Investigation of the Water-Retention Characteristics and Mechanical Behavior of Fibre-Reinforced Unsaturated Sand

Abstract

:1. Introduction

2. Materials and Method

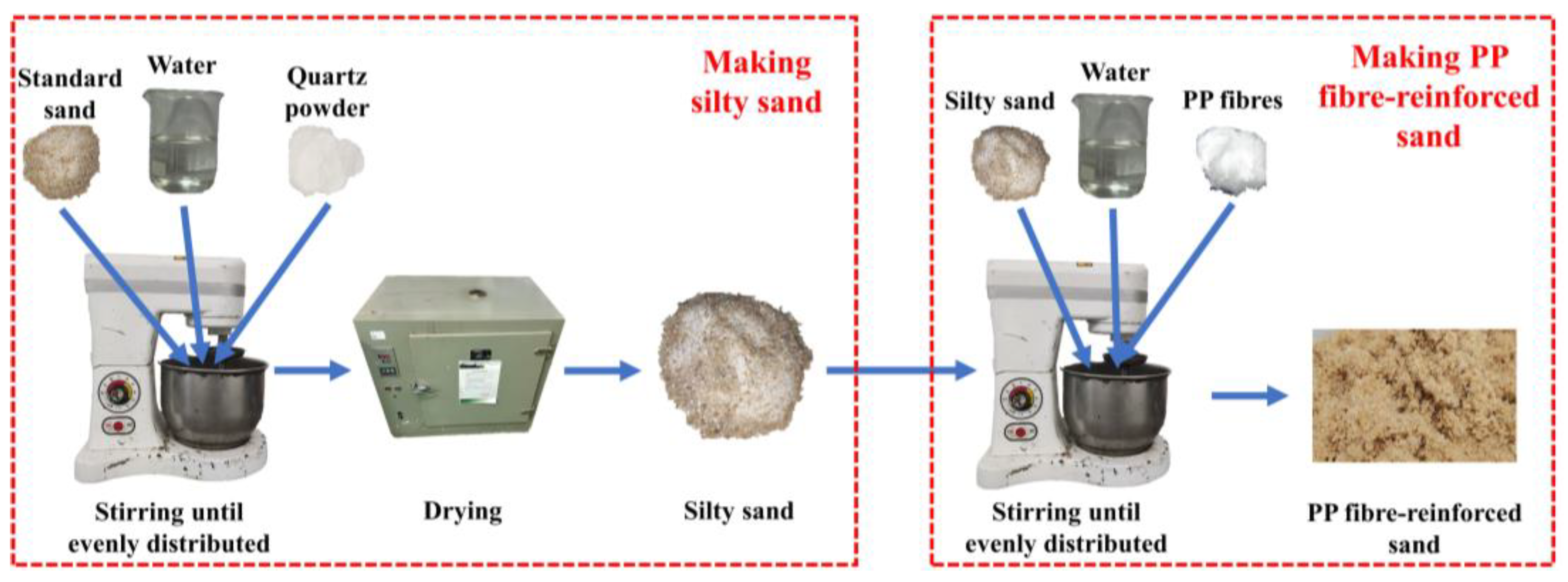

2.1. Materials and Test Preparation

2.2. Test Conditions

2.2.1. Consolidation Tests

2.2.2. Direct Shear Tests

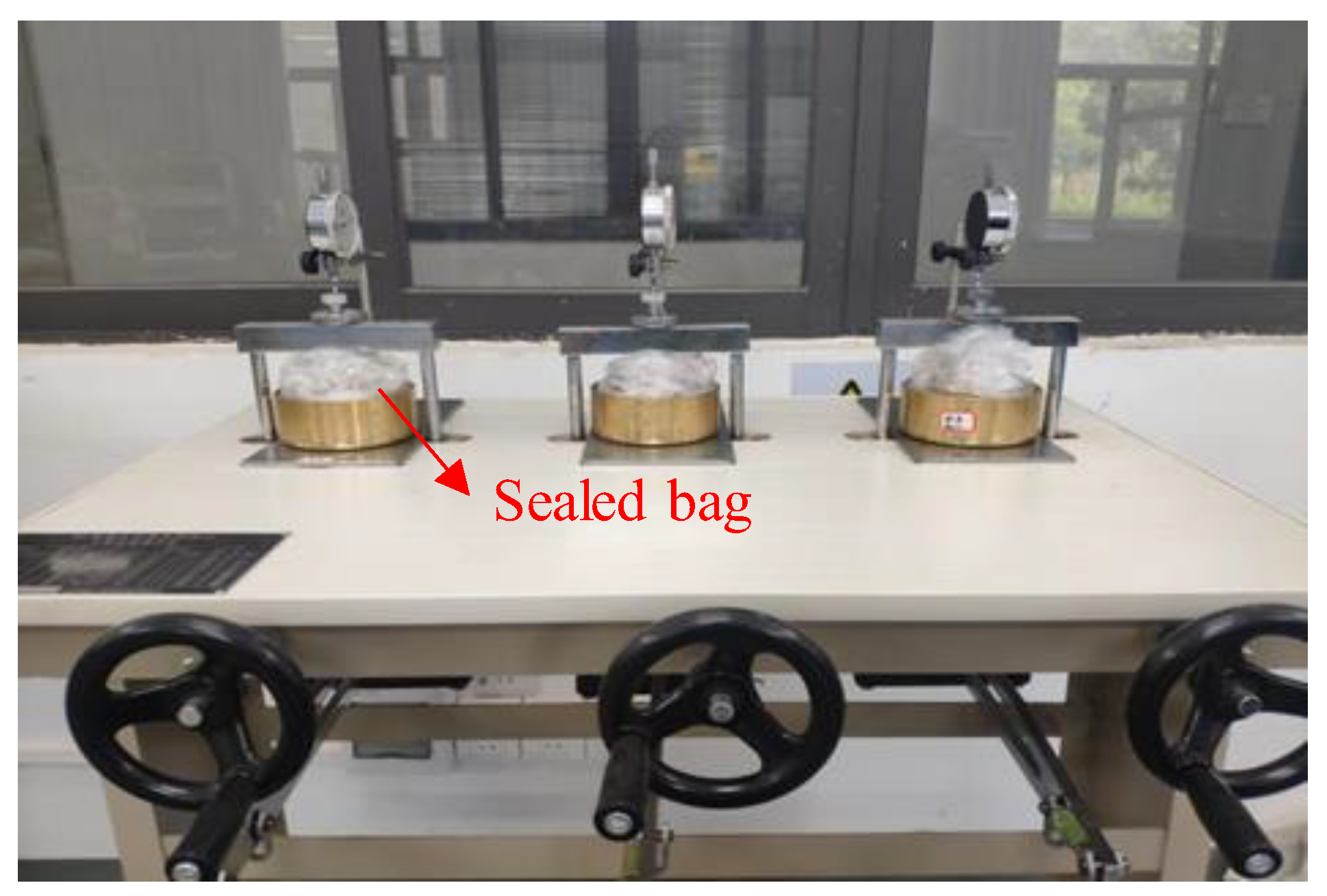

2.2.3. Water-Retention Tests

3. Results and Discussions

3.1. Mechanical Property Test Results

3.1.1. Consolidation Test Results

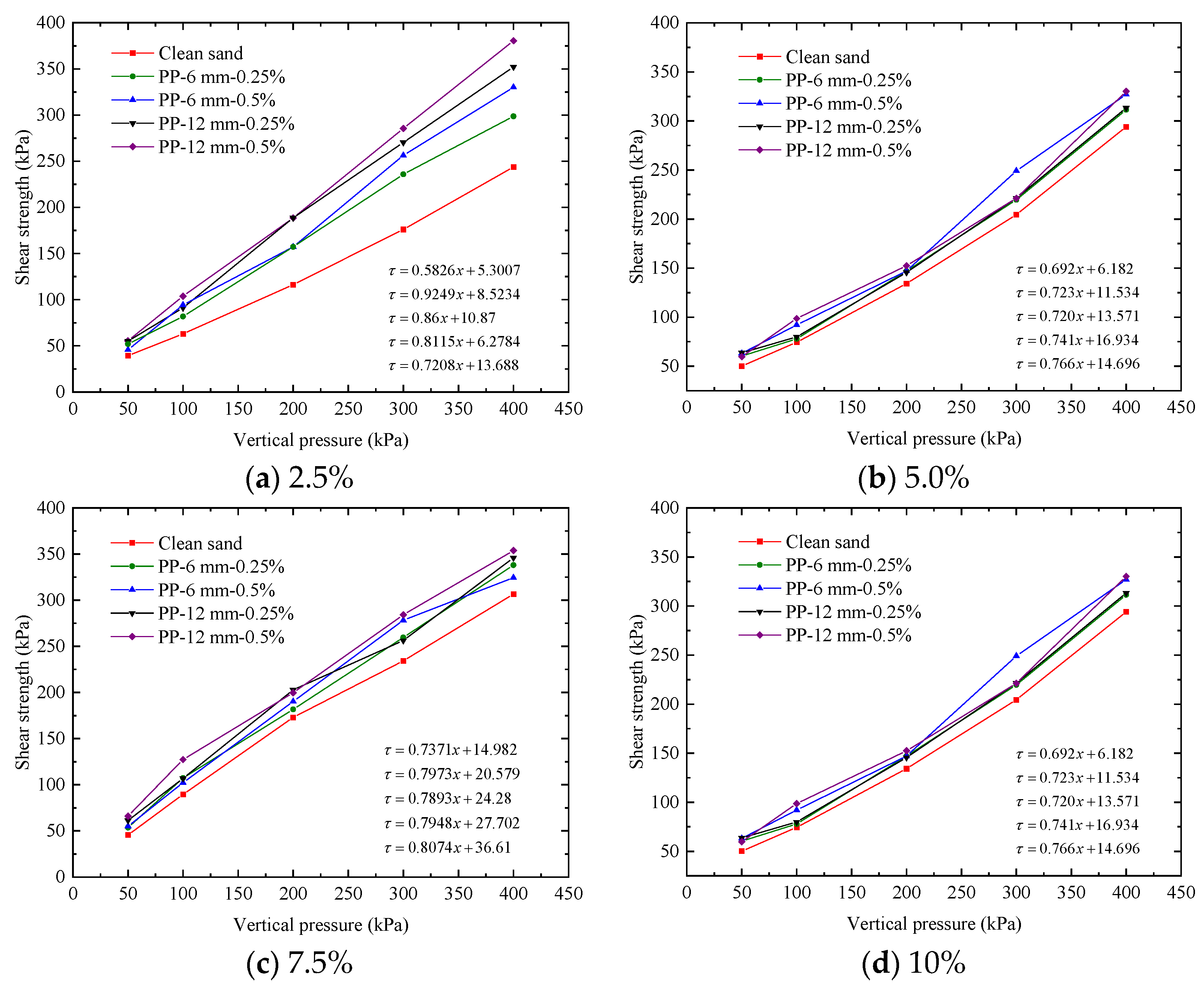

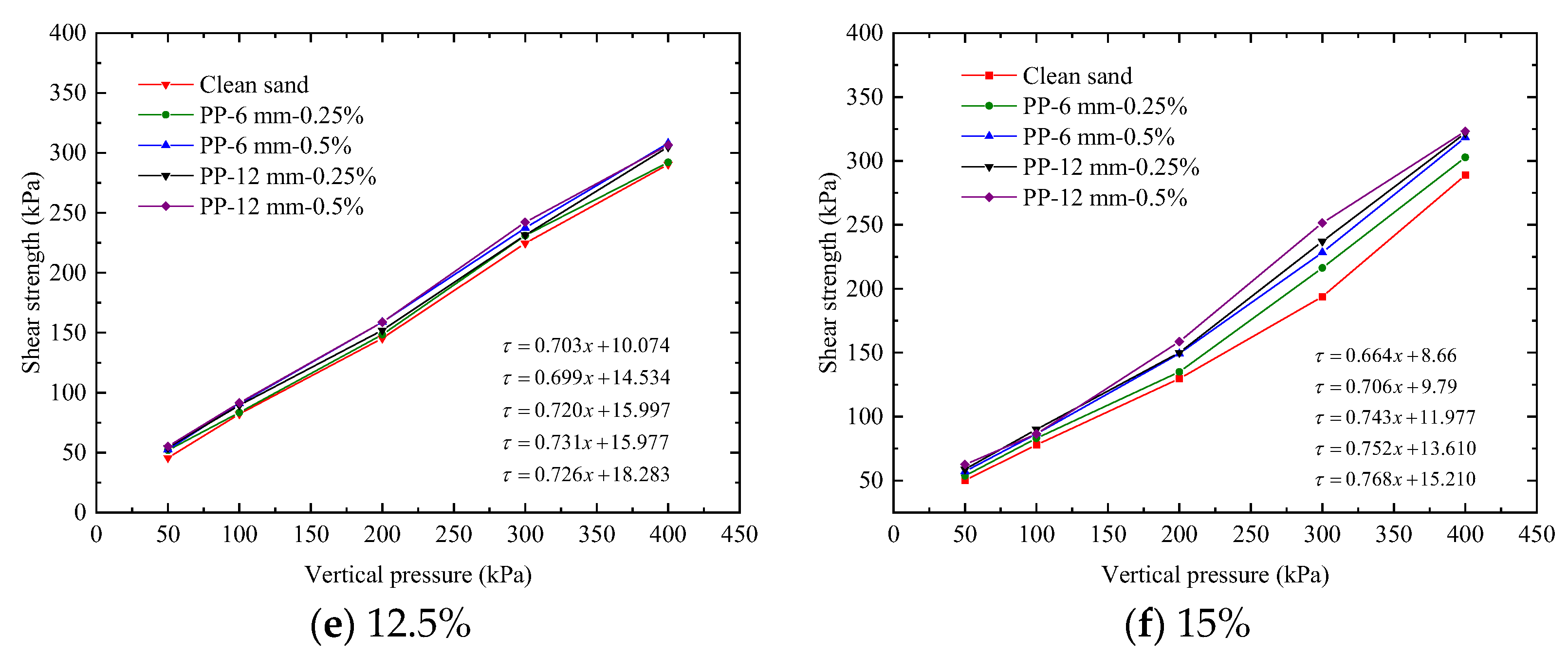

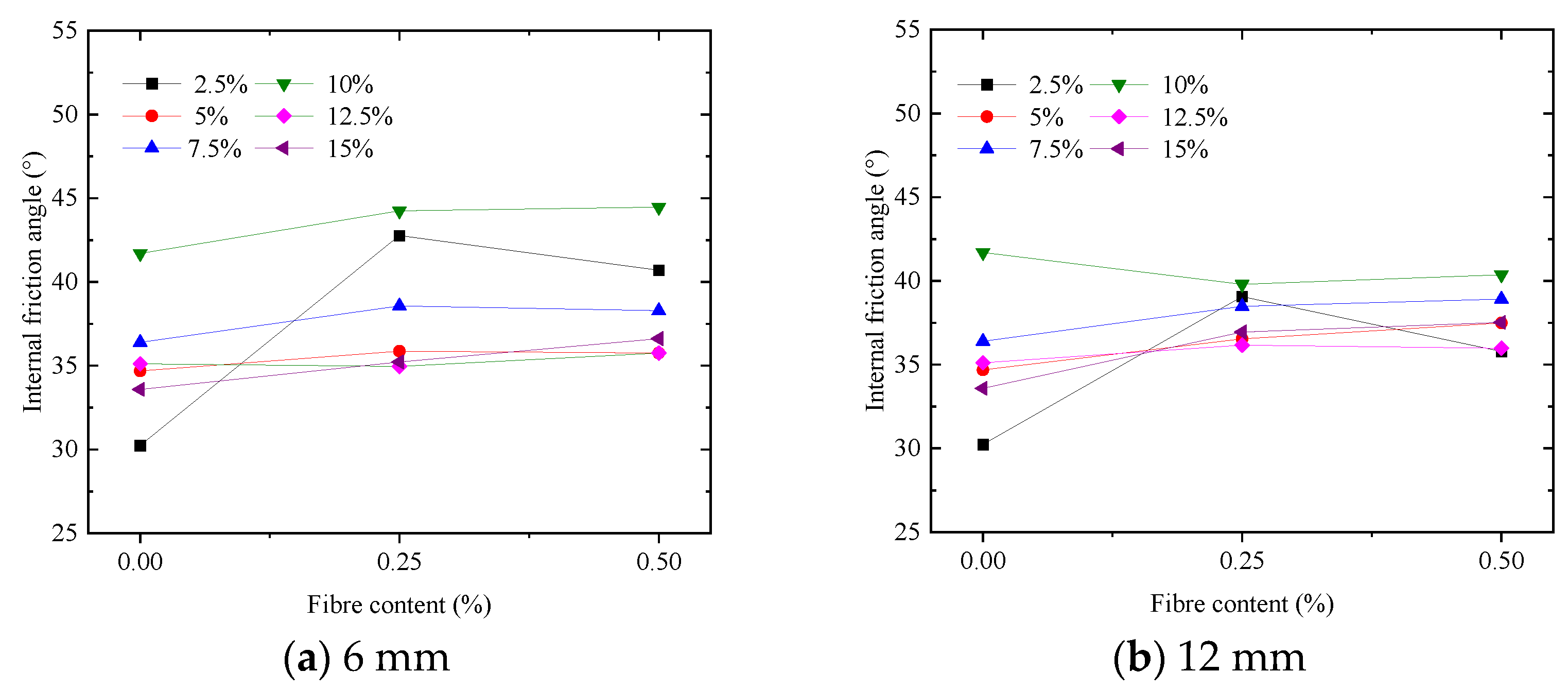

3.1.2. Direct Shear Test Results

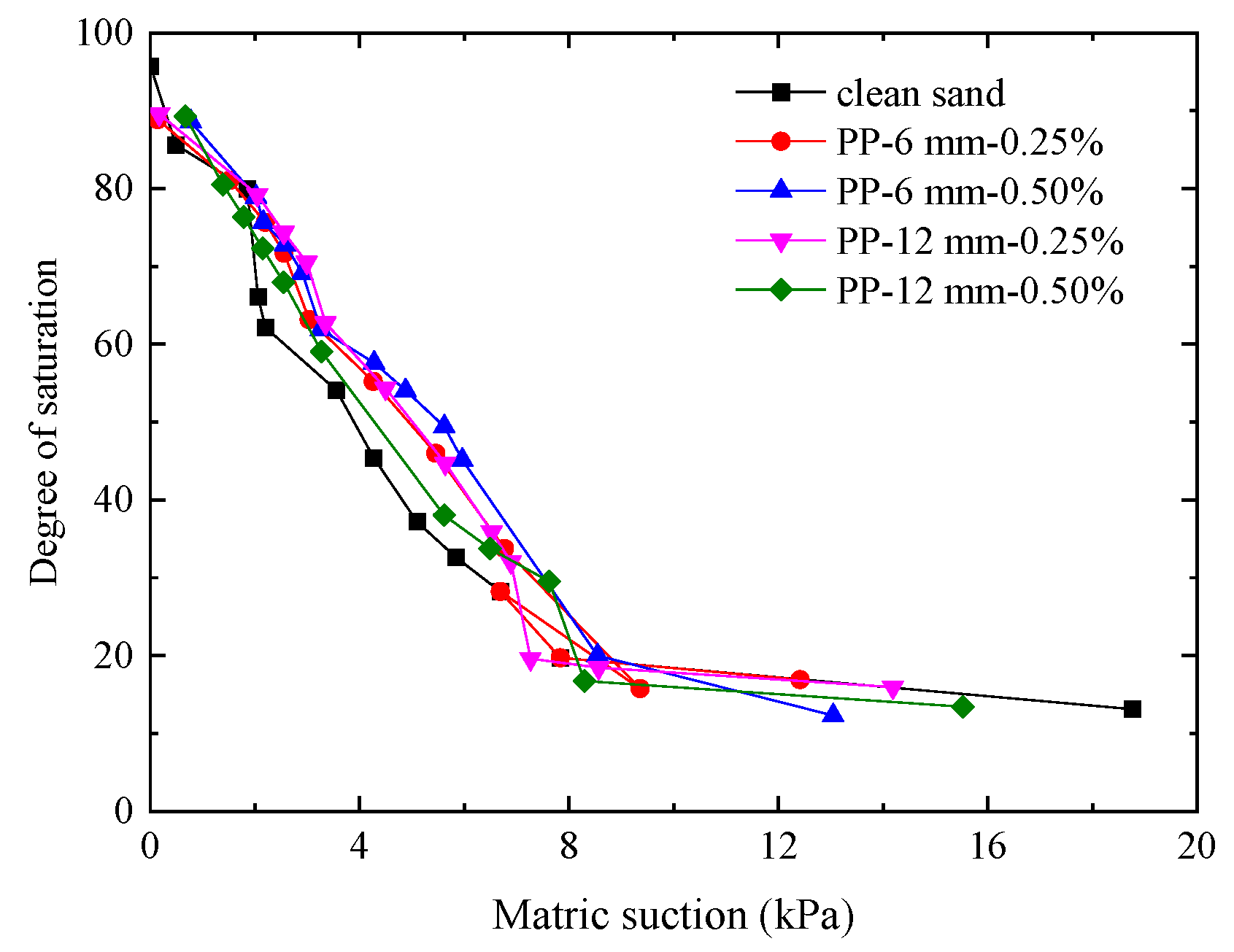

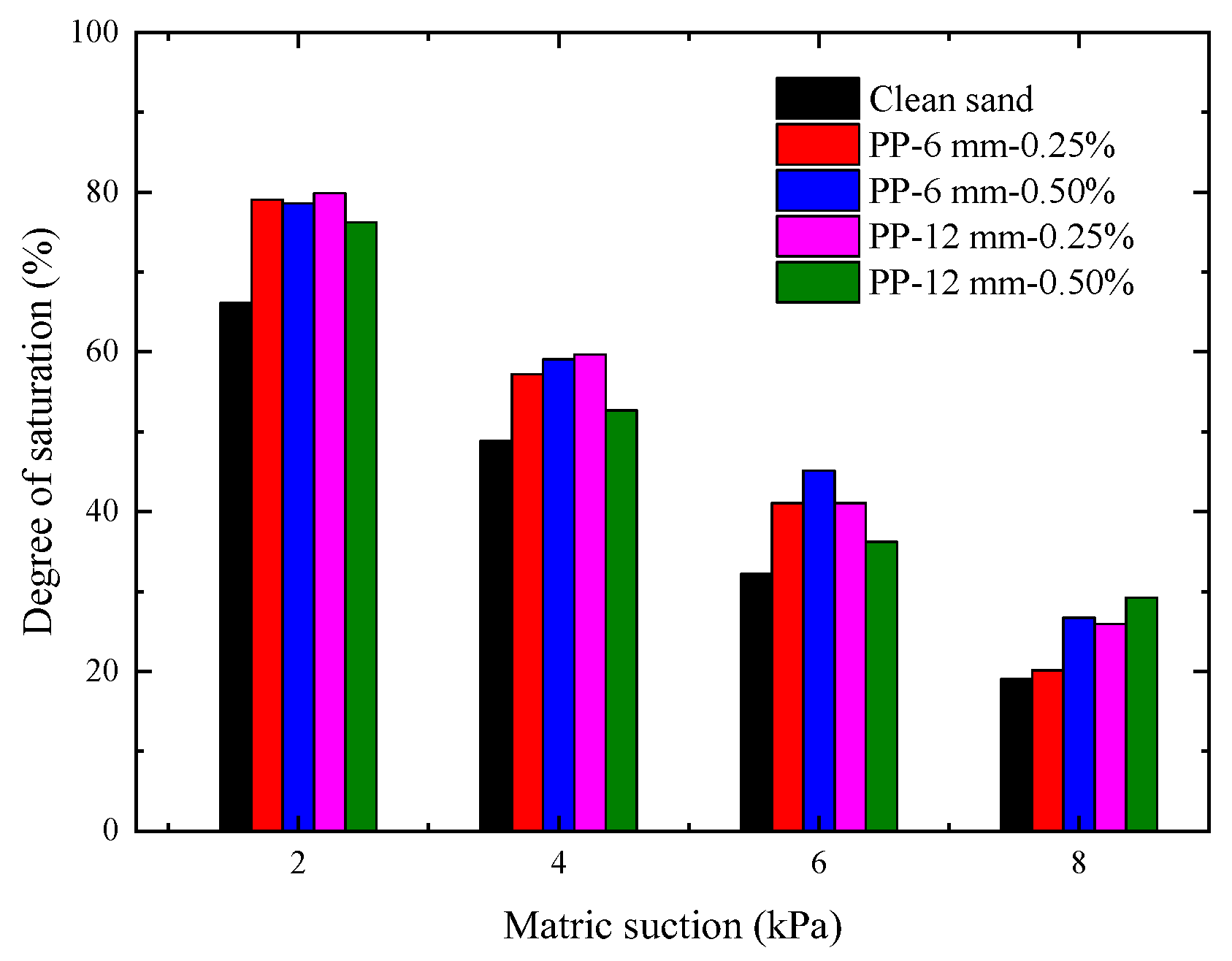

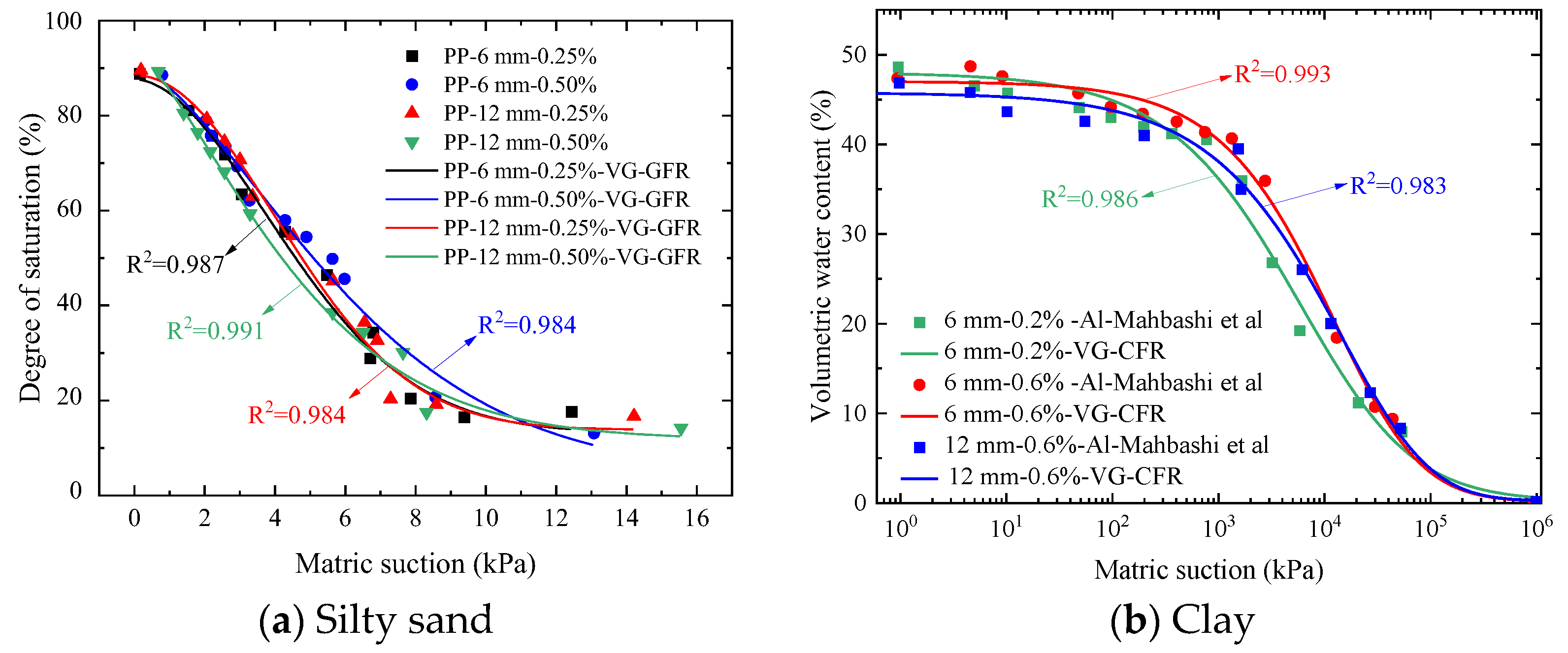

3.2. Determination of SWCC

4. SWCC Model Considering Fibre Reinforcement

5. Conclusions

- (1)

- The compressibility of soil decreases with increasing fibre length and content. The soil’s compression modulus increases with the fibre content and length, whereas the compressibility index exhibits an opposite trend. The addition of fibre increases the initial void ratio. The interface force at the fibre–soil interface can reduce the compressibility of sand;

- (2)

- Under the fibre content in this study, the influence of fibres on the internal friction angle is minor, while enhancing the cohesive forces to elevate the shear strength of the soil. Before reaching the critical water content, the internal friction angle and cohesion of the soil increase with increasing water content but decrease beyond the critical water content. Water can fill the soil pores, increasing the internal friction angle and cohesion. The main reason for the decrease in the internal friction angle and cohesion is the significant reduction in soil suction after exceeding the critical water content;

- (3)

- The test results of the axis-translation method show that the addition of fibres can improve the water retention of sand. The compression test shows that the addition of fibres can strengthen the initial void ratio of the soil, affect the capillarity of the soil, provide additional contact area between the soil and water molecules, and improve the water-retention characteristics of the soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choobbasti, A.J.; Samakoosh, M.A.; Kutanaei, S.S. Mechanical properties soil stabilized with nano calcium carbonate and reinforced with carpet waste fibers. Constr. Build. Mater. 2019, 211, 1094–1104. [Google Scholar] [CrossRef]

- Wicki, A.; Lehmann, P.; Hauck, C.; Seneviratne, S.I.; Waldner, P.; Staehli, M. Assessing the potential of soil moisture measurements for regional landslide early warning. Landslides 2020, 17, 1881–1896. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, D. Behavior of cement-stabilized fiber-reinforced pond ash, rice husk ash-soil mixtures. Geotext. Geomembr. 2016, 44, 466–474. [Google Scholar] [CrossRef]

- Festugato, L.; Menger, E.; Benezra, F.; Kipper, E.A.; Consoli, N.C. Fibre-reinforced cemented soils compressive and tensile strength assessment as a function of filament length. Geotext. Geomembr. 2017, 45, 77–82. [Google Scholar] [CrossRef]

- Lu, L.; Liu, C.; Qu, S.; Zhang, M. Experimental study on the mechanical and hydraulic behaviour of Fibre-Reinforced cemented soil with fly ash. Constr. Build. Mater. 2022, 321, 126374. [Google Scholar] [CrossRef]

- Consoli, N.C.; Bellaver Corte, M.; Festugato, L. Key parameter for tensile and compressive strength of fibre-reinforced soil-lime mixtures. Geosynth. Int. 2012, 19, 409–414. [Google Scholar] [CrossRef]

- Akbari, H.R.; Sharafi, H.; Goodarzi, A.R. Effect of polypropylene fiber and nano-zeolite on stabilized soft soil under wet-dry cycles. Geotext. Geomembr. 2021, 49, 1470–1482. [Google Scholar] [CrossRef]

- Wei, L.; Chai, S.X.; Zhang, H.Y.; Shi, Q. Mechanical properties of soil reinforced with both lime and four kinds of fiber. Constr. Build. Mater. 2018, 172, 300–308. [Google Scholar] [CrossRef]

- Rasouli, H.; Fatahi, B. Liquefaction and post-liquefaction resistance of sand reinforced with recycled geofibre. Geotext. Geomembr. 2022, 50, 69–81. [Google Scholar] [CrossRef]

- Ghadr, S.; Samadzadeh, A.; Bahadori, H.; Assadi-Langroudi, A. Liquefaction resistance of fibre-reinforced silty sands under cyclic loading. Geotext. Geomembr. 2020, 48, 812–827. [Google Scholar] [CrossRef]

- Akay, O.; Ozer, A.T.; Fox, G.A.; Wilson, G.V. Application of fibrous streambank protection against groundwater seepage erosion. J. Hydrol. 2018, 565, 27–38. [Google Scholar] [CrossRef]

- Yang, K.; Wei, S.; Adilehou, W.M.; Ho, H. Fiber-reinforced internally unstable soil against suffusion failure. Constr. Build. Mater. 2019, 222, 458–473. [Google Scholar] [CrossRef]

- Yang, K.; Adilehou, W.M.; Jian, S.; Wei, S. Hydraulic response of fibre-reinforced sand subject to seepage. Geosynth. Int. 2017, 24, 491–507. [Google Scholar] [CrossRef]

- Liu, C.; Lv, Y.; Yu, X.; Wu, X. Effects of freeze-thaw cycles on the unconfined compressive strength of straw fiber-reinforced soil. Geotext. Geomembr. 2020, 48, 581–590. [Google Scholar] [CrossRef]

- Abbaspour, M.; Narani, S.S.; Aflaki, E.; Moghadas Nejad, F.; Hosseini, S.M.M.M. Strength and swelling properties of a waste tire textile fiber-reinforced expansive soil. Geosynth. Int. 2020, 27, 476–489. [Google Scholar] [CrossRef]

- Tang, C.; Li, J.; Wang, D.; Shi, B. Investigation on the interfacial mechanical behavior of wave-shaped fiber reinforced soil by pullout test. Geotext. Geomembr. 2016, 44, 872–883. [Google Scholar] [CrossRef]

- Ehrlich, M.; Almeida, M.S.S.; Curcio, D. Hydro-mechanical behavior of a lateritic fiber-soil composite as a waste containment liner. Geotext. Geomembr. 2019, 47, 42–47. [Google Scholar] [CrossRef]

- Zhu, H.H.; Zhang, C.C.; Tang, C.S.; Shi, B.; Wang, B.J. Modeling the pullout behavior of short fiber in reinforced soil. Geotext. Geomembr. 2014, 42, 329–338. [Google Scholar] [CrossRef]

- Nataraj, M.S.; Mcmanis, K.L. Strength and deformation properties of soils reinforced with fibrillated fibers. Geosynth. Int. 1997, 4, 65–79. [Google Scholar] [CrossRef]

- Shan, Y.; Liang, J.; Tong, H.; Yuan, J.; Zhao, J. Effect of different fibers on small-strain dynamic properties of microbially induced calcite precipitation-fiber combined reinforced calcareous sand. Constr. Build. Mater. 2022, 322, 126343. [Google Scholar] [CrossRef]

- Bao, X.; Huang, Y.; Jin, Z.; Xiao, X.; Tang, W.; Cui, H.; Chen, X. Experimental investigation on mechanical properties of clay soil reinforced with carbon fiber. Constr. Build. Mater. 2021, 280, 122517. [Google Scholar] [CrossRef]

- Correia, N.S.; Rocha, S.A.; Lodi, P.C.; Mccartney, J.S. Shear strength behavior of clayey soil reinforced with polypropylene fibers under drained and undrained conditions. Geotext. Geomembr. 2021, 49, 1419–1426. [Google Scholar] [CrossRef]

- Sotomayor, J.M.G.; Casagrande, M.D.T. The Performance of a Sand Reinforced with Coconut Fibers Through Plate Load Tests on a True Scale Physical Model. Soils Rocks 2018, 41, 361–368. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Mohamed, M.; Arulrajah, A.; Horpibulsuk, S.; Anggraini, V. Practical approach to predict the shear strength of fibre-reinforced clay. Geosynth. Int. 2018, 25, 50–66. [Google Scholar] [CrossRef]

- Kumar, R.; Kanaujia, V.K.; Chandra, D. Engineering behaviour of fibre-reinforced pond ash and silty sand. Geosynth. Int. 1999, 6, 509–518. [Google Scholar] [CrossRef]

- Lovisa, J.; Shukla, S.K.; Sivakugan, N. Shear strength of randomly distributed moist fibre-reinforced sand. Geosynth. Int. 2010, 17, 100–106. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A. Swell compression characteristics of a fiber-reinforced expansive soil. Geotext. Geomembr. 2018, 46, 183–189. [Google Scholar] [CrossRef]

- Oliveira, P.J.; Correia, A.; Teles, J.; Custodio, D.G. Effect of fibre type on the compressive and tensile strength of a soft soil chemically stabilised. Geosynth. Int. 2016, 23, 171–182. [Google Scholar] [CrossRef]

- Shen, Y.S.; Tang, Y.; Yin, J.; Li, M.P.; Wen, T. An experimental investigation on strength characteristics of fiber-reinforced clayey soil treated with lime or cement. Constr. Build. Mater. 2021, 294, 123537. [Google Scholar] [CrossRef]

- Khiem, Q.T.; Satomi, T.; Takahashi, H. Improvement of mechanical behavior of cemented soil reinforced with waste cornsilk fibers. Constr. Build. Mater. 2018, 178, 204–210. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Namdar, P.; Javadi, A.A. Behavior of cement-stabilized clay reinforced with nylon fiber. Geosynth. Int. 2012, 19, 85–92. [Google Scholar] [CrossRef]

- Ibraim, E.; Diambra, A.; Russell, A.R.; Wood, D.M. Assessment of laboratory sample preparation for fibre reinforced sands. Geotext. Geomembr. 2012, 34, 69–79. [Google Scholar] [CrossRef]

- Ibraim, E.; Camenen, J.; Diambra, A.; Kairelis, K.; Visockaite, L.; Consoli, N.C. Energy efficiency of fibre reinforced soil formation at small element scale: Laboratory and numerical investigation. Geotext. Geomembr. 2018, 46, 497–510. [Google Scholar] [CrossRef]

- Diambra, A.; Ibraim, E.; Wood, D.M.; Russell, A.R. Fibre reinforced sands: Experiments and modelling. Geotext. Geomembr. 2010, 28, 238–250. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Anggraini, V.; Haque, A. X-ray computed tomography imaging of fibre-reinforced clay subjected to triaxial loading. Geosynth. Int. 2020, 27, 635–645. [Google Scholar] [CrossRef]

- Malekzadeh, M.; Bilsel, H. Hydro-mechanical Behavior of Polypropylene Fiber Reinforced Expansive Soils. KSCE J. Civ. Eng. 2014, 18, 2028–2033. [Google Scholar] [CrossRef]

- Soleimani Fard, H. Study on the Hydro-Mechanical Behavior of Fiber Reinforced Fine Grained Soils, with Application to the Preservation of Historical Monuments. Ph.D. Thesis, Ruhr-Universität Bochum, Bochum, Germany, 2015. [Google Scholar]

- Al-Mahbashi, A.M.; Al-Shamrani, M.A.; Moghal, A.A.B. Soil-Water Characteristic Curve and One-Dimensional Deformation Characteristics of Fiber-Reinforced Lime-Blended Expansive Soil. J. Mater. Civ. Eng. 2020, 32, 04020125. [Google Scholar] [CrossRef]

- Van genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Russo, D. Determining soil hydraulic properties by parameter estimation: On the selection of a model for the hydraulic properties. Water Resour. Res. 1988, 24, 453–459. [Google Scholar] [CrossRef]

- Mckee, C.R.; Bumb, A.C. The importance of unsaturated flow parameters in designing a monitoring system for hazardous wastes and environmental emergencies. In Proceedings of the Hazardous Materials Control Research Institute, National Conference, Houston, TX, USA, 12–14 March 1984; pp. 50–58. [Google Scholar]

- Fredlund, D.G.; Xing, A. Equations for the soil-water characteristic curve. Can. Geotech. J. 1994, 31, 1023–1025. [Google Scholar] [CrossRef]

- Bao, X.; Li, L.; Liao, Z.; Cui, H.; Tang, W.; Chen, X. Study of silty sand slope protection from seepage flows using short fiber-sand mixtures. Geosynth. Int. 2021, 28, 491–507. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Housing and Urban-Rural Development: Beijing, China, 2019.

- Fredlund, D.G. State of practice for use of the soil-water characteristic curve (SWCC) in geotechnical engineering. Can. Geotech. J. 2019, 56, 1059–1069. [Google Scholar] [CrossRef]

- Lu, N. Unsaturated Soil Mechanics: Fundamental Challenges, Breakthroughs, and Opportunities. J. Geotech. Geoenviron. Eng. 2020, 146, 02520001. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Cui, Y.; Chen, R.; Delage, P. The axis-translation and osmotic techniques in shear testing of unsaturated soils: A comparison. Soils Found. 2007, 47, 675–684. [Google Scholar] [CrossRef]

- Ahmadinezhad, A.; Jafarzadeh, F.; Sadeghi, H. Combination of water head control and axis translation techniques in new unsaturated cyclic simple shear tests. Soil Dyn. Earthq. Eng. 2019, 126, 105818. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Prabakar, J.; Sridhar, R.S. Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Zhao, L.Z. Interfacial shear strength of fiber reinforced soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Tang, C.S.; Pei, X.; Wang, D. Interfacial micro-mechanical behavior of discrete fiber-reinforced soil. In Soil Behavior and Geomechanics; American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 84–91. [Google Scholar] [CrossRef]

- Maleksaeedi, E.; Nuth, M. Evaluation of capillary water retention effects on the development of the suction stress characteristic curve. Can. Geotech. J. 2020, 57, 1439–1452. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, S.J.; Lu, N. Unified Elastic Modulus Characteristic Curve Equation for Variably Saturated Soils. J. Geotech. Geoenviron. Eng. 2022, 148, 04021171. [Google Scholar] [CrossRef]

- Bottiglieri, O.; Cafaro, F.; Cotecchia, F. Two-Scale Investigation of the Retention Behavior of a Well-Graded Mixed Soil. Geosciences 2021, 11, 431. [Google Scholar] [CrossRef]

- Li, S.; Wang, B.; Zhang, F.; Zhang, W. Soil suction of unsaturated soil slope in rainfall infiltration and evaporation process. Hydro-Sci. Eng. 2005, 31–36. [Google Scholar] [CrossRef]

- Mualem, Y. A new model for predicting the hydraulic conductivity of unsaturated porous media. Water Resour. Res. 1976, 12, 513–522. [Google Scholar] [CrossRef]

- Ahuja, L.R.; Swartzendruber, D. An improved form of soil-water diffusivity function. Soil Sci. Soc. Am. J. 1972, 36, 9. [Google Scholar] [CrossRef]

| Particle size (mm) | 1 | 0.5 | 0.25 | 0.1 | 0.075 | 0.06 | 0.04 | 0.025 | 0.01 |

| Cumulative percentage of fines (%) | 100 | 88.3 | 22.1 | 11.2 | 10.2 | 9.3 | 6.1 | 5.5 | 1.9 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Specific gravity, | 2.62 | Maximum dry density, (g/cm3) | 4.70 |

| Average particle size, (mm) | 0.33 | Minimum dry density, (g/cm3) | 1.46 |

| Uniformity coefficient, | 3.70 | Internal friction angle, (°) | 34.07 |

| Curvature coefficient, | 1.97 | Cohesion, (kPa) | 2.94 |

| Length (mm) | Diameter (μm) | Specific Gravity (g/cm3) | Elasticity Modulus (GPa) | Tensile Strength (MPa) | Melting Point (°C) |

|---|---|---|---|---|---|

| 6/12 | 30 | 0.91 | 1.0 | 350 | 165 |

| Fibre Length (mm) | Fibre Content (%) | Es (MPa−1) | Cc | Cs |

|---|---|---|---|---|

| / | / | 8.360 | 0.078 | 0.0071 |

| 6 | 0.25 | 12.22 | 0.0534 | 0.0042 |

| 6 | 0.50 | 14.59 | 0.0449 | 0.003 |

| 12 | 0.25 | 15.06 | 0.0438 | 0.0021 |

| 12 | 0.50 | 17.27 | 0.0381 | 0.0031 |

| Parameter | Clean Sand | PP-6 mm-0.25% | PP-6 mm-0.50% | PP-12 mm-0.25% | PP-12 mm-0.50% |

|---|---|---|---|---|---|

| α | 0.52 | 0.37 | 0.34 | 0.33 | 0.47 |

| AEV (kPa) | 1.92 | 2.70 | 2.94 | 3.03 | 2.13 |

| n | 1.95 | 2.20 | 2.16 | 2.32 | 2.03 |

| Srr (%) | 0.014 | 0.021 | 0.031 | 0.028 | 0.032 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, X.; Bao, Z.; Li, L.; Li, Y.; Peng, P.; Chen, X. Investigation of the Water-Retention Characteristics and Mechanical Behavior of Fibre-Reinforced Unsaturated Sand. Appl. Sci. 2023, 13, 11337. https://doi.org/10.3390/app132011337

Bao X, Bao Z, Li L, Li Y, Peng P, Chen X. Investigation of the Water-Retention Characteristics and Mechanical Behavior of Fibre-Reinforced Unsaturated Sand. Applied Sciences. 2023; 13(20):11337. https://doi.org/10.3390/app132011337

Chicago/Turabian StyleBao, Xiaohua, Zhizao Bao, Lijuan Li, Yingpeng Li, Peng Peng, and Xiangsheng Chen. 2023. "Investigation of the Water-Retention Characteristics and Mechanical Behavior of Fibre-Reinforced Unsaturated Sand" Applied Sciences 13, no. 20: 11337. https://doi.org/10.3390/app132011337

APA StyleBao, X., Bao, Z., Li, L., Li, Y., Peng, P., & Chen, X. (2023). Investigation of the Water-Retention Characteristics and Mechanical Behavior of Fibre-Reinforced Unsaturated Sand. Applied Sciences, 13(20), 11337. https://doi.org/10.3390/app132011337