Abstract

Open-pit mines are becoming more intelligent and unmanned. One of the core technologies for autonomous driving is high-definition map technology, while refined mine maps are also needed to support scenarios such as vehicle–shovel collaboration, loading and unloading, production scheduling, and traffic safety control. To better serve the construction of intelligent mines and address the autonomous driving needs in open-pit mining scenarios, a universal high-definition map data model oriented toward data production and exchange, Open-Pit Map (OP map for short), has been designed. Based on various working scenarios of open-pit mines, eight practical basic elements, eleven location elements, and eight traffic elements in OP map were proposed. A map visualization tool, MapViewer, was developed based on OP map, and the effectiveness and practicality of the data model in the practical application of an intelligent shipping system in a Chinese mine were validated.

1. Introduction

High-definition maps (HD maps for short), due to the demand for autonomous driving technology, are recognized as an indispensable core technology for autonomous driving [1]. Compared with the electronic navigation maps that are currently in common use, HD maps not only have higher absolute coordinate accuracy, but also have more detailed road traffic elements and higher real-time performance. In autonomous driving systems, HD maps can compensate for the limitations of sensor detection, are not affected by severe weather, and provide centimeter-level precision information, greatly improving the accuracy of perception and positioning. Accurate prior information on the surrounding environment of the road also ensures that a vehicle can drive under fault handling and emergency conditions, and plays an important role in the process of perception, positioning, planning, decision-making, and control [2,3].

An open-pit mine is a closed scene with simple traffic signs, low route complexity, low requirements for vehicle speed, and fewer pedestrians and other static distractions. The production and transportation operations of open-pit mines are planned and organized, and the value of the mining vehicle is high, meaning that mining enterprises have a high acceptance of high-cost and high-quality hardware. High-quality hardware leads to better implementation conditions for autonomous driving [4]. The realization of autonomous driving in open-pit mining areas can effectively reduce the safety risks caused by harsh environments and alleviate costs caused by labor shortages and labor cost increases, which is in line with the direction of green mines and intelligent mines [5].

HD maps are one of the core technologies that are needed to realize autonomous driving in open-pit mines. The support of HD maps in production operation, real-time path planning, real-time equipment scheduling, real-time safety control, and other businesses activities is crucial [6]. The creation of an HD map can not only meet the needs of autonomous driving, but also meet the needs of mine production management and production scheduling, which can effectively improve the effectiveness of comprehensive mining control.

At present, the international standard formats for HD maps include the Navigation Data Standard (NDS), Open Street Map (OSM), Geographic Data Files (GDF), OpenDRIVE, Lanelets, etc. These standard formats have rich element layer information and attribute information for highway or urban road scenes. These formats are not suitable for direct application in open-pit mines [7], because the attributes of roads in the open-pit mines scene have a lot of changes due to business management and production needs, so the data model of HD maps for open-pit mines not only includes the road layer, lane layer, map feature layer, but also includes the scene element layer and traffic information layer for the open-pit mines.

Some research on autonomous driving in open-pit mines has been conducted. Kasper Johansen [8] used unmanned aerial vehicles to automatically map indicators of safety, stability, and sustainability of rehabilitation efforts in coalmine sites. Ziyu Zhao and Lin Bi [9] proposed a path planning method based on a high-precision digital map. Xiaowei Wang et al. [10] proposed an HD map construction and update system for autonomous driving in open-pit mines. However, the structures and elements of the HD maps in these studies were neither detailed nor compatible for all of the common open-pit mining scenarios.

In this article, common open-pit mining scenarios have been summarized. A universal HD map data model, Open-Pit Map, oriented toward data production and exchange was designed specifically for different scenarios in open-pit mines. Based on the data model, the map visualization tool, MapViewer, was developed, and its practicability and effectiveness were verified in a Chinese mine intelligent loading system project. The universal data models and visualization tools is open source now (https://gitee.com/wang-zhuo2734/openpit_map, accessed on 29 October 2023), relevant researchers are welcome to participate in the improvement and extension of the data model.

2. Application Scenario of HD Maps for Open-Pit Mines

2.1. Research Status of HD maps

HD maps include a data model and storage file format, with the data models constituting the core [11]. The data model is the abstract and digital expression of the physical elements in the real scene, and the data logical structure that accurately reflects the scene elements and the road environment. The data model of HD maps usually includes elements (objects), attributes and relationships, classification and organization of data, coding of data, geometric and topological representation relations, and production and application expansion oriented toward the scenario requirements [12].

- “NDS (Open Lane Model)”. NDS is a navigation electronic map data storage standard based on an embedded database, which is oriented toward vehicle navigation and supports incremental updates [13]. It divides the content of map data into six logical functional structure units (building blocks): road, lane, name, basic map display, area of interest, and traffic information. The Open Lane Model 1.0 released by NDS is an independent release of the standard lane modeling, lane connection, lane identification, lane type attributes, and other elements to further promote the application of navigation maps in autonomous driving.

- “Lanelets”. Lanelets is an open source HD map format for autonomous driving [14,15]. A road network in Lanelets maps is made up of lanes, roads, and intersections. Each lane segment consists of left and right borders, which are themselves polylines. Interconnecting lanes (lanelets) can be used to describe the driving area of an autonomous vehicle, which can satisfy the path planning and traffic rule compliance of an autonomous vehicle. Lanelet2 describes the frame of the map in more detail. The basic elements are divided into two layers: the physical layer, which consists of real, observable elements, including strings of points and lines and the relationship layer, including traffic rules and applicable lanes.

- “OpenDRIVE”. OpenDRIVE is an open data standard and a description of a static road network, which is commonly used in driving simulation and traffic simulation [16]. It uses nodes and elements to organize various types of information in the road and adds detailed attributes. For example, roads, lanes, links, traffic lights, and intersections are used to build road traffic networks.

- “Apollo OpenDRIVE”. Baidu’s open source project, Apollo, has made some improvements to the OpenDRIVE format based on its own application scenarios and practical experience [17]. For example, Apollo Opendrive uses point sequences composed of absolute coordinate points to describe the geometric shape of elements, such as the description of road boundaries, which can describe complex lane shapes more efficiently and is more common in data expression.

Various international data standards [18] were extensively referenced when establishing a high-definition data model for an open-pit mine’s topographic map, the above three most widely used standards were selected for comparison, as shown in Table 1. The NDS format is oriented toward vehicle navigation applications and has a complex and rigorous storage format, which is difficult to apply directly. The Lanelets map format relies too much on small lanes (lanelets) and the topology of road networks is complex. Lanes in OpenDRIVE are created by lateral offset relative to the road reference line, which is complicated in a scenario with many lanes and variations. However, in open-pit mines, there is basically no multi-lane changing road in the same direction, and the OpenDRIVE data standard is the most widely used in Chinese autonomous driving technology companies. Therefore, the basic elements and formats involved in creating the road network in OpenDRIVE and Apollo are referenced and given a new meaning in conjunction with the open-pit scenario.

Table 1.

Comparison of NDS, Lanelets, and OpenDRIVE.

2.2. Application Scenarios of HD Maps in Open-Pit Mining

The mining industry is currently undergoing significant development towards automation, which includes the implementation of smart equipment and facilities, unmanned operational processes, and data-driven management methods. Among these advancements in automation, the fastest-growing sector is the autonomous driving system, which plays a pivotal role throughout the entire production management process [19].

Different open-pit mines may feature varying extraction environments and operational processes, but their mining methods and production activities share similarities. For instance, in the production operation zones, autonomous vehicles are required to autonomously locate themselves, follow designated paths, actively avoid collisions, coordinate loading and unloading tasks, and perform other functions. Maintenance areas within the mine must facilitate routine equipment maintenance and immediate fault repairs. The control center plays a critical role in tasks such as path planning, real-time monitoring, and data recording [20]. Diverse operational needs, including unmanned transport, shovel-truck coordination, queue management, and scheduling optimization, place greater demands on the elements and attribute representation within HD maps. This necessitates the categorization, definition, and organization of multidimensional data within open-pit mining scenarios [21,22,23]. In order to understand the creation concept of this data model, the typical application scenarios of HD maps in open-pit mines are described in detail.

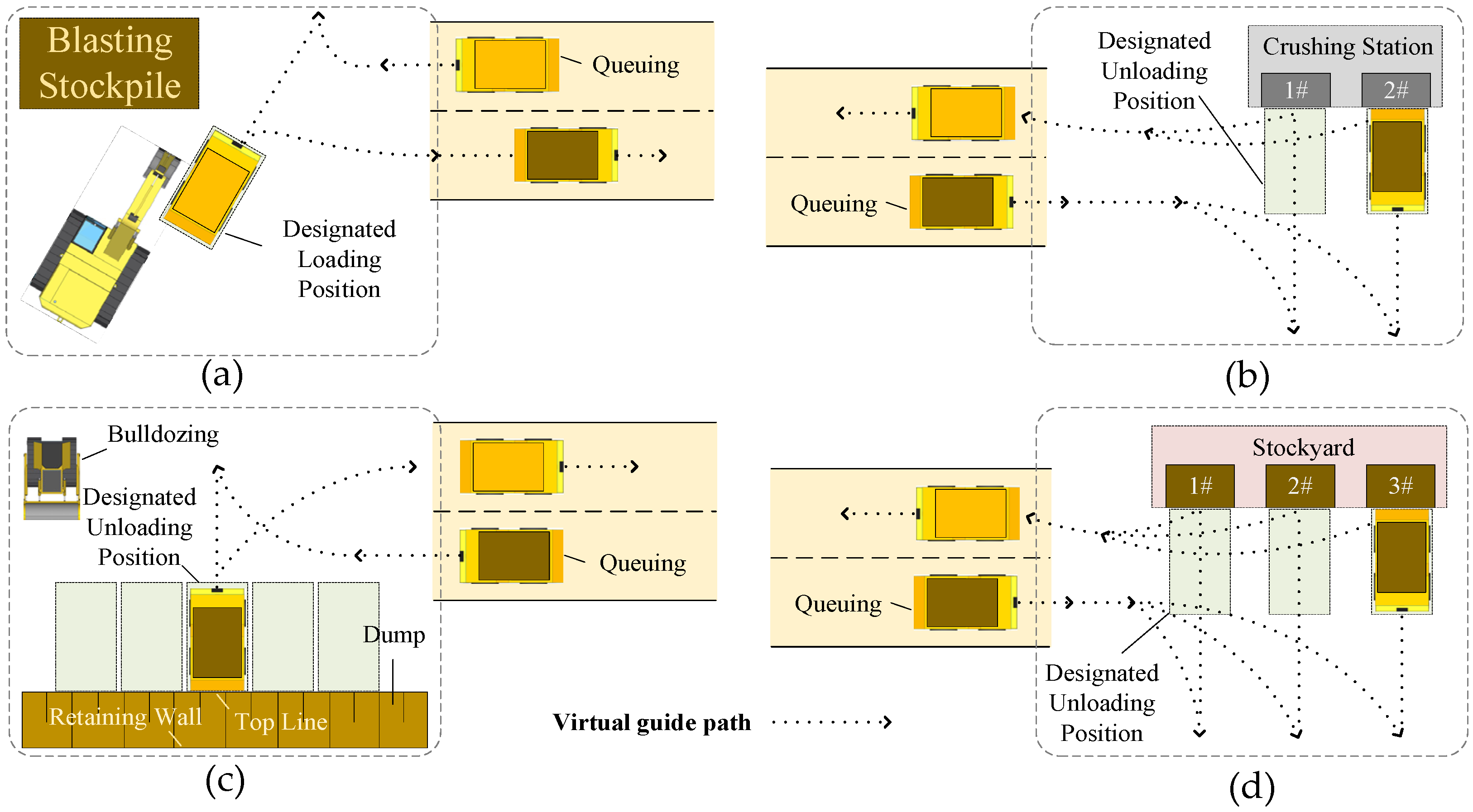

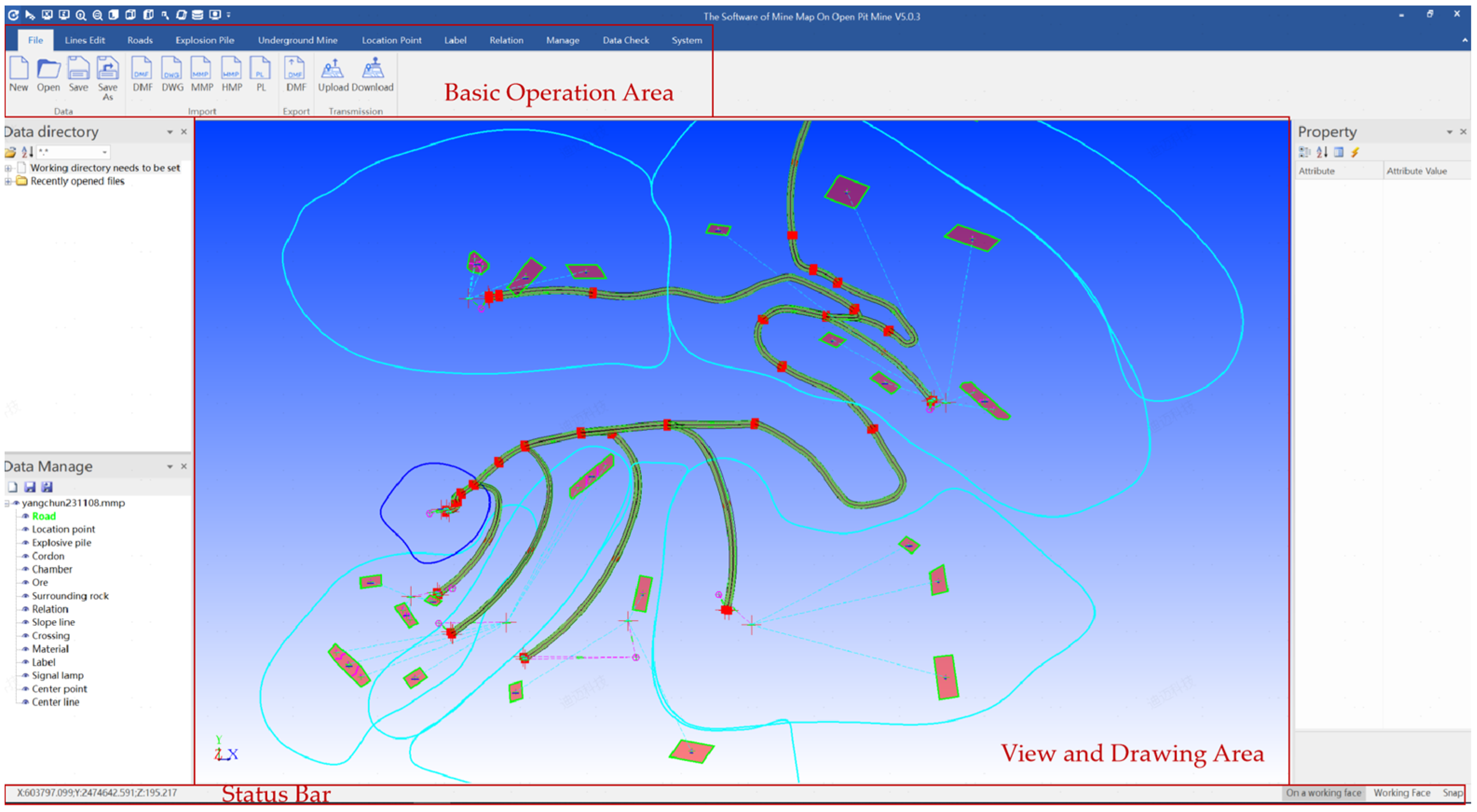

- Production operation coordination and exchange scenarios, including scenarios where mining trucks and shovels cooperate during loading operations, mining trucks coordinate with auxiliary vehicles during unloading operations, and mining trucks queue for exchange during loading and unloading operations.

- Loading operation coordination. Taking the example of coordination between mining trucks and shovels, in the loading area near the blasting stockpile, shovels excavate overburden and ore, loading them into transport trucks. During this process, the trucks and shovels must work together to determine the route for the trucks to enter the loading area. The scenario is described as follows: empty mining trucks enter the loading area and queue up in a designated zone, waiting for loading. The trucks receive information about the shovel’s position and their own loading bay. Upon receiving the instruction to enter the loading bay, the mining trucks move in, are loaded, and then depart.

- Unloading operation coordination. Mining trucks typically have three types of unloading points: dumpsites, crushing stations, and stockyards. When a mining truck enters an unloading area, coordination is required between the vehicles and auxiliary equipment. The scenario is described as follows: transport trucks enter the unloading area and wait in a designated zone for unloading, the truck receives the signal to unload, moves into the unloading bay, unloads, and then departs.

Loading and unloading locations typically lack precise road infrastructure. In HD maps, it is necessary to accurately define the blasting stockpile area, loading and unloading areas, mining truck loading and unloading positions, and waiting zones. This involves setting electronic fences and defining driving and exchange rules so that vehicles can autonomously trigger actions according to the positions. Figure 1 shows scenarios of collaboration in operations and shift.

Figure 1.

Collaboration in operations and shift scenarios. (a) Blasting stockpile loading. (b) Unloading at the crushing station. (c) Dumpsite unloading. (d) Stockyard unloading.

- 2.

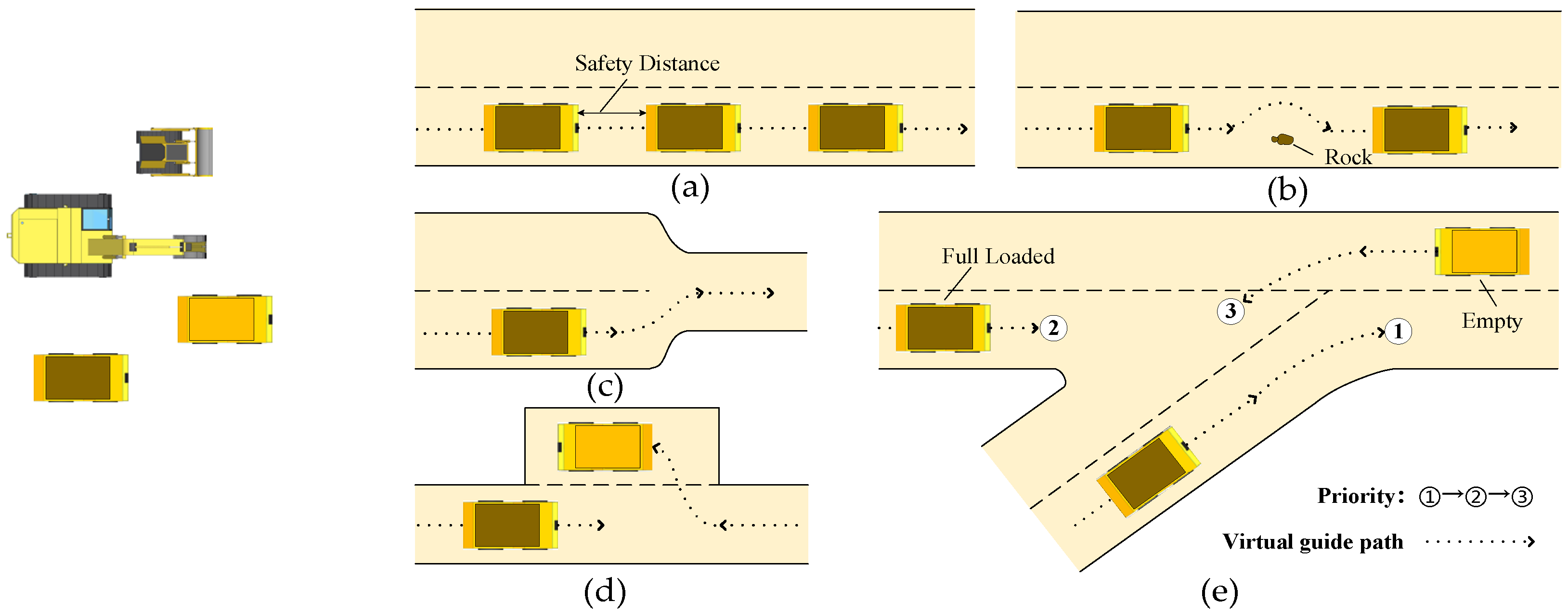

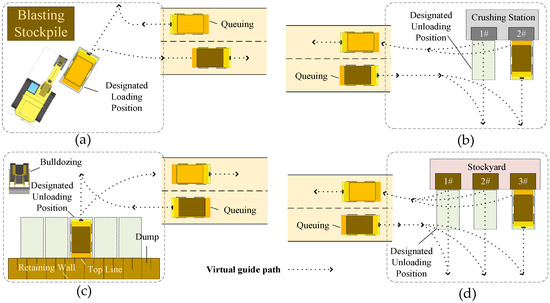

- Unmanned transportation and safety traffic management scenarios, which refer to scenarios in which mining trucks engage in activities such as platooning, obstacle avoidance, encounters, passing, and collision prevention.

- Vehicle platooning. Vehicles and equipment traveling on roads will continuously collect real-time information about the leading vehicle’s status, speed, and the distance between vehicles. Information is used to determine a safe following distance and guide the vehicle to either slow down or maintain its current speed.

- Vehicle obstacle avoidance. In addition to regular platooning in open-pit mining, real-time road conditions may involve overtaking actions by different types of operational equipment, detours around equipment undergoing maintenance, and obstacle avoidance in situations where large rocks and soil are scattered on the road. Vehicles and equipment must make real-time decisions and plan suitable routes in these scenarios.

- Intersection encounter and collision prevention. When multiple vehicles travel toward each other or encounter each other at intersections, real-time encounter information (vehicle type, speed, distance, etc.) is transmitted to each vehicle. Each vehicle, based on encounter rules (priority for heavy vehicles, priority for unmanned vehicles, etc.), will either stop or slow down to ensure smooth traffic flow at intersections. With knowledge of the drivable areas, vehicles can follow designated paths. Additionally, the precise three-dimensional positioning of vehicles within the scenario effectively prevents equipment collisions.

HD maps need to provide detailed descriptions of roads and lanes in open-pit mines, along with establishing prior scene information. By combining accurate vehicle and equipment positioning with real-time perception, vehicles and equipment can make timely decisions to prevent accidents in hazardous situations. Selected scenario illustrations are shown in Figure 2.

Figure 2.

Unmanned transportation and safe traffic management scenarios. (a) Platooning. (b) Obstacle avoidance. (c) Narrowing of lanes. (d) Passing bay. (e) Intersection.

- 3.

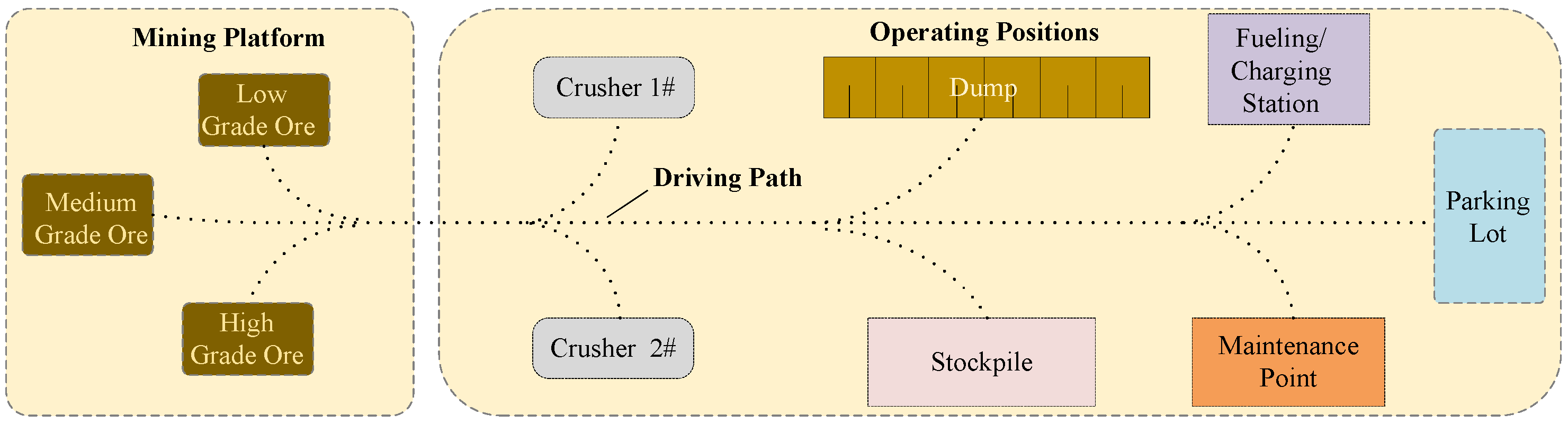

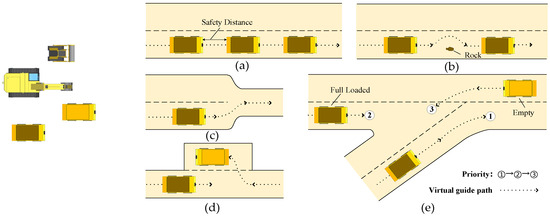

- Production scheduling and path planning scenarios. Production scheduling is crucial for ensuring orderly operations and optimal efficiency in a mining operation. Mining trucks shuttle between loading and unloading points based on ore allocation instructions. After each loading or unloading, the next optimal loading or unloading point and the best route are continuously evaluated. Additionally, equipment conditions such as fueling (charging) and maintenance needs are considered in real-time.

- Path planning. Based on scheduling directives, HD map generates a global planning path between the starting point and destination. Mining trucks are then driven following this path. In the process of driving, local path planning is carried out according to vehicle working conditions and real-time road conditions. When no predefined road exists, paths are generated in real-time using information from the HD map about drivable areas.

HD maps must provide accurate descriptions of information such as blasting stockpile details, material information, and ore grade levels. HD maps also need precise positioning of the road network and various location areas, establishing a topological map of the entire scene’s road network and creating precise paths between operational points. A conceptual representation of the scenario is provided in Figure 3.

Figure 3.

Production scheduling and path planning scenarios.

- 4.

- Safety alert and real-time road condition scenarios. In open-pit mining, roadside equipment and sensors on transportation vehicles identify information about road obstacles, road surface water accumulation, snow conditions, weather conditions, and more. This information is transmitted to the control center in real-time and is updated on the dynamic information layer of the HD map. It is promptly relayed to any potentially affected equipment. When the mining operation is planning explosives handling and blasting activities, it is essential to establish alert zones for both the construction phase and the blasting phase. During these phases, the entry of equipment and personnel is strictly prohibited. The HD map must clearly define the boundaries of these restricted areas.

3. OpenPit-Map Data Model

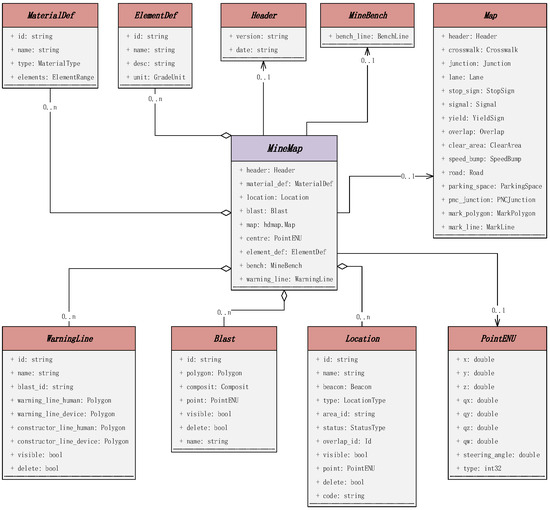

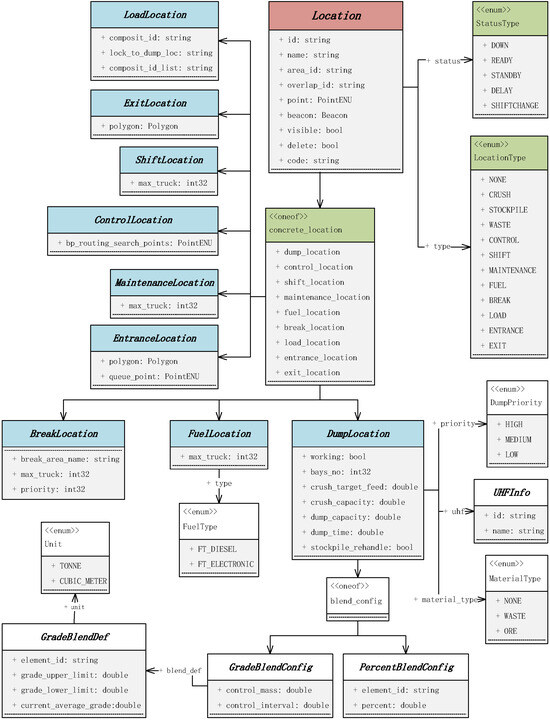

The HD map data model of an open-pit mine is defined according to the requirements of the application scenarios. The map data model adopts the format of the Google Protocol Buffer (ProtoBuf), which is convenient for reading and extending files in different types of programming languages and terminal applications. In this paper, part of the content is shown in the form of a UML class diagram, and its basic elements are shown in Figure 4. The definitions and naming of each basic element are described in detail below.

- “Header”. This section is used to describe version and date information in the HD map for open-pit mines.

- “PointENU”. This data structure is utilized to describe geometric points. A single point is used to represent key information in the HD map, such as the map’s center point and position points for various areas. Points are combined to create key line information, which can describe features like road centerlines, boundaries, and terraces in an open-pit mine. Additionally, points are used to form polygons to describe the shape of area positions, such as blasting stockpile boundaries, parking areas, and alert zones.

- “Map”. This section is used to describe and store the geometric and topological structure of the road network. It can be divided into five main parts. The first part consists of road elements, including roads, which are composed of one or more road sections. Each road section is made up of one or more lanes with different speed limits and travel directions. Each lane has left and right road boundaries. Lanes are formed by the road centerline, lane left and right boundaries, and lane sample association lines. Lane attributes include length, weight and weight limit, type, direction, turning, slope, name, lane closure status (default open), and topological relationships such as predecessors and successors, left and right adjacency. The second part consists of intersection elements, including junctions, which are represented by polygons that define their boundary ranges. The third part includes traffic signal elements, which consist of signal signs represented by boundary lines and stop lines, as well as other signal signs like stop signals and yield signs. The fourth part is about area information elements, including pedestrian areas, no-parking areas, speed bump areas, and parking areas. There are also marking lines used to mark important road elements in the open-pit mine scene, such as obstacles, gantries, and waiting lines. Marking polygons are used to describe free areas on uphill or downhill sections or areas where vehicles cannot follow lane paths. The fifth part consists of logical relationship elements, overlapping areas used to establish hierarchical or spatial connections between elements like roads, objects, and regions.

- “ElementDef”. It is used to describe the information of various elements produced by open-pit mines, such as the description of CaCO3, MgO, CaO, and other elements.

- “MaterialDef”. The information used to describe the material produced by open-pit mines is divided into two types: WASTE and ORE. Attributes contain one or more element information and ore grade ranges. The description of the material determines the ore blending method and mining scheduling plan of the open-pit mine.

- “Blast”. Used to describe the blasting range of ore in open-pit mines. It is represented by a polygon outlining its geometric scope. Blast is composed of one or more components of the blasting stockpile (Composites). Material is used to provide information about the materials produced by the blasting stockpile, including attributes such as average grade and bulk density. The definition of blasting stockpile information is crucial for the workflow of open-pit mining, as it is often associated with loading areas.

- “WarningLine”. This is used to describe alert zones during blasting and construction. It is represented by a polygon outlining its geometric range. Alert zones are categorized into personnel and equipment alert zones, which are relevant during both blasting and construction activities.

- “MineBench”. Used to describe the terraces in open-pit mining. A terrace is composed of multiple bench lines (BenchLine), with two types: BL_TOP (top line) and BL_BOTTOM (bottom line). Describing bench lines helps to define the drivable area for production operations.

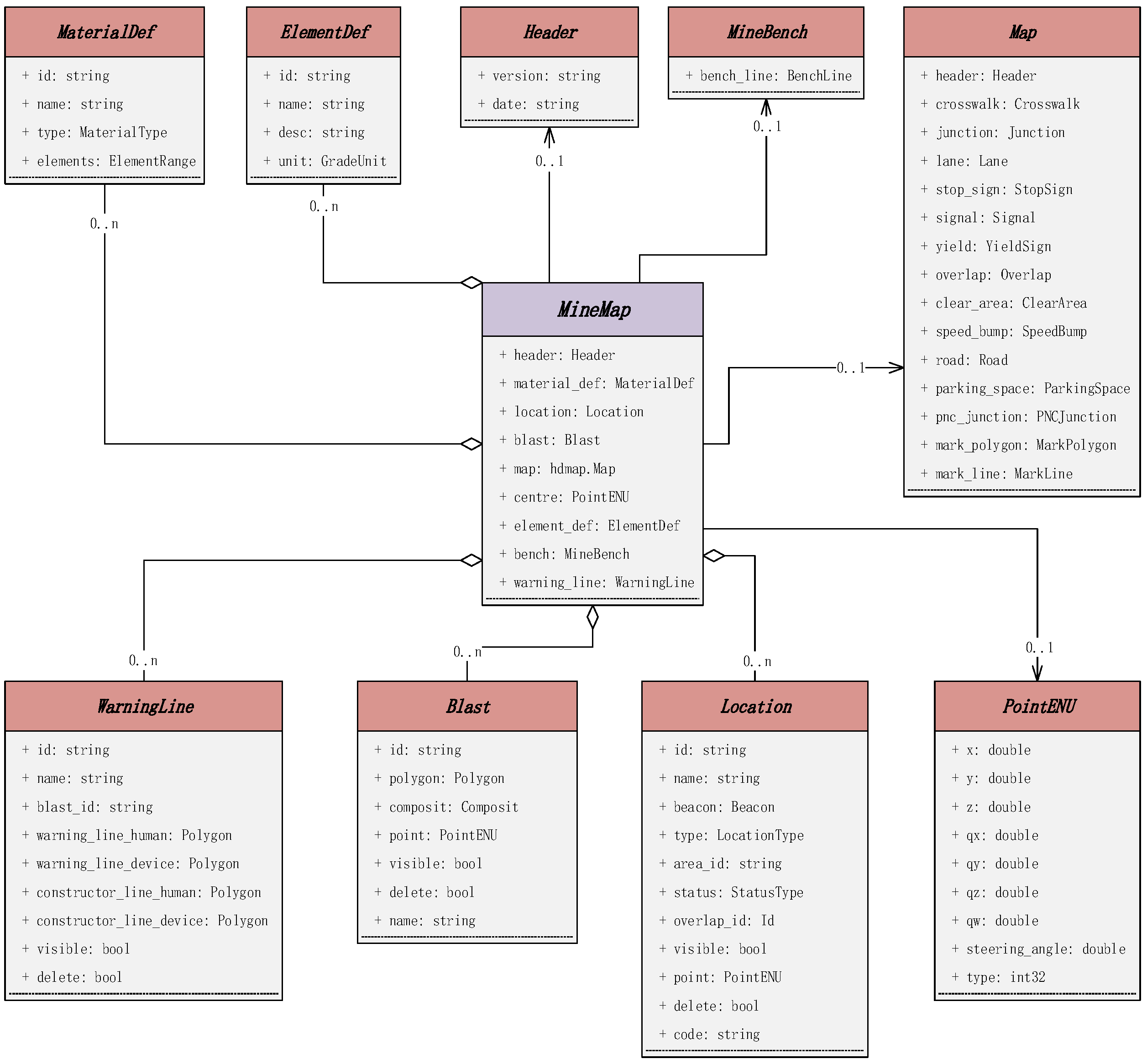

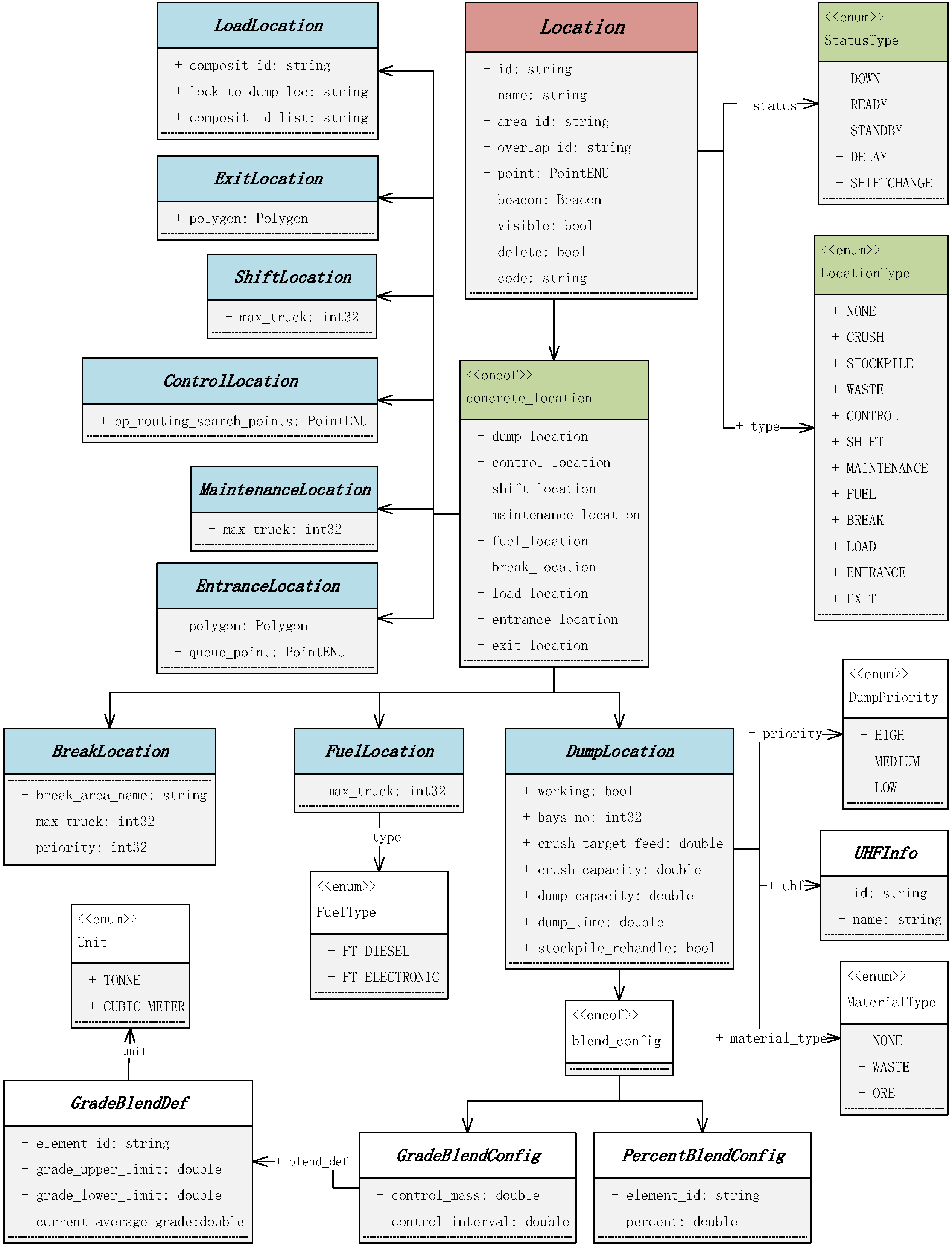

- “Location”. This is used to describe various area positions within the open-pit mining scene and is a core part of the data model. Defining and accurately locating these positions are crucial for mining production scheduling, path planning, and safety management. The UML class diagram of its data structure is shown in Figure 5. There are various types of locations, including crushing stations, stockyards, dumps, intersection control areas, maintenance areas, fueling stations, rest areas, loading points, shift change areas, area entrances, and area exits, totaling 11 types. When describing specific attributes for each type of location, the crushing stations, stockyards, and dumpsites are collectively referred to as ore unloading locations. For each type of location, there are descriptions of nine specific positions. Location status information (StatusType) includes closed, ready, standby, delayed, and shift change statuses. The definition of location status is important for real-time information during scheduling, ensuring real-time and optimal scheduling under both normal and emergency circumstances.

Figure 4.

UML class diagram of MineMap data structures.

Figure 4.

UML class diagram of MineMap data structures.

Figure 5.

UML class diagram of Location data structures.

Figure 5.

UML class diagram of Location data structures.

In the “Location” element, DumpLocation describes the unloading position of an open-pit mine. Vehicles need to transport waste rock to the dump and ore from the loading point to the crushing station or stockyard. ControlLocation describes the control area of a road intersection, defines the control point in addition to the job location point, the road endpoint, and the device will trigger real-time events when entering or leaving the control point area, such as real-time optimal path planning. ShiftLocation, MaintenanceLocation, and FuelLocation describe the shift location, equipment maintenance location and fueling location, respectively. The FuelType is used to indicate the type of fuel station, including diesel and electric. BreakLocation describes the resting (parking) location of the mine. LoadLocation describes the loading location. In order to meet the ore blending requirements and scheduling optimization in production operations, it is necessary to associate the loading position with the detonation reactor location and material information. EntranceLocation and ExitLocation are used to describe the points where vehicles or equipment enter and exit specific areas or regions. These points typically correspond to the entry and exit points during loading or unloading and are usually located at the end of a road where they overlap with the target area. Each exit point can only belong to one specific area. These locations are critical for managing the flow of vehicles and equipment, especially during loading and unloading operations.

For each type of area location, in addition to describing its positioning point, an electronic fence (Beacon) is used to define the area’s boundaries. This electronic fence serves as a virtual signal expression. When a vehicle needs to reach an area location as part of its work scheduling, the electronic fence’s role is to trigger real-time path planning, speed adjustments, and action information events when the vehicle enters or exits the area’s boundaries. Each location and road segment will have speed limit information (SpeedLimitInfo) as well as information describing triggering events (Event).

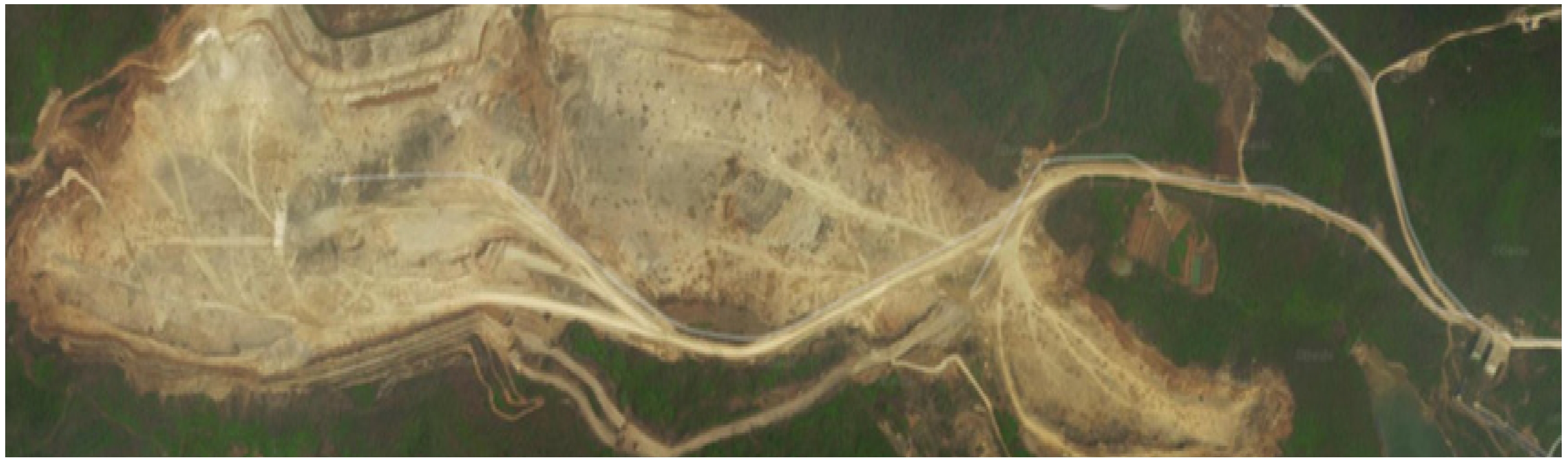

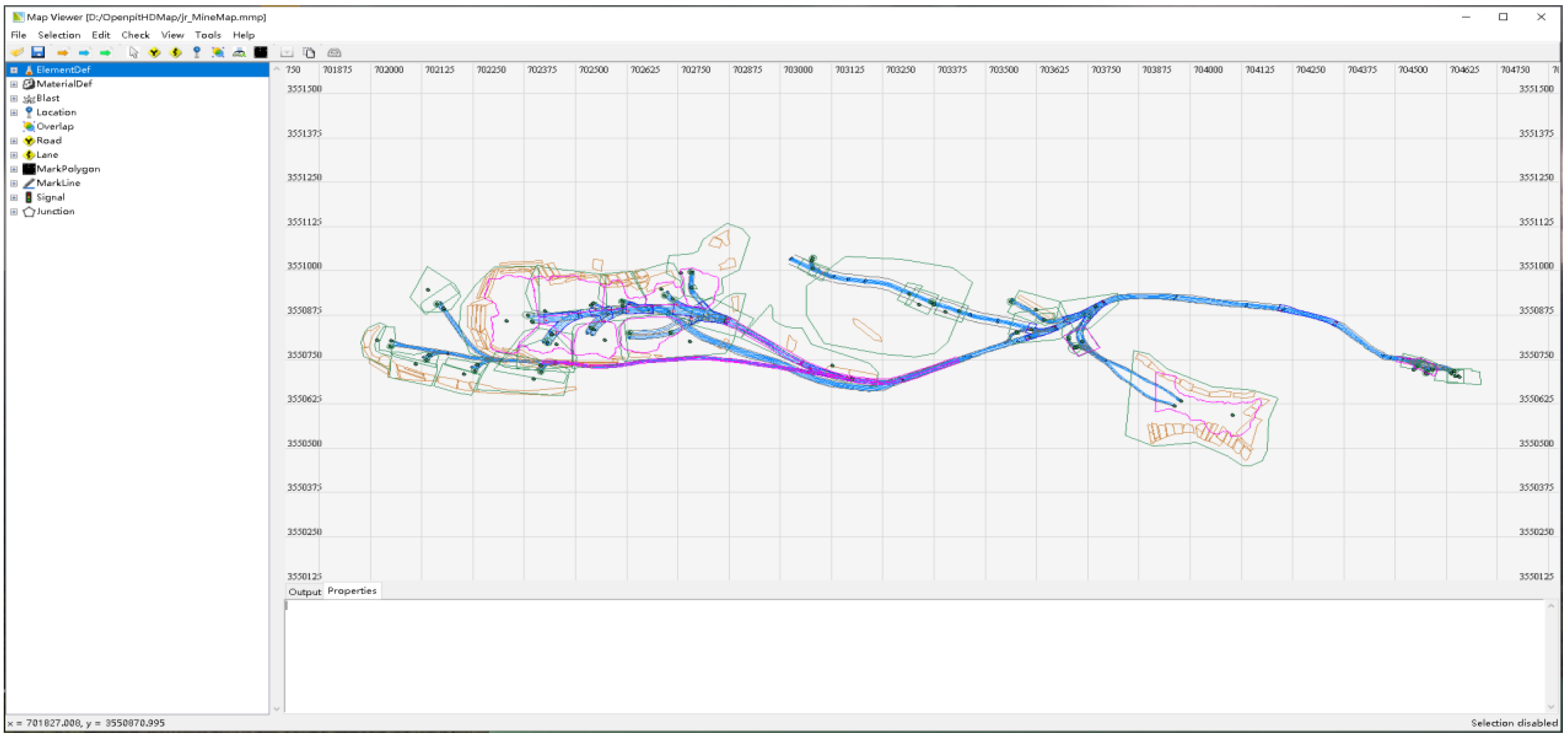

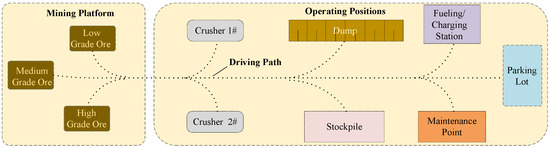

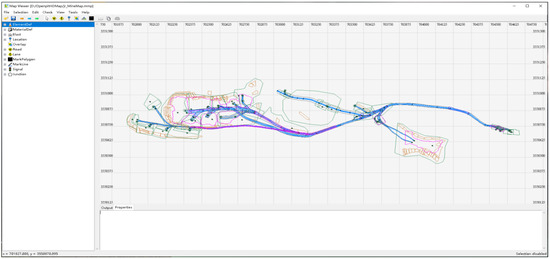

4. Layer Information and Visualization of the HD Map

This section will elucidate the layer information of the HD map for open-pit mines and the MapViewer, a map visualization tool developed based on this model. It allows for the reading and editing of the HD map. The mining data was obtained from the Jurong cement mine in Zhenjiang City, Jiangsu Province, China, which is primarily involved in the extraction of limestone for cement production. The mining scene is depicted in Figure 6. The visualization tool was developed based on Python, and the HD map data exchange specification was designed based on this model, which was defined as an mmp data file. Currently, its primary functions include reading data files, categorized display, distance measurement, information presentation, and so on. Figure 7 shows the HD map for the open-pit mine established within the software.

Figure 6.

Jurong cement mine.

Figure 7.

MapViewer visualisation of HD map for open-pit mines.

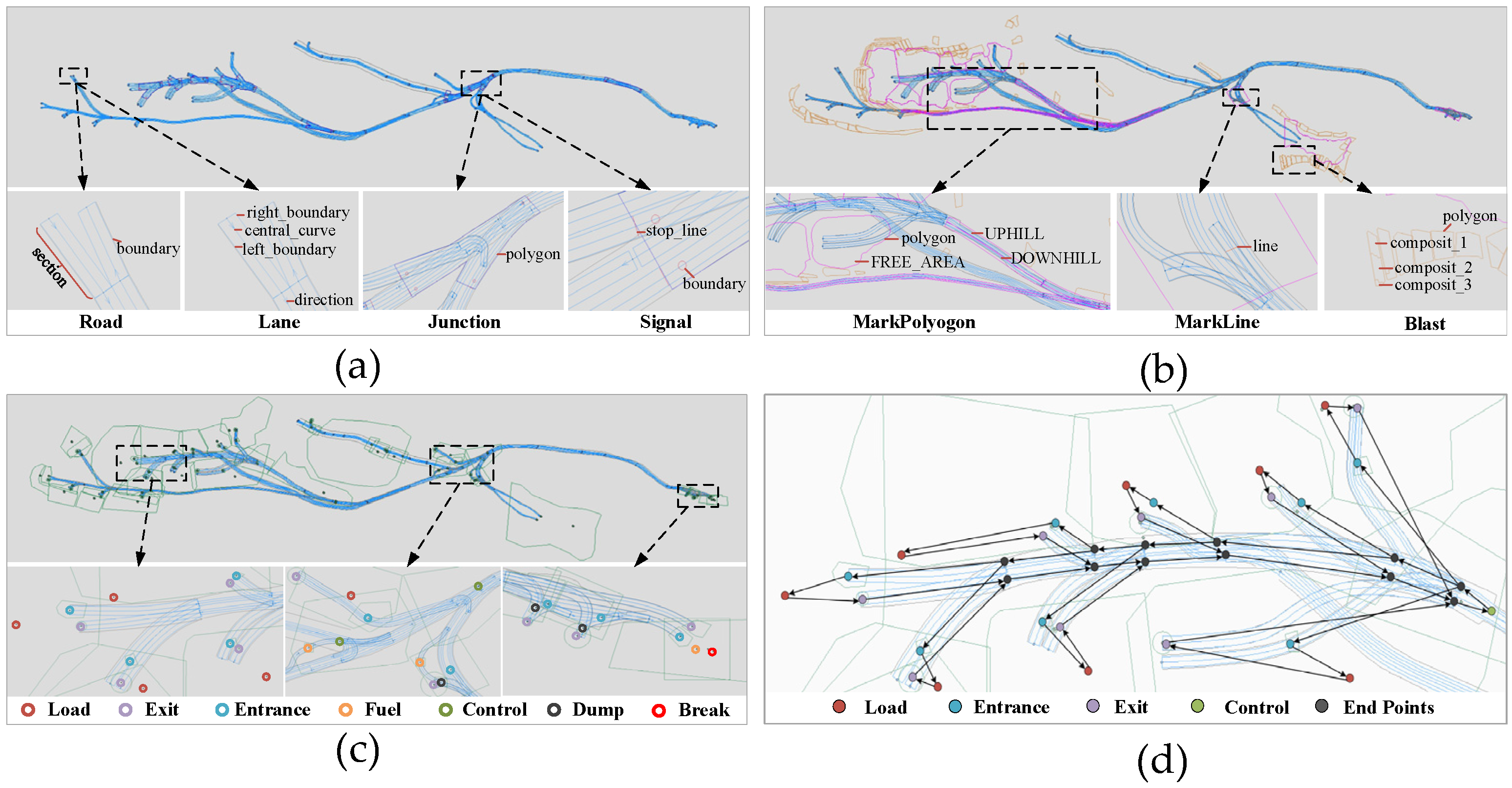

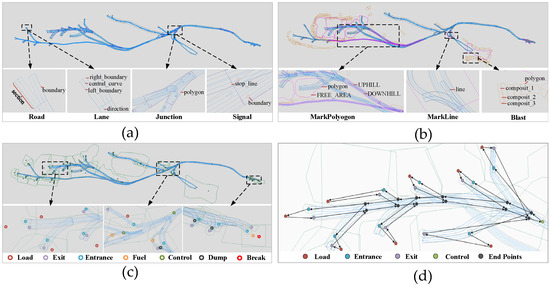

The geometric representation elements in the figure consist of eight primary components, including roads (Road), lanes (Lane), location areas (Location), blast areas (Blast), marking polygons (MarkPolygon), marking lines (MarkLine), traffic signals (Signal), and road intersections (Junction). Different geometric elements are represented using different colors. To provide a clearer description of the geometric structures within each part of the HD map, Figure 8a–c displays enlarged details of specific regions.

Figure 8.

Geometric representation of the elements of an HD map and local path topology. (a) Traffic elements. (b) Open-pit mining elements. (c) Geometric point sets. (d) Road network topology diagram.

The geometric representation of elements within the established open-pit mining scene comprises points and lines. Points are the fundamental elements in the map that carry three-dimensional positional information, and all other elements are directly or indirectly composed of points. Geometric point sets are connected to create the geometric boundaries and extents of various elements within the map. Individual geometric points within the map hold special significance, serving as reference points within the network for tasks such as path planning and scheduling optimization. These points are categorized into three types: operation points, control points, and road endpoints. Operation points include loading points, unloading points, shift change points, maintenance points, fueling points, and rest points, representing the locations for production operations within the open-pit mine. Entrance points and exit points are special operation points, often associated with a specific production operation point. Control points are typically located at road intersections and trigger corresponding actions when vehicle routes change. Road endpoints are points at the beginning and end of road segments.

The topological relationships among all the location points in the road network form the paths within the open-pit mining scene. A localized road network topology diagram is shown in Figure 8d. The routes formed between operational points are production paths, and multiple production paths can combine to create a production circuit. The routes formed between all location points can be established as a route map based on traffic rules and determine the specific routes to be traveled.

5. Application

To further validate the effectiveness and practicality of this data model, this section will introduce the successful application of this data model in a Chinese mining company’s intelligent shipping system project. The intelligent shipping system comprises multiple subsystems, and this section will focus on the intelligent scheduling system, production scenario maintenance system, and autonomous driving system.

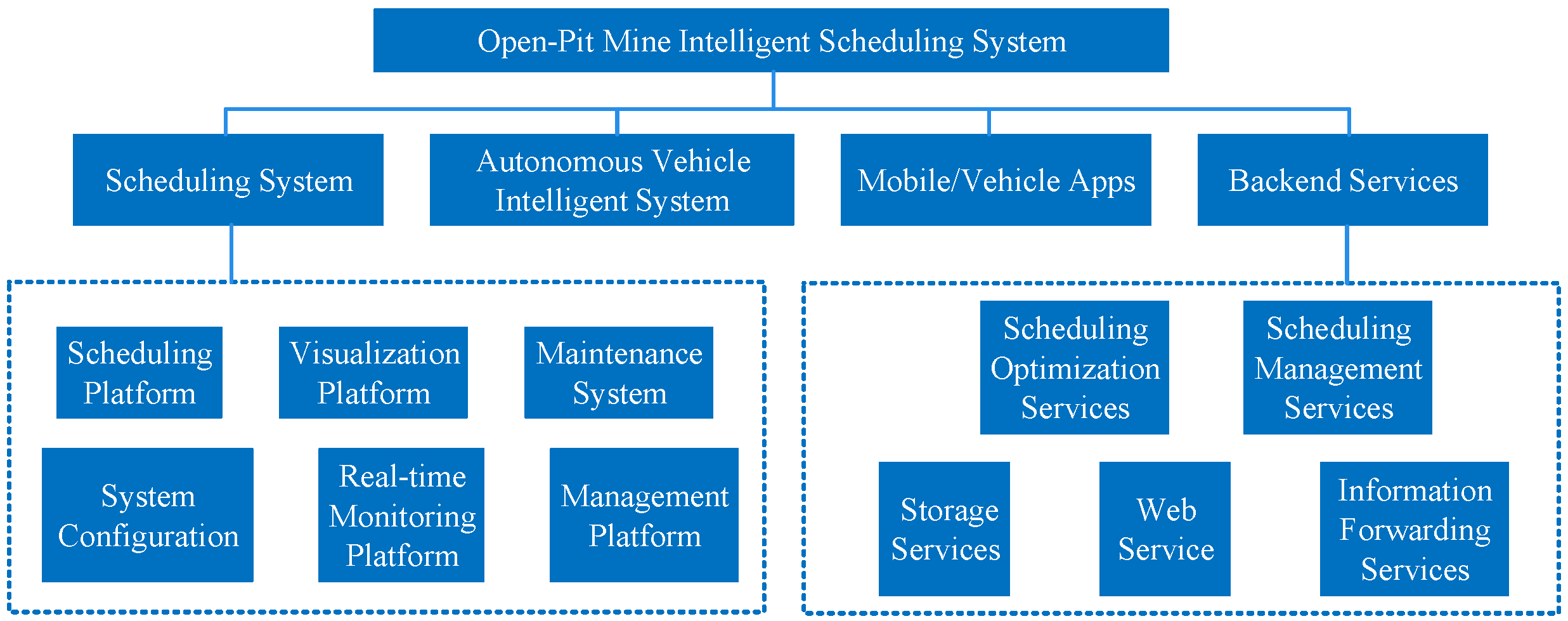

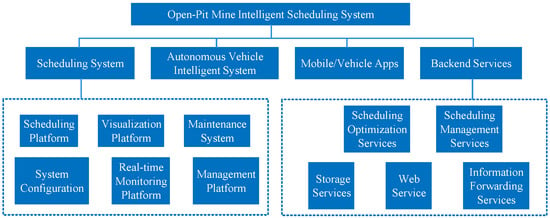

5.1. Intelligent Scheduling System

The Intelligent scheduling system is primarily used in mobile devices, automotive industrial panels, vehicles, scheduling centers, and the service backend, in accordance with mining scenarios. The system’s functional components are shown in Figure 9.

Figure 9.

Intelligent scheduling system interface display.

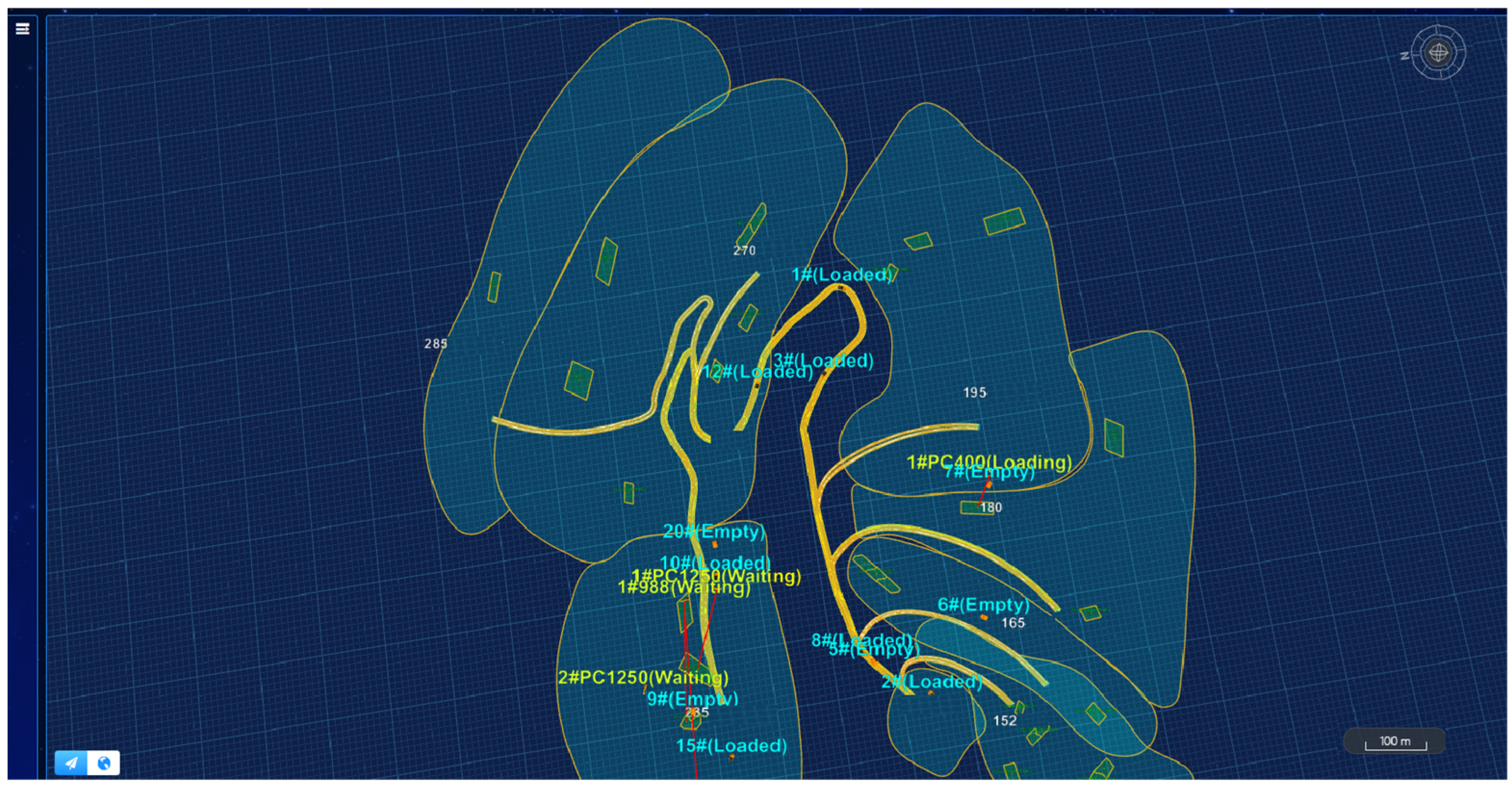

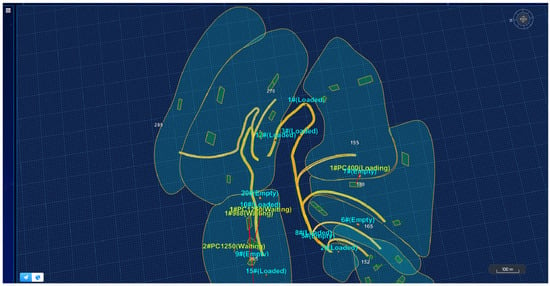

The intelligent scheduling system optimizes the task scheduling and travel paths of shipping equipment based on mining grade requirements and ore blending results. This optimization is aimed at enhancing shipping efficiency, thereby maximizing production efficiency. The system achieves the autonomous driving of haul trucks to designated loading and unloading points, ensuring proper loading and unloading postures. During the coexistence of both human-driven and autonomous driving phases, it supports the coordination of human and autonomous operations and ensures safety in operations. The scheduling visual interface is shown in Figure 10.

Figure 10.

Intelligent scheduling system interface display.

5.2. Production Scenarios Maintenance System

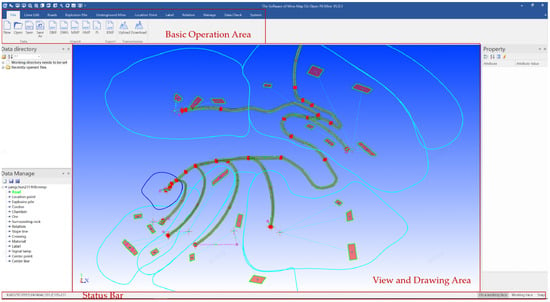

The maintenance system in production scenarios is based on on-site measurements of roadways, location points (including loading points, unloading points, fueling stations, etc.), terrain, blast areas, material information, and other data from open-pit mines. This system constructs the open-pit mining road network and other production elements, and ensures the dynamic updating and topological consistency of the open-pit scene. Fundamental three-dimensional spatial scene data for both manned and unmanned truck scheduling systems was provided in this system.

Figure 11 shows the interface of the system. It is mainly used to complete road network map editing and various related data configurations such as, for example, the maintenance and management of road networks and the mine map, the regional division and mine identification of the map, the addition or deletion of elements such as location points, electronic fences, roads, and displaying the best path.

Figure 11.

Production scenario maintenance system interface display.

5.3. Autonomous Driving System

This autonomous driving software architecture is built on the foundation of vehicle-mounted computing units and primarily consists of scene application software, sensor inputs, a functional software platform, and execution layer software modules.

Based on the actual mining production and the scope of vehicle transport activities, the open-pit mining site is divided into four major basic scenarios: ore transportation, mining, unloading, and parking (fueling, maintenance). Each basic scenario includes sub-scenarios such as automatic tracking, automatic following, obstacle avoidance, dynamic planning, automatic parking, automatic start and stop, vehicle infrastructure cooperation, and more. It also includes safety management modules for cooperative vehicle infrastructure mode management, scheduling management, functional safety, fault diagnosis, etc. This forms autonomous driving control strategies for different scenarios within the mining area, ensuring the safe and stable operation of vehicles.

6. Discussion

Different elements in the HD map for open-pit mines were provided in previous literatures [8,9,10]. But the application scenarios of open-pit mines were not closely connected with the elements. Compared to these literatures, there is not only traffic information for autonomous vehicles in the OP map, but also descriptions of rock types such as CaCO3, MgO, CaO, material information to distinguish waste and ore, blasting ranges in open-pit mines, warning zones, bench lines, etc. The OP map is more professional for mining industries. Therefore, the HD map can be used by all of the different departments in the mine. With these detailed elements in the OP map, the efficiency and quality of mining management can be improved.

However, the OP map has some limitations. For example, the selected location and traffic elements are common to different open-pit mines and can generally complete the construction of HD maps, fulfilling the business requirements of unmanned transportation activities. Nevertheless, open-pit mining employs various extraction methods, and the application of technical equipment also varies. Additionally, the division and naming of roads and zones may differ between mines. These are aspects for the future expansion and enhancement of the data model.

7. Conclusions

Currently, open-pit mines are continuously advancing toward intelligent and unmanned construction. Many business scenarios such as unmanned transportation, shovel-truck coordination, production scheduling, and safety control all require the support of a mining map. This article, based on the business requirements of open-pit mines, describes the application scenarios of an HD map, and designs a universal high-definition map data model called Open-Pit Map, abbreviated as OP map, for data creation and exchange. It helps meet the demands of various business scenarios with a single HD map, significantly enhancing the comprehensive control capabilities of mining areas. Eight definitions of basic elements and attributes in OP map were defined, including geometric points (PointENU), road network maps (Map), blast areas (Blast), output elements (ElementDef), output materials (MaterialDef), benches (MineBench), safety warning zones (WarningLine), and location areas (Location). Eleven detailed location elements in open-pit mines were proposed, including crushing stations, stockyards, dumps, intersection control areas, maintenance areas, fueling stations, rest areas, loading points, shift change areas, area entrances, and area exits. Eight common traffic elements in open-pit mines were proposed, including roads (Road), lanes (Lane), location areas (Location), blast areas (Blast), marking polygons (MarkPolygon), marking lines (MarkLine), traffic signals (Signal), and road intersections (Junction). The practicality and effectiveness of the data model were verified in the intelligent shipping system of the specified mine.

Author Contributions

Conceptualization, X.X. and L.B.; Methodology, X.X., Z.W. and L.B.; Validation, Z.W., P.H., S.T. and L.B.; Formal analysis, Z.W.; Data curation, Z.W. and P.H.; Writing—original draft, X.X. and Z.W.; Writing—review & editing, X.X., P.H., S.T. and L.B.; Visualization, S.T.; Supervision, L.B.; Funding acquisition, X.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the China University of Mining and Technology, grant number SKLCRSM21X003.

Data Availability Statement

This data model can be found here: https://gitee.com/wang-zhuo2734/openpit_map, accessed on 29 October 2023.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bao, Z.; Hossain, S.; Lang, H.; Lin, X. A review of high-definition map creation methods for autonomous driving. Eng. Appl. Artif. Intell. 2023, 122, 106125. [Google Scholar] [CrossRef]

- Liu, R.; Wang, J.; Zhang, B. High definition map for automated driving: Overview and analysis. J. Navig. 2020, 73, 324–341. [Google Scholar] [CrossRef]

- Liu, H.; Pan, W.; Hu, Y.; Li, C.; Yuan, X.; Long, T. A Detection and Tracking Method Based on Heterogeneous Multi-Sensor Fusion for Unmanned Mining Trucks. Sensors 2022, 22, 5989. [Google Scholar] [CrossRef] [PubMed]

- Jin, C.; Yi, T.; Shen, Y.; Khajepour, A.; Meng, Q. Comparative study on the economy of hybrid mining trucks for open-pit mining. IET Intell. Transp. Syst. 2019, 13, 201–208. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Atencio, E. In-Pit Disposal of Mine Tailings for a Sustainable Mine Closure: A Responsible Alternative to Develop Long-Term Green Mining Solutions. Sustainability 2023, 15, 6481. [Google Scholar] [CrossRef]

- Seif, H.G.; Hu, X. Autonomous driving in the iCity—HD maps as a key challenge of the automotive industry. Engineering 2016, 2, 159–162. [Google Scholar] [CrossRef]

- Li, Y.; Li, Z.; Teng, S.; Zhang, Y.; Zhou, Y.; Zhu, Y.; Cao, D.; Tian, B.; Ai, Y.; Xuanyuan, Z. AutoMine: An unmanned mine dataset. In Proceedings of the 2022 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), New Orleans, LA, USA, 18–24 June 2022; pp. 21308–21317. [Google Scholar]

- Johansen, K.; Erskine, P.D.; Mccabe, M.F. Using Unmanned Aerial Vehicles to assess the rehabilitation performance of open cut coal mines. J. Clean. Prod. 2019, 209, 819–833. [Google Scholar] [CrossRef]

- Zhao, Z.; Bi, L. A New Challenge: Path Planning for Autonomous Truck of Open-Pit Mines in The Last Transport Section. Appl. Sci. 2020, 10, 6622. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Hu, M.; Dou, Q.; Ouyang, W.; Ma, G.; Li, Y.; Qin, H. HD Map Construction and Update System for Autonomous Driving in Open-Pit Mines. IEEE Syst. J. 2023, 1–12. [Google Scholar] [CrossRef]

- Kang, Y.; Magdy, A. HiDaM: A unified data model for high-definition (HD) map data. In Proceedings of the 2020 IEEE 36th International Conference on Data Engineering Workshops (ICDEW), Dallas, TX, USA, 20–24 April 2020. [Google Scholar]

- Ruan, S.; Li, S.; Lu, C.; Gu, Q. A Real-Time Negative Obstacle Detection Method for Autonomous Trucks in Open-Pit Mines. Sustainability 2022, 15, 120. [Google Scholar] [CrossRef]

- Chen, L.; Sima, C.; Li, Y.; Zheng, Z.; Xu, J.; Geng, X.; Li, H.; He, C.; Shi, J.; Qiao, Y. PersFormer: 3D lane detection via perspective transformer and the openlane benchmark. In Proceedings of the 17th European Conference on Computer Vision—ECCV 2022, Tel Aviv, Israel, 23–27 October 2022; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Bender, P.; Ziegler, J.; Stiller, C. Lanelets: Efficient map representation for autonomous driving. In Proceedings of the 2014 IEEE Intelligent Vehicles Symposium Proceedings, Dearborn, MI, USA, 8–11 June 2014. [Google Scholar]

- Poggenhans, F.; Pauls, J.; Janosovits, J.; Orf, S.; Naumann, M.; Kuhnt, F.; Mayr, M. Lanelet2: A high-definition map framework for the future of automated driving. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2018. [Google Scholar]

- ASAM OpenDRIVE, v 1.7.0; Open Dynamic Road Information for Vehicle Environment; Association for Standardization of Automation and Measuring Systems: Hoehenkirchen, Germany, 2021.

- Fan, H.; Zhu, F.; Liu, C.; Zhang, L.; Zhuang, L.; Li, D.; Zhu, W.; Hu, J.; Li, H.; Kong, Q. Baidu apollo em motion planner. arXiv 2018, arXiv:1807.08048. [Google Scholar]

- Ge, S.; Wang, F.; Yang, J.; Ding, Z.; Wang, X.; Li, Y.; Teng, S.; Liu, Z.; Ai, Y.; Chen, L. Making standards for smart mining operations: Intelligent vehicles for autonomous mining transportation. IEEE Trans. Intell. Veh. 2022, 7, 413–416. [Google Scholar] [CrossRef]

- Brown, C. Autonomous vehicle technology in mining. Eng. Min. J. 2012, 213, 30. [Google Scholar]

- Tang, J.; Zhao, B.; Yang, C.; Zhou, C.; Chen, S.; Ni, X.; Ai, Y. An Architecture and Key Technologies of Autonomous Truck Dispatching System in Open-pit Mines. In Proceedings of the 2022 International Conference on Cyber-Physical Social Intelligence (ICCSI), Nanjing, China, 18–21 November 2022. [Google Scholar]

- Benlaajili, S.; Moutaouakkil, F.; Chebak, A. Infrastructural requirements for the implementation of autonomous trucks in open-pit mines. E3S Web Conf. 2021, 315, 03009. [Google Scholar] [CrossRef]

- Li, B.; Ouyang, Y.; Li, X.; Cao, D.; Zhang, T.; Wang, Y. Mixed-integer and conditional trajectory planning for an autonomous mining truck in loading/dumping scenarios: A global optimization approach. IEEE Trans. Intell. Veh. 2022, 8, 1512–1522. [Google Scholar] [CrossRef]

- Fang, Y.; Peng, X. Micro-Factors-Aware Scheduling of Multiple Autonomous Trucks in Open-Pit Mining via Enhanced Metaheuristics. Electronics 2023, 12, 3793. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).