Research on the Residual Stress Field of a Compression Bushing-Lug Plate in Cold Expansion Strengthening

Abstract

:1. Introduction

2. Materials and Methods

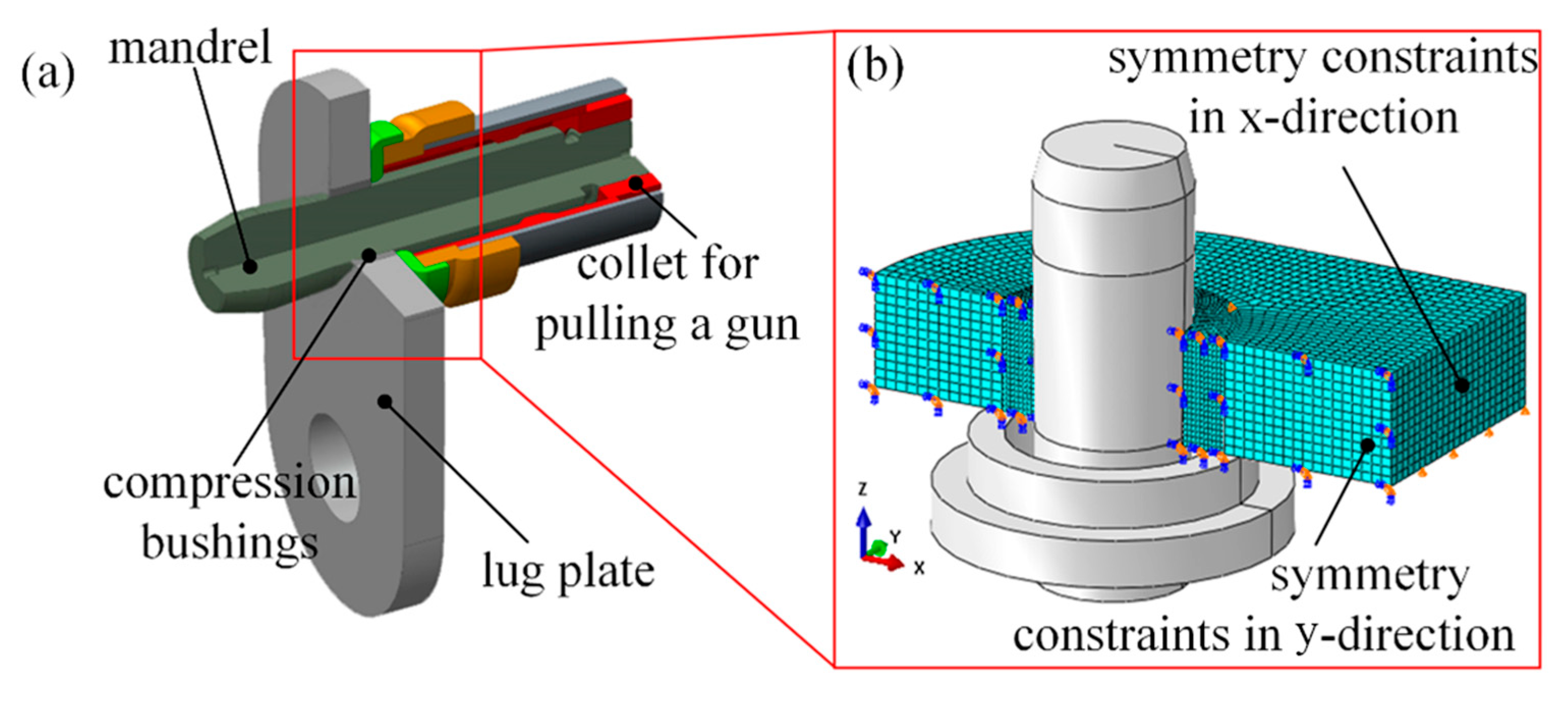

2.1. Finite Element Simulation Model

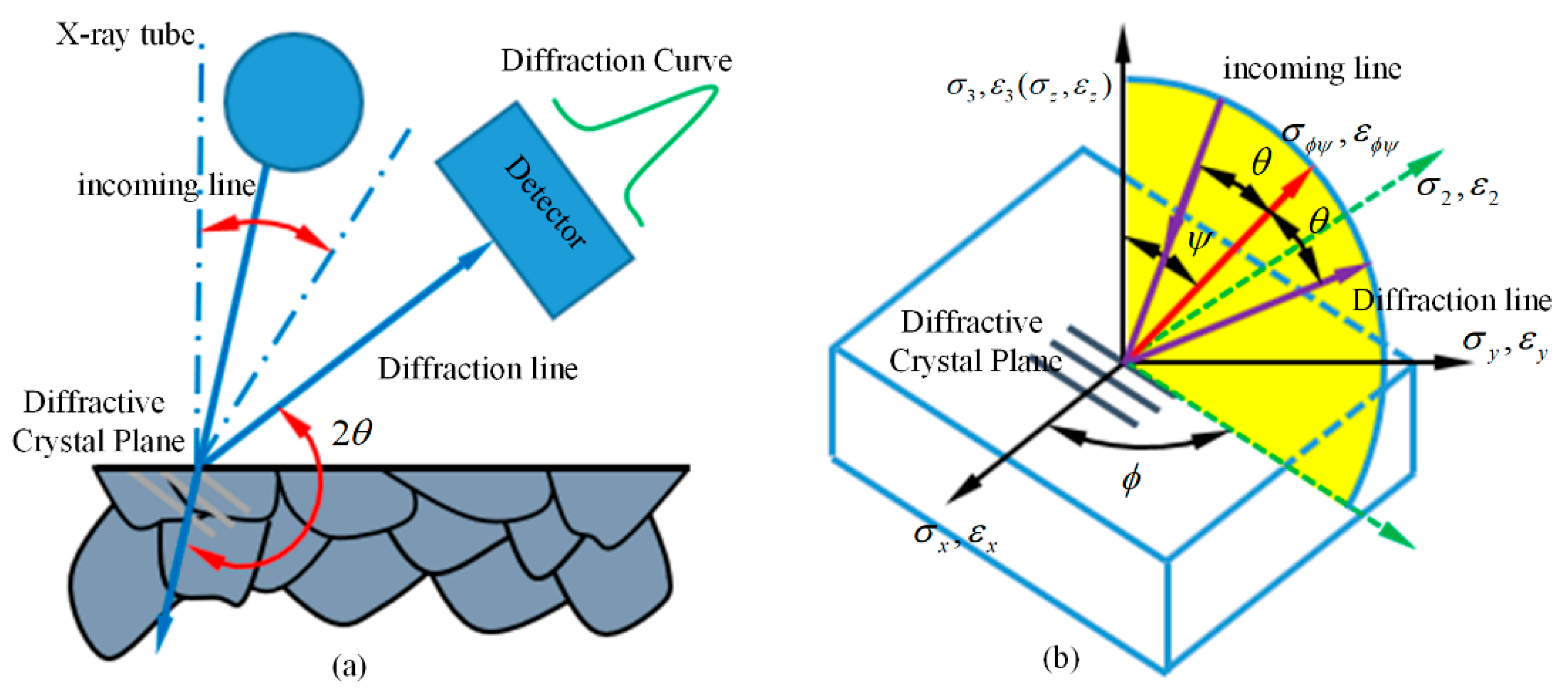

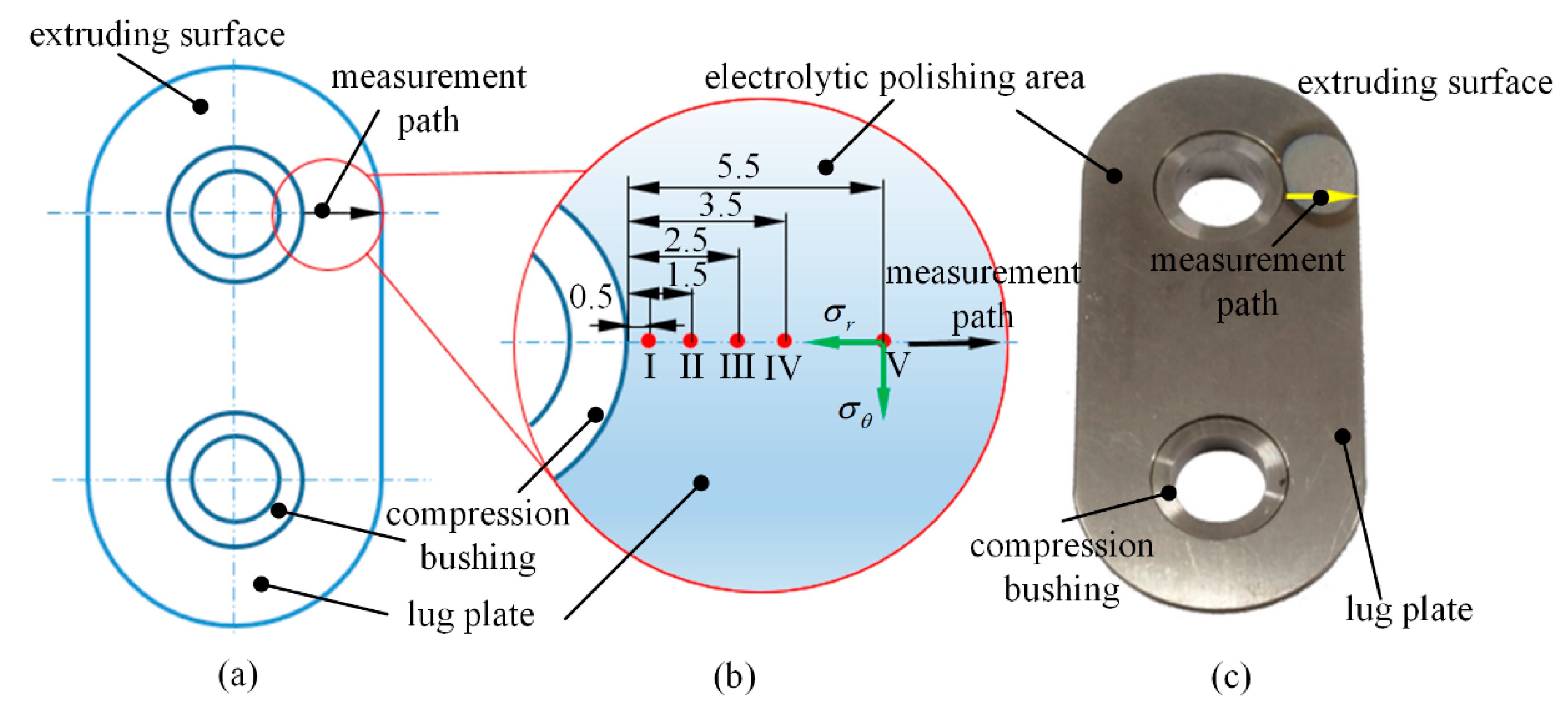

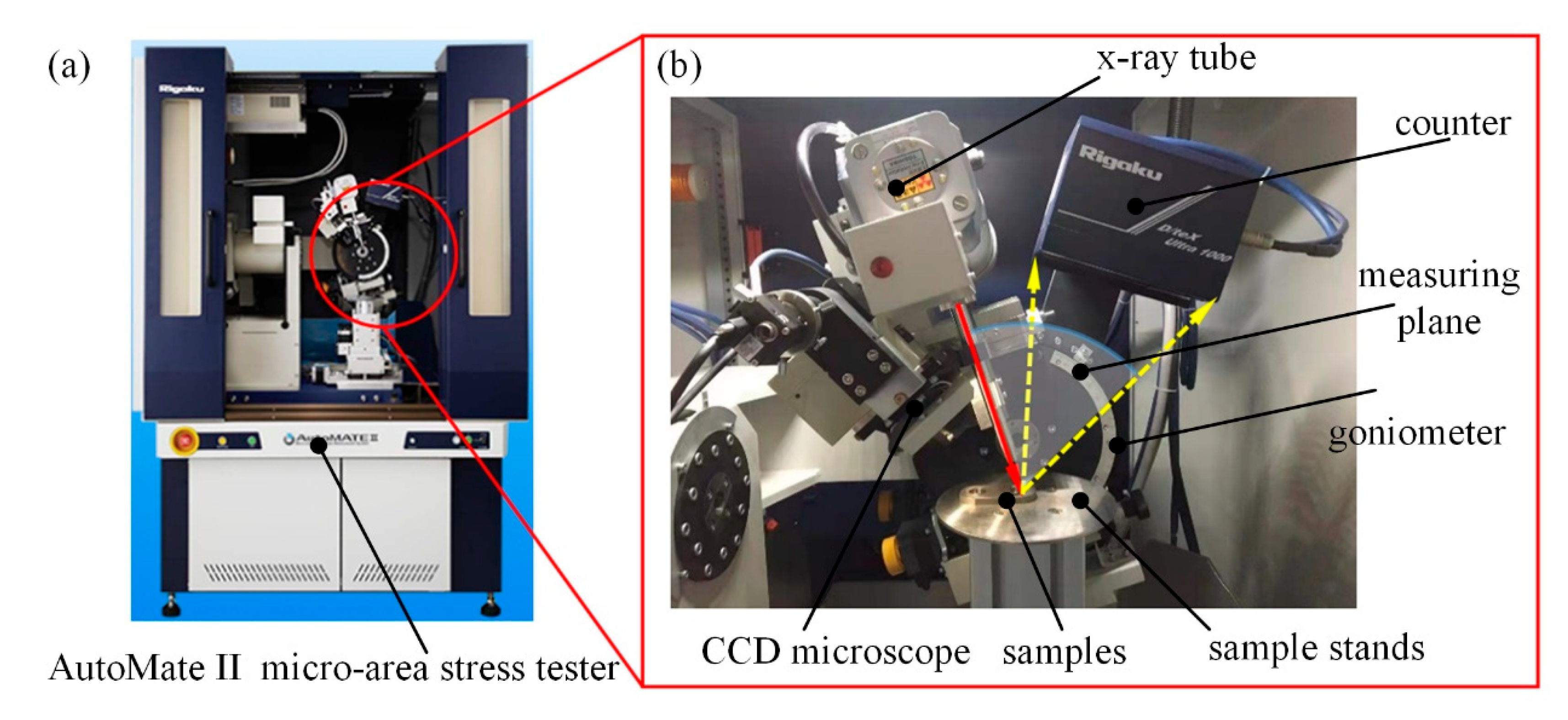

2.2. Experimental Principles and Equipment

3. Results and Analysis

3.1. Finite Element Simulation Results

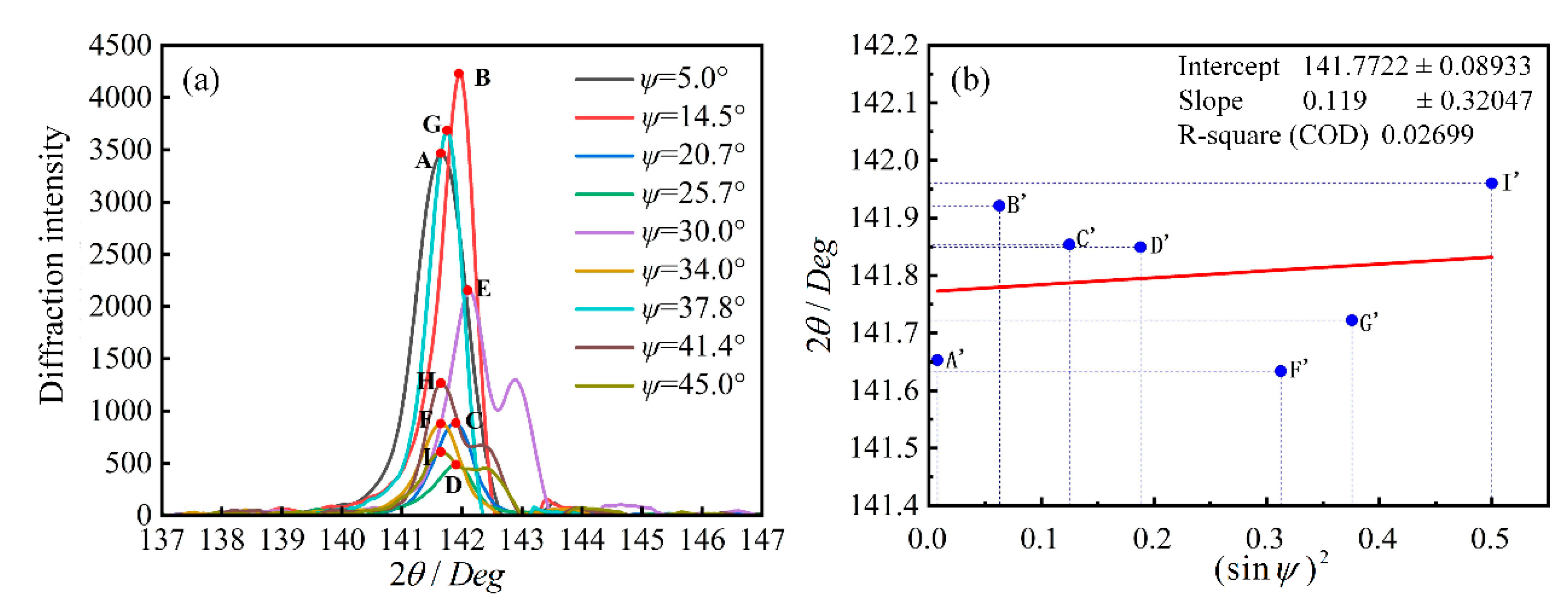

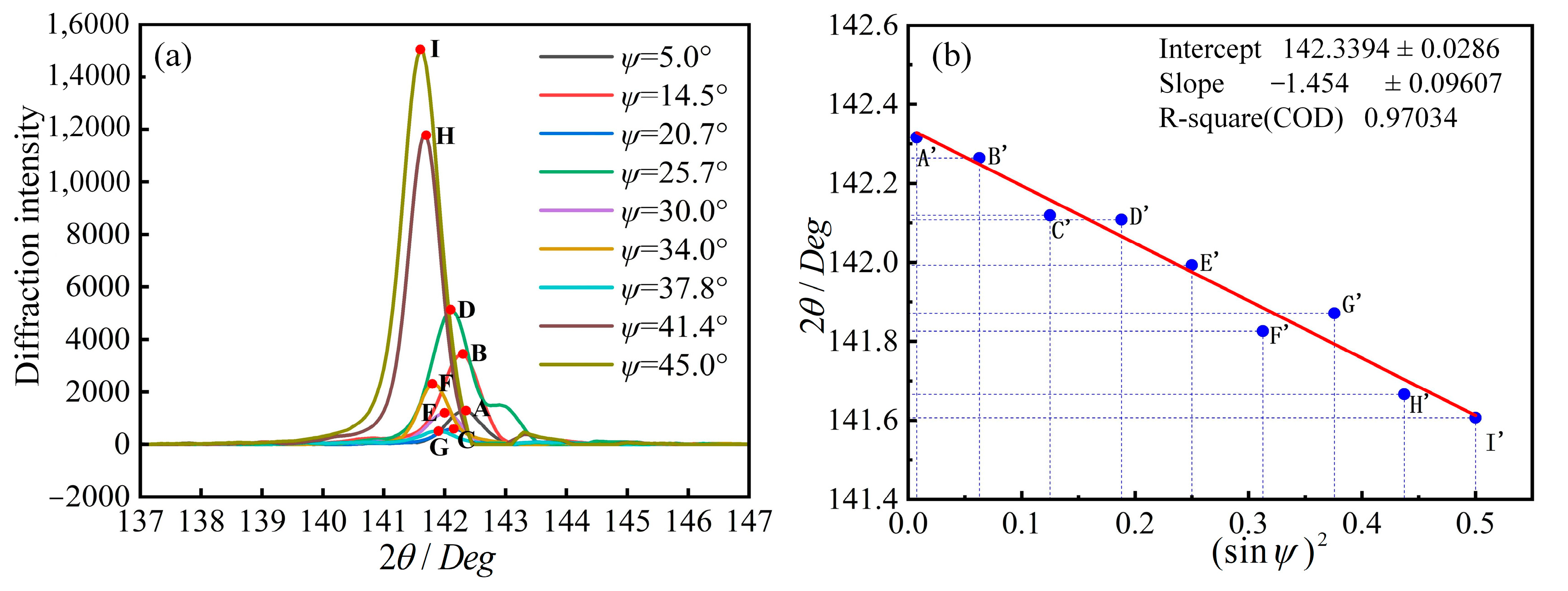

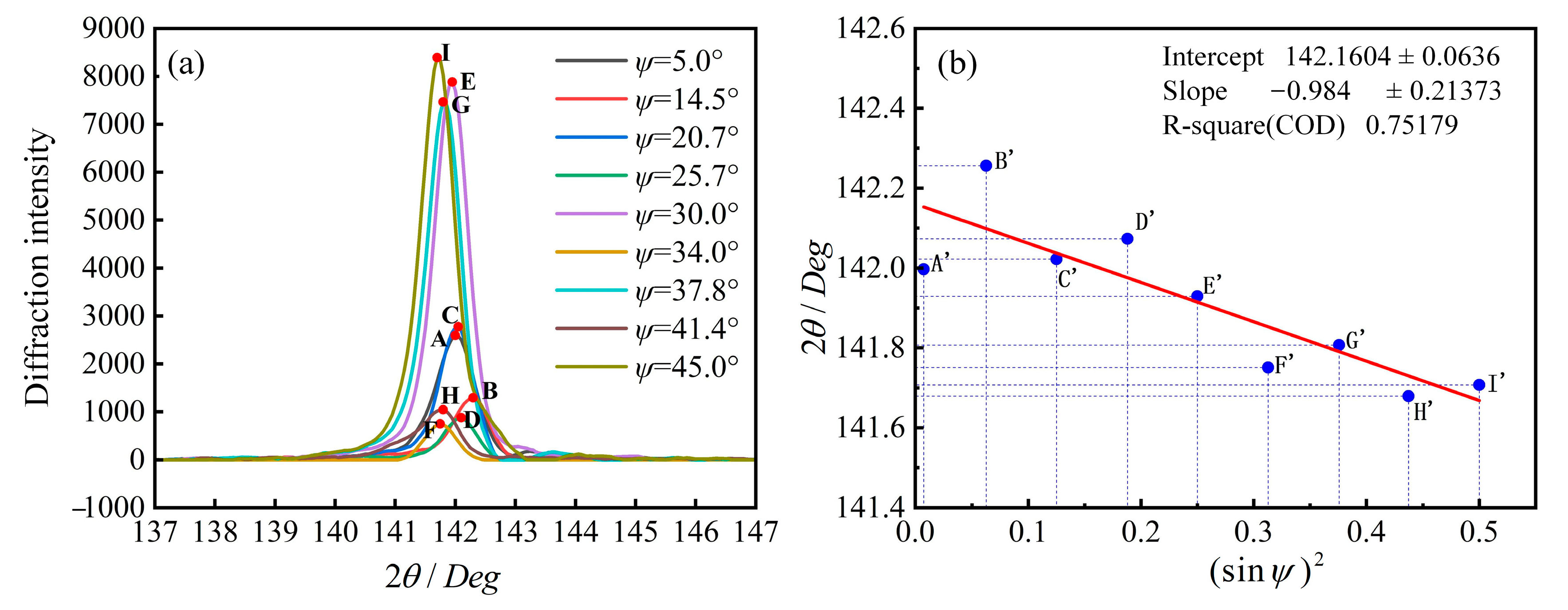

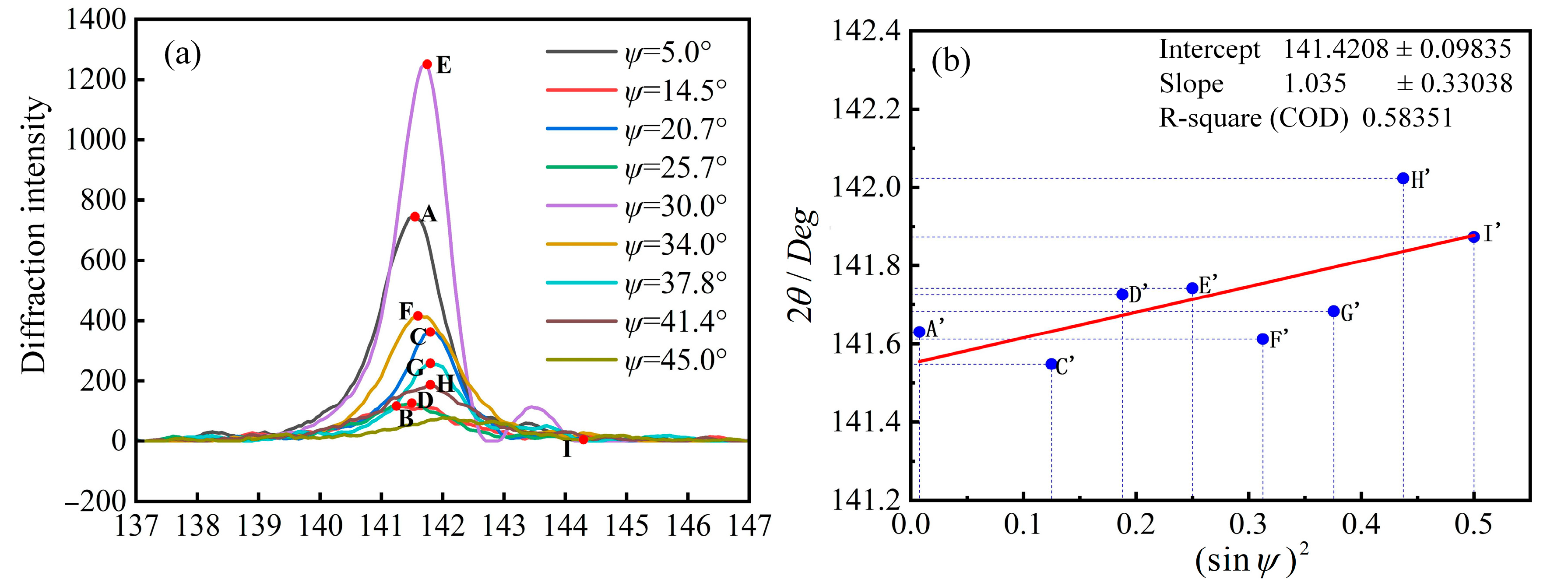

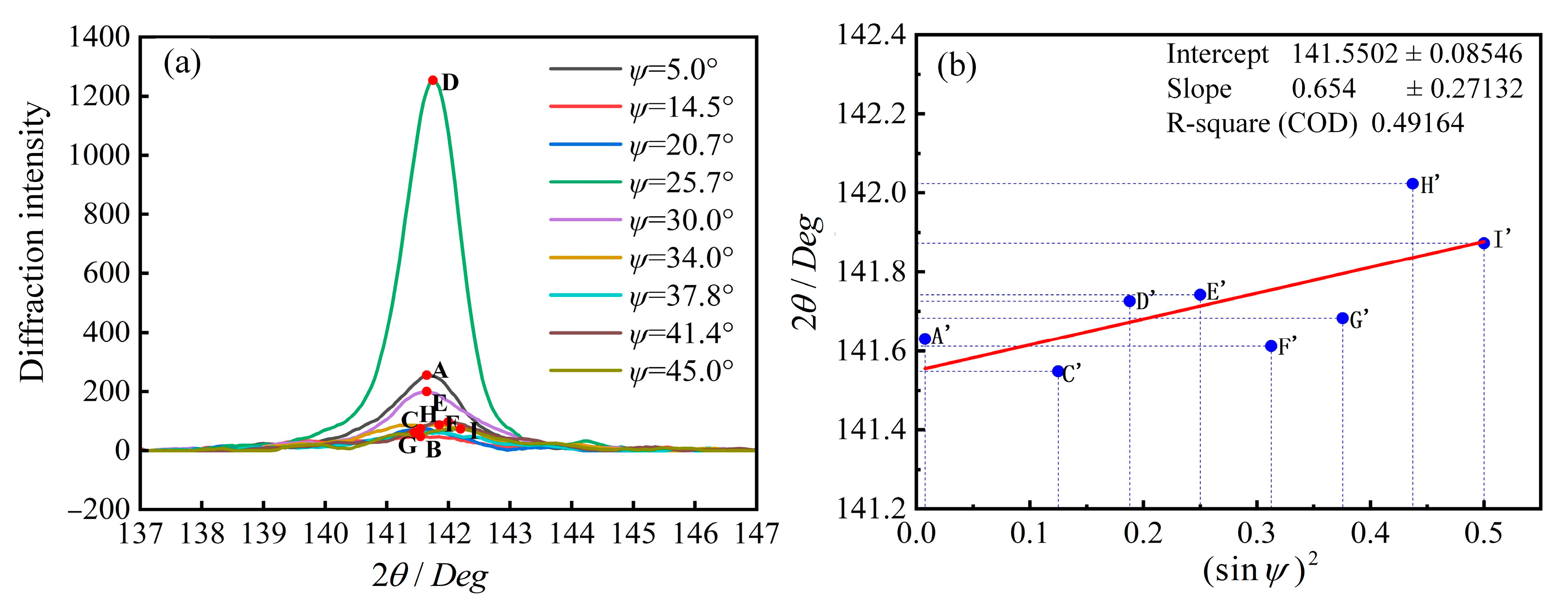

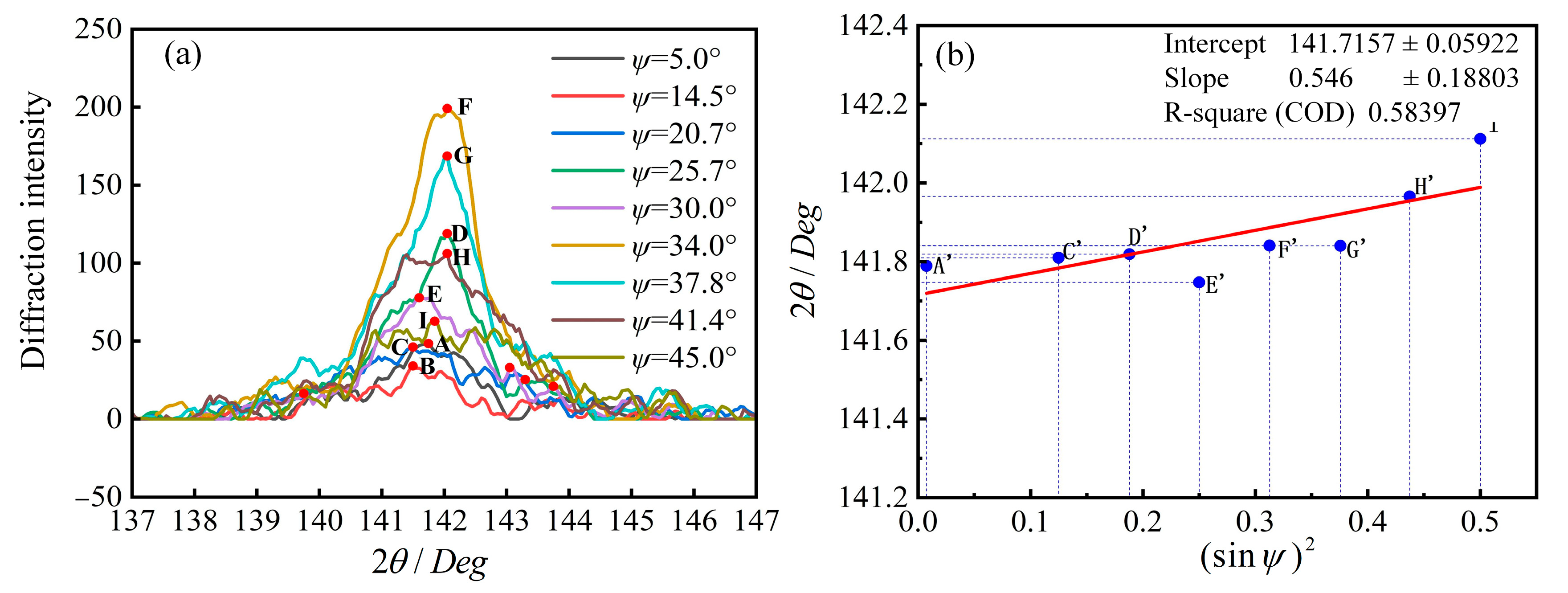

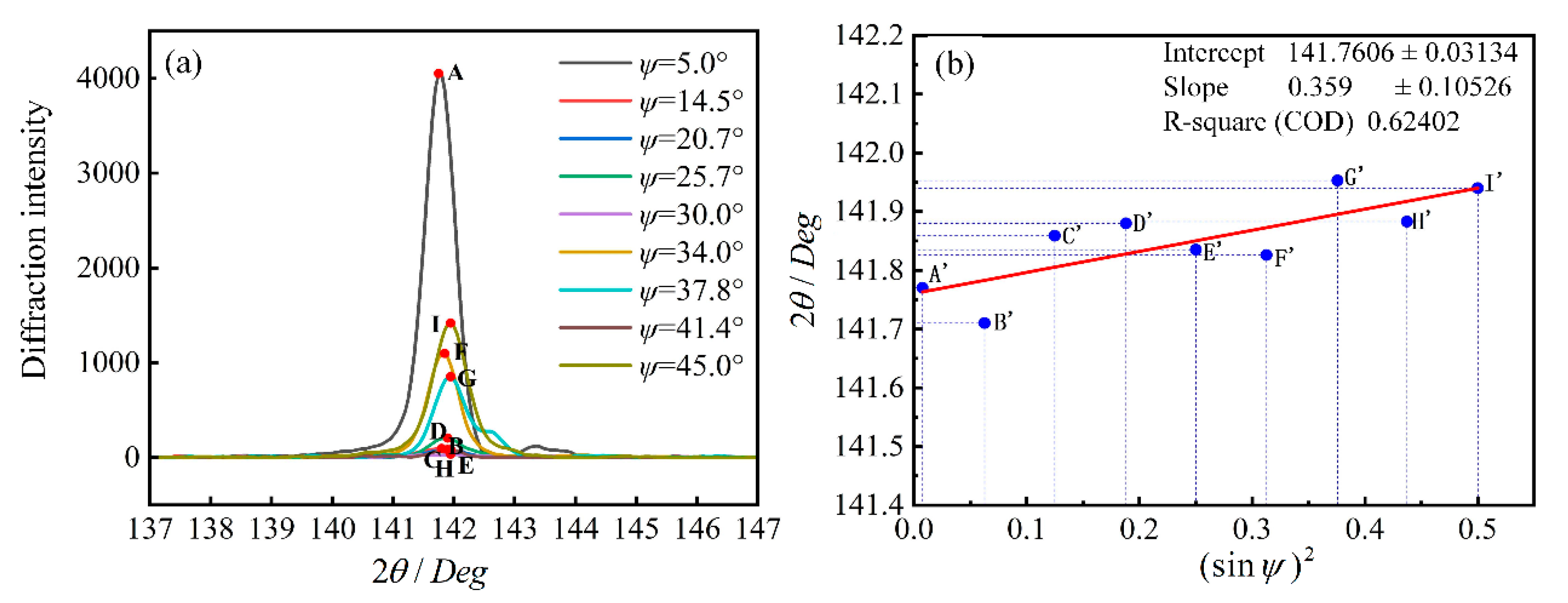

3.2. Raw Data Processing of Circumferential Stresses

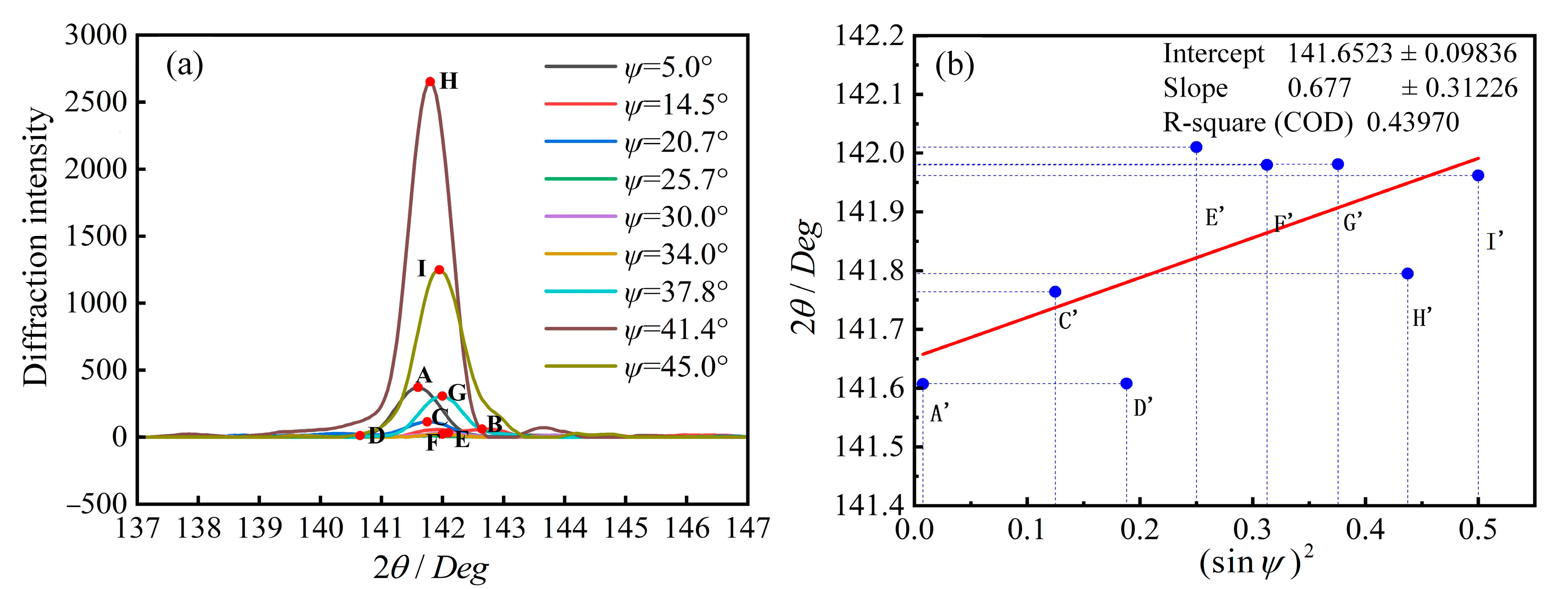

3.3. Raw Data Processing of Radial Stresses

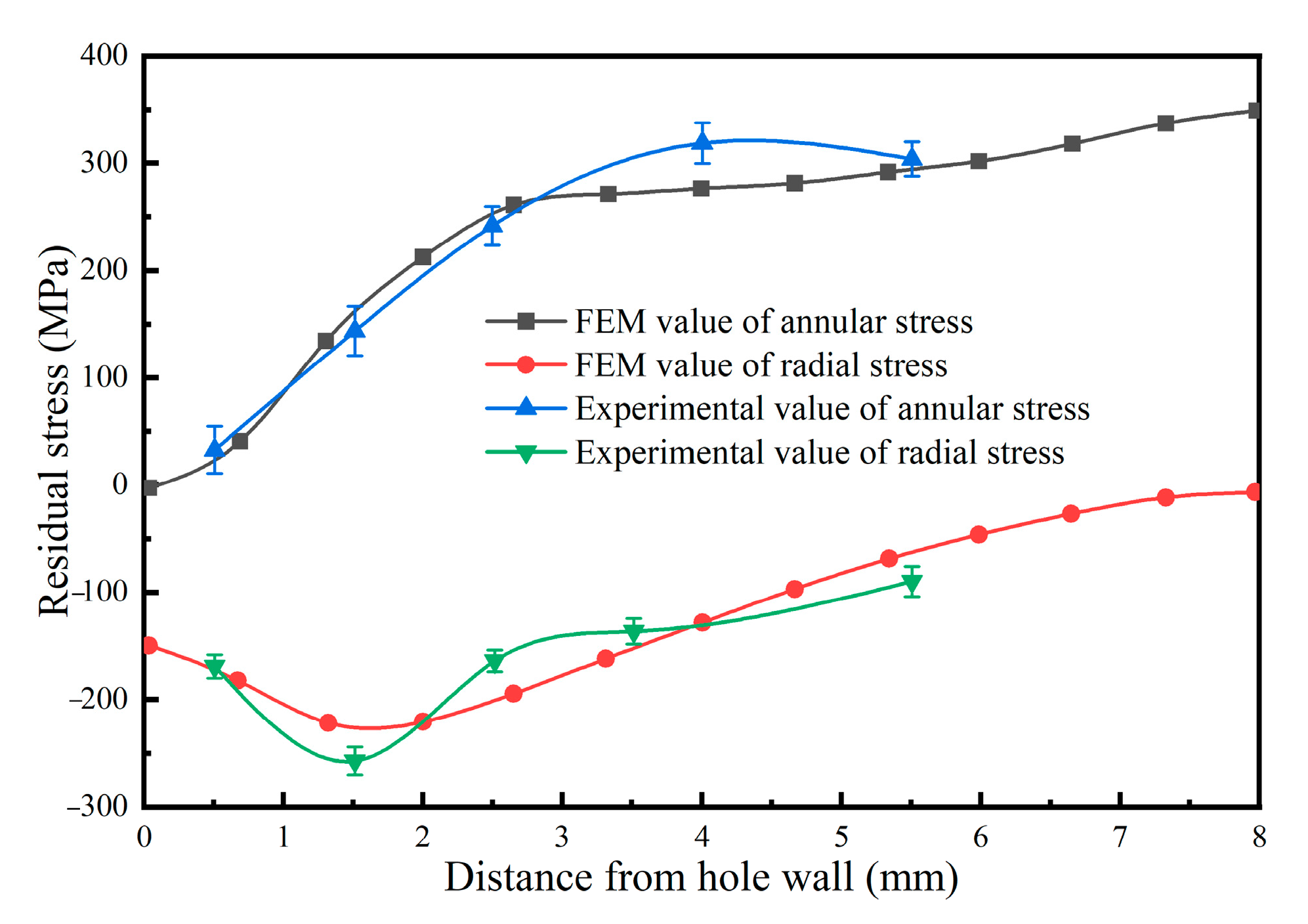

3.4. Verification of the Residual Stress Test Results

4. Conclusions

- (1)

- After cold expansion, large annular residual compressive stresses are distributed in the hole wall of the compression bushing, while the radial residual stresses also exist in the form of compressive stresses but with smaller values. The distribution of circumferential and radial stresses varies considerably on the expansion face, the intermediate face, and along the hole axis, and the increase in the relative expansion exacerbates the inhomogeneity of this distribution.

- (2)

- Compared to the hole structure without extrusion strengthening, the maximum circumferential stress on the hole wall of the hole structure after cold extrusion is significantly reduced during loading. The higher relative extrusion amount can effectively reduce the amplitude of annular stress on the hole wall, thereby improving fatigue life.

- (3)

- Combined with the X-ray diffraction method, the measured values of annular stress and radial stress distributed along the path of hazardous cross-section on the extruded surface of the lug plate after cold expansion were obtained. After comparing these with the simulation results obtained from the finite element model, it was found that experimental and simulation values were in good agreement, which verified the accuracy of the finite element results of the residual stresses.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, K.; Chen, X.; Lv, X.; Ding, F.; Dang, B.; Li, F.; Wei, D.; Zhang, P. Effect of split-sleeve cold hole expansion on the fatigue performance of an additive manufactured TC18 alloy. J. Mater. Res. 2023, 38, 841–852. [Google Scholar] [CrossRef]

- Hu, J.; Mi, S.; Yang, Z.; Wang, C.; Yang, Y.; Tian, W. An experimental investigation on bearing behavior and failure mechanism of bolted composite interference-fit joints under thermal effects. Eng. Fail. Anal. 2022, 131, 105830. [Google Scholar] [CrossRef]

- Liu, H.; Hu, D.; Wang, R.; Wang, X.; Jin, S.; Gu, Y. Experimental and numerical investigations on the influence of cold expansion on low cycle fatigue life of bolt holes in aeroengine superalloy disk at elevated temperature. Int. J. Fatigue 2020, 132, 105390. [Google Scholar] [CrossRef]

- Faghih, S.; Behravesh, S.B.; Kumar Shaha, S.; Jahed, H. Effect of split sleeve cold expansion on fatigue and fracture of rolled AZ31B magnesium alloy. Theor. Appl. Fract. Mech. 2023, 123, 103715. [Google Scholar] [CrossRef]

- Liu, J.; Xu, H.L.; Zhai, H.B.; Yue, Z.F. Effect of detail design on fatigue performance of fastener hole. Mater. Des. 2010, 31, 976–980. [Google Scholar] [CrossRef]

- Wang, C.; Zou, F.; Zhou, E.; Fan, Z.; Ge, E.; An, Q.; Ming, W.; Chen, M. Effect of split sleeve cold expansion on microstructure and fatigue performance of 7075-T6 aluminum alloy holes. Int. J. Fatigue 2023, 167, 107339. [Google Scholar] [CrossRef]

- Özdemir, A.T. Experimental assessment of the redistribution of 3-D residual stresses during early fatigue at split-sleeve cold expanded reamed A/C fastener holes. Sci. Iran. 2017, 25, 1153–1168. [Google Scholar] [CrossRef]

- Karparvarfard, S.; Shaha, S.K.; Behravesh, S.B.; Jahed, H.; Williams, B.W. Fatigue characteristics and modeling of cast and cast-forged ZK60 magnesium alloy. Int. J. Fatigue 2019, 118, 282–297. [Google Scholar] [CrossRef]

- Aid, A.; Semari, Z.; Benguediab, M. Cold expansion effect on the fatigue crack growth of Al 6082: Numerical investigation. Struct. Eng. Mech. 2014, 49, 225–235. [Google Scholar] [CrossRef]

- Chakherlou, T.N.; Taghizadeh, H.; Aghdam, A.B. Experimental and numerical comparison of cold expansion and interference fit methods in improving fatigue life of holed plate in double shear lap joints. Aerosp. Sci. Technol. 2013, 29, 351–362. [Google Scholar] [CrossRef]

- Curto-Cárdenas, D.; Calaf-Chica, J.; Bravo Díez, P.M.; Preciado Calzada, M.; Garcia-Tarrago, M.-J. Cold Expansion Process with Multiple Balls-Numerical Simulation and Comparison with Single Ball and Tapered Mandrels. Materials 2020, 13, 5536. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.Z.; Wang, X.S.; Gao, H.S.; Yue, Z.F. Effect of split sleeve cold expansion on cracking behaviors of titanium alloy TC4 holes. Eng. Fract. Mech. 2012, 88, 79–89. [Google Scholar] [CrossRef]

- Yuan, X.; Yue, Z.F.; Wen, S.F.; Li, L.; Feng, T. Numerical and experimental investigation of the cold expansion process with split sleeve in titanium alloy TC4. Int. J. Fatigue 2015, 77, 78–85. [Google Scholar] [CrossRef]

- Liu, X.; Cui, H.; Zhang, S.; Liu, H.; Liu, G.; Li, S. Experimental and numerical investigations on fatigue behavior of aluminum alloy 7050-T7451 single lap four-bolted joints. J. Mater. Sci. Technol. 2018, 34, 1205–1213. [Google Scholar] [CrossRef]

- Wan, N.; He, Q.; Jing, X.; Jiang, Y.; Zhou, H. Numerical and experimental investigation of the effect of cold extrusion process on residual stress and fatigue life of internal thread of high-strength steel. Int. J. Adv. Manuf. Technol. 2023, 127, 4713–4726. [Google Scholar] [CrossRef]

- Lv, Y.; Dong, M.; Zhang, T.; Wang, C.; Hou, B.; Li, C. Finite Element Analysis of Split Sleeve Cold Expansion Process on Multiple Hole Aluminum Alloy. Materials 2023, 16, 1109. [Google Scholar] [CrossRef]

- Dey, M.K.; Kim, D.; Tan, H. Finite element parametric study of the split sleeve cold expansion on residual stresses and pulling force. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 2447–2461. [Google Scholar] [CrossRef]

- Seifi, R. Total fatigue lives, crack growth paths and cycles in cold expanded adjacent holes. Int. J. Fatigue 2018, 113, 69–77. [Google Scholar] [CrossRef]

- Bueckner, H.F. Novel principle for the computation of stress intensity factors. Z. Fuer. Angew. Math. Mech. 1970, 50, 9. [Google Scholar]

- Moftakhar, A.A.; Glinka, G. Calculation of stress intensity factors by efficient integration of weight functions. Eng. Fract. Mech. 1992, 43, 749–756. [Google Scholar] [CrossRef]

- Vagarali, S.S.; Langdon, T.G. Deformation mechanisms in h.c.p. metals at elevated temperatures—II. Creep behavior of a Mg-0.8% Al solid solution alloy. Acta Metall. 1982, 30, 1157–1170. [Google Scholar] [CrossRef]

- Su, M.; Amrouche, A.; Mesmacque, G.; Benseddiq, N. Numerical study of double cold expansion of the hole at crack tip and the influence on the residual stresses field. Comput. Mater. Sci. 2008, 41, 350–355. [Google Scholar] [CrossRef]

- Kumar, B.M.; Panaskar, N.J.; Sharma, A. A fundamental investigation on rotating tool cold expansion: Numerical and experimental perspectives. Int. J. Adv. Manuf. Technol. 2014, 73, 1189–1200. [Google Scholar] [CrossRef]

- Sangid, M.D. The physics of fatigue crack initiation. Int. J. Fatigue 2013, 57, 58–72. [Google Scholar] [CrossRef]

- Liu, J.; Wu, H.; Yang, J.; Yue, Z. Effect of edge distance ratio on residual stresses induced by cold expansion and fatigue life of TC4 plates. Eng. Fract. Mech. 2013, 109, 130–137. [Google Scholar] [CrossRef]

- Semari, Z.; Aid, A.; Benhamena, A.; Amrouche, A.; Benguediab, M.; Sadok, A.; Benseddiq, N. Effect of residual stresses induced by cold expansion on the crack growth in 6082 aluminum alloy. Eng. Fract. Mech. 2013, 99, 159–168. [Google Scholar] [CrossRef]

- Stephen, G.J.; Pasang, T.; Withy, B.P. The effect of pitting corrosion on split sleeve cold hole expanded, bare 7075-T651 aluminium alloy. J. Manuf. Process. 2013, 15, 115–120. [Google Scholar] [CrossRef]

- Kim, H.K.; Carlson, S.S.; Stanfield, M.L.; Paddea, S.; Hosseinzadeh, F.; Bouchard, P.J. Mitigating Cutting-Induced Plasticity Errors in the Determination of Residual Stress at Cold Expanded Holes Using the Contour Method. Exp. Mech. 2022, 62, 3–18. [Google Scholar] [CrossRef]

- Liu, K.; Yang, X.; Zhou, L.; Li, M.; Zhu, W. Numerical investigation of the effect of hole reaming on fatigue life by cold expansion. Trans. Can. Soc. Mech. Eng. 2022, 46, 400–411. [Google Scholar] [CrossRef]

- Geng, H.; Xu, X.; Cao, Q.; Lai, Z.; Li, L. Improving the fatigue performance of AZ31 sheet with hole via electromagnetic cold expansion process. Int. J. Adv. Manuf. Technol. 2022, 120, 5057–5071. [Google Scholar] [CrossRef]

- Zeng, C.; Tian, W.; Liu, X.Y.; Xue, J.T. Experimental and numerical studies of stress/strain characteristics in riveted aircraft lap joints. J. Mech. Sci. Technol. 2019, 33, 3245–3255. [Google Scholar] [CrossRef]

- Guo, J.; Fu, H.; Pan, B.; Kang, R. Recent progress of residual stress measurement methods: A review. Chin. J. Aeronaut. 2021, 34, 54–78. [Google Scholar] [CrossRef]

- Fang, Z.-C.; Wu, Z.-L.; Huang, C.-G.; Wu, C.-W. Review on residual stress in selective laser melting additive manufacturing of alloy parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

| Type | Parameter |

|---|---|

| Voltage | 40 kV |

| Current | 40 mA |

| Crystal structure | Hexagonal |

| Diffraction crystal plane | {213} |

| Diffraction angle | 140° |

| Oscillation setting | 2° |

| Exposure time | 100 s |

| Collimator diameter | 1 mm |

| Peaking method | Half height and width method |

| Detection Point | (Deg) | Stress Constant (MPa/Deg) | Radial Stress (MPa) | |

|---|---|---|---|---|

| I | 141.772 | 0.119 | −246.003 | −29.274 |

| II | 141.607 | −0.585 | −247.149 | 144.582 |

| III | 142.131 | −0.992 | −243.515 | 241.567 |

| IV | 142.339 | −1.454 | −242.076 | 351.979 |

| V | 142.160 | −0.984 | −243.314 | 239.421 |

| Detection Point | (Deg) | Stress Constant (MPa/Deg) | Radial Stress (MPa) | |

|---|---|---|---|---|

| I | 141.652 | 0.678 | −246.836 | −167.355 |

| II | 141.421 | 1.035 | −248.441 | −257.136 |

| III | 141.550 | 0.654 | −247.545 | −161.894 |

| IV | 141.716 | 0.546 | −246.392 | −134.530 |

| V | 141.761 | 0.359 | −246.080 | −88.343 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Z.; Bai, Q.; Wang, H.; Wu, B.; Li, W. Research on the Residual Stress Field of a Compression Bushing-Lug Plate in Cold Expansion Strengthening. Appl. Sci. 2023, 13, 11694. https://doi.org/10.3390/app132111694

Lin Z, Bai Q, Wang H, Wu B, Li W. Research on the Residual Stress Field of a Compression Bushing-Lug Plate in Cold Expansion Strengthening. Applied Sciences. 2023; 13(21):11694. https://doi.org/10.3390/app132111694

Chicago/Turabian StyleLin, Zhongliang, Qingshun Bai, Hongfei Wang, Baoquan Wu, and Wensheng Li. 2023. "Research on the Residual Stress Field of a Compression Bushing-Lug Plate in Cold Expansion Strengthening" Applied Sciences 13, no. 21: 11694. https://doi.org/10.3390/app132111694

APA StyleLin, Z., Bai, Q., Wang, H., Wu, B., & Li, W. (2023). Research on the Residual Stress Field of a Compression Bushing-Lug Plate in Cold Expansion Strengthening. Applied Sciences, 13(21), 11694. https://doi.org/10.3390/app132111694