Effect of Shunt Resistor Value on the Performance of Resistive Superconducting Fault Current Limiters

Abstract

:1. Introduction

1.1. Background and Motivation

1.2. Literature Review

1.3. Contribution

1.4. Organization

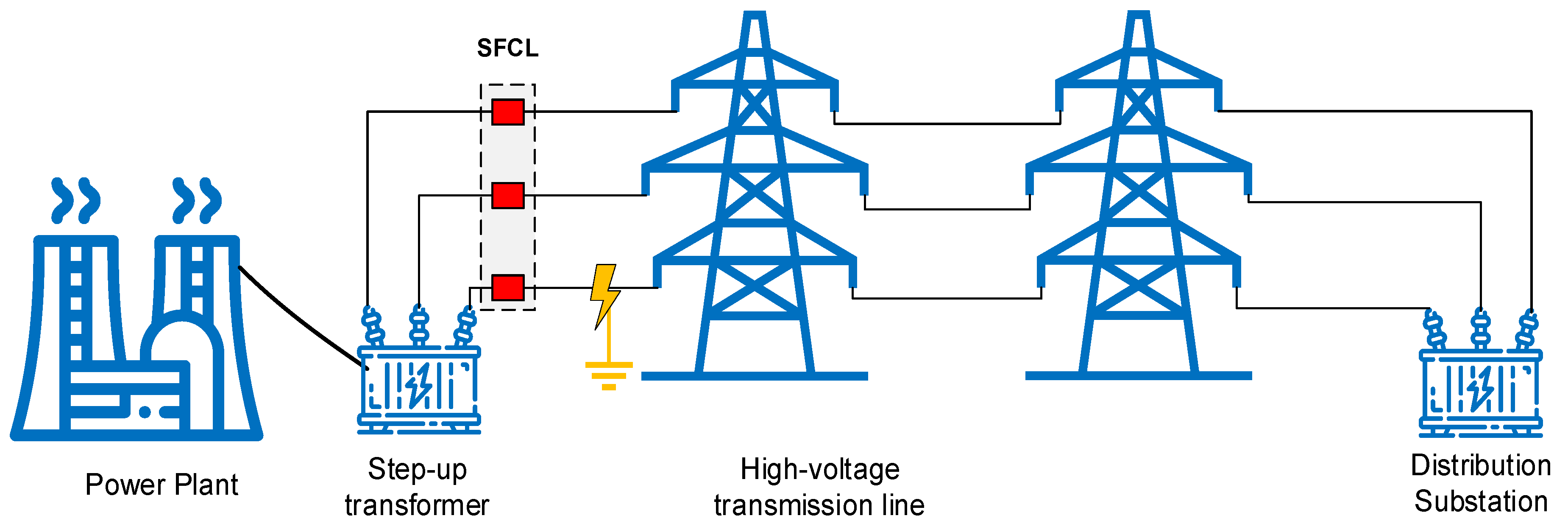

2. System Description

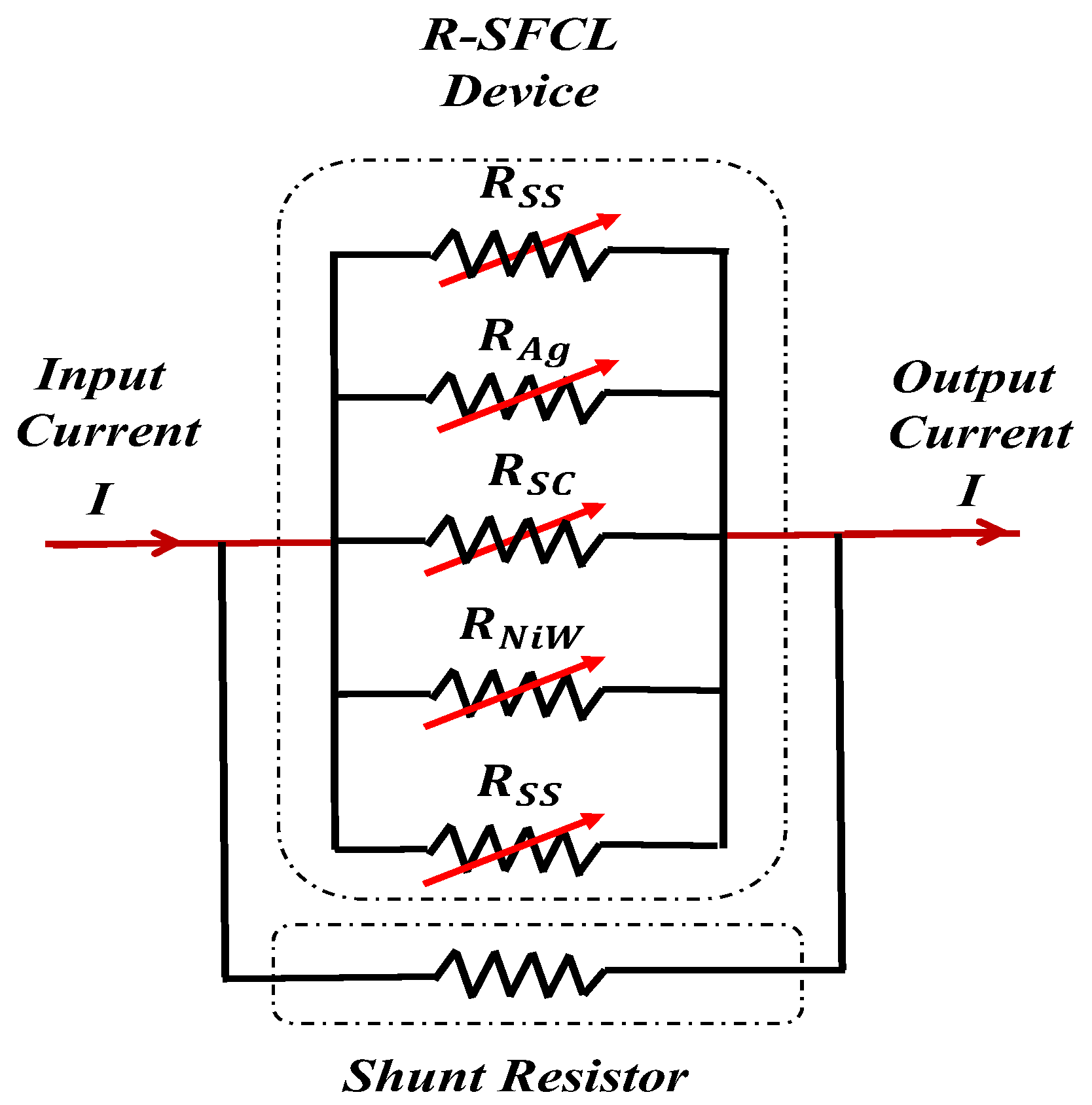

3. Superconducting Fault Current Limiter and Shunt Resistor Numerical Model

4. Simulation Results and Discussion

4.1. Case Studies

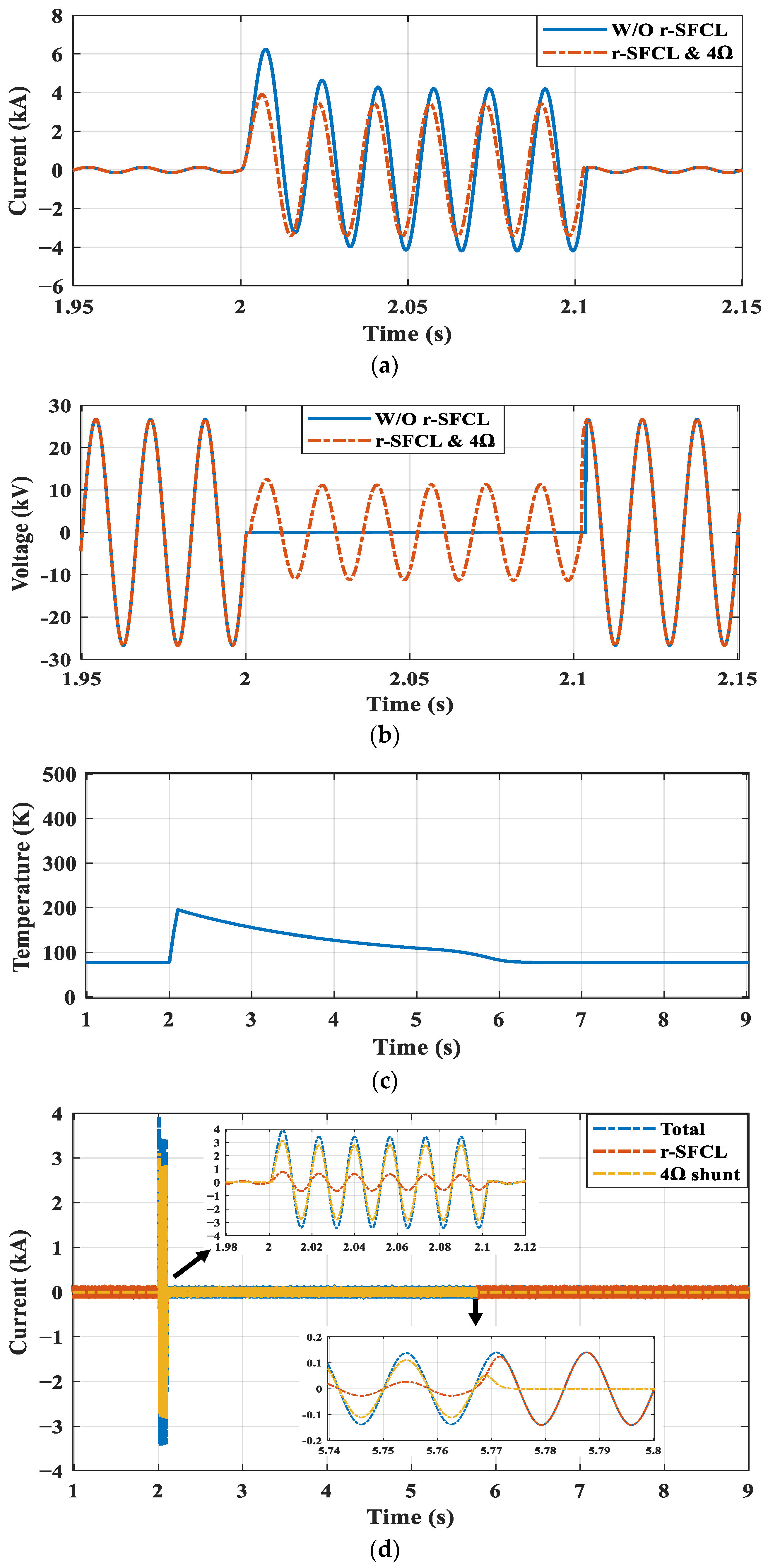

4.1.1. Case Study 1 (4 Ω Shunt Resistor)

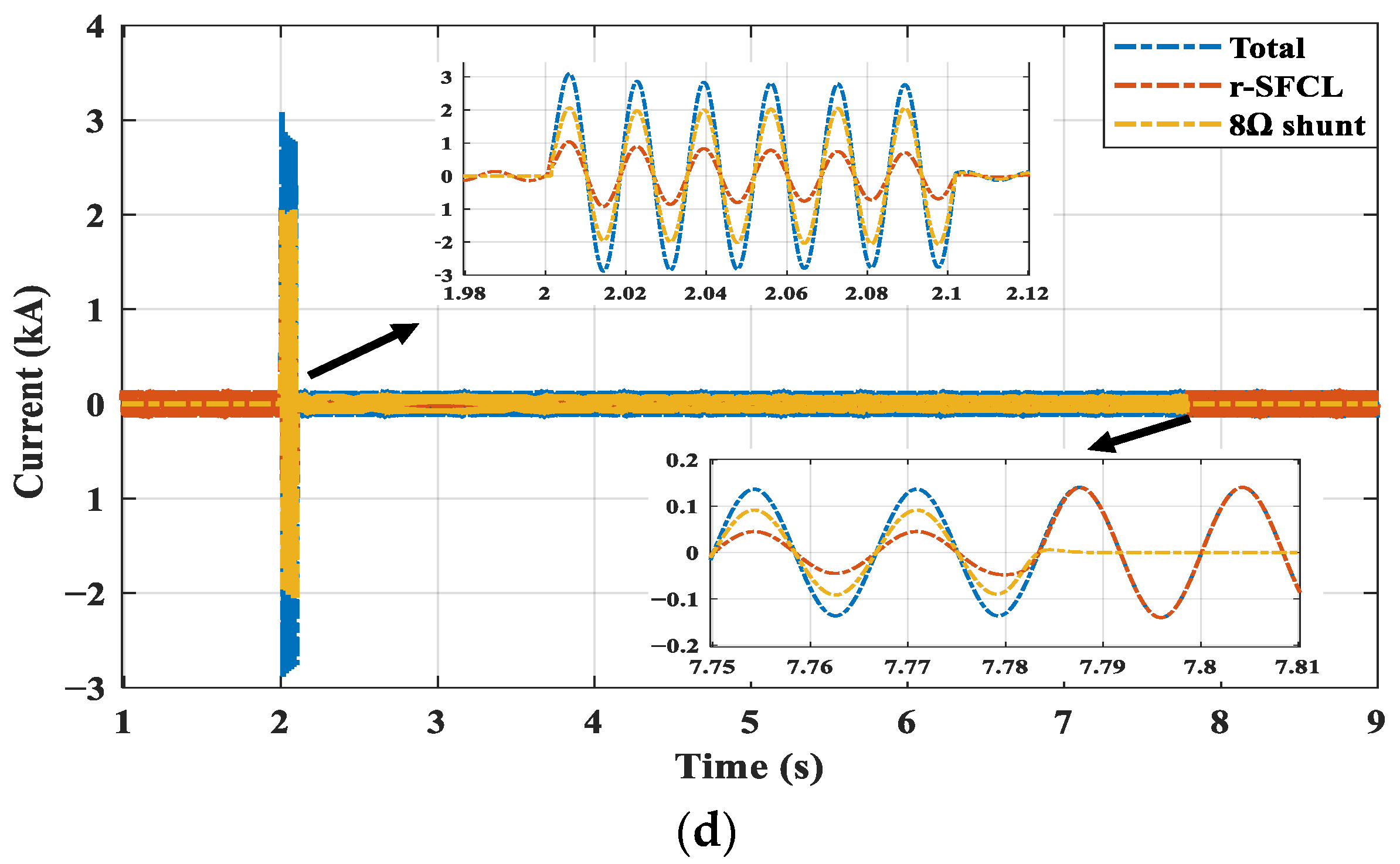

4.1.2. Case Study 2 (8 Ω Shunt Resistor)

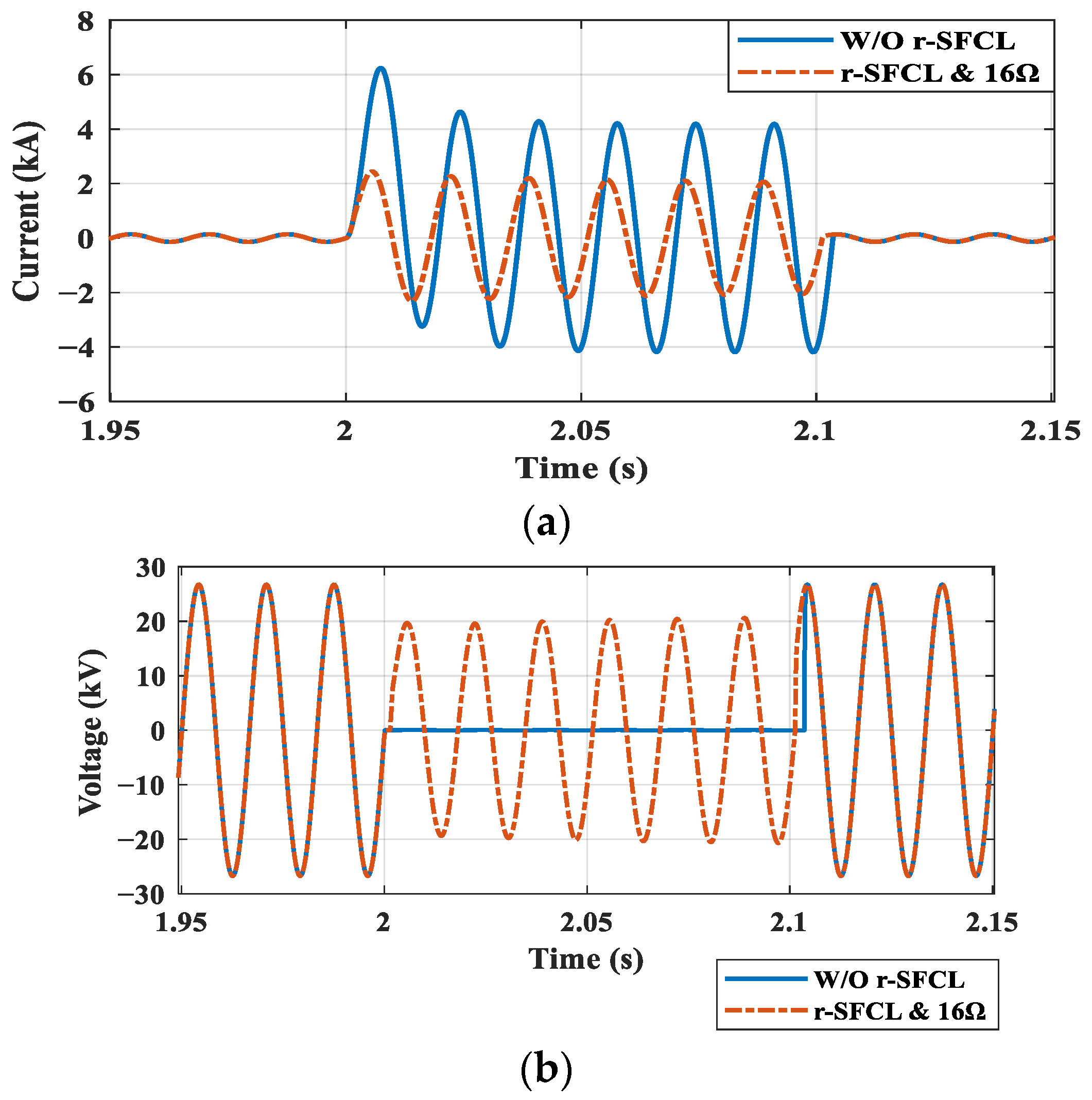

4.1.3. Case Study 3 (16 Ω Shunt Resistor)

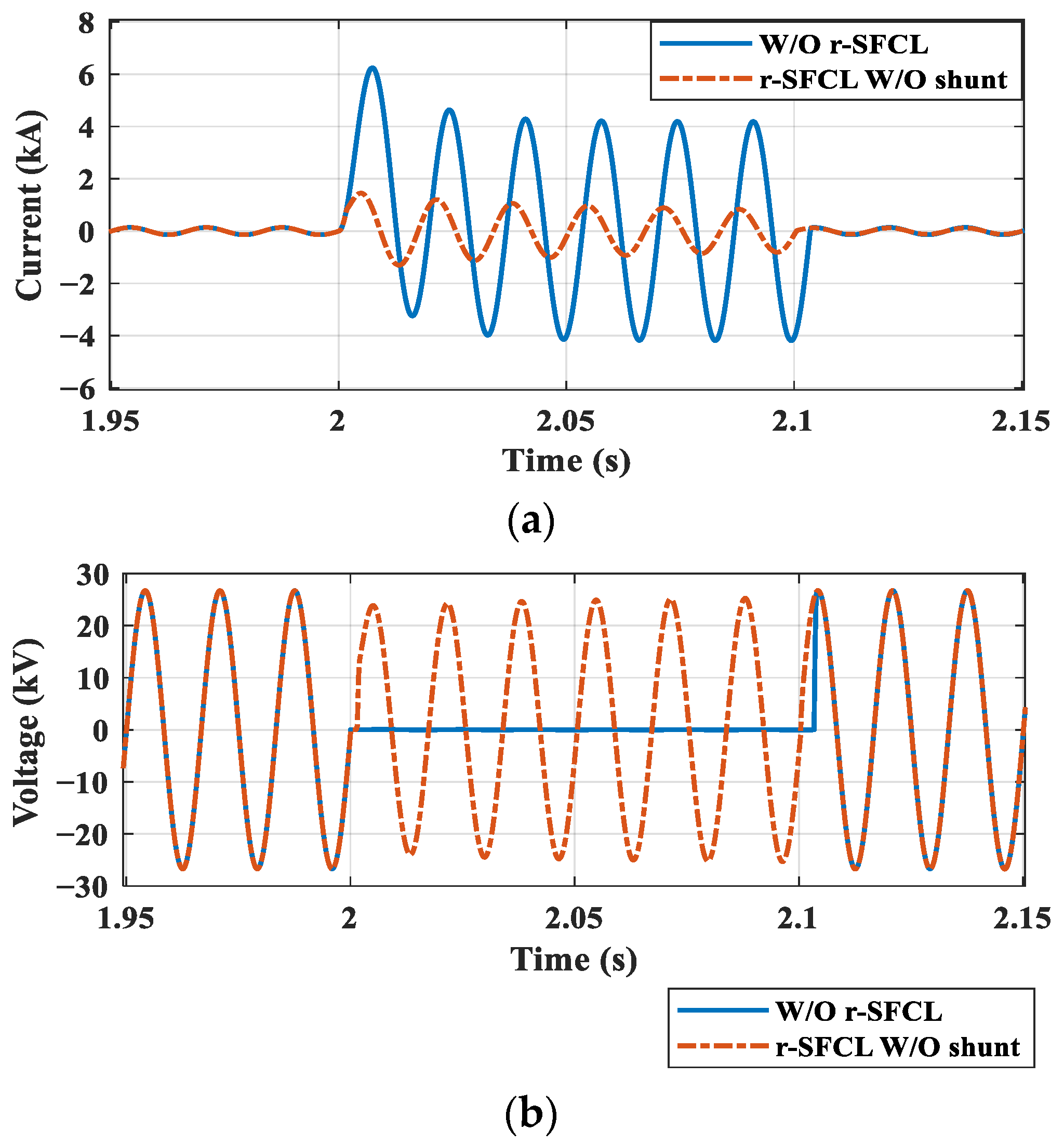

4.1.4. Case Study 4 (Without Shunt Resistor)

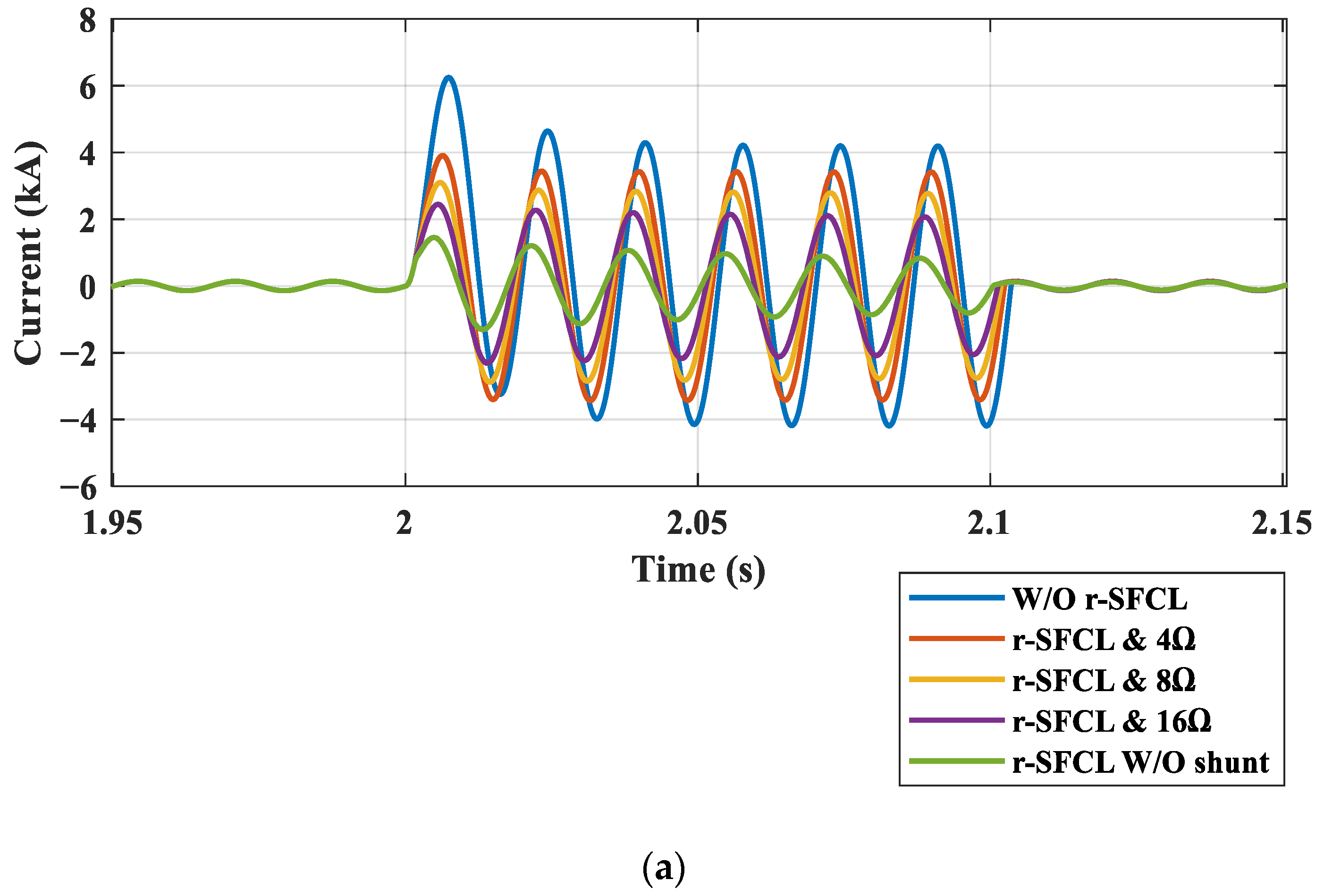

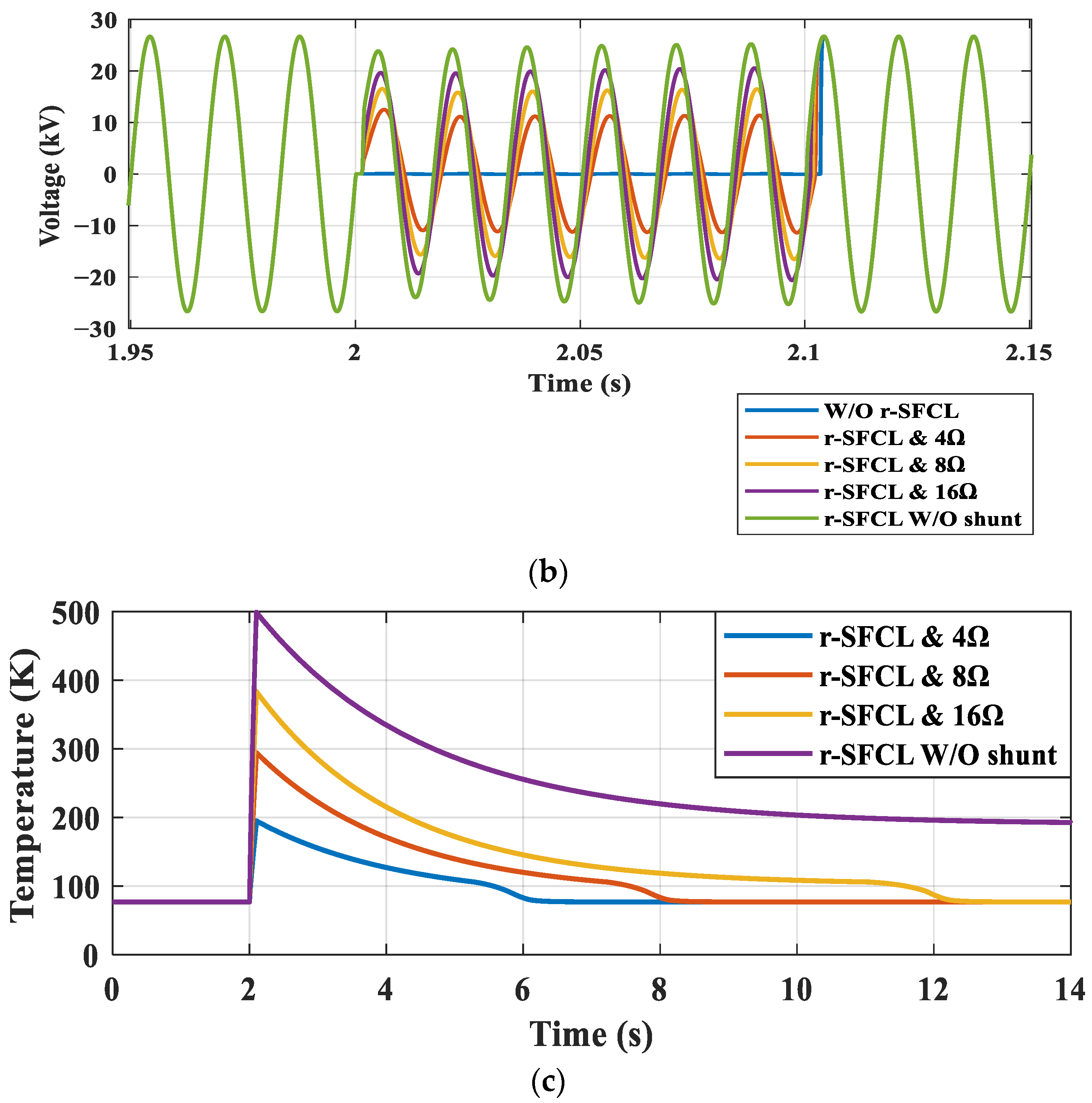

4.2. Discussion and Comparison

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Razavi, S.-E.; Rahimi, E.; Javadi, M.S.; Nezhad, A.E.; Lotfi, M.; Shafie-Khah, M.; Catalão, J.P. Impact of distributed generation on protection and voltage regulation of distribution systems: A review. Renew. Sustain. Energy Rev. 2019, 105, 157–167. [Google Scholar] [CrossRef]

- Tan, X.; Ren, L.; Liang, S.; Tang, Y.; Xu, Y.; Shi, J.; Li, Z. Analysis of R-SFCL with Shunt Resistor in MMC-HVDC System Using Novel R-Q Method. IEEE Trans. Appl. Supercond. 2020, 30, 5601405. [Google Scholar] [CrossRef]

- Shen, B.; Chen, Y.; Li, C.; Wang, S.; Chen, X. Superconducting fault current limiter (SFCL): Experiment and the simulation from finite-element method (FEM) to power/energy system software. Energy 2021, 234, 121251. [Google Scholar] [CrossRef]

- van Delft, D.; Kes, P. The discovery of superconductivity. Phys. Today 2010, 63, 38–43. [Google Scholar] [CrossRef]

- Miura, S.; Iwakuma, M.; Izumi, T. Lightweight Design of Tens-MW Fully-Superconducting Wind Turbine Generators with High-Performance REBa2Cu3Oy Wires. IEEE Trans. Appl. Supercond. 2020, 30, 5204106. [Google Scholar] [CrossRef]

- Weng, F.; Zhang, M.; Elwakeel, A.; Lan, T.; McNeill, N.; Yuan, W. Transient Test and AC Loss Study of a Cryogenic Propulsion Unit for All Electric Aircraft. IEEE Access 2021, 9, 59628–59636. [Google Scholar] [CrossRef]

- Song, X.; Buhrer, C.; Molgaard, A.; Andersen, R.S.; Brutsaert, P.; Bauer, M.; Hansen, J.; Rebsdorf, A.V.; Kellers, J.; Winkler, T.; et al. Commissioning of the World’s First Full-Scale MW-Class Superconducting Generator on a Direct Drive Wind Turbine. IEEE Trans. Energy Convers. 2020, 35, 1697–1704. [Google Scholar] [CrossRef]

- Yazdani-Asrami, M.; Zhang, M.; Yuan, W. Challenges for developing high temperature superconducting ring magnets for rotating electric machine applications in future electric aircrafts. J. Magn. Magn. Mater. 2021, 522, 167543. [Google Scholar] [CrossRef]

- Torrey, D.; Parizh, M.; Bray, J.; Stautner, W.; Tapadia, N.; Xu, M.; Wu, A.; Zierer, J. Superconducting Synchronous Motors for Electric Ship Propulsion. IEEE Trans. Appl. Supercond. 2020, 30, 5204708. [Google Scholar] [CrossRef]

- Yazdani-Asrami, M.; Seyyedbarzegar, S.; Sadeghi, A.; de Sousa, W.T.B.; Kottonau, D. High temperature superconducting cables and their performance against short circuit faults: Current development, challenges, solutions, and future trends. Supercond. Sci. Technol. 2022, 35, 083002. [Google Scholar] [CrossRef]

- Chen, X.; Xie, Q.; Bian, X.; Shen, B. Energy-saving superconducting magnetic energy storage (SMES) based interline DC dynamic voltage restorer. CSEE J. Power Energy Syst. 2022, 8, 238–248. [Google Scholar] [CrossRef]

- Elshiekh, M.E.; Mansour, D.-E.A.; Zhang, M.; Yuan, W.; Wang, H.; Xie, M. New Technique for Using SMES to Limit Fault Currents in Wind Farm Power Systems. IEEE Trans. Appl. Supercond. 2018, 28, 5602005. [Google Scholar] [CrossRef]

- Mishra, D.K.; Złotecka, D.; Li, L. Significance of SMES Devices for Power System Frequency Regulation Scheme considering Distributed Energy Resources in a Deregulated Environment. Energies 2022, 15, 1766. [Google Scholar] [CrossRef]

- Kim, Y.; Jo, H.-C.; Joo, S.-K. Analysis of Impacts of Superconducting Fault Current Limiter (SFCL) Placement on Distributed Generation (DG) Expansion. IEEE Trans. Appl. Supercond. 2016, 26, 5602305. [Google Scholar] [CrossRef]

- Yehia, D.M.; Taha, I.B.M. Application of Superconducting Fault Current Limiter as a Virtual Inertia for DC Distribution Systems. IEEE Access 2021, 9, 135384–135391. [Google Scholar] [CrossRef]

- Chen, L.; Ding, M.; Chen, H.; Wang, X.; Deng, X.; Li, G.; Li, Y.; Xia, F.; Wang, L.; He, H. Study on Resistive SFCL for Fault Ride-Through Fulfillment of Power Electronic Transformer Interconnecting MV and LV Power Systems. IEEE Trans. Appl. Supercond. 2021, 31, 5402106. [Google Scholar] [CrossRef]

- Elshiekh, M. Increasing Wind Energy Integration into Power Grids Using Multifunctional Superconducting Devices Design. Ph.D. Thesis, University of Bath, Bath, UK, 2020. [Google Scholar]

- Alam, S.; Abido, M.A.Y.; El-Amin, I. Fault Current Limiters in Power Systems: A Comprehensive Review. Energies 2018, 11, 1025. [Google Scholar] [CrossRef]

- de Sousa, W.T.B.; Dias, R.; da Silva, F.A.; Polasek, A.; de Andrade, R. Comparison Between the Fault Current Limiting Performance of Bi-2212 Bifilar Components and 2G YBCO Coils. IEEE Trans. Appl. Supercond. 2013, 23, 5602204. [Google Scholar] [CrossRef]

- Naderi, S.B.; Davari, P.; Zhou, D.; Negnevitsky, M.; Blaabjerg, F. A Review on Fault Current Limiting Devices to Enhance the Fault Ride-Through Capability of the Doubly-Fed Induction Generator Based Wind Turbine. Appl. Sci. 2018, 8, 2059. [Google Scholar] [CrossRef]

- Chen, L.; Chen, H.; Shu, Z.; Zhang, G.; Xia, T.; Ren, L. Comparison of Inductive and Resistive SFCL to Robustness Improvement of a VSC-HVDC System with Wind Plants Against DC Fault. IEEE Trans. Appl. Supercond. 2016, 26, 5603508. [Google Scholar] [CrossRef]

- Alafnan, H.; Zeng, X.; Pei, X.; Khedr, M.; Zhang, M.; Yuan, W. Analysing Faults and SFCL Response in Electric Aircraft. J. Phys. Conf. Ser. 2020, 1559, 012103. [Google Scholar] [CrossRef]

- Song, W.; Pei, X.; Alafnan, H.; Xi, J.; Zeng, X.; Yazdani-Asrami, M.; Xiang, B.; Liu, Z. Experimental and Simulation Study of Resistive Helical HTS Fault Current Limiters: Quench and Recovery Characteristics. IEEE Trans. Appl. Supercond. 2021, 31, 5601106. [Google Scholar] [CrossRef]

- Dai, S.; Ma, T.; Xue, C.; Zhao, L.; Huang, Y.; Hu, L.; Wang, B.; Zhang, T.; Xu, X.; Cai, L.; et al. Development and test of a 220 kV/1.5 kA resistive type superconducting fault current limiter. Phys. C Supercond. Appl. 2019, 565, 1253501. [Google Scholar] [CrossRef]

- Xiang, B.; Junaid, M.; Gao, L.; Liu, Z.; Geng, Y.; Wang, J.; Yanabu, S. Influencing Factors on Quench and Recovery of YBCO Tapes for DC Superconducting Fault Current Limiter. IEEE Trans. Appl. Supercond. 2019, 29, 5600806. [Google Scholar] [CrossRef]

- Alafnan, H.; Pei, X.; Mansour, D.-E.A.; Khedr, M.; Song, W.; Alsaleh, I.; Albaker, A.; Alturki, M.; Zeng, X. Impact of Copper Stabilizer Thickness on SFCL Performance with PV-Based DC Systems Using a Multilayer Thermoelectric Model. Sustainability 2023, 15, 7372. [Google Scholar] [CrossRef]

- Xiang, B.; Wang, W.; Li, H.; Gao, L.; Liu, Z.; Geng, Y.; Wang, J.; Tu, Y. Study on the influencing factors to reduce the recovery time of superconducting tapes and coils for the DC superconducting fault current limiter applications. High Volt. 2022, 7, 483–495. [Google Scholar] [CrossRef]

- Hong, Z.; Sheng, J.; Yao, L.; Gu, J.; Jin, Z. The Structure, Performance and Recovery Time of a 10 kV Resistive Type Superconducting Fault Current Limiter. IEEE Trans. Appl. Supercond. 2013, 23, 5601304. [Google Scholar] [CrossRef]

- American Superconductor. Amperium® Stainless Steel Laminated Wire Type 8602. 2023. Available online: https://www.amsc.com/wp-content/uploads/SSAMP8602_DS_A4_0414_WEB.pdf (accessed on 5 August 2023).

- Nam, K.; Lee, C.; Park, D.K.; Ko, T.K.; Seok, B.-Y. Thermal and Electrical Analysis of Coated Conductor Under AC Over-Current. IEEE Trans. Appl. Supercond. 2007, 17, 1923–1926. [Google Scholar] [CrossRef]

- Elshiekh, M.; Zhang, M.; Ravindra, H.; Chen, X.; Venuturumilli, S.; Huang, X.; Schoder, K.; Steurer, M.; Yuan, W. Effectiveness of Superconducting Fault Current Limiting Transformers in Power Systems. IEEE Trans. Appl. Supercond. 2018, 28, 5601607. [Google Scholar] [CrossRef]

- Matula, R.A. Electrical resistivity of copper, gold, palladium, and silver. J. Phys. Chem. Ref. Data 1979, 8, 1147–1298. [Google Scholar] [CrossRef]

- Bagrets, N.; Schwarz, M.; Barth, C.; Weiss, K.-P. Thermal conductivity of materials used for preparation of the hybrid layered conductors based on high temperature superconductors. AIP Conf. Proc. 2012, 1435, 281–285. [Google Scholar] [CrossRef]

- Ho, C.Y.; Chu, T.K. Electrical resistivity and thermal conductivity of nine selected AISI stainless steels. Thermophys. Electron. Prop. Inf. Anal. Cent. Lafayette 1977, CINDAS-45, 1–46. [Google Scholar]

- Perez-Chavez, J.J.; Trillaud, F.; Castro, L.M.; Queval, L.; Polasek, A.; Junior, R.d.A. Generic Model of Three-Phase (RE)BCO Resistive Superconducting Fault Current Limiters for Transient Analysis of Power Systems. IEEE Trans. Appl. Supercond. 2019, 29, 5601811. [Google Scholar] [CrossRef]

- Xiang, B.; Gao, L.; Liu, Z.; Geng, Y.; Wang, J. Short-circuit fault current-limiting characteristics of a resistive-type superconducting fault current limiter in DC grids. Supercond. Sci. Technol. 2020, 33, 024005. [Google Scholar] [CrossRef]

| Parameter | Quantity | Value |

|---|---|---|

| AC source | Three-phase | 60 Hz, 25 kV, 0.892 Ω source resistance |

| Step-up transformer | Three-phase | 25/33 kV, 10 MVA |

| Transmission lines | Three-phase | 33 kV, 0.06 Ω/km |

| r-SFCL devices | Three units | AMSC-8602, 300 m |

| Load | Three-phase | 60 Hz, 5.7 MW |

| Parameter | Value |

|---|---|

| Conductor type | AMSC-8602 |

| Conductor width (mm) | 12 |

| Critical current (A) | 241 |

| SC layer thickness (μm) | 1 |

| Substrate thickness (μm) | 75 |

| Substrate material | Ni-5at.%W |

| Stainless steel thickness (μm) | 75 × 2 layers |

| Stainless steel material | (SUS)316L |

| Tape length (m) | 300 |

| Shunt Resistor (Ω) | First Peak (kA) | Highest Temp. (K) | Recovery Time (s) |

|---|---|---|---|

| 4 | 3.9 | 195 | 5.77 |

| 8 | 3.1 | 294 | 7.78 |

| 16 | 2.44 | 384 | 9.88 |

| Without shunt | 1.45 | 499 | Not recovered |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alafnan, H.; Mansour, D.-E.A.; Pei, X.; Khedr, M.; Alturki, M.; Albaker, A.; Alsaleh, I.; Zeng, X. Effect of Shunt Resistor Value on the Performance of Resistive Superconducting Fault Current Limiters. Appl. Sci. 2023, 13, 11339. https://doi.org/10.3390/app132011339

Alafnan H, Mansour D-EA, Pei X, Khedr M, Alturki M, Albaker A, Alsaleh I, Zeng X. Effect of Shunt Resistor Value on the Performance of Resistive Superconducting Fault Current Limiters. Applied Sciences. 2023; 13(20):11339. https://doi.org/10.3390/app132011339

Chicago/Turabian StyleAlafnan, Hamoud, Diaa-Eldin A. Mansour, Xiaoze Pei, Moanis Khedr, Mansoor Alturki, Abdullah Albaker, Ibrahim Alsaleh, and Xianwu Zeng. 2023. "Effect of Shunt Resistor Value on the Performance of Resistive Superconducting Fault Current Limiters" Applied Sciences 13, no. 20: 11339. https://doi.org/10.3390/app132011339

APA StyleAlafnan, H., Mansour, D.-E. A., Pei, X., Khedr, M., Alturki, M., Albaker, A., Alsaleh, I., & Zeng, X. (2023). Effect of Shunt Resistor Value on the Performance of Resistive Superconducting Fault Current Limiters. Applied Sciences, 13(20), 11339. https://doi.org/10.3390/app132011339