiol. 2008, 105, 1–13. [Google Scholar] [CrossRef]

- Castro, H.P.; Teixeira, P.M.; Kirby, R. Storage of lyophilized cultures of Lactobacillus bulgaricus under different relative humidities and atmospheres. Appl. Microbiol. Biotechnol. 1995, 44, 172–176. [Google Scholar] [CrossRef]

- Santivarangkna, C.; Kulozik, U.; Foerst, P. Alternative drying processes for the industrial preservation of lactic acid starter cultures. Biotechnol. Prog. 2007, 23, 302–315. [Google Scholar] [CrossRef]

| Component | MPC-85 | NaCN |

|---|---|---|

| Protein (%) | 85.0 | 88.0 |

| Lactose (%) | 7.0 | 1.0 |

| Moisture (%) | 5.5 | 6.0 |

| Fat (%) | 4.0 | 1.8 |

| Ash (%) | 8.0 | 4.2 |

| Component | Amount Present in Milk Base |

|---|---|

| Total solids (%) | 13.7 |

| Total protein (%) MPC-85: 81%; NaCN: 19% | 10.3 |

| Ratio of casein to whey protein | 6:1 |

| Lactose (%) | 2.3 |

| Fat (%) | 0.5 |

| Ash (%) | 1.1 |

| Starter culture (DCU/100 L) | 50 |

| Sample No. | Storage Temperature (°C) | Storage Time (Weeks) |

|---|---|---|

| 1 | 5 | 2 |

| 2 | 20 | 2 |

| 3 | 5 | 8 |

| 4 | 20 | 8 |

| Storage temperature (oC) | 5 | 20 | ||||

| Storage time (weeks) | 0 | 2 | 8 | 0 | 2 | 8 |

| Streptococcus thermophilus (logCFU/g) | 8.2 a (0.06) | 8.19 a (0.05) | 8.16 a (0.02) | 8.2 a (0.06) | 7.98 a (0.03) | 7.56 b (0.08) |

| Lactobacillus delbrueckii subsp. lactis Lactobacillus acidophilus (logCFU/g) | 8.54 a (0.05) | 8.49 a (0.04) | 8.47 a (0.03) | 8.54 a (0.05) | 8.07 b (0.02) | 7.85 c (0.03) |

| Bifidobacterium lactis (logCFU/g) | 8.11 a (0.05) | 8.09 a (0.04) | 8.05 a (0.03) | 8.11 a (0.05) | 7.85 b (0.03) | 7.26 c (0.07) |

| Sample No. | Firmness (N) | Surf. Roughness Rq (nm) | Ultra. Viscosity (mPas·gcm−3) | Storage Mod. at 43.6 μNm (Pa) | Tan Delta at 43.6 μNm | Water Activity |

|---|---|---|---|---|---|---|

| 1 | 0.209 *a (0.02) | 412 a (14) | 369 a (18) | 22.8 a (0.04) | 0.261 a (0.004) | 0.944 d (0.003) |

| 2 | 0.199 b (0.03) | 452 b (16) | 326 b (9) | 21.9 b (0.03) | 0.262 a (0.008) | 0.951 c (0.002) |

| 3 | 0.184 c (0.03) | 589 c (12) | 294 c (11) | 22.7 a (0.03) | 0.255 a (0.004) | 0.956 b (0.002) |

| 4 | 0.170 d (0.06) | 764 d (31) | 234 b (18) | 18.4 c (0.05) | 0.270 b (0.006) | 0.967 a (0.004) |

| Firmness (N) | Surf. Roughness Rq (nm) | Ultra. Viscosity (mPas·gcm−3) | Storage Mod. at 43.6 μNm (Pa) | Tan Delta at 43.6 μNm | Water Activity | |

|---|---|---|---|---|---|---|

| Firmness (N) | 1 | |||||

| Surf. Roughness Rq (nm) | −0.96897 | 1 | ||||

| Ultra. viscosity (mPas · gcm−3) | 0.981541 | −0.97781 | 1 | |||

| Storage mod. at 43.6 μNm (Pa) | 0.734451 | −0.84357 | 0.84474 | 1 | ||

| Tan delta at 43.6 μNm | −0.36523 | 0.536141 | −0.52787 | −0.9 | 1 | |

| Water activity | −0.97483 | 0.979971 | −0.99928 | −0.86402 | 0.55872 | 1 |

| Storage temperature (°C) | 5 | 20 | ||||

| Storage time (weeks) | 0 | 2 | 8 | 0 | 2 | 8 |

| Incubation Time (hours) | 7.2 c (0.2) | 8.1 b (0.4) | 8.4 b (0.3) | 7.2 c (0.2) | 8.6 b (0.4) | 15.6 a (3.3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Terpiłowski, K.; Lange, I.; Kowalczyk, K.; Tomczyńska-Mleko, M.; Sapiga, V.; Wesołowska-Trojanowska, M.; Mleko, S.; Pérez-Huertas, S. Impact of Storage Conditions of Yogurt Dry Ingredients on the Physicochemical Properties of the Final Product. Appl. Sci. 2023, 13, 13201. https://doi.org/10.3390/app132413201

Terpiłowski K, Lange I, Kowalczyk K, Tomczyńska-Mleko M, Sapiga V, Wesołowska-Trojanowska M, Mleko S, Pérez-Huertas S. Impact of Storage Conditions of Yogurt Dry Ingredients on the Physicochemical Properties of the Final Product. Applied Sciences. 2023; 13(24):13201. https://doi.org/10.3390/app132413201

Chicago/Turabian StyleTerpiłowski, Konrad, Ignace Lange, Krzysztof Kowalczyk, Marta Tomczyńska-Mleko, Viktoria Sapiga, Marta Wesołowska-Trojanowska, Stanisław Mleko, and Salvador Pérez-Huertas. 2023. "Impact of Storage Conditions of Yogurt Dry Ingredients on the Physicochemical Properties of the Final Product" Applied Sciences 13, no. 24: 13201. https://doi.org/10.3390/app132413201

APA StyleTerpiłowski, K., Lange, I., Kowalczyk, K., Tomczyńska-Mleko, M., Sapiga, V., Wesołowska-Trojanowska, M., Mleko, S., & Pérez-Huertas, S. (2023). Impact of Storage Conditions of Yogurt Dry Ingredients on the Physicochemical Properties of the Final Product. Applied Sciences, 13(24), 13201. https://doi.org/10.3390/app132413201