A Data-Driven Approach to Predict the ROP of Deep Wells in Fukang Sag

Abstract

:1. Introduction

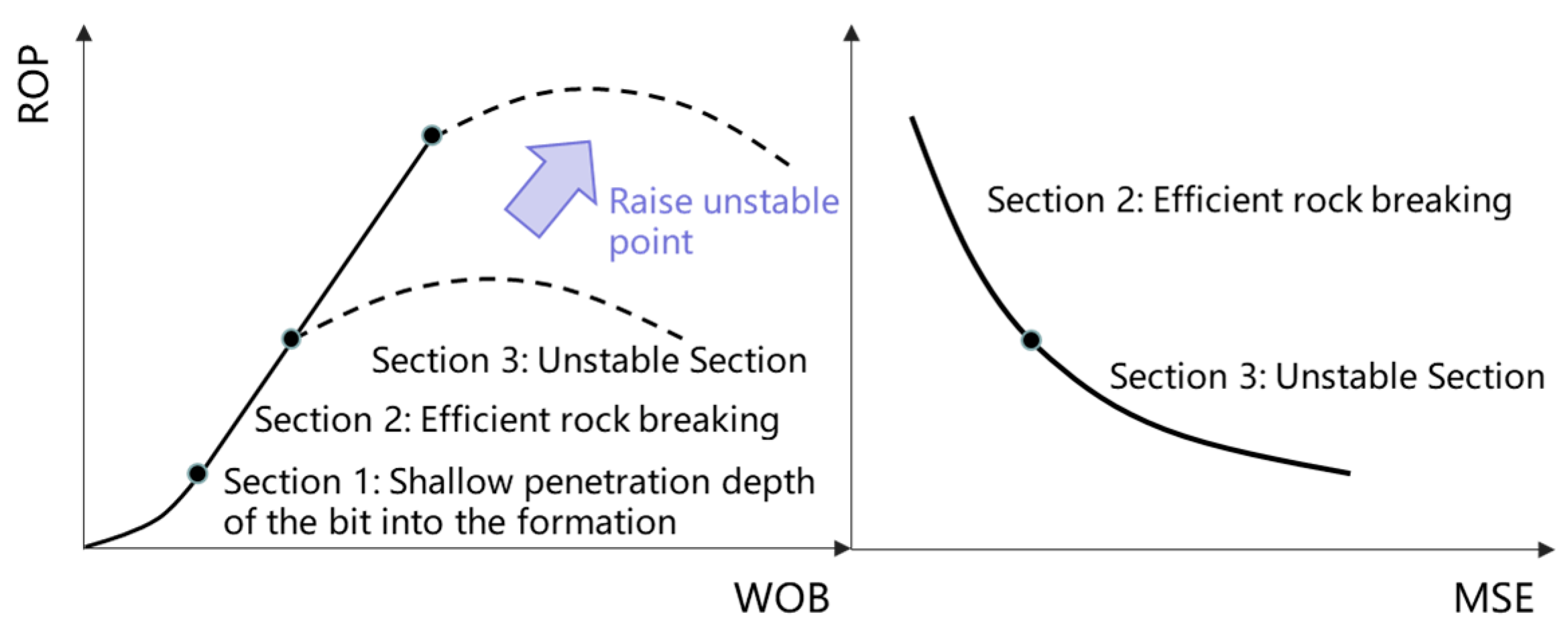

2. ROP Prediction Based on Mechanical-Specific Energy Theory

2.1. Drilling Rate Equations Based on Mechanical-Specific Energy Theory

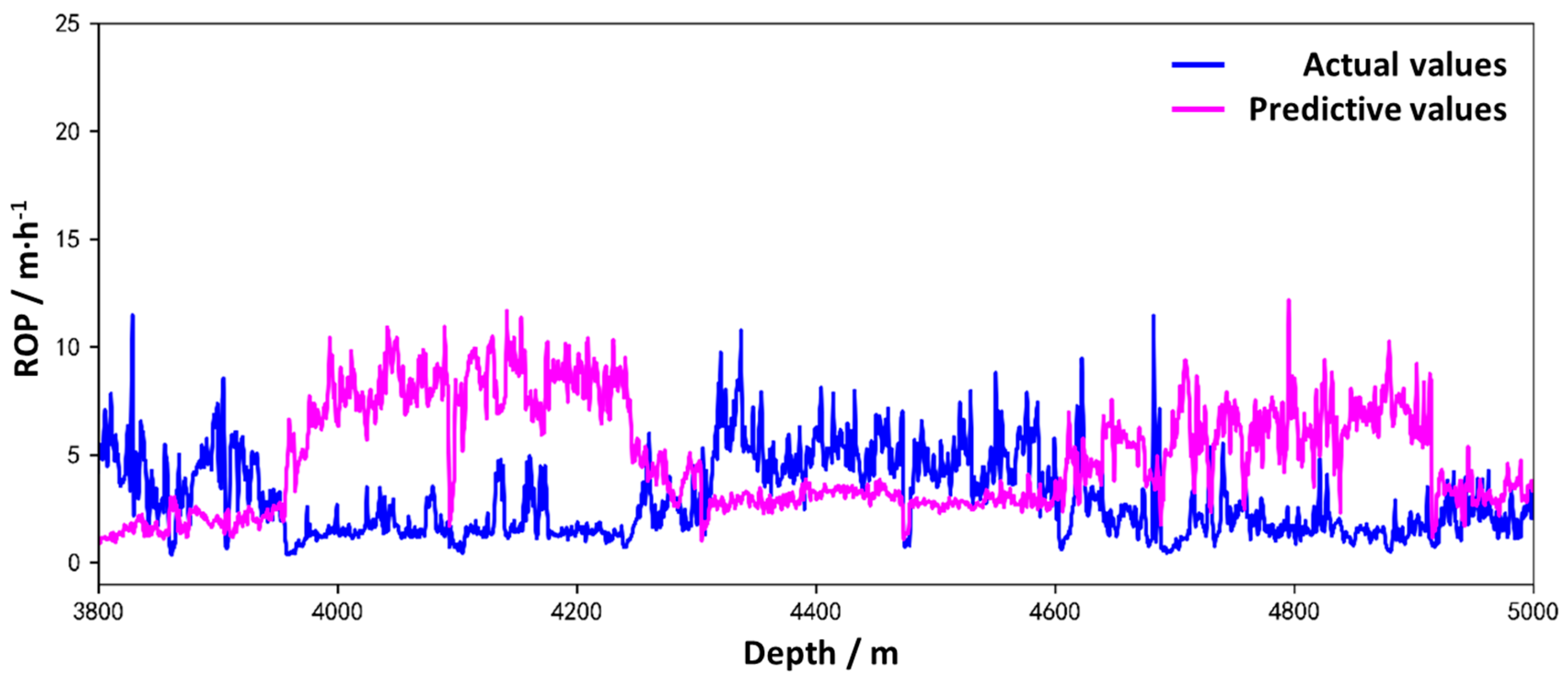

2.2. ROP Prediction Results

3. ROP Prediction Based on the Random Forest Machine Learning Model

3.1. Principles of the Random Forest Algorithm

3.2. Factor Analysis

3.3. Prediction Results and Model Performance Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Han, Z.; Wu, Z.; Lin, Z.; Wang, X.; Jiang, Z.; Ji, H.; Lai, Q.; Hu, H. Control of tectonic uplift and denudation on uranium mineralization in the eastern Junggar Basin. China Coal Soc. 2023, 48, 3471–3482. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Y.; Yang, H.; Li, S.; Liu, C.; Han, Y.; Chen, M. Genesis types and distribution of crude oil in Fukang Sag and its peripheral bulges, Junggar Basin. China Pet. Explor. 2023, 28, 94–107. [Google Scholar]

- Liu, H.; Zhu, Y.; Liu, L.; Yi, H.; Wang, X.; Du, X. Geological characteristics and exploration potential of shale oil of Permian Lucaogou Formation in hanging wall of Fukang fault zone, Junggar Basin. Lithol. Reserv. 2023, 35, 90–101. [Google Scholar]

- Liu, Z.; Zhao, L.; Zeng, Z.; Tian, J.; Li, Z.; Luo, J.; Hu, M. Shale oil accumulation conditions of Permian Lucaogou Formation in Fukang fault zone, Junggar Basin. Lithol. Reserv. 2023, 35, 126–137. [Google Scholar]

- Kuang, L.; Zhi, D.; Wang, X.; Li, J.; Liu, G.; He, W.; Ma, D. Oil and gas accumulation assemblages in deep to ultra-deep formations and exploration targets of petroliferous basins in Xinjiang region. China Pet. Explor. 2021, 26, 1–16. [Google Scholar]

- Shan, X.; Dou, Y.; Liu, C.; Pan, J.; Guo, H.; Peng, B.; Li, K. Characteristics and Controlling Factors of Deep Tight Sandstone Reservoirs: A Case Study of the Upper Wuerhe Formation in the Fukang Depression, Junggar Basin. Acta Sedimentol. Sin. 2023, 1–18. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, C.; Yan, W.; Li, S.; Li, H.; Chen, M.; Li, Z. Characteristics and Development Patterns of Deep-to-Ultra-Deep Reservoirs in the Upper Wuerhe Formation, Zhundong Sag. Nat. Gas Geosci. 2023, 1–22. Available online: http://KNs.cnki.net/kcms/detail/62.1177.TE.20231018.1515.006.html (accessed on 5 November 2023).

- Chen, S.; Jiang, Y.; Zhang, J.; Zeng, Y. Research and Application of Fast Drilling Technology in the Fudong Area of the Junggar Basin. Nat. Gas Technol. Econ. 2013, 7, 32–35+78. [Google Scholar] [CrossRef]

- Liu, Z. A Method of Improve the Drilling Speed of Hard Formation of Permian in Wuxia Fault Zone. Xinjiang Oil Gas 2020, 16, 12–15+4. [Google Scholar]

- Su, Y.; Chen, Y.; Yan, T.; Sun, X.; Wang, L.; Wang, K. Risk prediction of bit balling in gas drilling and its influential factors. Nat. Gas Ind. 2016, 36, 60–65. [Google Scholar]

- Jing, N.; Fan, H.; Ji, R.; Zhai, Y.; Liu, T. Data Mining Technology-based Research on the Prediction Method of Deepwell ROP. Pet. Mach. 2012, 40, 17–20. [Google Scholar]

- Lin, Y.; Zong, Y.; Liang, Z.; Shi, T.; Li, R. The Developments of ROP Prediction for Oil Drilling. Oil Drill. Technol. 2004, 10–13. [Google Scholar]

- Bourgoyne, A.T., Jr.; Young, F.S., Jr. A Multiple Regression Approach to Optimal Drilling and Abnormal Pressure Detection. Soc. Pet. Eng. J. 1974, 14, 371–384. [Google Scholar] [CrossRef]

- Rastegar, M.; Hareland, G.; Nygaard, R.; Bashari, A. Optimization of multiple bit runs based on ROP models and cost equation: A new methodology applied for one of the Persian Gulf carbonate fields. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition. OnePetro, Jakarta, Indonesia, 25–27 August 2008. [Google Scholar]

- Liu, S.; Yang, J.; Zhou, J.; Tang, H.X.; Wei, H.S.; Li, S.G. Research on relationship between weight-on-bit and drilling rate during jetting drilling in sub-bottom deepwater. Oil Drill. Prod. Technol. 2011, 33, 12–15. [Google Scholar]

- Li, C.; Zhao, J.; Yang, C.; Zhang, C.; Xu, S. Novel approach for assessing real-time bit working efficiency. Oil Drill. Technol. 2012, 36, 1–4. [Google Scholar]

- Chen, X.; Fan, H.; Guo, B.; Gao, D.; Wei, H.; Ye, Z. Real-Time Prediction and Optimization of Drilling Performance Based on a New Mechanical Specific Energy Model. Arab. J. Sci. Eng. 2014, 39, 8221–8231. [Google Scholar] [CrossRef]

- Soares, C.; Daigle, H.; Gray, K. Evaluation of PDC bit ROP models and the effect of rock strength on model coefficients. J. Nat. Gas Sci. Eng. 2016, 34, 1225–1236. [Google Scholar] [CrossRef]

- Amer, M.M.; Dahab, A.S.; El-Sayed, A.A.H. An ROP Predictive Model in Nile Delta Area Using Artificial Neural Networks. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24–27 April 2017. [Google Scholar]

- Shi, X.; Liu, G.; Gong, X.; Zhang, J.; Wang, J.; Zhang, H. An Efficient Approach for Real-Time Prediction of Rate of Penetration in Offshore Drilling. Math. Probl. Eng. 2016, 2016, 3575380. [Google Scholar] [CrossRef]

- Z, Y.; Sun, T.; Yang, J.; Li, Y.; Huang, Y.; Yan, Y. Offshore drilling machinery drilling speed monitoring and real-time optimization based on extreme learning machine. China Offshore Oil Gas 2019, 31, 138–142. [Google Scholar]

- Ahmed, O.S.; Adeniran, A.A.; Ariffin, S. Computational intelligence-based prediction of drilling rate of penetration: A comparative study. J. Pet. Sci. Eng. 2018, 172, 1–12. [Google Scholar] [CrossRef]

- Teale, R. The concept of specific energy in rock drilling. Int. J. Rock Mech. Min. Sci. 1965, 2, 57–63. [Google Scholar] [CrossRef]

- Chen, X.; Fan, H.; Gao, D.; Guo, B.; Peng, Q.; Liu, J.; Wang, E. Mechanical specific energy theory and its application in drilling engineering. Drill. Process 2015, 38, 6–10. [Google Scholar]

- Chicco, D.; Warrens, M.J.; Jurman, G. The coefficient of determination R-squared is more informative than SMAPE, MAE, MAPE, MSE and RMSE in regression analysis evaluation. PeerJ Comput. Sci. 2021, 7, e623. [Google Scholar] [CrossRef] [PubMed]

- Tofallis, C. A better measure of relative prediction accuracy for model selection and model estimation. J. Oper. Res. Soc. 2015, 66, 1352–1362. [Google Scholar] [CrossRef]

| Count | Mean | Std | Min | Max | |

|---|---|---|---|---|---|

| SPP/MPa | 50,000 | 22.5680 | 2.9507 | 11.18 | 25.64 |

| Torque/KN·m | 50,000 | 7.2473 | 2.7384 | 4.18 | 20.51 |

| WOB/KN | 50,000 | 50.7053 | 26.3114 | 10 | 201 |

| RPM | 50,000 | 109.6535 | 37.3567 | 46 | 185 |

| ECD/g·cm−3 | 50,000 | 1.4658 | 0.1457 | 1.03 | 1.82 |

| Viscosity/s | 50,000 | 88.3048 | 22.3630 | 12 | 152 |

| INF/L·s−1 | 50,000 | 47.2738 | 4.7340 | 24.74 | 58.26 |

| OUTF/L·s−1 | 50,000 | 39.4409 | 5.9599 | 22.79 | 56.45 |

| Pump Speed | 50,000 | 133.8123 | 36.3426 | 68 | 192 |

| ROP/m·s−1 | 50,000 | 19.1330 | 16.2476 | 0.37 | 130.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Tan, Q.; Wu, D.; Chen, H.; Hu, N.; Zhao, Y. A Data-Driven Approach to Predict the ROP of Deep Wells in Fukang Sag. Appl. Sci. 2023, 13, 12471. https://doi.org/10.3390/app132212471

Wang Y, Tan Q, Wu D, Chen H, Hu N, Zhao Y. A Data-Driven Approach to Predict the ROP of Deep Wells in Fukang Sag. Applied Sciences. 2023; 13(22):12471. https://doi.org/10.3390/app132212471

Chicago/Turabian StyleWang, Yingjie, Qiang Tan, Desheng Wu, Hao Chen, Naikun Hu, and Yuxuan Zhao. 2023. "A Data-Driven Approach to Predict the ROP of Deep Wells in Fukang Sag" Applied Sciences 13, no. 22: 12471. https://doi.org/10.3390/app132212471

APA StyleWang, Y., Tan, Q., Wu, D., Chen, H., Hu, N., & Zhao, Y. (2023). A Data-Driven Approach to Predict the ROP of Deep Wells in Fukang Sag. Applied Sciences, 13(22), 12471. https://doi.org/10.3390/app132212471