Modeling an Optimal Environmentally Friendly Energy-Saving Flexible Workshop

Abstract

:1. Introduction

1.1. Background and Motivation

1.2. Literature Review

1.3. Contribution

2. Multi-Objective Optimization Model of Green FJSP

2.1. Problem Description

2.2. Mathematical Model

- (1)

- The makespan Z1 is the shortest, that is, the maximum processing time of the last operation of the job is the minimum.

- (2)

- The total energy consumption of processing machines and AGV transportation Z2 is the smallest. The total energy consumption of machines includes three parts: the total energy consumption of machine operation, the total energy consumption of idle machines, and the total energy consumption of machine setting.

- (3)

- The processing quality Z3 of a certain operation on a machine is reflected by the qualified rates of the operation on the machine, that is, the processing quality is expressed by the qualified rates. A job includes n operations, and we regarded the average quality of all operations as the processing quality of the job.

- Constraints between operations and machines.

- (1)

- A operation can only be processed on one machine:

- (2)

- Machine processing sequence constraint, a machine can only process the next process after the previous process is completed and the machine setting is completed:

- (3)

- Each job includes multiple operations, and the operations have sequential constraints. The next operation can only be processed after the previous operation of the same job is completed:

- (4)

- After the machine starts processing an operation, it is not allowed to be interrupted:

- 2.

- Constraints between operations and AGVs.

- (1)

- Only one AGV can be selected for a transportation task:

- (2)

- The order of AGV transportation is restricted. The same AGV cannot transport multiple jobs at the same time, and the jobs are transported in the order of job processing:

- (3)

- The end time of the AGV to complete the task transportation is equal to the start transportation time plus the transportation time:

- 3.

- Constraints between AGVs and machines.

- (1)

- The AGV transports the job to the machine, and the operation can only be processed when the machine is idle:

- (2)

- The AGV transports the job from the unprocessed job storage area to the machine that processes the first operation:

- (3)

- The AGV transports the job from one machine to another for processing of the next operation of the job:

- (4)

- After the last operation of the job is completed, the AGV transports it to the finished job storage area:

3. An Improved Whale Optimization Algorithm (IWOA) for Solving the Green FJSP

3.1. Whale Optimization Algorithm (WOA)

3.2. Solution Encoding and Decoding

3.3. Improved Whale Optimization Algorithm (IWOA)

- (1)

- Nonlinear convergence factor

- (2)

- Nonlinear adaptive inertia weight

- (3)

- Improve the screw position update model

3.4. Loss Function Construction

3.5. The Procedure of IWOA

| Algorithm 1: Pseudo-code of the IWOA |

| Input: The parameter of green flexible job-shop scheduling models; Output: Minimum loss function f(x*i); Begin Set algorithm parameters: population size N, maximum iteration times tmax. While t < tmax do Initial population of whales xi; Calculate the loss function f(xi) of each whales; Retain the current best whales; for i to N do Randomly generate p values at [0, 1]; Update the adaptive inertia weight w by Equation (21); If p > 0.5 then Update the position of the current whale population by Equation (24); else Calculate the nonlinear convergence factor a by (20), Calculate A and C by Equation (16); If A > 1 then Generate a random individual xrand; Update the position of the current whale population by Equation (23); else Update the position of the current whale population by Equation (22); end if end if end for Update iteration counter t; end while Output the optimal loss function f(x*i); Output the optimal scheduling scheme; end |

4. Comprehensive Experiments

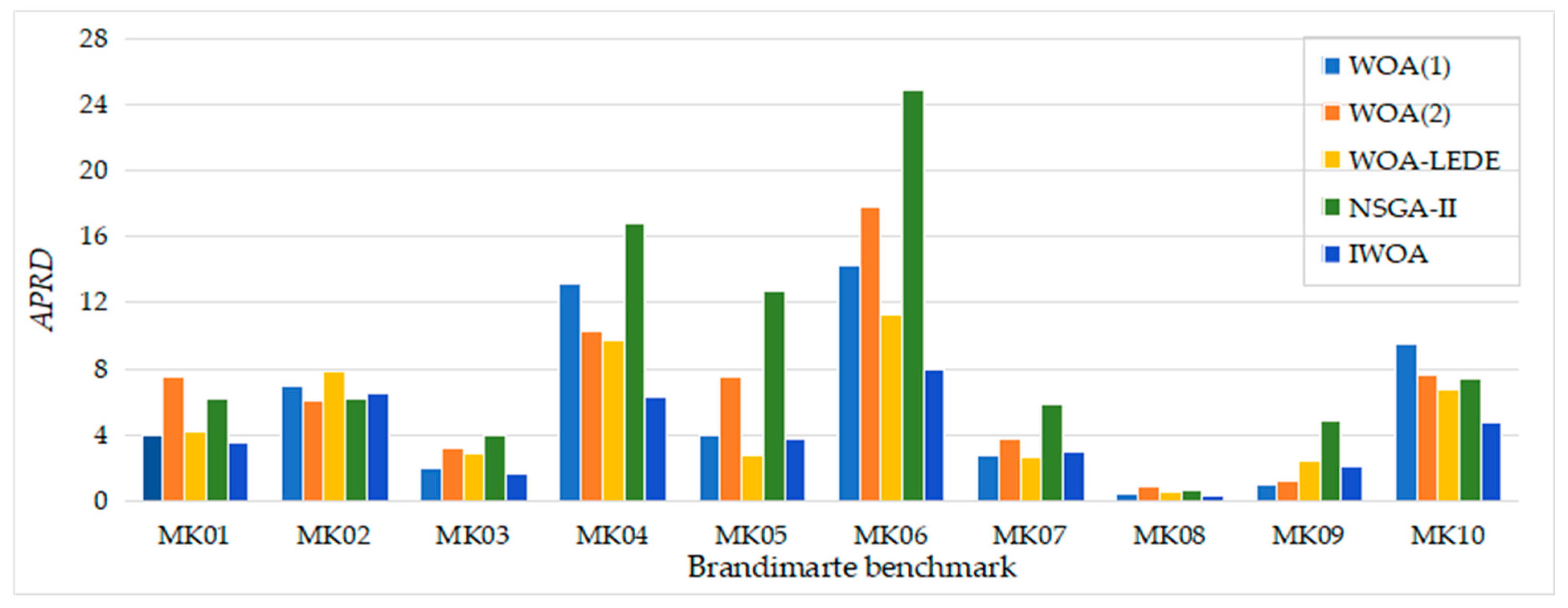

4.1. Benchmark Test

4.2. Effectiveness of Improvement Strategy

- (1)

- Effectiveness of nonlinear convergence factor: For comparison, the convergence speed of IWOA-I in the three small-scale instances MK01, MK02, and MK03 was greater than that of IWOA. Furthermore, it can also be calculated that the average running time difference between IWOA-I and IWOA in the five instances was −0.05 (22.71 − 22.76 = −0.05), and the average convergence speed of IWOA-I was ahead of the IWOA. The results show that the nonlinear convergence factor has a very important and positive effect on the convergence speed of the algorithm. This result from the convergence factors is a decrease nonlinearly with the increase in the number of evolutionary iterations, which ensures that whales conduct a global search with a large stride in the early stage of search, and conduct local optimization with a small stride in the later stage to improve the speed of the whole search process while ensuring the quality.

- (2)

- Effectiveness of nonlinear adaptive inertia weight: For the APRD value, the average difference between IWOA-II and IWOA (6.12 − 4.30 = 1.82) was significantly smaller than that between IWOA-I and IWOA (9.72 − 4.30 = 5.42), indicating that the nonlinear adaptive inertia weight has a greater impact on the optimization ability of the IWOA than the nonlinear convergence factor. In addition, for instance MK07 in Table 4, the optimization time of IWOA-II is better than that of IWOA-I, which shows that the nonlinear adaptive weight strategy can also accelerate the convergence speed of the algorithm.

- (3)

- Effectiveness of screw position update model: Compared with the two whale optimization algorithms based on Strategy I and Strategy II, the average APRD value of IWOA-III was closer to the whale optimization algorithm using three combined strategies, but the running time of the algorithm was inferior to IWOA-I and IWOA-II, which indicates that the screw position update model had the greatest impact on the model optimization accuracy. This result from the screw position update model can increase the diversity of the total group, which can effectively avoid the algorithm from falling into the local optimum, although the search time for the optimal solution increases.

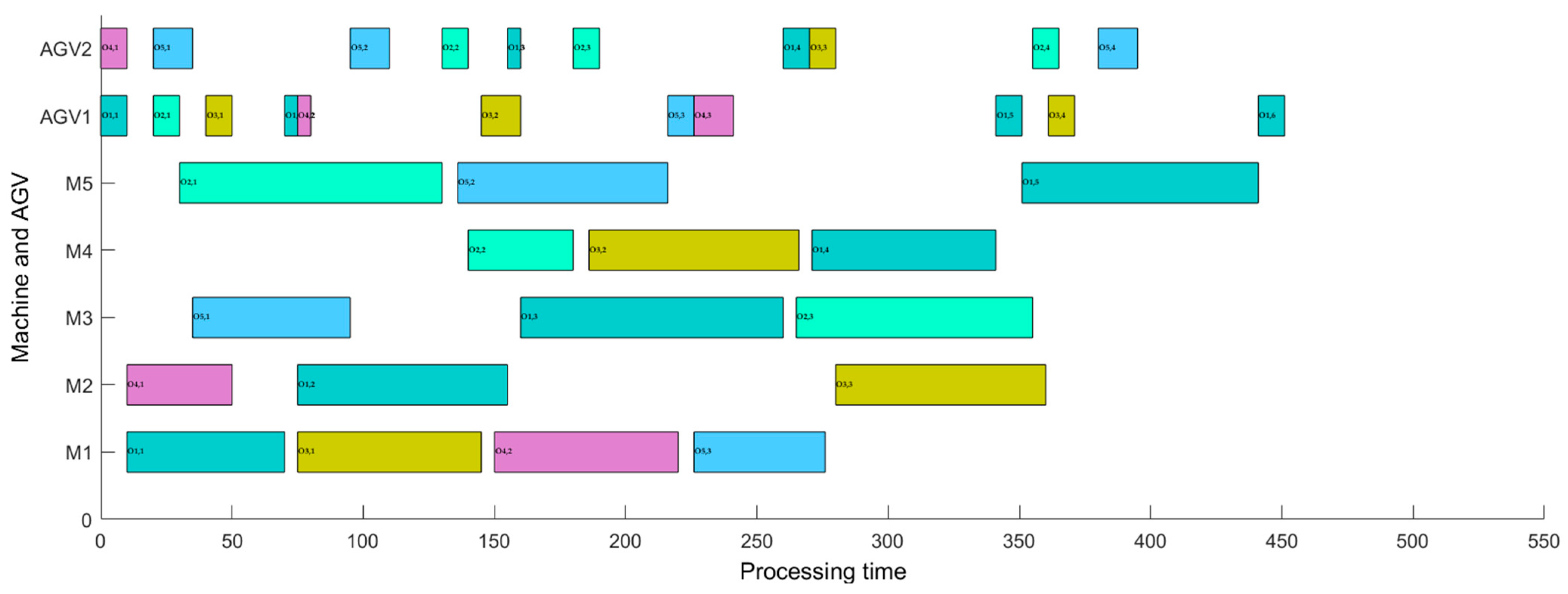

4.3. Workshop Example Simulation

- (1)

- Model convergence: From the convergence curve, the proposed IWOA algorithm had good global search performance and local information mining ability. The blue curve shows the iteration process of the IWOA. In the early stage of iteration, the curve jump distance is large, which indicates that the algorithm has better global detection ability. At the later stage of iteration, it still shows good search ability and frequent small distance down hops until finally stable, without falling into the local optimum. Formally, the convergence speed of the IWOA was better than IWOA(2) and WOA-LEDE on 5 × 5 instances. Although IWOA(1) and NSG-II converged before IWOA, their optimization effect was not good. In addition, in 5 × 15 instances, the convergence speed of IWOA was significantly better than that of the other four comparison algorithms. Therefore, it can be concluded that compared with small-scale scheduling problems, the proposed algorithm has stronger performance in large-scale numerical examples.

- (2)

- Model solution quality: According to the convergence curve, the loss function of the IWOA was 0.250 and 0.245, respectively, in two instances of different sizes, which is better than the loss of the comparison algorithm, and the multi-objective solution with the maximum satisfaction degree was obtained. In addition, it can be seen from Figure 9 that the mean value of loss function of IWOA in the 5 × 5 and 15 × 5 instances was 0.265 and 0.258, respectively, and its upper and lower limits were also much better than its comparison algorithm.

- (3)

- Stability of the model: Figure 9 shows that the loss function fluctuations of IWOA in the two instances were [0.251, 0.275] and [0.245, 0.273] respectively, which were significantly smaller than the loss fluctuation interval of the comparison algorithm. The algorithm shows good stability, and the stability performance on large-scale instances is superior.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Machine (Setup Time/Processing Time/Processing Quality/Average Energy Consumption Coefficient) | ||||||

|---|---|---|---|---|---|---|

| Job | Oper. | M1 | M2 | M3 | M4 | M5 |

| J1 | O11 | 5/60/0.80/2.1 | 4/52/0.84/2.6 | - | 5/65/0.80/1.8 | - |

| O12 | - | 5/80/0.85/1.8 | 7/70/0.80/2.4 | - | 5/75/0.87/2.60 | |

| O13 | 7/110/0.80/1.9 | 5/90/0.75/2.3 | 4/100/0.78/2.5 | - | 6/1000.85/2.5 | |

| O14 | 4/77/0.80/2.5 | - | 6/70/0.75/1.8 | 5/70/0.85/1.7 | 4/60/0.81/2.3 | |

| O15 | 5/90/0.77/2.5 | 7/105/0.85/2.9 | - | - | 5/90/0.88/3.1 | |

| J2 | O21 | 5/82/0.77/2.5 | - | 4/95/0.81/2.9 | 7/95/0.87/3.2 | 5/100/0.85/2.9 |

| O22 | - | 4/50/0.75/2.8 | 5/55/0.80/3.5 | 5/40/0.78/3.5 | - | |

| O23 | - | 8/70/0.76/2.0 | 5/90/0.82/1.8 | - | 5/75/0.78/2.5 | |

| J3 | O31 | 5/70/0.85/3.3 | - | 5/60/0.81/2.8 | - | 8/70/0.82/2.8 |

| O32 | - | 5/78/0.74/2.2 | - | 6/80/0.79/1.8 | 8/83/0.82/2.5 | |

| O33 | - | 5/80/0.87/2.9 | 4/92/0.85/2.7 | 5/80/0.82/2.5 | - | |

| J4 | O41 | 5/40/0.87/1.6 | - | 8/48/0.88/2.5 | 5/45/0.82/2.1 | |

| O42 | 5/70/0.80/2.6 | - | 7/70/0.85/2.5 | 5/88/0.79/2.2 | - | |

| J5 | O51 | - | - | 8/60/0.84/1.2 | 8/65/0.85/2.5 | 5/65/0.87/2.0 |

| O52 | - | 4/80/0.78/2.8 | - | 4/75/0.83/2.9 | 6/80/0.88/3.3 | |

| O53 | 6/50/0.83/3.6 | 8/65/0.85/3.2 | 6/55/0.76/2.9 | 5/50/0.78/3.5 | - | |

| μk | 0.3 | 0.2 | 0.3 | 0.4 | 0.5 | |

| σk | 0.8 | 0.6 | 0.7 | 1.1 | 0.8 | |

| Machine (Setup Time/Processing Time/Processing Quality/Average Energy Consumption Coefficient) | ||||||

|---|---|---|---|---|---|---|

| Job | Oper. | M1 | M2 | M3 | M4 | M5 |

| J1 | O11 | 5/110/0.88/2.3 | 5/105/0.87/1.6 | 4/100/0.84/1.8 | 6/95/0.79/2.5 | |

| O12 | 8/95/0.84/2.7 | 4/80/0.82/2.3 | 5/85/0.81/2.3 | 5/65/0.80/2.7 | 7/85/0.75/2.2 | |

| O13 | 5/80/0.75/2.1 | 5/85/0.82/2.4 | 6/70/0.85/2.5 | |||

| O14 | 7/60/0.88/3.1 | 5/55/0.82/2.5 | 4/60/0.75/2.3 | 5/50/0.81/2.7 | ||

| O15 | 8/85/0.82/2.5 | 5/95/0.77/2.3 | 5/100/0.80/2.5 | 6/90/0.84/2.9 | ||

| J2 | O21 | 7/100/0.77/2.3 | 3/120/0.80/2.5 | 4/110/0.81/2.3 | 4/100/0.83/2.9 | |

| O22 | 5/45/0.78/1.9 | 4/58/0.82/1.8 | 6/40/0.80/2.2 | 7/55/0.81/2.3 | ||

| O23 | 7/60/0.85/2.6 | 4/45/0.82/2.8 | 5/50/0.83/2.4 | 5/35/0.80/3.1 | ||

| J3 | O31 | 4/70/0.83/2.5 | 5/80/0.85/2.3 | 6/75/0.80/2.0 | 5/60/0.83/3.0 | |

| O32 | 5/25/0.75/2.2 | 6/30/0.84/2.8 | 7/20/0.82/2.4 | 5/20/0.80/2.2 | ||

| O33 | 5/50/0.85/2.5 | 5/60/0.83/2.5 | 7/55/0.85/2.1 | 6/40/0.78/1.8 | ||

| J4 | O41 | 5/45/0.81/2.3 | 6/40/0.79/2.5 | 7/55/0.82/2.8 | 5/40/0.84/2.8 | |

| O42 | 7/70/0.86/2.3 | 5/60/0.85/1.8 | 4/70/0.81/2.0 | |||

| J5 | O51 | 5/60/0.80/2.2 | 6/60/0.84/2.4 | 5/75/0.77/2.0 | ||

| O52 | 6/85/0.81/2.3 | 4/90/0.80/1.9 | 6/70/0.77/2.3 | 7/80/0.84/2.8 | ||

| O53 | 7/50/0.80/2.1 | 7/65/0.83/2.3 | 5/60/0.80/2.3 | |||

| J6 | O61 | 8/35/0.76/2.8 | 6/30/0.80/3.1 | 4/30/0.85/3.7 | 4/45/0.82/3.2 | |

| O62 | 7/50/0.84/2.4 | 3/50/0.75/2.1 | 6/45/0.82/2.5 | 5/60/0.78/2.5 | ||

| O63 | 5/75/0.75/2.5 | 6/75/0.78/2.8 | 7/80/0.84/3.1 | 5/95/0.81/2.8 | ||

| J7 | O71 | 6/55/0.77/3.1 | 5/65/0.82/2.6 | 5/70/0.85/2.8 | ||

| O72 | 4/30/0.82/2.3 | 5/25/0.78/2.3 | 5/40/0.85/2.6 | |||

| O73 | 5/55/0.84/1.9 | 5/60/0.80/2.3 | 6/50/0.84/2.7 | 7/38/0.75/2.6 | ||

| O74 | 7/100/0.82/3.5 | 5/110/0.84/3.8 | 4/90/0.79/3.5 | 5/105/0.78/2.6 | ||

| J8 | O81 | 4/90/0.85/1.8 | 5/100/0.78/2.3 | 3/85/0.87/2.4 | 6/105/0.74/2.3 | |

| O82 | 6/70/0.88/2.8 | 4/80/0.78/2.5 | 4/75/0.84/2.8 | 7/80/0.85/2.9 | ||

| O83 | 5/70/0.75/1.8 | 6/80/0.83/2.2 | 4/80/0.75/1.6 | 5/90/0.85/2.0 | ||

| J9 | O91 | 5/100/0.79/2.1 | 5/90/0.82/2.5 | 6/100/0.85/2.7 | ||

| O92 | 7/75/0.79/2.4 | 6/60/0.82/2.4 | 7/70/0.81/2.7 | |||

| J10 | O10,1 | 7/80/0.84/2.7 | 5/70/0.77/1.8 | 5/70/0.80/2.3 | 5/85/0.78/1.9 | |

| O10,2 | 6/55/0.77/3.2 | 4/40/0.75/2.8 | 5/50/0.86/2.4 | |||

| O10,3 | 7/110/0.76/2.3 | 5/95/0.88/2.7 | 4/90/0.78/2.5 | 6/100/0.85/2.5 | ||

| J11 | O11,1 | 5/30/0.76/2.7 | 4/30/0.83/2.7 | 5/35/0.85/2.3 | 5/45/0.75/2.2 | |

| O11,2 | 4/85/0.85/2.6 | 7/80/0.78/2.2 | 5/90/0.84/2.5 | 5/80/0.84/2.7 | ||

| O11,3 | 4/50/0.78/1.6 | 5/60/0.83/2.5 | 7/55/0.81/2.7 | 7/60/0.80/2.1 | ||

| J12 | O12,1 | 7/75/0.78/1.9 | 6/65/0.81/2.3 | 5/70/0.85/2.3 | ||

| O12,2 | 4/60/0.81/2.3 | 5/60/0.78/2.3 | 7/50/0.81/2.9 | |||

| O12,3 | 5/110/0.82/2.3 | 5/100/0.84/2.6 | 7/110/0.78/2.0 | |||

| O12,4 | 8/80/0.80/1.9 | 6/80/0.83/2.5 | 4/60/0.80/2.2 | 4/70/0.81/2.7 | ||

| J13 | O13,1 | 5/70/0.78/2.1 | 5/65/0.81/3.8 | 6/80/0.85/2.6 | ||

| O13,2 | 3/20/0.80/2.0 | 4/30/0.76/2.9 | 4/30/0.78/2.0 | 7/20/0.80/2.5 | ||

| O13,3 | 6/50/0.81/2.5 | 5/50/0.78/2.1 | 7/40/0.78/2.9 | 5/60/0.83/2.5 | ||

| J14 | O14,1 | 5/85/0.80/2.8 | 5/90/0.83/2.5 | 6/100/0.86/2.4 | ||

| O14,2 | 5/80/0.84/2.8 | 6/70/0.80/2.2 | 7/65/0.76/2.1 | |||

| O14,3 | 5/40/0.83/2.7 | 6/50/0.82/2.5 | 5/35/0.78/2.2 | |||

| O14,4 | 7/60/0.80/2.1 | 7/40/0.80/2.4 | 4/50/0.83/2.6 | 5/55/0.78/2.4 | ||

| J15 | O15,1 | 5/60/0.81/3.1 | 7/70/0.80/2.6 | 5/50/0.85/3.3 | ||

| O15,2 | 7/25/0.75/1.8 | 6/30/0.82/2.3 | 6/40/0.82/2.0 | 4/35/0.83/2.5 | ||

| O15,3 | 3/65/0.88/2.2 | 7/40/0.81/2.8 | 5/50/0.83/2.8 | 5/55/0.85/3.3 | ||

| μk | 0.3 | 0.2 | 0.3 | 0.4 | 0.5 | |

| σk | 0.8 | 0.6 | 0.7 | 1.1 | 0.8 | |

References

- Yao, X.; Lin, Y. Emerging manufacturing paradigm shifts for the incoming industrial revolution. Int. J. Adv. Manuf. Technol. 2016, 85, 1665–1676. [Google Scholar] [CrossRef]

- Jamili, A. Robust job shop scheduling problem: Mathematical models, exact and heuristic algorithms. Expert Syst. Appl. 2016, 55, 341–350. [Google Scholar] [CrossRef]

- Zhao, F.; Zhang, L.; Cao, J.; Tang, J. A cooperative water wave optimization algorithm with reinforcement learning for the distributed assembly no-idle flowshop scheduling problem. Comput. Ind. Eng. 2021, 153, 107082. [Google Scholar] [CrossRef]

- Huo, L.; Wang, J.Y. Flexible job shop scheduling based on digital twin and improved bacterial foraging. Int. J. Simul. Model. 2022, 21, 525–536. [Google Scholar] [CrossRef]

- Barak, S.; Moghdani, R.; Maghsoudlou, H. Energy-efficient multi-objective flexible manufacturing scheduling. J. Clean. Prod. 2021, 283, 124610. [Google Scholar] [CrossRef]

- Xing, Z.; Liu, H.T.; Wang, T.S.; Chew, E.P.; Lee, L.H.; Tan, K.C. Integrated automated guided vehicle dispatching and equipment scheduling with speed optimization. Transp. Res. E Logist. Transp. Rev. 2022, 169, 102993. [Google Scholar] [CrossRef]

- Abderrabi, F.; Godichaud, M.; Yalaoui, A.; Yalaoui, F.; Amodeo, L.; Qerimi, A.; Thivet, E. Flexible job shop scheduling problem with sequence dependent setup time and job splitting: Hospital catering case study. Appl. Sci. 2021, 11, 1504. [Google Scholar] [CrossRef]

- Wu, X.; Sun, Y. A green scheduling algorithm for flexible job shop with energy-saving measures. J. Clean. Prod. 2018, 172, 3249–3264. [Google Scholar] [CrossRef]

- Uzsoy, R. Scheduling a single batch processing machine with non-identical job sizes. Int. J. Prod. Res. 1994, 32, 1615–1635. [Google Scholar] [CrossRef]

- Shi, X.Q.; Long, W.; Li, Y.Y.; Wei, Y.L.; Deng, D.S. Different performances of different intelligent algorithms for solving FJSP: A perspective of structure. Comput. Intell. Neurosci. 2018, 4617816. [Google Scholar] [CrossRef]

- Zhou, S.; Xing, L.; Zheng, X.; Du, N.; Wang, L.; Zhang, Q. A self-adaptive differential evolution algorithm for scheduling a single batch-processing machine with arbitrary job sizes and release times. IEEE Trans. Cybern. 2019, 51, 1430–1442. [Google Scholar] [CrossRef] [PubMed]

- Gajsek, B.; Dukic, G.; Kovacic, M.; Brezocnik, M. A multi-objective genetic algorithms approach for modelling of order picking. Int. J. Simul. Model. 2021, 20, 719–729. [Google Scholar] [CrossRef]

- Zhao, F.; Di, S.; Cao, J.; Tang, J. A novel cooperative multi-stage hyper-heuristic for combination optimization problems. Complex Syst. Model. Simul. 2021, 1, 91–108. [Google Scholar] [CrossRef]

- Brandão, J. Iterated local search algorithm with ejection chains for the open vehicle routing problem with time windows. Comput. Ind. Eng. 2018, 120, 146–159. [Google Scholar] [CrossRef]

- Zheng, Y.; Xiao, Y.; Seo, Y. A tabu search algorithm for simultaneous machine/AGV scheduling problem. Int. J. Prod. Res. 2014, 52, 5748–5763. [Google Scholar] [CrossRef]

- Umar, U.A.; Ariffin, M.K.A.; Ismail, N.; Tang, S.H. Hybrid multiobjective genetic algorithms for integrated dynamic scheduling and routing of jobs and automated-guided vehicle (AGV) in flexible manufacturing systems (FMS) environment. Int. J. Adv. Manuf. Technol. 2015, 81, 2123–2141. [Google Scholar] [CrossRef]

- Saidi-Mehrabad, M.; Dehnavi-Arani, S.; Evazabadian, F.; Mahmoodian, V. An Ant Colony Algorithm (ACA) for solving the new integrated model of job shop scheduling and conflict-free routing of AGVs. Comput. Ind. Eng. 2015, 86, 2–13. [Google Scholar] [CrossRef]

- Sanches, D.S.; Silva Rocha, J.D.; Castoldi, M.F.; Morandin, O.; Kato, E.R.R. An adaptive genetic algorithm for production scheduling on manufacturing systems with simultaneous use of machines and agvs. J. Control Autom. Electr. Syst. 2015, 26, 225–234. [Google Scholar] [CrossRef]

- Nageswararao, M.; Narayanarao, K.; Rangajanardhana, G.S. Scheduling of machines and automated guided vehicles in FMS using gravitational search algorithm. Appl. Mech. Mater. 2017, 867, 307–313. [Google Scholar] [CrossRef]

- Fazlollahtabar, H.; Hassanli, S. Hybrid cost and time path planning for multiple autonomous guided vehicles. Appl. Intell. 2018, 48, 482–498. [Google Scholar] [CrossRef]

- Li, G.; Zeng, B.; Liao, W.; Li, X.; Gao, L. A new AGV scheduling algorithm based on harmony search for material transfer in a real-world manufacturing system. Adv. Mech. Eng. 2018, 10, 1687814018765560. [Google Scholar] [CrossRef]

- Lyu, X.; Song, Y.; He, C.; Lei, Q.; Guo, W. Approach to integrated scheduling problems considering optimal number of automated guided vehicles and conflict-free routing in flexible manufacturing systems. IEEE Access 2019, 7, 74909–74924. [Google Scholar] [CrossRef]

- Zhu, Z.; He, Y. An improved genetic algorithm for production scheduling on FMS with simultaneous use of machines and AGVs. In Proceedings of the 2019 11th International Conference on Intelligent Human-Machine Systems and Cybernetics (IHMSC), Hangzhou, China, 24–25 August 2019; Volume 1, pp. 245–249. [Google Scholar]

- Lei, C.; Zhao, N.; Ye, S.; Wu, X. Memetic algorithm for solving flexible flow-shop scheduling problems with dynamic transport waiting times. Comput. Ind. Eng. 2020, 139, 105984. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Ren, Y.; Ren, C. Mathematical modelling and optimisation of energy-conscious hybrid flow shop scheduling problem with unrelated parallel machines. Int. J. Prod. Res. 2019, 57, 1119–1145. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Ren, Y. MILP models for energy-aware flexible job shop scheduling problem. J. Clean. Prod. 2019, 210, 710–723. [Google Scholar] [CrossRef]

- Zhou, M.X.; Li, X. Low-carbon production control and resource allocation optimization. Int. J. Simul. Model. 2022, 21, 352–363. [Google Scholar] [CrossRef]

- Liu, C.; Yao, Y.; Zhu, H. Hybrid salp swarm algorithm for solving the green scheduling problem in a double-flexible job shop. Appl. Sci. 2021, 12, 205. [Google Scholar] [CrossRef]

- Liu, Q.H.; Wang, C.Y.; Li, X.Y.; Gao, L. A multi-population co-evolutionary algorithm for green integrated process planning and scheduling considering logistics system. Eng. Appl. Artif. Intell. 2023, 126, 107030. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, C.; Sun, Q.M. Green job shop scheduling problem with discrete whale optimization algorithm. IEEE Access 2019, 7, 43153–43166. [Google Scholar] [CrossRef]

- Yao, F.; Alkan, B.; Ahmad, B.; Harrison, R. Improving just-in-time delivery performance of IoT-enabled flexible manufacturing systems with AGV based material transportation. Sensors 2020, 20, 6333. [Google Scholar] [CrossRef]

- Jiang, T.; Zhu, H.; Deng, G. Improved African buffalo optimization algorithm for the green flexible job shop scheduling problem considering energy consumption. J. Intell. Fuzzy Syst. 2020, 38, 4573–4589. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, H.; Tang, H.; Feng, Y.; Yin, W. Research on flexible job-shop scheduling problem in green sustainable manufacturing based on learning effect. J. Intell. Manuf. 2021, 33, 1725–1746. [Google Scholar] [CrossRef]

- Afsar, S.; Palacios, J.J.; Puente, J.; Vela, C.R.; González-Rodríguez, I. Multi-objective enhanced memetic algorithm for green job shop scheduling with uncertain times. Swarm Evol. Comput. 2022, 68, 101016. [Google Scholar] [CrossRef]

- Chen, J.X.; Wu, Y.X.; Huang, S.; Wang, P. Multi-objective optimization for AGV energy efficient scheduling problem with customer satisfaction. AIMS Math. 2023, 8, 20097–20124. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The whale optimization algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Li, A.D.; He, Z. Multiobjective feature selection for key quality characteristic identification in production processes using a nondominated-sorting-based whale optimization algorithm. Comput. Ind. Eng. 2020, 149, 106852. [Google Scholar] [CrossRef]

- Zeng, N.; Song, D.; Li, H.; You, Y.; Liu, Y.; Alsaadi, F.E. A competitive mechanism integrated multi-objective whale optimization algorithm with differential evolution. Neurocomputing 2021, 432, 170–182. [Google Scholar] [CrossRef]

- Abd Elaziz, M.; Lu, S.; He, S. A multi-leader whale optimization algorithm for global optimization and image segmentation. Expert Syst. Appl. 2021, 175, 114841. [Google Scholar] [CrossRef]

- Yang, S.; Chen, D.; Li, S.; Wang, W. Carbon price forecasting based on modified ensemble empirical mode decomposition and long short-term memory optimized by improved whale optimization algorithm. Sci. Total Environ. 2020, 716, 137117. [Google Scholar] [CrossRef]

- Luan, F.; Cai, Z.; Wu, S.; Jiang, T.; Li, F.; Yang, J. Improved whale algorithm for solving the flexible job shop scheduling problem. Mathematics 2019, 7, 384. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, C.; Zhu, H.; Gu, J.; Deng, G. Energy-efficient scheduling for a job shop using an improved whale optimization algorithm. Mathematics 2018, 6, 220. [Google Scholar] [CrossRef]

- Liu, M.; Yao, X.; Li, Y. Hybrid whale optimization algorithm enhanced with Lévy flight and differential evolution for job shop scheduling problems. Appl. Soft Comput. 2020, 87, 105954. [Google Scholar] [CrossRef]

- Brandimarte, P. Routing and scheduling in a flexible job shop by tabu search. Ann. Oper. Res. 1993, 41, 157–183. [Google Scholar] [CrossRef]

- Rahimi, I.; Gandomi, A.H.; Deb, K.; Chen, F.; Nikoo, M.R. Scheduling by NSGA-II: Review and bibliometric analysis. Processes 2022, 10, 98. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, X.; Huang, H.; Cheng, S.; Wu, M. A NSGA-II algorithm for task scheduling in UAV-enabled MEC system. IEEE Trans. Intell. Transp. Syst. 2021, 23, 9414–9429. [Google Scholar] [CrossRef]

- Li, H.; Zhu, H.; Jiang, T. Modified migrating birds optimization for energy-aware flexible job shop scheduling problem. Algorithms 2020, 13, 44. [Google Scholar] [CrossRef]

| Notations | Definition | Notations | Definition |

|---|---|---|---|

| i | Set of jobs, i = {1, 2, 3, ..., I} | tijkk’v | Transport time of operation Oij from machine mk to machine mk’ by AGV wv |

| j | Set of operations, j = {1, 2, 3, ..., Ji} | qijk | Processing quality of operation Oij on machine mk |

| Ji | Number of operations for job i | αijk | Energy consumption of operation Oij on machine mk |

| M | Set of processing machines, M = {m1, m2, ..., mk} | μk | Energy consumption of machine mk in idle state |

| W | Set of AGV, W = {w1, w2, ..., wv} | σk | Setup energy consumption coefficient of machine mk |

| Osijk | Starting time of operation Oij on machine mk | τv | Energy consumption of AGV wv driving |

| Oijk | Processing time of operation Oij on machine mk | Mijk | Setup time of machine mk for operation Oij |

| Oeijk | Completion time of operation Oij on machine mk | L | A big positive number |

| tsijv | Starting time of AGV v transport operation Oij | xijk | If operation Oij is to be processed on machine mk, xijk = 1; otherwise, xijk = 0 |

| teijv | Completion time of AGV wv transport operation Oij | yijv | If operation Oij is transported by AGV wv, yijv = 1; otherwise, yijv = 0 |

| tij0kv | Transport time of operation Oij from unprocessed job storage area M0 to machine mk by AGV wv | xiji’j’k | If Oij is processed on machine mk prior to Oi’j’, xiji’j’k = 1; otherwise, xiji’j’k = 0 |

| tijkk+1v | Transport time of operation Oij from machine mk to finished job storage area Mk+1 by AGV wv | yiji’j’v | If Oij is transported by AGV wv prior to Oi’j’, yiji’j’v = 1; otherwise, yiji’j’v = 0 |

| Algorithm | Parameters |

|---|---|

| WOA(1) | Maximum convergence factor amax = 2; minimum convergence factor amax = 0; constant b = 1; spiral shape control parameters l ∈ [−1, 1]. |

| WOA(2) | a varies with the number of iterations t; constant b = 1; spiral shape control parameters l ∈ [−1, 1]. |

| WOA-LEDE | a is decreased linearly from 2 to 0; constant b = 1; spiral shape control parameters l ∈ [−1, 1]; the position vector of a random whale a0 = 0.01; β = 1.5; crossover rate CR = 0.9; adjusts parameters F ∈ [0.1, 0.9]. |

| NSGA-II | Mutation probability is 0.3; the crossover probability is 0.9. |

| IWOA | Maximum convergence factor amax = 2; minimum convergence factor amax = 0; constant b = 1; spiral shape control parameters l ∈ [−1, 1]. |

| Instance | Oij × mk | LB | IWOA(1) | IWOA(2) | WOA-LEDE | NSGA-II | IWOA | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Best | SD | Best | SD | Best | SD | Best | SD | Best | SD | |||

| MK01 | 10 × 6 | 39 | 40 | 0.60 | 41 | 0.85 | 39 | 0.51 | 41 | 0.7 | 39 | 0.50 |

| MK02 | 10 × 6 | 26 | 27 | 0.65 | 26 | 0.79 | 27 | 0.75 | 29 | 1.17 | 26 | 0.74 |

| MK03 | 15 × 8 | 204 | 204 | 3.59 | 207 | 2.53 | 204 | 3.36 | 207 | 3.39 | 207 | 3.18 |

| MK04 | 15 × 8 | 60 | 65 | 3.25 | 60 | 4.81 | 62 | 3.02 | 67 | 4.34 | 60 | 3.59 |

| MK05 | 15 × 4 | 172 | 175 | 4.01 | 179 | 4.54 | 172 | 3.87 | 188 | 5.84 | 175 | 3.55 |

| MK06 | 10 × 15 | 58 | 63 | 3.16 | 63 | 4.87 | 61 | 2.01 | 67 | 5.59 | 61 | 1.62 |

| MK07 | 20 × 5 | 139 | 139 | 4.03 | 140 | 4.3 | 139 | 3.86 | 142 | 4.58 | 139 | 4.16 |

| MK08 | 20 × 10 | 523 | 523 | 3.56 | 523 | 4.46 | 523 | 3.11 | 523 | 4.12 | 523 | 3.46 |

| MK09 | 20 × 10 | 307 | 307 | 3.68 | 307 | 4.01 | 312 | 3.55 | 317 | 5.86 | 309 | 3.27 |

| MK10 | 20 × 15 | 198 | 214 | 4.37 | 206 | 5.17 | 206 | 4.26 | 208 | 6.63 | 205 | 3.64 |

| Instance | IWOA | IWOA-I | IWOA-II | IWOA-III | ||||

|---|---|---|---|---|---|---|---|---|

| APRD | Time [s] | APRD | Time [s] | APRD | Time [s] | APRD | Time [s] | |

| MK01 | 3.54 | 7.41 | 8.72 | 6.56 | 4.32 | 7.85 | 3.77 | 8.55 |

| MK02 | 6.53 | 13.84 | 7.45 | 8.42 | 6.94 | 15.68 | 7.44 | 17.24 |

| MK04 | 6.27 | 21.45 | 12.62 | 17.28 | 7.81 | 28.74 | 8.15 | 24.31 |

| MK07 | 3.01 | 25.31 | 5.33 | 29.69 | 4.84 | 29.43 | 3.92 | 32.58 |

| MK08 | 2.15 | 45.80 | 14.47 | 51.61 | 6.63 | 51.84 | 4.97 | 55.67 |

| Average | 4.30 | 22.76 | 9.72 | 22.71 | 6.12 | 26.708 | 5.65 | 27.67 |

| Machine Number | M0 | M1 | M2 | M3 | M4 | M5 | M6 |

|---|---|---|---|---|---|---|---|

| M0 | 0 | 10 | 15 | 20 | 20 | 10 | 15 |

| M1 | 10 | 0 | 5 | 10 | 20 | 15 | 20 |

| M2 | 15 | 5 | 0 | 5 | 15 | 15 | 15 |

| M3 | 20 | 10 | 5 | 0 | 10 | 20 | 10 |

| M4 | 20 | 20 | 15 | 10 | 0 | 10 | 10 |

| M5 | 10 | 15 | 15 | 20 | 10 | 0 | 20 |

| M6 | 15 | 20 | 15 | 10 | 10 | 20 | 0 |

| μ | μ1 | μ2 | μ3 | Z1 | Z2 | Z3 | |

|---|---|---|---|---|---|---|---|

| WOA(1) | 0.726 | 0.70 | 0.89 | 0.59 | 449 | 3784 | 0.827 |

| WOA(2) | 0.720 | 0.76 | 0.55 | 0.85 | 445 | 4004 | 0.836 |

| WOA-LEDE | 0.743 | 0.70 | 0.85 | 0.68 | 449 | 3808 | 0.830 |

| NSGA-II | 0.715 | 0.55 | 0.83 | 0.76 | 459 | 3823 | 0.833 |

| IWOA | 0.747 | 0.67 | 0.75 | 0.82 | 451 | 3918 | 0.834 |

| IWOA VS. | Instance | Statistic | p-Value | p < a (a = 0.05) |

|---|---|---|---|---|

| WOA(1) | 5 × 5 | 0.0 | 3.815 × 10−6 | yes |

| 15 × 5 | 32.0 | 9.452 × 10−3 | yes | |

| WOA(2) | 5 × 5 | 0.0 | 3.815 × 10−6 | yes |

| 15 × 5 | 19.0 | 1.171 × 10−3 | yes | |

| WOA-LEDE | 5 × 5 | 37.0 | 1.809 × 10−2 | no |

| 15 × 5 | 8.0 | 9.537 × 10−5 | yes | |

| NSGA-II | 5 × 5 | 0.0 | 3.815 × 10−6 | yes |

| 15 × 5 | 0.0 | 3.815 × 10−6 | yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Wei, M.; Gao, X. Modeling an Optimal Environmentally Friendly Energy-Saving Flexible Workshop. Appl. Sci. 2023, 13, 11896. https://doi.org/10.3390/app132111896

Zhang T, Wei M, Gao X. Modeling an Optimal Environmentally Friendly Energy-Saving Flexible Workshop. Applied Sciences. 2023; 13(21):11896. https://doi.org/10.3390/app132111896

Chicago/Turabian StyleZhang, Tianrui, Mingqi Wei, and Xiuxiu Gao. 2023. "Modeling an Optimal Environmentally Friendly Energy-Saving Flexible Workshop" Applied Sciences 13, no. 21: 11896. https://doi.org/10.3390/app132111896

APA StyleZhang, T., Wei, M., & Gao, X. (2023). Modeling an Optimal Environmentally Friendly Energy-Saving Flexible Workshop. Applied Sciences, 13(21), 11896. https://doi.org/10.3390/app132111896