Deformation and Stress Law of Surrounding Rock for a Bifurcated Tunnel with a Super-Large Section: A Case Study

Abstract

:1. Introduction

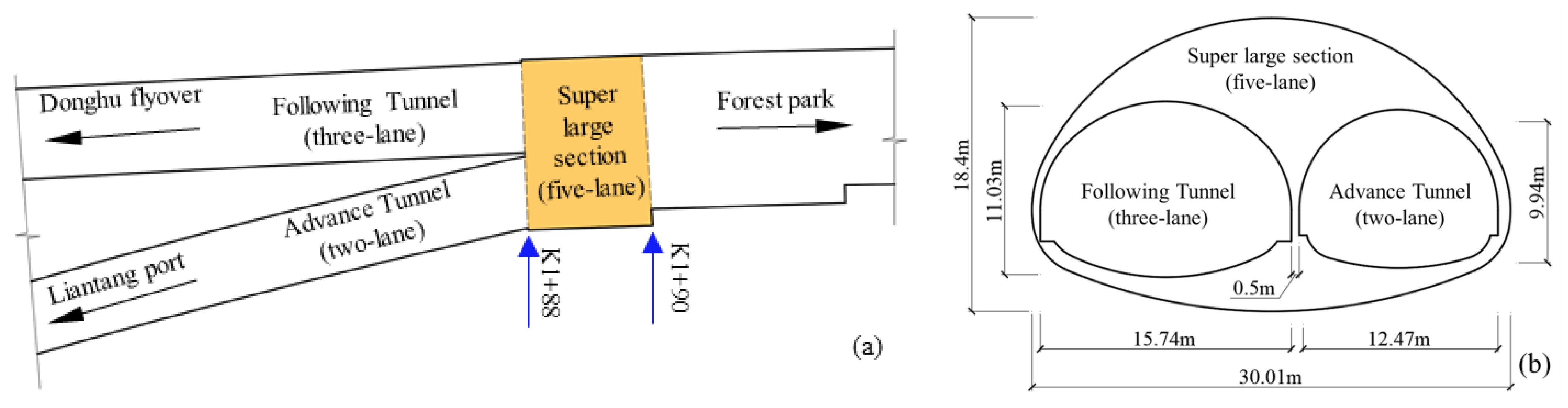

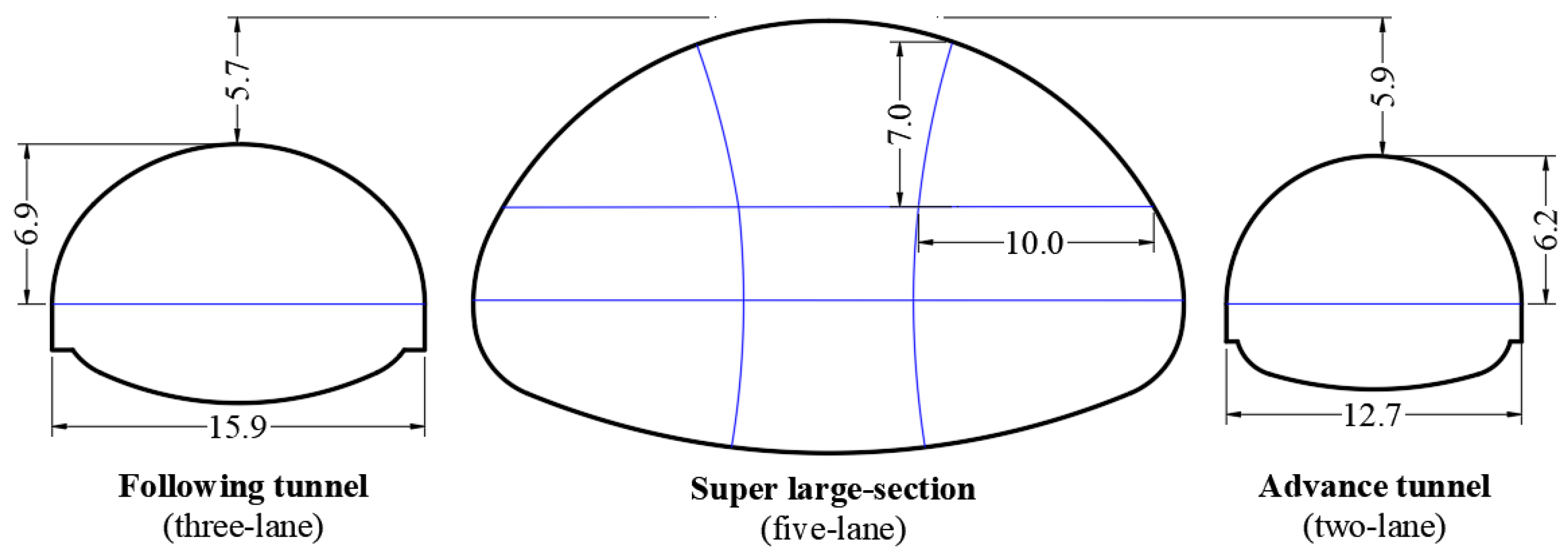

2. Project Overview, Problems, and Solutions

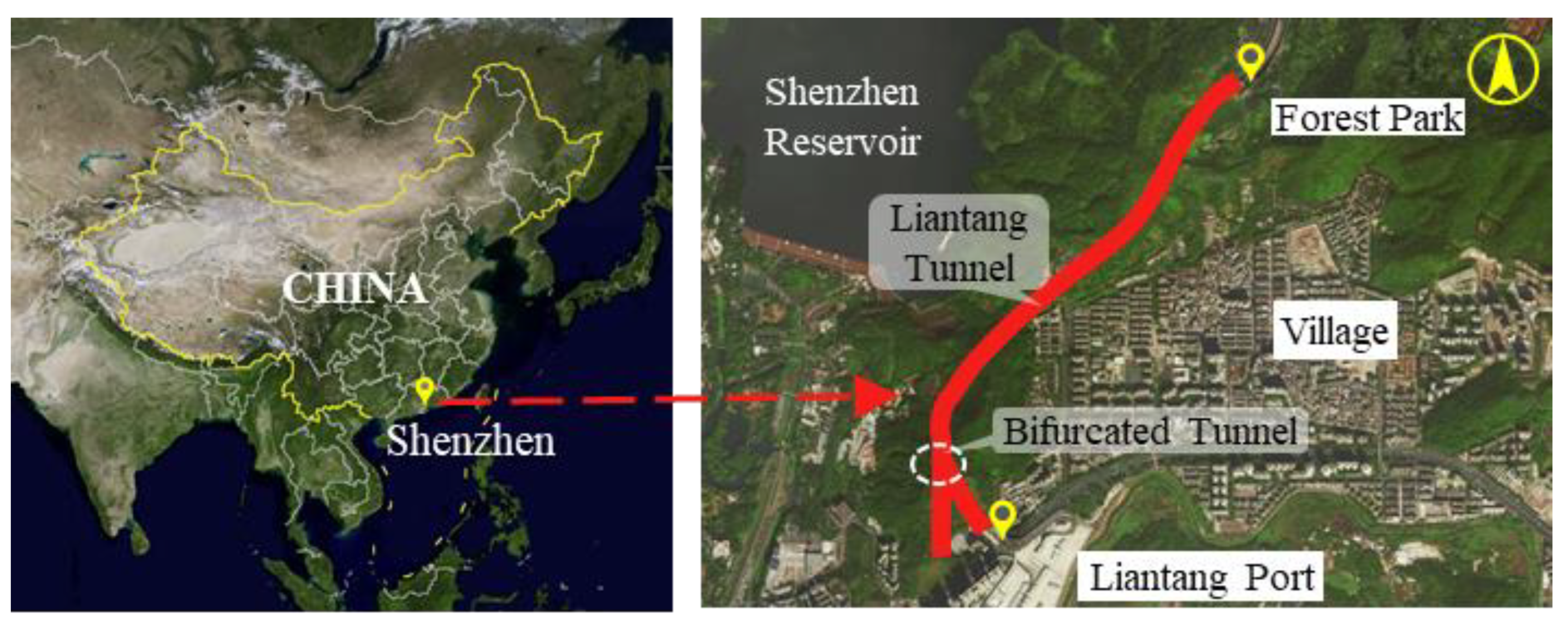

2.1. Engineering Background

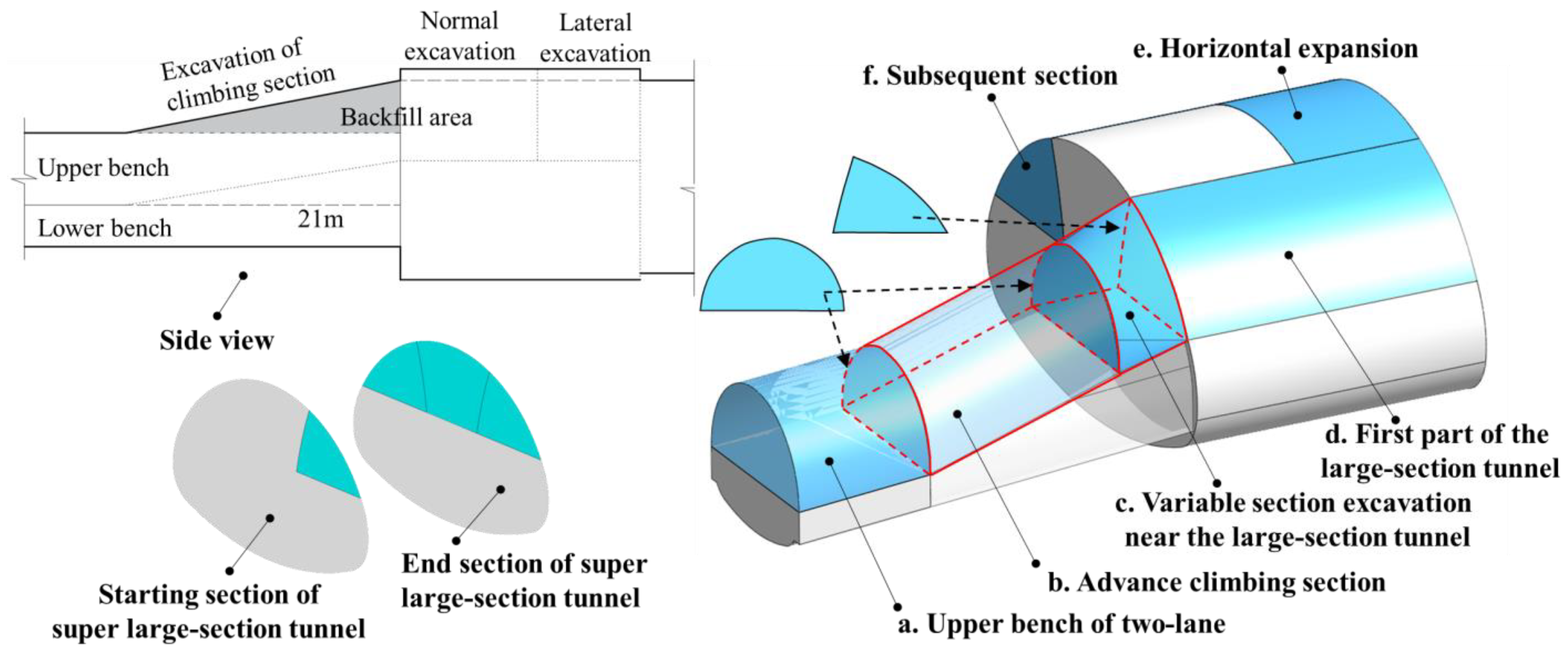

2.2. Section Zoning Excavation Scheme

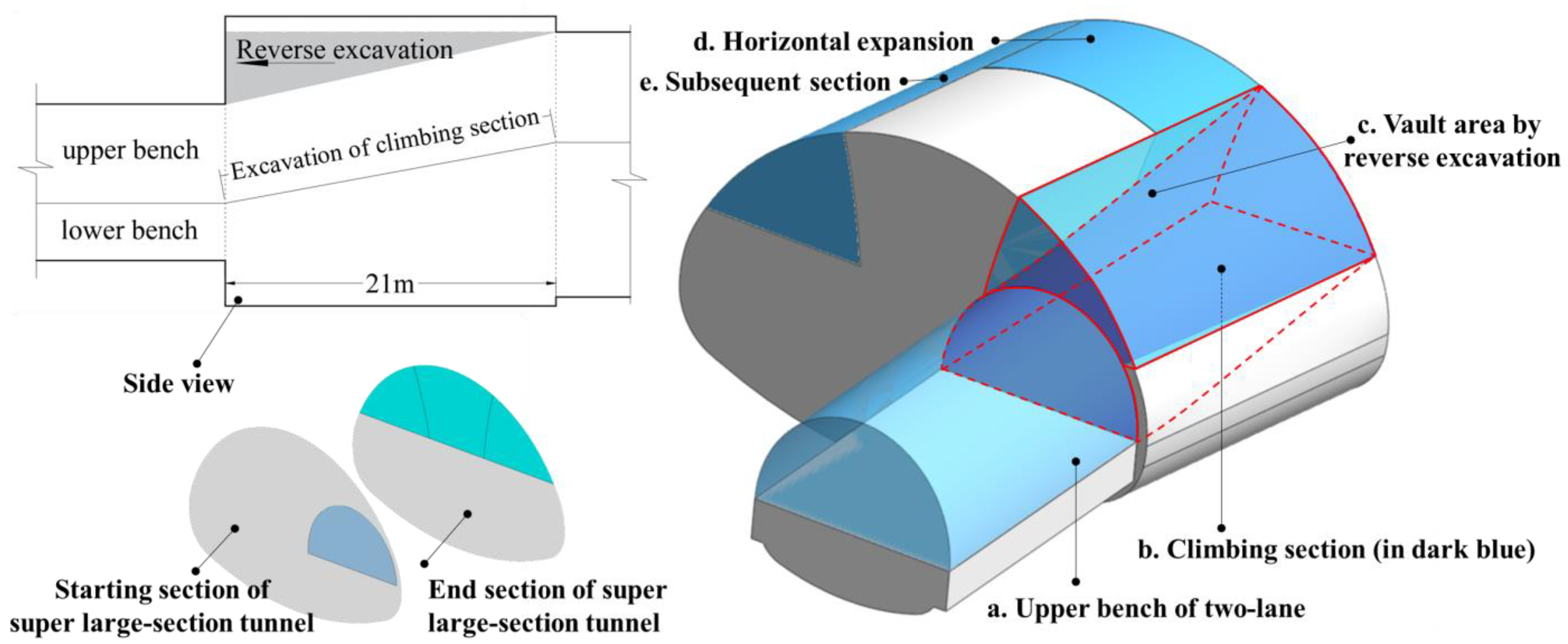

2.3. Construction Design for the Bifurcation Tunnel

2.3.1. The Characteristic of RTM

- (a)

- The angle of the IPT is a fixed value determined by the length of the large section. The climbing angle is a fixed value determined by the relationship between the two-lane section and the position of the large section on the plan. The shorter the length of the large-section segment, the steeper the climbing angle.

- (b)

- The difficulty lies in controlling the drilling angle, and there is a high risk factor for workers during construction. In step c of Figure 5, irregular arc-shaped thin rock layers require multiple blasts for excavation. When workers drill holes, the bottom of the drilling rig needs to be treated for debris, and a horizontal working platform needs to be installed. If horizontal drilling and blasting are used, it is difficult to control the drilling angle, which may lead to slabbing. If vertical drilling is adopted, controlling the depth of the borehole is challenging, and the downward-facing borehole opening is not conducive to charging and blocking, resulting in a high risk factor for workers.

- (c)

- Blasting in the vault area causes cumulative damage to the top of the large section, and the resulting debris blocks the tunnel entrance. During the excavation by reverse top heading blasting, the surrounding rock of the large section in this area undergoes multiple cumulative damages, affecting the stability of the surrounding rock of the large-section tunnel. At the same time, the direction of the blasted rock fragments from the top will be downwards, and the resulting debris will block the IPT entrance, forming a sealed space that hinders subsequent operations and affects the construction schedule of follow-up work.

- (d)

- Changes in the original zoning plan for the super-large section result in changes to the sequence of support operations. Changes in the partitioning plan for the dual-side walls of the large section lead to changes in subsequent work processes and the sequence of support operations. For large sections over 400 m2, the synchronization of construction sequences and support plays an important role in the stability of the surrounding rock.

2.3.2. The Characteristic of ACM

- (a)

- The starting point of inclined pilot tunnel is flexible. The slope is started in a reasonable location on the stepped section. Through analyzing the impact of the starting point on the stress of the surrounding rock and the backfill volume, the climbing angle is quantitatively calculated to ensure the stability of the surrounding rock. This method has broader applicability in similar projects.

- (b)

- The original excavation zoning scheme of a super-large cross-section tunnel will not change. Multi-stage excavation and the unloading of energy have an impact on the surrounding rock and support structures. Therefore, precise control of blasting technology is required for excavation. Synchronization of the support process is also crucial. After the completion of the climbing section excavation, the construction sequence of the large section is aligned with the design plan, ensuring the safety of tunnel construction.

- (c)

- Horizontal expansion will increase the number of workfaces, which is beneficial to improving the construction progress. After horizontal excavation, the subsequent construction processes can be easily connected, allowing for the addition of two to three working faces, effectively improving the progress of subsequent works.

3. Numerical Simulation of Tunnel Excavation

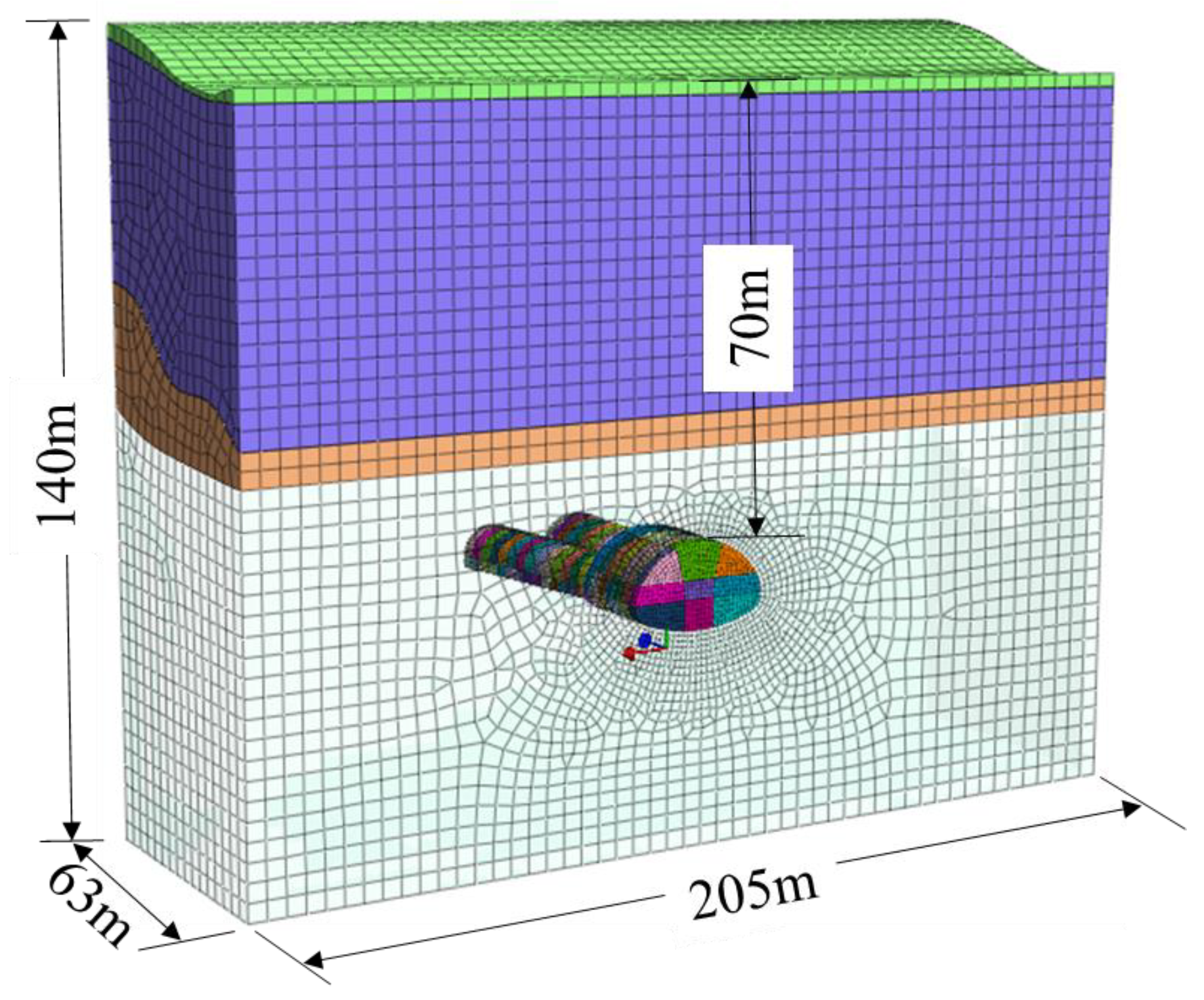

3.1. Computational Model and Material Parameters

3.2. Analysis of Calculation Results

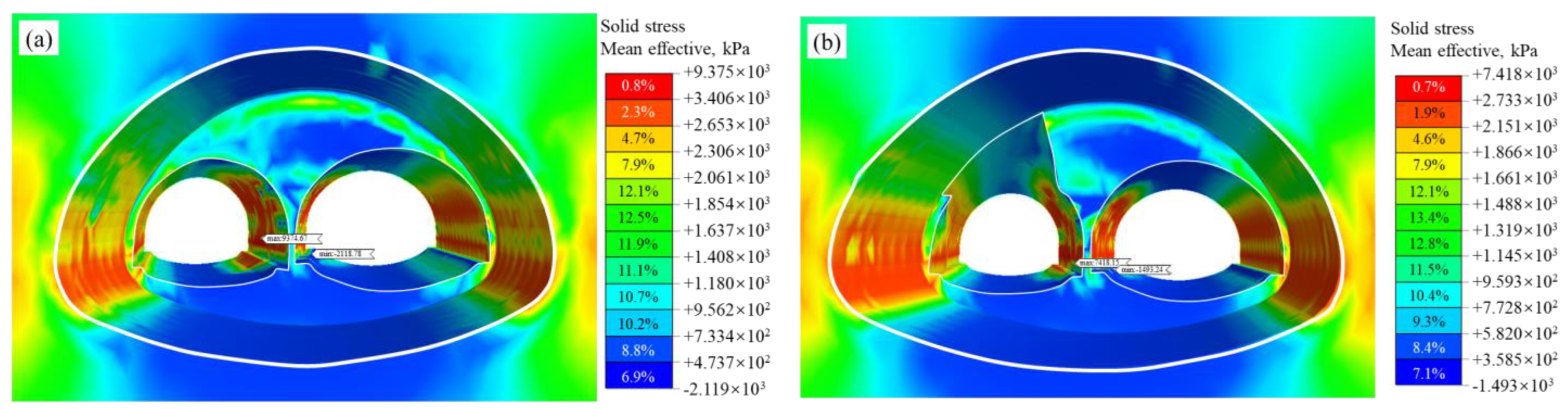

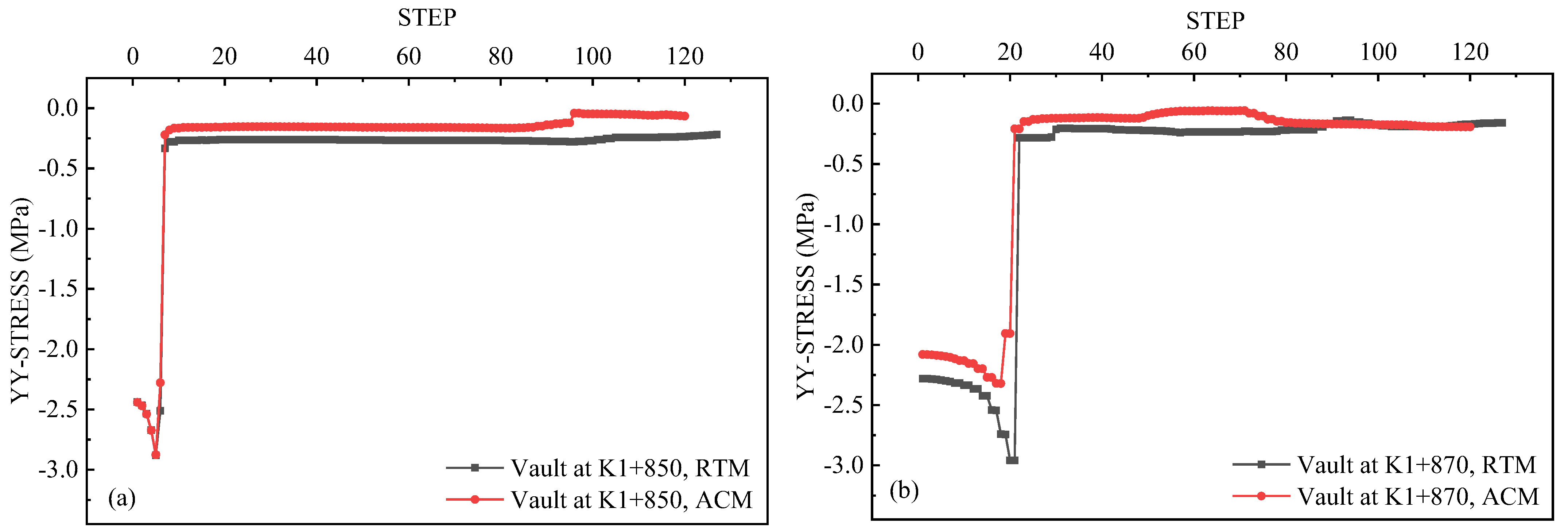

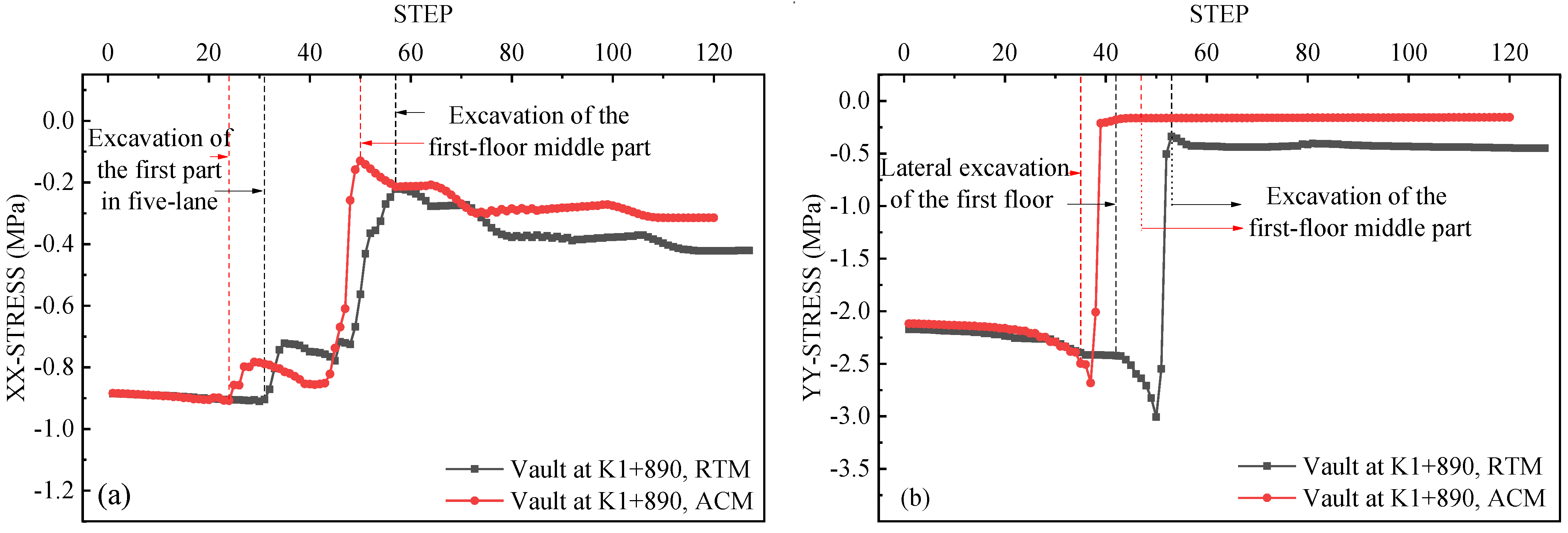

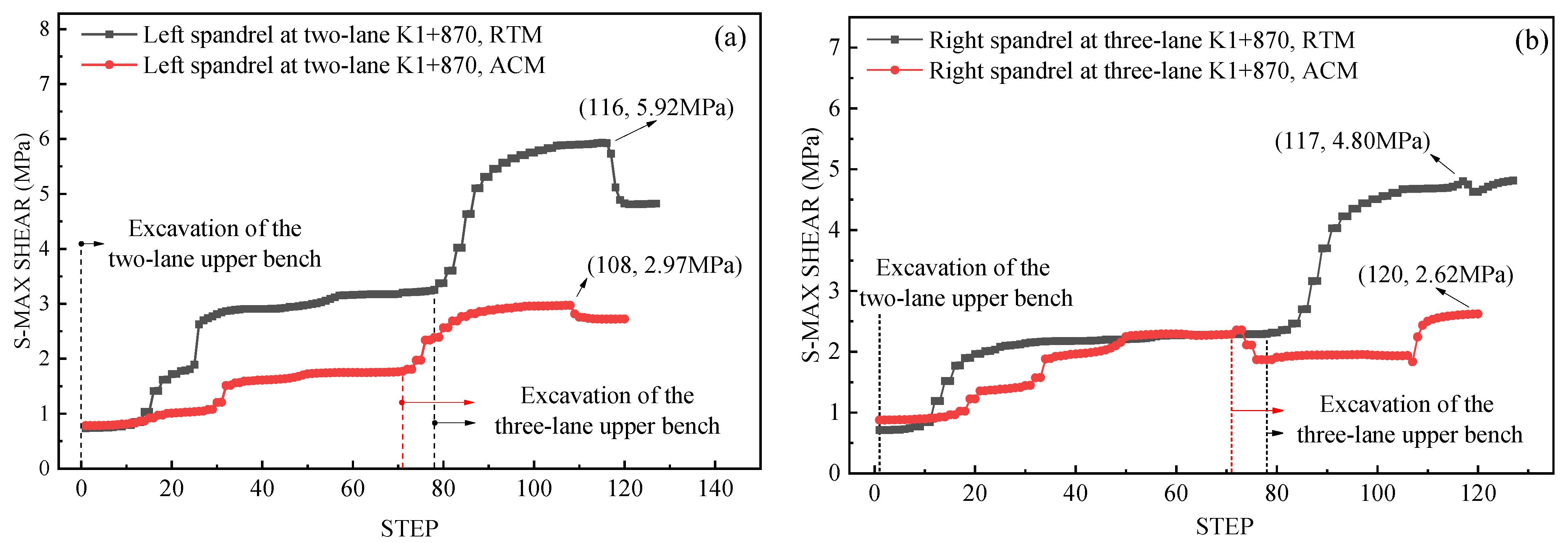

3.2.1. Force Characteristics of the Bifurcated Tunnel Envelope at Different Construction Steps

- (1)

- Analysis of the forces on the vault of the two-lane

- (2)

- Analysis of the forces on the vault of the five-lane tunnel

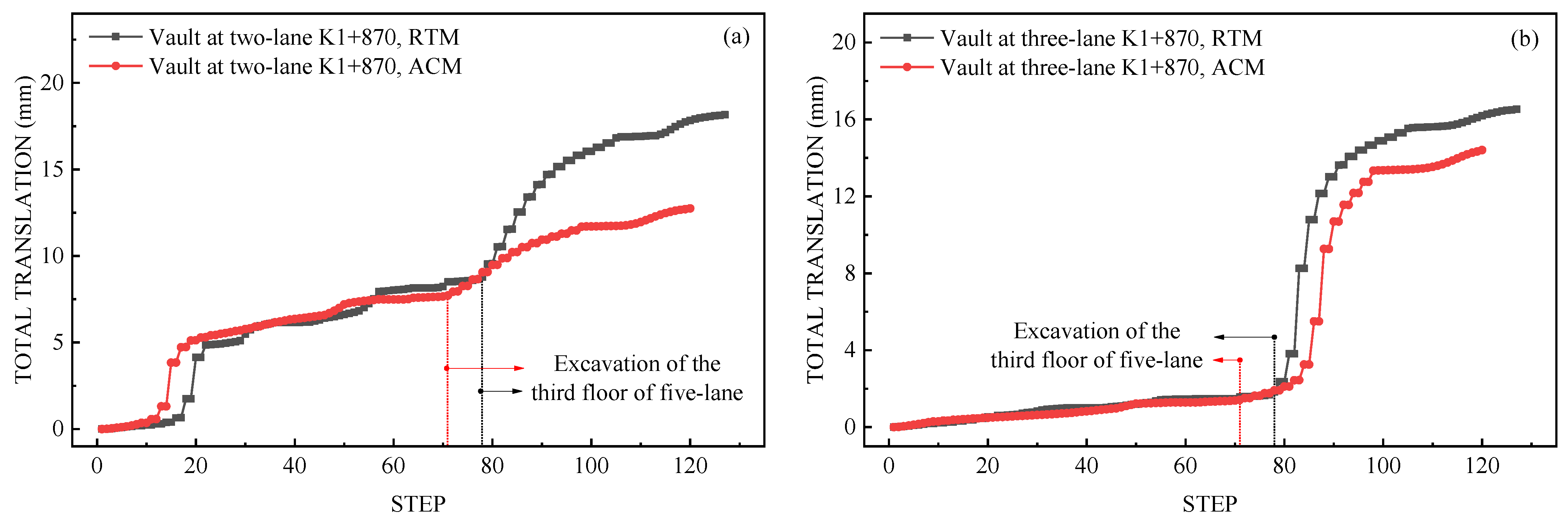

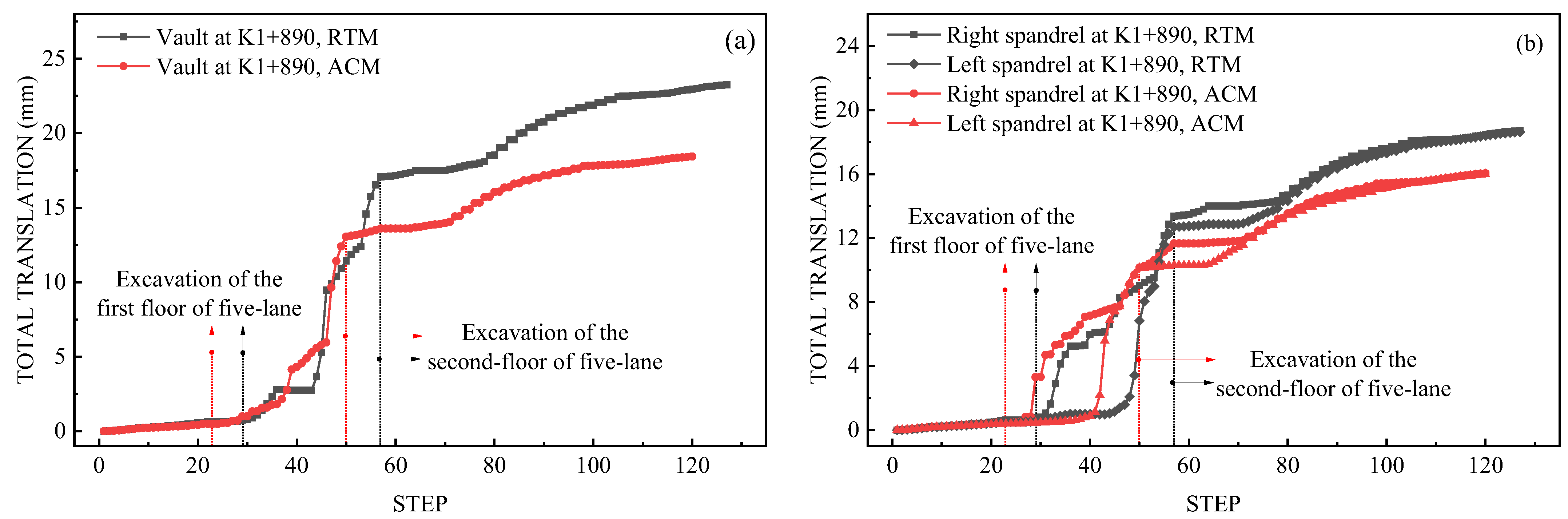

3.2.2. Deformation Patterns of the Bifurcated Tunnel Envelope at Different Construction Steps

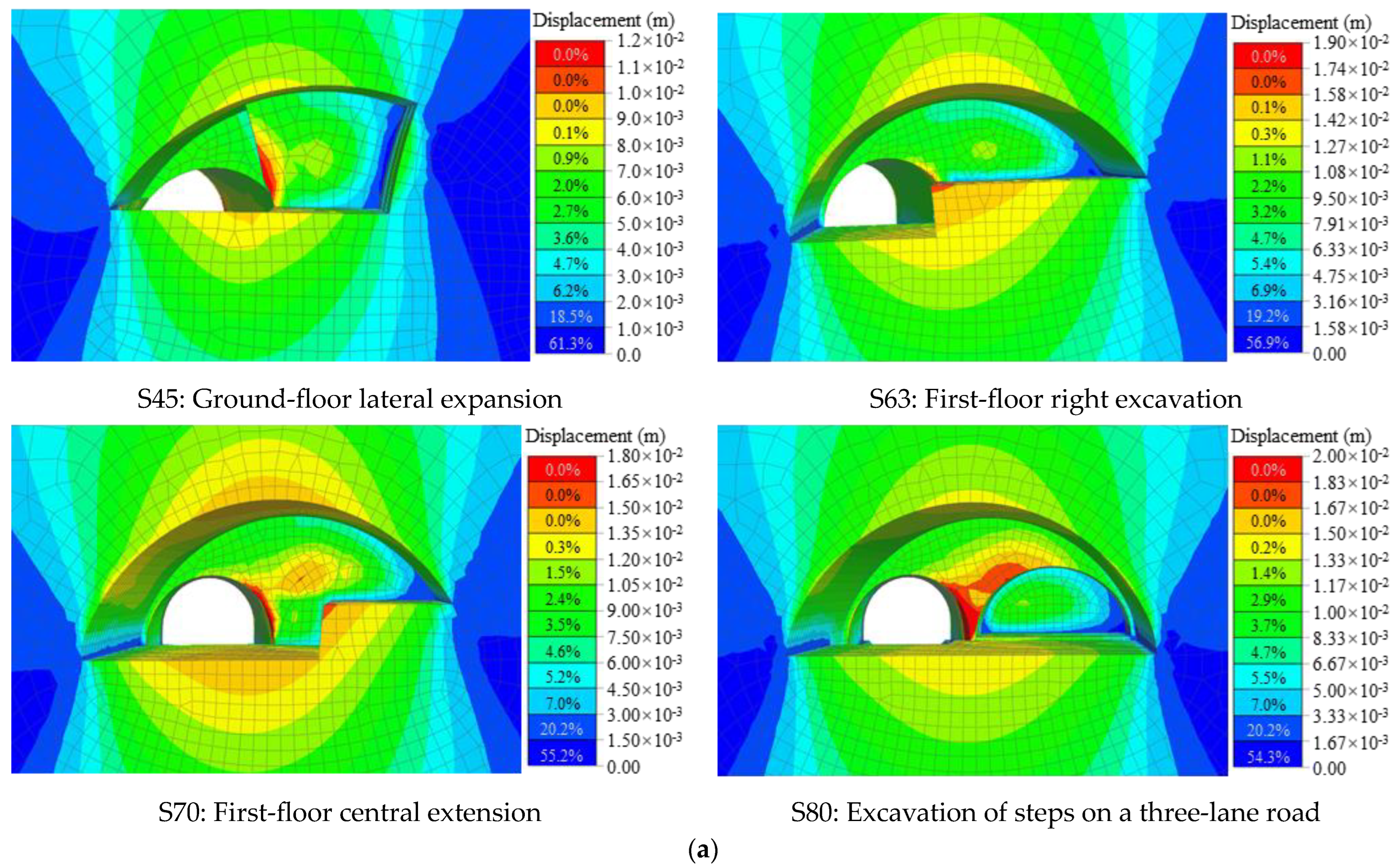

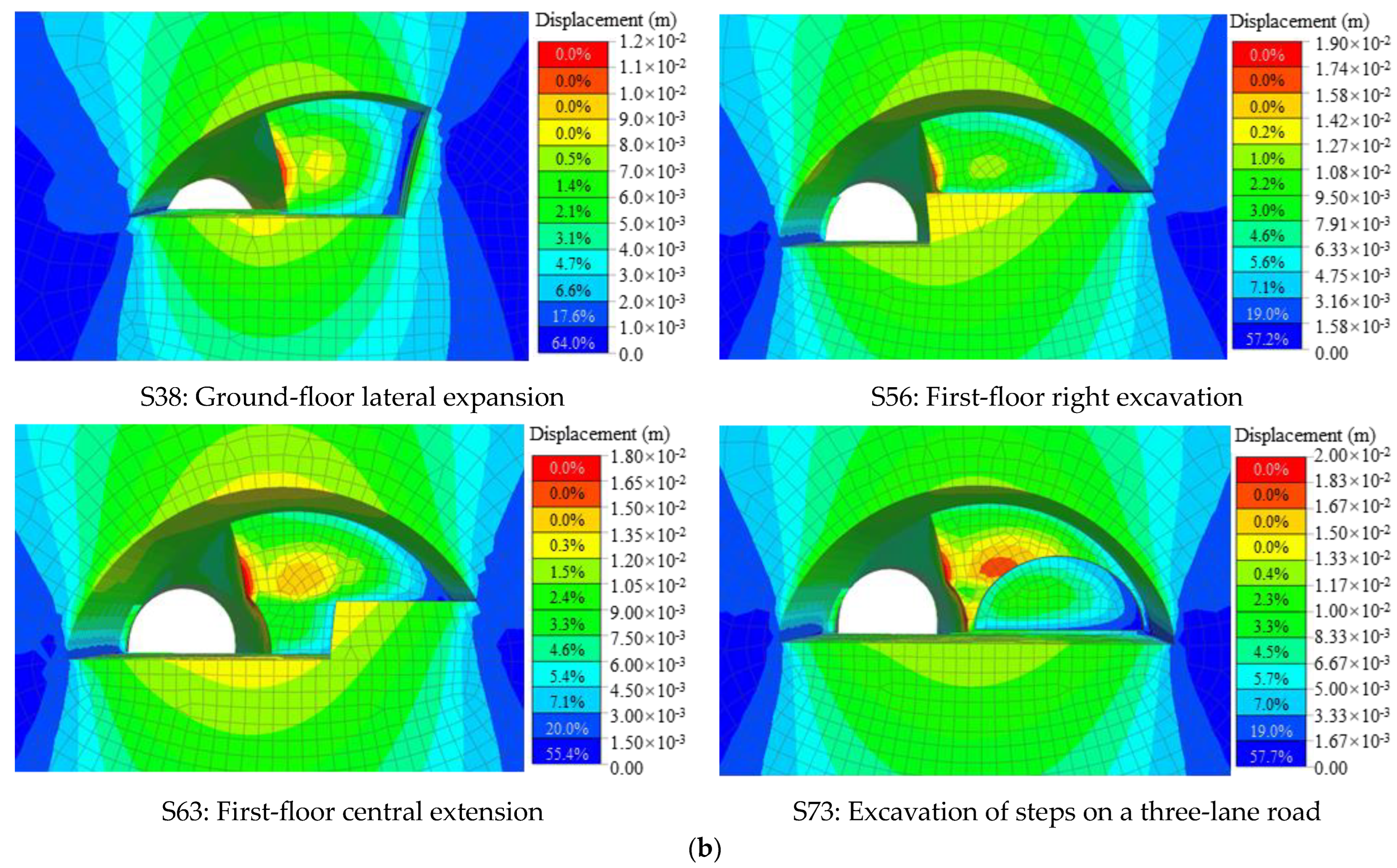

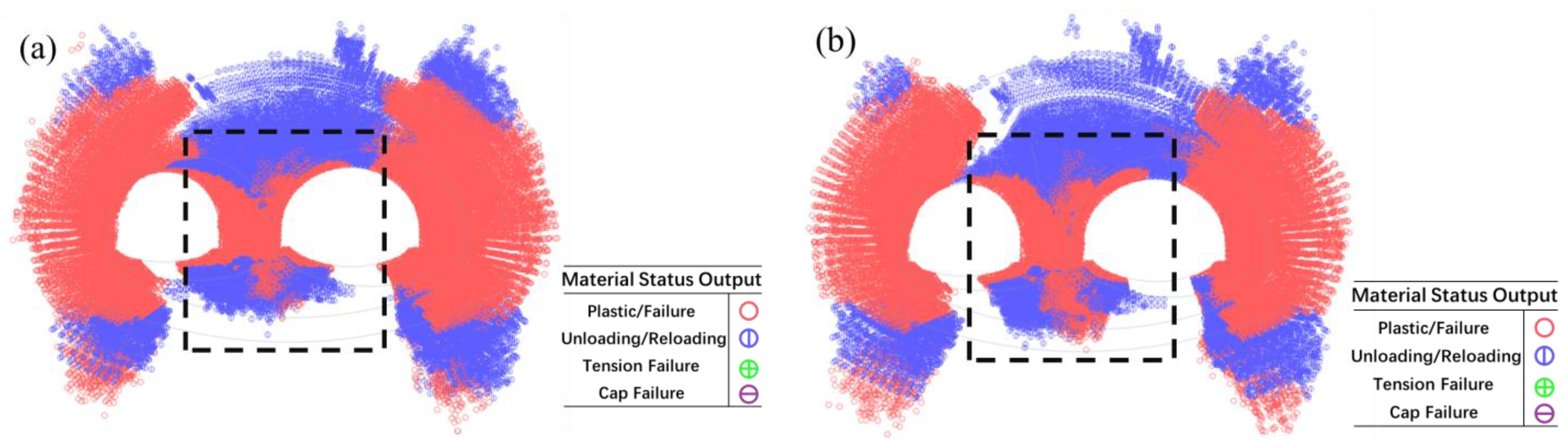

3.2.3. Distribution of Plastic Zones in Bifurcated Tunnels with Different Construction Steps

4. Monitoring and Measurement Results and Analysis of the Bifurcated Tunnel Construction Process

4.1. Monitoring and Measurement Scheme

4.2. Monitoring Results for the Two-Lane Section

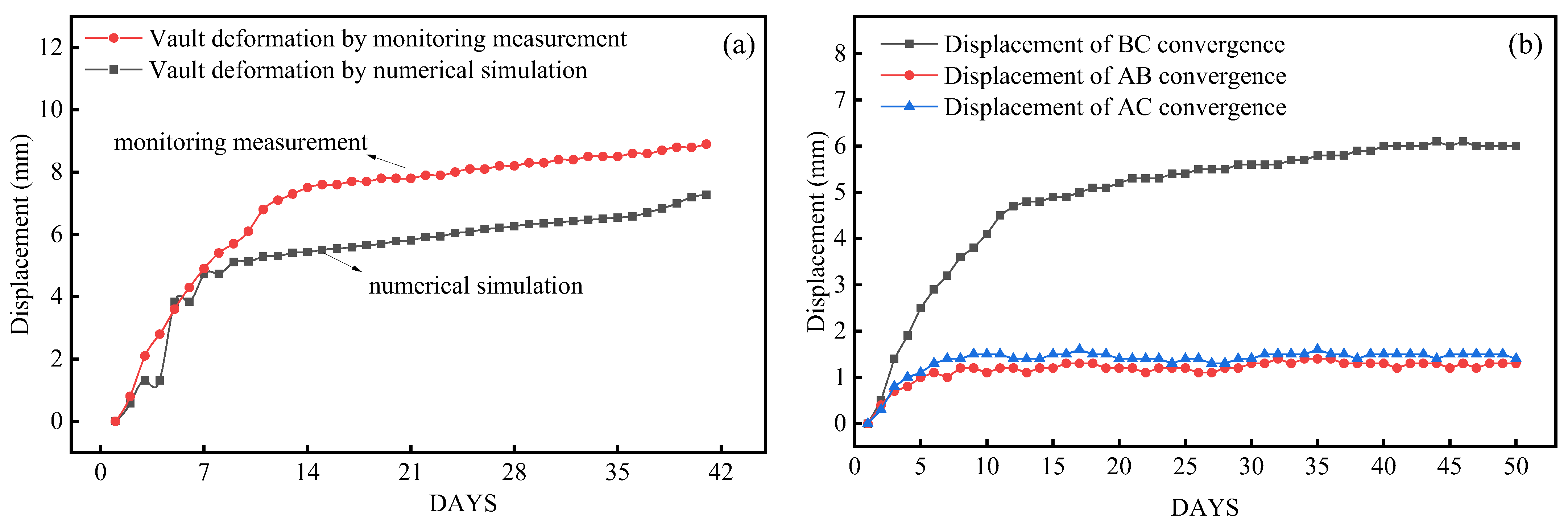

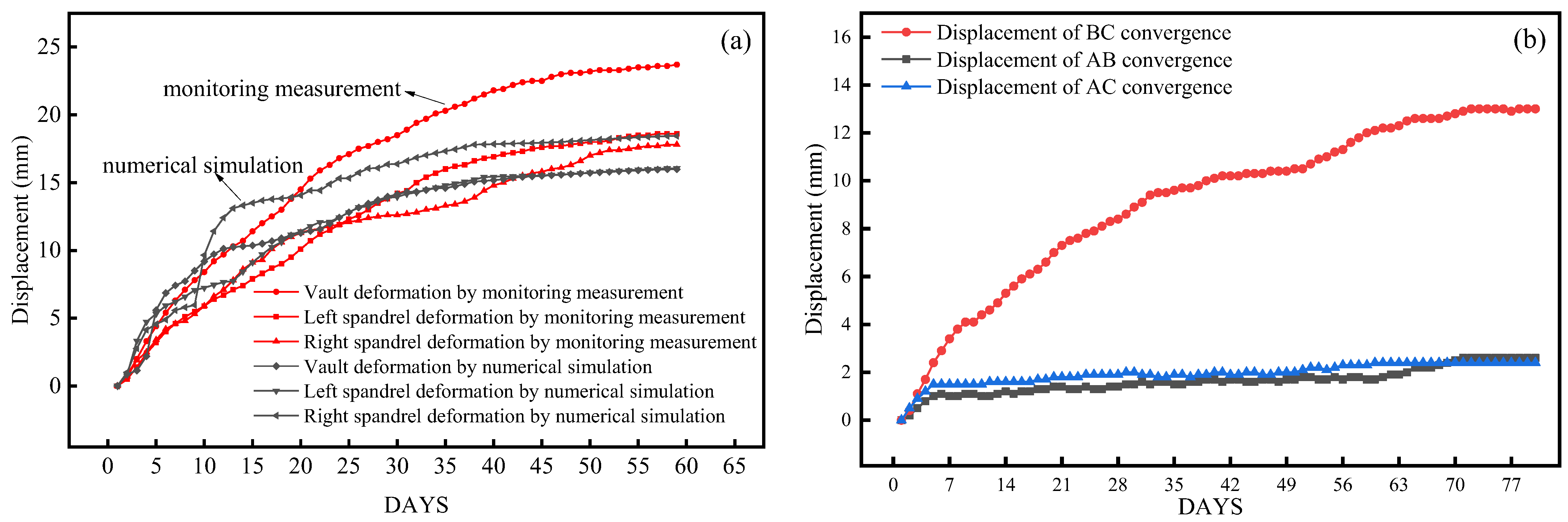

4.2.1. Changes in the Pattern of the Sinking of the Surrounding Rock Vault and Convergence around the Tunnel

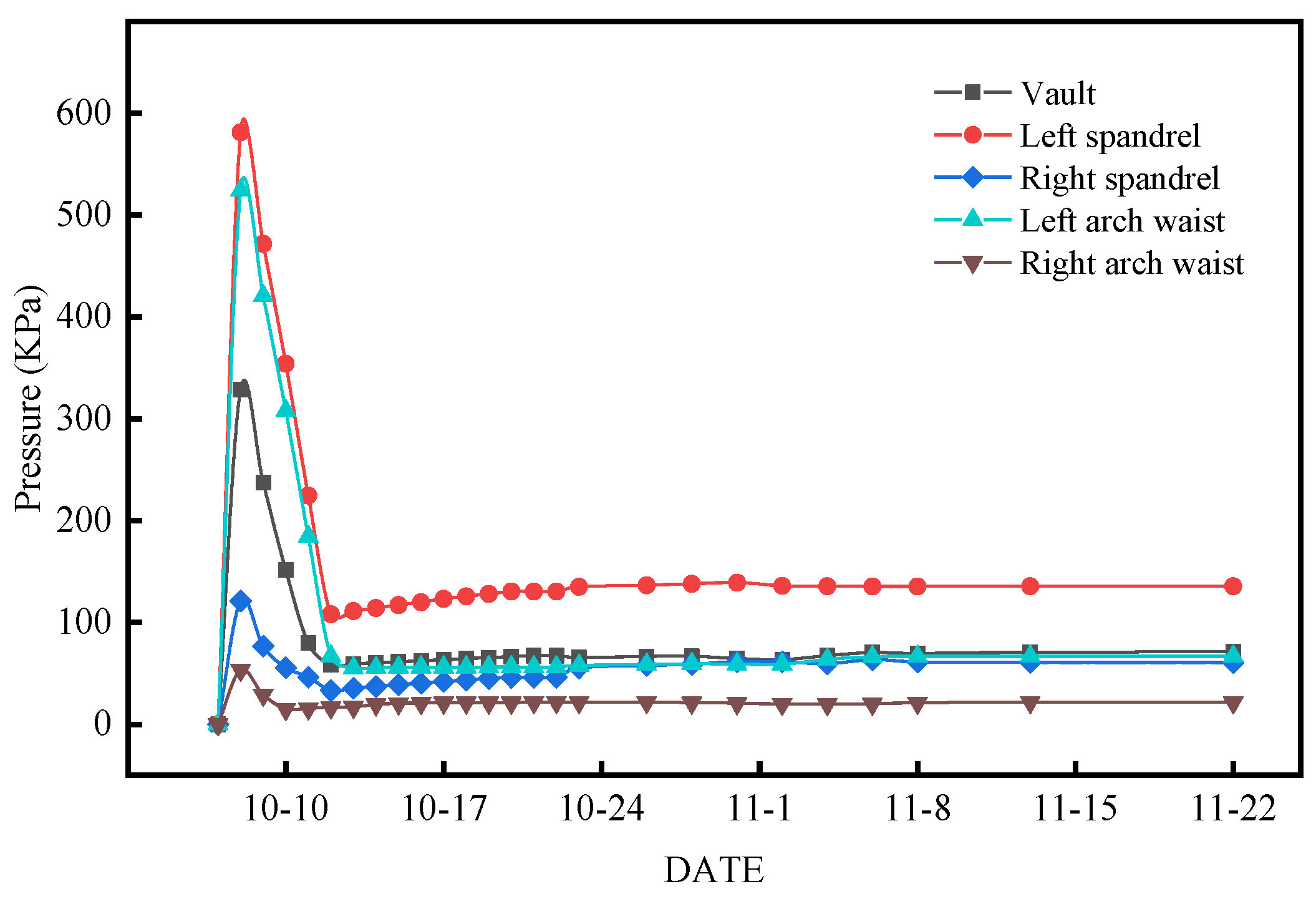

4.2.2. Force Characteristics of the Surrounding Rock Support Structure

4.3. Construction Monitoring Results for the Five-Lane Section

4.3.1. Changes in the Pattern of the Sinking of the Surrounding Rock Vault and Convergence around the Tunnel

4.3.2. Force Characteristics of the Surrounding Rock Support Structure

4.4. Analysis and Evaluation of the Reasonableness of Construction Methods

5. Conclusions

- (1)

- Taking the bifurcated section of the Liantang Tunnel, the largest cross-section highway tunnel currently, as the research object, two excavation schemes for transitioning from a small cross-section to a large cross-section tunnel were proposed. Numerical simulation was used to analyze the stress and deformation characteristics of the surrounding rock during the excavation process in the bifurcation section, and on-site verification was conducted. The calculation results provide a theoretical basis for the design of the transitional excavation scheme, optimization of excavation steps, and support recommendations. They are of significant reference value for the future formulation of design specifications for super-large cross-sections with more than four lanes.

- (2)

- A three-dimensional computational model for the excavation of a large cross-section bifurcation tunnel was established using the MIDAS GTS NX software, and the calculation results of the two schemes were analyzed. During the construction process, the total displacement of the crown in the large section and the small-clearance section in the RTM was 1.2 to 1.4 times that of the ACM. After construction stabilization, the vertical stress at the crown in the ACM was approximately three times that of the RTM. During the excavation of the large section, the maximum shear stress of the intermediate rock in the RTM exceeded the plastic failure threshold of 5.92 MPa for rock, while the ACM remained within the safe range. The calculation results indicate that the ACM is the optimal excavation scheme.

- (3)

- The on-site monitoring results of the Liantang tunnel show that after adopting the ACM, the large section was excavated using the double sidewall method. The maximum cumulative displacement in the large-section tunnel was 23.7 mm, and for the two lanes, it was 8.5 mm. The peak pressures of the initial support and secondary lining were concentrated in the waist areas on both sides, reaching 0.4 MPa for the large section and 0.58 MPa for the two lanes, located near the shoulder and waist areas close to the intermediate rock. The crown sinking and convergence displacements of the surrounding rock in the Liantang bifurcated tunnel were within the allowable displacement safety range for highway tunnels, confirming the rationality of the ACM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Wu, J.; Yan, C.; Gou, X.; Ye, L.; Feng, J. Construction technology of super-large section of highway tunnels with four or more lanes in China. China J. Highw. Transp. 2020, 33, 14–31. [Google Scholar] [CrossRef]

- Hong, K.; Feng, H. Development trends and views of highway tunnels in China over the past decade. China J. Highw. Transp. 2020, 33, 62–76. [Google Scholar] [CrossRef]

- Zhang, J.; Li, S.; Li, L.; Zhang, Q.; Xu, Z.; Xu, Z.; Wu, J.; He, P. Grouting effects evaluation of water-rich faults and its engineering application in Qingdao Jiaozhou Bay Subsea Tunnel, China. Geomech. Eng. 2017, 12, 35–52. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, J.; Gong, Y.; Xu, X.; Zhang, H.; Ye, L. Study on construction method optimization and construction mechanical characteristics of a single-span five-lane highway tunnel. Tunn. Constr. 2021, 41, 831–840. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, S.; Zhou, D. Stability analysis of bifurcated highway tunnels with large section in tiger leaping gorge. Highway 2021, 66, 342–346. [Google Scholar]

- Barla, G. Full-face excavation of large tunnels in difficult conditions. J. Rock Mech. Geotech. Eng. 2016, 8, 294–303. [Google Scholar] [CrossRef]

- Rehman, H.; Naji, A.M.; Ali, W.; Junaid, M.; Abdullah, R.A.; Yoo, H.-K. Numerical evaluation of new Austrian tunneling method excavation sequences: A case study. Int. J. Min. Sci. Technol. 2020, 30, 381–386. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhao, J.; Tan, Z.; Zhou, X. Mechanical responses in the construction process of super-large cross-section tunnel: A case study of Gongbei tunnel. Tunn. Undergr. Space Technol. 2021, 115, 104044. [Google Scholar] [CrossRef]

- Cao, Z.; Xie, Q.; Song, Z.; Wang, J. Effect of unloading on surrounding rock pressure of super large-section tunnel. Chin. J. Rock Mech. Eng. 2020, 39 (Suppl. S1), 2882–2891. [Google Scholar] [CrossRef]

- Luo, Y.; Chen, J.; Gao, S.; Deng, X.; Diao, P. Stability analysis of super-large-section tunnel in loess ground considering water infiltration caused by irrigation. Environ. Earth Sci. 2017, 76, 763. [Google Scholar] [CrossRef]

- Tu, H.; Zhou, H.; Qiao, C.; Gao, Y. Excavation and kinematic analysis of a shallow large-span tunnel in an up-soft/low-hard rock stratum. Tunn. Undergr. Space Technol. 2020, 97, 103245. [Google Scholar] [CrossRef]

- Qiu, W.; Sun, K.; Wang, L.; Ma, M.; He, Y.; Chen, J.; Wen, Z.; Wang, G. Primary support optimization of large section tunnel based on surrounding rock stability. China Civ. Eng. J. 2017, 50 (Suppl. S2), 8–13. [Google Scholar]

- Zhang, W.; Qi, J.; Zhang, G.; Niu, R.; Zhang, C.; He, L.; Lyu, J. Full-scale experimental study on failure characteristics of the key segment in shield tunnel with super-large cross-section. Tunn. Undergr. Space Technol. 2022, 129, 104671. [Google Scholar] [CrossRef]

- Hu, Y. Research on bi-directional construction technology for super-closely-spaced bifurcated tunnel with long span. Railw. Constr. Technol. 2018, 12, 77–80. [Google Scholar]

- Yan, Z.; Zhang, L.; Lu, J.; Zou, J. Study on Construction Method of the Intersection of the Urban Underground Interchange Tunnel. Mod. Tunn. Technol. 2019, 56, 176–184. [Google Scholar] [CrossRef]

- Zhang, F.; Lei, S.; Yang, R.; Shi, L.; Sun, W.; Qiao, Q. Numerical simulation of the construction of forked tunnels with super small spacing. China Sci. Pap. 2019, 14, 157–163. [Google Scholar]

- Liu, C.; Peng, Z.; Cui, J.; Huang, X.; Li, Y.; Chen, W. Development of crack and damage in shield tunnel lining under seismic loading: Refined 3D finite element modeling and analyses. Thin-Walled Struct. 2023, 185, 110647. [Google Scholar] [CrossRef]

- Hu, D.; Li, Y.; Yang, X.; Liang, X.; Zhang, K.; Liang, X. Experiment and Application of NATM Tunnel Deformation Monitoring Based on 3D Laser Scanning. Struct. Control. Health Monit. 2023, 2023, 3341788. [Google Scholar] [CrossRef]

- Ji, L.; Zhou, C.; Lu, S.; Jiang, N.; Li, H. Modeling study of cumulative damage effects and safety criterion of surrounding rock under multiple full-face blasting of a large cross-section tunnel. Int. J. Rock Mech. Min. Sci. 2021, 147, 104882. [Google Scholar] [CrossRef]

- Gao, Y.; Xu, F.; Zhang, Q.; He, P.; Qin, Z. Geotechnical monitoring and analyses on the stability and health of a large cross-section railway tunnel constructed in a seismic area. Measurement 2018, 122, 620–629. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Pan, Y.; Hao, Z.; Chen, S.; Cheng, F. Experimental study on the mechanical behavior and deformation characteristics of lining structure of super-large section tunnels with a small clearance. Eng. Fail. Anal. 2022, 136, 106186. [Google Scholar] [CrossRef]

- Yu, J.; Zhu, Y.; Yao, W.; Liu, X.; Ren, C.; Cai, Y.; Tang, X. Stress relaxation behaviour of marble under cyclic weak disturbance and confining pressures. Measurement 2021, 182, 109777. [Google Scholar] [CrossRef]

- Zhao, J.; Tan, Z.; Yu, R.; Li, Z.; Wang, X. Mechanical responses of a shallow-buried super-large-section tunnel in weak surrounding rock: A case study in Guizhou. Tunn. Undergr. Space Technol. 2023, 131, 104850. [Google Scholar] [CrossRef]

- Jiang, S.; Lin, Z.; Wang, S. China’s road tunnel development in 2018. Tunn. Constr. 2019, 39, 1217. [Google Scholar]

- Liu, J.; Lu, Z.; Zhang, W.; Zhang, L. Research on the Structure Design for Four-tracked-double Station Tunnel in Steep Dip Stratum. J. Railw. Eng. Soc. 2016, 33, 113–117. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Y. Partition failure characteristic of rock material loading and unloading based on Mohr-Coulomb criterion. J. China Coal Soc. 2019, 44, 1049–1058. [Google Scholar] [CrossRef]

- Zheng, L. Research on Quantitative Three-dimensional Description of Rough Surface and the Correlation between Shear Strength and Parameter. Master’s Thesis, Chengdu University of Technology, Chengdu, China, 2017. [Google Scholar]

- Jiang, K.; Xia, C. Analysis of monitoring and measurement of small clear spacing highway tunnel with eight lanes. Chin. J. Rock Mech. Eng. 2010, 29 (Suppl. S2), 3755. [Google Scholar]

- Zhou, D.; Cao, L.; Qu, H.; Yi, L.; Fang, S. Deformation monitoring and control of super large section highway tunnel with different surrounding rocks. Chin. J. Rock Mech. Eng. 2009, 28, 2510–2519. [Google Scholar] [CrossRef]

| Rock Formation | Bulk Density (kN·m−3) | Elastic Modulus (GPa) | Poisson’s Ratio | Cohesion (kN·m−2) | Internal Friction Angle (°) |

|---|---|---|---|---|---|

| silty clay | 19.0 | 0.6 | 0.4 | 26.5 | 25 |

| slightly weathered sandstone | 23.0 | 6.0 | 0.3 | 500 | 33 |

| slightly weathered rhyolite | 25.0 | 12.0 | 0.27 | 900 | 45 |

| Excavate Section | Monitoring Section | Cumulative Displacement/mm | Ratio of Displacement to Span/% | Allowable Displacement/mm | Robustness Factor (f) |

|---|---|---|---|---|---|

| two-lane tunnel | K1+870 | 8.5 | 0.067 | 18.09 | 4.14 |

| five-lane tunnel | K1+890 | 23.7 | 0.091 | 42.74 | 4.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Li, Y.; Gong, M.; Wu, H.; Wu, Y. Deformation and Stress Law of Surrounding Rock for a Bifurcated Tunnel with a Super-Large Section: A Case Study. Appl. Sci. 2023, 13, 12852. https://doi.org/10.3390/app132312852

Wu X, Li Y, Gong M, Wu H, Wu Y. Deformation and Stress Law of Surrounding Rock for a Bifurcated Tunnel with a Super-Large Section: A Case Study. Applied Sciences. 2023; 13(23):12852. https://doi.org/10.3390/app132312852

Chicago/Turabian StyleWu, Xiaodong, Yu Li, Min Gong, Haojun Wu, and Yifan Wu. 2023. "Deformation and Stress Law of Surrounding Rock for a Bifurcated Tunnel with a Super-Large Section: A Case Study" Applied Sciences 13, no. 23: 12852. https://doi.org/10.3390/app132312852

APA StyleWu, X., Li, Y., Gong, M., Wu, H., & Wu, Y. (2023). Deformation and Stress Law of Surrounding Rock for a Bifurcated Tunnel with a Super-Large Section: A Case Study. Applied Sciences, 13(23), 12852. https://doi.org/10.3390/app132312852