Structural Optimization of MicroMED Dust Analyzer

Abstract

:Featured Application

Abstract

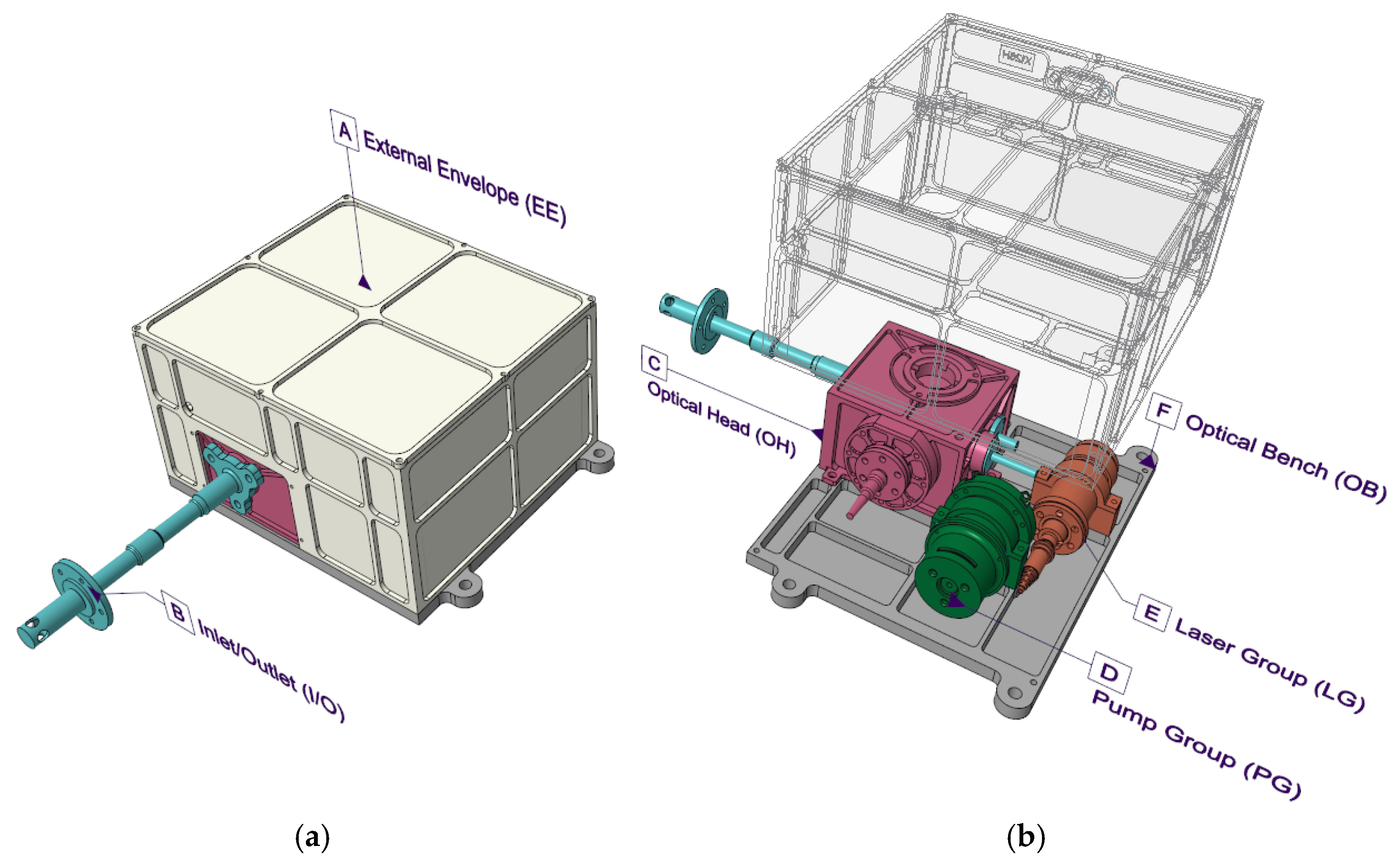

1. Introduction

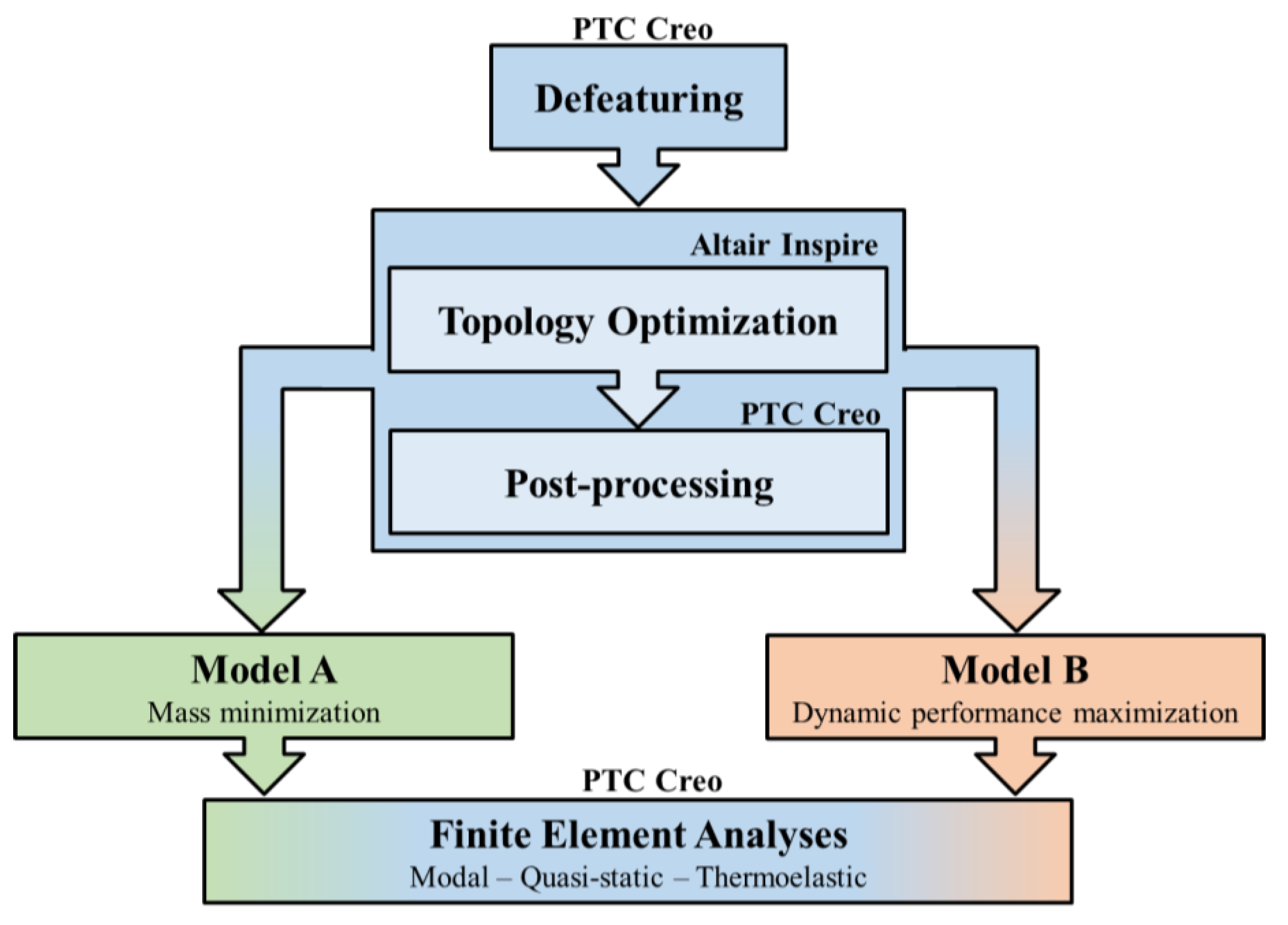

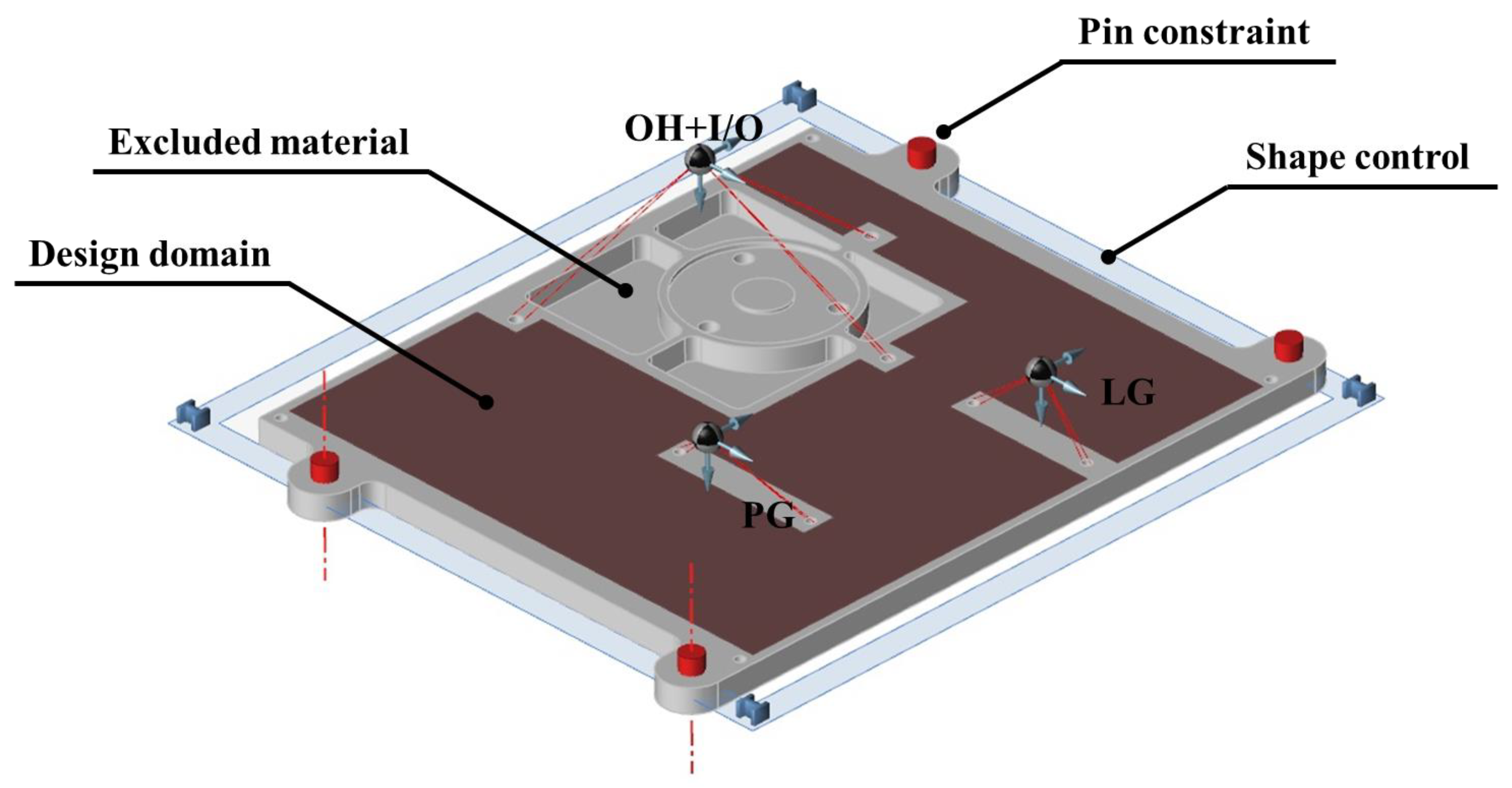

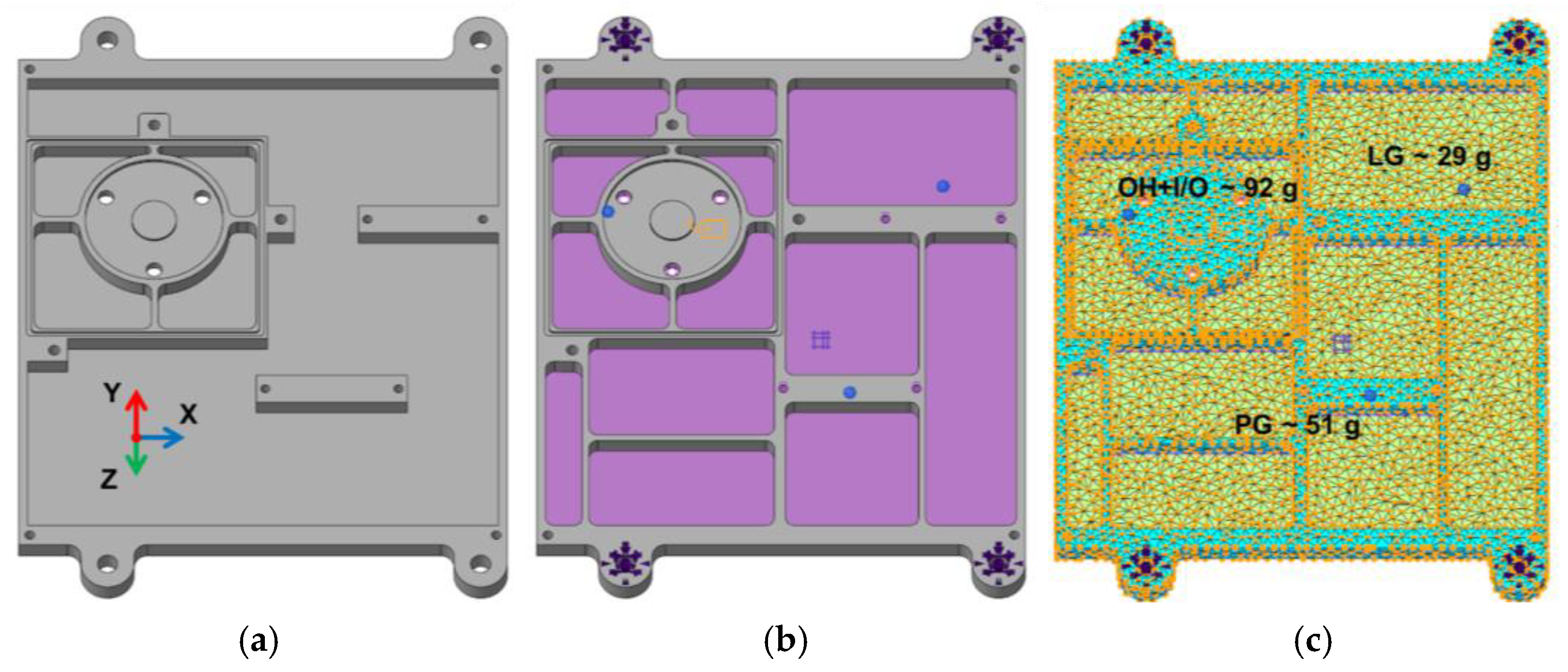

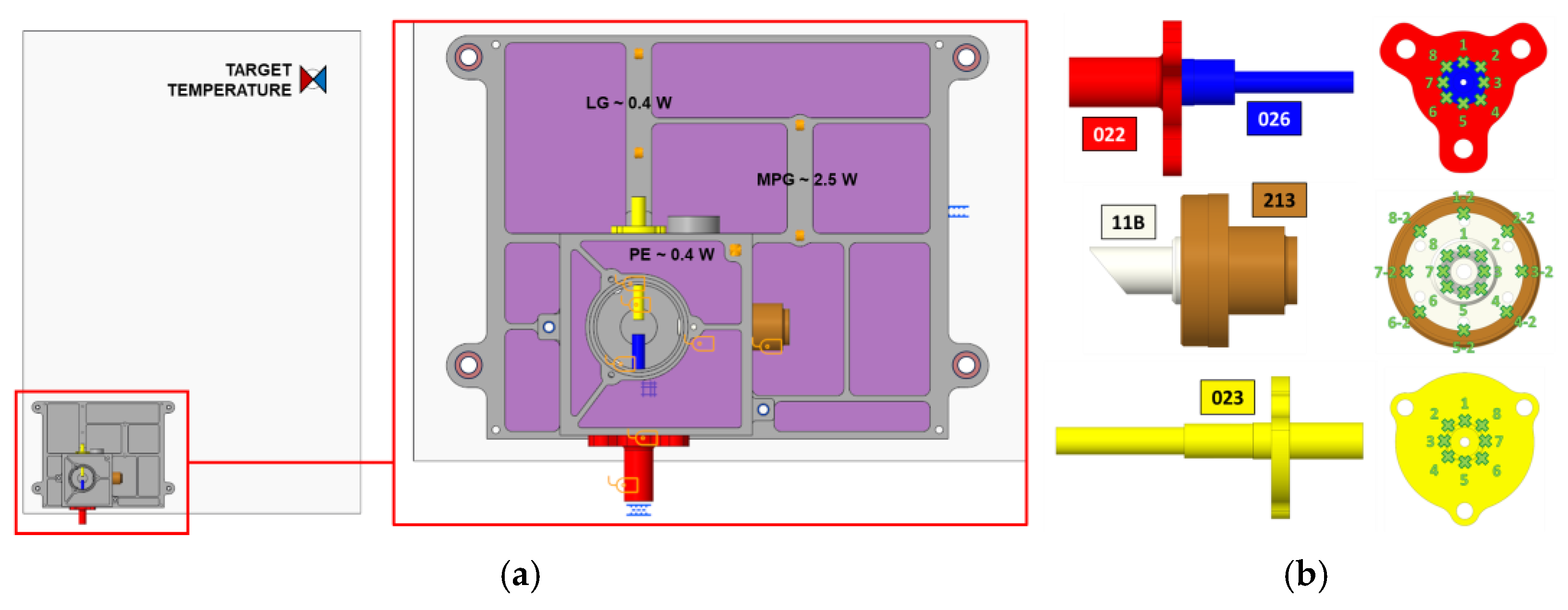

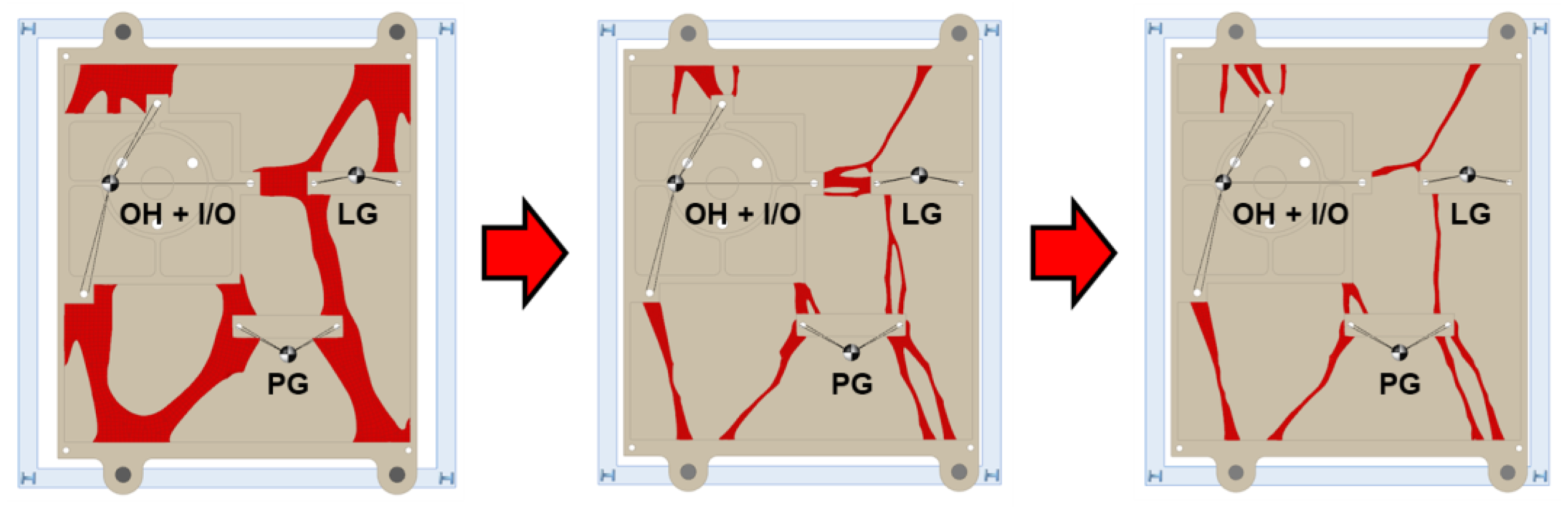

2. Materials and Methods

- Modal analysis aiming to estimate the first five natural frequencies;

- Quasi-static analyses applying a load of 1000 m/s2, probing the state of stress distribution of the models considering three different loading directions (i.e., X, Y, and Z according to the reference frame reported in Figure 4) and resembling the excitation expected during the takeoff and landing phases of the mission; and

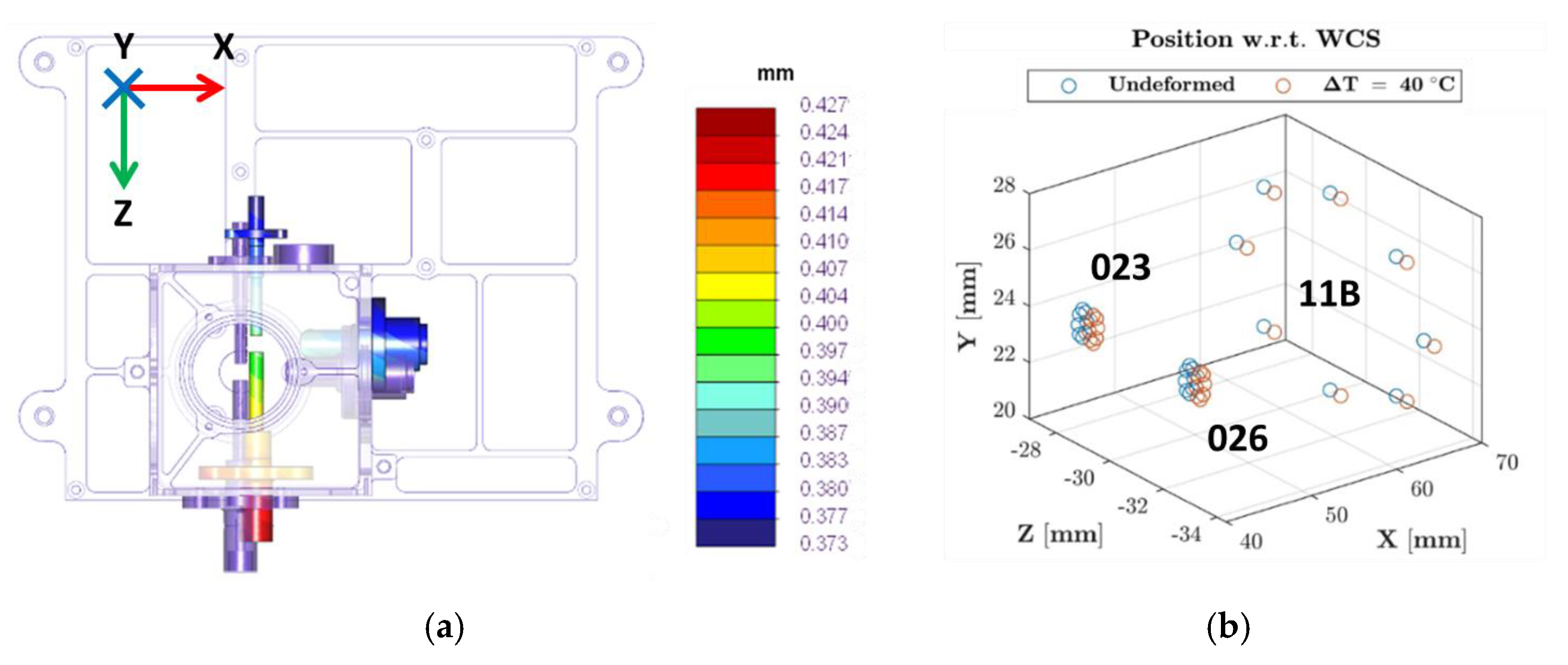

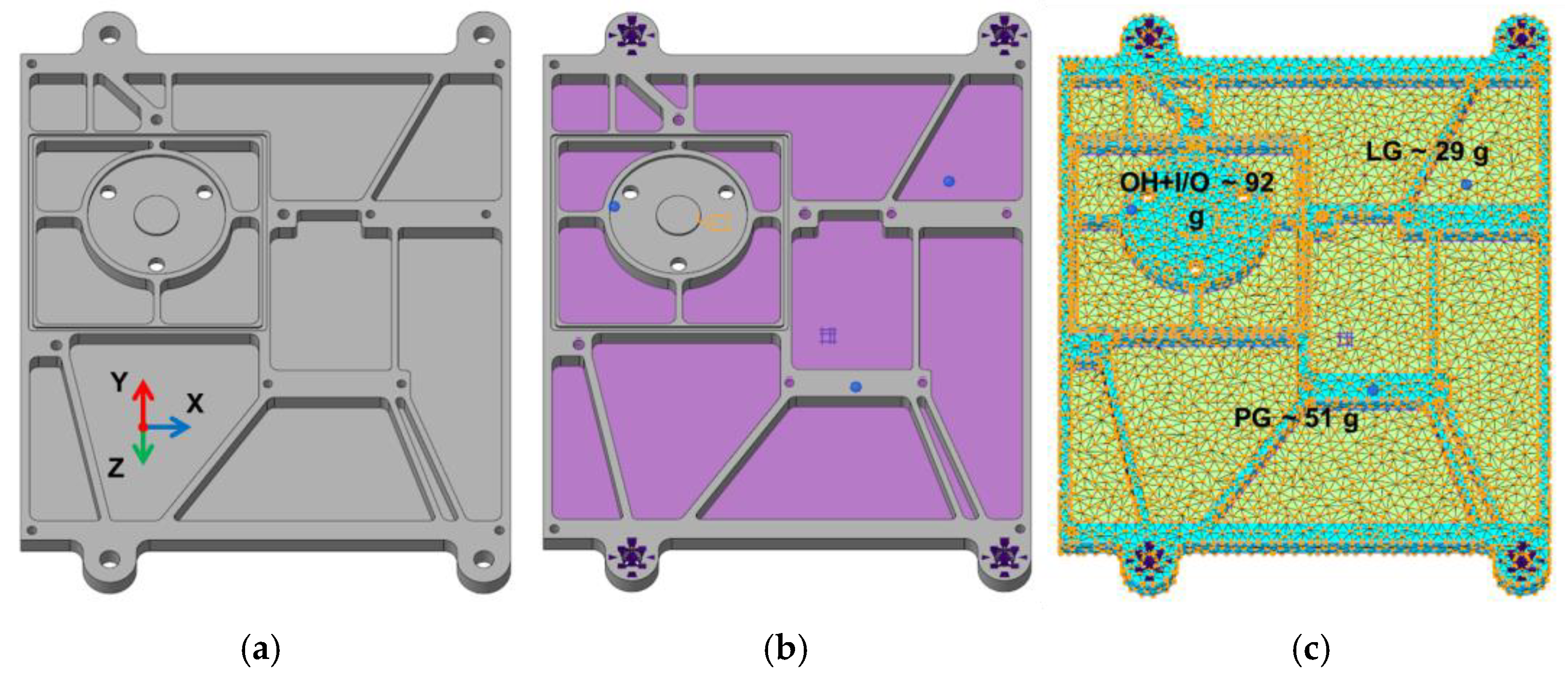

- Thermoelastic analyses in either non-operational (i.e., the cold case, considering a temperature shift from the reference +20 °C to the target −40 °C) or operational (i.e., the hot case, likewise the cold case but within the range +20 °C and +40 °C) conditions.

3. Results

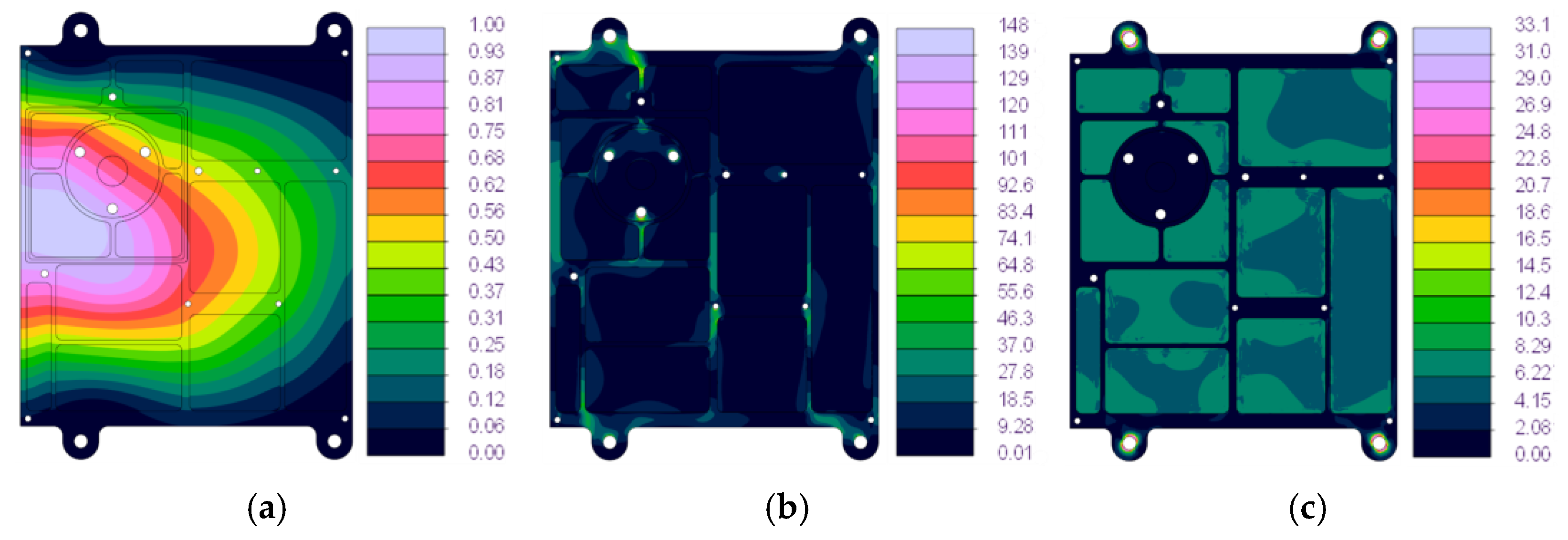

3.1. Current OB

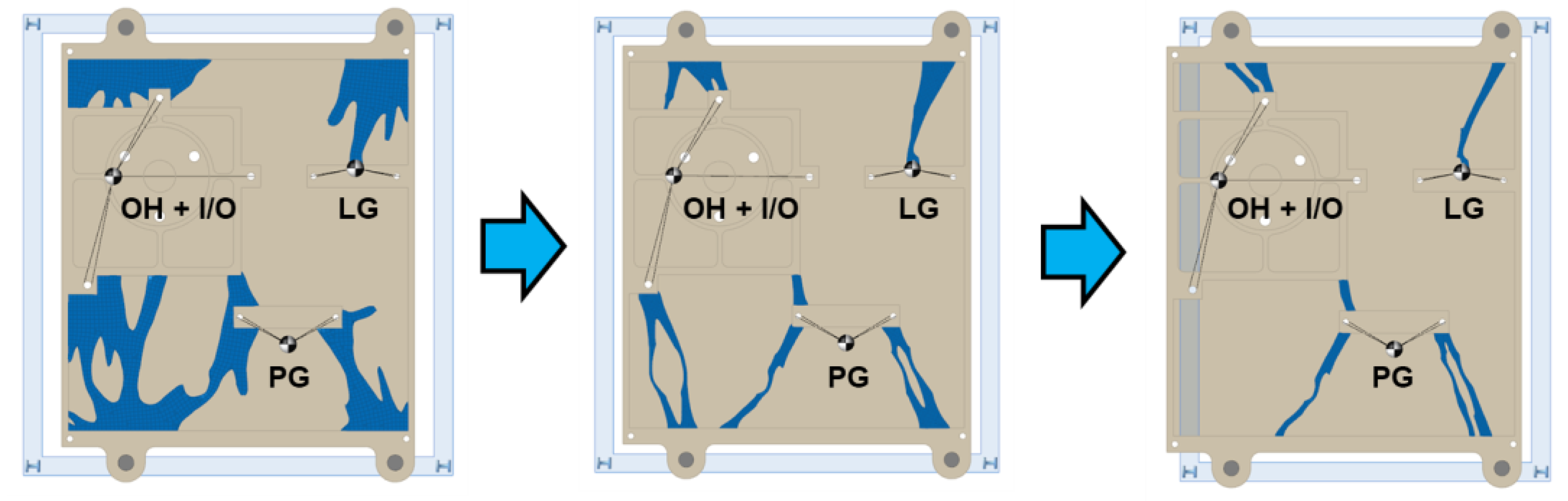

3.2. Optimal OB—Model A

3.3. Optimal OB-Model B

3.4. Optimizations Findings Discussion

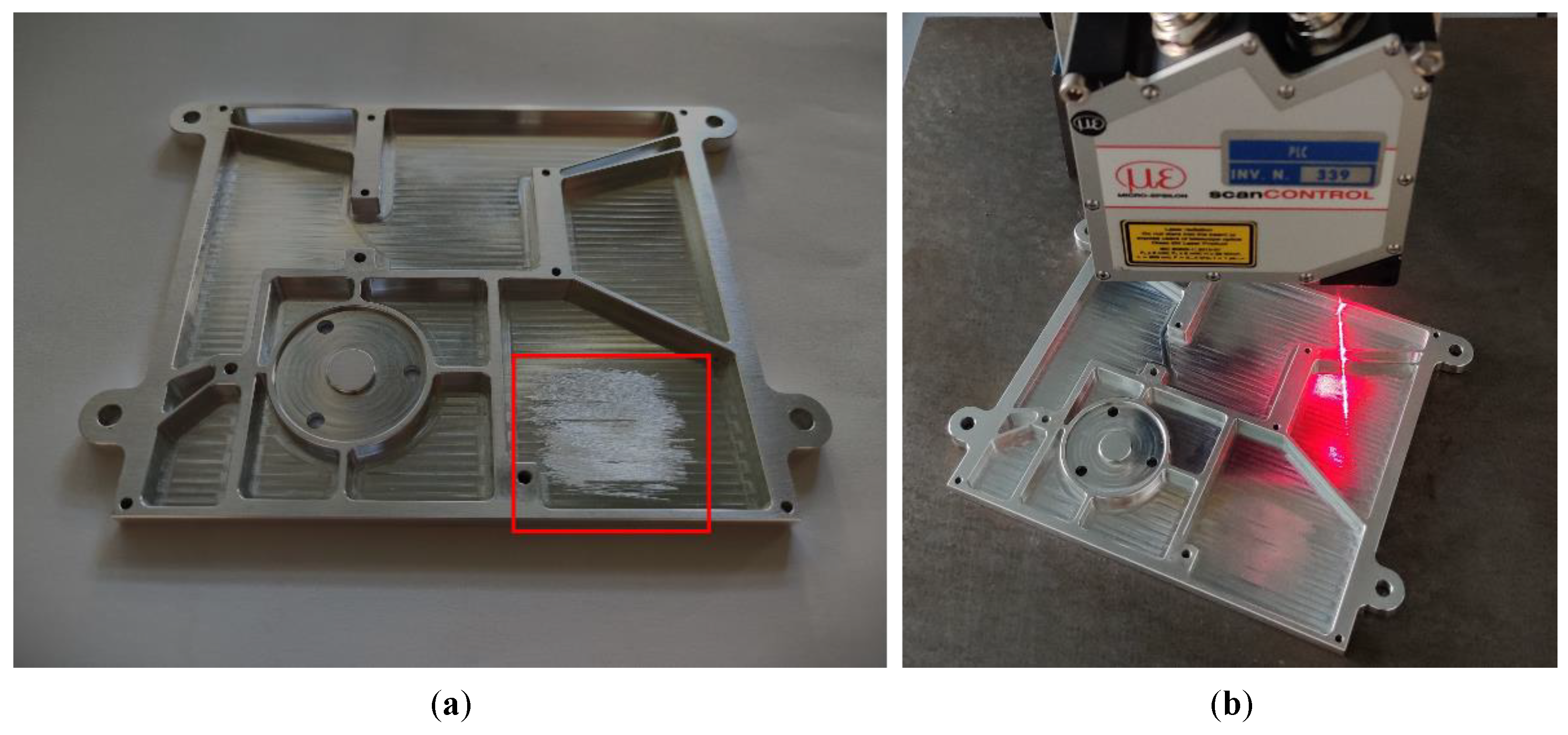

4. Experimental Assessment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

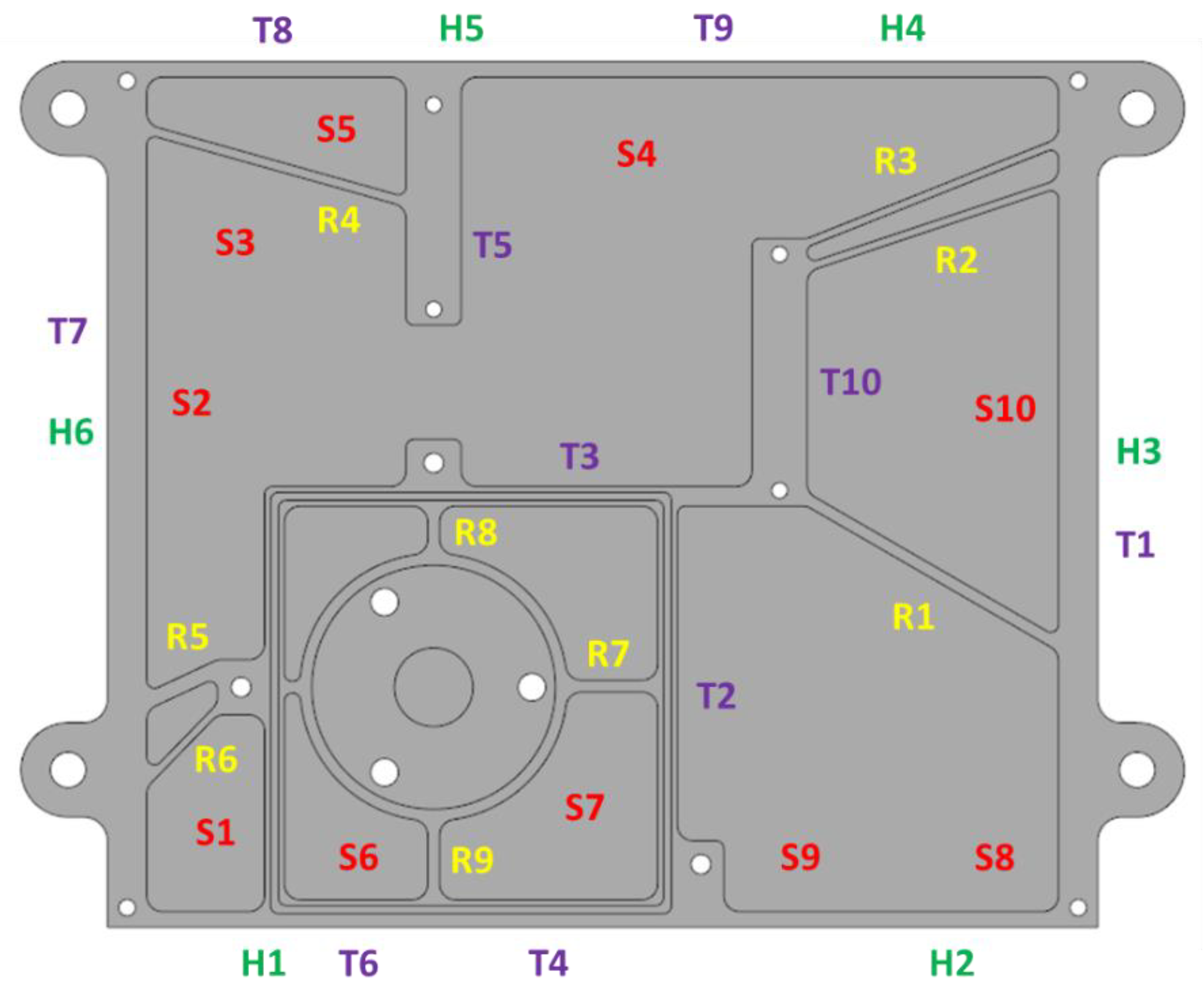

Appendix A

| Fiftieths Linear Gauge (RES 0.02 mm) | Laser Scanner (RES 0.002 mm) | ||||

| Model A footprint: 110.04 × 125.98 mm | Ref. | Measured [mm] | Nominal [mm] | ||

| Gibertini balance (RES 0.01 g) | R1 | 1.484 | 1.500 | ||

| Measured mass [g] | Nominal mass [g] | R2 | 0.988 | 1.000 | |

| 63.88 | 64.63 | R3 | 1.002 | 1.000 | |

| Mitutoyo micrometer (RES 0.001 mm) | R4 | 1.192 | 1.200 | ||

| Ref. | Measured [mm] | Nominal [mm] | R5 | 1.940 | 2.000 |

| S1 | 0.289 | 0.300 | R6 | 0.984 | 1.000 |

| S2 | 0.283 | 0.300 | R7 | 1.466 | 1.500 |

| S3 | 0.282 | 0.300 | R8 | 1.480 | 1.500 |

| S4 | 0.284 | 0.300 | R9 | 1.464 | 1.500 |

| S5 | 0.287 | 0.300 | Fiftieths linear gauge (RES 0.02 mm) | ||

| S6 | 0.288 | 0.300 | Ref. | Measured [mm] | Nominal [mm] |

| S7 | 0.289 | 0.300 | T1 | 5.00 | 5.00 |

| S8 | 0.283 | 0.300 | T2 | 2.44 | 2.50 |

| S9 | 0.282 | 0.300 | T3 | 2.44 | 2.50 |

| S10 | 0.284 | 0.300 | T4 | 3.50 | 3.50 |

| H1 | 0.287 | 5.000 | T5 | 7.00 | 7.00 |

| H2 | 0.288 | 5.000 | T6 | 3.44 | 3.50 |

| H3 | 0.292 | 5.000 | T7 | 4.94 | 5.00 |

| H4 | 0.283 | 5.000 | T8 | 1.92 | 2.00 |

| H5 | 0.285 | 5.000 | T9 | 1.94 | 2.00 |

| H6 | 0.284 | 5.000 | T10 | 6.96 | 7.00 |

Appendix B

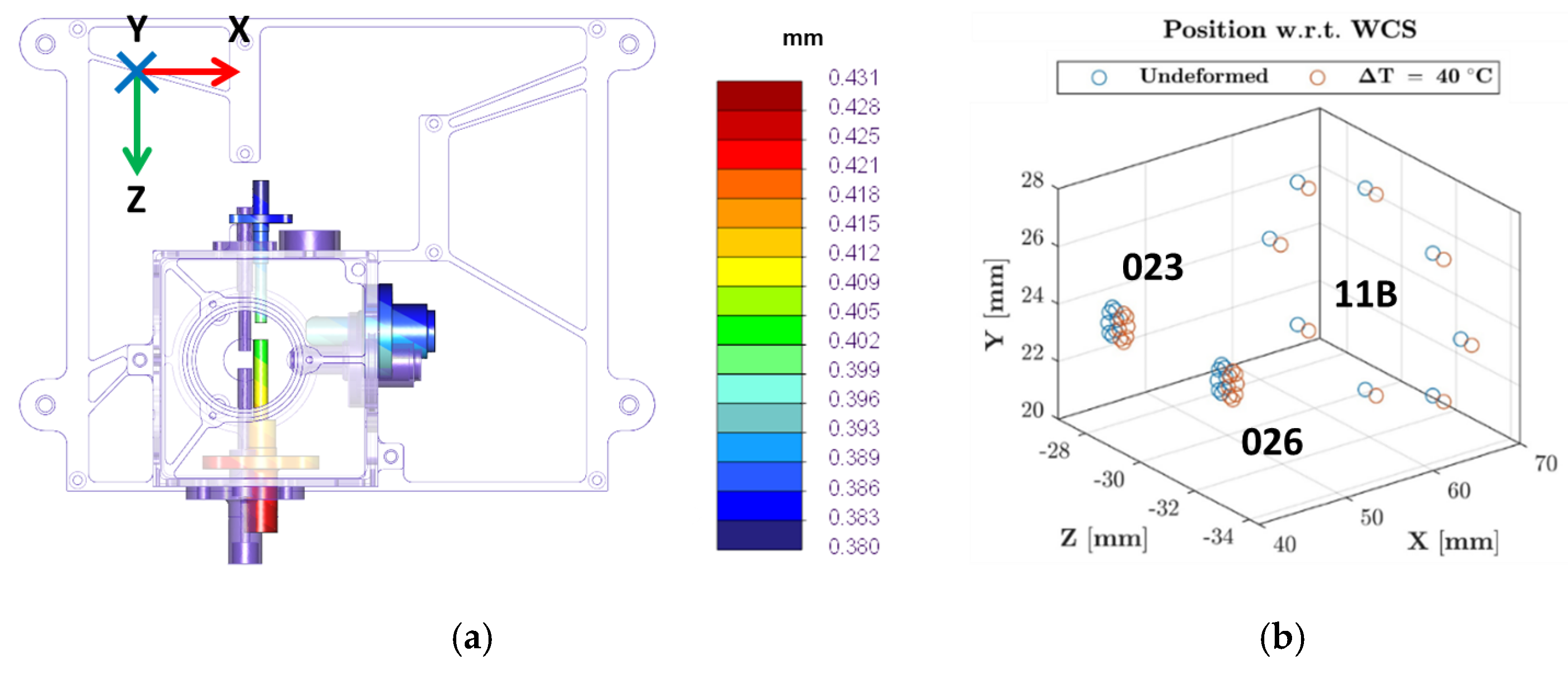

| Probe ID | Displacement with Respect to the Initial Probe Coordinates | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Current OB | Model A | Model B | |||||||

| X [mm] | Y [mm] | Z [mm] | X [mm] | Y [mm] | Z [mm] | X [mm] | Y [mm] | Z [mm] | |

| 023-1 | 0.19028 | −0.06133 | −0.34073 | 0.19263 | −0.06926 | −0.34490 | 0.18705 | −0.11086 | −0.34656 |

| 023-2 | 0.19056 | −0.06134 | −0.34078 | 0.19292 | −0.06925 | −0.34492 | 0.18733 | −0.11086 | −0.34659 |

| 023-3 | 0.19077 | −0.06114 | −0.34089 | 0.19311 | −0.06905 | −0.34494 | 0.18753 | −0.11067 | −0.34663 |

| 023-4 | 0.19078 | −0.06086 | −0.34100 | 0.19311 | −0.06877 | −0.34495 | 0.18753 | −0.11039 | −0.34665 |

| 023-5 | 0.19059 | −0.06065 | −0.34103 | 0.19290 | −0.06857 | −0.34494 | 0.18734 | −0.11019 | −0.34664 |

| 023-6 | 0.19030 | −0.06064 | −0.34098 | 0.19262 | −0.06858 | −0.34492 | 0.18706 | −0.11019 | −0.34661 |

| 023-7 | 0.19009 | −0.06083 | −0.34086 | 0.19242 | −0.06878 | −0.34490 | 0.18686 | −0.11038 | −0.34657 |

| 023-8 | 0.19008 | −0.06112 | −0.34076 | 0.19243 | −0.06906 | −0.34489 | 0.18686 | −0.11066 | −0.34655 |

| 026-1 | 0.19168 | −0.06069 | −0.34280 | 0.19463 | −0.06844 | −0.34713 | 0.18922 | −0.11004 | −0.34864 |

| 026-2 | 0.19149 | −0.06045 | −0.34282 | 0.19443 | −0.06822 | −0.34713 | 0.18904 | −0.10981 | −0.34863 |

| 026-3 | 0.19152 | −0.06016 | −0.34291 | 0.19445 | −0.06792 | −0.34714 | 0.18906 | −0.10952 | −0.34865 |

| 026-4 | 0.19176 | −0.05997 | −0.34300 | 0.19467 | −0.06773 | −0.34715 | 0.18929 | −0.10933 | −0.34867 |

| 026-5 | 0.19205 | −0.06000 | −0.34304 | 0.19496 | −0.06774 | −0.34716 | 0.18959 | −0.10936 | −0.34869 |

| 026-6 | 0.19224 | −0.06023 | −0.34302 | 0.19516 | −0.06797 | −0.34716 | 0.18977 | −0.10959 | −0.34870 |

| 026-7 | 0.19221 | −0.06053 | −0.34293 | 0.19514 | −0.06826 | −0.34716 | 0.18974 | −0.10988 | −0.34868 |

| 026-8 | 0.19198 | −0.06072 | −0.34284 | 0.19492 | −0.06846 | −0.34715 | 0.18952 | −0.11007 | −0.34866 |

| 11B-1 | 0.17442 | −0.05467 | −0.33993 | 0.17718 | −0.06385 | −0.34491 | 0.17205 | −0.10487 | −0.34594 |

| 11B-2 | 0.17477 | −0.05345 | −0.33846 | 0.17747 | −0.06320 | −0.34318 | 0.17239 | −0.10417 | −0.34427 |

| 11B-3 | 0.17562 | −0.05153 | −0.33828 | 0.17823 | −0.06149 | −0.34241 | 0.17322 | −0.10248 | −0.34358 |

| 11B-4 | 0.17644 | −0.05008 | −0.33949 | 0.17899 | −0.05978 | −0.34306 | 0.17402 | −0.10083 | −0.34427 |

| 11B-5 | 0.17678 | −0.04990 | −0.34139 | 0.17933 | −0.05902 | −0.34475 | 0.17436 | −0.10015 | −0.34595 |

| 11B-6 | 0.17643 | −0.05112 | −0.34286 | 0.17904 | −0.05967 | −0.34648 | 0.17401 | −0.10085 | −0.34761 |

| 11B-7 | 0.17558 | −0.05304 | −0.34304 | 0.17829 | −0.06138 | −0.34725 | 0.17318 | −0.10254 | −0.34830 |

| 11B-8 | 0.17476 | −0.05449 | −0.34183 | 0.17753 | −0.06309 | −0.34660 | 0.17238 | −0.10419 | −0.34761 |

References

- Saraçyakupoğlu, T. Usage of Additive Manufacturing and Topology Optimization Process for Weight Reduction Studies in the Aviation History. Adv. Sci. Technol. Eng. Syst. J. 2021, 6, 815–820. [Google Scholar] [CrossRef]

- Scaccabarozzi, D.; Saggin, B.; Alberti, E. Design and Testing of a Roto-Translational Shutter Mechanism for Planetary Operation. Acta Astronaut. 2014, 93, 207–216. [Google Scholar] [CrossRef]

- Shatalina, I.; Saggin, B.; Scaccabarozzi, D.; Panzeri, R. MicroMIMA FTS: Design of Spectrometer for Mars Atmosphere Investigation. In Proceedings of the XVIII SPIE Remote Sensing of Clouds and the Atmosphere, Dresden, Germany, 17 October 2013. [Google Scholar] [CrossRef]

- Satya Hanush, S.; Manjaiah, M. Topology Optimization of Aerospace Part to Enhance the Performance by Additive Manufacturing Process. Mater. Today Proc. 2022, 62, 7373–7378. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, A.E. Progress in Structural Materials for Aerospace Systems. Acta Mater. 2003, 51, 5775–5779. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Zhang, W.-H.; Xia, L. Topology Optimization in Aircraft and Aerospace Structures Design. Arch. Comput. Methods Eng. 2016, 23, 595–622. [Google Scholar] [CrossRef]

- Ooms, T.; Vantyghem, G.; Thienpont, T.; Van Coile, R.; De Corte, W. Compliance-based Topology Optimization of Structural Components Subjected to Thermo-mechanical Loading. Struct. Multidiscip. Optim. 2023, 66, 126. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Q.; Wang, C.; Gong, P.; Shi, Y.; Yu, Y.; Liu, Z. Topology Optimization Design and Experimental Research of a 3D-Printed Metal Aerospace Bracket Considering Fatigue Performance. Appl. Sci. 2021, 11, 6671. [Google Scholar] [CrossRef]

- Li, H.; Liu, R.; He, S.; Xin, R.; Wang, H.; Yu, Z.; Xu, Z. Bionic Design of the Vertical Bracket of Wide Angle Auroral Imager by Additive Manufacturing. Appl. Sci. 2022, 12, 5274. [Google Scholar] [CrossRef]

- Berrocal, L.; Fernández, R.; González, S.; Periñán Santos Tudela, A.; Vilanova, J.; Rubio, L.; Márquez, J.M.M.; Guerrero, J.; Lasagni, F. Topology Optimization and Additive Manufacturing for Aerospace Components. Prog. Addit. Manuf. 2019, 4, 83–95. [Google Scholar] [CrossRef]

- Seabra, M.; Azevedo, J.; Araújo, A.; Reis, L.; Pinto, E.; Alves, N.; Santos, R.; Mortágua, J.P. Selective Laser Melting (SLM) and Topology Optimization for Lighter Aerospace Components. Procedia Struct. Integr. 2016, 1, 289–296. [Google Scholar] [CrossRef]

- Shapiro, A.A.; Borgonia, J.P.; Chen, Q.N.; Dillon, R.P.; McEnerney, B.; Polit-Casillas, R.; Soloway, L. Additive Manufacturing for Aerospace Flight Applications. J. Spacecr. Rocket. Spec. Sel. Adv. Small Satell. Technol. Appl. 2016, 53, 952–959. [Google Scholar] [CrossRef]

- Herrera, A.C. Optimization Driven Design and Additive Manufacturing Applied for ESA Sentinel-1 Antenna Bracket. In Proceedings of the 9th UK Altair Technology Conference, Stratford-Upon-Avon, UK, 16 June 2015; Available online: https://cdn2.hubspot.net/hubfs/47251/UKATC2015_RUAG.pdf?t=1490380914857 (accessed on 24 October 2023).

- Harvey, B. ExoMars; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Vago, J.; Witasse, O.; Svedheim, H.; Baglioni, P.; Haldemann, A.; Gianfiglio, G.; Blancquaert, T.; McCoy, D.; de Groot, R. ESA ExoMars Program: The Next Step in Exploring Mars. Sol. Syst. Res. 2015, 49, 518–528. [Google Scholar] [CrossRef]

- Rodionov, D.; Zelenyi, L.; Korablev, O.; Chulkov, I.; Anufreychik, K.; Marchenkov, K.; and Vago, J. ExoMars-2020 Landing Platform Scientific Payload. In Proceedings of the EGU General Assembly 2020, Online, 4–8 May 2020. [Google Scholar] [CrossRef]

- Scaccabarozzi, D.; Tarabini, M.; Almasio, L.; Saggin, B.; Esposito, F.; Cozzolino, F. Characterization of a Pumping System in Martian-like Environment. In Proceedings of the IEEE International Workshop on Metrology for Aerospace (MetroAeroSpace), Benevento, Italy, 12 May 2014. [Google Scholar] [CrossRef]

- Scaccabarozzi, D.; Saggin, B.; Pagliara, C.; Magni, M.; Tarabini, M.; Esposito, F.; Molfese, C.; Cozzolino, F.; Cortecchia, F.; Dolnikov, G.; et al. MicroMED, Design of a Particle Analyzer for Mars. Measurements 2018, 122, 466–472. [Google Scholar] [CrossRef]

- Scaccabarozzi, D.; Saggin, B.; Somaschini, R.; Magni, M.; Valnegri, P.; Esposito, F.; Molfese, C.; Cozzolino, F.; Mongelluzzo, F. MicroMED Optical Particle Counter: From Design to Flight Model. Sensors 2020, 20, 611. [Google Scholar] [CrossRef]

- Mongelluzzo, G.; Esposito, F.; Cozzolino, F.; Molfese, F.; Silvestro, S.; Ionut Popa, C.; Dall’Ora, M.; Lubieniecki, M.; Cortecchia, F.; Saggin, B.; et al. Optimization of the Fluid Dynamic Design of the Dust Suite-MicroMED Sensor for the ExoMars 2020 Mission. In Proceedings of the IEEE International Workshop on Metrology for Aerospace (MetroAeroSpace), Rome, Italy, 20 June 2018. [Google Scholar] [CrossRef]

- Mongelluzzo, G.; Esposito, F.; Cozzolino, F.; Molfese, C.; Silvestro, S.; Franzese, G.; Ionut Popa, C.; Lubieniecki, M.; Cortecchia, F.; Saggin, B.; et al. CFD Analysis and Optimization of the MicroMED for the ExoMars 2020 Mission. Measurements 2019, 147, 106824. [Google Scholar] [CrossRef]

- Mongelluzzo, G.; Esposito, F.; Cozzolino, F.; Franzese, G.; Ruggeri, A.C.; Porto, C.; Molfese, C.; Scaccabarozzi, D.; Saggin, B. Design and CFD Analysis of the Fluid Dynamic Sampling System of the MicroMED Optical Particle Counter. Sensors 2019, 19, 5037. [Google Scholar] [CrossRef] [PubMed]

- Corti, M.G.; Scaccabarozzi, D.; Saggin, B.; Valnegri, P.; Esposito, F.; Cozzolino, F.; Mongelluzzo, G. Topology Optimization of the Optical Bench for the MicroMED Dust Analyzer. In Proceedings of the IEEE International Workshop on Metrology for Aerospace (MetroAeroSpace), Naples, Italy, 23 June 2021. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods, and Applications, 2nd ed.; Springer: Berlin, Germany, 2011. [Google Scholar] [CrossRef]

- Gandhi, Y.; Minak, G. A Review on Topology Optimization Strategies for Additively Manufactured Continuous Fiber-Reinforced Composite Structures. Appl. Sci. 2022, 12, 11211. [Google Scholar] [CrossRef]

- Kandemir, V.; Dogan, O.; Yaman, U. Topology Optimization of 2.5D Parts Using the SIMP Method with a Variable Thickness Approach. Procedia Manuf. 2018, 17, 29–36. [Google Scholar] [CrossRef]

- Fetisov, K.V.; Maksimov, P.V. Topology Optimization and Laser Additive Manufacturing in Design Process of Efficiency Lightweight Aerospace Parts. J. Phys. Conf. Ser. 2018, 1015, 052006. [Google Scholar] [CrossRef]

- European Cooperation for Space Standardization (ECSS). Space Engineering: Mechanisms—ECSS-E-ST-33-01C. ESA-ESTEC, Noordwijk. 2019. Available online: https://ecss.nl/standard/ecss-e-st-33-01c-rev-2-1-march-2019-space-engineering-mechanisms/ (accessed on 24 October 2023).

| Resonances [Hz] | Von Mises Quasi-Static Stresses [MPa] | ||||||||||||

| f1 | f2 | f3 | f4 | f5 | |||||||||

| 407 | 530 | 798 | 926 | 1193 | 29 | 10.7 | 84 | 2.99 | 45 | 6.50 | |||

| Von Mises Thermoelastic Stresses [MPa] | |||||||||||||

| Cold case | Hot case | ||||||||||||

| 12 | 28 | 4 | 88 | ||||||||||

| Resonances [Hz] | Von Mises Quasi-Static Stresses [MPa] | ||||||||||||

| f1 | f2 | f3 | f4 | f5 | |||||||||

| 412 | 521 | 627 | 745 | 791 | 39 | 7.50 | 107 | 2.12 | 50 | 5.74 | |||

| Von Mises Thermoelastic Stresses [MPa] | |||||||||||||

| Cold case | Hot case | ||||||||||||

| 11 | 29 | 4 | 88 | ||||||||||

| Resonances [Hz] | Von Mises Quasi-Static Stresses [MPa] | ||||||||||||

| f1 | f2 | f3 | f4 | f5 | |||||||||

| 607 | 725 | 872 | 1104 | 1240 | 25 | 12.6 | 87 | 2.86 | 34 | 8.85 | |||

| Von Mises Thermoelastic Stresses [MPa] | |||||||||||||

| Cold case | Hot case | ||||||||||||

| 31 | 9.9 | 10 | 31.7 | ||||||||||

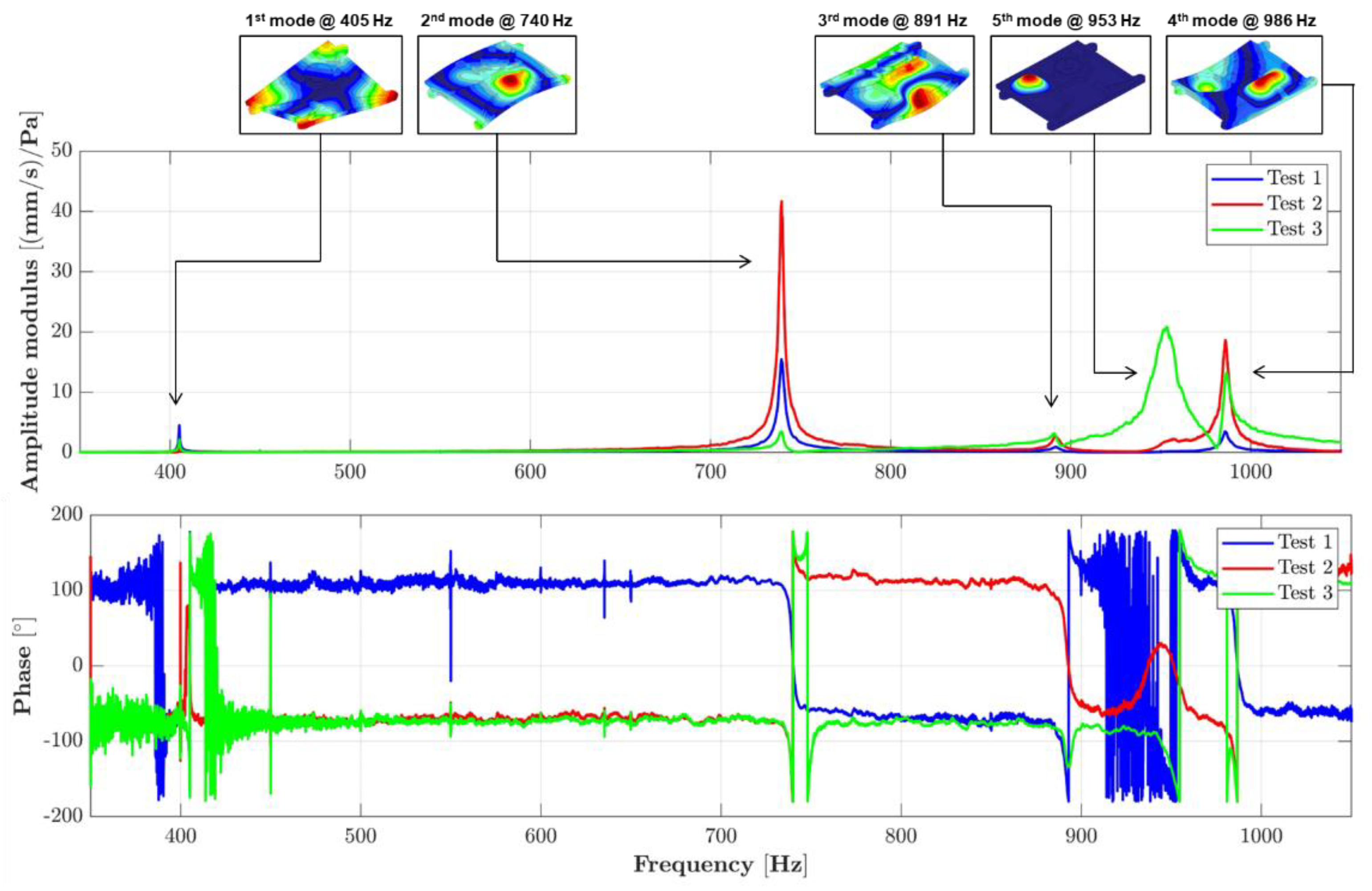

| Natural Vibrating Resonances [Hz] | ||||

|---|---|---|---|---|

| f1 | f2 | f3 | f4 | f5 |

| 392 | 747 | 898 | 990 | 1159 |

| (390) | (742) | (904) | (991) | (1168) |

| Vibrating Mode | Numerical [Hz] | Experimental [Hz] | ∆ |

|---|---|---|---|

| 1st | 392 | 405 | +3.32% |

| 2nd | 747 | 740 | −1.00% |

| 3rd | 898 | 891 | −0.74% |

| 4th | 990 | 986 | −0.42% |

| 5th | 1159 | 953 | −17.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corti, M.G.; Saggin, B.; Esposito, F.; Franzese, G.; Porto, C.; Mongelluzzo, G.; Cozzolino, F.; Scaccabarozzi, D. Structural Optimization of MicroMED Dust Analyzer. Appl. Sci. 2023, 13, 12810. https://doi.org/10.3390/app132312810

Corti MG, Saggin B, Esposito F, Franzese G, Porto C, Mongelluzzo G, Cozzolino F, Scaccabarozzi D. Structural Optimization of MicroMED Dust Analyzer. Applied Sciences. 2023; 13(23):12810. https://doi.org/10.3390/app132312810

Chicago/Turabian StyleCorti, Marco Giovanni, Bortolino Saggin, Francesca Esposito, Gabriele Franzese, Carmen Porto, Giuseppe Mongelluzzo, Fabio Cozzolino, and Diego Scaccabarozzi. 2023. "Structural Optimization of MicroMED Dust Analyzer" Applied Sciences 13, no. 23: 12810. https://doi.org/10.3390/app132312810

APA StyleCorti, M. G., Saggin, B., Esposito, F., Franzese, G., Porto, C., Mongelluzzo, G., Cozzolino, F., & Scaccabarozzi, D. (2023). Structural Optimization of MicroMED Dust Analyzer. Applied Sciences, 13(23), 12810. https://doi.org/10.3390/app132312810