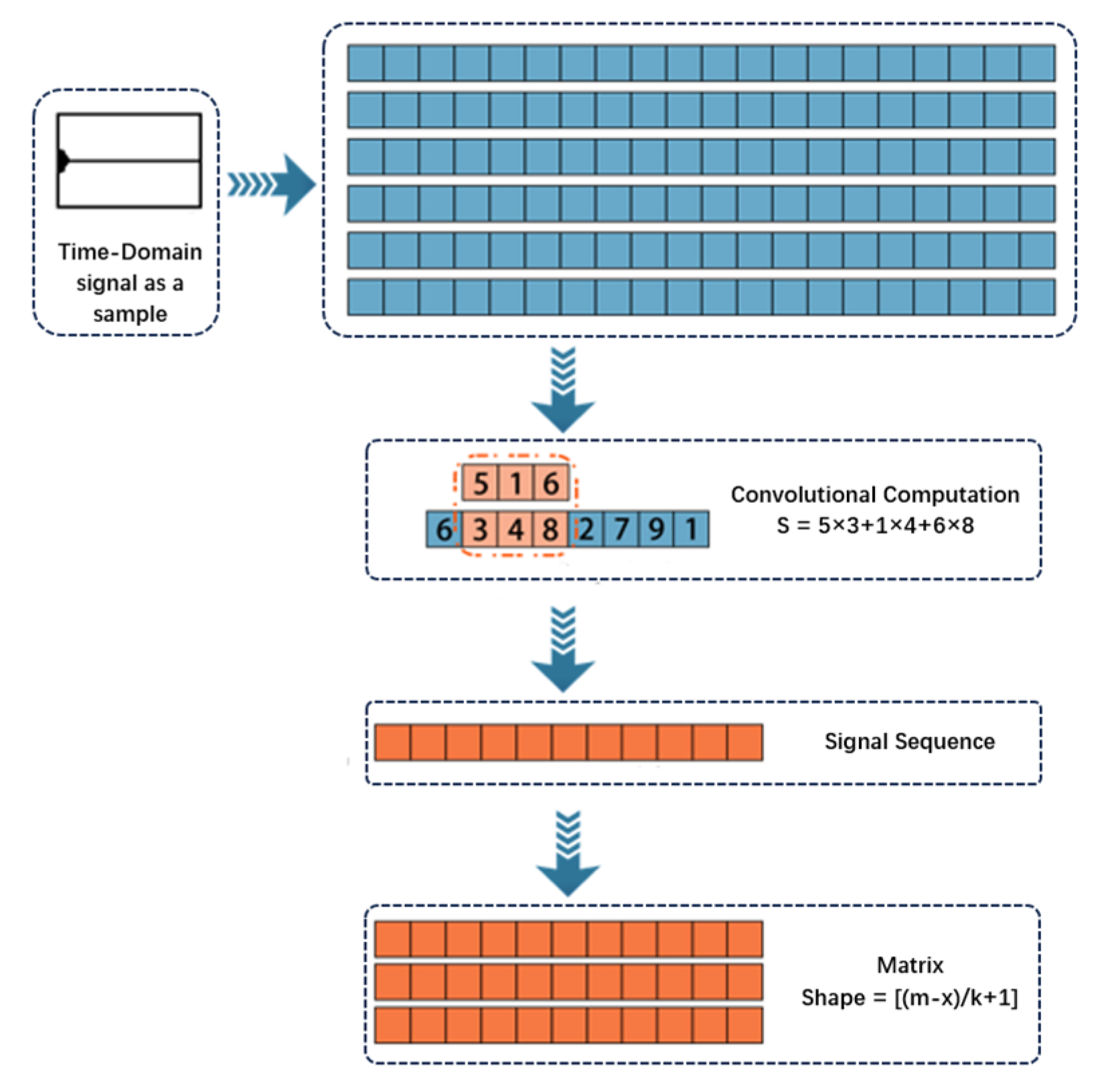

3.2. Preprocessing

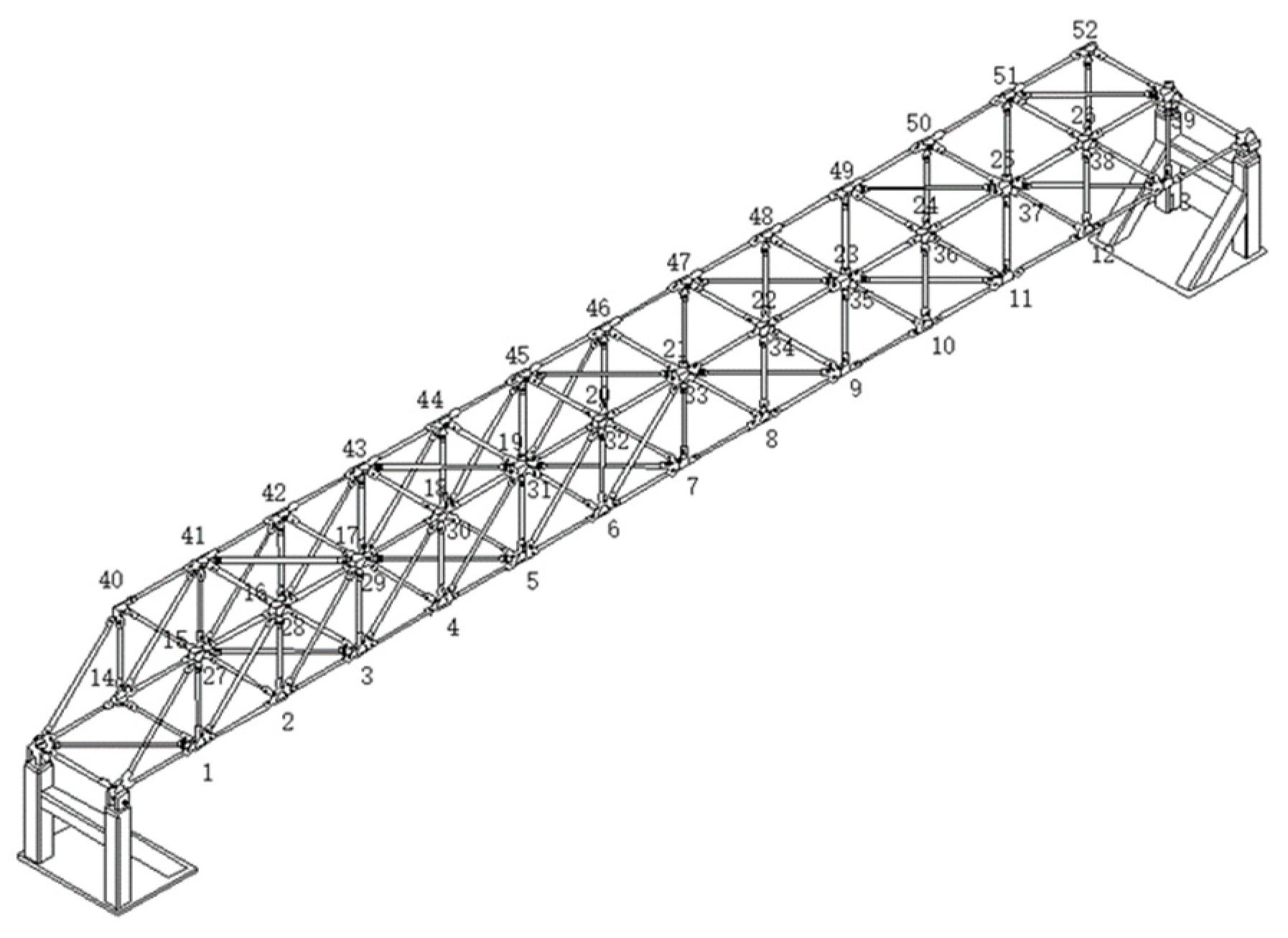

The number of rods in the experimental model is divided into 160 units, and the units are numbered. The sizes of chord, vertical, and belly rods are 0.4 m and 0.65 m, and are divided into 11 working conditions. Damage was created in units 7, 10, and 35. In this experiment, the cutting length is positively correlated with the damage degree. The longer the cutting length is, the lower the stiffness of the rod, and the greater the degree of damage. The cutting length is 10 cm and 20 cm, respectively, and the setting of experimental conditions is shown in

Table 2.

The steel truss structure model has a total of 56 nodes, as shown in the figure. Because the two ends of the model adopt simple support constraints, no sensors are arranged at the two ends of the model, and sensors are only arranged for the remaining 52 nodes, as shown in

Figure 7. Due to the limitation of the number of sensors, the modal test is divided into four groups. The acceleration data of each measuring point under pulse excitation were collected with a sampling frequency of 1000 Hz and sampling time of 5 s.

For the single-signal data measured by sensor at a fixed frequency, since there is a strong correlation between signals at a certain measuring point on the same time scale, the measured acceleration responses at the measuring point within the same time interval are combined with continuous signals, and the signals are integrated into one-dimensional time series data segments. By hammering the center of the bar between different nodes, the damage is caused in different positions of the structure.

The multi-label classification method is used to label the measured data under different damage backgrounds as the label of the working condition, so as to ensure the classification effect of the model is more accurate. By combining the datasets from different operating conditions for all sensor points and their corresponding labels, an original dataset is obtained. The original dataset consists of 11 unprocessed data sets with dimensions of 12,288 × 56, where the operating condition number serves as the label. The 11 original datasets are concatenated, resulting in an intergrated dataset with dimensions of 12,288 × 616. The intergrated dataset is labeled based on the operating condition number. The damaged operating conditions and their corresponding labels are shown in

Table 3.

3.3. Implementation Details

The platform configuration used in this experiment is as follows: platform system—Windows11; hardware configuration—CPU is 11th Gen Intel(R) Core(TM) i7-11800H, memory is 16 G; the graphics card is an NVIDIA GeForce RTX3050Ti 8G*2; experimental framework—Tensorflow2.3.0.

The intergrated dataset was processed using z-score standardization for the preliminary processing of one-dimensional sequence data of each measurement point:

In Formula (11), is the single-signal data in the measuring point, is the mean value of all signal values at the measuring point, and is the variance of all signal values at the measuring point. Basic attributes such as dimension, quantity and length of data segment do not change after z-score processing, and standardized processing can avoid extreme outliers in the data. The obtained new time series data is defined as a window by the sliding average window, and the sliding window is updated by the fixed sliding window. The sequential average of the window is calculated successively, and the obtained sequential average is connected to generate a new equilong time interval to obtain the dimensionality reduction dataset.

To verify whether the VMD preprocessing step provides positive value to the subsequent neural network, this study first applies noise addition to the aforementioned dimensionality reduction dataset. Gaussian noise with a noise rate of 0.10

, resulting in the noisy dataset. The

as described in Equation (12).

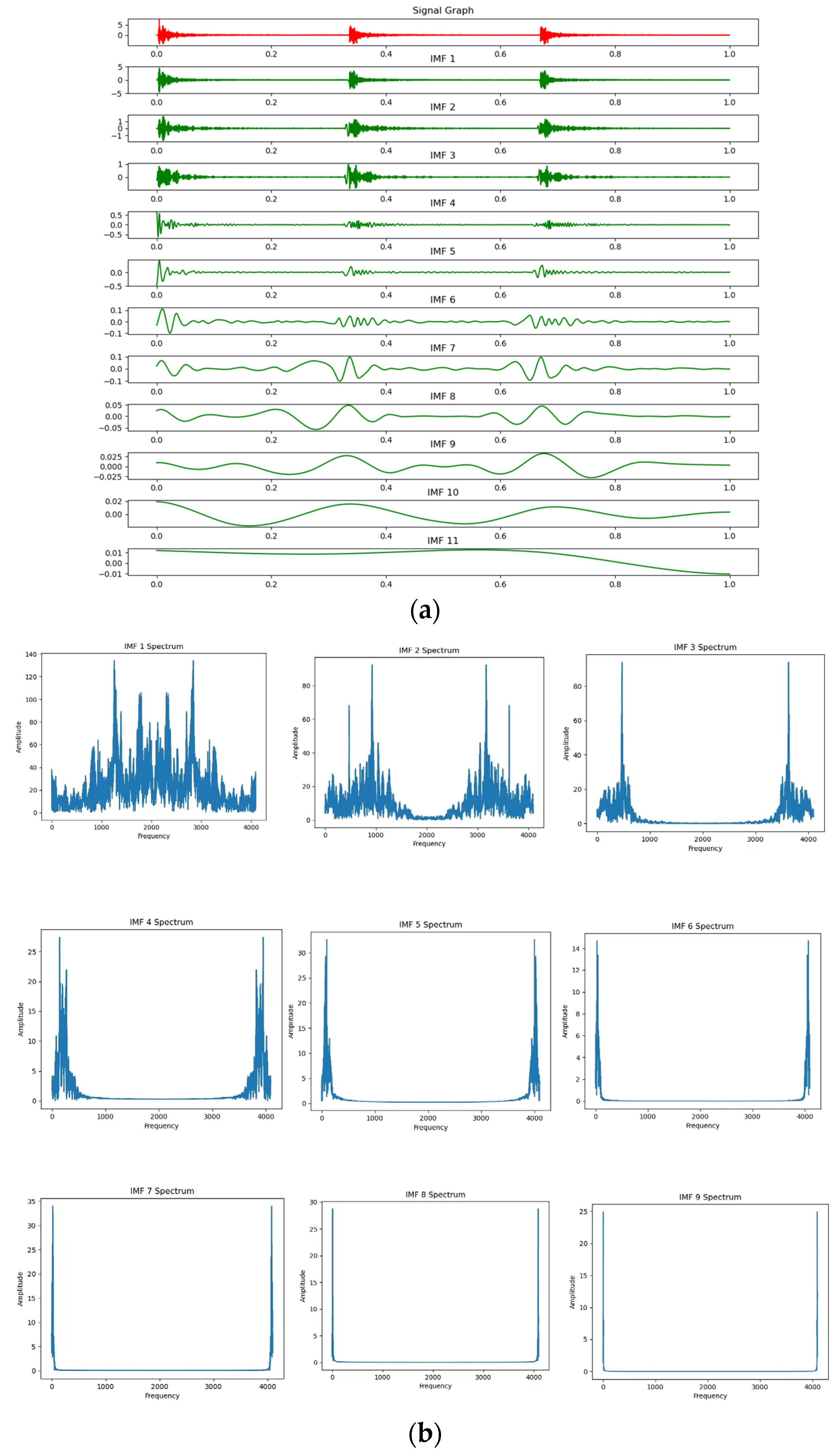

To simulate the interference effects of external environmental factors on the signal data in real-world scenarios, noise is added to the data, and then both EMD and VMD are applied for processing.

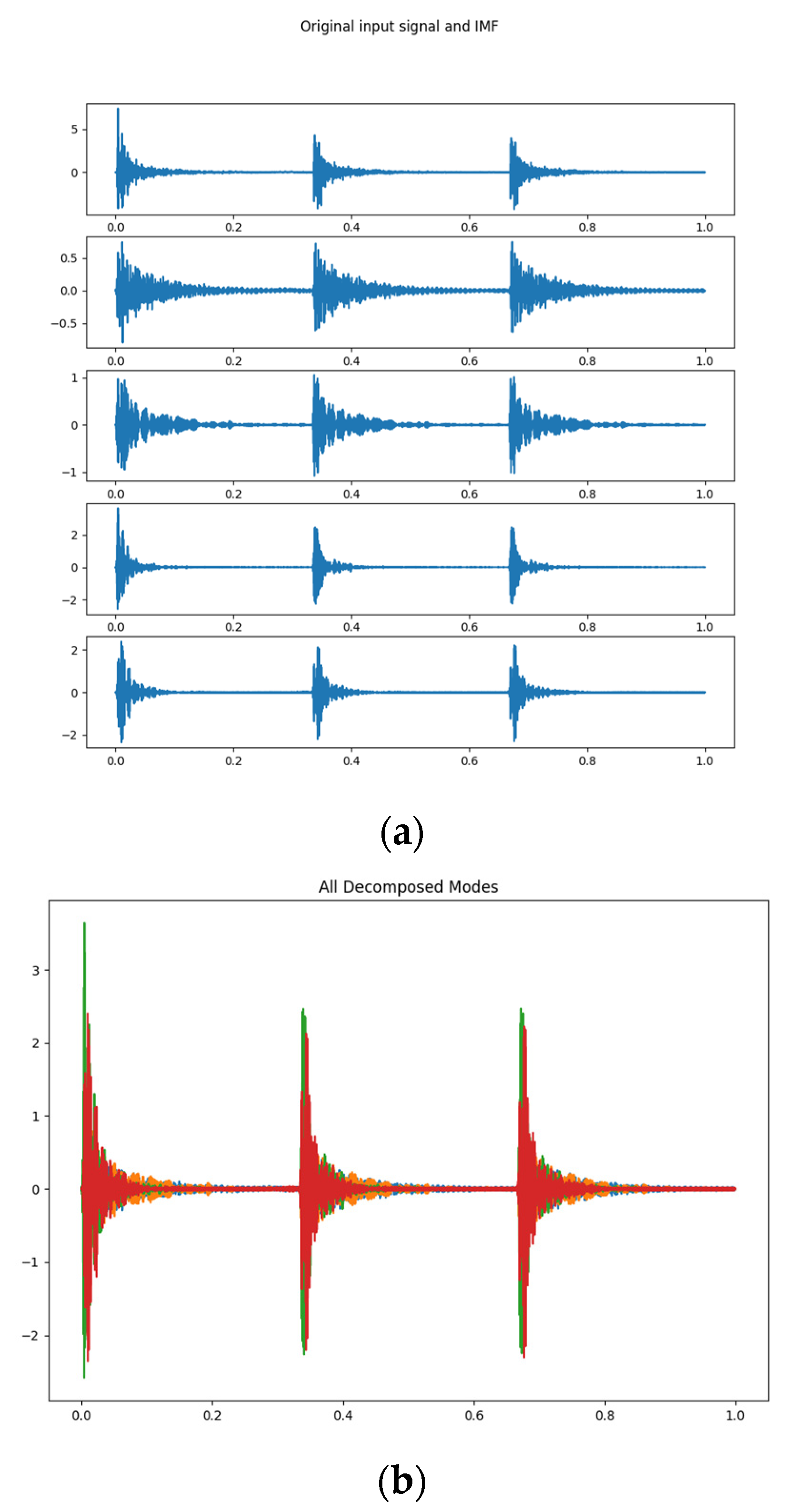

Figure 8a displays the time-domain waveforms of the original signal and the IMF components obtained after EMD decomposition, while

Figure 8b shows the FFT spectra of the IMF components. During the actual experiment, it was observed that the waveforms of the modal components after IMF1 gradually disperse, and the FFT spectra beyond IMF9 become too boundary-dominated, losing their reference value. Therefore, only the FFT spectra of IMF1 to IMF9 are presented.

In the decomposition process of VMD, the Lagrangian multiplier and quadratic penalty play crucial roles as smoothing mechanisms. The Lagrangian multiplier strengthens the constraints, while the quadratic penalty enhances convergence. The Lagrangian multiplier method transforms the constraints into penalty terms in the objective function and adjusts the weight of the penalty term using Lagrangian multipliers. During the hyperparameter tuning process, the regularization strength or weight of the regularization term can be flexibly controlled by setting the penalty factor of VMD, allowing for better control over the smoothness or sparsity of the decomposed mode functions. Additionally, the algorithm’s noise tolerance is set to 0. The mode functions are uniformly initialized, with their initial values set as random numbers from a uniform distribution. The convergence of the algorithm is controlled by setting the tolerance parameter. The decomposition scale is shown in

Table 4, with the center frequencies of f_1 to f_4 set as 2, 24, 128, and 288, respectively. The core hyperparameters of VMD are listed in

Table 4.

Figure 9a shows the time-domain waveforms of the original signal and the IMF components obtained after VMD decomposition.

Figure 9b displays all the IMF components,

Figure 9c shows the FFT spectra of each IMF component.

By comparing the signal representations of intrinsic mode functions (IMFs) obtained through empirical mode decomposition (EMD) and variational mode decomposition (VMD), it is evident that EMD, due to its inability to set the number of decomposed IMFs as hyperparameters, produces multiple signal components that deviate significantly from the original data. In contrast, VMD, with controllable parameters and decomposition guided by the central frequency , yields IMFs that are relatively uniformly dispersed around the original signal.

Additionally, analyzing the FFT spectra of the IMF components obtained from EMD and VMD reveals distinct differences. The FFT spectrum of EMD exhibits gradual marginalization from IMF1 onwards, with IMF10 and IMF11 being severely marginalized, resulting in poor visualization. Therefore, these components are not included in the analysis. In contrast, the FFT spectra of the VMD-decomposed IMFs demonstrate distinct frequency distributions for each IMF component, indicating their potential value for data analysis and experimentation.

Furthermore, in accordance with the theoretical framework outlined in reference [

10], this study incorporates Gaussian noise with a 10% noise level into the data, under the prior setting of Lagrangian multipliers and quadratic penalty factors. The purpose is to simulate VMD’s ability to withstand external disturbances and achieve noise robustness under generalized conditions, through its inherent central constraint and non-smooth band decomposition. The resulting decomposition plots clearly indicate that the IMF components generated by VMD do not exhibit sparsity.

It is worth mentioning that in subsequent experimental sections, where VMD decomposition is utilized as input for a neural network model, the final recognition performance further confirms the robustness of VMD’s processing capabilities.

Then, the data set was decomposed by variational mode to obtain the modal component IMF of the data, and the IMF data and noisy dataset were horizontally expanded to obtain the dataset to be trained with dimension 4096 × 1232.

To investigate the impact of acceleration response signal selection criteria on the effectiveness of structural damage identification in this experiment, three experimental schemes were adopted under impact excitation. These schemes involved the selection of three different operating conditions (i.e., extracting data from the dataset with matching labels of the corresponding operating condition number):

- (1)

Working conditions WC1, WC3, WC5, WC7, and WC9 are selected;

- (2)

Working conditions WC2, 4, 6, 8, and 10 are selected;

- (3)

All working conditions are selected.

In different experimental schemes, the quantity of IMF components is determined by the decomposition scale parameter,

, in VMD. Leveraging the inherent mode superposition property of VMD, the IMF components can be combined and averaged to accentuate the representation of crucial information, as demonstrated in Equation (13).

In Equation (13), represents the original signal, and represents the mode component.

Through a trial-and-error approach, an evaluation is conducted on each segment obtained by directly concatenating IMF components with the original signal and on the new signal segment obtained by averaging several IMF components and concatenating it with the original signal. Evaluation criteria include assessing whether the IMF signals deviate significantly from the structural resonance characteristics, whether nonlinear breakpoints occur at the concatenation points of the new signal segments, and whether the overall smoothness of the new signal is reduced. After selecting effective components [

44] suitable for horizontal concatenation with the original signal, the selected effective components and the new signal data obtained from the original dataset replace the original data. The final selection of effective IMF components related to structural characteristics and the total number of IMF components obtained after VMD decomposition for each of the three schemes are presented in

Table 5.

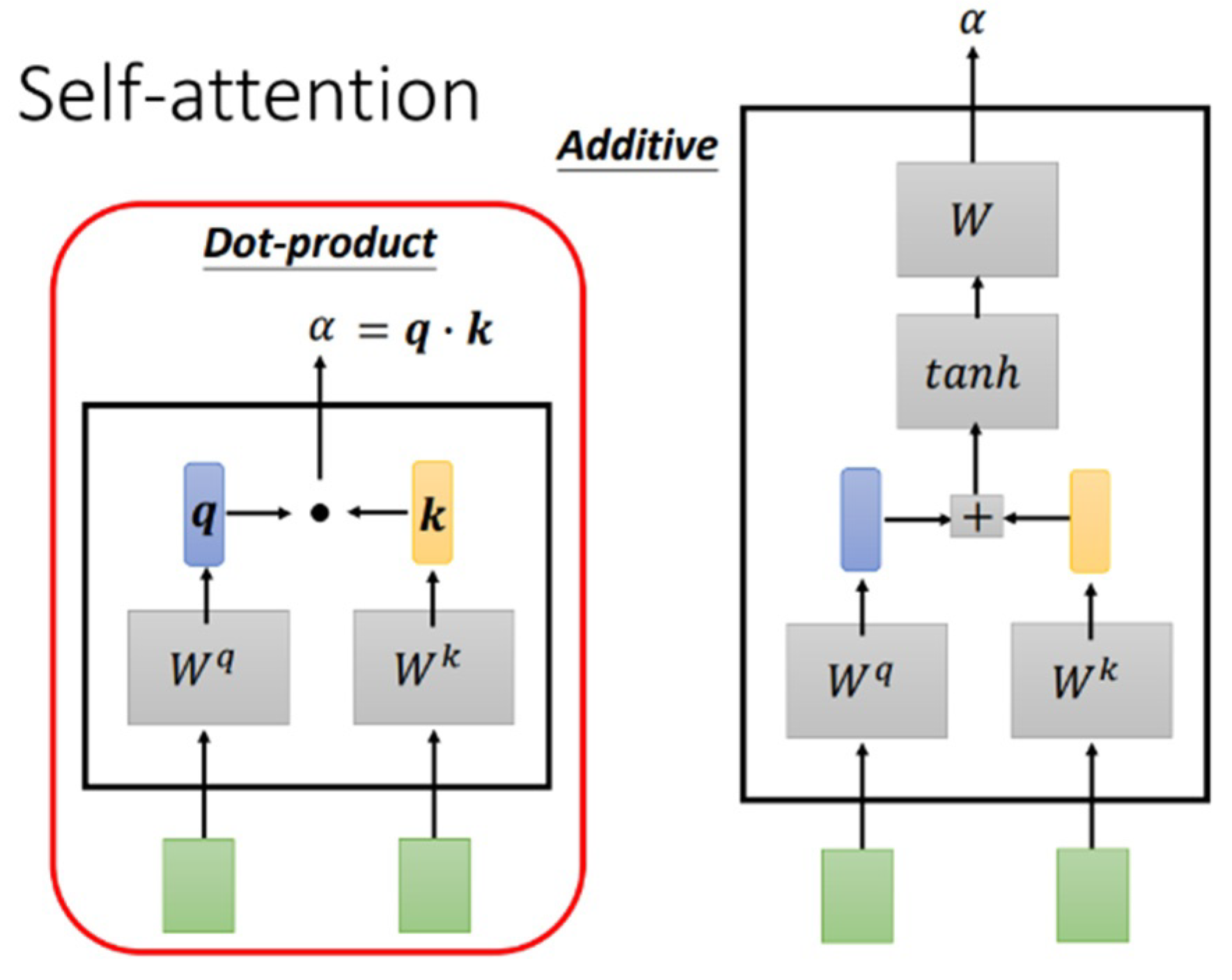

The VMD-CSANN model in this paper consists of two sets of hyperparameters. The first set pertains to the parameters that need to be adjusted for VMD decomposition, as described in

Table 4. The second set pertains to the hyperparameters that need to be adjusted for the CSANN model, such as the convolution layer size, dropout layer ratio, learning rate, etc. The hyperparameters of the two parts have influence on the final recognition effect of the experiment. There are many methods available for network parameter optimization. In this paper, grid search is used to combine key parameters in the model, take the average accuracy of the final verification set as the objective function, and make multiple comparison adjustments to optimize parameters. Finally, the CSANN model is established by parameter combination as shown in

Table 6.

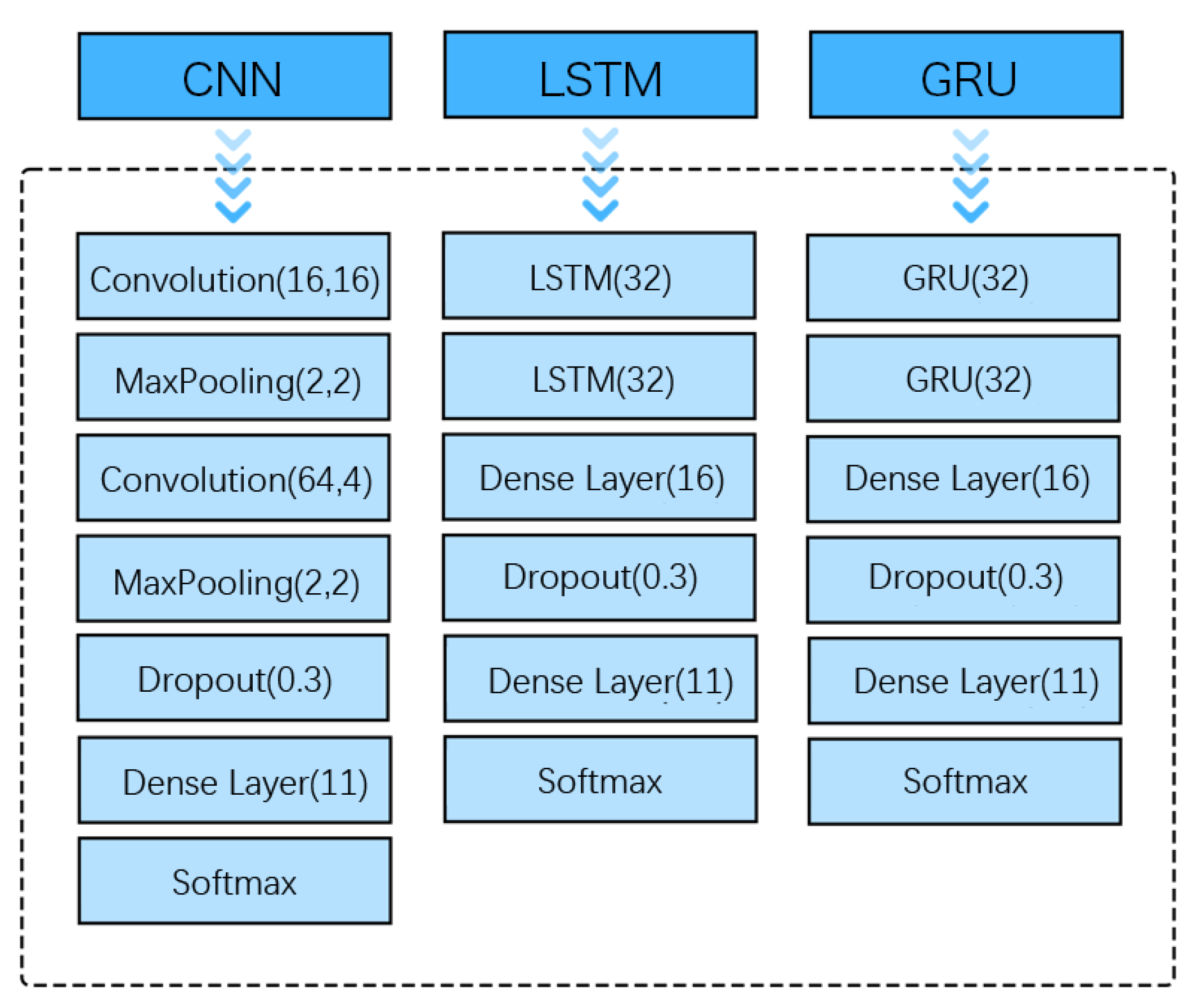

Through comparison experiments between VMD-CSANN and the iconic CNN, LSTM, and GRU models, the effect of the VMD-CSANN model is verified. The comparison neural network models are shown in

Figure 10.

3.4. Results

In this paper, the structural damage identification experiment can be regarded as a multi-label classification of multivariate time series. The reference criteria for evaluating the model effect are accuracy of validation set, loss value, F1 score, precision and recall. The accuracy rate is the average of the K validation sets obtained by K-fold cross-validation value and variance, F1 score, accuracy rate, and recall rate are the mean of the K validation sets obtained by K-fold cross-validation, The loss function adopts the cross entropy loss function. For the three experimental schemes, the comprehensive recognition accuracy and loss values of each comparison model were compared horizontally, as shown in

Table 7. F-1 value, accuracy rate and recall rate are shown in

Table 8. The running time of each comparison model is shown in

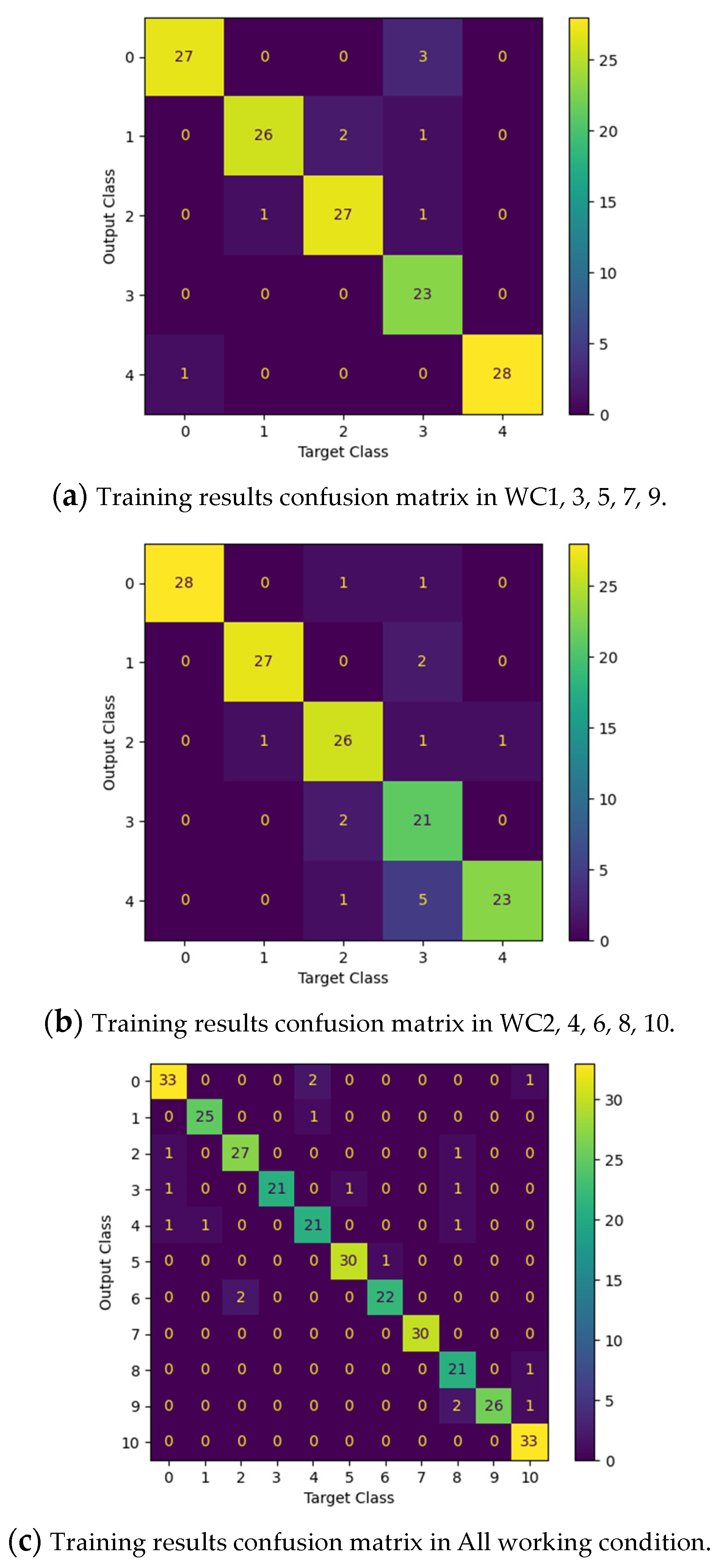

Table 9. The confusion matrix generated by the three experimental schemes is shown in

Figure 11.

Under the condition of keeping the hyperparameters such as epoch and learning rate consistent among all the compared models, the VMD-CSANN combined model demonstrates superior performance in terms of accuracy, loss value, F1 score, precision, and recall metrics compared to other models. This is attributed to the ability of variational mode decomposition to decompose the original signal, including noisy and non-smooth segments, into several relatively smooth segments. This substantiates that augmenting the VMD-CSANN model with both VMD and self-attention mechanisms leads to improved recognition capabilities, whether for specific working conditions or across the board.

However, it is worth noting that the recognition effectiveness for all working conditions, particularly those with larger datasets, is marginally less optimal compared to specific working conditions. This nuanced difference underscores the importance of considering the specific characteristics and complexities of the data when evaluating model performance.