A Study of the Characteristics of Micro-Seismic (ME) and Electromagnetic Radiation (EMR) Signals under the Static Load Conditions of Rocks

Abstract

:1. Introduction

2. Objective and Research Motivation

3. Materials and Methodology

3.1. Preparation of Specimen

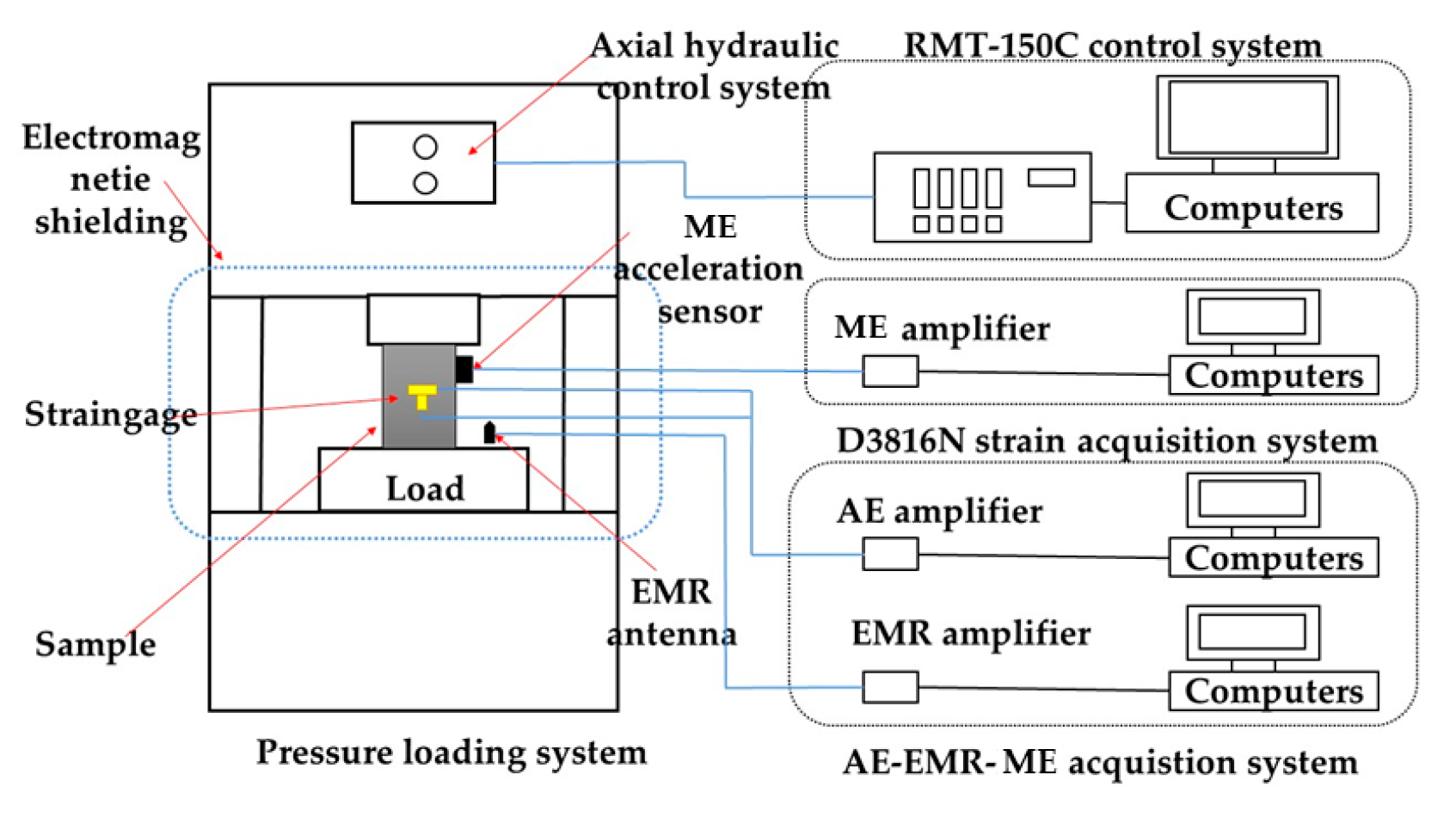

3.2. Testing System

3.3. Procedure of Test

3.4. Fracture of Specimen

4. Test Results: Analysis and Interpretation

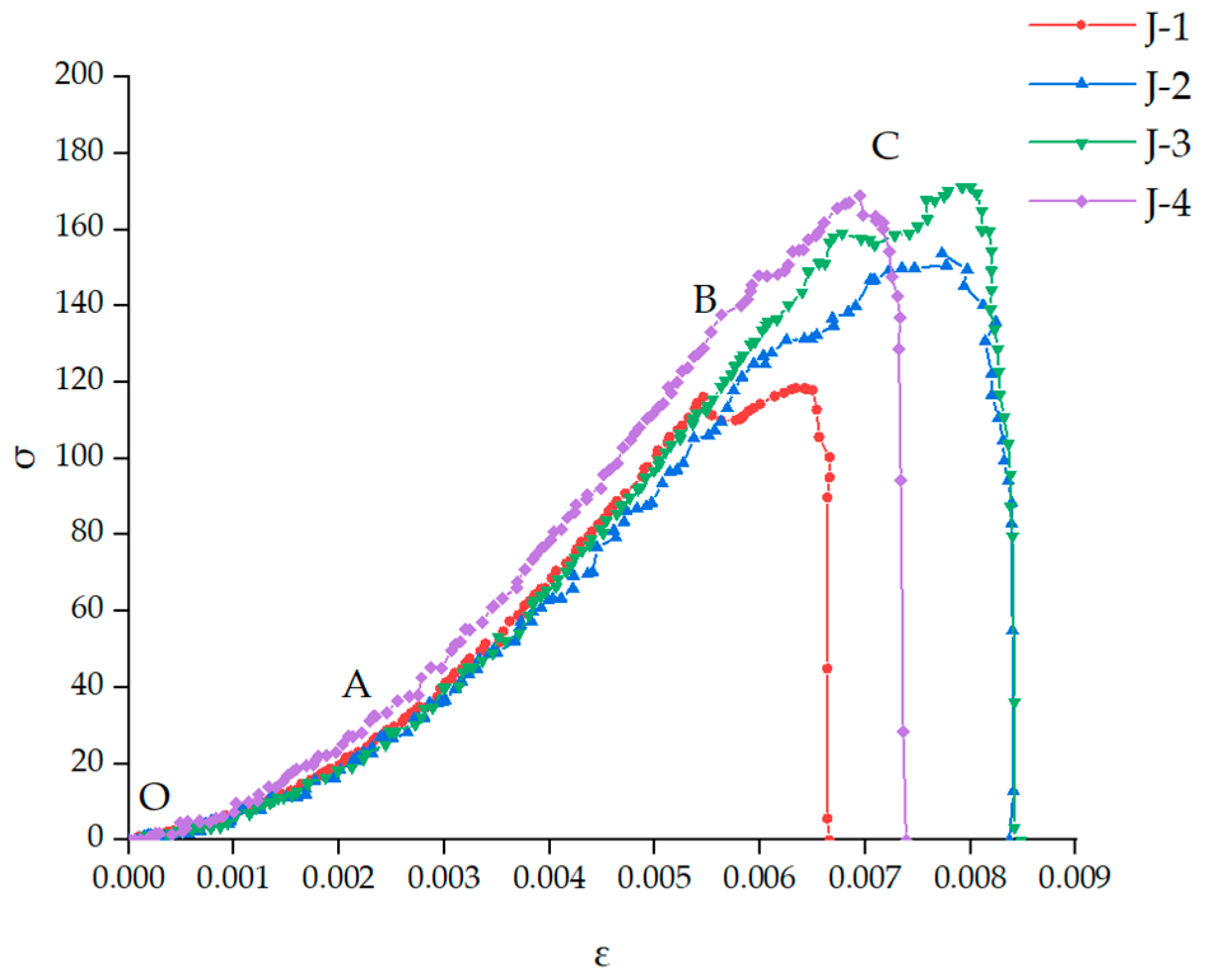

4.1. Stress–Strain Curve of Specimen Failure

4.2. Signal Extraction

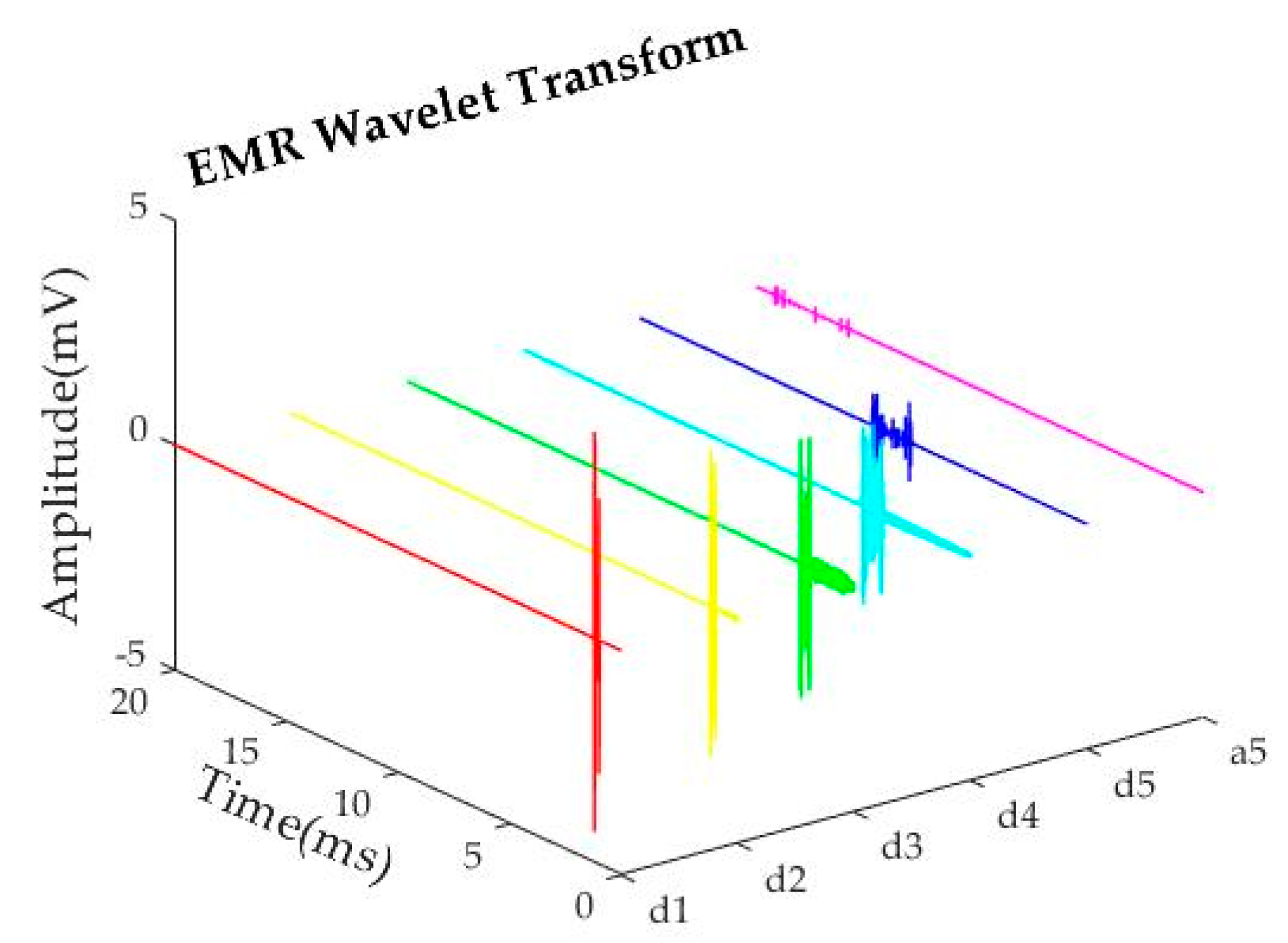

4.3. Wavelet Iterative Threshold Denoising

4.4. Signal Waveform Analysis after Noise Reduction

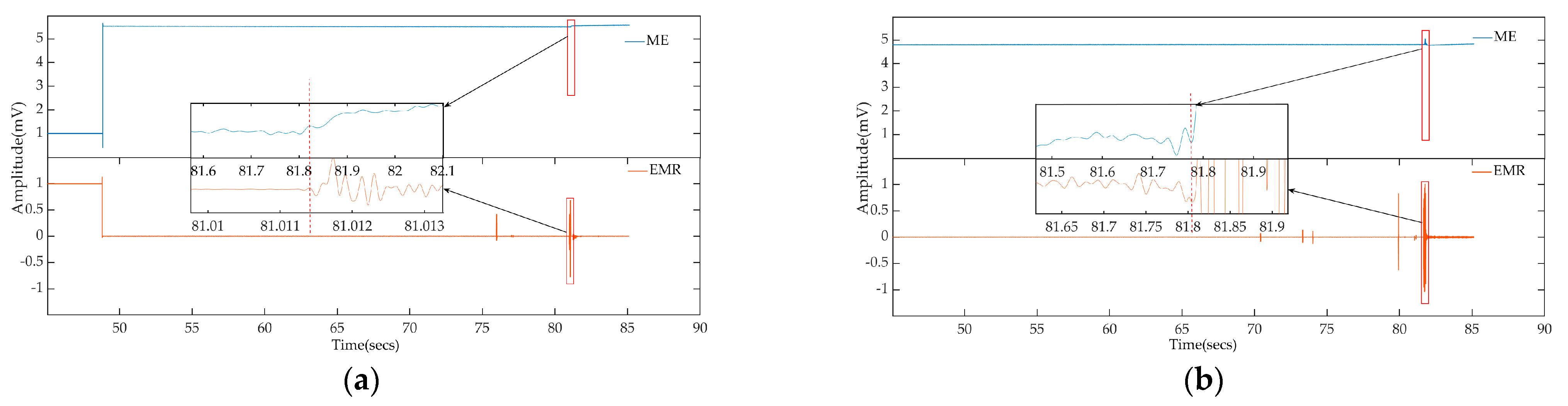

5. Coupling Analysis of the ME Signal and EMR Signal

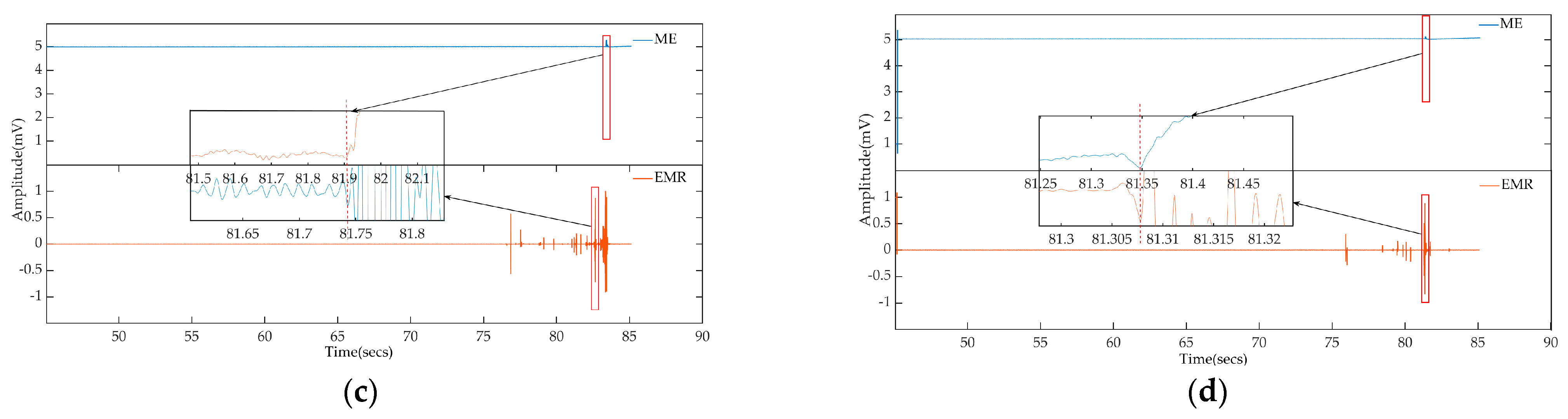

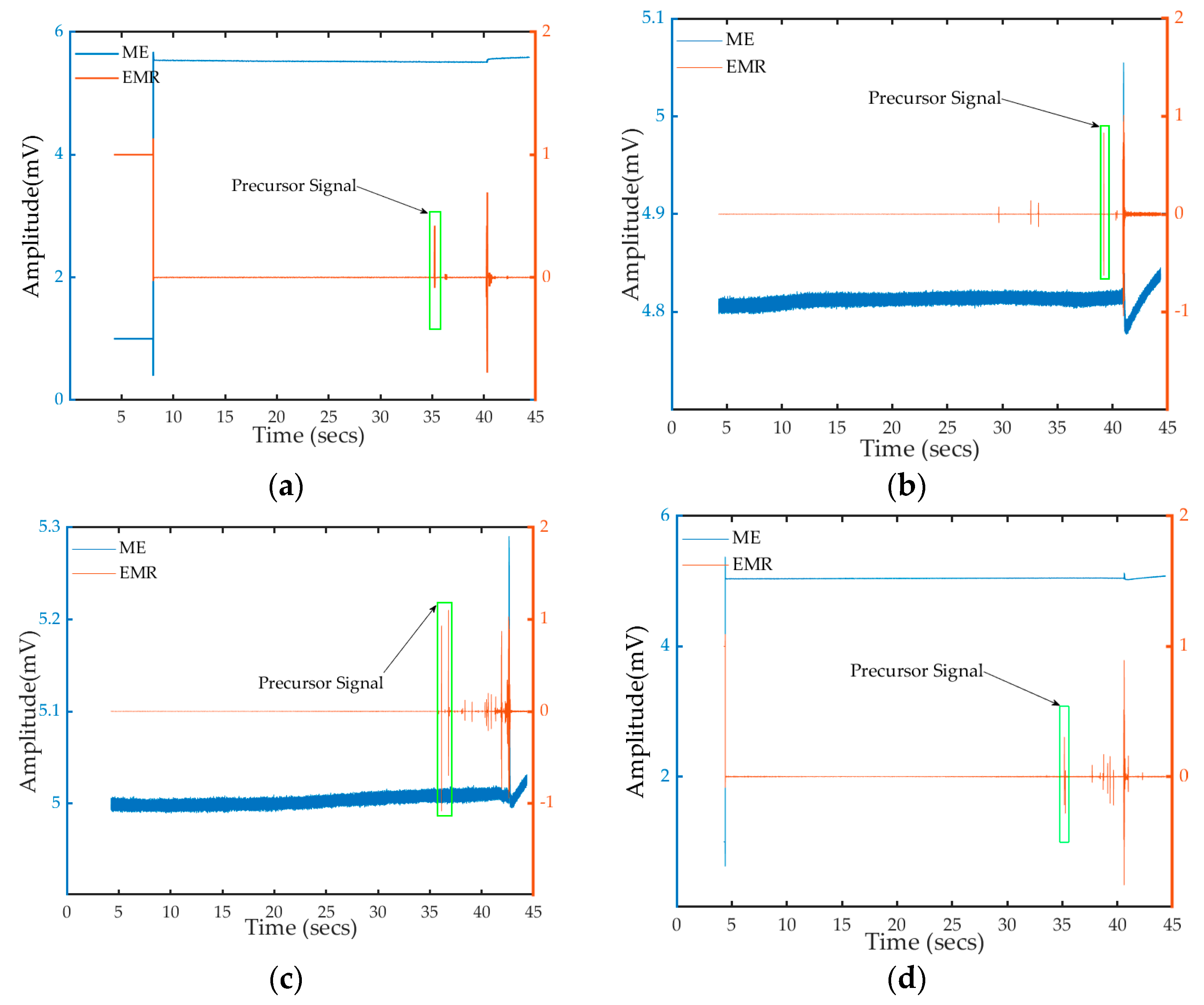

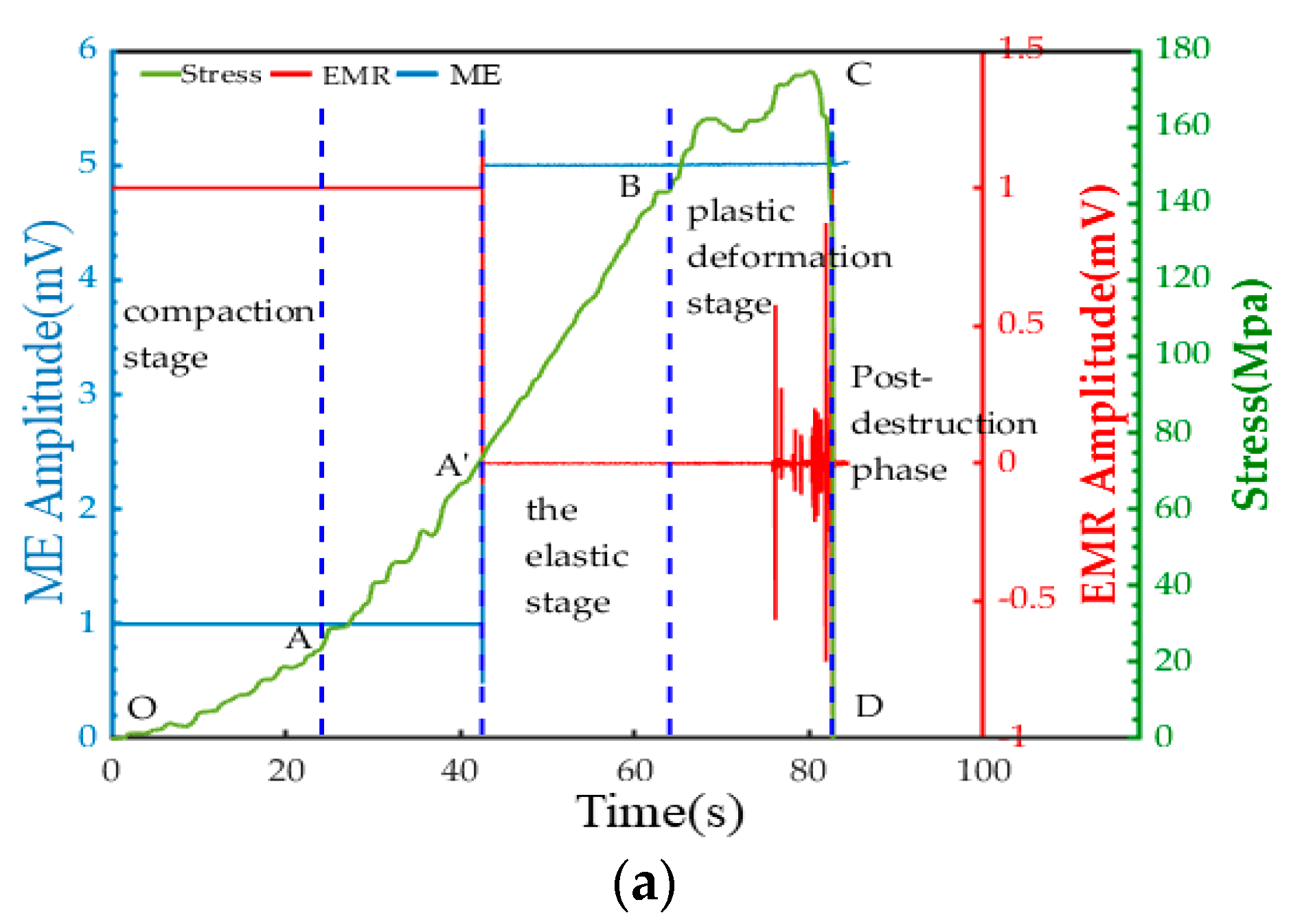

5.1. Time Domain Characteristics Analysis

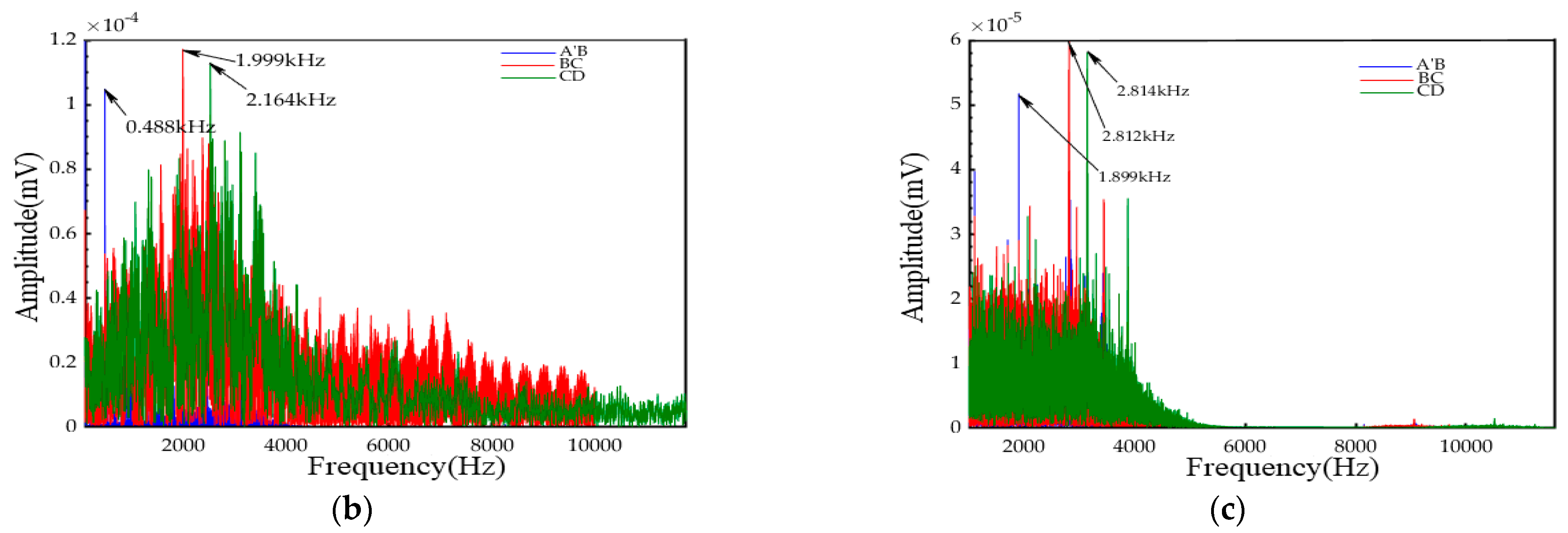

5.2. Frequency Characteristics Analysis

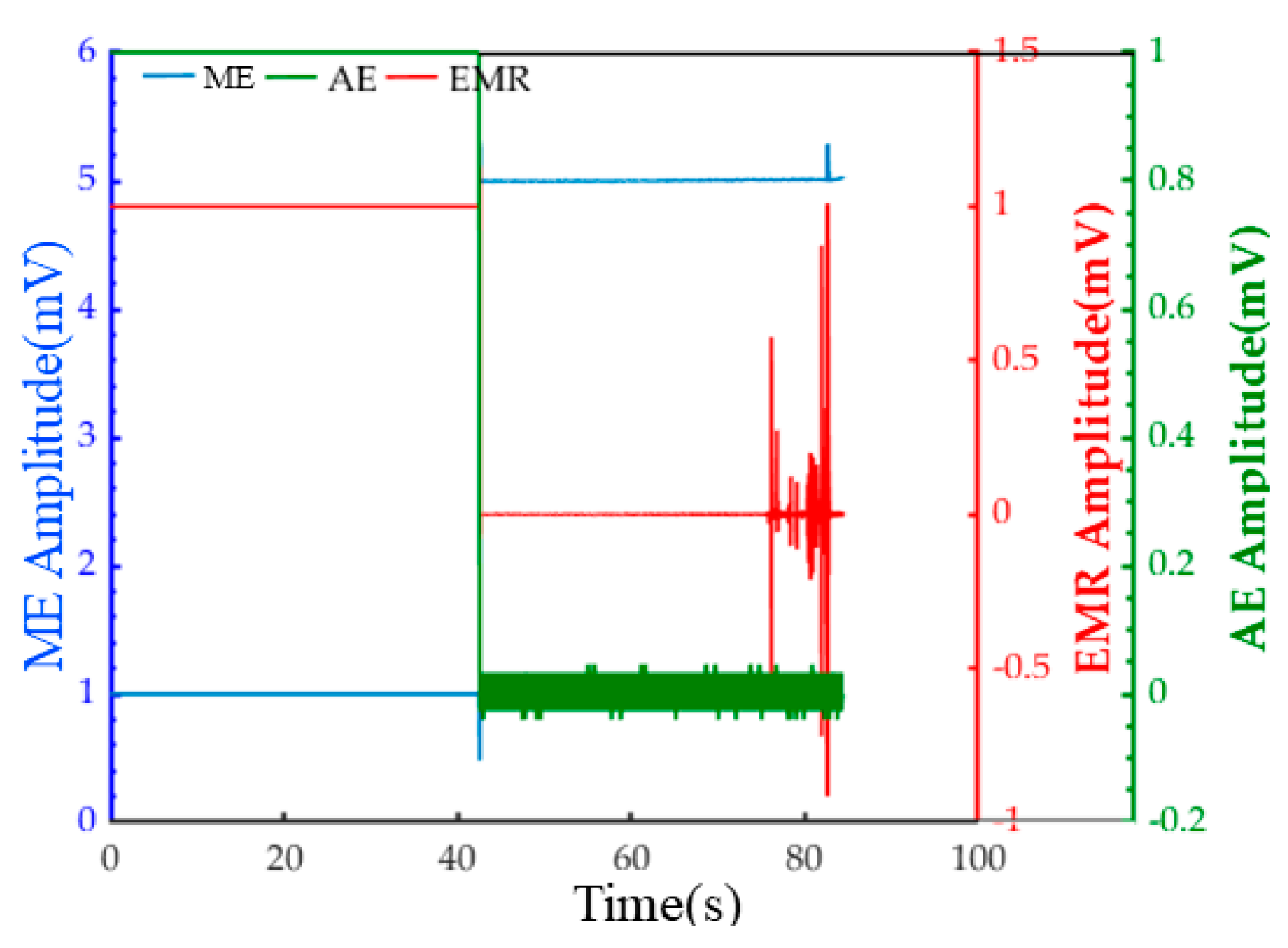

5.3. Analysis of the Signal Coupling Effect

6. Discussion and Conclusions

6.1. Discussion

6.2. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, H.; Dou, L.M.; Gong, S.Y.; He, J.; Zheng, Y.L.; Zhang, X. ME and electromagnetic coupling method for coal bump risk assessment based on dynamic static energy principles. Saf. Sci. 2019, 114, 30–39. [Google Scholar] [CrossRef]

- Qi, F.Z.; Yang, D.W.; Li, B.; Ma, Z.G.; Qi, F.Z.; Wang, Z.L.; Ma, W.X. Stability control mechanism of high-stress roadway surrounding rock by roof fracturing and rock mass filling. Adv. Civ. Eng. 2021, 2021, 6658317. [Google Scholar] [CrossRef]

- Ge, M.C. Efficient mine ME monitoring. Int. J. Coal Geol. 2005, 64, 44–56. [Google Scholar] [CrossRef]

- Qiu, L.M.; Zhu, Y.; Song, D.Z.; He, X.Q.; Wang, W.X.; Liu, Y.; Xiao, Y.Z.; Wei, M.H.; Yin, S.; Liu, Q. Study on the Nonlinear Characteristics of EMR and AE during Coal Splitting Tests. Minerals 2022, 12, 108. [Google Scholar] [CrossRef]

- Sharma, S.K.; Chauhan, V.S.; Sinapius, M. A review on deformation-induced electromagnetic radiation detection: History and current status of the technique. J. Mater. Sci. 2021, 56, 4500–4551. [Google Scholar] [CrossRef]

- Lin, P.; Wei, P.C.; Wang, C.; Kang, S.Z.; Wang, X. Effect of rock mechanical properties on electromagnetic radiation mechanism of rock fracturing. J. Rock. Mech. Geotech. 2021, 13, 798–810. [Google Scholar] [CrossRef]

- Ogawa, T.; Oike, K. Electromagnetic radiation from rocks. J. Geophys. Res.-Atmos. 1985, 90, 6245–6249. [Google Scholar] [CrossRef]

- Cress, G.O.; Brady, B.T.; Rowell, G.A. Sources of electromagnetic radiation from fracture of rock samples in the laboratory. Geophys. Res. Lett. 2013, 14, 331–334. [Google Scholar] [CrossRef]

- Mastrogiannis, D.; Antsygina, T.N.; Chishko, K.A.; Mavromatou, C.; Hadjicontis, V. Relationship between electromagnetic and acoustic emissions in deformed piezoelectric media: Microcracking signals. Int. J. Solids Struct. 2015, 56–57, 118–125. [Google Scholar] [CrossRef]

- Li, X.; Li, H.; Yang, Z.; Li, H.; Zuo, H.; Wang, X.; Li, H. Stress-Electromagnetic Radiation (EMR) Numerical Model and EMR Evolution Law of Composite Coal-Rock under Load. ACS Omega 2022, 7, 40399–40418. [Google Scholar] [CrossRef]

- He, X.Q.; Zhao, Y.J.; Liu, Y.; Song, D.Z.; Qiu, L.M.; Wei, M.H.; Yin, S.; Guo, L. Research on vector characteristics and applications of electromagnetic radiation induced by rock failure. Meas Sci Technol. 2022, 47, 3654–3667. [Google Scholar]

- Li, H.R.; Qiao, Y.F.; Shen, R.X.; He, M.C. Electromagnetic radiation signal monitoring and multi-fractal analysis during uniaxial compression of water-bearing sandstone. Measurement 2023, 34(4), 111245. [Google Scholar] [CrossRef]

- Di, Y.Y.; Wang, E.Y.; Li, Z.H.; Liu, X.F.; Huang, T.; Yao, J.J. Comprehensive early warning method of microseismic, acoustic emission, and electromagnetic radiation signals of rock burst based on deep learning. Int. J. Rock Mech. Min. 2023, 170, 105519. [Google Scholar] [CrossRef]

- Feng, X.; Hu, Q.; Ding, Z.; Wang, D.; Zhao, X.; Wei, Q. Crack Propagation and AE/EMR Response Characteristics of Pre-Holed Coal Specimens under Uniaxial Compression. Sustainability 2022, 14, 15196. [Google Scholar] [CrossRef]

- Nan, L.; Ge, M.C.; Wang, E.Y. Two types of multiple solutions for microseismic source location based on arrival-time-difference approach. Nat. Hazards. 2014, 73, 829–847. [Google Scholar]

- Ai, D.; Li, C.; Zhao, Y.; Li, G. Investigation on micro-seismic, electromagnetic radiation and crack propagation characteristics of coal under static loading. Rock. Soil. Mech. 2020, 41, 2043–2051. [Google Scholar]

- Ge, M.C. Source location error analysis and optimization methods. J. Rock Mech. Geotech. 2012, 4, 1–10. [Google Scholar] [CrossRef]

- Li, X.L.; Chen, S.J.; Wang, E.Y.; Li, Z.H. Rock burst mechanism in coal rock with structural surface and the ME (MS) and electromagnetic radiation (EMR) response. Eng. Fail. Anal. 2021, 124, 105396. [Google Scholar] [CrossRef]

- Chen, J.; Yu, S.; Wei, W.; Ma, Y. Matrix-based method for solving decision domains of neighbourhood multigranulation decision-theoretic rough sets. Caai T Intell. Technol. 2022, 7, 313–327. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Li, W. Probabilistic time series forecasting with deep non-linear state space models. Caai T Intell. Techno. 2023, 8, 3–13. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhang, C.S.; Wang, Y.X.; Lin, H. Shear-related roughness classification and strength model of natural rock joint based on fuzzy comprehensive evaluation. Int. J. Rock. Mech. Min. Sci. 2021, 137, 104550. [Google Scholar] [CrossRef]

- Ren, S.; Zhao, Y.; Liao, J.; Liu, Q.; Li, Y. Lugeon Test and Grouting Application Research Based on RQD of Grouting Sections. Sustainability 2022, 14, 12748. [Google Scholar] [CrossRef]

- Hu, X.H.; Kuang, Q.H.; Cai, Q.H.; Xue, Y.; Zhou, W.X.; Li, Y. A Coherent Pattern Mining Algorithm Based on All Contiguous Column Bicluster. J. Artif. Intell. Technol. 2022, 2, 80–92. [Google Scholar] [CrossRef]

- Zhao, H.M.; Ma, L.W. Several rough set models in quotient space. Caai T Intell. Technol. 2022, 7, 69–80. [Google Scholar] [CrossRef]

- Hsiao, I.H.; Chung, C.Y. AI-infused semantic model to enrich and expand programming question generation. J. Artif. Intell. Technol. 2022, 2, 47–54. [Google Scholar] [CrossRef]

- Zhang, Z.; De Luca, G.; Archambault, B.; Chavez, J.; Rice, B. Traffic Dataset and Dynamic Routing Algorithm in Traffic Simulation. J. Artif. Intell. Technol. 2022, 2, 111–122. [Google Scholar] [CrossRef]

- Lou, Q.; Song, D.Z.; He, X.Q.; Li, Z.L.; Qiu, L.M.; Wei, M.H.; He, S.Q. Correlations between acoustic and electromagnetic emissions and stress drop induced by burst-prone coal and rock fracture. Safety Sci. 2019, 115, 310–319. [Google Scholar] [CrossRef]

- Fan, X.; Chen, R.; Lin, H.; Lai, H.P.; Zhang, C.Y.; Zhao, Q.H. Cracking and failure in rock specimen containing combined flaw and hole under uniaxial compression. Adv. Civ. Eng. 2018, 2018, 9818250. [Google Scholar] [CrossRef]

- Song, X.; Li, X.; Li, Z.; Zhang, Z.; Cheng, F.; Chen, P.; Liu, Y. Study on the charac-teristics of coal rock electromagnetic radiation (EMR) and the main influencing factors. J. Appl. Geophys. 2018, 148, 216–225. [Google Scholar] [CrossRef]

- Tian, X.H.; Song, D.Z.; He, X.Q.; Khan, M.; Li, Z.L.; Qiu, L.M.; Liu, X.F. On the characterization and correlation of the rock failure-induced electromagnetic radiation and micro-vibration. Eng. Geol. 2022, 311, 106879. [Google Scholar] [CrossRef]

- Liu, Y.; He, K.; Chen, G.; Leow, W.R.; Chen, X. Nature-inspired structural materials for flexible electronic devices. Chem. Rev. 2017, 117, 12893–12941. [Google Scholar] [CrossRef]

- Wu, C.Z.; Chen, Q.; Basack, S.; Xu, R.Q.; Shi, R.M. Biaxial creep test study on the influence of structural anisotropy on rheological behaviour of hard rock. J. Mater. Civil. Eng. 2016, 28, 04016104. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, Q.; Basack, S.; Karekal, S. Laboratory investigation on rheological properties of greenschist considering anisotropy under multi-stage compressive creep condition. J. Struct. Geol. 2018, 114, 111–120. [Google Scholar] [CrossRef]

- Duan, G.; Li, J.; Zhang, J.; Assefa, E.; Sun, X. Mechanical properties and failure modes of rock specimens with specific joint geometries in triaxial unloading compressive test. Adv. Mater. Sci. Eng. 2019, 2019, 1–14. [Google Scholar] [CrossRef]

- Tang, L.; Wang, Y.; Sun, Y.; Chen, Y.; Zhao, Z. A Review on the failure modes of rock and soil mass under compression and the exploration about constitutive equations of rock and soil mass. Adv. Civ. Eng. 2022, 2022, 1–13. [Google Scholar] [CrossRef]

- Nardi, A.; Caputo, M. Monitoring the mechanical stress of rocks through the electromagnetic emission produced by fracturing. Int. J. Rock Mech. Min. 2009, 46, 940–945. [Google Scholar] [CrossRef]

- Di, Y.Y.; Wang, E.Y. Rock burst precursor electromagnetic radiation signal recognition method and early warning application based on recurrent neural networks. Rock Mech. Rock Eng. 2021, 54, 1449–1461. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Li, Q.; An, B. A Study of the Characteristics of Micro-Seismic (ME) and Electromagnetic Radiation (EMR) Signals under the Static Load Conditions of Rocks. Appl. Sci. 2023, 13, 12910. https://doi.org/10.3390/app132312910

He L, Li Q, An B. A Study of the Characteristics of Micro-Seismic (ME) and Electromagnetic Radiation (EMR) Signals under the Static Load Conditions of Rocks. Applied Sciences. 2023; 13(23):12910. https://doi.org/10.3390/app132312910

Chicago/Turabian StyleHe, Liao, Qingfeng Li, and Baifu An. 2023. "A Study of the Characteristics of Micro-Seismic (ME) and Electromagnetic Radiation (EMR) Signals under the Static Load Conditions of Rocks" Applied Sciences 13, no. 23: 12910. https://doi.org/10.3390/app132312910

APA StyleHe, L., Li, Q., & An, B. (2023). A Study of the Characteristics of Micro-Seismic (ME) and Electromagnetic Radiation (EMR) Signals under the Static Load Conditions of Rocks. Applied Sciences, 13(23), 12910. https://doi.org/10.3390/app132312910